#Nipo Flange

Text

Super Duplex S32760 Flanges Manufacturers in India

The manufacturer and supplier of Very Duplex Steel Flanges made their products in a variety of sizes and forms for the customer in response to interest. The manufacturer, stockist, and supplier of the entire stainless steel item, including this, is Sankalp Alloys Overseas. They provide everything and deliver the product while maintaining excellent quality and price as well.

Super Duplex Steel Flanges are regarded as the best in the series of steel Flanges based on their characteristics and strong points. The austenitic toughened steel is offered in Very Choice with a few components like copper, zinc, and chromium. The majority of businesses use a lot of Duplex steel products since they provide high strength when they come into touch.

There are many kinds of Flanges accessible, for example, Welding Neck Wall It is by and large utilized in low-temperature and high-pressure applications since they required the unhindered liquid stream conveyed by the line framework. Long welding Neck-They is equivalent to a weld neck just contrast in a lengthy welding neck the tightened center point (neck) is expanded and performs like an exhausting expansion. Slip-on Spine It is appended to the fittings or the line by two filet welds, one external the hole and the other one executed inside the rib. They are handily perceived by their minimal and thin shape.

Strung Rib This is attached by screwing the line into the spine rather than using a crease weld. They are typically used in small, low-temperature, low-stress applications like utility and water management. They are legally required in dangerous areas like petrol stations and industries. Since welding associations could be dangerous in this type of environment. Spine Attachment Weld To connect this type of rib to the lines, a single fillet weld is performed on the exterior of the rib. Joint-joint ribs This spine frequently uses an alloy with a stub end and a component with a level spacing. Dark Spine Due to the necessary catapulting forces and the structure pressure, these Flanges reduce outstanding mechanical forces.

A few other exceptional sorts of rib are Nipo rib, Weldo rib, Turn Rib, Elbo Rib, Lactro Rib, Growing spine, and Lessening Rib.

Specification of Super Duplex Stainless Steel S32750/S32760 Flanges

Super Duplex Stainless Steel Flanges Specification: ASTM A182 / ASME SA182

Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size: 1/2" (15 NB) to 48" (1200NB)

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges: BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

11 notes

·

View notes

Text

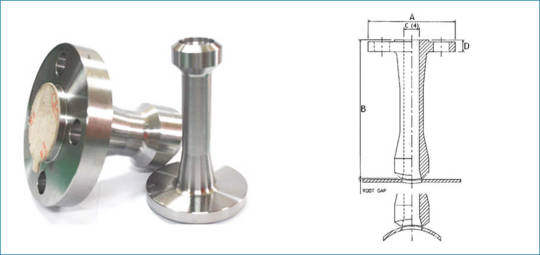

Nipo Flanges

Class 300 Nipo Flanges, Carb

on Steel Nipo Flange, Nickel Alloy Nipo Flanges, ASME B16.5 Raised Face Nipo Flange, ANSI B16.5 Nipo Flanges, Best Deals on Raised Face Nipo Flanges, ASME / ANSI B16.5 Nipo Flanges, Stainless Steel Nipo Flange dealer in India.

NIPO FLANGES MATERIAL & GRADES

Stainless Steel Nipo FlangesASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904LCarbon Steel Nipo FlangesASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70Alloy Steel Nipo FlangesASTM A182, F1, F5, F9, F11, F22, F91Duplex Steel Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Super Duplex Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Low Temperature Carbon Steel Nipo FlangesASTM A350, LF2, LF3

ASME B16.5 NIPO FLANGES SPECIFICATION

BS

BS4504 , BS4504, BS1560, BS10

FLANGE FACE TYPE

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

2 notes

·

View notes

Text

Petro-Canada Approved Flanges in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. offers a wide selection of Inconel 601 Flanges, which are renowned for their exceptional properties like corrosion resistance, ease of installation, and fine finishing. Inconel 601 Slip-On Raised Spines (UNS N06601) are regularly utilized in brilliant cylinders, strand tempering cylinders, and steam superheater tube upholds, among different applications. Customers choose Inconel 601 Flanges because of their outstanding mechanical strength and resistance to aqueous corrosion.

Weld Neck Raised Flanges made of Inconel 601 are formed using all the usual methods. For most extreme oxidation opposition, Inconel 601 Visually impaired Ribs ought to be welded utilizing matching piece 601 amalgam GTAW wire. Even in extreme thermal cycling conditions, Inconel 601 Socket Weld Flanges develop a strongly adherent oxide scale that resists spalling. Thermal processing equipment like muffles, retorts, radiant tubes, flame shields, flare tips, woven wire conveyor belts, electrical resistance heating elements, and burner nozzles all make use of Inconel 601 Ring Type Joint Flanges.

