#Operating Principles of Textile Dyeing

Explore tagged Tumblr posts

Text

Special Application Cases of Acid-Resistant Asbestos Rubber Sheets in the Textile Industry

The textile industry is vital worldwide. It supplies many textile products. Manufacturers use many materials and tools to keep production running smoothly. Acid-resistant asbestos rubber sheets are a special material. They are widely used in the textile industry. This article will analyze a case. It will explore using acid-resistant asbestos rubber sheets in the textile industry.

Case Study

To fix this, the manufacturer sought a corrosion-resistant material for acidic environments. It also needed to have high sealing performance and durability. After much research, they chose acid-resistant asbestos rubber sheets.

Manufacturers make acid-resistant asbestos rubber sheets from asbestos rubber materials and acid-resistant adhesives. They have the following main characteristics:

1. Corrosion resistance: Acid-resistant asbestos rubber sheets resist corrosion. You can use them for a long time in acidic environments without damage. This is crucial for dye manufacturers. It reduces downtime and maintenance from acid leaks.

2. High sealing performance: Acid-resistant, asbestos rubber sheets can seal pipes and prevent acid leaks. They are key to the smooth operation of the production process.

3. Wear resistance: The textile industry’s production process involves high friction and wear. Acid-resistant asbestos rubber sheets can withstand these pressures and remain stable.

4. Heat resistance: Some textile processes must high temperatures. Acid-resistant asbestos rubber sheets can perform well under such conditions.

The dye manufacturer saw results after using acid-resistant asbestos rubber sheets. The pipeline replacement completely fixed the acid leak. They no longer had frequent shutdowns and maintenance. It improved the production line’s efficiency. It also cut costs and labor.

Also, acid-resistant asbestos rubber sheets are eco-friendly and meet environmental rules. Since the dye maker started using this material, its process is now eco-friendly. It now follows sustainable development principles.

Conclusion

The examples above highlight a rare use of acid-resistant asbestos rubber sheets in textiles. Acid-resistant asbestos rubber sheets are a key material in textile production. They are corrosion-resistant, highly sealed, wear-resistant, and heat-resistant. This special material has solved pipeline leaks. It has improved production efficiency and product quality. Dye manufacturers chose it for these reasons. Also, the acid-resistant asbestos rubber sheets protect the environment. They meet the textile industry’s sustainable development goals.

In summary, acid-resistant asbestos rubber sheets are a special material. They are widely used in the textile industry. Their properties make them an ideal choice for solving problems in acidic environments. In textile production, this material boosts efficiency, cuts costs, and meets eco-friendly standards. As industries seek better materials, acid-resistant asbestos rubber sheets will have wider use.Products | Hongwo Sealing Sheet

0 notes

Text

Reusing Treated Sewage Water: Opportunities for Industries in 2025

Water scarcity and environmental sustainability have become top priorities for industries worldwide. As freshwater sources face increasing pressure, industries are shifting towards alternative solutions like reusing treated sewage water. In 2025, this trend is gaining momentum, driven by both environmental obligations and the economic advantages it brings. By investing in advanced sewage water treatment plants, industries can significantly reduce their dependency on freshwater, lower operating costs, and align with government regulations.

Why Reuse Treated Sewage Water?

Water is essential for industrial operations—whether it’s for processing, cooling, washing, or as a raw material. However, the growing water crisis and increasing costs are compelling industries to rethink their water strategies. Reusing treated sewage water offers a viable solution. Instead of discharging wastewater or relying solely on freshwater, industries can treat and reuse sewage water efficiently. This not only conserves freshwater resources but also promotes circular water usage, an essential principle of sustainable industrial practices.

Benefits: Economic, Environmental, and Strategic

Economic Benefits: Reusing treated sewage water helps industries cut costs associated with water procurement and wastewater disposal. With freshwater becoming more expensive and scarce, treating sewage water on-site or sourcing treated water from municipal plants is often more cost-effective.

Environmental Benefits: Treated water reuse minimizes environmental degradation caused by excessive freshwater extraction and wastewater discharge. It reduces the strain on natural water bodies, prevents groundwater depletion, and supports biodiversity conservation.

Strategic Benefits: Industries that proactively adopt water reuse strategies position themselves as sustainability leaders. This enhances brand reputation, attracts environmentally conscious investors, and ensures operational continuity, especially in water-stressed regions.

Industries Benefiting from Reuse of Treated Water from Sewage Treatment Plants

Many sectors have already embraced sewage water reuse:

Textile Industry: Water-intensive dyeing and finishing processes can be sustained with treated sewage water, reducing freshwater use significantly.

Power Plants: Cooling towers in thermal and nuclear plants can effectively operate using treated sewage water.

Paper and Pulp Industry: The treatment and reuse of water in pulp processing and washing processes help maintain production efficiency.

Chemical and Petrochemical Units: Water for cleaning, washing, and non-critical process needs can be replaced with treated sewage water.

Construction Industry: Treated water is used in curing, concrete mixing, and dust suppression.

By 2025, more sectors are expected to follow suit, especially as regulations tighten and water costs rise.

Treated Sewage Water Quality Requirements

While treated sewage water is suitable for many industrial applications, its quality must meet specific standards to ensure process safety and product integrity. Common quality parameters include:

BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand): Must be within permissible limits to avoid microbial growth and odor.

TSS (Total Suspended Solids): Low TSS is necessary to prevent clogging in pipelines and nozzles.

pH and Turbidity: Balanced pH and clarity are critical for processes involving heating or cooling.

Pathogen Removal: Adequate disinfection (e.g., chlorination, UV treatment) ensures no biological contamination.

Quality standards vary by industry, and modern sewage treatment plants can be customized accordingly.

Regulatory Framework and 2025 Compliance Mandates

Governments across the globe are implementing stricter regulations regarding water consumption and wastewater discharge. In India, for instance, the Central Pollution Control Board (CPCB) mandates zero liquid discharge (ZLD) policies for certain industries. Many state pollution control boards have also made it compulsory for industries to use a percentage of treated sewage water for non-potable applications.

By 2025, these regulations are expected to become even more rigorous, pushing industries to adopt advanced sewage treatment and reuse practices. Failing to comply may result in heavy fines, operational restrictions, or even plant shutdowns.

Technologies Enabling Efficient Reuse

Modern sewage water treatment plants incorporate a range of advanced technologies to ensure water is treated to the required standards:

Membrane Bioreactors (MBR): Combines biological treatment with membrane filtration for high-quality output.

Ultrafiltration (UF) and Reverse Osmosis (RO): Removes dissolved salts and micro-pollutants, ideal for high-purity applications.

Moving Bed Biofilm Reactors (MBBR): Offers efficient treatment in compact spaces, perfect for retrofitting in existing facilities.

UV and Ozone Disinfection: Ensures pathogen-free water without using chemicals.

Integration of IoT and automation in sewage treatment is also helping industries monitor water quality in real-time and optimize treatment efficiency.

Challenges and Solutions

Despite the many advantages, industries face a few challenges when adopting treated sewage water reuse:

Perception Issues: Some industries fear that using treated sewage water may affect product quality or brand image.

Infrastructure Costs: Initial investment in treatment plants and distribution pipelines can be high.

Maintenance and Monitoring: Ensuring consistent quality requires skilled operation and regular maintenance.

Solutions include:

Government Incentives: Availing subsidies and tax benefits for installing sewage treatment plants.

Public-Private Partnerships (PPP): Collaborating with municipal bodies to access treated sewage water at reduced costs.

Awareness and Training: Educating teams and stakeholders about the safety and benefits of using treated water.

Future Outlook: The Road Ahead for 2030

Looking forward to 2030, the reuse of treated sewage water will no longer be optional but a necessity. Industries that invest early in treatment infrastructure and water management strategies will have a competitive edge. We can expect:

Increased decentralization of sewage treatment at industrial estates.

Integration of AI and predictive analytics for water quality monitoring.

Wider adoption of modular, scalable STP units.

Tighter global benchmarks for industrial water consumption and discharge.

Water-positive certification and ESG (Environmental, Social, and Governance) reporting will also push companies to document and optimize their water reuse efforts.

