#Narrow Web Slitting Rewindings

Explore tagged Tumblr posts

Text

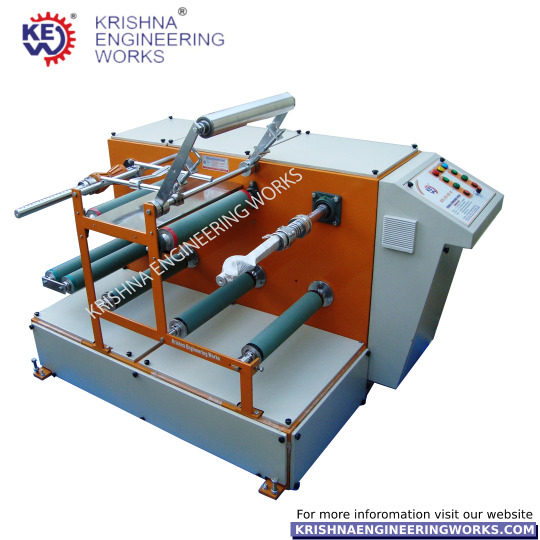

Narrow Web Slitting Rewinding Machine – Precision & Efficiency by KEW ENGG. & MFG. PVT. LTD.

KEW ENGG. & MFG. PVT. LTD. has designed and developed a cutting-edge Narrow Web Slitting Rewinding Machine, engineered for slitting, salvage winding, and de-lamination of rolls. With precision engineering and superior technology, this machine guarantees accurate inspection and high-performance web slitting.

#kewengg#machinemanufacture#exporter#supply#services#industry#narrowwebslittingrewindingmahcine#slittingrewindingmachine#windingrewindingmachine#printingindustry#flexiblepackaging

1 note

·

View note

Text

Key Printing Processes for Wine Labels

A bottle of high-quality wine is like a piece of exquisite artwork, and in this regard, the wine bottle and label play a crucial role. In the field of packaging printing, the printing process for wine labels is highly regarded. Here is an exploration of wine labels and their printing techniques. Wine labels typically include information such as the winery's name, the wine's name, variety, volume, alcohol content, country of origin, production year, and bottling location. For consumers, these details are very important. The design of the wine label often features the winery's logo, particularly noble emblems, royal seals, or depictions of the winery's landscape and architecture. Additionally, since each year's wine is printed with its vintage, many wine enthusiasts keep the beautifully designed labels with production years for later enjoyment and remembrance. With so much information contained on such a small wine label, how can it be beautifully presented? Modern narrow-web rotary printing technology, which uses high-tech methods, can fully showcase the details of the wine label.

Printing of the Main Image on Wine Labels

The main design on a wine label usually features intricate, exquisite, and classical patterns. Offset printing is the most suitable method for handling these designs, as it offers excellent halftone reproduction and the ability to reproduce fine text and lines. Furthermore, offset printing technology has been fully developed, and its supporting raw materials are well-established, making it a cost-effective option.

Printing Other Parts of the Wine Label

For smaller text or security microtext and patterns, offset printing can be used. If the label includes standard text, barcodes, and color blocks, flexographic printing is a good choice.

Post-Printing Processing for Wine Labels

Wine labels need to convey a sense of nobility and stability, so after printing, they often undergo additional finishing processes. For example, gold and silver effects can be added to the company logo or decorative lines using cold transfer or hot foil stamping techniques. In addition, the wine labels undergo processes such as embossing, die-cutting, waste stripping, slitting, and rewinding. The first color group uses flexographic printing or screen printing for the base layer on transparent wine labels. The second, third, fourth, and fifth color groups use offset printing for fine halftone images. The sixth color group employs screen printing for special effects. The seventh color group uses flexographic printing for text and color blocks. The ninth color group utilizes cold transfer or hot foil stamping to achieve gold and silver effects. The tenth color group applies flexographic printing for gloss coating. Subsequent color groups include embossing, die-cutting, waste stripping, slitting, rewinding, and other processes. Since platform exchange technology is used, various printing and processing methods can be switched freely, allowing for flexible adjustments in the process layout.