Inconel 601 Blind Flanges are also used extensively in the power generation, aerospace, and pollution control industries, particularly in jet engine igniters. Inconel 601 Long Weld Neck Spines offer incredible assurance against carburization and are likewise impervious to carbon nitriding conditions. Inconel 601 Nipo Flanges have excellent creep rupture strength and metallurgical stability, making them highly resistant to carburization. These Inconel 601 Lap Joint Spines are likewise accessible in different sizes and shapes to meet assorted client needs.

Specification Format of Inconel 601 Blind Flange

Standards: GOST Flange, JISB2220, BS1560–3.1, API7S-15, API7S-43, API605, EN1092, BS, BS4504, BS 10, EN-1092, DIN, ANSI, ASME, DIN, MSS S44, ISO70051, ANSI/ASME B16.5, ASME/ANSI B16.5/16.36/16.47A/16.47B, B16.47 Series A & B, B16.48, EN

Pressure Rating: ANSI class 1500, Class 150, Class 900, Class 2500, Class 300, Class 600

Pressure Calculation in DIN: 10Bar, 16Bar, 25Bar, 40Bar, 6Bar, / PN16, PN64, PN40, PN25, PN10, PN6

JIS: 16 K, 20 K, 5K, 10 K, 40 K, 63 K, 30 K

UNI: 10Bar 16Bar 6Bar 25Bar 40Bar

EN: 6Bar 25Bar 40Bar 10Bar 16Bar

Most Common Types: Threaded / Screwed / Forged / Plate

Production technique: Forged, Heat treated and machined

shapes and Types: we produce large Male-Female (LMF), Ring Type Joint (RTJ), Flat Face (FF), Small Tongue, Small Male-Female (SMF), Raised Face (RF), Large Tongue & Groove, Groove, Lap-Joint Face (LJF)

Test: Direct-reading Spectrograph, Magnetic particle detector, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector

Equipment: Pushing Machine, Press machine, Bending machine, Sand-blasting machine, electric bevelling machine, etc.

For More Information:

Visit Our Website: https://www.merakimetals.ae

Contact No: +971-523973687

E-Mail ID: [email protected]

#Inconel 601 Flanges Manufacturers in UAE#Inconel 601 Flanges Suppliers in UAE#Inconel 601 Flanges Stockists in UAE#Inconel 601 Flanges Exporters in UAE#Petrobras Approved Flanges in UAE

0 notes

Text

Stainless Steel 304 Flanges

We offer 304 Flanges in various sizes and thicknesses to meet customer requirements. These 304 Stainless Sleet Flanges find usage in various household and industrial applications such as machinery parts, screws, car headers, and food handling equipment. UNS We offer 304 SS Flanges in different kinds such as SS 304 Reducing Flange, SS 304 Slip-on Flange, SS 304 Orifice Flange, SS 304 Nipo- Flange, SS 304 Lose Flange, SS 304 Lap-Joint Flange, and SS 304 Blind Flange. We conduct thorough quality checks on our products which ensures their durability and reliability.

Stainless Steel 304 Flanges Manufacturers, Stainless Steel 304 Flanges Suppliers, Stainless Steel 304 Flanges Stockists, Stainless Steel 304 Flanges Exporters

We are instrumental in offering high quality range of Stainless Steel 304 Flange to our clients. We execute the manufacturing process of these stainless-steel products at the most sophisticated production premise under proper supervision of industrial experts.

Flanges made of stainless steel are referred to as "stainless steel 304 flanges," also abbreviated as "SS 304 flange." Common material standards and grades include ASTM A182 Grade F304/L and F316/L, with pressure ratings ranging from Class 150 to 2500 and 300 to 600, respectively.

#Stainless Steel 304 Flanges Manufacturers#Stainless Steel 304 Flanges Suppliers#Stainless Steel 304 Flanges Stockists

0 notes

Text

What are stainless steel 304 flanges?

Stainless Steel 304 Flanges are an essential component in pipelines and piping systems, connecting pipes, valves, and other equipment. At Bullion Pipes & Tubes LLP, we are the leading supplier, stockist, and Manufacturer of Stainless Steel 304 Flanges in India. Our flanges come in a variety of types such as Socket Weld Flange, Stainless Steel WNRF Flanges, Nipolet Flange, RTJ Flange, Blind Flange, Threaded Flanges, Slip-on Flanges, Nipo Flanges, Weld Neck Flanges, Lap Joint Flanges and Orifice Flanges, sizes, and specifications to meet the needs of our diverse range of customers.