Take the Lead in Sustainable Growth with a State-of-the-art Sewage Water Treatment Plant

In 2025, water reuse is more than an environmental initiative—it’s a smart business strategy. By installing or upgrading to a state-of-the-art sewage water treatment plant, your industry can ensure compliance, save costs, and contribute to a more sustainable future.

CleanTech Water offers cutting-edge sewage treatment solutions tailored to your industry’s needs. From compact modular systems to large-scale plants with zero liquid discharge capability, we help you turn wastewater into a valuable resource.

Read More: https://www.cleantechwater.co.in/reusing-treated-sewage-water-industries-2025/

0 notes

Text

Creative Career Paths in Interior Design, Photography & Textile Desig

In today’s evolving world, creative fields such as interior designing, photography, and textile designing are gaining immense popularity. If you're passionate about design, aesthetics, or capturing the world through a lens, then choosing a creative academic path can lead you toward a fulfilling and dynamic career. Courses like MBA in Interior Designing, Professional Photography Courses in Pune, and Textile Design Courses offer you the opportunity to explore your talents, refine your skills, and turn your passion into a profession.

MBA in Interior Designing: Transforming Spaces with Strategy

What is MBA in Interior Designing?

An MBA in Interior Designing is a specialized postgraduate program that combines interior design principles with business and management strategies. This course is perfect for students who not only have a flair for aesthetics but also wish to lead design businesses or start their own interior design firm.

Why Choose MBA in Interior Designing?

Leadership Skills: Develop the managerial skills needed to lead design projects and teams.

Creative Thinking: Enhance your ability to create functional and visually appealing interior spaces.

Entrepreneurial Edge: Gain insights into business management, marketing, finance, and operations within the design industry.

Industry Exposure: Benefit from internships, live projects, and workshops conducted by top architects and designers.

Career Opportunities After MBA in Interior Designing

Graduates can take on roles such as:

Interior Design Manager

Creative Director

Design Consultant

Project Manager – Interior Projects

Entrepreneur (Start your own interior design firm)

This course bridges the gap between creative design and strategic management, making it ideal for future-ready designers who aspire to take on leadership roles in the industry.

Professional Photography Courses in Pune: Capturing Life with Every Click

Why Choose Pune for Photography Courses?

Pune is not only a cultural and educational hub but also a city buzzing with creativity. From urban architecture and traditional festivals to fashion events and nature trails, Pune provides the perfect backdrop for aspiring photographers.

What Do Professional Photography Courses Offer?

Professional Photography Courses in Pune are designed to equip students with in-depth knowledge and hands-on experience in photography. These courses generally include:

Basics of Camera Handling

Composition and Lighting Techniques

Fashion, Wildlife, Product, and Event Photography

Editing & Post-Processing

Portfolio Development

Courses range from short-term certifications to advanced diploma programs and are often led by experienced photographers and industry experts.

Benefits of Taking Professional Photography Courses in Pune

Live Projects: Opportunities to work with media houses, fashion brands, and event companies.

Mentor Sessions: Learn from successful photographers.

Internships: Real-world exposure during the course.

Workshops & Exhibitions: Participate in national and international photography showcases.

Career Scope in Photography

Once trained, you can explore exciting careers such as:

Fashion Photographer

Wedding/Event Photographer

Product and Commercial Photographer

Photojournalist

Visual Storyteller or Content Creator

Freelance Photographer

Whether you aim to work in media, start your own studio, or travel the world with your camera, Pune’s vibrant atmosphere and structured programs can help make your dream a reality.

Textile Design Courses: Weaving Creativity into Fabric

What is Textile Design?

Textile Design is the art of creating innovative patterns, designs, and structures for fabrics. From fashion to interiors, the textile industry plays a crucial role in style and functionality. Textile Design Courses focus on teaching the techniques of designing, dyeing, printing, and weaving textiles.

Highlights of Textile Design Courses

Fundamentals of Textile Science

Fabric Development and Material Exploration

Digital and Traditional Printing Techniques

Color Theory and Trend Forecasting

Surface Ornamentation

Design Software Training (CAD for Textiles)

Why Opt for Textile Design Courses?

High Demand Industry: With the rise of sustainable and functional fashion, textile designers are in great demand.

Creative Exploration: Gives freedom to express through patterns and fabrics.

Versatile Career Options: Textile designers work in fashion, interior décor, automotive, and even medical industries.

Career Options After Textile Design Courses

Textile Designer

Fabric Specialist

Surface Ornamentation Expert

Product Developer

Color Analyst

Entrepreneur (Start your own label or fabric studio)

With innovation at its core, textile design is a field where tradition meets technology. Pursuing Textile Design Courses empowers students with creative and technical skills to bring their designs to life.

Why Choose a Career in Creative Design Fields?

In a world increasingly driven by aesthetics, design and creativity hold immense value. Pursuing professional courses in these fields not only sharpens your skills but also opens doors to global career opportunities. Whether you're fascinated by structured spaces, striking photographs, or tactile fabrics, there is a professional path tailored for you.

Benefits of Pursuing Creative Courses

Flexibility in career paths

Global opportunities

Scope for freelancing and entrepreneurship

High income potential with experience

Chance to make a real-world impact through art and design

How to Choose the Right Institute?

To get the best out of your academic journey in design, it’s essential to choose a reputed institute that offers:

Industry-relevant curriculum

Experienced mentors and faculty

State-of-the-art infrastructure

Strong industry connections

Placement assistance and internships

In India, institutions like INSD (International School of Design) are widely recognized for offering top-quality education in design, photography, textile, and fashion with hands-on learning and real-world exposure.

Conclusion:

Choosing a career in the creative domain is more than just following your passion — it's about making a mark in an ever-evolving world. Whether you wish to manage luxury spaces through an MBA in Interior Designing, capture the world’s beauty through a lens via Professional Photography Courses in Pune, or weave stories through fabrics in Textile Design Courses, there’s a path waiting for you.

Now is the time to explore your creative calling, acquire professional training, and set yourself up for a fulfilling and successful career in the design industry.

1 note

·

View note

Text

The Role of Fair Trade in Sustainable T-Shirt Manufacturing

Sustainable fashion is no longer a trend—it’s a necessity. As the fashion industry grapples with its environmental impact, Fair Trade practices have emerged as a vital solution in sustainable T-shirt manufacturing. Ethical sourcing, eco-friendly production, and fair wages are now essential factors for conscious consumers looking for responsible choices.

One brand leading the way in sustainable T-shirt printing is Lasuma. With a strong commitment to ethical production and environmentally friendly materials, Lasuma ensures that every T-shirt aligns with the principles of Fair Trade. Their focus on eco-friendly T-shirts makes them a preferred choice for those who value both style and sustainability.

Understanding Fair Trade in T-Shirt Manufacturing

Fair Trade is a movement that ensures ethical treatment of workers, sustainable material sourcing, and environmentally responsible manufacturing processes. In T-shirt production, Fair Trade practices mean that cotton farmers receive fair compensation, factory workers operate in safe conditions, and harmful chemicals are avoided in the printing process. This approach creates a transparent supply chain where every step, from growing cotton to printing designs, follows ethical and environmental guidelines.

By choosing Fair Trade, brands ensure that their sustainable T-shirt printing process does not exploit workers or harm the environment. Conventional textile manufacturing often relies on cheap labor, excessive water usage, and toxic dyes, all of which contribute to global pollution. Fair Trade combats these issues by setting strict standards for sustainability and worker welfare.

The Environmental Benefits of Fair Trade in Sustainable T-Shirt Printing

One of the biggest advantages of Fair Trade in sustainable T-shirt manufacturing is its emphasis on eco-friendly materials and processes. Unlike conventional cotton, which requires vast amounts of water and pesticides, Fair Trade cotton is grown using organic farming techniques that preserve soil health and reduce water consumption. This method ensures that farmers are not exposed to harmful chemicals while also reducing pollution.

