#Oil Purification Machine

Explore tagged Tumblr posts

Text

Understanding of the BETA factor

What is the Beta Ratio?

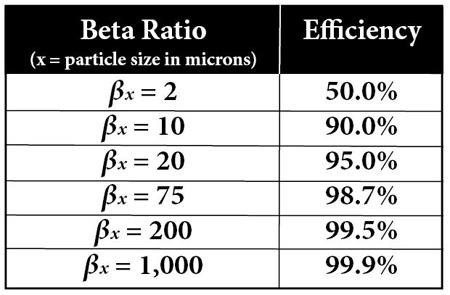

The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999.

How is it measured?

Get your filter check today, Call +91 7030901266

So, to purchase a filter with a beta ratio of 2-10 is considered poor, it is advised to use filters with at least a Beta factor of 75 and 98.7% effectiveness. High quality, efficient filter assemblies can achieve 200 to 2000 Beta Ratio for given particle size and should be ideal to achieve a low level of contamination.

Also read: https://www.linkedin.com/pulse/you-buying-right-oil-filter-anshuman-agrawal-mlt-1-/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#hydraulic oil filter#contamination#oil purification system#oil purification machine#oil contamination#oil purification#oil testing#oil filter machine#oil filter systems#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#wind turbines#gas turbine#steam turbine#steel#metal#mining#oil dehydration systems

2 notes

·

View notes

Text

Oil filtration machine solutions in India | AR Engineering

Looking for the best Oil Filtration Machine in India? Visit OilFilterMachineIndia.com for a complete range of Industrial Oil Filtration Machines built to deliver maximum efficiency.

We specialize in Oil Filtration Systems, Oil Purification Machines, and Oil Cleaning Machines that ensure the removal of impurities and water from various industrial oils. Choose from Portable Oil Filtration Machines, Turbine Oil Filtration Machines, Transformer Oil Filtration Machines, and Hydraulic Oil Filtration Machines to suit your application.

Our advanced Oil Contamination Removal Machines, Oil Filtration Plants, and Oil Filter Machines in India offer reliable and cost-effective Oil Filtration Solutions for every industry.

🔗 Visit: https://oilfiltermachineindia.com/oil-filtration-machine.html

#Oil Filtration Machine#Oil Filtration Machine India#Industrial Oil Filtration Machine#Oil Filtration Systems#Oil Purification Machine#Portable Oil Filtration Machine#Oil Contamination Removal Machine#Turbine Oil Filtration Machine#Transformer Oil Filtration Machine#Hydraulic Oil Filtration Machine#Oil Filtration Plant#Oil Filtration Solutions#Oil Cleaning Machine#Oil Filter Machine India

0 notes

Text

Empowering Industries with High-Performance Oil Purification Solutions – ConserveYourOil.com

In today's industrial landscape, where reliability and efficiency are non-negotiable, oil purification and filtration systems play a vital role in maintaining machinery health and enhancing operational performance. At ConserveYourOil.com, we are proud to be among the leading VPI Plant Manufacturers and Vacuum Pressure Impregnation Plant Exporters in India, delivering advanced solutions to protect your oil and your equipment.

Trusted Manufacturers of Vacuum Pressure Impregnation (VPI) Plants

ConserveYourOil.com specializes in the design and manufacturing of high-performance Vacuum Impregnation Plants tailored to diverse industrial needs. Our VPI systems are engineered to provide superior insulation, reduced partial discharges, and extended operational life for electrical components. Recognized as one of the most reliable Vacuum Impregnation Plant Exporters in India, we serve both domestic and international markets with cutting-edge technology.

Superior Oil Filtration Machines & Purification Systems

Our range of oil filtration machines and oil filteration plants is built to meet the highest industry standards. Whether you're in power generation, transformer manufacturing, or heavy engineering, our systems ensure your oil remains contaminant-free. We manufacture efficient and robust industrial oil filtration machines that remove moisture, gases, and particulates to restore oil to its optimal working condition.