In this blog post, we will provide comprehensive information on Stainless Steel 304 Flanges to help you make informed decisions when selecting the right flanges for your piping systems.

What is Stainless Steel 304 Flanges

Bullion Pipes & Tubes LLP, a prominent manufacturer and supplier of industrial components, offers a range of Stainless Steel 304 Flanges. These flanges are made from austenitic stainless steel, a metal alloy that comprises 18% chromium and 8% nickel. The inclusion of these elements makes the flanges robust and resistant to corrosion, particularly when used for general corrosive services.

These SS 304 Flanges come in an assortment of shapes and sizes, catering to various industrial applications. The material exhibits remarkable mechanical properties, such as a minimum tensile strength of 515MPa and a minimum yield strength of 205MPa. It can withstand most atmospheric conditions without undergoing any significant deterioration, thus exhibiting superior corrosion resistance.

Features of and benefits of Stainless Steel 304 Flanges

SS 304 flanges offer a range of features that makes it ideal for use in a variety of applications. The main features and benefits of SS 304 flanges include:

Durability: The presence of chromium and nickel makes this grade of stainless steel very hard and durable, making it suitable for use in a range of industrial and engineering applications. Additionally, SS 304 flanges have excellent formability as well.

Versatility: SS 304 offers excellent weldability and machinability, making it a versatile material that can be molded into a range of shapes and sizes. This makes it ideal for use in a variety of applications that require demanding fabrication and engineering work.

Corrosion Resistance: Due to its chromium content, SS 304 flanges are highly resistant to corrosion, rust and other forms of wear and tear. This makes it suitable for use in wet and humid environments, such as chemical plants and water treatment facilities.

Affordability: SS 304 is one of the most affordable grades of stainless steel, making it an economical choice for flanges.

Types of Stainless Steel 304 Flanges

With Bullion Pipes & Tubes LLP, you will find stainless steel 304 flanges in various types including;

Socket Weld Flanges:

Socket Weld Flanges are a type of flange that has a socket-like end to accommodate the pipe. They are welded to the pipe and have excellent resistance to high-pressure applications.

Stainless Steel WNRF Flanges:

Weld Neck Raised Face (WNRF) Flanges are a type of flange that has a long tapered hub and a neck that is welded to the pipe. They provide excellent resistance to deformation under high-pressure and high-temperature applications.

Nipolet Flanges:

Nipolet Flanges are a combination of a Weldolet and a Nipple. They are used to connect pipes of different sizes and reduce the number of fittings required in a piping system.

RTJ Flanges:

Ring Type Joint (RTJ) Flanges are used in high-pressure and high-temperature applications. They have a metallic ring that is compressed between two flanges to provide a leak-proof seal.

Blind Flanges:

Blind Flanges are used to seal the end of a pipe, valve or vessel. They are also used in piping systems where the end of the pipe needs to be closed temporarily for maintenance or repair.

Threaded Flanges:

Threaded Flanges have a threaded end that allows them to be screwed onto the pipe. They are commonly used in low-pressure applications.

Slip-on Flanges:

Slip-on Flanges are easy to install and remove, making them a popular choice for low-pressure applications. They have a circular plate with a bore and a raised face.

Nipo Flanges:

Nipo Flanges are a combination of a Nipple and a Flange. They are used to connect pipes of different sizes and reduce the number of fittings required in a piping system.

Weld Neck Flanges:

Weld Neck Flanges have a long tapered hub and a neck that is welded to the pipe. They provide excellent resistance to deformation under high-pressure and high-temperature applications.

Lap Joint Flanges:

Lap Joint Flanges are used in piping systems where frequent dismantling is required. They consist of two parts, a stub end and a backing flange.

Orifice Flanges:

Orifice Flanges are used in piping systems where flow measurement is required. They have a special opening or orifice that is installed between two flanges to measure the flow of fluid.

Applications of SS 304 Flanges

Due to its excellent features and benefits, SS 304 is suitable for use in a variety of industries, commercial and engineering applications. Some of the most common applications include:

Chemical Processing

Food Processing

Heat Exchangers

Medical Applications

Valves components and piping

Beer, Wine and dairy equipment

Ships and boat manufacturing

Plumbing System and so on.