Sustainable T-shirt printing further supports the environment by using water-based and plant-based inks instead of petroleum-based options. These inks contain fewer toxic compounds, making them safer for both workers and consumers. Additionally, energy-efficient printing techniques, such as low-impact dyeing and digital printing, help conserve water and electricity.

Lasuma embraces these eco-friendly solutions by incorporating organic cotton, biodegradable dyes, and non-toxic printing methods in their T-shirts. This commitment makes their products truly eco-friendly T-shirts, ensuring that fashion lovers can wear stylish apparel without contributing to environmental degradation.

Behind every T-shirt is a long supply chain that involves numerous workers, from cotton farmers to factory employees. In many fast fashion production units, these workers are often underpaid and forced to work in unsafe conditions. Fair Trade-certified factories eliminate these issues by guaranteeing fair wages, safe working conditions, and no child labor.

For brands like Lasuma, ethical production is a core value. By working with Fair Trade-certified suppliers, they ensure that workers are treated fairly and compensated adequately. This transparency allows consumers to trust that their purchases support a humane and just manufacturing system.

When consumers choose Fair Trade sustainable T-shirt printing, they are not only purchasing a high-quality product but also supporting a system that values human rights and sustainability. Every Fair Trade T-shirt purchased contributes to better livelihoods for workers and promotes responsible fashion practices.

The carbon footprint of traditional T-shirt manufacturing is alarmingly high. From transporting raw materials across the globe to the excessive use of synthetic dyes, each stage of the process adds to environmental pollution. Fair Trade brands minimize this impact by using renewable energy, local sourcing, and carbon offset programs.

Lasuma takes additional steps by incorporating sustainable packaging solutions and reducing waste in their production line. By choosing Fair Trade eco-friendly T-shirts, consumers play a part in lowering the industry’s overall carbon emissions. This approach not only benefits the environment but also sets a precedent for other fashion brands to follow.

Why Consumers Should Support Fair Trade and Sustainable T-Shirts

Fair Trade in sustainable T-shirt manufacturing is about more than just environmental benefits—it’s about making a conscious choice that supports ethical business practices. Consumers today have the power to influence the industry by demanding transparency and sustainability from brands.

When shoppers choose Fair Trade sustainable T-shirt printing, they:

Support ethical labor practices and fair wages

Reduce environmental harm caused by conventional textile manufacturing

Invest in high-quality, long-lasting apparel

Encourage more brands to adopt responsible production methods

Lasuma continues to be a pioneer in this space, offering eco-friendly T-shirts that not only look great but also align with ethical fashion values. Their dedication to sustainable materials, ethical production, and innovative printing techniques makes them a standout brand in the industry.

The Future of Fair Trade and Sustainable T-Shirt Manufacturing

As awareness grows, more consumers and brands are embracing Fair Trade principles in T-shirt manufacturing. Governments and organizations are also pushing for stricter regulations to ensure that fashion companies operate responsibly. The rise of sustainable T-shirt printing is a promising step toward a greener, fairer industry. Lasuma remains at the forefront of this transformation by continuously innovating and improving its sustainability practices. With more consumers opting for eco-friendly T-shirts, the demand for ethical and sustainable fashion is set to increase. By choosing Fair Trade and sustainable options, consumers can drive meaningful change, proving that fashion doesn’t have to come at the cost of the environment or human rights. The next time you shop for a T-shirt, consider choosing a Fair Trade, sustainable, and eco-friendly option—because every purchase makes a difference.

0 notes

Text

A3 Technocrafts: Revolutionary Effluent Treatment Plants for Sustainable Industrial Operations

Pioneering Wastewater Management Solutions In today's environmentally conscious industrial landscape, effective wastewater management has become a critical component of responsible manufacturing. A3 Technocrafts stands at the forefront of this essential field, designing and manufacturing state-of-the-art Effluent Treatment Plants that transform industrial waste streams into compliant, reusable water resources. Our comprehensive solutions address the complex challenges faced by diverse industries while supporting environmental sustainability and regulatory compliance.

Industry-Specific Effluent Treatment Plants Tailored Solutions for Textile Manufacturers The textile industry produces wastewater containing dyes, chemicals, and suspended solids that require specialized treatment processes. Our Effluent Treatment Plants for textile manufacturers incorporate advanced oxidation technologies and membrane filtration systems that effectively remove color and chemical contaminants, allowing facilities to meet stringent discharge standards while recovering valuable resources.

Pharmaceutical Waste Management Pharmaceutical manufacturing generates wastewater with unique challenges, including active pharmaceutical ingredients and biological compounds. A3 Technocrafts' specialized Effluent Treatment Plants for this sector utilize multi-stage processes, including advanced oxidation and biological treatment, to neutralize complex organic compounds and ensure full compliance with pharmaceutical waste regulations.

Food Processing Industry Solutions For food processing operations, our Effluent Treatment Plants handle high organic loads and variable pH levels with efficient biological treatment systems and solids separation technologies. These solutions not only ensure regulatory compliance but also create opportunities for water reuse in non-critical applications, reducing overall water consumption.

Chemical Industry Wastewater ProcessingChemical manufacturing facilities require robust Effluent Treatment Plants capable of handling diverse contaminants and fluctuating waste streams. Our systems incorporate chemical neutralization, precipitation, and advanced oxidation processes to effectively treat these challenging wastewaters and protect receiving environments.

Technological Excellence in Wastewater Treatment Advanced Treatment Methodologies Our Effluent Treatment Plants integrate multiple treatment technologies, sequenced for optimal performance. From primary physical processes like screening and sedimentation to advanced chemical treatments and biological systems, each plant is designed as a comprehensive solution tailored to specific waste characteristics. Automation and Process Control Modern manufacturing demands intelligent systems. A3 Technocrafts incorporates sophisticated automation and monitoring capabilities into all Effluent Treatment Plants, enabling precise control over treatment parameters, real-time performance analysis, and predictive maintenance to maximize operational efficiency.

Sustainability Benefits Beyond Compliance Resource Recovery and Recycling Beyond simply treating wastewater, our Effluent Treatment Plants incorporate resource recovery technologies that extract valuable materials from waste streams. This approach transforms waste management from a cost center to a potential revenue source while supporting circular economy principles.

Energy OptimizationTraditional wastewater treatment can be energy-intensive. A3 Technocrafts designs energy-efficient Effluent Treatment Plants that minimize power consumption through innovative aeration systems, energy recovery components, and smart process sequencing, reducing both operational costs and carbon footprint.

Partnership Approach to Implementation We understand that effective wastewater management requires more than equipment installation. Our comprehensive service model includes thorough site assessment, customized design, expert installation, operator training, and ongoing technical support. This holistic approach ensures that each Effluent Treatment Plant performs optimally throughout its operational life.

Investing in Environmental Responsibility Implementing advanced Effluent Treatment Plants represents more than regulatory compliance—it demonstrates a commitment to environmental stewardship and sustainable operations. A3 Technocrafts partners with forward-thinking companies to transform wastewater challenges into opportunities for innovation, efficiency, and corporate responsibility. Choose A3 Technocrafts for Effluent Treatment Plants that combine technological excellence with environmental vision, creating sustainable water management solutions for the industries of today and tomorrow.

Original Source:- https://a3technocrafts3.wordpress.com/2025/03/11/a3-technocrafts-revolutionary-effluent-treatment-plants-for-sustainable-industrial-operations/

0 notes

Text

Reliable China Textile Manufacturer - Suzhou Zanying Co., Ltd.

Welcome to Suzhou Zanying Import and Export Trade Co., Ltd., your trusted partner in premium textile manufacturing and supply. Renowned as a leading China textile manufacturer, our company is committed to delivering exceptional quality, innovative designs, and unparalleled service to clients worldwide. With a strong foundation in the rich textile heritage of Suzhou, we bring decades of expertise to meet your unique requirements.

Who We Are

At Suzhou Zanying Co., Ltd., we pride ourselves on being a versatile and reliable China textile manufacturer. Our business is built on the principles of quality, sustainability, and client satisfaction. Our extensive product line includes fabrics for fashion, home décor, industrial use, and more. Whether you’re looking for natural fibers, synthetic blends, or custom textile solutions, we are your go-to source.

