#Over Feed For Textile Machinery

Explore tagged Tumblr posts

Text

Title: Biomass vs. Solar and Wind: Choosing the Right Renewable Energy for Industrial Use

As India moves toward a cleaner and greener energy future, industries are under increasing pressure to shift from fossil fuels to renewable energy. Among the most discussed options are solar, wind, and biomass gasification. While each technology has its strengths, the right solution often depends on the industry type, location, and energy requirements.

In many cases, especially in agro-based or rural industries, biomass gasifiers offer a more practical and cost-effective solution. Veera Group, a trusted name in sustainable industrial solutions, is helping companies make this shift by providing advanced, high-efficiency biomass gasifier machines that are tailor-made for Indian industries.

Solar and Wind: Popular, But Limited

Solar and wind power are well-established renewable sources in India. They are ideal for large-scale grid feed-in or commercial campuses. However, they come with limitations for industrial use:

Intermittency: Solar only works during daylight, and wind depends on weather conditions. This inconsistency requires expensive battery backups or diesel generators.

Land Requirements: Large solar or wind farms need significant space—something not all factories or industries can spare.

Upfront Costs: While costs have dropped, the initial investment for solar or wind setups, especially with storage, can still be steep.

These challenges make solar and wind less viable for industries that need continuous power, thermal energy, or operate in semi-urban and rural areas.

Biomass Gasifiers: A Reliable Industrial Solution

Unlike solar or wind, biomass gasifiers generate energy on demand and are not reliant on weather or sunlight. These systems convert agricultural waste like wood chips, coconut shells, rice husk, and sawdust into producer gas—a clean, combustible fuel that can be used for:

Electricity generation

Thermal heating in boilers

Powering industrial machinery

Veera Group’s biomass gasifier machine is engineered for high-efficiency performance and reliability, specifically targeting industrial use cases. These machines are capable of running continuously, are easy to maintain, and utilize locally available biomass—cutting fuel costs and dependence on external suppliers.

Industrial Sectors Benefiting from Biomass

Numerous industries are now turning to biomass gasification for their daily energy needs. These include:

Textile units using it for hot water and steam.

Food processing units using it for roasting, drying, or baking.

Small manufacturing plants running machinery with electricity generated by gasifiers.

Veera Group has helped several industrial clients replace diesel generators with biomass systems—cutting both emissions and energy bills.

To explore such case studies and industry insights, check out the Veera Group Blog, where they regularly publish updates on renewable technologies and their industrial applications.

Why Industries Choose Biomass Over Other Renewables

Here’s a quick comparison table: FeatureBiomass GasifiersSolar EnergyWind EnergyReliabilityHigh (on-demand)Low (daylight only)Low (depends on wind)Industrial HeatingYesNoNoEnergy Storage NeededNoYesYesSpace RequirementLowMedium-HighHighFuel CostLow (local biomass)Free (after setup)Free (after setup)Initial InvestmentModerateHigh (with batteries)High

Clearly, for many industrial setups—especially in rural or agro-based sectors—biomass gasifiers provide a more stable and scalable energy solution.

Veera Group: Your Partner in Clean Industrial Power

With decades of experience in engineering and clean technology, Veera Group is at the forefront of India's industrial energy revolution. Their biomass gasifier machines are built with precision, tested under tough industrial conditions, and backed by expert support. Whether you're a small enterprise or a large-scale manufacturer, they offer custom solutions to help you transition smoothly to renewable energy.

Conclusion

While solar and wind are excellent renewable sources in the right context, biomass gasification stands out as the most practical choice for many industries—especially those looking for round-the-clock power and thermal energy. Thanks to Veera Group and their cutting-edge gasifier machines, Indian industries now have a reliable, sustainable, and cost-effective energy alternative.

