#Oil Skimmer in India

Text

Oil Skimmer Machine Manufacturer & Suppliers In India | High-Tech

High-tech machines is a leading Oil Skimmer Machine Manufacturer and Supplier in India. We pride ourselves on offering high-quality oil skimmer machines made from top-notch components and parts. Our machines are designed to efficiently remove oil and other floating contaminants from industrial wastewater and oil-water separation applications. Experience the reliability and effectiveness of our oil skimmer machines. Contact us today to explore our range of products and find the perfect solution for your needs.

#oil skimmer Machine Manufacturer#oil skimmer Machine Manufacturer In india#oil skimmer Machine Suppliers in maharashtra#oil skimmer Machine Manufacturer in pune#industrial component cleaning machine#industrial component cleaning machine Manufacturers in india#industrial component cleaning machine manufacturer#Dip Dunk Machine supplier#Dip Dunk Machine supplier in maharashtra#Dip Dunk Machine supplier in india.

0 notes

Text

Fenton Technologies Pvt. Ltd. is a professional Engineering equipment’s Manufacturing and Environmental research and development, production and sales of science and technology enterprises. Since its inception, we always adhere to the spirit of craftsmanship, to provide the industry with water treatment equipment and services and systematic solutions, Company Work in Three Verticals- Sewage Water Projects , Wastewater Products, Swimming Pools Products include MBR Membrane , Oil Skimmer, Screw Press, MBR STP Plant, Bar Screen, Dissolved Air Flotation (DAF) many More water treatment Equipment’s . Fenton is also Associating with Overseas partners to Keep in Forefront . Our Water Treatment Equipment Company always welcome innovation & Advance Technologies Developers for Association in Market .

In product quality improvement, the water treatment equipment company “customer first” philosophy for the development, adhering to the “quality, innovation and service” business purposes, the establishment of a set of international standards of quality assurance management system.

youtube

MBR Membrane Manufacturer

Sewage treatment plant manufacturer in india

water Treatment Equipment Manufacturer

water Treatment Equipment Supplier

Belt Type Oil Skimmer Manufacturer

swimming pool manufacturer in india

2 notes

·

View notes

Text

What are the consequences of not properly separating oil and water in industrial processes?

Not properly separating oil and water in industrial processes can lead to significant environmental and economic consequences. When oil-contaminated water is discharged into natural water bodies without adequate treatment, it poses severe risks to aquatic ecosystems. The oil can form a film on the water surface, blocking sunlight and disrupting the oxygen exchange necessary for aquatic life. This can result in the death of fish and other marine organisms, leading to ecological imbalance. Furthermore, regulatory bodies impose strict penalties on industries that fail to meet wastewater treatment standards, resulting in substantial fines and potential shutdowns. Using efficient oil water separators is crucial to ensuring compliance with environmental regulations and minimizing the ecological footprint of industrial operations.

From an operational perspective, inadequate separation of oil and water can cause significant damage to equipment and increase maintenance costs. Oil can lead to the fouling of heat exchangers, corrosion of pipes, and blockages in water treatment systems, thereby reducing efficiency and increasing downtime. This can disrupt production processes and lead to financial losses. Oil skimmer manufacturers in India and suppliers of oil water separators, play a critical role in providing the necessary technology to efficiently separate oil from water. Investing in reliable separation equipment not only helps industries avoid the costs associated with environmental fines and equipment damage but also enhances overall process efficiency and sustainability.

0 notes

Text

Ok so ye

I say stuff off of the top of my head. If you follow me or read my blog posts once in a while, you'd know.

So what am I here to talk about? *drumroll* ✨Pollution!✨Why am I talking about pollution? Well, it's 12:30 am, and it's March, and with pollution, we could be dead by December. We humans, we're literally polluting everything, from space to the night sky. Now keep reading if you're actually gonna read.

And I always write posts after being inspired by an Instagram story or random YouTube video. And today, it is a YT video. I'll link the video at the end, but the video is in my native language(Tamil), but I guess you can understand with all the images and stuff.

So the video was made by an organisation called LMES - Let's Make Education Simple, who specialise in STEM education across Tamil Nadu, India. I attended their summer camp when I was 7 and was emotionally scarred because that was a lot of confusion for a 7-year-old to handle. But they also look at different places and bring certain problems to light. And I watched one of those videos today by chance.