Why Choose Us?

Exceptional Quality – We source the finest raw materials and employ advanced production techniques to ensure the durability and aesthetic appeal of our textiles.

Sustainable Practices – As a forward-thinking China textile manufacturer, we are committed to eco-friendly practices. We implement sustainable sourcing, energy-efficient production methods, and waste reduction measures.

Customization Options – Our dedicated team collaborates with clients to create bespoke textile solutions tailored to specific needs and industry standards.

Competitive Pricing – With our well-established supply chain and efficient manufacturing processes, we provide cost-effective solutions without compromising on quality.

Global Reach – From Asia to Europe, North America, and beyond, our products are trusted by businesses around the globe.

Our Products

At Suzhou Zanying Import and Export Trade Co., Ltd., we offer a diverse range of textiles to suit various applications:

Apparel Fabrics: Including cotton, polyester, silk, and blended fabrics for casual wear, formal attire, and activewear.

Home Textiles: Such as curtains, upholstery, bedding materials, and decorative items.

Industrial Textiles: Featuring durable, high-performance fabrics for specialized applications.

Custom Fabrics: Tailored designs, colors, and patterns to meet specific market demands.

Our Manufacturing Process

Our state-of-the-art facilities in Suzhou are equipped with cutting-edge machinery and operated by skilled professionals. We follow stringent quality control measures at every stage, from material selection to final inspection, ensuring that our textiles meet international standards.

Key aspects of our manufacturing process include:

Advanced dyeing and finishing techniques.

Rigorous testing for strength, colorfastness, and texture.

Flexible production capabilities for small and large orders alike.

Commitment to Sustainability

As an environmentally conscious China textile manufacturer, we embrace sustainable practices throughout our operations. These include:

Using renewable and biodegradable raw materials.

Recycling water and reducing chemical usage in production.

Partnering with suppliers who share our commitment to sustainability.

Our green initiatives not only minimize our environmental impact but also align with the values of our environmentally conscious clientele.

Industries We Serve

Our textiles cater to a wide range of industries, including:

Fashion and Apparel: For designers and retailers seeking high-quality fabrics that inspire creativity.

Interior Design: Supplying stylish and functional materials for home and commercial spaces.

Automotive and Industrial: Offering durable fabrics designed for rigorous use.

Medical and Healthcare: Providing textiles that meet stringent safety and hygiene standards.

Our Vision

At Suzhou Zanying Co., Ltd., we aim to be the global leader in textile innovation, setting benchmarks for quality, sustainability, and customer satisfaction. We envision a future where our textiles contribute to a better, more connected world.

Testimonials

Don’t just take our word for it! Here’s what our clients say:

“Suzhou Zanying has been our trusted China textile manufacturer for years. Their quality and reliability are unmatched.” – Fashion Brand Owner

“We appreciate their dedication to sustainability and their ability to deliver custom solutions on time.” – Interior Designer

Partner With Us

Are you ready to elevate your projects with top-notch textiles? Partner with Suzhou Zanying Import and Export Trade Co., Ltd., and experience the difference that comes with working with a trusted China textile manufacturer.

Contact us today to discuss your requirements. Let us help you bring your vision to life with our exceptional textile solutions.

Contact Information

Suzhou Zanying Import and Export Trade Co., Ltd. Address: No.177,Fuxiang Rd., Taoyuan Town ,Suzhou City,Jiangsu, China,P.C. 215236 Phone: +86 18261811538 Email: [email protected] Website: https://www.zanying.net/

We look forward to collaborating with you and turning your textile needs into reality. Join the growing family of satisfied clients who trust Suzhou Zanying Co., Ltd. as their preferred China textile manufacturer.

0 notes

Text

Specialty Chemicals Manufacturers in Hyderabad

Hyderabad, often referred to as the pharmaceutical and industrial hub of India, is home to numerous companies specializing in cutting-edge chemical innovations. Among these, Sainor Labs has carved a niche as one of the leading specialty chemicals manufacturers in the region. Renowned for its commitment to quality, sustainability, and innovation, Sainor Labs serves a diverse array of industries, making it a trusted name in the specialty chemicals sector.

What Are Specialty Chemicals?

Specialty chemicals, also known as performance chemicals, are unique compounds tailored for specific applications. Unlike bulk chemicals, these products are produced in smaller volumes but offer high value due to their precise formulations and functionality. Specialty chemicals play a pivotal role in industries such as pharmaceuticals, agriculture, textiles, paints, adhesives, and personal care.

Why Choose Sainor Labs?

As a forward-thinking specialty chemicals manufacturer in Hyderabad, Sainor Labs focuses on meeting the evolving demands of the market with a customer-centric approach. Here's what sets them apart:

Wide Range of Products Sainor Labs boasts a diverse portfolio of specialty chemicals tailored for industries like healthcare, coatings, agrochemicals, and water treatment. Their innovative formulations ensure optimal performance and efficiency in applications.

State-of-the-Art Infrastructure The company operates with advanced manufacturing facilities equipped with modern technology to produce high-purity chemicals. Their stringent quality control processes ensure every product meets global standards.

Sustainable Practices Sustainability is a cornerstone of Sainor Labs' operations. The company adopts eco-friendly practices, minimizes waste, and uses green chemistry principles wherever possible.

R&D Capabilities With a strong emphasis on research and development, Sainor Labs consistently delivers innovative solutions. Their team of experts works on developing customized chemicals to address specific client requirements.

Customer-Centric Approach Sainor Labs believes in building long-term relationships with clients. Their ability to offer tailored solutions, technical support, and on-time delivery has made them a trusted partner for businesses across various sectors.

Applications of Specialty Chemicals

Specialty chemicals from Sainor Labs find applications in a variety of industries, such as:

Pharmaceuticals: Active ingredients and intermediates for drug manufacturing.

Agriculture: Fertilizers, crop protection chemicals, and soil enhancers.

Paints and Coatings: Additives for durability, color retention, and surface protection.

Textiles: Specialty dyes, coatings, and finishing agents for high-performance fabrics.

Water Treatment: Chemicals for purification and wastewater management.

Why Hyderabad Is a Hub for Specialty Chemicals

Hyderabad's robust infrastructure, skilled workforce, and favorable policies make it an ideal location for specialty chemicals manufacturing. The city provides access to a well-connected logistics network and a collaborative ecosystem of industries, research institutions, and regulatory bodies.

Partner with Sainor Labs for Excellence

When it comes to specialty chemicals, choosing a reliable manufacturer like Sainor Labs ensures you receive high-quality, innovative, and sustainable solutions tailored to your needs. With a proven track record and a dedication to excellence, Sainor Labs is your go-to partner for specialty chemical requirements.

If you're looking for advanced specialty chemicals to enhance your business operations, connect with Sainor Labs today and experience unmatched quality and service.

0 notes

Text

Ethical Textile Manufacturing in Mumbai – Labisa: Pioneering Sustainability and Quality

In the fast-paced world of textiles, where sustainability often takes a backseat, Labisa emerges as a game-changer. Committed to revolutionizing the textile industry, Labisa leads the way in ethical textile manufacturing in Mumbai, delivering eco-friendly, high-quality fabrics to bulk buyers, distributors, wholesalers, and stockists. With a strong emphasis on ethical practices, Labisa is shaping a better future for fashion and textiles.

Introduction to Labisa: A Leader in Ethical Textile Manufacturing

The Values Driving Labisa’s Ethical Practices

Labisa believes in crafting textiles that not only look good but do good. Its core values—sustainability, transparency, and fair labor practices—are at the heart of its operations. Labisa’s ethical framework ensures every fabric tells a story of responsibility and care, creating lasting value for clients and the environment.

Overview of Labisa’s Role in Mumbai’s Textile Industry

Operating from Mumbai, the hub of India’s textile trade, Labisa has grown into a prominent ethical textile manufacturer. Known for its innovative approach, the company supplies high-quality, sustainable textiles that cater to the diverse needs of businesses in fashion, corporate sectors, and beyond.

What Does Ethical Textile Manufacturing Mean?