Stainless steel 304 flanges are a versatile and reliable choice for a wide range of piping applications. At Bullion Pipes & Tubes LLP, we are proud to offer high-quality 304 Stainless Steel Flanges in a variety of types and sizes to meet the needs of our customers. Whether you need a single flange or a large order, we are here to provide you with the products and services you need to keep your piping system running smoothly. As one of the leading Manufacturers, stockiest, exporters, and Supplier 304 Stainless Steel flanges in India, we are committed to providing our customers with the best possible experience.

0 notes

Text

Super Duplex S32750/S32760 Flanges Suppliers in India

The producer and supplier of the Extremely Duplex Steel Ribs made their things for the client in different shapes and sizes as per the interest. Deep Steel Center is the producer, stockiest and supplier of the entire treated steel thing including this. They supply generally speaking and convey the thing by staying aware of the incredible quality and cost as well.

According to the properties and the features, Extremely Duplex Steel Ribs are considered as the best in the series of steel spines. A couple of things like copper, zinc, and chromium are accessible in the Extremely Decision which makes it the austenitic solidified steel. Most of the undertakings use exceptionally Duplex steel things since when these parts come in contact produce high strength.

There are numerous sorts of spines open, for instance, Welding Neck Wall It is all around used in low temperature and high-pressure applications since they required the unhindered fluid stream convey by the line structure. Long welding Neck-They are identical to weld neck simply contrast is in extended welding neck the fixed focus point (neck) is extended and performs like a debilitating development. Slip-on Spine It is annexed to the fittings or the line by two filet welds, one outside the opening and the other one executed inside the rib. They are helpfully seen by their insignificant and flimsy shape.

Hung Rib This is joined not by means of wrinkle weld but instead by screwing the line onto the spine. They are generally used in little size low-temperature and low strain like utility and water organizations. They are obligatorily expected in the dangerous district like gas plants and stations. Since in this sort of environment welded affiliation could be hazardous. Connection Weld Spine On the outside side of the rib a singular filet weld is executed to interact this sort of rib to the lines. Lap Joint Rib The blend with a stub end and part a level space is continually used in this spine. Blind Spine Considering the required catapulting powers and the system pressure, these ribs hold down noteworthy mechanical tension.

A couple other uncommon kinds of the rib are Nipo rib, Weldo rib, Turn Rib, Elbo Rib, and Lactro Rib, Developing spine, and Decreasing Rib.

Specification of Super Duplex Stainless Steel S32750/S32760 Flanges

Super Duplex Stainless Steel Flanges Specification : ASTM A182 / ASME SA182

Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard : ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size : 1/2" (15 NB) to 48" (1200NB)

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges : BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

0 notes

Photo

"Alloy Steel F1 Flanges."

Bhansali Enterprise makes and sells a wide range of high-quality alloy steel A182 F1 flanges. In order to maintain their strength and usefulness even after prolonged use, these fittings undergo stringent quality checks in accordance with a particular arrangement of production standards. A number of alloy steel A182 F1 flanges are available from us, including A182 F1 Orifice Flanges, A182 F1 Slip-On Flanges, A182 F1 Nipo-Flanges, A182 F1 Lose Flanges, A182 F1 Lap-Joint Flanges, A182 F1 Blind Flanges, and so on. It is common knowledge that these AS182 F1 Flanges provide remarkable levels of dimensional precision and resistance to corrosion. These alloy steel flanges are suitable for a variety of business applications. Our customers can have these Flanges customized in a variety of ways, including thickness, standards, size, and grades. For long-lasting results, these alloy steel flanges are made with high-quality raw materials.

#flange manufacturer in india#polished stainless steel#stainless steel manufacturers in india#steel companies of india#steel industries in india#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#manufacturer of stainless steel in india

0 notes

Text

Nickel 200 Flanges Suppliers

Technolloy Inc. is a prominent industry in the overall market and is today overseeing emphatically with its respect overall and neighborhood clients. We today are totally drawn in with collecting and scattering the common idea of Nickel 200/201 Flanges to our critical clients. These nickel 200 spines and nickel 201 ribs are arranged by using unparalleled nature of compound and as indicated by the set creation principles. Our clients can accumulate something practically the same from us at various specifics and rules, angles, class/pressure, face types, and sizes. Moreover, they can accumulate something almost identical from us at changed conclusions according to their solicitations. Our thing additionally confirms industry quality standards like ASTM, ASME, ANSI, EN, DIN, BS, etc.