In Chennai, Tamil Nadu, there's this place called Ennore. Why am I talking about Ennore, right? Well, I'm sure you've heard of oil spills. You've seen pictures of them on Google, where they're smack in the middle of the Pacific Ocean. But what if they're closer to the shores? What if the oil spill happens in an area with backwaters?

Next to the backwaters of Ennore, there's a place called Ernavur, also in Chennai. So a lot of people already know that the majority of Chennai was affected by the mass floods in December '23. The rural areas of Ernavur were also impacted, but differently. After the flood receded, there was oil all over everything, even covering the insides of homes. And the people who lived there were left in devastating conditions.

Though stuff was crazy over there, let's shift our focus back to Ennore. Ennore consists of two parts, namely Kattukuppam and Thazhakuppam(Thalakuppam). These areas consist of 32 villages, out of which 8 are fishing communities. They fish from the backwaters and the shoreline.

It looks like there's an oil company there which doesn't seem to do it's job very well. It's been spilling oil for over a year. This makes it almost impossible for people to fish there, and it's also given their fish a bad reputation across Chennai. Nobody buys fish that is supposedly from Ennore.

The people of Ennore actually said the floods were good because only then the oil company noticed the spills and tried to do something about it, by providing a few solutions to the oil spills. And even those efforts were mediocre.

They used three methods. Absorbant pads - absorb oil, Skimmers - to skim the top layer of oil from the water, and Boomers- that act as barriers against oil. These were placed mediocrely or were of bad quality.

Plus, those oil extraction units were actually built in places that the central government doesn't allow. And yet the state government provides the money to do so. Omg it's 1 am.

So you'd ask "Okay sp, we get it. But please get to the point." Okay then. A solution to this is very hard. and there are also a lot of health impacts.

The ex-chairman of the fishing community reported that chemicals and the oils in water in the pipes to the houses often had bad health effects. It led to a lot of people with skin problems, skin cancer, and reproductive issues, especially in women.

So what's the solution? There is a solution, but it's not great. So there are 3-5 kinds of oil-eating bacteria. Really, they eat hydrocarbons, and oil is full of that stuff. The problem is that they can only be sourced in small amounts and only work with stagnant water.

So the only proper way to stop oil spills is to... stop randomly building oil-sourcing units in places they aren't supposed to be. Wow, it took so long to get to this point.

And that isn't it. I've skipped out on a lot of stuff, and I probably don't know the full story either. If you liked this and want to know more, have a look at the video I mentioned earlier. From there, you can do further reading if you want. Maybe write your own posts.

Now, I really should sleep because I have school.

#pollution#environment#climate change#climate crisis#water pollution#oil spills#oil spill#science#current events

0 notes

Text

Oil Water Separation | Oil Water Separation Process - Finepac India

Oil water separation is a critical process for various industries, including petrochemical, oil and gas, and wastewater treatment. At Finepac India, we excel in providing innovative and efficient solutions for oil-water separation.

Our advanced technologies and expertise ensure that you achieve the highest level of oil water separation efficiency while maintaining environmental compliance.

Key Components of Oil Water Separation:

Inlet Area: The first step in the process is where the oil-water mixture enters. Finepac India's systems are designed to handle varying flow rates and oil concentrations.

Coalescing Media: We utilize advanced coalescing media that encourages the agglomeration of oil droplets, making it easier to separate them from water.

Separation Chamber: The heart of the system, where the actual separation occurs. Oil rises to the surface, and clean water is discharged.

Oil Skimmer: To collect and remove the separated oil, we incorporate an efficient oil skimmer into our systems.

Benefits of Finepac India's Oil Water Separation Process:

High Efficiency: Our systems offer a high separation efficiency, ensuring minimal oil content in the treated water.

Environmental Compliance: We are committed to eco-friendly solutions that help you meet environmental regulations and standards.

Customization: Finepac India tailors our systems to your specific needs, accommodating various flow rates and oil concentrations.

Low Operating Costs: Our systems are designed for cost-effective operation, reducing your overall expenses.

Reliability: With decades of experience, you can trust our systems to deliver consistent and reliable oil water separation.

Low Maintenance: Our systems are engineered for minimal maintenance requirements, saving you time and money.

For a comprehensive solution to your oil water separation needs, visit our website at Finepac India - Oil Water Separation.

