#PLC-based AHU control system

Explore tagged Tumblr posts

Text

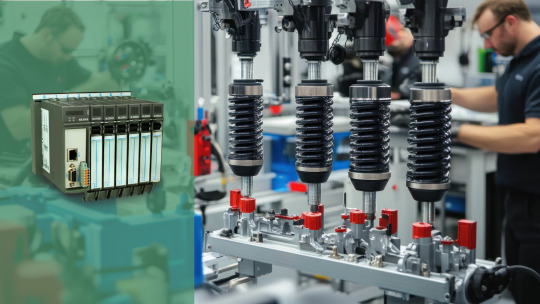

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

Advanced Engineering Design Services That Power Industrial Innovation

In the modern industrial era, where every operation must be streamlined, every watt must be conserved, and every square foot must deliver value—engineering design stands as the backbone of progress. At Asset Eyes, we are proud to be more than just a service provider—we are your engineering partner. Specializing in electrical control panel design, machine design, HVAC systems, and precision CAD drafting, we help industries optimize processes, reduce costs, and boost efficiency.

Our design services are rooted in innovation, accuracy, and reliability. From concept to completion, every design project is approached with a solution-first mindset, ensuring that your systems are as robust and scalable as your business vision.

1. Engineering the Future: Our Multi-Disciplinary Expertise

At Asset Eyes, we understand that industrial needs aren't one-dimensional. That’s why our services span across electrical, mechanical, and HVAC domains—integrating them into cohesive systems that work in harmony.

We offer:

Electrical control panel design for optimized energy distribution

Machine design that’s tailor-made for your operational goals

HVAC equipment design and layout planning for comfort and compliance

Industrial ventilation system design to ensure workplace air quality

Evaporative cooling system design for energy-efficient climate control

SolidWorks 2D drafting for high-precision documentation

HVAC CAD drafting services that align with architectural and MEP coordination

Let’s explore each of these in detail.

2. Electrical Control Panel Design: The Nerve Center of Your Operations

A well-engineered electrical control panel design is critical to ensuring the safe and efficient operation of machinery and processes. Our panels are designed to manage, monitor, and protect electrical systems—whether for a single machine or a full production line.

We take into account:

Load analysis and component selection

Short circuit protection and surge safety

Ergonomic layout for ease of maintenance

Integration with PLCs, VFDs, and HMI interfaces

Full compliance with IEC, NEC, and other global standards

Our team ensures that every panel is custom-built for your needs while being easy to scale or troubleshoot in the future.

3. Machine Design Company: Precision at Every Step

As a reputed machine design company, Asset Eyes brings mechanical concepts to life. We create mechanical systems that work smarter, last longer, and adapt easily to the ever-changing manufacturing environment.

Our process includes:

Requirement analysis and mechanical conceptualization

3D modeling and simulation

Material selection and stress analysis

Motion study and kinematic chain optimization

Assembly drawings and manufacturing details

Whether you're developing a packaging unit, a material handling solution, or an automated fixture, our machine design services are tailored to meet your exact production requirements.

4. HVAC Equipment Design: Engineered for Comfort and Efficiency

Comfort, air quality, and temperature control are more than just operational perks—they’re essential for regulatory compliance and employee productivity. Our HVAC equipment design services are geared toward energy efficiency and system longevity.

We deliver:

System sizing and duct layout

Equipment selection (chillers, AHUs, FCUs, etc.)

Heat load calculations

Control strategy development

Integration with BMS and smart building systems

Our HVAC designs are not only energy efficient but also reduce your maintenance burden over time.

5. Evaporative Cooling System Design: Sustainable Cooling Solutions

For industries operating in hot and dry climates, evaporative cooling system design offers a sustainable alternative to traditional HVAC systems. We specialize in the design of direct and indirect evaporative cooling solutions that provide comfort without the high operational cost of refrigerant-based systems.

Our approach includes:

Airflow planning for optimal cooling

Media selection and water distribution

Pump and fan sizing

Environmental impact and energy consumption analysis

Evaporative systems are especially effective in warehouses, workshops, and other large, open facilities.

6. Industrial Ventilation and Exhaust System Design: Clean Air, Safe Spaces

Air quality is often overlooked—until it becomes a problem. We offer industrial ventilation system design and industrial exhaust system design services to ensure your workspace is free from harmful fumes, dust, and particulate matter.

Our designs meet OSHA, ASHRAE, and local environmental standards. Key components include:

Local exhaust ventilation (LEV)

General exhaust and make-up air systems

High-efficiency filtration systems

Noise control solutions

CFD simulation for airflow optimization

Good ventilation doesn’t just protect your people—it protects your equipment and extends the lifespan of your production facility.

7. Motor Control Panel Design: Driving Industrial Automation

Automation begins at the motor. Our motor control panel design services ensure your motors are controlled efficiently, safely, and with room for diagnostics. Whether it’s a DOL starter, star-delta configuration, or a VFD-based control, we have the expertise to design panels for all scenarios.

Each motor panel design includes:

Fault and overload protection

Soft starters or variable frequency drives

Remote monitoring capabilities

Logical sequencing and safety interlocks

Panel layout drawings with wire schedules

Automation and control are key to increasing your throughput—and Asset Eyes makes it happen seamlessly.

8. SolidWorks 2D Drafting: Precision Documentation for Seamless Execution

From engineering concepts to buildable plans, SolidWorks 2D drafting bridges the gap. We offer industry-standard mechanical drafting that’s detailed, clear, and compliant.

Our deliverables include:

Part and assembly drawings

GD&T and tolerance analysis

Exploded views for manufacturing

Sheet metal and fabrication detailing

Revision control and layer management

These drawings not only serve as your manufacturing guide but also simplify collaboration between design, engineering, and fabrication teams.

9. HVAC CAD Drafting: Precision That Aligns with Your Building Plans

With complex architectural layouts and MEP coordination needs, our HVAC CAD drafting services are designed to deliver clean, clash-free, and ready-for-approval drawings. We work closely with architects, consultants, and contractors to ensure the HVAC systems integrate smoothly into your overall project design.

Services include:

Duct routing and sizing plans

Equipment layout and schedules

Cross-sectional views and details

MEP coordination with electrical and plumbing services

As-built drawings and markups

Our detailed drafting helps reduce errors, avoid clashes, and speed up installation.

10. Why Asset Eyes?

Choosing Asset Eyes means choosing precision, performance, and peace of mind. Here’s why clients across industries trust us:

Multi-disciplinary expertise: From mechanical to electrical to HVAC, we handle it all under one roof.

Client-focused approach: We listen, we analyze, and we tailor each design to your unique business case.

Cutting-edge tools: Our use of platforms like SolidWorks and AutoCAD ensures design accuracy and manufacturability.

Global standards compliance: We adhere to ISO, IEC, ASHRAE, and other relevant codes.

Scalability: Our designs support your growth—whether you're starting small or scaling fast.

Timely delivery: We understand the value of time in industrial projects and deliver as promised.