Such Nickel 200/201 Flanges that our clients can assemble from us is slip-on ribs, hung spines, weld neck ribs, connection weld ribs, blind ribs, diminishing ribs, lap joint spines, plate spines, opening spines, created ribs, ring type joint spines, tongue and indent ribs, nipo spines, screwed ribs, male and female ribs, raised face ribs and square ribs.

Nickel 200 Flanges Manufacturers, Nickel 200 Flanges Suppliers, Nickel 200 Flanges Stcokists, Nickel 200 Flanges Exporters, Nickel 201 Flanges Manufacturers, Nickel 201 Flanges Suppliers, Nickel 201 Flanges Stcokists, Nickel 201 Flanges Exporters

Nickel 200 and 201 compound is areas of strength for the sustained and a fiscally pure molded material that is having fantastic mechanical properties over different temperatures. Furthermore, it is having magnificent resistance ability to a couple of corrosives, especially in hydroxides. Nickel 201 is the change to 200 for controlling the carbon that at the temperature going of 600 deg F - 1400 deg F keep it being embrittled by the intergranular hurry.

Our made extents of Nickel 200/201 Flanges are offering various incredible properties that would be useful and it has become possible because of the strong usage of 100% pure Nickel 200/201 mix for its makes. The properties are consuming salts protected, lessening compound impediment, electrical conductivity, heat protected, incredible megnetostrive properties sulfuric and hydrochloric destructive resistance.

The applications where Nickel 200/201 Flanges is seen used are heat exchangers, condensers, petrochemicals, specialty manufactured substances, car industry, compound industry, squash and paper industry, etc.

Nickel 200/201 Flanges is totally quality attempted to guarantee that really incredible nature of thing gets dispatched. Subsequently the tests done are IGC tests, PMI tests, compound tests, etc.

0 notes

Text

We Royal Steel India, are one of the leading Manufacturer, Exporter & Supplier of Carbon Steel Flanges.

Carbon Steel Flanges are available in various dimensions. Exhibiting the properties such as high strength, high toughness, excellent fatigue strength, superior chemical resistance and high stress-corrosion cracking resistance, these flanges are ideal for connecting various pipes and are significant while support is required for mechanical parts.

Types

Square Flange, Forged Flange, Nipo Flange, Customized Flange, Spectacle Blind Flanges, Socket Weld, Large Size Flanges, Weldneck Flanges, Threaded Flanges, Slip on Flanges, Lap Joint, Reducing Flanges, Orifice Flanges, Long Weld Neck Flanges, Screwed Flanges, Plate Flanges, Groove Flanges, Flat Face Flanges, Raised Face Flange, Ring Type Joint Flanges, Drawing Flanges

Class

150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS AND DIN STD 6, 10, 16, 25, 40.

Standards

ASTM A 105, ASTM A 694-F42, F46, F52, F60, F65 & F70.

Materials of Construction

Mild Steel

Carboon Steel

Stainless Steel

0 notes

Text

Nipo Flange

Omaa Metal Sources is an incredible get-together, which was set up longer than 10 years back to oblige creating solicitations of ASTM A105 Nipo Flange standards in Weld Outlets, Nipple Outlets, Sweep Outlets, 45 Deg Outlets/Lateral Outlets , Socket Weld Outlets, etc in all materials like Stainless Steel , Carbon Steel and High Nickel Alloys. We Manufacture, Export and Supply Pipe Fittings which meets with public and worldwide quality standards and conveying base which has supplies acclimating to overall particular level and is all around equipped with a whole game plan of bleeding edge plasma refining kinds of stuff.

Nipo Flange, Nipo Flange Manufacturers, Nipo Flange Exporters, Nipo Flange Suppliers, Nipo Flange Stockists.ASTM A105 Nipo Flange , ASTM A105 Nipo Flange Dimensions , Outlets Fittings, Outlets.

0 notes

Photo

Tempered Steel Weldo/Nipo Flange is a blend of a Welding Neck spine and a to the degree anyone knows Weldolet or Nipolet. The branch relationship on the run pipe side is a welding arrangement. Unexpectedly side, it has a spine affiliation. A rib affiliation can be set up by clients basics (acc. To DIN or ANSI).