0 notes

Video

youtube

The Surprising Truth About U.S. China TRADE Nobody Tells You

The U.S.-China trade relationship is one of the most economically significant in the world. Both countries import and export a wide variety of goods to and from each other, but tensions over tariffs, national security, and supply chain concerns have disrupted this flow, prompting shifts in global trade routes. Here's a detailed matrix-style breakdown of goods traded between the U.S. and China, descriptions of each category, alternative suppliers/buyers, and who loses in the trade conflict: 🇨🇳 China Imports from 🇺🇸 U.S. Category Description Alt. Suppliers to China Losers if trade stops Soybeans & Ag. Products Animal feed, cooking oil; major input for China's livestock sector Brazil, Argentina, Russia U.S. farmers, Chinese livestock producers (costs ↑) Semiconductors & Chips High-end processors used in phones, computers, AI, military tech Taiwan (TSMC), South Korea (Samsung) U.S. chipmakers, Chinese tech firms Aircraft (Boeing) Used by Chinese airlines for fleet expansion Airbus (EU) Boeing, Chinese aviation industry (delivery delays) Natural Gas & Oil For energy security and economic diversification Qatar, Australia, Russia U.S. energy exporters, Chinese industries Industrial Machinery Equipment for manufacturing, infrastructure Germany, Japan U.S. exporters, Chinese manufacturers Medical Devices Diagnostics, surgical tools Germany, Japan, South Korea U.S. companies, Chinese hospitals 🇨🇳 China Exports to 🇺🇸 U.S. Category Description Alt. Suppliers to U.S. Losers if trade stops Consumer Electronics Phones, laptops, TVs (iPhones, etc.) Vietnam, India, Mexico U.S. consumers (prices ↑), Chinese factories Apparel & Textiles Clothes, shoes, accessories Bangladesh, Vietnam, India U.S. retailers, Chinese garment factories Furniture Low- to mid-range home and office furniture Vietnam, Malaysia, Mexico U.S. importers, Chinese manufacturers Toys & Games Dolls, action figures, educational toys Vietnam, Mexico, India U.S. toy brands, Chinese producers Machinery & Tools Power tools, parts, household appliances Germany, Taiwan, South Korea U.S. construction/DIY industries, Chinese exporters Solar Panels & Batteries Key components for renewable energy push Malaysia, South Korea, India U.S. green energy sector, Chinese green tech industry 🌐 Who is the Loser in this Trade Fiasco? Here's a simple impact matrix to illustrate: Party Loss Level Why U.S. Farmers 🔴 High Lost huge export market (especially soybeans) Chinese Tech Companies 🔴 High Lost access to advanced U.S. chips, especially in AI U.S. Consumers 🟠 Medium-High Prices rise due to tariffs and supply chain shifts Chinese Manufacturers 🟠 Medium-High Lost access to U.S. market or face higher tariffs U.S. Tech Firms (e.g. Apple, Nvidia) 🟠 Medium Production and sales affected by Chinese retaliation and decoupling Southeast Asia (e.g. Vietnam) 🟢 Winner Gained investment and manufacturing shift from China Mexico 🟢 Winner Benefited from nearshoring by U.S. firms EU (Germany, France) 🟢 Winner Increased exports to both countries as substitutes 🧠 Summary U.S. farmers and chipmakers suffer most from export bans and tariffs. Chinese manufacturers and tech lose access to vital components and markets. Consumers in both countries pay more due to inefficiencies and tariffs. Third-party countries (Vietnam, Mexico, EU) are the winners, gaining trade and manufacturing opportunities.

0 notes

Text

Applications of Worm Reduction Gearboxes in the Textile Industry

In this industry, a high starting torque is considered a necessity for the selection of mechanical transmission components. Thus, a high proportion of gearboxes are best suited to such high loads. It has the majority of applications in the textile industry as it offers constant speeds and torques. It ensures smooth operation and consistent performance. It is used in various machines as it provides precision, durability, and efficiency.

Some of its applications in the textile industry are as follows:

Spinning machines

During the manufacturing process, it is important to control thread tension and manage the movement of textiles. This machine helps convert fibers into yarns. This is considered to be a very crucial step in the gearbox manufacturing process. Thus, these machines require precise control over speed and torque. They are built in such a way that they can handle delicate fibers without breakage.

Function of gearboxes:

It helps provide high torque at low speeds, which is very important for spinning operations. It will ensure vibration-free operation and smooth maintenance of good quality. With limited machine space, you can get various compact design fits.

Dyeing machines

In this step, the fibers are treated with chemicals and dyes in order to get the required design. These finishing machines can help give you your desired finish, color, and texture. These kinds of machines mainly require variable speed control.