Let’s Build the Future Together

Whether you’re designing a new facility, retrofitting an existing system, or upgrading your industrial controls, Asset Eyes is ready to collaborate. Our end-to-end design solutions allow you to focus on execution while we handle the technical intricacies of engineering design.

1 note

·

View note

Text

Small & Scalable Solution For Entry-Level Automation: NX-ERA Xpress

NX-ERA Xpress is the mini PLC with macro features from Messung, India's first indigenous PLC manufacturer and leader in process automation.

Amongst the top PLC automation companies in Pune, and indeed, in India, Messung has developed this world-class programmable logic controller in India at a cost-effective price - especially for entry-level applications.

Packed with advanced features, NX-ERA Xpress micro PLC in India delivers high-speed processing power in a compact design with embedded I/O. The PLC system can be easily expanded - a great advantage for OEMs with needs of small, scalable applications.

Indeed, with its compact dimensions and competitive pricing, NX-ERA Xpress has opened up new perspectives in industrial automation. Many applications for which automation was a difficult option can now benefit from the many advantages of these entry-level programmable logic controllers.

The NX-ERA Xpress product portfolio targets small PLC panels or programmable controller systems, offering models containing from a few digital inputs and outputs up to options with 43 I/O points concentrated in a single controller, including analog inputs and outputs with temperature support (RTD sensors).

NX-ERA Xpress Applications

NX-ERA Xpress is suitable for small applications and remote distributed I/O in verticals such as factory automation, machines, infrastructure, building automation, water, wastewater, food, textiles, and several other OEM solutions. Additionally, it is an ideal solution for complementing big applications along with NX-ERA Series portfolio, extending the range of applications using the same technology and engineering environment.

Messung has successfully applied NX-ERA Xpress for:

· plastic injection machine controllers

· blow moulding machine controllers

· pharma machine controllers

· machine tool controllers

· SPM controllers

· textile machine controllers

· bandsaw controller

· general purpose machine controllers.

The embedded I/O PLC has also proved itself for:

· Dust analyser

· Continuous furnace

· Pressure testing

· Hydraulic press

· Robotic cell

· Boiler automation

· Battery management system.

NX-ERA Xpress has also enhanced performance and control in:

· material handling controllers

· motion control systems

· water purification systems

· energy management controllers

· process controllers

· PID controllers

· servo motion controllers

· AHU controllers.

Advanced features, economical price

NX-ERA Xpress is Industry 4.0 based controller with OPC-UA, MQTT features inbuilt. Thus, data generated by the machines can be used along the entire value chain. In smart home or building automation applications, with this MQTT based PLC, status information from sensors can be sent to mobile devices from where control commands can be sent back.

In case of additional I/O needs, the PLC system can be easily expanded through CANopen using the Remote I/O Mode. NX-ERA Xpress can connect to external devices such as sensors, electro mechanical actuators, VFDs and servo motors located far away from the main control cabinet via various protocols, namely Modbus, CANopen, and Messung's own 'Mesbus'.

It can also be expanded using other available ports like Ethernet and RS-485.

The other advanced features include:

· High density I/O both Digital & Analog

· Programming by Codesys (r) - IEC 61131 based software

· Integrated communication with international standard protocols like Modbus TCP, Modbus RTU, Ethernet I/P, CANopen

· Industry 4.0 enabled IIOT interface with MQTT & OPC UA protocol

· RS-485 port with Modbus RTU Master protocol

· SCADA and HMI interfaces available

· Built in HTML web server

Indigenous innovation at its best

NX-ERA Xpress represents the ongoing innovation of Messung, under its ‘Navonmesh – Make in India initiative’. Since it pioneered India’s first indigenous PLC in India in 1984, Messung continuously designs and manufactures world-class industrial automation solutions at an affordable price.

Messung is a leading PLC automation company in India. With four decades of experience and expertise in the field, inhouse R&D centre plus proven all-India reach and service support, Messung is the preferred partner for all your small to large industrial automation needs.

Besides a range of world-class Programmable Logic Controllers in India, Messungalso offers Remote I/O Modules, Servo & Motion Control solutions, VFDs, Human Machine Interface (HMI) and SCADAapplications for a gamut of applications across diverse industries. Contact Messung for your automation requirements today.

#mini PLC#PLC manufacturer#PLC automation companies in Pune#programmable logic controller in India#process automation#micro PLC in India#PLC system#industrial automation.#programmable logic controllers#PLC panels#programmable controller#material handling controllers#motion control systems#water purification systems#energy management controllers#process controllers#PID controllers#servo motion controllers#AHU controllers.#MQTT based PLC#CANopen#VFDs#PLC in India#industrial automation solutions#PLC automation company in India

0 notes

Photo

Messung's solutions are designed to share information and make sure your systems work together maximizing both comfort and energy efficiency while reducing energy expenses. Whether new construction or retrofit applications, Messung’s expert can help you to design, install, integrate and maintain your control system with efficient energy management. Messung's solutions have the flexibility and scalability to adapt, and deliver results for your building environment.

About AHU

An Air Handling Unit (AHU) regulates and circulates air as part of a heating, ventilating and air-conditioning (HVAC) system. It consists of a blower, heating or cooling elements, filter racks, sound attenuators and dampers. It is usually connected to a ductwork system that distributes the conditioned air through the building and returns it to the AHU.

Sometimes, AHUs discharge and admit air directly to and from the space without ductwork.

With the growing emphasis on energy performance in buildings, and new standards to study and improve energy efficiency, buildings need automation & control systems to achieve high levels of energy efficiency.

HVAC is one area where huge amount of power is consumed, and where plants with energy-optimised design, installation and commissioning are a must. Automation with AHU-specific functions ensures more systems' energy efficiency, operational reliability and availability. Automation also monitors room and outdoor temperatures to reduce cooling energy needs and improve comfort levels.

MESSUNG is an Automation Partner capable of Supplying Solutions to any Project of Air Handling Units and Environment Control Systems.

A Case Study

“Our Customer is a Bengaluru based company involved into manufacturing of Products like Metal Working Tools, Mining, Foundation Drilling cutting Tools, Tungsten carbide wear components etc.. required for Industries like Aerospace, Additive manufacturing, Machine Tool Industry, Energy, Earthworks.”

Basic AHU for Coating Room

The project required Messung’s solution to ensure that the coating room is maintained under 5 Pa Negative pressure with respect to ambient and within the room temperature zone of 21.1 Deg. C to 24.4 Deg. C and RH Zone of 40% to 60%. Since the system is working round the clock, it is necessary to control the system in such a way that minimum power is consumed by the HVAC system.

In addition, in case of any process gas leakage in the coating room, fresh air supply and exhaust to be operated at the it’s full capacity to exhaust the leaked gases promptly.

Messung’s solution

- Messung proposed an AHU System which can maintain acceptable room conditions using 2 stage evaporative cooling or using chilled water cooling coil, depending on the ambient air conditions throughout the day and year.