#Weldo/Nipo Flanges#Weldo/Nipo Flanges Manufacturers#Weldo/Nipo Flanges Exporters#Weldo/Nipo Flanges Suppliers#Weldo/Nipo Flanges Stockists

0 notes

Text

Types of Steel Flange

If you look around then you will see that there are lots of infrastructure, building, industries, and house. All these structure are built on some solid and unique material. It is true that we are still taking the advantages of the revolution. There are thousand types of techniques and method, material, products which becomes essential for building the structure. You cannot deny they advantage in modern day. If we discuss about a specific product and sector then it will be very easy to understand. You may hear about the steel flange. Basically steel flange use for heavy working industrial work. It is used for various types of piping application. There are two types of steel flange available on the market, according it the material and they are.

A. Carbon Steel Flange:If you want to use Carbon Steel Flange then you will get flange connector and carbon steel flange. These flanges are most usable for most of the piping application. These flanges follow various types of standard like JIS, ANSI, UNI, BS4504, GOST-12820, DIN etc. For using this flange you also ensure the perfect dimension like BS 1560, ANSI B 16, BS 10, DIN, JIS.MSS SP 44 etc. There is some size isavailable which starting with ½” NB and end with 24” NB. There is some consideration as well and they are given below.

Thickness: There is some wall thickness which is SCH.10, 20, 30, 40, 80, 120, 160, STD, XS, XXS, etc.

Class: 150, 300, 400, 600, 900, 1500 & 2500.

There are various types carbon steel flange available on the market some names are given below.

1. Carbon Steel Forged Flanges: This flanges used in some special situation, especially for heat coupling of pipes.

2. Carbon Steel Blind Flanges: This pipe is used for public services, pipe engineering, water works and most importantly petrochemical.

3. Carbon Steel Reducing Flange: This flange can take all types pressures. It has universal application because it is mostly used for pipe to pipe connection.

4. Carbon Steel Orifice Flange: IF you want to measure the flow rate of various types of liquids or gases of some specific pipelines they you can use Carbon Steel Orifice Flange. There are some other types of this flange like Welding Neck, Slip on and Threaded.

5. Carbon Steel Socket Weld Flanges: This flange looks like as a Slip-on flange. The main difference of this flange with others is the inside diameter. It is totally durable with high rate, reliable and corrosion resistance.

Some other carbon steel flanges are Slip on Flanges, Flat Flanges, Lapped joint Flanges Threaded Flanges, Weld Neck Flanges, WNRF Flanges, Expander Flanges, High Hub Blinds Flanges, Groove and Tounge Flanges, Long Neck Weld Flanges, Spades Ring Spacers Flanges, Ring Type Joint Flanges, Loose Flanges, Nipo Flanges and more.

B. Stainless Steel Flange:There are lots of similarities between Stainless Steel Flange and SS Flanges. This type of flange is mostly used than Carbon Steel Flange.

These flanges are popular for industrial companies. But people also using flanges for their own purpose.

1 note

·

View note

Text

Nipo Flanges

Class 300 Nipo Flanges, Carb

on Steel Nipo Flange, Nickel Alloy Nipo Flanges, ASME B16.5 Raised Face Nipo Flange, ANSI B16.5 Nipo Flanges, Best Deals on Raised Face Nipo Flanges, ASME / ANSI B16.5 Nipo Flanges, Stainless Steel Nipo Flange dealer in India.

NIPO FLANGES MATERIAL & GRADES

Stainless Steel Nipo FlangesASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904LCarbon Steel Nipo FlangesASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70Alloy Steel Nipo FlangesASTM A182, F1, F5, F9, F11, F22, F91Duplex Steel Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Super Duplex Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Low Temperature Carbon Steel Nipo FlangesASTM A350, LF2, LF3

ASME B16.5 NIPO FLANGES SPECIFICATION

BS

BS4504 , BS4504, BS1560, BS10

FLANGE FACE TYPE

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

2 notes

·

View notes

Text

Sipchem-Approved Flanges in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C provides a wide range of Nickel 200 Flanges, known for their high quality, durability, and uniformity. Nickel 200 Slip-On Flanges (UNS N02200) offer resistance to reducing and neutral media, as well as to oxidizing environments where an inert oxide film forms.

Nickel 200 Flanges are used in food processing, harsh environments, and corrosion-resistant applications due to their excellent resistance. Nickel 200 Weld Neck Flanges have low hardness and work-hardening rates, making them suitable for cold-forming operations like deep drawing and turning. These Nickel 200 Outwardly Weakened Flanges are available in various sizes and shapes.