Key Principles of Ethical Production in the Textile Industry

Ethical textile manufacturing is built on principles such as sustainability, worker rights, and environmentally friendly processes. It ensures fabrics are produced without harming the planet or exploiting labor, making it a vital part of the modern textile ecosystem.

Why Ethical Manufacturing Matters in Today’s Market

Consumers and businesses alike are demanding transparency and sustainability. For bulk buyers and distributors, partnering with a trusted ethical textile supplier in Mumbai like Labisa is an opportunity to meet market demands while making a positive impact.

Labisa’s Commitment to Ethical and Sustainable Textiles

Labisa prioritizes ethical manufacturing at every step, from sourcing raw materials responsibly to reducing waste. Its innovative practices make it a trusted partner for clients seeking ethical textile solutions.

Labisa’s Ethical Manufacturing Practices: A Closer Look

Responsible Sourcing of Raw Materials

Labisa sources its raw materials from certified suppliers who adhere to ethical and environmental standards. This ensures the fabrics are not only sustainable but also of the highest quality.

Sustainable Production Techniques

From energy-efficient machinery to water-saving dyeing methods, Labisa employs advanced techniques to minimize environmental impact. These practices make it a standout in ethical textile manufacturing.

Fair Labor Practices and Community Empowerment

Labisa is deeply committed to fair wages, safe working conditions, and empowering local artisans. By investing in training and development, the company supports its workers while delivering premium products to its clients.

Sustainability in Action: Labisa’s Environmental Initiatives

Reducing Carbon Footprint in Manufacturing

Labisa continuously explores ways to lower its carbon emissions. From using renewable energy sources to optimizing logistics, every effort is made to reduce the company’s ecological footprint.

Waste Management and Recycling Efforts

Waste reduction is a key priority. Labisa incorporates recycling into its processes, turning scraps into usable products and promoting circular fashion.

Incorporating Eco-Friendly Textiles into Collections

Labisa’s eco-friendly collections include organic cotton, recycled polyester, and biodegradable fabrics. These options empower businesses to adopt sustainable practices without compromising on quality or style.

Why Choose Labisa for Ethical Textile Manufacturing in Mumbai?

Trusted Partner for Bulk Buyers, Wholesalers, and Distributors

For B2B clients, reliability and scalability are critical. Labisa excels in providing consistent quality, meeting deadlines, and accommodating bulk orders, making it a preferred ethical textile supplier in Mumbai.

Tailored Solutions for Sustainable Fashion Brands

Labisa offers customizable fabrics to meet the unique requirements of fashion brands striving for sustainability. Whether you’re designing corporate uniforms or launching an eco-friendly collection, Labisa delivers solutions that align with your goals.

Competitive Pricing with a Focus on Ethical Excellence

Ethical practices don’t have to come at a premium. Labisa ensures competitive pricing without compromising on its values, providing cost-effective solutions for large-scale clients.

Key Products Offered by Labisa in Ethical Textiles

Organic Cotton and Eco-Friendly Fabrics

Labisa’s range of organic cotton and eco-friendly fabrics is perfect for businesses looking to reduce their environmental footprint. These materials are free from harmful chemicals and safe for both people and the planet.

Handcrafted Sustainable Textiles

Labisa celebrates India’s rich textile heritage by offering handcrafted fabrics that support local artisans. These unique textiles are ideal for businesses seeking exclusive, high-quality products.

Custom Ethical Fabrics for Fashion and Corporate Needs

Whether it’s creating bespoke designs for high-end fashion or durable materials for corporate uniforms, Labisa delivers customized solutions tailored to your specific needs.

How Labisa Supports Ethical Practices in the Supply Chain

Transparency in Production Processes

Labisa ensures complete transparency in its operations, providing clients with detailed insights into how their fabrics are produced. This builds trust and strengthens partnerships.

Collaboration with Ethical Suppliers and Artisans

Labisa’s supply chain is built on collaboration. By working with ethical suppliers and local artisans, the company ensures every step of production aligns with its sustainability goals.

Labisa’s Impact on Mumbai’s Textile Industry and Beyond

Promoting Ethical Standards Across the Industry

Labisa is at the forefront of promoting ethical practices, inspiring other manufacturers to adopt similar standards. Its leadership in ethical textile manufacturing is helping shape a more responsible industry.

Supporting Mumbai’s Economy Through Sustainable Practices

By creating jobs, supporting artisans, and sourcing locally, Labisa contributes significantly to Mumbai’s economy. Its efforts resonate beyond profits, making a meaningful difference in the community.

FAQs About Ethical Textile Manufacturing with Labisa

Q1: What certifications does Labisa hold for ethical practices? A: Labisa works with certified suppliers and adheres to industry standards to ensure ethical compliance at every stage.

Q2: Can Labisa accommodate bulk orders for sustainable fabrics? A: Yes, Labisa specializes in fulfilling large-scale orders, catering to wholesalers, distributors, and stockists.

Q3: Does Labisa offer customization in eco-friendly textiles? A: Absolutely! Labisa provides tailored fabric solutions to meet specific client requirements.

Q4: What is the price range for Labisa’s ethical fabric offerings? A: Pricing varies based on fabric type and order size. Contact Labisa for a competitive quote.

Q5: How does Labisa ensure fair labor practices? A: Labisa prioritizes worker rights, offering fair wages, safe conditions, and development opportunities.

Contact Labisa: Get Started with Ethical Textile Solutions

Looking to source high-quality, sustainable fabrics for your business? Partner with Labisa today!

Contact Afzal: +91 98929 39564

Labisa Sales: +91 81699 85975

Email: [email protected], [email protected]

Address: Sion West, Dharavi, Mumbai, Mumbai 400017

Discover why Labisa is the leading name in ethical textile manufacturing in Mumbai by exploring their range of products and services.

Conclusion: Join Labisa in Driving Ethical Textile Manufacturing in Mumbai

Labisa is redefining what it means to be an ethical textile manufacturer. By combining sustainability, quality, and affordability, Labisa empowers B2B clients to make responsible choices without sacrificing style or performance.

Elevate your textile business with ethical solutions that make a difference. Contact Labisa today and join the movement toward a sustainable future!

0 notes

Text

"Why Clean Water Starts with Canadian Crystalline: A Deep Dive into RO Systems"

Water is an essential resource for the global industry. However, using water directly from natural sources in many sectors is not viable. Here's where industrial RO (Reverse Osmosis) plants come in. These systems purify vast amounts of water by removing impurities, making it safe and acceptable for various uses. But what exactly is an industrial RO plant, and why is Canadian Crystalline, a Chennai-based manufacturer, a market leader in this industry?

Let’s dive into the details.

What is an Industrial RO Plant?

A large-scale water filtering system that applies the osmosis principle in reverse is called an industrial ro plant. Water is forced through a semi-permeable membrane, which removes chemicals, salts, and other contaminants to provide clean, pure water. Industries including as pharmaceuticals, food and beverage, power plants, and textile production employ a lot of RO plants. Any industry that requires high-purity water, whether for processing, cooling or as an ingredient in production, can profit from RO technology.

When desalinating salt from seawater and in areas with limited or contaminated freshwater sources, reverse osmosis is especially useful. For enterprises trying to achieve strict water quality regulations, RO plants are a perfect solution because of their great efficiency.

Key Components of an Industrial RO Plant

While the basic principle of reverse osmosis is simple, industrial RO plants are highly sophisticated. Here are the main components involved:

Pre-Treatment Unit: Water entering the system first goes through pre-treatment to remove larger particles and impurities. This step often includes sediment filters, activated carbon filters, and softeners to protect the RO membrane from damage.

High-Pressure Pump: Pressure is necessary for reverse osmosis to push water through the membrane. This force is produced by a high-pressure pump, guaranteeing ideal filtration.

RO Membrane: The core of the system, the RO membrane allows water molecules to pass while blocking larger contaminants like salts, heavy metals, and other dissolved substances.

Post-Treatment Unit: After passing through the membrane, water may undergo additional filtration, such as UV sterilization or dechlorination, depending on the intended use.

Storage Tanks and Distribution System: Once purified, the water is stored in tanks before being distributed throughout the facility.