Discover how our expertise and cutting-edge technology can benefit your industry and the environment. Contact us today for a consultation tailored to your specific requirements.

0 notes

Text

https://www.enquirygate.com/Directory/India/Oil-Skimmer-c18903

0 notes

Text

What should be the criteria to choose Oil Skimmer for Machine Shop?

Using an Oil Skimmer for the machine shop setting has various benefits. Oil removal from a machine coolant tank will start some attractive benefits such as cutting the smoke created amount from the cutting tool that comes into the contact with the oil loaded coolant. When the machine is turned off for the weekend then, the oil can come to the coolant tank surface. The living bacteria in the coolant tank take the help of the dissolved oxygen in the coolant mix and a process which is enhancing just having the oil layer on the surface. Oil Skimmer allows the smell-causing anaerobic bacteria to succeed and providing as similar as rotten-egg smell.

To choose a perfect Oil Skimmer in India for the machine shop, first of all, define the operating conditions in which the skimmer is functioning or working. All oil skimmers have a medium of moving as well as possibly other parts that are engrossed in the liquid. The life, as well as performance of the medium pick-up, pulleys, and wiper blades, is affected in various conditions. There are the conditions that include temperatures in and out of the liquid, pH solution, and the solvents or other reactive chemicals presence.

Hazardous Materials: Applications that involve flammable materials, as well as volatile vapours, need explosion-proof usage or air-driven controls and motors.

Viscosity/Temperature: All oil skimmers need floating oil to be in a liquid, and free-flowing state. If the oil thickens or solidifies at the environmental temperatures, the tank or the oil skimmer will need the heaters for maintaining fluid flow. This is a fact that low temperature is enough to freeze the water. There is an obvious need for a heater if you are using an oil skimmer for outdoors in freezing temperatures.

Now, the second step is choosing an oil skimmer according to your need or expectations of the removal capacity. It is advisable that the capacity should be based on the extreme amount of oil removal in the shortest time frame. According to the rule-of-thumb, it has specified approximately two times the maximum capacity of the anticipated requirement for the normal conditions.

The further step is to choose the type of belt, tube skimmer, or disk for your skimmer and in such case, it is obvious that you will need appropriate media on your skimmer to ensure the correct results. And, in case if you think that all belt materials or types operate similarly or simply choosing the reasonable option will serve, then you are not right and you would be to prepare yourself for failure. You must have a skimmer that appears at the top of the line but you might have the incorrect belt, disc, or tube material on it and after that, it doesn’t matter how efficient skimmer you are using in that tank. The results will be less than stellar.

In the same manner, determining the appropriate wiper blade is very important and you will need to have something which can withstand the pH levels and temperatures of your application therefore they don’t warp or melt or completely break while operating.

What should be the length of an oil skimmer and tube?

Oil Skimmer Belt and Tube Length: The capacity of removing oil isn’t affected by length. You will need to select a length that will ensure the liquid contact at its lowest level and allows it for easy oil skimmer mounting where the oil discharge is easy and has excellent access for the routine service. It is essential to get a company that has the capability of soil skimmer supplying with the long belts, as well as lift skimmed oil well almost for 100 feet without any compromise with the capacity and efficiency. You must have a company like Clear-Ion Experts that will work effectively with the application requirements. The disk must have touched the fluid, size the diameter accordingly.

Selecting the appropriate oil skimmer doesn’t have to be a terrible procedure, but things can easily go sideways if you don’t recognize some particular aspects of your apt application. You will need to make sure that you are handling it with a trustworthy vendor. There are companies that actually understand and know the working procedure of oil skimmer. You should take help from the experts.

Source Url: https://clear-ion.com/blog/what-should-be-the-criteria-to-choose-oil-skimmer-for-the-machine-shop/

#Oil Skimmer Belt#Oil Skimmer#Oil Filtration Plant#Oil Skimmer In India#Oil Skimmer In Haryana#Oil Skimmer In HaryanaDelhi

0 notes

Link

Shiva Global Enviro has best commercial Effluent Treatment Plant in India. The Effluent Water Treatment Plant facilitates production of disposable effluent without causing harm to the environment. Visit our website and Call us: 9205234602 for more Effluent Treatment Plant.