- Variation of ambient conditions in Bengaluru through the day and year is such that the ambient air conditions can be used to maintain the desired room conditions for much of the time, mainly in cooler nights and winter season.

- Since the plant is working round the clock, Messung decided to make use of favorable ambient conditions to the best possible extent to minimize the power consumption by AHU system.

- Messung divided the variation of ambient air conditions throughout year, into 3 parts:

o Mode -I, where in the ambient condition is hot and dry, where either single stage or 2 stage evaporative cooling can be used to maintain room conditions.

o Mode – II, Monsoon conditions with high RH and not so cold temperature, wherein conventional chilled water cooling coil will be used to cool and de humidify and maintain the designed room conditions

o Mode – III, typically winter conditions, Messung proposed to modulate return air and cold fresh, as well as single stage evaporative cooling to maintain the designed room conditions.

Proposed Control System

Salient Features

• Versatile CPU with large Input/output signals handling capacity

• Capturing real time data for Temperature, Relative Humidity,Running hours for AHU

• Large program memory for implementing complex Relative Humidity formulas

• Incorporating of Program Algorithm based on Psychometric chart readings

• Connection of CPU with 15 nos. of VFD’s on MODBUS RTU control network.

• Prompt monitoring & Controlling the entire system using HMI

Psychrometric Chart

Conclusion

Messung's NX-ERA Series of PLCs for industrial automation help to monitor, control and optimise AHUs to ensure performance and efficiency of HVAC systems. Messung's AHU control systems feature these latest technology PLCs with user-friendly interface to monitor and control each component of the AHU including fans, heating, cooling, humidification, heat recovery, etc. The systems offer design flexibility with variable size options and a wide range of choices to make your facility more productive and energy-efficient.

#industrial automation & control systems suppliers#industrial automation & control solutions in India#plc automation companies in India

0 notes

Link

DESCRIPTION OF SYSTEM

In the process of automatic coating of tablets the coater needs to be supplemented by a correctly designed, versatile coating system.

CHITRA’S Coating System have been designed after a careful study of the needs of expert coaters such as Rotational Speed, Efficient AHU system, inlet & exhaust air cfm & efficient solution spraying system etc.. etc...

CHITRA’S Coating System have very heavy & sturdy structure, made from SS304 pipes & sheets. Complete structure covered from outside. Processing Chamber designed with sealed from all side, in which negative pressure can be achieve. Chamber with 02 nos. of covers with hinges provided on two sides ( left & right ) of the structure to clean and remove / replace the pan.

Perforated pan with drive and mounting facility in the chamber.

Chamber with facility of wash water drain port with manually operated ball valve.

Motor with worm reduction gear unit and a bearing housing with shaft for pan drive. Variable Frequency drive for variable speed of pan.

Inlet air & exhaust air duct with b/f valve and Open – Close type pneumatic actuator, inside the chamber.

A FLP lamp at top of the chamber.

Spray nozzle mounting facility at chamber.

Perforated pan made from 10 SWG, SS316 material and polish to the mirror finish from inside & outside, with baffles & tablet unloading attachment.

AHU with pre filters, inlet air blower, cooling coil, phase & by pass system, heating coil, micro v & hepa filters with temperature sensor and Rh Sensor ( OR Dew point sensor – Optional ) & exhaust air blower.

Inlet and outlet air duct. (Non insulated – 06 meter each)

Solution preparation vessel with spraying system.

Model available 12”, 24”, 36”, 48”, 60” .

SPECIAL FEATURES : ( WHICH ARE INCLUDED IN BASIC COST OF THE M/C )

Pan fabricated from 2.5 mm thick, SS Sheet of SS 316 quality with 3.0 mm perforation at 4.5 mm triangle pitch for adequate opening area for better performance.

12” & 24” model are on wheel & 36”, 48” & 60” model with Anti vibrating unit provided for proper leveling, hence no requirement of foundation.

AHU with inside SS sheeting + Pre, Micro V & Hepa filter in SS Box + Cooling coil in copper tube and aluminum fins & Heating Coil in SS Tube & Aluminum Fins. ( if steam heated model ) and electrical heaters if electrically heated model.

Rh Sensor at air inlet line.

Differential Pressure Gauge at Hepa Filter.

Differential Pressure Gauge at Process Chamber.

Inlet air, Product Bed & Exhaust air temperature Sensor.

Variable Frequency Drive for (AC Drive) Pan Drive Motor, Inlet Air & Exhaust Air Blower.

RPM Indication facility.

FLP Lamp.

Port with Spray Ball for CIP. ( CIP system will be in customer scope )

Tablet Discharge Spout.

Inlet Air Blower.

Exhaust Air Blower.

Solution Preparation Vessel with propeller type stirrer with variable rpm facility. (Plain – Non Jacketed – Non FLP Model).

Pan Drive Motor flameproof.

Spraying Nozzle. ( Make - Spraying System – USA ).

Peristaltic Pump. ( Make – Master Flex – USA ).

Manually operated Atomizing Air Pressure Regulator & Fan Width Pressure Regulator.

Butterfly Valve at Inlet & Exhaust air duct with Actuator.

PLC & Touch Screen of Mitsubishi make (Touch Screen).

Inlet & Exhaust air duct – 5 Meter/ each.

OPTIONAL FEATURE WHICH WILL BE PROVIDE AT EXTRA COST, IF REQUIRED :

Dew Point Sensor at inlet air duct, instead of Rh sensor.

Velocity Trans-meter at inlet & exhaust air duct.

Differential Trans-meter at AHU & Process Chamber, instead of D.P.G. (02 nos.)

Jacketed Vessel instead of plain. (for Solution Preparation.).

Flameproof Model Vessel for Solution Preparation.

Flameproof Motor at inlet & Exhaust air blower.

Wet Scrubber at exhaust air.

Steam & Chilled Water Controlling Valve. (02 nos.)

Non FLP / FLP

Atomizing Air Pressure Regulator & Fan Width Pressure Regulator operating through Touch Screen.

Flameproof/Weatherproof Enclosure for Touch Screen.

Additional Duct per 1 Meter – Non insulated.

( for Inlet & Exhaust air ).

SPECIAL FEATURES WHICH COMPRISING OF FOLLOWINGS :

Horizontal, cylindrical vessel (Pan) of size 300 mm diameters, capable to coat 0.5 to 1.0 Kg. having welded on torispherical dished ends at both sides. The shell body is perforated properly (triangular pitch) to ensure optimum hot air inlet. The pan having a frontal opening for easy loading and unloading of tablets.

The pan driven by 0.5 HP flameproof motor through suitable reduction gearbox to achieve a variable rotational speed 5 – 25 RPM by means of Variable Frequency Drive (VFD).

Special type baffles with proper spacing are provided inside the pan for exposing all the tablet surfaces to get uniform coating and tablet (rolling) turning while rotating of the pan.

