#Web Slitting Rewinding

Explore tagged Tumblr posts

Text

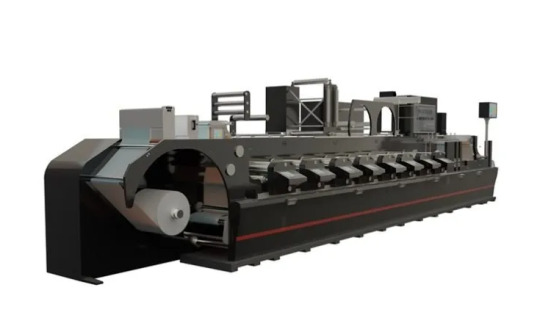

Narrow Web Slitting Rewinding Machine – Precision & Efficiency by KEW ENGG. & MFG. PVT. LTD.

KEW ENGG. & MFG. PVT. LTD. has designed and developed a cutting-edge Narrow Web Slitting Rewinding Machine, engineered for slitting, salvage winding, and de-lamination of rolls. With precision engineering and superior technology, this machine guarantees accurate inspection and high-performance web slitting.

#kewengg#machinemanufacture#exporter#supply#services#industry#narrowwebslittingrewindingmahcine#slittingrewindingmachine#windingrewindingmachine#printingindustry#flexiblepackaging

1 note

·

View note

Text

Webtech Group’s live demonstrations at Printpack 2025

Webtech Group, a leading manufacturer of printing and paper-converting machinery, will showcase its range of machines at Printpack 2025, to be held from 1 to 5 February 2024, at India Expo Centre and Mart in Greater Noida. It show demonstrate the fully servo flexographic printing machine in 450 mm working width, thermal roll slitting rewinding machine with single color online flexo printing, honeycomb paper die cutting machine, and servo-controlled label slitter rewinder machine

Along with the showcased machines, the Webtech team will highlight its entire range of products, including fully servo flexographic printing machines, web offset printing machines, slitting rewinding machines, and die cutting machines at its stand. The team will discuss technological advancements, share insights into the industry’s trajectory, and offer tailored solutions.

Singh emphasized the strategic importance of participating in Printpack 2025. “Printpack provides a vital platform to showcase technological advancements to a global audience and expand our clientele. The exhibition offers invaluable insights into emerging trends and challenges, enabling us to enhance our product offerings and stay ahead of market demands,” he said.

By participating in such exhibitions, Webtech aims to solidify its industry presence while forging new relationships with global clients. “For Printpack 2025, we aim to build on our previous successes by introducing our latest fully servo flexographic printing machine and other innovations. We look forward to engaging with industry leaders and further strengthening our position in the market,” Singh added.

Singh highlighted the evolution of the printing and packaging industry, driven by increasing demand for sustainable and flexible packaging solutions. Key advancements, such as fully servo-driven machines, automation, and eco-friendly substrates, are shaping the future of the industry.

“The printing and packaging sector is experiencing robust growth, with sustainability and precision at its core. We are poised to capitalize on these trends by offering innovative and efficient machinery that addresses challenges such as waste reduction and enhance productivity,” Singh explained.

Webtech International Machineries will be present in hall no 5, stands C19 and C28.

0 notes

Text

Key Printing Processes for Wine Labels

A bottle of high-quality wine is like a piece of exquisite artwork, and in this regard, the wine bottle and label play a crucial role. In the field of packaging printing, the printing process for wine labels is highly regarded. Here is an exploration of wine labels and their printing techniques. Wine labels typically include information such as the winery's name, the wine's name, variety, volume, alcohol content, country of origin, production year, and bottling location. For consumers, these details are very important. The design of the wine label often features the winery's logo, particularly noble emblems, royal seals, or depictions of the winery's landscape and architecture. Additionally, since each year's wine is printed with its vintage, many wine enthusiasts keep the beautifully designed labels with production years for later enjoyment and remembrance. With so much information contained on such a small wine label, how can it be beautifully presented? Modern narrow-web rotary printing technology, which uses high-tech methods, can fully showcase the details of the wine label.

Printing of the Main Image on Wine Labels

The main design on a wine label usually features intricate, exquisite, and classical patterns. Offset printing is the most suitable method for handling these designs, as it offers excellent halftone reproduction and the ability to reproduce fine text and lines. Furthermore, offset printing technology has been fully developed, and its supporting raw materials are well-established, making it a cost-effective option.

Printing Other Parts of the Wine Label

For smaller text or security microtext and patterns, offset printing can be used. If the label includes standard text, barcodes, and color blocks, flexographic printing is a good choice.