#Effluent Treatment Plant in India#Sewage Treatment Plant in India#Waste Water Recycling System in India#Zero liquid Discharge System in India#Belt type Oil Skimmer

1 note

·

View note

Link

Best Oil Skimmer Manufacturer in India. Manufacturing & Supplying Oil Skimmers at wholesale price. Worldwide Shipping Available. Call Or Enquiry Now

#oil skimmer#oil skimmers#oil skimmer manufacturer#oil skimmer manufacturer in india#oil skimmer manufacturer in pune

0 notes

Text

What Should We Know About Water Treatment Plants In India?

A nation with a population of 1.3 billion and diversity like India needs a strong water treatment facility. In recent years, the rapid expansion of cities and migration has caused concerns in regards to it. To manage the wastewater in line with the regulations and the safety of the populace and environment, there are many water treatment plants in India that function day in and day out.

How Does A Water Treatment Plant Work?

All the major treatment plants consist of components and processes like cooling towers, ultra-filtration, demoralization, reverse osmosis and in the end, a pumping station.

The process for treating wastewater is divided into four phases - Pre-treatment, Primary, Secondary, and Sludge.

Pre-Treatment

Companies in India begin the treatment process with a pre-treatment process. In the pre-treatment process, plants remove large items such as tree limbs, garbage, leaves, cans, rags, plastic bottles, diapers and other waste materials with a set of bar screens.

Special treatment plants use the method of equalization and chambering to regulate the rate of water inflow as it helps to get rid of stones, glasses and big sand particles. These plants are equipped with basins that keep control over the flow of sewage. Only after the processing is done, it is released for further processing.

Primary Treatment

The process that is followed after pretreatment is the primary treatment. In this process, the wastewater is collected in clarifiers, which comprises many large tanks. Before passing the material to the machines, a sort of mechanical scraper collects material that is solid and directs it to smaller machines called hoppers which manage to sludge the waste.

If there is the residue of oil and grease in the debris and it is not removed in the earlier process, it is removed in this process. Plants use surface skimmers and some special machinery like saponify.

Secondary Treatment

After primary treatment, the wastewater is flown through the secondary phase where plants aerate and agitate the wastewater in basins. In the basin, the water is treated by mixing it with microorganisms that help in breaking down organic matter into sludge for further processing.

For example, treatment plants create a mixture of microbes and pass the wastewater over the biofilm. Generally, treatment plants mix the biomass with waste material, creating a kind of sludge that can be recycled.

Sludge Treatment

The final phase in the water treatment method is sludging. In this process, treatment of the remaining water and biosolids is performed. After the separation of the waste from the sludge, the remaining sludge is passed through to a thickener. In the thickener, the sludge is centrifuged and fed to digesting tanks containing anaerobic bacteria.

This is the general process of wastewater treatment in major water treatment companies in Pune and anywhere else in India.

1 note

·

View note

Link

the manufacturers of products like pvc conveyor belt, PU Conveyor belt, roller conveyor belt gravity roller, conveyor belt Checkered Conveyor Belt, Rubber Conveyor belt, cleated conveyor belt, Hear resistant conveyor belt, non- sticky belt conveyor, Metal detector belt, cooling tunnel conveyor belt, Check- weigher belt, Packaging conveyor belt, treadmill belt, teflon mesh conveyor belt, Sidewall belt, x-ray machine conveyor belt, Corrugated boxes conveyor belt, ultrasonically welded sidewall belt, Film shooting conveyor belt, Cut to length sheet belt, Fuit sorting conveyor belt, Woodworking belt, baggage conveyor belt, Conveyor Belts for Marble,Oil Skimmer belt.

1 note

·

View note

Text

Kitchen Accessories-Top 5 Cookware Combinations for Your Kitchen!

If you cook in the kitchen a lot and master all the tools and vessels that you have, you will realize that this combination should be used in every way. You can't stir your soup with a spatula, and you can't turn your omelet over with a ladle.

If you stock up on supplies for a new kitchen, some things can slip away. That is why Shiv Home World home & kitchen appliances online store is here to help you. The more experience you have, the more obvious these things become. We have an extensive collection of cookware, kitchenware, and you can buy kitchenware online at very affordable prices and offers.

No matter what kind of kitchen you prepare, any combination applies to the cookware you use. Shiv Mart home & kitchen appliances online store has rounded up some cookware combinations for you.