Function of gearboxes:

The gearboxes are very reliable and provide adjustable speed control. You can control it according to your requirements. In some cases, they help handle heavy loads during fabric dipping or drying stages. As this process is surrounded by a chemical-rich environment. Thus, it is recommended to have corrosion-resistant options.

Conveyors

It is used to transfer materials or goods between different points. Within the manufacturing plant, it helps transfer materials such as fabrics and fibers. Hence, there is a requirement for effective reliable drive systems.

Function of gearboxes:

The self-locking feature helps prevent the conveyors from back-driving, which helps maintain the load’s position. They also offer quiet operation, which reduces noise pollution in factories. In addition, with consistent torque output, they can handle varying loads.

Printing machines

These machines help add designs and patterns to your fabrics. Thus, they require precise control over the rulers and plates. Only sharp and consistent prints can be achieved.

Function of gearboxes:

The gears are utilized to control the paper feeding and output processes. It helps provide accurate synchronization of roller movements and provides a steady torque. As a result, it prevents any misalignments during printing and offers smooth operation.

Some of the major benefits of these gearboxes are as follows-

It can generate high reduction ratios. As a result, it can have high torque multiplication.

It can be used as a speed reducer.

The reduction ratio is only based on the number of gear teeth. And as a result, they are more compact when compared to other gears.

The gears are made of softer materials. And as a result, it can absorb shock loads.

It has a comparatively low initial cost and minimum maintenance cost which reduces the overall operational expenses.

It is available in various ratios and designs. Hence, you can customize it according to your specific textile machinery need.

Conclusion

Gearboxes are very important in the textile industry, as they offer versatility, efficiency, and reliability. They have many applications, from spinning to printing, and provide the necessary speed and torque control to ensure smooth operation.

#Gearboxes Textile Industry Ahmedabad#gear box manufacturer in ahmedabad#gearbox manufacturer in ahmedabad#gear manufacturer in ahmedabad#worm gear manufacturers near me#reduction gearbox manufacturers#worm gearbox manufacturers#horizontal to vertical gearbox#gearbox manufacturer in gujarat#worm reduction gearbox near me#buy worm reduction gearbox#vertical to horizontal gearbox#worm reduction gearbox manufacturers#worm gearbox manufacturers in india#worm gear box manufacturer

0 notes

Text

5 Reasons to Make Pashupati Group Your Sustainability Partner

With a legacy of over 4 decades, the prestigious Pashupati Group has earned all the reasons to gain your trust as a reliable and responsible sustainability partner.

5 of the Reasons That Must Be Considered Before Making the Final Decision Are

Zero Liquid Discharge (ZLD) Policy

The ETP and R.O. plants work towards 100% recycling of processed water to strictly maintain a Zero Liquid Discharge (ZLD) across the entire Group. This is a very conscious approach that speaks volumes about how the business takes its footprints very responsibly. With an intention to share visions, the Group takes pride in extending such conscious policies with its partner companies.

International Quality

From Bottles to Yarn, Technical Textile & Master batches, and Recycled PP Granules & sacks, the latest machinery has been procured to ensure the best quality outcome for every product manufactured under the Pashupati name. Globally advanced quality control equipment has been imported and installed as a part of the larger setup to offer unmatched product quality at every stage of the production process. With ZLD, waste management, and 100% assured quality, the Group proves its everlasting commitment to customers and the environment.

Customized Manufacturing Capabilities

The Group takes pride in dedicating respective divisions to in-house research, manufacture, and development of an extensive product list. This gives the business an edge to cater to all kinds of sustainable manufacturing demands of partner companies. Everything from rPSF (solid, hollow, and dyed fiber), Specialty Fibers like Anti-Bacterial, Fire Retardant, Hydrophilic, Reinforcement, Easy Dyeable, Easy Dyeable Cationic (Acrylic Feel), Low Melt, Biodegradable, Nylon 66/6, PP fibers, Woven fabrics and so much more comes in an unthinkable variety of colors and quality.

Large-scale Production

We currently recycle 105 tons PET Bottles per day, which gives the Pashupati Group an even higher edge in its mass production. Our next milestone is to achieve 2,42,646 Tons of feed processing capacity by 2025 and maintains all norms with such high quality of processing.