The coating pan is enclosed within double walled cubical, totally enclosed to ensure leak proof operation, provided with side doors for easy excess to the pan, the doors are duly insulated / properly sealed with food grade quality rubber with appropriate shore hardness. Locking device on both the doors and rounded interior corners, which helps easy cleaning and maintenance of coating pan.

A wash sink with proper drainage is provided at the lower plenum of the cabinet to conduct the washing of the perforated pan by increasing the speed of the pan in wash solution.

A luminous flameproof electric lamp is fitted on the top wall at the cubical above the coating pan to ensure sufficient effulgence to the working zone.

A peristaltic pump ( Indian make ) for precise and rapid priming facility for proper and accurate dosing of solution, supply shall be complete with solution transfer tube.

Highly sophisticated and efficient 01 No. Spray gun, ( Spraying System – USA make ) completely free from choking problem, controls both the application rate and the droplet size for all type of coating.

The guns are mounted on SS retractable header with angle adjustable arrangement.

In built type, PUF insulated double skin AHU with inside SS304 sheeting & all filters in SS304 box, comprising of Pre , Micro V & Hepa Filters, Inlet air Blower, cooling coil, Rh & inlet air temperature sensor and electric heating arrangements of 12 KW electrical load.

There are 5 micron pre filters at air inlet prior to the blower.

Centrifugal type blower fan of 100 CFM. The fan shall be dynamically balanced and with backward curved blades. Material of Construction SS304. Direct coupled 0.5 HP non flameproof electric drive motor of 415 V. Prior to inlet blower there shall be 5 micron pre filter.

The cooling section will operate if the process air entering the cooling section with high humidity at the start of the process. The cooling section will reduce the relative humidity of the air entering the air handling unit.

Shell & Tube, extended area, fixed tube sheet made with Copper tube and Aluminum Fins. ( The chilled water will be supplied by customer. )

12 KW electrical heaters made from SS tube will be at AHU for efficient & fast heating arrangement.

Micro V of 3 micron & Hepa filters 0.3 micron with attachments, viz. pressure drop / choking measurement across hepa filter by means of differential pressure gauge, DOP testing port for checking the integrity of Hepa filter, etc.

Rh sensor & inlet air temperature sensor will be provide at APU.

Phase & by pass system for precise control of inlet air temperature.

Centrifugal type blower fan of 150 CFM. The fan shall be dynamically balanced and with backward curved blades. Material of Construction MS duly painted or powder coated. Direct coupled 1.0 HP non flameproof electric drive motor of 415 V.

The quantum of exhaust air is higher than inlet air creates a negative pressure at coating zone, thus faster drying will take place. The quantum of air shall be controlled by means of variable frequency drive to both blowers.

MS power panel duly powder coated or painted comprises of contactors, relays, fuse links with base, transformers, ON-OFF switch etc. Proper ferruling and color coding will be provided for the wirings. It shall be mounted at servicing zone.

Operating panel shall be fabricated from SS304 material.

The automatic tablets coating system is operated through a user-friendly integrated control panel suitable for manual and automatic operation. The panel includes Mitsubishi make PLC & TOUCH SCREEN. The material of construction of the panel shall be of AISI 304Q. The panel having the following features :

Automatically controlled process parameters with indication and display such as :

- Inlet / Outlet Air Temperature. - Bed / cabinet temperature. - Pan RPM. - Inlet air Rh. - Spray on time. - inlet & outlet air cfm. - RPM of peristaltic pump. - Air pressure of Atomization air.

Automatic stoppage of spray in case of :

- Pan rotation stops. - Exhaust blower stops. - Hot air blower stops. - Atomization air pressure falls below set point.

All process contact parts are made of AISI 316 Q Stainless Steel. All non-process contact parts are made of AISI 304 Q Stainless Steel or heavy parts made out of mild steel and claded or covered with SS304 material.

Electric supply : 15.5 Kw. (Max.) ( In electrically heated model )

Electric supply : 3.5 Kw. (Max.) ( In steam heated model )

Steam : 30 Kgs./Hr.

Air : 20 CFM

Chilled water for AC 12” : 20 GPM : 5 DEG. C. inlet water temp.

0.5 HP FLP FOR MAIN PAN.

0.5 HP NFLP FOR INLET AIR.

1.0 HP NFLP FOR EXHAUST AIR.

0.5 HP NFLP FOR PERISTALTIC PUMP.

0.25 HP FOR STIRRER OF SOLUTION TANK

0 notes

Text

Enhancing AHU Performance with PLC-Based Control Systems

Imagine a world where your building breathes in oxygen. Where comfort meets air quality, and where energy is saved. It is the world where AHUs and PLC control systems are the starting point of everything in the domain of Energy management systems.

These AHU controllers (Air Handling Units) are the primary components of any new HVAC system. They serve as the lungs. But to make those lungs breathe better, smarter, and cleaner, you need a brain—enter the Programmable Logic Controllers (PLC).

We at Messung Industrial Automation are not just manufacturing PLC automation systems. We engineer intelligence. Smart PLC control is our ambition, and we aim to revolutionize the way AHU controllers operate, using a range of technologies, including Modbus, MQTT, compact PLCs, or IOT-enabled PLC.

What is a PLC-Based AHU Control System?

A PLC-based AHU control system is the ultimate HVAC master conductor. The flow, cooling, heating, and energy consumption of air are all controlled by real-time logic and precision through automation controllers.

Decision-making is the primary responsibility of a IoT enabled PLC (programmable logic controller), not just following instructions. Your AHU is designed to respond to data, adjust to changing surroundings, and function like a finely tuned machine with the help of intelligent controllers.

Whether it’s a mini PLC for a compact setup or a modular PLC for a multi-zone building, this IEC 61131-3 standard controller is the heartbeat of your air management system.

Core Functions of PLC Automation in AHU Controllers Applications

Sensor Integration

Temperature, humidity, CO2, and differential pressure are all sensors that your AHU controllers are equipped with. When it comes to Energy management systems, PLC control systems are necessary for reading, interpreting, and operating raw data.

Our intelligent PLCs work together with sensors to capture every detail of your indoor environment.

Data Analysis & Decision Making

After submitting the data, the PLC Automation magic begins. Our IEC 61131 based PLCs utilize advanced logic and maintain monitoring of variables such as:

Room occupancy

Outdoor air quality

Return air temperature

The intelligence in this scenario is not confined to automation alone it expands to the action of the PLC Control Systems.

Control Actions via Actuators

Now let's talk about the muscle of the operation. By utilizing PLC and Modbus TCP/IP, your automation controllers can dynamically control VFDs (Variable Frequency Drives) to regulate fan speeds while minimizing energy usage.

Actuated Dampers

Want zoned cooling in your building? Each damper is given precise guidance on when and where it should be opened or closed by our compact PLC, down to the second.

Valves

Our PLC automation system manages both hot and chilled water circuits, ensuring thermal comfort with accuracy.