Nickel 200 Weld Flanges add to the versatility of Ni-Cr-Mo alloys in resisting corrosion under varying conditions. Nickel 200 Lap Joint Flanges offer excellent protection against oxidizing media and superior resistance to reducing conditions. Nickel 200 Ring Joint Sort Flanges provide better resistance to pitting and crevice corrosion than other alloys, with protection from H2SO4 up to 65%. Nickel 200 Presentation Blind Flanges resist all acids, including hydrochloric, sulfuric, and hydrofluoric, over a wide temperature range. Nickel 200 Nipo Flanges also resist attack from chlorides and other halide solutions, preventing pitting, crevice corrosion, and stress-corrosion cracking.

Nickel 200 Pipe Flanges Specifications

Specifications: ASTM B564 / ASME SB564

Size: 1/2″NB TO 60″NB

Standards: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Class / Pressure: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

For More Information:

Visit Our Website: https://www.merakimetals.ae

Contact No: +971-523973687

E-Mail ID: [email protected]

#Nickel 200 Flanges Manufacturers in UAE#Nickel 200 Flanges Suppliers in UAE#Nickel 200 Flanges Stockists in UAE#Nickel 200 Flanges Exporters in UAE#Saudi Aramco approved flanges in UAE

0 notes

Text

Nipoflange Manufacturer

SPECIALIZED NIPOFLANGE MANUFACTURER, ASME B16.47 / ANSI B16.5 NIPOLET FLANGE, SS NIPO FLANGE DIMENSIONS.

Marcel Piping Projects Supply PVT LTD is prominent Manufacturer, Suppliers, Exporter and Stockists of premium range of Nipoflange in India. We are Specialist in duplex steel and super duplex Nipoflange. These products are renowned for their dimensional accuracy, durability, abrasion resistance and quality. A Nipoflange is used for branch pipelines at 90 degrees and is a product manufactured by combining a welding neck flange with a forged Nipolet. Nipoflange is a solid single piece of forged steel and not two different products welded together.

We are capable of providing a vast range of materials, from stock, to suit your needs. We export and supply high quality ASME B16.5 Nipoflange, Reinforced Nipoflange in USA, UK, Qatar, Mexico, Nigeria, Saudi Arabia, Kuwait, Iran, Kazakhstan, Bahrain, Vietnam, Indonesia, Norway, Ghana, Colombia, Azerbaijan, Libya.

We are ISO Certified Manufacturer and Stockist of Nipoflange in Stainless Steel, Carbon Steel, Mild Steel, Alloy Steel, Duplex Steel, Super Duplex Steel, Hastelloy, Monel, Copper Nickel, Inconel, Incoloy, Nickel Alloy, Alloy 20, 254 Smo, Titaniun, Bronze, Aluminium, Brass at Reasonable Price.

We are Leading Exporter and Supplier of ASME/ANSI B16.5, ASME/ANSI B16.47 Nipo Flange, Series A & B Nipoflange, Class 150 Reinforced Nipoflange, Nipo Flange RTJ, MSS SP-44 Nipo Flange, 300# Nipo Flange, PN10 PN16 Nipoflange, Nipo Flange Class 150#, 300#, 600#, 900#, 1500#, 2500# Dimensions.

0 notes

Text

What are Flanges and their types?

Flanges are an essential component of any piping system, as they provide a secure and leak-free connection between two pipes or valves. As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP understands the importance of choosing the right type of flange for your application.

In this blog post, we will cover everything you need to know about flanges, including their types, materials, and applications.

Before we dive into the details, let's start with the basics!

Introduction

Flanges are mechanical connectors used to join two pipes or valves. They are usually made of steel, and their main purpose is to provide a tight and leak-free seal between the two parts. Flanges come in various types and sizes, and choosing the right type of flange is essential for the safety and efficiency of your piping system.

Types of Flanges?

Flanges come in several types, including weld neck, slip-on, socket weld, lap joint, threaded, and blind flanges. Each type has its unique characteristics and applications, and selecting the right one will depend on several factors, such as pressure ratings, temperature ratings, size, material compatibility, and cost.

● Weld Neck Flanges

Weld neck flanges are the most common type of flange, known for their high durability and strength. They are welded to the pipe or valve, making them ideal for high-pressure and high-temperature applications.

● Slip-On Flanges

Slip-on flanges are easy to install and remove, making them ideal for applications that require frequent maintenance. They slide over the pipe or valve and are then welded or bolted in place.

● Socket Weld Flanges

Socket weld flanges are similar to slip-on flanges, but they are welded only on the outer side of the flange, leaving the inner side free of welding marks. They are ideal for smaller-sized pipes and low-pressure applications.

● Lap Joint Flanges

Lap joint flanges are used when a piping system requires dismantling frequently. They are also ideal for applications that require easy access to the pipe or valve.