Post-Printing Processing for Wine Labels

Wine labels need to convey a sense of nobility and stability, so after printing, they often undergo additional finishing processes. For example, gold and silver effects can be added to the company logo or decorative lines using cold transfer or hot foil stamping techniques. In addition, the wine labels undergo processes such as embossing, die-cutting, waste stripping, slitting, and rewinding. The first color group uses flexographic printing or screen printing for the base layer on transparent wine labels. The second, third, fourth, and fifth color groups use offset printing for fine halftone images. The sixth color group employs screen printing for special effects. The seventh color group uses flexographic printing for text and color blocks. The ninth color group utilizes cold transfer or hot foil stamping to achieve gold and silver effects. The tenth color group applies flexographic printing for gloss coating. Subsequent color groups include embossing, die-cutting, waste stripping, slitting, rewinding, and other processes. Since platform exchange technology is used, various printing and processing methods can be switched freely, allowing for flexible adjustments in the process layout.

Explore our book printing services on the printing in China page. Additionally, high-tech applications on wine labels also rely on modern narrow-web rotary printing technology. For example, the double-layer wine label is a typical use of advanced printing technology, where the first layer can be easily removed, allowing consumers to collect it or easily find the same wine in a crowded wine shop. The second layer provides detailed information about the wine’s characteristics and the winemaker’s evaluation. Wine brand names and production years are often the most eye-catching elements for consumers. By using screen printing, a three-dimensional effect and vivid, saturated colors can be achieved, making it easier to attract consumer attention.

0 notes

Text

🚀 **Breaking Ground in Innovation: Unveiling India's First Thermal Roll Slitting Rewinding Machine with 2 Colors Online Flexo Printing!**

🔗 https://youtu.be/T8yDT-HoAnM?si=FpheJDEHJF_sF7ZD

Dear Valued Customers and Industry Pioneers,

We are thrilled to announce the groundbreaking launch of our latest technological marvel – the **Webtech Thermal Roll Slitting Rewinding Machine with 2 Colors Online Flexo Printing attachment**! This is a historic moment for us as we introduce the first-ever machine of its kind in India, setting new standards in precision and efficiency.

🌐 **Key Features:**

- **Web Guide Technology:** Ensuring seamless web alignment for flawless operations.

- **Electronic Brake:** Offering advanced control and safety in the production process.

- **2 Colors Flexo Printing Units:** Unleashing a world of vibrant possibilities for your printing needs.

- **Turnbar for Reverse Printing:** Elevating flexibility in design and output.

- **Slitting Rewinding Unit:** Providing superior accuracy in the final product.

⚡ **High-Speed Precision:**

Our machine is not just about innovation; it's about performance. With high-speed capabilities and unmatched accuracy, it delivers robust results, even at accelerated production rates.

🔧 **Robust Design, Perfect Output:**

The Webtech Thermal Roll Slitting Rewinding Machine is crafted with a robust design to withstand the rigors of industrial production. Expect perfection in every roll, even at the highest speeds.

🌟 **Why Choose Webtech?**

At Webtech, we don't just manufacture machines; we engineer solutions. Our commitment to excellence, coupled with cutting-edge technology, makes us the go-to choice for industry leaders.

📅 **Availability:**

Be among the first to experience the future of printing technology! Contact us now to inquire about availability and secure your spot in revolutionizing your production process.

Thank you for choosing Webtech – Where Innovation Meets Precision!

0 notes

Text

Top Benefits Of An Air Shaft In Manufacturing

The manufacturing industry-centric air shaft is employed for fitting into the core that wounds a variety of materials, including paper, cards, and plastic films. It readily expands on fitting into a core, leading to flawless operation during the manufacturing cycle.

Plenty of industrial converting machines employ the product. A slitting machine, widely known as a slitter rewinder has an air shaft in its core. It is basically designed to cut or slit large rolls of different types of material into smaller rollers. How does its engineering work? In this regard, you can connect with a reputed air shaft manufacturer.

An air shaft is also recognized by many other names in the industry circles, including air expandable shaft and air expanding shaft.

Salient Features of the Air Shaft

A premium quality air shaft displays the following salient features during application:

Competent to adjust to different speed variations

Proficient to adjust to different core widths

Demonstrates high speed, when repositioning of the product doesn’t happen

Efficient gripping

Efficient core centering

Manages uneven cores

For detailed information, collaborate with a prominent air shaft manufacturer in Ahmedabad.