Humidifiers & Dehumidifiers

System Overview: The NX-ERA JET Advantage

NX-ERA JET PLC is a digital command centre that is agile, adaptive, and always on alert as the AHU controllers. We have developed an intelligent and IEC 61131-3 standard PLC Control Systems that combine advanced logic, seamless connectivity, and flexible scalability. The NX-ERA JET is the key to ensuring that every component of your AHU system, including sensors and actuators, operates in perfect harmony.

Features of this IoT enabled PLC at a Glance

Modular PLC architecture is flexible and can be easily scaled for multi-zone management in large or changing infrastructure

The utilization of PLC with TCP/IP facilitates fast and secure communication between devices, including devices connected to remote systems

The integration of MODBUS RTU, Modbus TCP, and MQTT with BMS, SCADA, or cloud-based IoT platforms is facilitated by the native support provided by these protocols.

An integrated HMI that provides real-time, intuitive monitoring, diagnostics, and manual overrides.

Benefits of IoT enabled PLC for AHUs

In modern air handling, the focus isn’t just on moving air but moving it forward. Why? Integrating PLC control systems into AHUs can offer a transformative advantage in performance, sustainability, and adaptability for buildings. We should examine why PLC automation is the primary driving force behind intelligent HVAC solutions.

Improved Energy Efficiency

The value of energy is high, and PLC for energy systems with IEC 61131-3 standards optimizes every kilowatt. We can use our IoT enabled PLCs to save energy - up to 30% a time with intelligently controlled fan speeds, valve positions and damper angles that are real-time. Measurable reductions through these intelligent controllers help to reduce operational costs and greener footprints are not just numbers.

High Precision Control

AHU controllers equate performance with precision. Why? Our IEC 61131-3 compliant PLCs provide precise control over airflow, temperature and humidity. The result? Consistent comfort, efficient performance and strict environmental regulations.

Advanced Diagnostics

The use of intelligent PLCs with IoT systems means that problems can be prevented rather than delayed. With real-time monitoring and fault detection, teams can receive predictive maintenance insights to minimize downtime and maximize up time.

Scalability and Modularity

Our modular PLCs are designed to accommodate the growth of your building, offering compact systems and multi-zone installations. Do you require an immediate upgrade or expansion? These intelligent controllers can scale without complexity.

BMS Integration

Our PLC Control Systems with IEC 61131-3 standard integrates seamlessly with Building Management Systems, creating one intelligent ecosystem. Whether it’s HVAC, lighting, fire alarms, or access control—everything talks to everything for smoother operations.

In a world where data and efficiency are the primary drivers of change, PLC-controlled AHU controllers provide more than just automation; they also offer confidence. Our IoT enabled PLCs enable buildings to thrive rather than just functioning.

Intelligent PLC Control Systems for Smart Buildings

HMI with PLC Controllers - An HMI with PLC controller enables the observation of invisible areas. The entire package, including fan speed and filter life, is conveniently located at your fingertips.

MQTT based PLC and IoT Systems - The integration of IoT enabled PLC and MQTT support enables your AHU to communicate with the cloud, apps, and analytics platforms, simplifying the process of achieving predictive control and remote access.

Real-World Applications

Through PLC-based AHU control systems, we at Messung are changing the possibilities of environments from sterile labs to busy malls. With precision, adaptability, and unparalleled reliability, our intelligent automation controllers tackle the challenges associated with every application.

Pharma Cleanrooms - The precision of pharmaceutical products is essential in their application. The strict GMP standards are adhered to by our PLC control systems, which involve managing temperature, humidity, pressure differentials. The result? Zones that are sterile, upholding drug integrity and safety.

Commercial Buildings - Employee comfort drives efficiency. Our HVAC automation enables seamless climate management of all floors and departments. By utilizing intelligent design, efficient air circulation, and real-time monitoring, our IoT enabled PLCs enhance the productivity and satisfaction of customers in spaces.

Data Centers - Servers demand a stable climate 24/7. Even minor temperature fluctuations can compromise data. Our intelligent PLC Control Systems with IEC 61131-3 standard ensure uninterrupted cooling performance, reducing thermal risk and operational downtime.

Energy-Efficient Manufacturing - Today's manufacturers must strike a balance between sustainability and production. Without compromising comfort or compliance, our PLCs maximize AHU performance to reduce energy footprints, reduce emissions, and guarantee stable internal environments.

Wherever there's air to manage and performance to perfect, our Compact PLCs lead the way with intelligent control.

Messung’s Expertise in HVAC Automation

We at Messung lead the way in HVAC automation innovation for organizing smart air movement. Our legacy is created on trust, performance, and innovative control systems that transform indoor environments, not only on technology

Why Choose Messung PLC Automation?

We design smart automation systems rather than only selling PLC Control Systems. With more than four decades of engineering expertise, our PLCs are the favoured option of architects, MEP consultants, HVAC contractors, and facility managers across India and globally. Our internal R&D, field-tested dependability, and quick support system turn us into a progress partner rather than just a supplier.

Built on IEC 61131-3 Standard

To ensure every Messung programmable logic controller is consistent, dependable, and compatible with worldwide systems—today and tomorrow — our automation controllers follow this internationally recognized IEC 61131-3 standard.

Flexible Form Factors

Whether you are managing many air zones throughout a smart high-rise or automating a small rooftop AHU, our compact and modular PLCs meet every architectural and functional requirement.

Comfort, control, and conservation are not optional but rather vital in the quickly changing realm of smart infrastructure of today. Furthermore, realizing this potent triad calls for smart, adaptive control rather than just automation. That is what Messung's PLC-based AHU systems precisely provide. Our programmable logic controllers redefine air handling performance for buildings of all sizes with real-time responsiveness, easy BMS integration, IoT readiness, and IEC 61131-3 standard. Our intelligent controllers offer precision, dependability, and next-generation energy efficiency from sterile zones to skyscrapers. Should excellence be your goal, our IoT enabled PLC guarantees you lead rather than merely follow. Why settle for fundamentals when you may automate brilliance with our smart automation controllers?

FAQs

What makes a PLC suitable for AHU control?

Real-time processing, sensor compatibility, actuator control, and smooth BMS integration define good automation controllers. Messung's smart PLCs with IoT systems check every box

Can a modular PLC (Programmable logic controllers) handle multiple AHU zones?

Absolutely. Modular PLCs like Messung’s NX-ERA JET are great for big buildings since they can span levels and zones.

How does Messung's IoT enabled PLC enhance building performance?

Connecting to cloud systems and providing remote access help our IoT enabled PLCs to maximize energy efficiency and real-time maintenance cycles.

Why is Messung’s NX-ERA JET the ideal, affordable PLC choice for midscale operations compared to traditional compact or mini PLCs?

Messung’s NX-ERA JET offers advanced performance at an affordable price, making it perfect for midscale operations. It outperforms mini PLCs with better speed, scalability, and flexibility, without breaking the budget.

Are MQTT based Programmable logic controllers better than traditional protocols?

MQTT-based PLCs offer faster, lighter, and more effective communication than conventional systems like MODBUS RTU for remote and IoT-intensive applications.