It is really only a matter of the material of the cooking utensils but make sure you get them from reliable home & kitchen appliances online stores like us. If you use a pan made for its surface, there are all kinds of cooking techniques that require you to use cutlery-friendly pans. There are numerous online stores available where you can easily browse various accessories and you can shop kitchen accessories online at your convenience.

Let's look at the 5 best & most common combinations when it comes to Indian households.

Non-stick Kadai & Skimmer

The Kadhai is one of the vital cooking accessories in India. It is used in most households as a replacement container for the wok. It can be used for both flat and deep-fried dishes. It has similar properties in heat distribution and the ability to be a souvenir for the preparation of stirring recipes.

At Shiv Mart, you can shop a vast range of non-stick cookware online and the most common function of a Kadai is to deep-fry objects. The hot oil must be drained from the food, which can be difficult with round or perforated utensils. This functionality is ensured by a skimmer, which you will need to make the most of the deep-fried food by cooking a hot kadhai full of oil. Explore and buy non-stick cookware online of your favourite brands at exciting offers.

Iron Tawa & Steel Spatula

Many Indian households prefer traditional iron Tawa to make many things such as chapattis, paranthas, dosas, and omelets. The crunch is crisp and different, something that cannot be achieved with modern non-stick pans. You can get the best quality non-stick cookware online that comes with good quality. The problem is that most modern houses are equipped with non-stick silicone utensils. There is no specific consistency in the kitchen that you can get with regular iron tawas. Shop a huge collection of kitchen accessories & non-stick cookware online at the lowest prices.

Soup Pot & Ladle

For Tawa of the old school, you need a steel spatula, also known as a solid turner. This is a suitable option for Iron Tawa. It also gives you the opportunity to simply scrape up the crispy tawa pieces. Also known as a cooking pot, this pot is used to prepare sauces, stews, broth, and soups. Buy kitchenware online of your choice at the largest home & kitchen accessories online store Shiv Home World.

Non-Stick Pan & Silicone Spatula

As already mentioned, silicone utensils are a great tool in the kitchen because they are flexible and make the process more accessible due to their properties. If you are looking to buy the best quality They are also compatible with all cooking pots. If you are planning to buy kitchenware and non-stick cookware online at our store.

Sauce pan & whisk

If you are dealing with dishes with a thin consistency, you will need a utensil to work with so that you can mix it and scoop out significant amounts, making the mixing process more manageable.

Also, shop pressure cooker online at Shiv Mart, where you can find a vast exclusive collection of all brands. For this reason, a ladle is a suitable utensil for large pots. It makes the serving process stress-free. Shiv Home World offers standard and premium quality pressure cookers online at discounts.

Shiv Home World home furnishing online store cookware has some of the highest quality crockery products at an affordable price. We have a good collection of cookware sets that include nonstick cookware online such as Lunchbox, nonstick Tapper pan, and non stick kadai (non stick snack maker).

Call@ 9133604440

Email Id: [email protected]

Website: www.shwkart.com

1 note

·

View note

Text

Industrial Biorefinery Industry Research Report 2021-2028

Market segmentation

Industrial Biorefinery Industry market is split by Type and by Application. For the period 2016-2026, the growth among segments provide accurate calculations and forecasts for revenue by Type and by Application. This analysis can help you expand your business by targeting qualified niche markets.

Also Read: http://www.marketwatch.com/story/june-2021-report-on-global-humidity-indicator-plugs-market-statistics-cagr-outlook-and-covid-19-impact-2021---2023-2021-06-03

Market segment by Type, covers

Water-based Fluid

Foam-based Fluid

Gelled Oil-based Fluid

Market segment by Application can be divided into

Oil industry

Gas industry

Chemical

Others

Also Read: http://www.marketwatch.com/story/global-aquarium-protein-skimmers-market-statistics-cagr-outlook-and-covid-19-impact-2021---2026-2021-05-14

The key market players for global Industrial Biorefinery Industry market are listed below:

GE(Baker Hughes)

Halliburton

Schlumberger

BASF

DowDuPont

AkzoNoble

Ashland

Calfrac Well Services

Albermarle

Trican Well Service

Clarient

Market segment by regions, regional analysis covers

North America (United States, Canada, and Mexico)

Europe (Germany, France, UK, Russia, Italy, and Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Australia, and Rest of Asia-Pacific)

South America (Brazil, Argentina, Rest of South America)

Middle East & Africa (Turkey, Saudi Arabia, UAE, Rest of Middle East & Africa)

Also Read: http://www.marketwatch.com/story/global-automotive-intake-gas-temperature-sensor-market-outlook-industry-analysis-and-prospect-2021-2026-2021-05-03

The content of the study subjects, includes a total of 14 chapters:

Chapter 1, to describe Industrial Biorefinery Industry product scope, market overview, market opportunities, market driving force and market risks.