Manufacturing Industries Drawing Benefits from the Air Shaft

Manufacturing industries galore are drawing benefits from mechanical product, including:

Packaging

Steel

Paper

As far as dimension of the air shaft is concerned, it is available in different dimensions. In case, you are searching for a custom-designed air shaft, you can collaborate with a reputed air shaft manufacturer.

Applications

An airshaft is a mechanical device designed for handling winding reels in the processing of web-fed materials.

0 notes

Text

Get High Quality and Exceptional Load Capacity with Expanding Shafts from Zen Coretech Engineers

For various industries across India and beyond, Zen Coretech Engineers is a trusted air shaft manufacturers in India. With a focus on quality, innovation, and customer satisfaction, the company has become a go-to provider for businesses seeking reliable solutions that enhance their operational efficiency and productivity.

At Zen Coretech Engineers, the company’s air shaft manufacturing process is the result of decades of experience and innovation. As air expanding shaft manufacturers, our air shafts offer world-class performance, durability, and precision for all your web handling needs. The company’s products have been designed with customer requirements in mind and have found success in numerous industries, including printing, packaging, and paper processing. With a large portfolio of customizable air shaft products, Zen Coretech Engineers is uniquely positioned to meet every customer’s specific requirements, including quick turnaround times and specialized designs.

Among Zen Coretech Engineers product range, the expanding shaft deserves special mention. These shafts provide a high degree of grip and are suitable for use in virtually any industry. They’re commonly used in rewind and unwind applications, as well as core winding and slitting processes. Offering exceptional load capacity, durability, and accuracy, expanding shafts are an excellent choice for businesses seeking to optimize production efficiency.

World-Class Performance, Durability & Precision - Zen Coretech Engineers

In addition to air shafts and expanding shafts, the company also produces banana rollers. These uniquely shaped rollers are ideal for use in the printing industry, where they can help to reduce wrinkles and improve print quality. Zen Coretech Engineers metal bow banana rollers offer superior performance and durability, making them especially well-suited for high-volume production environments. Whether you’re printing on paper, plastic, or a range of other materials, these rollers can help ensure a smooth, wrinkle-free process.

For businesses seeking to remove wrinkles from their production process, Zen Coretech Engineers’ wrinkle removing bowed roller are the perfect solution. Featuring a special shape that makes them ideal for smoothing out wrinkles, these rollers can play an important role in improving the quality of your end product. Zen Coretech Engineers wrinkle-removing bowed rollers feature precise engineering, ensuring that you get the results you need each and every time.

#air expanding shaft#bow banana roller#wrinkle removing bowed roller#air expanding shaft manufacturers

0 notes

Link

We are Manufacturer Of Narrow Web Slitting Rewinding Machine Manufacturer allows to accurate inspection and narrow web slitting of lamination film materials like Narrow Web Slitting Rewinding, Web Slitting Rewinding, Slitting Rewinding, Slitting Rewinding Machine, Slitter Rewinder Machine, Slitter Rewinder Manufacturer, Slitter Rewinding Machine. The units feature multiple diameter differential or air-expanding Rewinder. It allows accurate inspection and narrow web slitting.

#Narrow Web Slitting Rewinding Machine#Narrow Web Slitting Rewinding Machine Manufacturer#Web Slitting Rewinding#Web Slitting Rewinding Machine#Slitting Rewinding Machine#Slitting Rewinding Machines#Slitting Rewinding Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machines#Slitter Rewinder Machine Manufacturer#Slitting Rewinding#Slitter Rewinder

0 notes

Link

High-quality Rewinder Machine Manufacturer, Rewinding Machine, all type of high-speed Rewinder Machine with Web Aligner for different type of material and industry. All types of Rewinder Machine with Web Aligner for all types of Roto Gravure Printing Machine, Lamination, Coating Machine, Slitting Rewinding Machine, Extruder Machine, Textile Machine, Tyre Machine, etc. The Rewinder Machine is available with: Web Aligner System, Mechanical or Pneumatic Brake, Tension Control System, Line Guide System, Rollers, Safety Chucks, Bow Roller, Unwinder Drive & Control Panel (Optional), Shaft less Unwinder Unit. Rubber Roller Manufacturer, Rewinder Unwinder Manufacturer, Slitting Machine, Slitting Rewinder Machine Manufacturer in India.