Social Responsibility

Last but not the least, when a company comes forward to partner with the Pashupati Group, an unsaid advantage that tags along are the collective environmental benefit. The more is the collection of waste from across the country and across industries, to match the increased demand of the clients, the more benefits are the business able to pass on to the environment.

Picking the Pashupati Group as your sustainability partner would directly mean contributing to the conservation of 3.72 Trillion (BTU) of heat energy per year, 0.51 Million Crude Oil Consumption, saving 1.03 Million (Cubic Yard) of plastic landfill space, and overall greenhouse gas reduction. That would be a fair deal, wouldn’t it?

0 notes

Text

I live in England and even the kids over here aren't getting dressed up like it's time to do some Dickens novel cosplay, even though our cost of living crisis is driving more and more into serious poverty every single day

it's so fascinating and so sickening that "poor Victorian/Edwardian working child aesthetic" is real and being sold in fucking department stores in the USA

and not upper class department stores, places like Target which are like, middle class shoppers, mostly -- although if it's being sold there for rich people kids, I guarantee you the framing is "stylish historically inspired outfit with classic accessories" rather than "SEND YOUR KID TO THE MINES BUT DO IT IN CLASSIC SWAG"

I'm going to guess they aren't selling shit like this styled in this way for the rich kids whose parents are shopping at Macy's or Bloomingdales, but if they are, pay attention to how they display it and how it's framed.

in the second photo I also want to point out the ruffle collar plaid dress on the mannequin next to the "chimney sweep boy/newspaper sales boy" outfit

it looks like the dresses which were made out of recycled textiles like old window curtains that poor families would make for young children.

the neck ruffle looks like the ruffle along the top of old curtains that was sewn into a neck line; this was very common for girls whose families could not afford necklaces, scarves, or the additional fabric for the high necked collars that were popular at the time. it was reasonably stylish without being expensive.

notice the length of the skirt/dress, too (hard to tell if it's a two piece outfit or not)-- this might be intended to evoke the style of hiked up shorter dresses or bloomers that girls would wear when working in factories (to avoid skirts and under layers from getting pulled into machinery and to prevent tripping hazards).

what's next, a fucking burlap texture dress, to evoke the visual style of recycled feed bag dresses from the fucking Depression era?

this is really bizarre shit.

stop dressing kids like Victorian working children, this is not an aesthetic to desire for obvious reasons, and stop trying so fucking hard to destroy child labour laws.

jesus christ we live in hell

42K notes

·

View notes

Text

Asteks to exhibit its advanced integrated cots grinding solutions at ITM 2024

Offering aprons, cots and multifunctional cots grinding solutions that directly affect the quality and productivity of yarn manufacturers, Asteks will attract attention at the ITM 2024 with its automation and integration-oriented innovations and rich product portfolio.

Asteks, the leading manufacturer of advanced grinding and automation solutions, will share its innovative products with the local and global textile industry at the international textile exhibition ITM 2024 to be held in TÜYAP on June, 4-8. Asteks, at the booth 705B in Hall 7, will display both its rich product portfolio and its strength to access the global market and to textile professionals from different parts of the world. Visitors will be able to see the multifunctional 401-SF&M cots grinding machine and the UV-305 Cots’ Surface Treatment Machine working integrated each other maintaining continuous process from grinding to UV treatment at the Asteks booth.

Stating that R&D-oriented product development and a successful supply chain were effective in Asteks’ rapid growth process in the global market, Asteks Marketing and Sales Manager Sabri İlknur noted that this strategic growth also reflects the power of the Turkish textile industry. İlknur said; “Our products, which show the power of Turkish engineering, are very competitive in terms of price-performance balance as well as quality and longevity criteria. For this reason, we make a great contribution to the export power of the Turkish textile industry with both our aprons and cots products and our cots grinding machines. We attribute great importance to ITM 2024 to showcase our best spinning and automation solutions. In addition to exhibiting our cots grinding machinery and solutions at our two-storey booth, we will also have rest/meeting areas where we can easily meet with our visitors. As the only company that provides end-to-end solutions with our cots grinding machinery, as well as aprons and cots products, we will be happy to see all textile manufacturers at our booth.”