#messing 1st blog ahu link#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#AHU controllers#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#AHU controllers systems#NX-ERA JET#HVAC solutions#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#Pharma Cleanrooms#Commercial Buildings#Data Centers#smart automation systems#programmable logic controller#BMS integration#smart PLCs#Modular PLCs

0 notes

Text

Choosing the Right PLC: A Guide for Small & Medium Industries

Finding the Perfect PLC for Your Application.

In today’s fast-paced industrial environment, choosing the right Programmable Logic Controller (PLC) is crucial for ensuring efficiency, reliability, and scalability. Small and medium industries often struggle to find a cost-effective solution that balances performance with flexibility.

Whether you're automating a machine tool, packaging line, water treatment plant, or a textile process, selecting the right PLC can significantly impact your productivity.

Key Factors to Consider When Selecting a PLC

✅ Application Complexity – Does your process require simple ON/OFF control, or do you need advanced motion and data handling?

✅ I/O Requirements – How many digital and analog inputs/outputs do you need?

✅ Communication & Connectivity – Is the PLC compatible with industry-standard protocols like Modbus, Ethernet/IP, or MQTT?

✅ Scalability & Future Expansion – Can the PLC adapt to your growing automation needs?

✅ Advanced Control Capabilities – Does the PLC support PID control for maintaining precise process parameters?

✅ Ease of Programming – Is the PLC supported by intuitive, user-friendly programming software?

✅ Cost & Support – Does the solution offer the best value without compromising on quality and support?

Messung XMPRO Series: Designed for Your Industrial Needs

At Messung, we understand the challenges industries face when selecting automation solutions. Our XMPRO-10 PLC series offers:

🔹 Compact & Scalable Solutions – Suitable for both small and medium industries, ensuring cost-effectiveness without performance compromises.

🔹 Advanced Connectivity – Supports Modbus, Ethernet/IP, and MQTT for seamless data exchange, real-time remote monitoring, and Industry 4.0 integration.

🔹 Precision Process Control with PID – Ideal for temperature, pressure, and flow control applications, ensuring optimized performance with minimal manual intervention.

🔹 User-Friendly Programming – Developed with XMPS-2000 software, making programming intuitive and efficient.

🔹 High Reliability & Performance – Built with robust hardware and backed by 4 Decades of expertise in industrial automation.

Proven Applications of XMPRO-10 PLC

Messung’s XMPRO-10 PLC has already been successfully implemented in a variety of industrial applications, including:

Testing & Automotive Industry:

✔Pressure Testing Machines – Ensuring precise pressure control.

✔ Leak Testing Machines – High-accuracy monitoring for quality assurance.

✔ Engine Test Systems/Benches – Automating real-time engine performance analysis.

✔ Vehicle & Transmission Test Machines – Advanced testing for automotive components.

✔ Battery Tray Leak Test Machines – Reliable testing solutions for EV battery components.

Manufacturing & Process Automation:

✔ Drilling, Tapping & Press Machines – Improving precision and repeatability.

✔ Core Shooters (Forging) – Optimizing metal casting processes.

✔ Shot Blasting Machines – Automating surface treatment applications.

✔ Salt Spray Chamber/Corrosion Testing – Enhancing material durability testing.

✔ Automated Liquid Filling Machines – Efficient and precise liquid handling solutions.

Textile & Environmental Control:

✔ Yarn Steaming Autoclaves – Optimized temperature and pressure regulation.

✔ Stator Varnishing Machines – Enhancing insulation durability in motor manufacturing.

✔ STP, ETP, WTP – Reliable PLC-based automation for sewage, effluent, and water treatment plants.

✔ Industrial Water Chillers & HVAC Systems – Seamless integration for environmental control solutions.

✔ AHU & Dehumidifiers – Smart control for air handling and moisture management.

Upgrade to a Smarter PLC Today!

Choosing the right PLC doesn’t have to be complicated. Messung’s XMPRO-10 PLC series is designed to meet the diverse needs of small and medium industries, delivering cutting-edge automation at an affordable cost.💡 Want expert guidance? Our team can help you select the best PLC for your specific application. Contact us today!

#PLC#Programmable Logic Controller (PLC)#XMPRO-10 PLC series#Industry 4.0#PLC-based automation#Smart control#best PLC#messung plc#water treatment plants

0 notes

Text

EXPLORE MESSUNG INDUSTRIAL AUTOMATION FROM THE COMFORT OF YOUR HOME @ AUTOMATION EXPO 2021

Starting 22nd September 2021, Automation Expo Connect is the first virtual expo for Automation & Instrumentation in S.E.Asia.Using a new virtual exhibition platform, Automation Expo Connect will enable more live sessions, meeting possibilities, and better person-to-person networking.

Automation Expo Connect will showcase high-quality trends through presentations of latest technologies, live interactions with the visitors. The virtual environment will also make it easier to meet customers from around the globe, and discuss their latest developments with our industry partners.

Messung is a regular exhibitor at Automation Expo, and this year too, looks forward to connecting with potential customers from India and abroad.

SHOWCASING AT AUTOMATION EXPO CONNECT 2021

In the spotlight at Messung's stall in Automation Expo Connect are Messung's NX-ERA range of innovative high-performance programmable logic controllers and XM-PRO Series of Remote I/O modules, for simple to complex industrial applications.

Messung’s portfolio includes:

NX-ERA Xpress This is a powerful mini PLC (Programmable Logic Controller) developed by Messung, leading micro PLC manufacturer.

NX-ERA Xpress enables enhanced performance and control in material handling controllers, energy management controllers, PID controllers and AHU controllers. The embedded I/O PLC has been successfully commissioned in applications such as Dust analyser, Continuous furnace, Pressure testing, Hydraulic press, Robotic cell, Boiler automation, Battery management system and water purification system.

NX-ERA Premium This advanced PLC system with redundancy is IEC 61131-3 compliant. It is able to control in a distributed and redundant way, complex industrial processes, high performance machines and production lines.

The Integrated Distributed Control Systems (DCS) features, programming and configuration environment based on IEC 61131-3 standard, help to speed up development and reduce engineering and commissioning costs.

NX-ERA Jet This is an ideal, cost-effective CPU for compact automation solutions with embedded I/O, for large and distributed systems as well as medium to small sized applications.

NX-ERA Jet has all the important features of the popular NX-ERA Series. It turns into a selection of input and output modules where requirements such as hot swapping and advanced functionalities such as OTD (One Touch Diagnostics) and EPS (Easy Plug System) are no longer necessary.

XM-PRO Remote I/Os Indigenously designed and manufactured by Messung under its ‘Navonmesh’ Make in India initiative, the XM-PRO Series of Remote I/O modules are CE marked and certified for usage in harsh industrial environments.

The XM-PRO range for CANopen and MODbus is expandable up to 128 I/O. They enable users to greatly increase the capacity of the automation solutions enabling connections via various protocols to electro mechanical actuators, sensors, VFDs and Servomotors, which are placed far away from the main control Cabinet.

