#Oil Filters

Explore tagged Tumblr posts

Text

The alien invaders collected cars like humans collect butterfly, without any compassion for the lives of the innocent.

Life - March 19th 1956

#1956#oil filters#automotive#car care#vintage ads#vintage ad#advertising#advertisement#1950s#1950s ad#1950's#1950's ad#funny#humor#humour

44 notes

·

View notes

Text

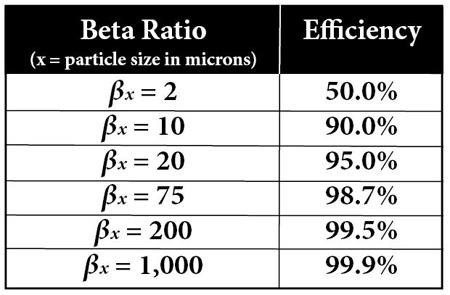

Understanding of the BETA factor

What is the Beta Ratio?

The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999.

How is it measured?

Get your filter check today, Call +91 7030901266

So, to purchase a filter with a beta ratio of 2-10 is considered poor, it is advised to use filters with at least a Beta factor of 75 and 98.7% effectiveness. High quality, efficient filter assemblies can achieve 200 to 2000 Beta Ratio for given particle size and should be ideal to achieve a low level of contamination.

Also read: https://www.linkedin.com/pulse/you-buying-right-oil-filter-anshuman-agrawal-mlt-1-/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#hydraulic oil filter#contamination#oil purification system#oil purification machine#oil contamination#oil purification#oil testing#oil filter machine#oil filter systems#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#wind turbines#gas turbine#steam turbine#steel#metal#mining#oil dehydration systems

2 notes

·

View notes

Text

6 notes

·

View notes

Text

Choosing the Right Oil Filters for Your Vehicle’s Health

Using good oil filters is important to keep your car’s engine clean and working well. Oil filters catch dirt and debris from the oil, stopping them from damaging the engine parts. When you change your vehicle oil filters regularly, it helps your engine run smoothly, lasts longer, and saves you from costly repairs. Keeping your oil filters in good shape makes driving safer and gives you peace of mind on the road.

0 notes

Text

Maximize Hydraulic Pump Efficiency Today

Hydraulic Pump Efficiency: What Affects It and How to Optimize It

In any fluid power system, hydraulic pumps are the foundation for consistent performance, speed, and power delivery. However, even the best pump can underperform if not operating at peak efficiency. Whether it's an industrial press, construction equipment, or mobile hydraulic application, the efficiency of your pump has a direct impact on energy consumption, heat generation, and the lifespan of your entire system.

At Techknow Engineering Enterprise, we’ve helped countless businesses fine-tune their systems for better productivity. And let’s be clear—hydraulic pumps don’t lose efficiency overnight. It's a gradual process influenced by multiple mechanical and environmental factors. Knowing what affects pump efficiency, and how to optimize it, can make a world of difference to operational output and cost-effectiveness.

Understanding Hydraulic Pump Efficiency

Before diving into optimization, it’s essential to understand the types of efficiency involved:

Volumetric Efficiency – The ratio of actual fluid delivered versus the theoretical maximum. Losses here often stem from internal leakage.

Mechanical Efficiency – This focuses on frictional losses between moving components inside the pump.

Overall Efficiency – A combination of both volumetric and mechanical efficiencies. It gives the most accurate picture of a pump’s true performance.

All three are affected by a variety of internal and external conditions. Here’s what to look out for.

Factors That Reduce Hydraulic Pump Efficiency

1. Internal Leakage

As a hydraulic pump ages, wear and tear on internal components—especially seals and clearances—can cause fluid to leak internally. This leakage reduces volumetric efficiency, meaning less flow for the same input power.

What to Watch:

Reduced system pressure

Slow actuator movement

Rising fluid temperature

Techknow Engineering Enterprise often addresses internal leakage through reconditioning, precision seal replacement, or full pump rebuilds.

2. Fluid Contamination

One of the silent killers of hydraulic pumps is dirty or contaminated fluid. Dirt, water, or metal particles in the oil can cause abrasion, clog passageways, and wear out tight tolerances, compromising both volumetric and mechanical efficiency.