Cots Grinding Machine the 401-SF&M and UV Treatment Machine the UV-305 will be offered in integration

Asteks’ new generation 401-SF&M cots grinding machine has strengthened its flagship position with the interest it has received since it was introduced to the market. The model, which has gained great popularity in the market with the slogan ‘two machines built-in one’, makes a difference with its unique features. While, one of the two independent grinding units on the machine processes the short cots for ring spinning and roving frames in automatic motion and the other unit processes long cots for draw frames and combing machines, at the same time, simultaneously.

This machine provides more automation and efficiency to the cots grinding process and has further increased its appeal with the latest innovation offered by Asteks to textile businesses. Thanks to the Smart Feeding System, the cots are processed automatically without the need to line them up one by one. In addition, by the auto-rejection system over outer diameter, the measurements of the cots for grinding are carried out automatically with the laser system, thus saving labour in the operations. The high-capacity and fully automatic 401-SF&M cots grinding machine guarantees spinners the best efficiency, higher productivity and better standard operation.

“An integrated cots grinding department with the new UV-305 offers great opportunities”

Asteks cots grinding machines, which are among the indispensable element of roller covering departments, can now be integrated with the new UV-305 Cots’ Surface UV Treatment Machine. The UV-305 Cots’ Surface UV Treatment Machine, which was first announced at the ITMA Milano last year, contributes to increasing yarn quality while reducing costs of maintenance. Focusing on the automation and integration of cots grinding departments in spinning mills, Asteks will demonstrate this at the exhibition by operating 401-SF&M and UV-305 integrated to each other.

This new solution significantly increases the life of the cots for draw frame and combing machines and yarn quality and is designed for enterprises with high spindle capacity. The machine, which processes the cots surface with 4000-Watt Ultraviolet (UV) irradiation, can work fully integrated with Asteks’ cots grinding machines due to its high performance and automation capability. Thanks to the integration, the cots that come out of grinding process on the 401-SF&M cots grinding machine are irradiated in UV-305 without the need for any operator attendance, and then become ready for direct use.

Pointing out that the UV-305 Cots’ Surface UV Treatment Machine has several advantages, Sabri İlknur said; “Improving the surface of the cots with UV after cots grinding on short staple fibre spinning machines processing synthetic and blended fibres provides many benefits. First of all, the risk of fibre lapping on the cots is reduced. The start-up becomes easier and better efficient after doffing on spinning machines, and this saves labour and prevents losses in productivity. Since the cots surface is improved by UV, less fibre is carried to the upper flock roller, which cleans the cot in the spinning machine. This also means reducing raw material loss. UV-305, which provides perfect operation as an optional integration into 401 series cots grinding machines, can also be used independently. The transformation of cots grinding departments into a fully integrated structure will provide better efficiency and thus higher profitability that yarn manufacturers need more than ever in recent tougher operational circumstances. This ultimately leads to increased competitiveness. This is exactly what we do as Asteks.”

Innovative aprons-cots solutions will be featured at the Asteks booth

ITM visitors will also be able to see aprons and cots products at the Asteks booth, which attract great attention in the market with their quality and durability as well as price-performance balance. GESA/OPS-performance perforated aprons designed for compact spinning systems, the best-selling NT-86/S aprons, the Apron reinforced by Carbon , the CTA, designed for higher wear resistance offering better performance in tougher fancy spinning conditions like core yarn and synthetic fibre blend yarn production, S/TE-682 texturing system aprons, new generation late fouling Draw Frame cots with this feature and many other innovative products will be displayed throughout the exhibition.

Sabri İlknur said that they are looking forward to the ITM 2024 to discuss new investments and developments with the textile industry and added that the exhibition will not only contribute to the competitive and sustainable power of the textile industry, but also will have a serious impact on a global scale.

1 note

·

View note

Text

Innovations in Packaging Machinery and Gluing Solutions

Innovations in Packaging Machinery and Gluing Solutions

....................................................................................

Innovations in Packaging Machinery and Gluing Solutions

Gluing Machines

&

Order price below 5,000$

Top products in Packaging Machines

(01) Stainless Steel Table Top Paper Hot Melt Glue Gluing Machine

Introduction

In the ever-evolving world of manufacturing and production, efficiency and precision are key. COLORDOWELL's Stainless Steel Table Top Paper Hot Melt Glue Gluing Machine emerges as a reliable and innovative solution for a variety of industries. From food and beverage to medical and apparel, this gluing machine proves to be a versatile asset with its user-friendly design and top-notch features.