Explore our book printing services on the printing in China page. Additionally, high-tech applications on wine labels also rely on modern narrow-web rotary printing technology. For example, the double-layer wine label is a typical use of advanced printing technology, where the first layer can be easily removed, allowing consumers to collect it or easily find the same wine in a crowded wine shop. The second layer provides detailed information about the wine’s characteristics and the winemaker’s evaluation. Wine brand names and production years are often the most eye-catching elements for consumers. By using screen printing, a three-dimensional effect and vivid, saturated colors can be achieved, making it easier to attract consumer attention.

0 notes

Text

Martin Automatic’s finishing solutions for label industry

At Labelexpo India 2024, Travis Yang, representing Martin Automatic, talked to Packaging South Asia and shared insights into the company’s operations, products, and market presence. Martin Automatic, a US-based manufacturer of automatic splicers and rewinders, is known for its advanced solutions catering to the label and packaging industries.

Yang said that Martin Automatic operates from a single manufacturing plant in the United States. In Asia, the company’s sales and service needs are managed by a team based in Taiwan. "We have four employees in Taiwan, and I personally handle much of the travel across South Asia and Southeast Asia," Yang explained.

Product offerings

Martin Automatic’s equipment is designed to integrate seamlessly at both the front and back ends of flexographic presses and various converting lines. Yang described their products as suitable for a wide range of web-based materials. "We provide solutions for slitting, rewinding, and other finishing processes," he said, terming the company as a key player in the label finishing sector.

The company has achieved notable penetration in the Indian market, with 13 installations catering to both narrow-web and mid-to-wide-web applications. Martin Automatic’s solutions serve industries ranging from cigarette packaging to flexographic and non-woven packaging.

However, Yang acknowledged the competitive challenges in India. "The volume is there, but it’s a price-sensitive market with strong competition from local and Chinese brands," he said. "We focus on the top-tier clients to stay competitive."

Labelexpo India 2024: A platform for engagement

Reflecting on the event, Yang remarked, "The second day was busier, but overall, it has been an okay experience." The expo provided a platform for Martin Automatic to connect with industry professionals and reinforce its commitment to delivering innovative, high-quality solutions.

0 notes

Link

We are a has Narrow Web Slitting Rewinding Machine Manufacturer India with custom application for printed film, Slitter Rewinder Machine, Slitting Machine, Slitter Rewinder Machine Manufacturer, Narrow Web Slitting Rewinding, Doctoring Slitting Rewinding Machine for Batch Printing, Doctoring Rewinding Machine, Doctor Re Reeling Machine, Label Stock Doctoring Rewinding Machine, Doctoring Slitting Rewinding Slitting Rewinding Machine for Batch Printing and Coding packaging materials.

#Narrow Web Slitting Rewinding Machine#Narrow Web Slitting Rewinding#Slitting Rewinding#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Narrow Web Slitting Rewindings#Narrow Web Slitting Machine#Doctoring Slitting Rewinding

0 notes

Link

We have been manufacturing Inspection Slitting Machine, We have designed Narrow Web Slitting Rewinding Machine as ideal for slitting salvage winding Machine. We have designed and built Narrow Web Slitting Rewinding Machine, Slitter Rewinder Machine, Slitter Rewinder, Slitting rewinder Machine, Doctor Rewinder Machine, Doctor Rewinder, Doctor Rewinding, Doctoring Rewinder Machine unit as ideal for slitting salvage winding, and de-laminatio of rolls. It allows accurate inspection and narrow web slitting.

#Narrow Web Slitting Rewinding Machine#Slitting Rewinding Machine#Slitting Rewinding#Slitting Rewinding Machine Manufacturer#Inspection Slitting Machine#Slitting Rewindings#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Slitting Rewinder Machine#Slitting Rewinder Machines#Slitting Rewinder

0 notes

Link

We are Manufacturer Of Narrow Web Slitting Rewinding Machine, has designed and built Narrow Web Slitter Rewinder Machine as ideal for slitting salvage winding Machine. The units feature multiple diameter differential or air-expanding Rewinder. It allows accurate inspection and narrow web slitting. Narrow Web Slitting Rewinding Machine unit as ideal for slitting salvage winding, and de-laminatio of rolls. Film Label Roll Paper Narrow Web Slitter Counter Rewinder Roller Cutter Converter Machine.