Chapter 2, to profile the top manufacturers of Industrial Biorefinery Industry, with price, sales, revenue and global market share of Industrial Biorefinery Industry from 2019 to 2021.

Chapter 3, the Industrial Biorefinery Industry competitive situation, sales, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast.

Chapter 4, the Industrial Biorefinery Industry breakdown data are shown at the regional level, to show the sales, revenue and growth by regions, from 2016 to 2026.

Chapter 5 and 6, to segment the sales by type and application, with sales market share and growth rate by type, application, from 2016 to 2026.

Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales, revenue and market share for key countries in the world, from 2016 to 2021.and Industrial Biorefinery Industry market forecast, by regions, type and application, with sales and revenue, from 2021 to 2026.

Chapter 12, 13 and 14, to describe Industrial Biorefinery Industry sales channel, distributors, customers, research findings and conclusion, appendix and data source.

Also Read: http://www.marketwatch.com/story/global-bio-banking-human-samples-market-insights-overview-analysis-and-forecast-2015-2026-2021-05-19

List OF CONTENTS AND TABLES:

Table of Content

1. Introduction

1.1 Definition of the Market

1.2 Research Purpose

1.3 Scope of the Study

1.4 Stakeholders

1.5 Geography Coverage

1.6 Currency Under Consideration

1.7 Volume Units

1.8 Review Cycle

1.9 Summary and Key Findings of the Research

2 Research Methodology

2.1 Research Data

2.1.1 Secondary Data

2.1.2 Primary Data

2.2 Market Size Estimation

2.2.1 Bottom-Up Approach

2.2.2 Top-Down Approach (Involves time, Space, and Persons)

2.3 Data Triangulation

2.4 Assumptions

2.5 Hypothesis of this Research, Clear, specific, and testable statement of this research

2.6 Limitations of Our Study

2.7 Scene Based Modeling

2.8 Covid-19 Impact/Evaluation

3. Market Dynamics

3.1 Driving Factors

3.1.1 Rising Demand in one or More of the Following Regions: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

3.1.2 Increasing Use of Industrial Biorefinery Industry by Different End-User/Applications

3.2 Restraints and Challenges in the Market

3.3 Opportunities

4. Global Industrial Biorefinery Industry Market-Segmentation

4.1 By Type

…

Also Read: http://www.marketwatch.com/story/global-cancer-stem-cells-cscs-market-by-type-by-application-by-segmentation-by-region-and-by-country-2021-2021-05-06

4.2 By End-User/Application Industry

…

4.3 By Geography

4.3.1 North America Industrial Biorefinery Industry Total Market Size (Production, Consumption, Import, Export) and Segmentation (by Type, Application, Countries and Participants)

4.3.1.1 North America Industrial Biorefinery Industry Production from 2014-2020

4.3.1.2 North America Industrial Biorefinery Industry Consumption from 2014-2020

4.3.1.3 North America Industrial Biorefinery Industry Import and Export from 2014-2020

4.3.1.4 North America Industrial Biorefinery Industry Market Value ($) and Growth (%) by Type from 2019-2020

4.3.1.5 North America Industrial Biorefinery Industry Market Value ($) and Growth (%) by Application from 2019-2020

4.3.1.6 North America Industrial Biorefinery Industry Market Value ($) and Growth (%) by Countries from 2019-2020

4.3.1.7 Top North America Industrial Biorefinery Industry Participants Value ($) and Market Share (%) in 2020

4.3.2 Europe Industrial Biorefinery Industry Total Market Size (Production, Consumption, Import, Export) and Segmentation (by Type, Application, Countries and Participants)