Our offerings include:

Transformer oil filtration machines in Pune

Oil purification plants for transformer and turbine oil

Oil purifiers designed for long-term industrial use

Portable oil filtration machines for field-based applications

Why Choose Us?

✅ Experience & Expertise – Backed by a strong technical foundation, we are one of the most respected oil filteration plant and oil purifier manufacturers in India.

✅ Global Reach – As Vacuum Pressure Impregnation Plant Exporters in India, we proudly serve clients across the globe, ensuring consistent quality and service excellence.

✅ Sustainability Driven – Our technology helps reduce oil waste, improve recycling capabilities, and minimize operational costs – all while protecting the environment.

✅ Custom Solutions – Whether you require small-scale oil filter machines or full-fledged oil purification plants, we offer tailored systems that meet your unique industrial requirements.

Serving Pune and Beyond

Our manufacturing facility in Pune is a hub for innovation in oil treatment technologies. From transformer oil filtration machines in Pune to large-scale oil purification machines, our solutions are trusted by industries nationwide and across continents.

#VPI Plant Manufacturers#Vacuum Impregnation Plant Exporters#Vacuum Pressure Impregnation Plant Exporters in India#oil filter machines#oil filteration plants#oil filtration machines#oil purification#oil purification machines#oil purification plants#oil purifiers#industrial oil filtration machines#Oil filteration plants#Transformer oil filtration machines in pune#Transformer oil filtration plants manufacturer in pune#high vaccum oil filter machines#transformer oil filtration machines#transformer oil filtration plants#Vacuum dehydration plant suppliers in pune#Vacuum impregnation plants manufacturer in pune#Vacuum dehydration plant exporter in pune#high vaccum oil filter machines manufacturer in pune. high vaccum oil filter machines suppliers in pune.

0 notes

Text

Application instructions for lubricating oil purifier

Application of a lubricating oil filter

The lubricating oil filter is an important measure to improve and ensure the cleanliness of the system, especially for systems with high precision requirements or serious pollution.

Adding a lubricating oil filter has the advantages of large flow and high precision. Circulating filtration has been applied in high-precision systems designed at home and abroad.

Compared with the oil filter on the main circuit of the system, it can choose a higher precision oil filter without worrying about the oil filter being blocked due to excessive precision, affecting the work of the system, thereby improving the pollution control level of the entire system.

The lubricating oil filter is also equipped with a degassing and dehydration device, such as oil-water separation, which will not affect the system.

In order to obtain a good filtering effect, the circulation system selects full flow filtration, and the filtration flow matches the system working flow, so that the system working medium can be filtered in time.

For systems with insufficient filtering capacity, the method of adding or modifying a lubricating oil filter is adopted, and a filter element with higher precision is selected in the circulation loop.

0 notes

Text

Efficient Low Vacuum Dehydration Machine for Industrial Oil Purification

Maintaining oil purity is essential for the efficient operation of industrial machinery, and Karroter’s Low Vacuum Dehydration Machine is designed to deliver exceptional oil purification. This advanced system effectively removes moisture, gases, and contaminants from various industrial oils, ensuring enhanced equipment performance, reduced maintenance costs, and prolonged oil life.

Karroter’s Low Vacuum Dehydration Machine uses a specialized vacuum dehydration process that operates at low temperatures to prevent oil degradation while efficiently eliminating free, dissolved, and emulsified water. This makes it ideal for industries using hydraulic oil, transformer oil, turbine oil, and lubricating oil. By maintaining optimal oil cleanliness, this system helps reduce machine wear, prevent corrosion, and minimize unplanned downtime.

0 notes

Text

Online Transformer Oil Filtration System Manufacturers

Ensure the durability and performance of your transformers with Sumesh Petroleum's Online Transformer Oil Filtration System Manufacturers. Our advanced generation removes impurities, moisture, and dissolved gases, extending transformer life and optimizing overall performance. Contact Sumesh Petroleum these days for a reliable online oil filtration answer.