#Narrow Web Slitting Rewinding Machine#Narrow Web Slitting Rewinding#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitting Rewinding#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Slitting Rewinder Machine#Slitter Rewinding Machine#Slitter Rewinders

0 notes

Link

We are Manufacturer Of Narrow Web Slitting Rewinding Machine Manufacturer allows to accurate inspection and narrow web slitting of lamination film materials like Narrow Web Slitting Rewinding, Web Slitting Rewinding, Slitting Rewinding, Slitting Rewinding Machine, Slitter Rewinder Machine, Slitter Rewinder Manufacturer, Slitter Rewinding Machine. The units feature multiple diameter differential or air-expanding Rewinder. It allows accurate inspection and narrow web slitting.

#Narrow Web Slitting Rewinding Machine#Narrow Web Slitting Rewinding Machine Manufacturer#Web Slitting Rewinding#Web Slitting Rewinding Machine#Slitting Rewinding Machine#Slitting Rewinding Machines#Slitting Rewinding Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machines#Slitter Rewinder Machine Manufacturer#Slitting Rewinding#Slitter Rewinder

0 notes

Text

WEBTECH INTERNATIONAL MACHINERIES

GST 06AACFW8816A1ZC

IndiaMART Verified Leading Supplier

~ https://www.webtechengg.com/

~ https://www.webtechmachineries.com/

BRIEF INTRODUCTION :

Established in the year 1998, “WEBTECH GROUP” is the leading Manufacturer of Wide Range of Printing and Paper Converting Machineries :

~ Wide Web & Narrow Web Flexographic Printing Machine

~ Web Offset Printing Machines

~ ATM POS & Other Thermal Roll Slitting Rewinding Machines

~ Other Reel to Reel Slitting Rewinding Machines

~ Servo Controlled Reel to Sheet Cutting Machines

~ E-COMMERCE Courier Bag Making Machines

~ Automatic A4 Copier Manufacturing Machines

~ Blank Label Die Cutting Machines

~ High Speed Label Inspection Machines etc.

~ Honeycomb Paper Die Cutting Machine

☎️ Call us at : +91 9999779973

Also Please Subscribe to our YouTube Channel for more latest updates : 💫 👇

https://www.youtube.com/channel/UCKpciPWoG7D-AMaTOHbmbPg/videos?view_as=subscriber

0 notes

Text

Roll Slitting Machines Market Size Outlook 2027: Top Companies, Trends And Future Prospects Details For Business Development- TMR

Global Roll Slitting Machines Market – Introduction

A roll slitting machine is an industrial equipment employed to cut large rolls of materials, such as aluminum and paper, into narrower rolls in specific dimensions. Roll slitting machines are also known as baloney slicers, bologna cutters, or log slitters.

A roll slitting machine has two types of slitting i.e. log slitting and rewind slitting. In addition to this, rewind slitting is run or unwound through lasers or knives in order to form narrower rolls before being rewound on one or more shafts. Log slitting is used to roll the material without performing the process of unrolling or re-reeling. In rewind slitting, the web is unwound and run through the machine, passing through knives or lasers, before being rewound on one or more shafts to form narrower rolls.

Moreover, roll slitting machines have a wide range of applications in manufacturing processes such as material printing, coating, and lamination

Are you a start-up willing to make it big in the business? Grab an exclusive PDF Brochure of this report

Global Roll Slitting Machines Market – DynamicsKey Drivers of Global Roll Slitting Machines Market

Growing usage of metal cutting activities in the manufacturing sector is expected to fuel the global roll slitting machines market during the forecast period

Growth of global plastic and paper industries is expected to propel the global roll slitting machines market between 2019 and 2027, due to rising deployment of these machines in plastic and paper industries

Increasing adoption of artificial intelligence (AI) and automation solutions across different industries for improving efficiency along with effectiveness is expected to boost the global roll slitting machines market during the forecast period

Growth of the packaging sector across developed and developing economies is estimated to boost the demand for roll slitting machines during the forecast period, as the packaging sector is a prominent end-user of roll slitting machines

North America to Hold a Major Share of Global Roll Slitting Machines Market

North America is expected to hold a significant share of the global roll slitting machines market during the forecast period, due to strong position in manufacturing activities. This, in turn, is estimated to drive the roll slitting machines market in North America from 2019 to 2027.

The roll slitting machines market in Asia Pacific is likely to expand at a significant rate during the forecast period, due to increasing adoption of roll slitting machines in paper, textile, and plastic industries in the region

Europe is projected to be hold a considerable share of the global market for roll slitting machines during the forecast period, due to rise in prices of pulp and increase in the demand for packaging in the region. Roll slitting machines are used in pulp and packaging industries for operations such as die cutting or shearing.