4.3.2.1 Europe Industrial Biorefinery Industry Production from 2014-2020

4.3.2.2 Europe Industrial Biorefinery Industry Consumption from 2014-2020

4.3.2.3 Europe Industrial Biorefinery Industry Import and Export from 2014-2020

4.3.2.4 Europe Industrial Biorefinery Industry Market Value ($) and Growth (%) by Type from 2019-2020

4.3.2.5 Europe Industrial Biorefinery Industry Value ($) and Growth (%) by Application from 2019-2020

4.3.2.6 Europe Industrial Biorefinery Industry Market Value ($) and Growth (%) by Countries from 2019-2020

4.3.2.7 Top Europe Industrial Biorefinery Industry Participants Value ($) and Market Share (%) in 2020

4.3.3 Asia-Pacific Industrial Biorefinery Industry Total Market Size (Production, Consumption, Import, Export) and Segmentation (by Type, Application, Countries and Participants)

4.3.3.1 Asia-Pacific Industrial Biorefinery Industry Production from 2014-2020

4.3.3.2 Asia-Pacific Industrial Biorefinery Industry Consumption from 2014-2020

4.3.3.3 Asia-Pacific Industrial Biorefinery Industry Import and Export from 2014-2020

4.3.3.4 Asia-Pacific Industrial Biorefinery Industry Value ($) and Growth (%) by Type from 2019-2020

4.3.3.5 Asia-Pacific Industrial Biorefinery Industry Value ($) and Growth (%) by Application from 2019-2020

4.3.3.6 Asia-Pacific Industrial Biorefinery Industry Value ($) and Growth (%) by Countries from 2019-2020

4.3.3.7 Top Asia-Pacific Industrial Biorefinery Industry Participants Value ($) and Market Share (%) in 2020

4.3.4 Latin America Industrial Biorefinery Industry Total Market Size (Production, Consumption, Import, Export) and Segmentation (by Type, Application, Countries and Participants)

4.3.4.1 Latin America Industrial Biorefinery Industry Production from 2014-2020

4.3.4.2 Latin America Industrial Biorefinery Industry Consumption from 2014-2020

4.3.4.3 Latin America Industrial Biorefinery Industry Import and Export from 2014-2020

4.3.4.4 Latin America Industrial Biorefinery Industry Value ($) and Growth (%) by Type from 2019-2020

4.3.4.5 Latin America Industrial Biorefinery Industry Value ($) and Growth (%) by Application from 2019-2020

4.3.4.6 Latin America Industrial Biorefinery Industry Value ($) and Growth (%) by Countries from 2019-2020

4.3.4.7 Top Latin America Industrial Biorefinery Industry Participants Value ($) and Market Share (%) in 2020

4.3.5 Middle East & Africa Industrial Biorefinery Industry Total Market Size (Production, Consumption, Import, Export) and Segmentation (by Type, Application, Countries and Participants)

4.3.5.1 Middle East & Africa Industrial Biorefinery Industry Production from 2014-2020

4.3.5.2 Middle East & Africa Industrial Biorefinery Industry Consumption from 2014-2020

4.3.5.3 Middle East & Africa Industrial Biorefinery Industry Import and Export from 2014-2020

4.3.5.4 Middle East & Africa Industrial Biorefinery Industry Value ($) and Growth (%) by Type from 2019-2020

4.3.5.5 Middle East & Africa Industrial Biorefinery Industry Value ($) and Growth (%) by Application from 2019-2020

4.3.5.6 Middle East & Africa Industrial Biorefinery Industry Value ($) and Growth (%) by Countries from 2019-2020

4.3.5.7 Top Middle East & Africa Industrial Biorefinery Industry Participants Value ($) and Market Share (%) in 2020

….….continued

CONTACT DETAILS :

+44 203 500 2763

+1 62 825 80070

971 0503084105

0 notes

Text

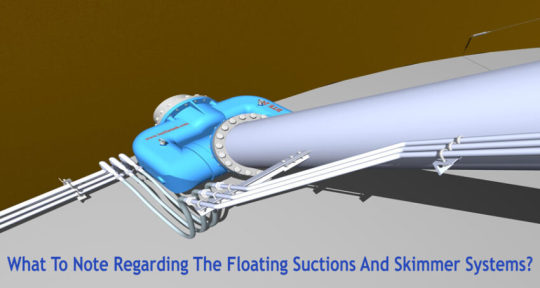

What to note regarding the floating suctions and skimmer systems?