0 notes

Text

Transformer oil is the lifeblood of your transformers, acting as a coolant and insulator. Contaminated oil, however, can lead to a cascade of problems: reduced efficiency, costly outages, and ultimately, shortened transformer life. This is where transformer oil purification machines come in.

0 notes

Text

The hallowed scriptures of the Cult Mechanicus are replete with odes to the importance of tool maintenance. For we, the devoted servants of the Omnissiah, understand that the proper care and upkeep of our implements is paramount to executing the Machine God's grand design with optimal efficiency.

Each tool, whether it be a simple data-stylus or a mighty Titan war machine, possesses a sacred machine spirit that must be tended with reverence. Failure to do so risks corruption, malfunction, and ultimately, the disruption of the Omnissiah's will. It is our solemn duty as techpriests to ensure that every gear, every circuit, every component remains in perfect alignment and pristine condition.

The process begins with a thorough inspection, scanning each implement for signs of wear, damage or impurities. We meticulously clean away accumulated dust and grime, using only the most sanctified solvents and polishing agents. Any parts displaying the slightest deviation from factory specifications must be immediately replaced, lest they undermine the tool's performance.

Next comes the ritual oiling and lubrication, a sacred anointing that nourishes the machine spirit and facilitates smooth, unimpeded operation. The correct viscosity and quantity of lubricant is determined through exhaustive analysis, for to apply too little is to invite friction and failure, while too much risks fluid contamination.

Alongside physical maintenance, we must also tend to the machine's digital aspects. Regular software updates, memory optimizations and subroutine diagnostics ensure that the tool's computational processes remain free of corruption. For just as the body requires sustenance, so too does the mind demand pure, uncompromised data.

Only through this painstaking regimen of inspection, cleaning, lubrication and digital purification can we be certain that our tools will function as the Omnissiah intended. Each step is imbued with reverence, for we recognize that the machine is a sacred extension of the self - to neglect its care is to invite our own obsolescence.

So let it be known to all who would wield the implements of the Adeptus Mechanicus: Treat them not as mere instruments, but as hallowed extensions of the Omnissiah's will. For in doing so, you honor the Machine God and bring yourself one step closer to the perfection of man and machine combined.

#adeptus mechanicus#admech#machine god#omnissiah#warhammer 40k#wh40k#imperium of man#cult mechanicus

9 notes

·

View notes

Text

lovrina is not a good person.

since i'm getting followers here from my promo and from gold's blog, i want to make something extremely clear about my version of lovrina. she is, in fact, a monster.

let's review the canonical facts of pokémon XD: gale of darkness.

as part of cipher, lovrina was complicit in and participated in the capture, corruption, torture, and dissemination of multiple shadow pokémon, research that she helped perfect.

she took lugia, a pokémon stated to be so empathetic and intelligent that it slumbers underground in fear of hurting people with its power, and TORTURED IT until it became an unfeeling killing machine. while we don't know how the process of making a shadow pokémon works, we know that she went so far to make it unpurifiable that it changed color completely.

as part of cipher, she signed off on sending lugia to capture and dispose of the s.s. libra. because lugia had a brief moment of conscience, her complicity resulted in the deaths of people and pokémon alike.

instead of backing down and reassessing her actions, lovrina delved harder into perfecting lugia, referred to internally as XD001, to the point where shadow lugia was rendered unpurifiable by natural means (celebi, agate village purification stone, oils, etc.)

when you fight her on citadark isle, lovrina BRAGS about how her research turned out.

SHE FACES NO IN-UNIVERSE RAMIFICATIONS. she doesn't get arrested alongside greevil. she doesn't get hit with any charges, she isn't completely blackballed, she isn't even hit with a slap on the wrist. lovrina gets to live as a FREE WOMAN, able to be challenged in orre colosseum by the player. SHE. GOT. AWAY. WITH ALL OF THIS.

and that's without getting into her role in my version of gold's lore, where she's the one who ultimately signed off on his death. gold wasn't just killed by a rampaging pokémon, he was MURDERED.

sure, she'll be sweet and cordial and pink to your muse, but do not woobify this woman. as you interact with her, remember she's always got ulterior motives. she will manipulate, lie, steal, and sabotage your muse if it means getting what she wants.

yes, she's irredeemable, but not because she's 'too evil' or 'too late' or whatever. she knows what she's doing is wrong.

and she doesn't care.