Easy to Operate

One of the standout features of the COLORDOWELL Gluing Machine is its user-friendly design. With a straightforward manual feeding system and easy operation, even those new to the manufacturing process can quickly adapt. This ensures a seamless integration into different production setups, making it an ideal choice for various businesses.

Diverse Applications

The gluing machine's adaptability is truly impressive. It caters to a wide range of industries including food, beverage, commodity, medical, chemical, machinery & hardware, apparel, and textiles. Whether you're working with cartons, cans, bottles, barrels, bags, film, pouches, or cases, this machine handles it all. This versatility makes it a valuable asset for businesses with diverse production needs.

Sturdy Construction

Crafted from high-quality stainless steel, the machine guarantees durability and longevity. The robust build ensures stability during operation, and its compact dimensions (1060390430mm) make it suitable for various workshop sizes. The 65 KG weight adds to the stability without compromising on portability.

Water-base Glue Technology

The use of water-based glue technology not only contributes to a more environmentally friendly operation but also ensures a secure and efficient bonding process. This feature aligns with modern sustainability standards, making it an appealing choice for eco-conscious businesses.

Semi-Automatic Operation

The semi-automatic grade and electric-driven type of the gluing machine strike a balance between manual control and automated precision. This ensures that operators have control over the process while benefiting from the efficiency and consistency provided by automation.

Conclusion

In the competitive landscape of manufacturing, COLORDOWELL's Stainless Steel Gluing Machine stands out as a reliable and versatile choice. Its ease of use, diverse applications, sturdy construction, and eco-friendly glue technology make it a game-changer for businesses looking to enhance their production processes. With a one-year warranty on core components, investing in this machine not only ensures immediate benefits but also long-term reliability. Upgrade your production capabilities with the COLORDOWELL Gluing Machine and experience a new level of efficiency in your operations.

Quick Details

Applicable Industries : Manufacturing Plant, Machinery Repair Shops, Restaurant, Printing Shops, Advertising Company

Showroom Location : None

Video outgoing-inspection : Not Available

Machinery Test Report : Not Available

Warranty of core components : 1 Year

Core Components : Motor

Place of Origin : Zhejiang, China

Weight : 65 KG

Warranty : 1 Year

Key Selling Points : Easy to Operate

Type : Gluing Machine

Condition : New

Application : Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, APPAREL, Textiles

Packaging Type : Cartons, CANS, Bottles, Barrel, Bags, Film, Pouch, case

Packaging Material : Plastic, Paper, Metal, Glass

Automatic Grade : Semi-automatic

Driven Type : Electric

Voltage : 220V

Brand Name : COLORDOWELL

Dimension(L*W*H) : 1060*390*430mm

Product name : Gluing Machine

Glue type : Water-base Glue

Feeding way : Manul Feeding

Max. gluing width : 700mm

Buy Now & Read More

(02) High quality manual corrugated gluing machine paper gluing machine gluing machines

Introduction

In the dynamic landscape of manufacturing machinery, the Allraise OR-2000 emerges as a standout solution, particularly in the realm of gluing machines designed for food packaging. This semi-automatic gluing machine is a testament to efficiency, boasting high productivity and precision in its operations.

Versatility for Various Industries

The Allraise OR-2000 is a versatile gluing machine that finds applications across diverse industries, including hotels, garment shops, manufacturing plants, food and beverage factories, and more. Its adaptability makes it a valuable asset for businesses involved in packaging and production.

Robust Construction for Longevity

Crafted in Henan, China, the OR-2000 embodies robust construction, weighing 400 KG and guaranteeing durability for extended usage. The high-quality materials and meticulous engineering ensure that this machine stands the test of time in demanding industrial environments.

Intelligent Control with PLC Technology

At its core, the Allraise OR-2000 is equipped with a PLC (Programmable Logic Controller) system, providing intelligent control over its operations. This not only enhances the precision of gluing but also contributes to the overall efficiency of the packaging process.

Semi-Automatic for User-Friendly Operation

Designed with user convenience in mind, the OR-2000 operates on a semi-automatic mode. This ensures that operators have control and flexibility in managing the gluing process while benefiting from the efficiency and speed that automation brings.