Applications of Industrial RO Plants

Industrial RO systems are incredibly versatile. Here are some common applications:

Pharmaceuticals: Industries in this sector require ultrapure water for manufacturing medicines and maintaining clean environments.

Food and Beverage Industry: In this industry, water purity is crucial for both product quality and regulatory compliance.

Power Plants: These plants use large amounts of water for cooling processes, and RO systems help maintain efficiency by preventing scaling and corrosion.

Textile Manufacturing: In the textile industry, water needs to be free from hardness and contaminants to ensure consistent dyeing and fabric processing.

Why Choose Canadian Crystalline Industrial RO Plants?

When it comes to industrial RO plants, Canadian Crystalline is a well-known brand, particularly in India. Modern technology, dependability, and a dedication to excellence characterize this Chennai-based firm. The following are the reasons why industries worldwide select Canadian Crystalline:

Cutting-edge Technology: Canadian Crystalline incorporates the most recent developments in RO technology to guarantee optimal performance and minimal energy usage. Their systems are built for long-term, trouble-free operation, which is critical in businesses that rely on continuous water filtration.

Tailored Approach: The requirements for water treatment differ greatly among businesses. Canadian Crystalline provides tailored solutions, creating and producing RO systems that satisfy industry-specific specifications. Their solutions are customized to meet your requirements, regardless of whether your focus is on producing potable water, treating wastewater, or desalinating saltwater.

Global Presence: Canadian Crystalline has installations in more than 50 countries, despite having its headquarters located in Chennai. Their experience exporting and installing large-scale RO plants makes them a reliable partner for enterprises around the world.

Complete After-Sales Support: Maintaining intricate water treatment systems is one of the major issues that industries deal with. Canadian Crystalline offers extensive after-sales service, including annual maintenance, system updates, and technical assistance, to ensure that their operations run at peak efficiency.

Sustainability Focus: As environmental concerns grow, many businesses are transitioning to more sustainable methods. Leading this movement are energy-efficient systems from Canadian Crystalline, which assist enterprises in cutting back on their environmental impact while upholding water purity regulations.

The Future of Industrial RO Systems

As water shortage remains a global concern, the demand for effective water treatment technologies such as industrial RO systems will only rise. Energy recovery systems, more lasting membranes, and smart monitoring technology will all improve the systems' efficiency and cost-effectiveness.

Industries that invest in high-quality RO plants from reputable manufacturers like Canadian Crystalline are not only ensuring compliance with current regulations but are also future-proofing their operations against potential water shortages.

Making the Right Choice

The stakes are very high when selecting an industrial RO system plant for your company. The quality of your water treatment system has a direct impact on your productivity, product quality, and environmental compliance. Because of their knowledge and dedication to sustainability and innovation, Canadian Crystalline is a great option for a wide range of industries. What comes next, then? Are you willing to invest in a system that provides not only filtered water but also peace of mind? Choosing the appropriate RO plant is critical, and with Canadian Crystalline, you're not simply purchasing a product; you're also partnering with a company that values your success.

#industrial ro plant manufacturers in chennai#industrial ro manufacturers in chennai#industrial ro plant in chennai#industrial ro plant manufacturer#industrial ro plant#industrial ro system#industrial reverse osmosis plant#ro plant#ro system

0 notes

Text

Working Principle of a 20 HP Screw Air Compressor: Uses and Benefits

A screw air compressor is an essential equipment in various industrial sectors due to its durability, reliability, and efficiency. The 20 hp screw air compressor of reputable screw compressor manufacturers supplies excellent power and performance for medium to large industrial applications. A screw air compressor is a type of rotary compressor air compressor that uses a pair of helical rotors to compress air, providing a constant supply of pressurised air for various tasks. In this article, we will explore how the 20 hp screw air compressors works, its various applications across industries, and the multiple benefits it offers.

How a 20 hp screw air compressor works

The working principle of a screw air compressor is simple and effective. The core components include two helical rotors (screws), an intake valve, a discharge valve, a motor, and a cooling system.

Air intake

The process begins as air enters the compressor through the intake valve. The compression process starts as the air fills the gap between the male and female rotors.

Compression stage

Powered by a 20-horsepower motor, the rotors rotate in opposite directions. As they rotate, the air is trapped between the rotor teeth. The continuous rotation reduces the air volume and compresses it. This compression happens smoothly and evenly due to the precision of the rotors, which minimises energy loss during the process.

Air discharge

Once the air is compressed, it is forced through a discharge valve into a storage tank or directly into the system, depending on the requirement. The relief valve controls compressed air flow, ensuring optimal pressure and backflow control.

Cooling and lubrication

Compression develops heat, which must be controlled to ensure the longevity and efficiency of the compressor. In oil-lubricated screw compressors, oil cools and lubricates the system while providing a minimal gap between the rotors. After compression, the oil is separated from the compressed air before it exits the unit. Oil-free screw compressors are also available for industries requiring contamination-free air.

Applications of a 20 hp screw air compressor

The screw air compressor of reliable screw compressor manufacturers is powered by a 20-horsepower motor, making it suitable for medium to large industrial applications where a constant supply of compressed air is required. These compressors are designed to operate efficiently for long hours and can handle high workloads, making them a popular choice in manufacturing, food processing, automotive, and more. Here are some of its critical applications:

Manufacturing

In manufacturing plants, a 20 hp screw air compressor powers machinery, conveyors, and air tools. Screw compressor manufacturers ensure that air pressure is for assembly, cutting, and finishing, helping maintain product quality and efficiency.

Automotive industry

Screw compressors are essential in automotive plants, where they operate air-powered tools such as wrenches, spray guns, and lifting equipment. They also play a crucial role in tire inflation and assembly line operations.

Food and beverage industry

In food processing, a rotary screw air compressor is used for packaging, filling, and bottling. Reputable screw compressor manufacturers offer oil-free screw compressors to prevent contamination and maintain product purity.

Construction

In the construction industry, rotary screw air compressor power tools like drills and jackhammers. The 20 hp screw air compressor provides the needed energy to keep tools working on large construction sites.

Pharmaceutical industry

Clean, compressed air is crucial for various production and packaging processes in the pharmaceutical sector. It is also used to maintain sterile environments in HVAC systems.

Textile industry

In the textile industry, weaving, dyeing, and spinning machines depend on a constant supply of compressed air. The 20 hp screw air compressor ensures continuous airflow, which directly impacts the quality and speed of production.

Benefits of using a 20 hp screw air compressor

The 20 hp screw air compressor offers numerous benefits, making it a popular choice in many industries. Here are some of the noteworthy advantages:

Energy efficiency

One of the most essential advantages of rotary screw air compressors is their energy efficiency. The continuous rotation of the rotors stops the need for frequent start-stop cycles, which can consume more energy in other compressors. As a result, the 20 hp screw air compressor works more efficiently over long periods, lowering energy costs.

Continuous operation

Unlike piston compressors, which require rest periods to prevent overheating, 20 hp screw air compressors can run continuously without compromising performance. This is important for industries that need a constant supply of compressed air for extended durations.

Low maintenance

The design of screw air compressors involves fewer moving parts, which reduces wear and tear. This not only lowers maintenance requirements but also minimises downtime, making the 20 hp screw air compressor a cost-effective option for long-term use.

Quiet operation

Screw air compressors are known for their more silent process compared to piston compressors. This is due to the smooth, continuous movement of the rotors, which reduces noise and vibration. As a result, these compressors can be used in indoor or noise-sensitive environments without causing disruptions.

Compact size

Despite their powerful performance, 20 hp screw air compressors are compact and easy to install. Their small footprint allows them to be integrated into various setups, from small workshops to large industrial plants.

High reliability

The robust structure of screw air compressors ensures they can handle demanding technical applications without sacrificing efficiency. This makes them a reliable choice for businesses that require constant performance over the long term.

Superior air quality

For industries like food processing and pharmaceuticals, oil-free screw air compressors provide dry, clean air, which is essential for maintaining product quality and safety. Due to the advanced filtration systems produced by screw compressor manufacturers, oil-free air compressors ensure the final output air is free from contaminants.