#Winder Rewinder#Rewinder Machine#Rewinding Machine#Slitting Machine#Slitting Rewinding Machine#Slitter Rewinder Machine Manufacturer#Roto Gravure Printing#Printing Machine#Extruder Machine#Textile Machine#Line Guide System#Tracking Rollers Assembly#Bow Roller#Unwinder Drive#Rubber Roller Manufacturer#Coating Machine#tyre machine#Web Aligner System

2 notes

·

View notes

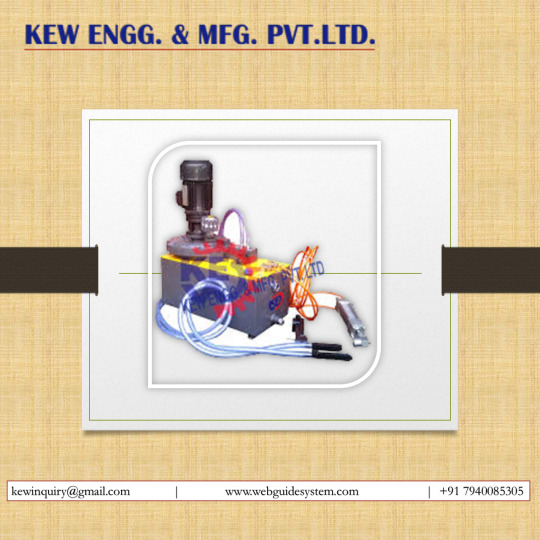

Link

Web Guiding System Manufacturer, Rewinding Unwinding is a process to rewind - unwind your material available in roll form like, flexible packaging, film, paper, foil, etc. Rewinding Unwinding is a repetitive process with high accuracy to wind or rewind your material in roll form. Unwinding or Rewinding Machine designed and suitable for all types of machines like Roto Gravure Printing Machine, Lamination, Coating Machine, Slitting Rewinding Machine, Extruder Machine, Textile Machine, Tyre Machine, etc. Web Guiding System Manufacturer, Rewinding Unwinding, Web Guiding System, Slitting Rewinding Machine, Doctoring Salvage Rewinder, Salvage Rewinders, Slitter Rewinder Machine , Winding Rewinding, Web Guiding Salvage Rewinding, Web Guiding System Manufacturer

#Web Guiding System Manufacturer#Rewinding Unwinding#Web Guiding System#Slitting Rewinding Machine#Doctoring Salvage Rewinder#Salvage Rewinders#Slitter Rewinder Machine#Winding Rewinding#Web Guiding Salvage Rewinding

1 note

·

View note

Link

We are a leading Manufacturer of Web Aligner for Slitting Rewinding Machine, Web Aligner Unit, Hydraulic Power Pack, Web Guiding Unit, Web Aligner System, Edge Guiding System, Slitting Rewinding Machine All type of Web Guiding System. Web Aligner for Slitting Rewinding Machine, Web Guiding Systems are used to automatically guide all type of all type of flexible material of any width, under any load, at any seed. Web Aligner for Slitting Rewinding Machine which serves various applications for all type of flexible printing, packaging & converting machineries.

#Web Aligner#Web Aligner Unit#Web Aligner System#Web Aligner System Manufacturer#Web Aligner for Slitting Rewinding Machine#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Web Guiding System#Web Guiding System Manufacturer#Web Guiding Unit#Web Guide System#Web Guide Unit#Edge Guiding System#Hydraulic Power Pack

2 notes

·

View notes

Link

Web Guiding Systems for different machines and industry, manufacturer and supplier of heavy duty Web Guiding System with 0.5 and 1.0 hp motor. Web Guiding System different types of Edge Guiding System, , Web Guide System, Web Aligner, Hydraulic Power Pack System, Center Guiding with Web Guiding System, Unwinding Machine with Web Guiding System, Rewinding Machine with Web Guiding System, Web Guiding System for Slitting Rewinding Machine, Line Guiding System, Tension Control System, Pneumatic Brake etc..

#Web Guiding Systems#Web Guiding Systems Manufacturer#Web Guiding System#Web Guiding System Manufacturer#Web Guide System#Web Guide System Manufacturer#Edge Guiding System#Web Aligner#Web Aligner System#Web Aligner Unit#Hydraulic Power Pack System#Hydraulic Power Pack System Manufacturer#Hydraulic Power Pack Unit#Rewinding Machine with Web Guiding System#Web Guiding System for Slitting Rewinding Machine#Line Guiding System#Tension Control System

1 note

·

View note

Link

#Web Guiding System#Web Guide System#Web Aligner#Slitting Rewinding Machine#Slitter Rewinder Machine

0 notes

Text

Martin Automatic’s finishing solutions for label industry

At Labelexpo India 2024, Travis Yang, representing Martin Automatic, talked to Packaging South Asia and shared insights into the company’s operations, products, and market presence. Martin Automatic, a US-based manufacturer of automatic splicers and rewinders, is known for its advanced solutions catering to the label and packaging industries.