What to Watch:

Scratched or damaged components

Increased maintenance cycles

Pump noise

At Techknow Engineering Enterprise, we recommend strict fluid cleanliness levels, installing high-efficiency filtration, and routine fluid testing.

3. Improper Fluid Viscosity

If the hydraulic fluid is too thick (high viscosity), it increases friction and heat. If it’s too thin (low viscosity), it won’t lubricate components properly and can lead to internal leakage.

What to Watch:

Difficulty starting in cold temperatures

Overheating during extended operation

Inconsistent pressure

The right fluid selection, aligned with OEM recommendations, is a standard part of our consulting approach at Techknow Engineering Enterprise.

4. Excessive Heat

Heat is both a cause and effect of reduced hydraulic pump efficiency. Rising temperatures lower fluid viscosity, damage seals, and expand metal components, leading to further inefficiencies.

What to Watch:

High oil temperature readings

Burnt smell from fluid

Seal degradation

We advise all our clients to invest in proper heat exchangers or cooling fans and to avoid oversizing pumps, which can unnecessarily generate excess heat.

5. Misalignment or Poor Installation

A misaligned pump shaft or improper coupling can increase mechanical drag and bearing load. These installation faults silently destroy mechanical efficiency over time.

What to Watch:

Increased vibration

Premature bearing failure

Uneven wear on drive components

Every hydraulic pump installed by Techknow Engineering Enterprise is precisely aligned using laser tools or dial indicators to avoid such efficiency-robbing issues.

How to Optimize Hydraulic Pump Efficiency

1. Regular Maintenance

Don’t just wait for a pump to fail. Preventive and predictive maintenance schedules ensure that filters are changed, fluids are tested, and internal wear is spotted early.

2. Use Energy-Efficient Components

Modern variable displacement hydraulic pumps adapt flow based on demand, reducing energy waste and heat generation. These are ideal upgrades for older fixed-displacement systems.

Techknow Engineering Enterprise routinely upgrades systems with energy-conscious components to align with sustainability and performance goals.

3. Optimize System Design

A well-designed hydraulic system matches pump size, pressure rating, and flow rate to actual application requirements. Oversizing or undersizing the pump can severely reduce efficiency.

We conduct system audits to ensure pump selection and circuit design are perfectly tuned. It’s not just about power—it’s about the right power in the right place at the right time.

4. Monitor Real-Time Performance

Sensors and digital controllers now allow real-time monitoring of flow, pressure, and temperature. This data helps predict when performance is slipping and corrective action is needed.

Techknow Engineering Enterprise integrates smart diagnostics in client systems, allowing for data-driven maintenance and performance tuning.

The efficiency of your hydraulic pump isn’t a set-it-and-forget-it affair. It’s a dynamic metric shaped by how you operate, maintain, and support your system. Staying ahead of the curve not only improves output but also extends the life of every other component in the hydraulic circuit.

0 notes

Text

All about Oil Filters - Mark Lawrence

Really interesting look at the properties of oil filters by Mark Lawrence Here

0 notes

Text

Unlock the Power of Wheel Aligner Machines: 10 Benefits You Need to Know

Empower your vehicle's longevity with quality oil filter maintenance, which plays a significant role in enhancing its life. There are various things you should do to keep your vehicle running smoothly. Do you know oil filters also play a significant role in enhancing the life of a car’s engine? Well, maintaining the oil balance in your car with proper filtration is vital for the optimum performance and longevity of the engine. Let us know how a good quality oil filter contributes to a vehicle’s engine performance and longevity. Read this article until the end and understand the vital role of oil filters in an engine’s longevity. Here are the factors that you can understand, empowering you with the knowledge to make informed decisions about your vehicle's maintenance.

Remove Contaminants from the Oil

Good-quality oil filters remove contaminants, such as dirt, metal particles, sludge, etc., from the oil and make it easy to flow. They also reduce any kind of blockages so that the engine can run smoothly. Regular filtration keeps the oil clean, preventing the engine components from wearing out before their expected lifespan, a condition known as 'premature wear and tear ', which is the early deterioration of engine parts due to dirty or contaminated oil. This means that the engine parts do not last as long as they should, leading to increased maintenance and repair costs. Hence, good-quality oil filters lead to extended engine life.