Long-term cost savings

Although the initial cost of a screw air compressor may be higher than other types, the long-term savings in terms of energy efficiency, reduced maintenance, and dependable operation make it a cost-effective investment for businesses.

In summary:

The 20 hp screw air compressor is a powerful and efficient device that plays an essential role in many industries. Its working principle, based on the smooth compression of air through rotors, ensures energy-efficient, continuous operation. With applications varying from manufacturing to food processing and construction, the 20 hp screw air compressor stands out for its reliability, low maintenance, and superior air quality.

For businesses seeking a durable, long-term solution to their compressed air needs, a 20 hp screw air compressor is an excellent investment. Its numerous benefits, including energy savings and operational efficiency, make it essential for achieving industrial productivity.

0 notes

Text

Premium T-Shirt Manufacturers in Tirupur

Welcome to Stillvoll Garments, the leading t-shirt manufacturer in Tirupur, India. Located in Tirupur’s renowned textile district, we specialize in producing high-quality t-shirts that offer exceptional style, comfort, and durability. As a top t-shirt manufacturer Tirupur, we are committed to delivering outstanding products and services tailored to your specific needs.

Why Choose Us as Your T-Shirt Manufacturer in Tirupur?

Superior Quality and Craftsmanship

As a premier t-shirt manufacturer in Tirupur, our focus is on superior quality and expert craftsmanship. Our advanced manufacturing facilities and skilled team ensure that each t-shirt meets the highest standards. This commitment to excellence sets us apart from other t-shirt manufacturers in Tirupur.

Wide Range of T-Shirts

We offer a comprehensive range of t-shirts, showcasing our versatility as a leading t-shirt manufacturer in Tirupur:

Basic T-Shirts: Essential, comfortable designs perfect for everyday wear.

Printed T-Shirts: Distinctive designs that make a bold statement.

Polo T-Shirts: Stylish options suitable for both casual and formal occasions.

Sports T-Shirts: High-performance fabrics designed for active use.

Organic T-Shirts: Environmentally friendly options made from sustainable materials.

Customization to Elevate Your Brand

We understand the importance of brand identity. As a leading t-shirt manufacturer in Tirupur, we offer extensive customization options to ensure your t-shirts align perfectly with your brand. From premium fabric selections to detailed design customizations, our services help your t-shirts stand out, making us a preferred choice among t-shirt manufacturers Tirupur.

Commitment to Sustainable Practices

Sustainability is a core principle at Stillvoll Garments. As an eco-friendly t-shirt manufacturer in Tirupur, India, we prioritize using sustainable materials and practices to reduce our environmental impact. Our dedication to eco-conscious manufacturing practices sets us apart from other t-shirt manufacturers in Tirupur, India.

Top Wholesale T-Shirt Manufacturer in Tirupur

For bulk orders, Stillvoll Garments is your go-to wholesale t-shirt manufacturer in Tirupur. We provide high-quality t-shirts at competitive prices, making us a top choice among wholesale t-shirt manufacturers in Tirupur, India. Our wholesale services are ideal for:

Retailers: Offering a wide range of trendy and classic t-shirt designs.

Corporate Clients: Supplying customized apparel for businesses and corporate events.

Start-Up Brands: Providing flexible solutions to build your brand’s market presence.

Why Partner with Us for Wholesale T-Shirt Manufacturing?

Competitive Pricing

Our efficient production processes and strategic location enable us to offer competitive pricing while maintaining high quality. As a leading wholesale t-shirt manufacturer Tirupur, we deliver exceptional value, making us a preferred choice among wholesale t-shirt manufacturers in Tirupur.

Global Reach and Reliability

With a strong international network, we are a reliable wholesale t-shirt manufacturer Tirupur, serving major brands and retailers around the world. Our ability to handle large orders with consistent quality makes us a trusted partner for global distribution.

Rigorous Quality Control

Quality control is integral to our operations. As a respected wholesale t-shirt manufacturer in Tirupur, we conduct thorough quality checks throughout the production process. From fabric selection to final inspection, we ensure each t-shirt meets our high standards.

Efficient Manufacturing Process

Our reputation as a leading t-shirt manufacturer in Tirupur is built on a streamlined manufacturing process:

Sourcing: Selecting high-quality fabrics from reliable suppliers.

Knitting and Dyeing: Using advanced technology to ensure vibrant colors and durability.

Cutting and Sewing: Implementing precise techniques to adhere to international standards.

Quality Control: Performing detailed inspections to guarantee flawless garments.

Dedicated to a Sustainable Future

At Stillvoll Garments, we are committed to fostering a sustainable future. As an eco-conscious t-shirt manufacturer in Tirupur, we focus on minimizing our environmental impact through sustainable practices and organic materials. This commitment enables us to provide high-quality products while supporting environmental responsibility.

Partner with Tirupur’s Leading T-Shirt Manufacturer

Choosing Stillvoll Garments as your t-shirt manufacturer in Tirupur means partnering with a company that values quality, sustainability, and customer satisfaction. Whether you are a boutique brand or a large retailer, our extensive product range and customization options are designed to meet your needs. Discover the excellence of Tirupur’s textile industry with a trusted tirupur t shirt manufacturers.

Contact us today to learn more about our products and services and see why we are the preferred choice for t-shirt manufacturing in Tirupur, India.

Address: STILLVOLL GARMENTS Phone: +91 9003683184 Email: [email protected] Website: http://stillvoll.com/

t-shirt manufacturers, t-shirt manufacturers in tirupur, t-shirt manufacturers tirupur, t-shirt manufacturer in tirupur, wholesale t-shirt manufacturers in tirupur, t-shirt manufacturers india, t-shirt manufacturers in india, t-shirt manufacturer in tirupur india, t-shirt manufacturer tirupur india, t shirt manufacturer in tirupur india

t-shirt manufacturing company, t-shirt manufacturing company in tirupur, t-shirt manufacturing company in india, t-shirt manufacturing company in tirupur india, wholesale t shirt manufacturers, wholesale t-shirt manufacturers in tirupur, wholesale t-shirt manufacturers in india, wholesale t-shirt manufacturer in tirupur india

t shirt factory, t-shirt factory in tirupur, t shirt factory in india, t-shirt factory in tirupur india, t shirt company, t-shirt company in tirupur, t-shirt company in india, tirupur clothing company, t shirt factories, t-shirt factories in tirupur, t shirt factories in india, t shirt factories in tirupur india

garments wholesale in tirupur, garments manufacturers, garments manufacturers in tirupur, garments manufacturers in india, top t-shirt manufacturers in tirupur, tirupur t-shirt manufacturing company, clothing manufacturing company, clothing manufacturing company tirupur, clothing manufacturing company india, clothing wholesale, clothing wholesale in india, Clothing wholesale in tirupur, Clothing Wholesale In tirupur india

0 notes

Text

Why ZLD is the Future of Eco-Friendly Sewage Treatment

As water scarcity becomes a growing concern and environmental regulations tighten globally, industries and municipalities are shifting towards sustainable wastewater treatment solutions. Among the most promising innovations is Zero-Liquid Discharge (ZLD), a method that ensures absolutely no liquid waste leaves the treatment facility. ZLD is redefining how we view and manage wastewater — not as waste, but as a resource to be recovered and reused.

Let’s delve deeper into why ZLD is gaining traction and how it is shaping the future of eco-friendly sewage treatment.

What is Zero-Liquid Discharge (ZLD)?

Zero-Liquid Discharge (ZLD) is a water treatment process that eliminates all liquid waste from a system. It maximizes water recovery by treating and recycling wastewater, leaving behind only solid waste that can be safely disposed of or utilized in other ways. The core idea is to prevent any effluent from being discharged into the environment.

The ZLD process typically involves multiple stages such as pre-treatment, membrane filtration (like reverse osmosis), evaporation, and crystallization. These stages work collectively to reclaim clean water while concentrating and isolating contaminants in solid form.

Reasons Behind the Growing Demand for ZLD Systems

Several key factors are fueling the global demand for ZLD systems:

Water Scarcity: In many regions, freshwater sources are depleting rapidly. ZLD allows for maximum water reuse, reducing dependence on external water supplies.