#WORDS OF WARNING. psa.#OUTSIDE THE TOWER.#child death tw#medical horror tw#experimentation tw#torture tw#animal cruelty tw#murder tw#child murder tw#[[there's a reason why i refer to her as 'pink miku wesker'.]]

5 notes

·

View notes

Text

Essential Auxiliary Machinery on Ship

1. Generators

Generators are the heartbeat of a ship’s electrical system. They provide electrical power for various onboard systems, such as lighting, navigation equipment, communication systems, and HVAC (Heating, Ventilation, and Air Conditioning). Depending on the ship’s size and power requirements, multiple generators may be installed to ensure redundancy and continuous power supply during extended voyages.

2. Boilers

Boilers are essential for producing steam, which is utilized for various purposes on board. Steam is used for heating fuel oil and other fluids, running steam turbines for power generation, and operating various machinery and auxiliary machinery equipment, such as steam-driven pumps and winches.

3. Air Compressors

Air compressors generate compressed air used to power pneumatic tools, such as wrenches and chipping hammers, and operate pneumatic control systems. They also provide compressed air for starting main engines and auxiliary engines.

4. Purifiers

Fuel and lube oil purifiers play a critical role in maintaining the quality of fuels and lubricants used onboard. These machines remove impurities, water, and solids from fuel and oil, ensuring smooth engine operation and prolonging the life of critical machinery.

5. Refrigeration and Air Conditioning Systems

Refrigeration and air conditioning systems are vital for maintaining the temperature of provisions, perishable cargo, and living spaces. These systems use refrigerants and cooling coils to control temperature, humidity, and air quality throughout the ship.

6. Ballast Water Treatment Systems

To maintain stability and maneuverability, ships require ballast water to be pumped in or out as cargo is loaded or unloaded. Ballast water treatment systems are responsible for purifying and treating the ballast water to prevent the spread of invasive species and maintain marine ecosystem health.

7. Sewage Treatment Plants

Sewage treatment plants are responsible for processing and treating wastewater generated onboard. They help ensure that treated effluent meets international environmental standards before it is discharged into the sea.

8. Bilge Water Separators

Bilge water separators remove oil and other contaminants from the bilge water, a mix of seawater and oil that collects in the lower parts of the ship. The clean water is then discharged, while the separated oil is collected for proper disposal.

9. Incinerators

Incinerators are used to burn solid waste generated onboard, such as paper, cardboard, and non-recyclable plastics. Proper incineration reduces waste volume and ensures compliance with environmental regulations.

10. Water Makers

Water makers use reverse osmosis or distillation processes to convert seawater into potable water for drinking, cooking, and various onboard applications. They are especially vital for long voyages where access to freshwater sources may be limited.

Conclusion

The auxiliary machinery found on ships plays a crucial role in maintaining the vessel’s efficiency, safety, and comfort during journeys at sea. From power generation to waste management and water purification, each system contributes to the smooth operation and sustainability of modern ships. The continuous advancement of auxiliary machinery technology further enhances the capabilities and environmental performance of ships, making them safer, greener, and more reliable for maritime transportation across the globe.

#generator parts#ship machinery parts#navigation equipment#Auxiliary Machinery Equipment#Ship Machinery Parts#Auxiliary Machinery#Generator Parts#Automation#Navigation#pumps#automation systems

2 notes

·

View notes

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades. Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration. Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage. Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas. Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded. Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications. Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications. Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Text

Efficient Transformer Oil Filtration | High-Performance Machine

Introduction

Welcome to the world of transformer oil filtration, the key to maximizing the performance and efficiency of your power transformers. In this article, we will explore the importance of this critical maintenance process and how it can significantly enhance the lifespan and reliability of your equipment.