MORE ABOUT MESSUNG

Messung is India's leading PLC manufacturer, with expertise in industrial automation proven over four decades in industry. For Process Automation, Messung has joined hands with Altus of Brazil, and leverages their in-depth knowledge to help process industries meet their quality and productivity challenges.

Messung’s industrial automation capabilities span three broad categories:

Process Automation Messung offers high-end process automation & control solutions in India to help process industries meet their quality and productivity challenges. Messung partners throughout the complete life cycle of your plant, and customises solutions that meet the highest technical demands for speed, quality, operational reliability, system availability and more.

Messung has joined hands with Altus, Brazil, to deliver customised process automation solutions for a gamut of industries including:

· Oil & Gas

· Sugar

· Pulp & Paper

· Water & Sewage Treatment

· Power

Servo & Motion Control Automation Messung develops fully integrated, future-proof solutions incorporating programmable logic controllers, motion control systems, servo drive products, VFDs, HMIs and much more – to bring flexibility, consistency and long-term availability for factory automation.

Messung provides high-speed, high-performance solutions for:

· Robotics & Handling Systems

· Plastic Technology

· Packaging & Food

· Printing & Paper

· Textile Machinery

· Machine Tools for Cutting & Forming

· Energy

General Purpose Automation Messung’s cutting-edge technology in PLC systems, remote I/Os, servo drives, VFDs, etc. enables high-performance, flexible machines that are information-enabled, and easy to integrate. They deliver real-timed diagnostics and maximise control, optimising safety, speed, productivity and efficiencies – for the competitive edge.

Messung offers smart, compact, economical solutions for:

· Special Purpose Machines

· Utility Applications

· Material Handling

· Machineries of General Usage

Do visit Messung in the Process Automation and Factory Automation pavilions at Automation Expo Connect 2021. On from 22nd to 25th September, this virtual expo offers 4 days to connect with Messung's advanced industrial automation offerings, without leaving your office or home.

0 notes

Text

Complete report about Air Handling Units Market forecast to 2028

Air handling units market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, the impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on the air handling units market, contact Data Bridge Market Research for an Analyst Brief. Our team will help you make an informed market decision to achieve market growth.

Download Sample Report @ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-air-handling-units-market

Market Analysis and Insights

The air handling units market is expected to witness market growth at a rate of 5.4% in the forecast period of 2021 to 2028. Data Bridge Market Research report on air handling units market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecast period while providing their impacts on the market’s growth. The rise in the novel technologically advanced products is escalating the growth of the air handling units market.

The air handling unit (AHU), also known as air handler, is referred to as a central air filtration system that reconditions the air to maintain the air quality and indoor temperatures. It is generally accumulated utilizing a metallic frame that is made of aluminum, galvanized steel, and other alloys, and it is armed with double-walled panels for energy efficiency.

Major factors that are expected to boost the growth of the air handling units market in the forecast period are the rise in the technological developments in air handling units. Furthermore, an increase in the need chemical, food and beverages, pharmaceutical, and oil and gas industries is further anticipated to propel the growth of the air handling units market. Moreover, the rise in the pollution level across the globe is further estimated to cushion the growth of the air handling units market. On the other hand, inactive development of the air handling units market is further projected to impede the growth of the air handling units market in the timeline period.

Get TOC @ https://www.databridgemarketresearch.com/toc/?dbmr=global-air-handling-units-market

You will get an answer for following questions like

What CGAR Air Handling Units Market can expand?

What is the estimated valuation for the Air Handling Units Market?

Who are the key players of the Air Handling Units Market?

What are the technology segments of the Air Handling Units Market?

The Key players included in the Air Handling Units Market report

Daikin Industries, Ltd., Carrier.

Trane Technologies plc

Johnson Controls

G.E.A. Group Aktiengesellschaft

Systemair AB

Flaktwoods India Pvt. Ltd.

CIAT Group

TROX GmbH

Lennox International

Airedale Air Conditioning

Sabiana SpA

WOLF GmbH

Novenco,

Euroclima SpA

V.T.S. Group

Hitachi, Ltd

The countries covered in the Aerospace Materials Market report are

U.S.

Canada, and Mexico in North America

Germany

France

U.K.

Netherlands

Switzerland

Belgium

Russia

Italy

Spain

Turkey

rest of Europe in Europe

View full report @ https://www.databridgemarketresearch.com/reports/global-air-handling-units-market

Customization Available: Global Air Handling Units Market

Data Bridge Market Research is a leader in consulting and advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include production cost analysis, trade route analysis, price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), import-export and a grey area results data, literature review, consumer analysis, and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Factbook) or can assist you in creating presentations from the data sets available in the report.

Browse related report @

Night Vision System and Driver Monitoring System Market

Off-highway Electric Vehicle Market

Railway System Market

Rolling Stock Management Market

Smart Parking Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

0 notes

Text

Messung Indigenous Innovation At work :NX-ERA Xpress

NX-ERA Xpress is a powerful mini PLC (Programmable Logic Controller) developed by Messung, leading micro PLC manufacturer underits ‘Navonmesh - Make in India initiative’. A micro PLC with macro features, NX-ERA Xpress is creating waves in small, scalable applications.

Messung’s reputation and expertise in industrial automation goes back four decades. Since it pioneered India’s first indigenous PLC in India in 1984, Messung has stayed committed to developing world-class industrial automation solutions at cost-effective prices.

NX-ERA Xpress is the latest in a long tradition of ongoing innovation at Messung, one of theleading PLC automation companies in Pune. This mini programmable logic controller in India comes at a cost-effective price - especially for entry-level applications.

NX-ERA Xpress Features

· High density I/O both Digital & Analog

· Programming by Codesys (r) - IEC 61131 based software

· Integrated communication with international standard protocols like Modbus TCP, Modbus RTU, Ethernet I/P, CANopen

· Industry 4.0 enabled IIOT interface with MQTT & OPC UA protocol

· RS-485 port with Modbus RTU Master protocol

· SCADA and HMI interfaces available

· Built in HTML web server

· High speed CPU

· Real time clock

· Scalable within NX-ERA family of PLCs, it covers small to large solutions

· Easily expanded through CANopen using the Remote I/O Mode: can connect to external devices such as sensors, electro mechanical actuators, VFDs and servo motors located far away from the main control cabinet via various protocols

Diverse applications of NX-ERA Xpress

NX-ERA Xpress has been successfully applied for:

· general purpose machine controllers

· SPM controllers

· textile machine controllers

· machine tool controllers

· blow moulding machine controllers

· pharma machine controllers

· bandsaw controller

· plastic injection machine controllers

The embedded I/O PLC has also proved itself in applications such as Dust analyser, Continuous furnace, Pressure testing, Hydraulic press, Robotic cell, Boiler automation,Battery management system and water purification system.