Strict Regulatory Standards: Governments and environmental bodies are enforcing tougher discharge norms, making ZLD a strategic solution for compliance.

Sustainability Goals: Industries are under increasing pressure to demonstrate their environmental responsibility. ZLD supports corporate ESG (Environmental, Social, and Governance) targets.

Rising Operational Costs: By reusing water, industries can cut costs related to water procurement and wastewater disposal.

Public Awareness: With growing awareness around pollution and climate change, businesses are embracing eco-conscious operations.

Environmental Benefits of ZLD

ZLD systems offer a range of environmental advantages, making them a critical component of green infrastructure:

Zero Water Pollution: No untreated effluent is released into water bodies, protecting aquatic life and water quality.

Conservation of Freshwater: With treated water being reused internally, there is reduced pressure on freshwater ecosystems.

Safe Waste Handling: Solid residues are more manageable and can be processed safely, minimizing environmental hazards.

Improved Air and Soil Quality: Eliminating liquid discharges prevents the contamination of nearby land and air, especially in urban and industrial zones.

ZLD and Circular Economy in Wastewater Management

The principles of the circular economy—reduce, reuse, and recycle—are at the core of ZLD systems. Instead of discarding wastewater, ZLD enables facilities to reclaim water, recover by-products, and reduce overall waste.

Water Reuse: Recovered water can be used for cooling, cleaning, or industrial processes, reducing the need for fresh supplies.

By-product Recovery: Valuable materials such as salts, minerals, and metals can be extracted from the solid waste and reused or sold.

Energy Integration: Waste heat from industrial processes can be used to power ZLD systems, further boosting sustainability.

ZLD transforms waste into resources, supporting closed-loop systems and long-term environmental resilience.

Industries Leading the ZLD Adoption

Some industries have taken the lead in adopting ZLD due to the volume and nature of their wastewater:

Textiles and Dyeing: Known for generating heavily polluted effluents, textile plants use ZLD to comply with regulations and reduce their environmental footprint.

Pharmaceuticals and Chemicals: These sectors handle hazardous wastewater that must be treated carefully. ZLD ensures safe disposal and recovery of water.

Power Generation: Power plants, particularly thermal units, consume vast quantities of water. ZLD allows them to recycle water and reduce withdrawal.

Oil & Gas: Refineries and petrochemical units benefit from ZLD by safely treating complex effluents and recovering hydrocarbons and salts.

Food and Beverage: These facilities increasingly use ZLD to manage high-organic-content wastewater sustainably.

Technological Innovations Making ZLD More Efficient

Technology is playing a crucial role in advancing ZLD systems, making them more affordable, scalable, and energy-efficient.

High-Efficiency Membranes: Improved filtration membranes reduce energy use and enhance separation performance.

Mechanical Vapor Recompression (MVR): This technology captures and reuses vapor energy, lowering the energy consumption of evaporation.

Hybrid Systems: Combining membrane and thermal processes provides better water recovery and adaptability across different effluent types.

Automation and Remote Monitoring: Smart sensors and IoT-based controls allow real-time system optimization and preventive maintenance, minimizing downtime and human error.

Modular Designs: Scalable ZLD units are now available, making the technology accessible to small and mid-sized facilities.

These innovations are helping industries reduce the operational and environmental costs associated with traditional water treatment.

Challenges and Considerations

Despite its benefits, ZLD implementation comes with certain challenges:

High Initial Investment: Setting up a ZLD plant requires significant capital, which may be a hurdle for smaller operations.

Energy Demand: Evaporation and crystallization stages can be energy-intensive, although recent technologies are reducing this burden.

Operational Complexity: ZLD systems require skilled manpower and regular maintenance to function optimally.

Sludge Management: While liquid waste is eliminated, the remaining solid waste must be carefully handled to avoid environmental harm.

Industries must weigh these factors carefully and work with experienced technology partners to implement effective ZLD solutions.

Why ZLD is the Future of Eco-Friendly Sewage Treatment

ZLD represents the next generation of wastewater treatment—where environmental responsibility, regulatory compliance, and operational efficiency converge. As the demand for sustainable water management rises, ZLD provides a clear path toward achieving zero discharge, reduced freshwater consumption, and enhanced resource recovery.

Adopting ZLD is not just a regulatory necessity but a forward-thinking strategy that aligns with global sustainability movements and climate action goals. As innovations continue to improve ZLD’s feasibility and efficiency, it is set to become the gold standard for eco-friendly sewage treatment systems.

Take the Lead in Sustainable Water Management with a Smart Wastewater Treatment Plant

Future-ready organizations understand the importance of sustainable practices and are already investing in smart wastewater treatment solutions like ZLD. By partnering with the right technology provider, industries can transform their water management approach, reduce risks, and create long-term value.

Cleantech Water offers customized ZLD solutions that combine efficiency, reliability, and environmental stewardship. Explore how your facility can transition to a Zero-Liquid Discharge system that supports your sustainability goals and ensures compliance with tomorrow’s water regulations.

Read More: https://www.cleantechwater.co.in/zld-future-eco-friendly-sewage-treatment/

0 notes

Text

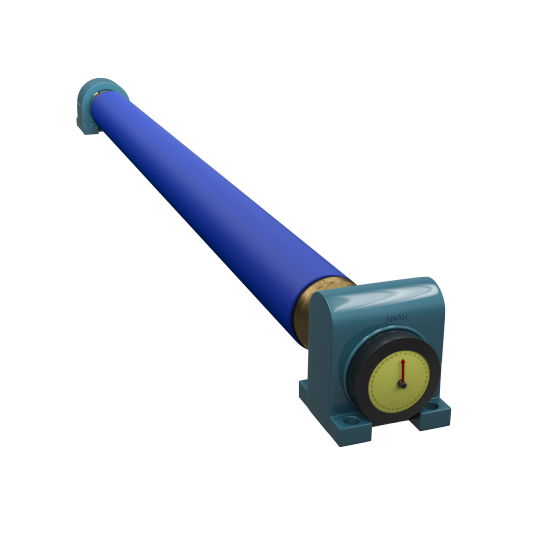

Understanding the Importance of Bow Banana Rollers in Industrial Applications

In the realm of industrial machinery and material handling, the bow banana roller plays a pivotal role. These rollers are essential components in various industries, including textile, paper, film, foil, and more. This blog delves into the intricacies of bow banana rollers, exploring their functions, benefits, and applications. By the end, you’ll have a comprehensive understanding of why these rollers are indispensable in many industrial settings.

What is a Bow Banana Roller?

A bow banana roller is a specialized type of roller designed to remove wrinkles and creases from continuous web materials such as textiles, films, paper, and foils. The term "banana" comes from the roller's distinctive curved shape, which resembles a banana. This unique shape is key to its function, as it creates a differential stretch across the web, effectively eliminating any unwanted wrinkles.

How Does a Bow Banana Roller Work?

The working principle of a bow banana roller is quite simple yet highly effective. As the web material passes over the curved surface of the roller, the differential stretch applied helps to spread and flatten the material. This is particularly important in processes where smooth, wrinkle-free material is crucial for quality and efficiency.

Material Handling: As the material enters the roller, the curvature begins to act, applying tension across the width of the web.

Wrinkle Removal: The differential stretch applied by the bow roller helps to remove any creases or wrinkles present in the material.

Smooth Output: The material exits the roller in a smooth, wrinkle-free state, ready for the next stage of processing.

Benefits of Using Bow Banana Rollers

The use of bow banana rollers offers several benefits across various industrial applications. Here are some of the most notable advantages:

Improved Material Quality

One of the primary benefits of using a banana roller is the significant improvement in the quality of the processed material. By removing wrinkles and creases, these rollers ensure that the end product is smooth and defect-free, which is crucial in industries like textiles and packaging.

Enhanced Process Efficiency

In industrial processes, efficiency is paramount. Bow rollers help to streamline operations by preventing material jams and ensuring smooth, continuous processing. This not only reduces downtime but also enhances overall productivity.

Versatility