Improve Filtration Efficiency

Good-quality car or bike oil filters, such as Cruiser oil filters or Spin-on oil filters, improve filtration efficiency. They work more smoothly and keep the oil clean all the time, which helps the engine run smoothly. Clean oil reduces the pressure on the engine to run fast by requiring more effort. As the engine runs smoothly, its lifespan will definitely enhance. There will be no chance of obstacles in its path.

Prevent Engine from Damaging

As the oil is filtered and cleaned, the engine is under less stress to perform its task. This reduced stress and pressure significantly decreases the chances of damaging the engine components. Oil filter manufacturers have designed filters that can identify and remove even tiny particles, ensuring the oil runs smoothly and the various engine parts perform their work without facing hurdles. This reassures you that your vehicle is well-protected and can perform at its best.

Maintain Oil Viscosity

Contaminated oil loses its viscosity, reducing its power to lubricate the engine components effectively. To prevent this, it is crucial to use the best-quality car or tractor oil filter. This proactive step not only enhances the performance and lifespan of your vehicle but also ensures the oil maintains its viscosity, which is crucial for adequate engine lubrication.

Reduce Maintenance Cost

Investing in good-quality oil filters at best price in India can help you save money in the long run. By regularly changing the oil filters, you can prevent the need for costly engine repairs and replacements. This proactive approach to maintenance can significantly reduce your overall maintenance costs, making it a financially savvy choice for vehicle owners. It is a responsible and cost-effective way to ensure your vehicle's longevity.

Good Anti-Drainback Technology

High-quality oil filters have a unique feature that prevents the oil from returning to the engine when you switch off your vehicle. This is quite beneficial in the winter season when the oil can thicken and cause damage to the engine. When you start your vehicle again, you can get the best lubrication. Well, having this feature can protect your engine, especially the critical components, from damage due to lack of lubrication. Hydraulic oil filters also have this feature.

Pressure Resistance

Good-quality oil filters are more robust, durable, and pressure-resistant. Oil filters like Cruiser oil filters, Spin-on oil filters, etc., are designed with strength and durability in mind. Such oil filters can handle higher oil pressure without any issues. High-quality oil filters can give exceptional performance even in challenging conditions.

Budget-friendly

Adopting high-quality filters is also budget-friendly. Once you buy one, it will benefit you for a long time in terms of money. It is a one-time investment. The lifespan of the oil filter and your vehicle’s engine will enhance; therefore, you need not spend money every time repairing or replacing them. Therefore, you can focus on the quality of the engine instead of other things.

Help the Engine Work Smoothly

High-quality oil filters help the engine work smoothly. Oil filtration by using the best quality oil filter makes the work process of a vehicle’s engine more efficient and effective. The work process is smooth and easygoing. It even helps to keep the vehicle’s engines safe and protected.

These are the significant benefits of buying superb-quality oil filters for your vehicle. You can consult the best manufacturer and supplier near your area or buy them online. So, make an intelligent decision and enhance the life of your vehicle’s engine in a budget-friendly manner.

0 notes

Text

0 notes

Text

Cabin Filters and Fuel Filters Breathe Fresh, Drive Smooth with Action Group

Action Group's Cabin and Fuel Filters are made for maximum performance and best possible vehicle health. They will enhance your driving experience. Our Cabin Filters guarantee that your car's inside is clean and comfortable while capturing dust, pollen, and other pollutants to provide you a breath of fresh air. Our selection of fuel filters protects your engine by keeping contaminants from getting to vital parts, guaranteeing a smooth and effective fuel delivery system. You can rely on Action Group to provide high-quality filters that prolong the life of your car and improve driving comfort. Take a look at our selection now and benefit from improved engine performance and cleaner air. Drive with assurance and the Action Group at your side.