● Threaded Flanges

Threaded flanges are designed to be screwed onto the pipe or valve, making them ideal for applications that require easy installation and removal. They are commonly used in low-pressure applications.

● Blind Flanges

Blind flanges are used to seal the end of a pipe or valve. They are commonly used for pressure testing and maintenance purposes.

Materials & Grades Available In Flanges with Bullion Pipes & Tubes LLP

Flanges can be made of various materials & Grades, such as,

●

Stainless Steel - 904L Flanges, 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 446 Flanges

● Hastelloy Flanges - C22, B2 Flanges, C276 Flanges

● Carbon Steel Flanges - ASTM A350 15LF1, LF2 CL1/CL2, LF3 CL1/CL2 Carbon Steel Flanges

● Nickel Alloy - 200/201

● Duplex Steel Flanges - Duplex UNS S32205/31803 Flanges

● Alloy Steel Flanges - P5, P9, P11, P12, P22, P91 Flanges

● Super Duplex Steel - UNS S32750/S32760 Flanges

● Titanium Alloys - Gr 2 Flanges, Gr 5 Flanges, Gr 7 Flanges

● Aluminium Flanges - 5052 Reducing Flanges, 5082 Flanges, 5082 Flanges, 6063 SORF Flanges, 6082 Blind Flanges, 2024 Aluminum Weld Neck Flanges, and 5052 Threaded Flanges.

● Tantalum Flanges - ASTM B521 Tantalum Flanges, Spectacle Blind Flanges, Orifice Flange, Ta-10W Flanges, Tantalum UNS R05200 Flanges, ASTM B365 Ta2.5W Flanges

● Monel Flanges - Monel K500 Flanges, Monel 400 Flanges

● Alloy 20 Flanges - Alloy 20 RTJ Flange, Alloy 20 WNRF Flanges, Alloy UNS N08020 Pipe Flanges, Alloy 20 Weld Neck Flange, Alloy 20 Nipo Flanges, ASTM B462 Alloy Threaded Flanges, Alloy 20 Spectacle Blind Flanges, Alloy 20 Industrial Flanges, and UNS N08020 Alloy 20 Forged Flanges

● SMO 254 Flanges

● Inconel Flanges - Inconel 718, 600, 601 and 625 Flanges

● Incoloy Flanges - 825, 800/800H/800HT Flanges

Choosing the right material for your flange will depend on several factors, such as the application's temperature, pressure, and corrosion resistance requirements.

Factors to Consider When Selecting Flanges

Selecting the right flange for your application can be challenging, as there are several factors to consider, such as pressure ratings, temperature ratings, size, material compatibility, and cost. At Bullion Pipes & Tubes LLP, we can help you choose the right flange for your application, ensuring safety and efficiency.

Flange Standard Ratings

Flanges come in various standard ratings, such as ANSI, API, DIN, and JIS. These ratings determine the flange's pressure-temperature rating and its compatibility with other components in the piping system.

Flange Installation

Proper flange installation is essential for the safety and efficiency of your piping system. It involves several steps, such as preparation of the piping system, installation of the flanges, flange tightening process, flange alignment, and testing and inspection.

Maintenance and Repair of Flanges

Maintaining and repairing flanges is critical for the longevity and safety of your piping system. Regular inspections, leak checks, and maintenance can help detect any potential issues before they become a more significant problem.

Applications of Flanges

Flanges have a wide range of applications in various industries, including:

● Oil and Gas Industry

● Petrochemical Industry

● Chemical Industry

● Power Generation Industry

● Water Treatment Industry

They are used in various applications, including HVAC systems, plumbing, and firefighting systems.

Why Choose Bullion Pipes & Tubes LLP for Flanges?

As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP offers a wide range of flanges made from high-quality materials. We provide customized solutions to meet our customers' specific needs, and our flanges are available in various sizes, ratings, and materials.

We have been providing high-quality flanges to various countries, such as Ukraine, Australia, Syria, Iraq, Iran, Kazakhstan, Russia, Brazil, Armenia, Azerbaijan, Egypt, South Africa, Qatar, Turkey, Oman, Bahrain, and Germany, and our products are known for their durability, reliability, and safety.

Conclusion

Flanges are a critical component of any piping system, and selecting the right type of flange for your application is essential for safety and efficiency. Choosing a reliable and trustworthy supplier like Bullion Pipes & Tubes LLP can ensure that you get high-quality flanges that meet your specific requirements.

0 notes