Looking for exclusive expert insights from business experts? Request a custom report here

Global Roll Slitting Machines Market – Competition LandscapeKey Players Operating in Global Market

A few local, regional, and international players operate in the roll slitting machines market. Manufacturers of roll slitting machines are adopting various strategies for design and manufacture of roll slitting machines to cater to the rising demand in numerous industries. The global roll slitting machines market is highly concentrated, with the top manufacturers accounting for approximately 25%–30% of the market share. A few of the key players operating in the global roll slitting machines market are as listed below:

ALS

CMC Converting Machinery Cevenini Srl

Ghezzi & Annoni

H. R. (Paper) Machinery Private Limited

Hariram Engineering

K M Trivedi Engineering Pvt. Ltd.

Kashif Saeed General Trading LLC

Kuen Yuh Machinery Engineering Co., Ltd.

Manfred Oilk Rohrwerkstechnik GmbH & CO. KG

Orion Graphic Machinery

Oteman

R. K. Label Printing Machinery Private Limited

Rosenthal MFG

Svegea

Windmoller & Holscher Machinery k.s.

Global Roll Slitting Machines Market – Research Scope

The global roll slitting machines market can be segmented based on:

Operation Type

Slitter Blade

Distribution Channel

Industry

Region

Global Roll Slitting Machines Market, by Operation Type

Automatic

Semi-automatic

Manual

Global Roll Slitting Machines Market, by Slitter Blade

Large Circular Blade

Fixed Band Blade

Global Roll Slitting Machines Market, by Distribution Channel

Direct Sales (OEM)

Indirect Sales

Global Roll Slitting Machines Market, by Industry

Paper & Pulp

Textile

Packaging

Others (Manufacturing)

Global Roll Slitting Machines Market, by Region

North America

Europe

Asia Pacific

South America

Middle East & Africa

U.S.

Canada

Rest of North America

Germany

France

U.K.

Rest of Europe

China

Japan

India

ASEAN

Rest of Asia Pacific

Brazil

Rest of South America

UAE

Saudi Arabia

South Africa

Rest of Middle East & Africa

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

Request For Covid19 Impact Analysis Across Industries And Markets – https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=76765

Related Reports Press-Release –

https://www.prnewswire.com/news-releases/anti-microbial-and-stain-free-design-of-period-panties-menstrual-underwear-to-inundate-market-growth-noted-tmr-300870237.html

https://www.prnewswire.com/news-releases/cognitive-computing-market-to-expand-at-phenomenal-rate-of-cagr-49-9-cloud-applications-to-promote-growth—tmr-300845175.html

https://www.prnewswire.com/news-releases/smart-home-as-a-service-market-to-reach-us10-9-bn-by-2025–owing-to-rise-in-energy-management-systems-noted-tmr-300818411.html

About Us

Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.

Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with your aims. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information, we offer customized solutions through adhocreports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.

TMR believes that unison of solutions for clients-specific problems with right methodology of research is the key tohelp enterprises reach right decision.

Contact

Transparency Market Research

State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Website: https://www.transparencymarketresearch.com

0 notes

Link

Krishna Engineering Works is biggest manufacturer of Doctoring Slitting Rewinding Machine for batch printing. We are also manufacturing all types of Slitting Rewinding Machine like slitter rewinder for batch printing, Inspection Slitting Rewinding Machine, Narrow web Slitting Rewinding Machine, Winding Rewinding Slitting with one stage slitting, and many more. Doctoring Slitting Rewinding for Batch Printing designed and built with Speed: 100 to 150 Mtrs / min. For Laminates like Film, Paper, Aluminium Foil, PVC, Plastic, LD, LDPE, PP, BOPP, Cloth, Biscuit Wrapper, Oil Wrapper, Soap Wrapper, Detergent Wrappers and many more.

#slitting rewinding machine manufacturer#slitting rewinding machine#slitter rewinder manufacturers#paper rewinder machine#paper rewinder machine manufacturers#paper slitting and rewinding machine#doctoring slitting rewinding machine#paper winding machine#paper slitter rewinder machine#slitter rewinder for sale#slitting and winding machine#paper roll slitter rewinder

5 notes

·

View notes

Text

Purchase Non-Woven Rewinder Machine- Avail of The Best Offer Now

Are you planning to invest in a nonwoven Rewinder? Investing in a business is tricky because you have to take care of everything. Like you need to consider the quality, price, whether you are going to purchase the first hand or second hand and many more thing. In this piece article, we are trying to cover the buyer's guide so that this will be helpful for all.