NX-ERA Xpress also enables enhanced performance and control in material handling controllers, energy management controllers, PID controllers and AHU controllers. It is making a mark in verticals such as factory automation, machines, infrastructure, building automation, water, wastewater, food, textiles, and several other OEM solutions. Additionally, along with NX-ERA Series portfolio, it complements big applications, extending the range using the same technology and engineering environment.

Benefit from Messung’s‘Navonmesh – Make in India initiative’

NX-ERA Xpress, developed by Messung,is a compact PLC in India delivering high-speed processing power in a compact design with embedded I/O. For applications where automation is a difficult option, NX-ERA Xpress offers models containing from a few digital inputs and outputs up to options with 43 I/O points concentrated in a single controller, including analog inputs and outputs with temperature support (RTD sensors). With its compact dimensions and competitive pricing, NX-ERA Xpress mini programmable logic controller has opened up new perspectives in industrial automation.NX-ERA Xpress comes enriched with Messung’sfour decades of experience in the field, and backed by our inhouse R&D centre, proven all-India reach and service support. Besides a range of high-performance programmable logic controllers in India, Messung also offers Remote I/O Modules, Servo & Motion Control solutions, VFDs, Human Machine Interface (HMI) and SCADAapplications to deliver integrated solutions for varied industrial automation applications.

#Programmable Logic Controller#SCADAapplications#material handling controllers energy management controllers PID controllers#water purification system.#CANopen#compact plc#compact PLC in India#mini plc#mi

0 notes

Text

PLC POWER IN INDUSTRIAL AUTOMATION

The PLC is the heart and brain of industrial automation & control systems. As industrial automation & control systems continue to advance, growing in function and sophistication, PLCs too will have to evolve to keep pace.

Messung offers best-in-class PLCs and automation system components to help you build future-ready systems for diverse industrial applications.

Messung is the pioneer of India’s first indigenous Programmable Logic Controller. Messung was founded in 1981 when the founder began developing a prototype PLC in a humble garage. By 1984, India's first indigenous 1-bit processor-based PLC was launched - and went on to transform industry, replacing the traditional relay contactor logic.

Since then, it's been one continuous journey of innovation and excellence in industrial automation.

Today, Messung offers two advanced PLCs under its Nx-era brand: Nx-era Premium PLC and Nx-era Xpress mini PLC. Let's take a closer look at these feature-rich innovations designed and developed at Messung.

NX-ERA XPRESS MINI PLC

A compact PLC, NX-ERA Xpress offers full PLC performance with a small footprint. With its compact dimensions and competitive pricing, NX-ERA Xpress micro PLC has opened up new perspectives in industrial automation. Many applications for which automation was a difficult option can now benefit from the many advantages of these entry-level programmable logic controllers.

Nx-Era Xpress Highlights

· High density I/O both Digital & Analog

· Up to 42 I/Os in a single unit

· Programming by Codesys (r) - IEC 61131 based software

· Ethernet Port - TCP/IP, Modbus TCP/IP

· Industry 4.0 ready - OPC-UA, MQTT features

· RS-485 port with Modbus RTU Master protocol

· CANopen Master/Slave protocol

· SCADA and HMI interfaces available

· Built in HTML web server

Nx-Era Xpress Applications

NX-ERA Xpress is suitable for small applications and remote distributed I/O. It may be applied in verticals such as factory automation, machines, infrastructure, building automation, water, wastewater, food, textiles, and several other OEM solutions.

Messung has successfully applied NX-ERA Xpress to:

· Bandsaw

· Dust analyser

· Continuous furnace

· Pressure testing

· Hydraulic press

· Robotic cell

· Boiler automation

· Battery management system

· Salt spray chamber

· AHU application

· Milling machine

· Flat dipping machine

· Trunnion fixer machine

NX-ERA PREMIUM PLC

NX-ERA Premium is an IEC 61131-3 - compliant solution for any automation system. NX-ERA Premium Programmable Logic Controller is a modular PLC system able to control in a distributed and redundant way, complex industrial processes, high performance machines and production lines.

Itpresents resources for all stages of your application life cycle with its Integrated Distributed Control Systems (DCS) features, programming and configuration environment which is based on IEC 61131-3 standard, speeding up development and reducing engineering and commissioning costs.

The PLC controller also offers advanced diagnostics and hot swapping, minimizing or eliminating downtime for maintenance and ensuring a continuous production process.

With its modular architecture, NX-ERA Series stands out for its flexibility, fitting the exact size of your applications.

Nx-era Premium Highlights

BUS EXPANSION RACK High performance and advanced features for systems with a large number of I/Os

DISTRIBUTED SYSTEMS More reach to your control network, ideal for building automation, refrigeration and sanitation

HIGH AVAILABILITY CPU redundancy (for CPU Power Supply, Supervision, Control Networks and Field Buses) and hot swap modules, perfect for non-stop applications

Other Features

· IEC 61131-3

· High speed CPU

· Hot swapping

· Large memory

· OTD (One Touch Advanced Diagnostics)

· OFD (On Board Full Documentation)

· Industry 4.0

· BFO (Battery Free Operations)

· EPS (Easy Plug System)

· Multiple protocols - ProfibusDP, OPC, Modbus, Ethernet, Ethernet IP up to 2048 I/O

Nx-era Premium Applications

Nx-era Premium is designed to power process automation systems that automate and integrate entire processing lines for improved efficiencies and increased throughput. It has proved itself across processes in:

· Oil & GAs

· Sugar

· Pulp & Paper

· Water & Sewage treatment

· Power

CONCLUSION

Nx-era Xpress and Nx-era Premium represent Messung’s passion for innovation and factory automation. This PLC automation company’s goal is to empower businesses with the foremost technologies and high-performance products backed by deep domain knowledge and reliable support.

With over four decades of experience and expertise in the industrial automation business, Messung is a leading PLC manufacturer with a range of world-class Programmable Logic Controllers (PLC), Remote I/O Modules, Servo & Motion Control solutions, VFDs, Human Machine Interface (HMI) and SCADA applications for a gamut of applications across diverse industries.

Under its ‘Navonmesh – Make in India initiative’. Messung continuously designs and manufactures world-class industrial solutions at an affordable price. With its in-house R&D centre plus proven all-India reach and service support, Messung is the preferred partner for all small to large industrial automation needs.

#industrial automation#PLCs#Programmable Logic Controller#micro PLC#compact PLC#programmable logic controllers#•#CANopen#SCADA#factory automation#Bandsaw#Dust analyser#Robotic cell#Boiler automation#AHU application#IEC 61131-3 standard#PLC controller#process automation systems#PLC automation company’#PLC manufacturer#Programmable Logic Controllers (PLC)#Remote I/O Modules#Servo & Motion Control solutions#Human Machine Interface (HMI)

0 notes

Text

PLC POWER FOR INDUSTRIAL AUTOMATION, FROM MESSUNG

The PLC is the heart and brain of industrial automation & control systems. As industrial automation & control systems continue to advance, growing in function and sophistication, PLCs too will have to evolve to keep pace.

Messung offers best-in-class PLCs and automation system components to help you build future-ready systems for diverse industrial applications.