Company Name: ACTION GROUP

Phone No: +60362585868

#Cabin Filters#fuel filtes#Coolant filters#MANN+HUMMEL#Industrial Filters#OE Filters#car filters#Cabin filters#Car AirCon Filter#Car Replacement Filters#Fuel Filter#Heavy Duty Filters#Filtration Solutions#Aftermarket Filters#High Efficiency Filters#Auto filters#Hydraulic Filters#Air Oil Separator#Oil Filters#MANN FILTER#Car Air Filters#Performance Filters

0 notes

Text

Oil filters are polyamorous.

(Once again I had to add a new word to Windows stodgy dictionary)

#oil filters#automotive#vintage ads#vintage ad#advertising#advertisement#1960s#1960s ad#1960's#1960's ad#funny#humor#humour

12 notes

·

View notes

Text

Lubrication: Uses, Functions, Properties, and Maintenance

Introduction to Lubrication

Importance of Lubrication in Industrial Applications

Industries heavily rely on lubrication to enhance equipment performance. Some critical lubrication uses include:

Automotive Industry: The engine lubrication system ensures smooth operation, reduces engine wear, and prevents overheating.

Manufacturing Sector: Lubrication oil plays a pivotal role in reducing friction in CNC machines, conveyors, and robotic arms.

Mining and Construction: Heavy-duty lubrication types protect machinery from extreme temperature variations and harsh environments.

Power Plants: Lubrication systems ensure the longevity of turbines, generators, and compressors by preventing excessive wear.

Food and Beverage Industry: Specialized food-grade lubricants are used to ensure equipment hygiene and compliance with safety standards.

Understanding the diverse uses of lubrication enables industries to improve efficiency and extend equipment lifespan.

Key Functions of Lubrication

Lubrication performs multiple essential functions that contribute to machinery longevity and reliability:

Reduction of Friction and Wear: Creates a protective layer between surfaces to minimize direct metal-to-metal contact.

Heat Dissipation: Transfers heat away from friction points, preventing component failures.

Contaminant Removal: Lubrication oil acts as a medium to carry away dirt, dust, and metal shavings.

Corrosion and Oxidation Prevention: Lubricants contain additives that prevent rust and oxidation, protecting machinery.

Shock Absorption: Helps cushion impact loads, particularly in high-speed or heavy-duty applications.

Different Lubrication Types and Their Applications

Lubrication can be classified into various types, each suited to specific operating conditions:

Hydrodynamic Lubrication: A continuous fluid film separates moving surfaces, commonly found in bearings and gears.

Boundary Lubrication: A thin lubricant film prevents direct contact, often occurring in stop-start conditions or low-speed machinery.

Mixed Lubrication: A combination of hydrodynamic and boundary lubrication, suitable for gearboxes and automotive engines.

Elastohydrodynamic Lubrication: Found in rolling-element bearings, where high pressure causes temporary lubricant thickening.

Solid Lubrication: Utilizes materials like graphite and molybdenum disulfide for extreme environments where liquid lubricants are unsuitable.

Selecting the right lubrication type is crucial for achieving optimal performance and reducing maintenance costs.

Essential Lubrication Properties for Optimal Performance

The effectiveness of a lubricant depends on its fundamental properties:

Viscosity: Determines the flow characteristics and film strength under varying temperatures and loads.

Thermal Stability: Ensures that the lubricant does not degrade under high-temperature conditions.

Oxidation Resistance: Prevents sludge and varnish formation, extending lubricant service life.

Load-Carrying Capacity: This enables the lubricant to withstand extreme pressures without breaking down.

Water Resistance: Prevents emulsification and ensures effective separation in wet environments.

These lubrication properties dictate the overall efficiency and durability of machinery.

Understanding Lubrication Systems and Their Mechanism

A lubrication system ensures the efficient delivery of lubrication oil to machine components. Common lubrication systems include:

Manual Lubrication: Involves periodic application using grease guns or oil cans.

Automatic Lubrication Systems: Distribute lubricants continuously, reducing downtime and maintenance efforts.

Splash Lubrication: Relies on rotating components to distribute lubricant in gearboxes.

Forced Lubrication Systems: Utilize pumps to circulate oil under pressure, ensuring consistent lubrication.

Selecting the right lubrication system enhances equipment reliability and reduces operational costs.