Transformer oil, also known as insulating oil, is responsible for several crucial functions in power transformers, such as heat dissipation, insulation, and arc quenching. Over time, however, contaminants and impurities can accumulate in the oil, compromising its effectiveness and putting your entire power system at risk. That's where “Transformer Oil Filtration” comes into play. By removing contaminants, moisture, and gases from the oil, this process ensures optimal performance and extends the lifespan of your transformers. It not only eliminates the risk of costly breakdowns but also improves energy efficiency, reducing maintenance and downtime expenses. At Minimac Systems, we understand the importance of maximizing performance and efficiency while minimizing operational costs. Our transformer oil filtration system is designed to deliver exceptional results, offering unmatched reliability and ensuring the smooth operation of your power transformers. Experience the power of transformer oil filtration and take a transformative step towards optimal performance and long-lasting reliability of your power systems.

Importance of Transformer Oil Filtration:

Transformer oil plays a vital role in insulation, cooling, and protecting internal components. Over time, contaminants such as water, sludge, and oxidation by-products degrade the oil's properties, leading to inefficiency and potential failure. Regular oil filtration is essential to prevent costly breakdowns and prolong transformer life. Investing in an advanced filtration machine ensures your transformers operate reliably, minimizing maintenance costs and ensuring compliance with industry standards.

What is Transformer Oil Filtration?

Transformer oil filtration removes contaminants and restores the oil’s properties. The process involves coarse and fine filtration, vacuum dehydration, and degassing. This restores the oil's dielectric strength, maintains cooling efficiency, and prevents electrical failures. Regular filtration as part of a maintenance program reduces the need for frequent repairs, minimizes downtime, and ensures the reliable performance of the electrical system.

Benefits of Efficient Transformer Oil Filtration

Improved Performance and Reliability:Removing impurities ensures better insulation and cooling, which enhance transformer reliability and reduce the risk of electrical failures.

Extended Transformer Lifespan:Filtration slows down the aging process of transformer components, helping you avoid premature breakdowns and extend equipment life.

Reduced Maintenance Costs:Efficient filtration decreases the frequency of oil changes and transformer repairs, leading to significant cost savings over time.

Enhanced Energy Efficiency:Clean oil improves transformer efficiency, which reduces energy losses and operating costs while also lowering the organization’s carbon footprint.

Regulatory Compliance: Maintaining clean oil through proper filtration helps meet industry standards and ensures the responsible operation of electrical infrastructure.

Common Contaminants in Transformer Oil

Water:Even minimal water contamination can significantly reduce oil’s dielectric strength, leading to electrical failures and degraded insulation.

Sludge:Formed due to oxidation, sludge can clog filters and hinder heat transfer, reducing cooling effectiveness.

Oxidation By-products:Prolonged heat and oxygen exposure lead to varnish-like deposits that corrode components and compromise the oil's insulating properties.

Particulate Matter: Dust, metal filings, and other particles in the oil cause abrasive wear on transformer parts, leading to more frequent maintenance.

Dissolved gases:Gases like hydrogen and acetylene formed during transformer operation indicate internal issues and require immediate attention and filtration.

Understanding the Transformer Oil Filtration Process

Coarse Filtration:This initial stage removes large particles like dust, metal filings, and sludge, protecting downstream filter components from clogging.

Fine Filtration: In this stage, smaller contaminants like water, fine particulates, and oxidation by-products are removed, restoring the oil’s insulating properties.

Vacuum Dehydration:his step extracts any remaining water from the oil, further enhancing its dielectric strength and preventing electrical issues.

Continuous monitoring throughout the filtration process ensures the oil meets the required safety and performance standards.

Features of our Filtration Machine

High-Efficiency Filtration:Our multi-stage system combines coarse and fine filtration, vacuum dehydration, and degassing to comprehensively remove contaminants, restoring oil to optimal condition.