What is a winder or rewinder machine?

A rewinder or winder is a machine that will wind the web into a roll. Three types of industrial winders are available in the industry. A winder or roll-up can be used just to convert the large master roll into a smaller master roll. This machine also winds the loose sheets of material into rolls. There are sometimes wound onto the cores, but not all the time.

About Nonwoven Rewinder

The nonwoven rewinder is specially designed for the slitting and rewinding of different types of fabrics, especially sensitive ones and technical textiles. The manufacturer company will offer multiple types of rewinders with or without slits and for any kind of web-based fabric. There are multiple components that one should consider before searching for a nonwoven rewinder service provider, which include the nature of materials, customer care, optional administration, etc.

The metal slitters will take a wide coil and then slice them to a narrower width. This cycle should be possible for maintaining the stock and when a client requires that width. The sheet metal cutting will require specific hardware, and when it is set appropriately, you can make extra preparation that is more quick and exact.

When you are done with your metal cutting by a specialist manufacturer, you will get the same advantages. Keep all the items steady and lessen the scrap.

After purchasing the material, pre-sliced the completed items

Think before you buy a machine

When the product quality of nonwoven products is important to the unwind, rewind, process and prepare for the delivery to the next stage, i.e., converting the process. All this should be done in such a manner that you will get minimal stress and maximize the preservation of the characteristics of the product built-in. The manufacturing company has developed a rewinding, winding, finished reel removal, packaging/handling system, and all other associated automation. The rewinder will transfer the master rolls into smaller rolls. They also wind loose sheets of materials that will roll. These rolls can go of any length. Now you consider your workload before you purchase the material. Some of the machines are automatic, and some are manual.

Conclusion:

Once you have decided that you are going to buy the machine, find out the manufacturers, as there are numerous manufacturers available who will offer you the machine on a pocket-friendly budget. Now you decide what whether you want to buy the first hand or second hand. Visit the official web page. Take the necessary information related to the Nonwoven Rewinder machine from the page.

0 notes

Text

SP Ultraflex’s ROBOSLIT impresses Constantia Parikh

Vienna-based Constantia is one of the largest flexible packaging manufacturers globally. It now has several plants in India based on its acquisitions of Parikh Packaging and Creative Polypack. It also set up a Greenfield plant for its recyclable PE-based flexible packaging plant called Constantia Ecoflex in Ahmedabad, inaugurated in 2019. We are producing an edited version of an interview of Ahmedabad-based Pragnesh Shah, plant head of the Constantia Parikh Packaging sub-cluster below.

Please tell us a bit about the inception of Constantia Parikh Packaging and its area of focus within the flexible packaging segment.

Pragnesh Shah – Constantia Parikh Packaging was formed in 2013, when the Parikh family, promoters of Parikh Packaging, welcomed the Constantia Flexibles group as partners. Regular investments in infrastructure, systems, and plant and machinery enabled the company to grow 3x, and the monthly output now stands at 1800 MT. In 2017, we decided to venture into 100% recyclable laminates and set up our new state of art plant ‘Ecoflex’ in 2019. We launched ‘Ecolam,’ a 100% PE-based laminate to replace aluminum foil from the new unit. By 2025, we plan for 100% of all consumer and pharma packaging to be recyclable, reflecting our commitment to society for environmental friendliness.

Can you help us with an overview of the plant and machinery in your company?

Pragnesh Shah – We started with indigenous machines but were let down in terms of performance. As a result, we shifted to European and Korean technology. We are happy to share that after seeing improvements in Indian machines over the years, we have come full circle today. Most of the recent additions to our plant are from reputed Indian manufacturers.

Being one of the oldest and most reputed converters in the region, we would like to know how important the role of slitting rewinding machines in the overall process of converting is?

Pragnesh Shah – Slitting is usually the last process before the final product is delivered to our customer. Most of our customers are from the food industry and cannot afford stoppages in their packing lines due to slitting defects. In addition, slitting defects can undo all the efforts made in the printing and lamination processes. Therefore, we feel it is essential to invest in the best technology for slitter rewinders, mainly because their cost is a small fraction of the total investment.