Engine Lubrication System: A Vital Component for Efficiency

The engine lubrication system plays a crucial role in vehicle performance:

Provides continuous lubrication to reduce friction and wear.

Cools engine components by dissipating excess heat.

Cleans the engine by removing contaminants and metal debris.

Prevents corrosion and oxidation, extending engine lifespan.

Regular maintenance of the engine lubrication system is essential for preventing costly failures and ensuring optimal vehicle performance.

Lubrication Maintenance Strategies for Equipment Longevity

Implementing proactive lubrication maintenance practices helps prevent machinery breakdowns. Essential maintenance steps include:

Using the Correct Lubricant: Ensure compatibility with manufacturer recommendations.

Monitoring Lubricant Contamination: Regularly check for dirt, water ingress, and degradation.

Establishing a Lubrication Schedule: Follow a preventive maintenance plan to avoid failures.

Employing Oil Analysis: Use condition monitoring techniques to detect early signs of wear.

Applying the Right Quantity: Avoid over-lubrication or under-lubrication, both of which can cause damage.

Common Lubrication Problems and Solutions

Industries often face lubrication challenges that impact performance:

Contaminated Lubricants: Regular oil analysis helps detect impurities and improve filtration.

Incorrect Viscosity: Choosing the right viscosity prevents excessive wear and overheating.

Poor Lubricant Selection: Matching lubrication oil to application needs ensures reliability.

Inadequate Lubrication Practices: Proper training and monitoring improve lubrication effectiveness.

Addressing these challenges ensures long-term equipment reliability.

Conclusion

Lubrication is an essential aspect of industrial maintenance, reducing friction, preventing wear, and ensuring machinery longevity. Understanding lubrication types, properties, and maintenance strategies helps industries optimize operations and minimize downtime.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#lube oil filter#hydraulic oil#contamination#hydraulic oil filter#oil testing#oil filters#oil industry#oil and gas#flushing systems#flushing#oil purification machine#mlc lvdh#lvdh full form#frf condition systems#condition monitioring#oil condition#bdv

0 notes

Text

Unlock peak efficiency and performance with air compressor filters. These unsung heroes of industrial operations ensure clean, quality air, extending equipment life and minimizing downtime. Learn how the right filtration solutions can optimize your processes, boost productivity, and cut maintenance costs. It's the key to a smoother, more profitable operation, where your equipment runs at its best.

1 note

·

View note

Text

Buy Small Engine Fuel Filters at Low Cost | Car & Auto Fuel Filters

Need a good fuel filter for your car or small engine? HighFlow sells strong and reliable fuel filters that help your engine run better and last longer. Whether you drive a car, truck, or SUV, we have the right auto fuel filter for you. Our filters help keep dirt out of your fuel system and improve your engine’s performance. We also offer low fuel filter cost, so you don’t have to spend a lot to take care of your vehicle. Shop by your car's year, make, and model to find the perfect fit.

0 notes

Text

Cross Reference Filters

Today I come to recommend a great site that I found to cross-reference filters between various brands. The site is equivafiltros.com and by simply entering the filter code the page shows alternatives in different brands. If you have a workshop or are dedicated to replacing filters like me, do not hesitate to visit it.

1 note

·

View note

Text

guys guys im not dead look *waves this kris drawing in your face* ooooooo you like it ooooo you lov it

*dies once more*

#art block beating my ass but#i stole oil pastels from my skool and decided to experiment#this was hard nobody told me working wit pastels was spooky#anyways this is wit a filter if that wasnt obvious#the bald drawing looks funky#deltarune#kris dreemurr#kris deltarune#utdr#deltarune fanart#fanart#doodle#doodles#art

1K notes

·

View notes

Text

Sign That You Need An Oil Filter Replacement

Noisy engine sounds, discolored and dirty oil, as well as unusual texture, are all clear indicators of potential damage to your vehicle's engine, which can lead to severe long-term harm. Below is a complete breakdown of the signs that suggest you need an oil filter replacement.

#oil filter#oil filter replacement#mini truck#oil filters#sign that you need an oil filter replacement

0 notes