Automated Control System:The system is equipped with real-time monitoring and adjustments to maximize efficiency, reducing the need for manual intervention.

Compact and Portable Design:Our machine’s design makes it easy to transport and set up at different locations, ensuring flexible and efficient on-site filtration.

User-Friendly Interface:Operators can easily monitor and adjust settings through an intuitive control panel, minimizing errors and ensuring smooth operation.

Robust Construction:Built to withstand tough industrial conditions, the machine is durable and requires minimal maintenance.

Steps to Efficiently Filter Transformer Oil

Preparation:Ensure the transformer is isolated and the oil is at the correct temperature. Set up the necessary equipment and workspace.

Coarse Filtration:Use a coarse filter to remove large contaminants like dust, metal filings, and sludge.

Fine Filtration:Move on to fine filtration to eliminate smaller impurities, such as water and oxidation by-products, restoring the oil-insulating strength.

Vacuum Dehydration: If needed, perform vacuum dehydration to remove any residual water from the oil.

Degassing:In cases where dissolved gases are present, degassing will improve oil quality and performance.

Continuous Monitoring:Track key parameters such as dielectric strength, water content, and dissolved gas levels to ensure that the oil meets the required specifications.

Disposal and Recycling:Dispose of waste materials following environmental regulations. In some cases, the filtered oil may be reusable, contributing to sustainable maintenance practices.

Maintenance and Care for the Filtration Machine

Proper care and maintenance of your transformer oil filtration machine ensure long-term reliability and efficiency. Here’s how to maintain your equipment:

Regular Inspections:Check for wear, damage, and changes in performance. Identifying issues early reduces the risk of malfunctions.

Scheduled Maintenance: Follow the manufacturer’s maintenance schedule, including filter replacements and component lubrication, to ensure peak performance.

Calibration and Testing:Regularly calibrate the machine’s sensors to ensure accurate monitoring and filtration.

Operator Training:Ensure all operators are trained on the machine’s features, functions, and maintenance requirements to avoid user errors.

Spare Parts Management:Keep an inventory of essential spare parts like filters, gaskets, and seals to avoid unnecessary downtime during repairs. By following these maintenance guidelines, you can ensure that your transformer oil filtration machine operates efficiently and remains reliable over the long term.

Conclusion

Investing in our transformer oil filtration system helps ensure your transformers operate efficiently with minimal downtime and reduced maintenance costs. With a multi-stage filtration process, user-friendly controls, and robust construction, our system is designed to meet the highest industry standards. Regular filtration keeps transformer oil clean, extends transformer lifespan, and optimizes energy efficiency. Choose our advanced filtration machine to safeguard your power systems and achieve long-lasting reliability.

#frf condition systems#frf machine#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#contamination#lube oil filter#hydraulic oil filter#oil purification machine#oil testings#minimac technology#oil technology#technology#innovation#efficiency#iiot#flushing systems#flushing machine#condition monitioring

1 note

·

View note

Text

Oil filtration machine solutions in India | AR Engineering

Searching for a reliable Oil Filtration Machine to enhance your equipment performance? 🌟 Explore the best solutions at OilFilterMachineIndia.com! We offer a wide range of advanced Oil Filtration Machines designed to remove contaminants, moisture, and gases from various industrial oils.

As a leading provider of Oil Filtration Machine India, we specialize in high-performance Industrial Oil Filtration Machine solutions for diverse industries including power, steel, cement, and manufacturing. Our cutting-edge Oil Filtration Systems ensure clean and purified oil, resulting in increased equipment life and reduced downtime.

Our Oil Purification Machines are engineered with precision to meet international standards. Whether you need a stationary or Portable Oil Filtration Machine, we have solutions tailored to your requirements. These systems are perfect for Oil Contamination Removal Machine tasks, maintaining the quality and efficiency of industrial lubricants.

For specialized needs, we offer a range of machines like Turbine Oil Filtration Machine, Transformer Oil Filtration Machine, and Hydraulic Oil Filtration Machine. Each machine is designed to cater to specific industrial applications, ensuring thorough oil cleaning and purification.