Yang said that Martin Automatic operates from a single manufacturing plant in the United States. In Asia, the company’s sales and service needs are managed by a team based in Taiwan. "We have four employees in Taiwan, and I personally handle much of the travel across South Asia and Southeast Asia," Yang explained.

Product offerings

Martin Automatic’s equipment is designed to integrate seamlessly at both the front and back ends of flexographic presses and various converting lines. Yang described their products as suitable for a wide range of web-based materials. "We provide solutions for slitting, rewinding, and other finishing processes," he said, terming the company as a key player in the label finishing sector.

The company has achieved notable penetration in the Indian market, with 13 installations catering to both narrow-web and mid-to-wide-web applications. Martin Automatic’s solutions serve industries ranging from cigarette packaging to flexographic and non-woven packaging.

However, Yang acknowledged the competitive challenges in India. "The volume is there, but it’s a price-sensitive market with strong competition from local and Chinese brands," he said. "We focus on the top-tier clients to stay competitive."

Labelexpo India 2024: A platform for engagement

Reflecting on the event, Yang remarked, "The second day was busier, but overall, it has been an okay experience." The expo provided a platform for Martin Automatic to connect with industry professionals and reinforce its commitment to delivering innovative, high-quality solutions.

0 notes

Link

In our Unwinder Rewinder Machine with Web Guiding System, the Rolls goes into inspection & Tracking System and then the Roll goes in to Rewinder System. Unwinder Rewinder Machine with Web Guiding System manufacturer for all Paper Flexible Packaging Converters generally requires to make the smaller diameter rolls from Jumbo Rolls to shift smaller Rolls to different applications. Slitting may or may not be required for this application, which can be provided optional. In our Unwinder Rewinder Machine with Web Guiding System, from the Unwinder, the Rolls goes into inspection & Tracking System and then the Roll goes in to Rewinder System which is operated by Motor & Drive. Slitting Rewinding Machine and BOPP Tape Cutting Machine Manufacturer. Our Unwinder Machine & Rewinder Machine with Web Guiding System comes with Web Aligner System, which controls the edge of the Rewinder Roll. Slitting of Roll is optional. If required, slitting Operation can be incorporated in the Unwinder Rewinder System with Web Guiding System for Slitting of Rolls. However, Slitting will be for 2 or 3 maximum width rolls only. Ready in stock of all type of Web Guiding System with Slitter Rewinder Machine with International Standards.

#Web Guide System#Unwinder Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder Machine#Slitting Rewinding Machine#Slitting Rewinding#Slitter Machine#Rewinder Machine#Rewinding Machine#Slitting Machine#Slitter Rewinder Machine price#Film Slitter Rewinder Machine

0 notes

Link

Equipments Tyre Cord Dipping Plant, Two Stage Let off Station, Automatic Tension Control, Let-Off Accumulator, Centre Guiding System, Stretch Heat Zone, etc. Krishna Engineering Works is a leading manufacturer and exporter of Equipments Tyre Cord Dipping Plant, Tyre Cord and Technical Textile Fabric Dipping Plant/Machine and equipment with meeting the highest performance, safety, environment and cost criteria. It is designed for excellent quality of tire cord fabric for all categories of tyres.

#Tire Cord Machinery#Tyre Cord Dipping Plant#Tire Cord Machine Manufacturer#Tyre Cord Dipping Plant price#Web Guiding System#Web Guiding Systems Manufacturer#Tire Cord Machine#Automatic Tension Control#Slitting Rewinding Machine price#Slitters#Slitter Machine#Winder Rewinder Machine#Winding Rewinding Machine#tire cord manufacturer#tyre cord#Tire Cord Exporter

0 notes

Text

This Industrial roller for the paper industry is famous in industrial circles under various names, like a metal expander, banana roller, bow banana roller, wrinkle removing roller, spreader roller, etc. Next time, when someone says how banana roller help in the paper manufacturing industry, then don't get confused.

An excellence-driven product substantially accelerates the production cycle in a paper mill by performing a wide array of applications, including reducing slack ends, removal of wrinkles, spreading of film, separation of slit, coating, batching, and rewinding. Arvind Rub-Web Controls Ltd. is a reputed spreader roller manufacturer in Ahmedabad, India, having an exclusive modern manufacturing facility.

For more information visit the website https://www.arvindrubber.com/products/grooved-spreader-rollers.php

0 notes