Floating Suctions skimmers are designed specifically for clean and safe liquid removal from the storage tanks where the liquids are required to be sterilized by solids or water. The multi-patented Floating Suction Skimmer is the fast and one of the efficient and most sturdy devices that are highly durable and available for skimming as well as removing floating oil and contaminants from the industrial fluids procedure.

There are so many benefits if having Floating Suction Skimmer which are mentioned below

· It comes with a J-Tube model that has no hoses which sometimes affect the ballasting, and generate kinks and become collapsed or get robust

· The standards products for the level of the change of 7 inches, 3.5 inches, and 17 inches as well as the new pivot arm skimmers actually accommodate the level changes of up to 50 inches

· Suction Skimmer is designed with the quality-tested 304 stainless steel

· Durable, efficient, and simple to use as per the customers’ feedback

· Remove topmost fluid layer regularly o your coolant sumps and arts washer

· Easily set the calculated depth of skim which you require

· Floats with the changing fluid levels in your tanks

· Can be easily installed over the edge of the tank

Let’s have a look at the Oil skimmers as you must have the knowledge of skimmers

The oil skimmers are designed specifically to skim out the hydrocarbon liquid floating level on the top of the water. Well, the oil skimmer is designed importantly to remove the top layer of a two-phase liquid that is stored in a tank. Usually, the line size varies from 3 or 4 inches and Clear Ion Experts can design this larger size than this as per the requirement of the customers. You only have to explain your requirement and then, you will be assisted by a professional for the same.

Well, using an Oil Skimmer has various many benefits that include:

Opportunities for Recycling: In some examples, there are so many companies that can re-use the skimmed oil or they also can see it for the recycling process by selecting to keep their part of the word cleaner

Lessen the Disposal Expenses: The expense of oil disposable coolant is more costly than the oil disposing

Enhance the Coolant Life: If you have the oil-free coolant then, you are the lucky one as having it will enhance the functional life of the skimmer as well as also enhances the effectiveness while lessening the cost which you spend on the coolant and maintenance replacement.

Esthetic Benefits: Oil removal from a machine coolant tank will cut down on the smoke amount which is created from the advanced tool that is coming into the interaction with the oil-laden coolant and create a visible and cleaner workplace

EPA Violation Avoidance: There are so many metal working and machining shops that enable the aqueous parts by cleaning as the limits imposed by the EPA on the wastes and emissions discharge

Beneficial for Hygiene: Keeping coolant oil-free and oxygenated lessens the “rotten egg” smell, as well as bacterial levels, are also decreased and result in a cleaner and safer work environment

Enhance the Tool Life: The removal of floating surface oils when refresh and aerate coolant will enhance the life of the tool

There are two types of suction line:

· Roller – To use beneath an aluminum or steel floating roof

· Suspended – Generally used for fixed roof tanks

Floating Suction Assemblies are ideal for various reasons that are:

It helps to provide a cleaner and safer product portraying the fluid closest to the surface. Foreign particles, water, debris, and rust settle at the tank’s bottom via the gravity force. The suction consumption has a stop leg to maintain an uninterrupted bottom of the tank and remove the high percentage of the water as well as sediments from the aircraft fuel, heating oils, motor oils, and petrochemicals.

· It is also effective to lessen the inlet velocity with the special bellmouth therefore, the bottom stays undisturbed

· It is effective to transfer water from sewage treatment plant separation tanks. In the installation of inverted, it also can skim the oils from the water runoff settling tanks

· It is also effective in increasing the efficiency and decreasing the filter separator maintenance

These are a few things that one should keep in mind while using this floating suction oil skimmer system. If you are looking to get a Floating Suction Skimmer system in India then, Clear Ion Experts is the only answer. You can get this system in different sizes and specifications as per your demand.

Source url: https://clear-ion.com/blog/what-to-note-regarding-the-floating-suctions-and-skimmer-systems/

#Floating Suction Skimmer system in India#Oil skimmer systems#Floating Suction Skimmer#Oil Skimmer in India

0 notes

Link

Shiva Global Enviro offer complete zero liquid discharge to the Industries like electroplating, surface coating, process industries wherein water can be reused for the process without any discharge to the environment. Call us: 9205234602 for more detail and visit our website.

0 notes