Which performance parameters are critical and which features are ‘must haves’ on a good slitter rewinder?

Pragnesh Shah – First and foremost, the ITM (Intelligent tension management), is an absolute must to reduce dependency on operator expertise. Here, the PLC computes and maintains the tension levels suitable to the job. I see the next level of automation in the area of the job setup. The hygiene factor is also very important for food and pharma customers, and a close study of the layout from this perspective is most essential while finalizing the machine. Lastly, I would stress the static management system, which will soon be the need of the hour as more and more customers switch to high-speed packing machines that are most intolerant to residual static.

After installing multiple dual turret slitter machines worldwide, how has your experience with this technology been so far?

Pragnesh Shah – Slitter rewinders with dual turret rewinds are the order of the day in these competitive times where the focus is to increase efficiency. Unlike duplex slitters, these machines run virtually non-stop, offering higher productivity, improved efficiency of man and machine, and optimal use of floor space. Consistency in performance is also higher as compared to duplex machines. Opting for dual turret slitters would also reduce the total number of slitters required to support a given plant capacity over a period of time.

You installed a ROBOSLIT machine from SP Ultraflex a few months back. How was your experience?

Pragnesh Shah – The OHP version of the Roboslit was installed at our plant in February 2021, and we have found its performance to be at par with the best in the world. The team at SP Ultralflex puts in a lot of effort in learning, researching, and understanding the customer’s pain areas and channelizes their inputs to their design department, leading to continuous improvements and innovations. They are also very supportive, understanding the significance of our queries, and give clear and meaningful answers.

Pragnesh Shah, plant head of the Constantia Parikh Packaging sub-cluster[/caption]

In general, most converters prefer compact, rear-loading slitter rewinders. But you have purchased the overhead model of the Roboslit series, the Roboslit OHP. What made you go for that model?

Pragnesh Shah – The most admirable quality in the OHP version is the overhead web movement. Substrates running between idle rollers at high speed tend to develop static charge and attract dust. This is not acceptable, especially when it comes to food and pharma customers. The substrate is always at a good distance from the floor level in the OHP layout, leaving no scope for the dust to contaminate its surface. Other advantages of the overhead path include easy access to the cutting section and better visibility of the running substrate. Last but not least, this layout improves the safety quotient of the machine – something that is non-negotiable within the Constantia Flexibles group.

To what extent did SP Ultraflex meet the expectations of Constantia Flexibles in terms of output, quality, operator friendliness, and safety standards?

Pragnesh Shah – To start with, safety and user-friendliness are of utmost importance to Constantia Flexibles, and both these aspects are well taken care of in the machine. Coming to the output, I have already spoken about the increased productivity of this machine by virtue of its dual turret rewind. I want to share another important dimension, which affects productivity – the ratio of rework. We have seen a drastic reduction in the percentage of narrow width coils that need to be edge corrected on doctoring machines, thanks to the better quality of finished reels produced on this machine.

How, in your opinion, does the SP machine compare with the European make machines in your plant?

Pragnesh Shah – It is a good indigenous technology at par with global standards, with certain additional features and a good team.

What is the future focus for Constantia Parikh Packaging in terms of capital equipment technology? As mentioned earlier, we are looking for indigenous machines which will fulfill our requirements and expectations. We have a robust technical evaluation team that defines the ‘what’ and ‘why.’ If all such conditions and expectations are fulfilled, we would prefer Indian make machines, thereby supporting the Make in India movement.

0 notes

Link

We have been successfully manufacturing Winder Rewinder and built Label Application Doctoring Rewinding Machine for inspect the printing quality. It allows max width of inspect upto 300mm with label roll into smooth edge side surface. Doctoring Slitting Rewinding Machine for Batch Printing, Slitting Rewinding Machine for Batch Printing / Coding, Inspection Slitting Rewinding Machine, Narrow Web Slitting Rewinding Machine, Doctor Rewinder Machine, Doctoring Rewinder Machine.

#Label Application Doctoring Rewinding Machine#Label Application Doctoring Rewinding Machines#Doctoring Rewinding Machine#Doctoring Rewinding Machines#Doctoring Rewinding#Doctor Rewinder Machine#Doctor Rewinder Machines#Doctor Rewinder#Doctoring Rewinder Machine#Doctoring Rewinder Machines#Doctoring Rewinder

0 notes