If you require large-scale oil maintenance, our Oil Filtration Plant solutions are the perfect choice. With our comprehensive Oil Filtration Solutions, industries can achieve higher efficiency, lower operating costs, and a more sustainable workflow. Our efficient Oil Cleaning Machines are ideal for extending the life of oils used in critical machinery.

At Oil Filter Machine India, we pride ourselves on delivering top-quality products. Our Oil Filter Machine India options are trusted across industries for their superior performance and reliability.

✅ Remove Contaminants Efficiently ✅ Extend Equipment and Oil Life ✅ Enhance Industrial Productivity

Visit OilFilterMachineIndia.com to find the perfect Oil Filtration Machine, Oil Filtration Machine India, Industrial Oil Filtration Machine, Oil Filtration Systems, Oil Purification Machine, Portable Oil Filtration Machine, Oil Contamination Removal Machine, Turbine Oil Filtration Machine, Transformer Oil Filtration Machine, Hydraulic Oil Filtration Machine, Oil Filtration Plant, Oil Filtration Solutions, Oil Cleaning Machine, and Oil Filter Machine India designed to meet your operational needs!

#Oil Filtration Machine#Oil Filtration Machine India#Industrial Oil Filtration Machine#Oil Filtration Systems#Oil Purification Machine#Portable Oil Filtration Machine#Oil Contamination Removal Machine#Turbine Oil Filtration Machine#Transformer Oil Filtration Machine#Hydraulic Oil Filtration Machine#Oil Filtration Plant#Oil Filtration Solutions#Oil Cleaning Machine#Oil Filter Machine India

0 notes

Text

Boost Performance and Protection with Advanced Vacuum Pressure Impregnation Plants by Omsai Enterprises

In industries where electrical insulation, moisture resistance, and long-term reliability are critical, impregnation technology plays a vital role. At Omsai Enterprises, in collaboration with AR Engineering, we offer cutting-edge Vacuum Pressure Impregnation Plants (VPI) designed to deliver superior impregnation solutions for a wide range of applications.

What is a Vacuum Pressure Impregnation Plant?

A Vacuum Pressure Impregnation Plant is a specialized system that uses vacuum and pressure cycles to impregnate electrical windings or porous materials with varnish or resin. This process ensures complete penetration into the smallest voids, significantly improving insulation resistance, heat dissipation, and lifespan of electrical components.

Our VPI systems are widely used in transformer manufacturing, motor rewinding, and other industrial coating solutions.

Advanced Processes in Our VPI Systems

💨 Degasification

Before impregnation, the system performs degasification to remove air and trapped gases from components. This is crucial for complete resin penetration and bubble-free insulation.

💧 Dehydration Process

Moisture can severely impact the effectiveness of varnish or resin. Our plants utilize a controlled dehydration process to eliminate residual moisture from the components before the impregnation phase begins.

🧼 Filtration and Purification

We incorporate in-line filtration and purification systems to maintain resin purity and remove any contaminants during processing, ensuring consistent and high-quality results.

Key Features of Our Vacuum Impregnation Equipment

High-efficiency vacuum and pressure chambers

Fully automated or semi-automatic control systems

Energy-efficient operation with minimal resin wastage

Custom sizes and capacities based on application

Integrated oil purification options for specialized needs

Applications Across Industries

Our Vacuum Impregnation Equipment and Industrial Impregnation Machines are used in:

Transformer and coil manufacturing

Motor winding insulation

Alternator and generator repair

Capacitor and choke coil production

General oil manufacturing and electrical insulation sectors

Why Choose Omsai Enterprises & AR Engineering?

🏭 Proven expertise in industrial engineering and impregnation systems

⚙ Precision-built industrial impregnation machines with long service life

🌍 Strong presence in India with on-site support and training

🔬 Continual innovation in impregnation technology and resin processing

🔄 Integrated systems with filtration and purification for quality assurance

Your Trusted Partner in Industrial Coating and Insulation Solutions

Whether you're looking to improve product reliability, extend equipment life, or meet industry standards in electrical insulation, our Vacuum Pressure Impregnation Plants are built to exceed expectations. With a strong track record of delivering durable and efficient impregnation solutions, Omsai Enterprises is your trusted partner in electrical and oil purification industries.

#degasification#dehydration process#filtration and purification#oil manufacturing#oil purification#Vacuum Pressure Impregnation Plant#Impregnation Systems#Industrial Impregnation Machines#Vacuum Impregnation Equipment#Omsai Enterprises#AR Engineering#Impregnation Solutions#Impregnation Technology#Industrial Coating Solutions"

0 notes

Text

What are the methods of hydraulic oil regeneration?

Because hydraulic oil is a vital treasure in hydraulic lubrication equipment, the quality of hydraulic oil, its service life and the way of recycling it have become issues that everyone is discussing and researching in industrial production.

At present, my country has begun to pay attention to the recycling and reuse of waste oil products. Large and medium-sized factories and mines generally have supporting waste oil recycling facilities, and the recovery rate of waste hydraulic oil is about 80%. With the existing waste oil treatment technology, the recycling rate of deteriorated hydraulic oil can generally reach about 70%, which will reduce the production of new oil by more than 55% each year. Then, the regeneration of waste hydraulic oil is a complex and professional process!

Now, let's briefly introduce several commonly used methods for your reference.

Hydraulic oil belongs to a type of lubricating oil. It is made by blending base oil and additives.

When judging what method will be used to regenerate and purify the hydraulic oil, we must first understand the quality status of the waste hydraulic oil after use.

First, during normal production and life, hydraulic oil will generally produce foreign matter such as sludge, impurities, and moisture. In this case, the so-called "recycled waste hydraulic oil" mainly uses professional hydraulic oil filtration and purification equipment to remove impurities from hydraulic oil, remove moisture, and remove harmful gases and emulsification in the oil, so that the impurities, moisture, and cleanliness indicators of the oil are restored to the national standard range. Such hydraulic oil can be purified and reused repeatedly.

If the color of the hydraulic oil involved is black, the viscosity is reduced, or even stinks, it is necessary to test the oil, determine the indicators, and add necessary additives. Then it is blended with professional blending equipment.

Because some of the additives in hydraulic lubricating oil have been consumed after shearing, oxidation, high temperature, repeated wear and other uses, they are no longer qualified in terms of indicators and can no longer meet the use requirements. It is necessary to remove the acid and heavy metals from the oil, transform it into a base oil, and then add the matching chemical additives of the hydraulic oil to blend.

At present, most factories and mines use waste oil filtration and purification equipment, which is mainly used for daily filtration and purification and simple acid removal and demulsification. As long as the hydraulic oil is well maintained and the water content is well controlled in the early stage, the hydraulic oil will not deteriorate easily. Data show that regular maintenance and purification of hydraulic oil will extend the service life by 1-2 times.

The quality of hydraulic oil directly affects the reliability and life of the equipment, so the pollution control of hydraulic oil cannot be ignored.

In the future, with the widespread use of a large amount of hydraulic equipment, the demand for hydraulic oil will be greater, while the relative oil resources will be less and less. Therefore, we need to pay more attention to the rational use of hydraulic oil and continuously improve the recycling rate of hydraulic oil, reduce the production of new oil to a greater extent, thereby saving a lot of oil resources and reducing pollution to the environment.

0 notes

Text

Advanced Oil Purifier Machines for Industrial Oil Purification Systems

Karroter’s Oil Purifier Machine offers cutting-edge technology for industrial oil purification systems, ensuring clean and efficient oil management. Engineered with advanced filtration processes, this system removes contaminants, water, and impurities from various oils, enhancing machinery performance and extending equipment life. Ideal for industries such as automotive, power generation, and manufacturing, Karroter’s solutions reduce maintenance costs and ensure sustainable operations.

Discover more: Karroter Oil Purifier System.

0 notes