Reliable Performance with 1-Year Warranty

Allraise stands behind the quality of the OR-2000 by offering a 1-year warranty on its core components. This commitment to customer satisfaction reflects the brand's confidence in the reliability and performance of their product.

Carefully Packaged for Safe Delivery

The packaging of the Allraise OR-2000 is a testament to the brand's dedication to customer satisfaction. Housed in a robust wooden case, the machine is securely protected during transit, ensuring that it reaches customers in pristine condition.

Conclusion

In conclusion, the Allraise OR-2000 stands out as a high-quality, semi-automatic gluing machine that excels in the precision packaging of food products. Its versatility, durability, intelligent control, and user-friendly operation make it a valuable investment for businesses seeking to enhance their productivity in the packaging process. Backed by Allraise's commitment to quality and a 1-year warranty, the OR-2000 is a reliable choice for those looking to elevate their packaging operations to new heights.

Quick Details

Applicable Industries : Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Showroom Location : None

Video outgoing-inspection : Provided

Machinery Test Report : Provided

Warranty of core components : 1 Year

Core Components : PLC

Place of Origin : Henan, China

Weight : 400 KG

Warranty : 1 Year

Key Selling Points : High Productivity

Type : Gluing Machine

Application : Food

Packaging Type : case

Automatic Grade : Semi-automatic

Driven Type : Manual

Voltage : 220V

Brand Name : Allraise

Model : OR-2000

Packaging and delivery

Packaging Details,

1. Automatic PVC Card Foil Printer Hologram Signature Panel Printing Machine Holographic Images Hot Stamping Machine Price is packed in a strong wooden case.

2. As the customers' reasonable requires

Selling Units : Single item

Single package size : 127X122X183 cm

Single gross weight : 590.000 kg

Buy Now & Read More

(03) Fast Speed semi automatic Paper Box Cardboard Carton Cold Gluing Machines

Introduction

In the competitive world of printing, efficiency and precision are paramount, and the Befitter Cold Gluing Machine emerges as a true game-changer. This semi-automatic wonder is designed to revolutionize your printing process, offering a seamless experience with its cutting-edge features and user-friendly interface.

Unmatched Performance

The Befitter Cold Gluing Machine is engineered for excellence, making it an ideal choice for machinery repair shops, home use, retail, printing shops, and advertising companies alike. Its robust motor, a core component backed by a 1-year warranty, ensures durability and consistent performance. With a max gluing width of 380mm and an impressive max speed of 0-26m/min, this machine is built to handle a wide range of printing applications with precision and speed.

Easy to Operate

One of the key selling points of the Befitter Cold Gluing Machine is its user-friendly design. The machine's interface is intuitive and easy to operate, allowing users to seamlessly integrate it into their workflow. Whether you are a seasoned professional or a novice, the learning curve is minimal, ensuring that you can start maximizing your productivity from day one.

Versatile Application

The machine's versatility shines through in its application. Perfect for printing, it effortlessly handles various materials and projects with ease. The cold glue technology employed by the machine ensures a clean and efficient gluing process, catering to the diverse needs of the printing industry.

Compact and Durable

Weighing in at just 32kg and with dimensions of 600x410x360mm, the Befitter Cold Gluing Machine is compact and space-efficient. Its sturdy build and wooden packaging guarantee that it arrives in pristine condition, ready to be deployed for your printing requirements. The 1-year warranty provides peace of mind, showcasing the manufacturer's confidence in the machine's longevity.

Enhanced Support and Technical Assistance

Post-purchase, Befitter stands by its product with video technical support during the after-warranty period. This commitment ensures that you have continuous access to assistance and guidance, further solidifying the trust in your investment.

Conclusion

In the world of printing, the Befitter Cold Gluing Machine stands out as a reliable, efficient, and easy-to-operate solution. Its impressive features, coupled with the backing of a 1-year warranty and ongoing technical support, make it a smart investment for businesses looking to elevate their printing processes. Upgrade your operations with the Befitter Cold Gluing Machine and experience a new era of efficiency in the world of printing.

Quick Details

Applicable Industries : Machinery Repair Shops, Home Use, Retail, Printing Shops, Advertising Company

Showroom Location : None

Video outgoing-inspection : Provided

Machinery Test Report : Provided

Warranty of core components : 1 Year

Core Components : Motor

Place of Origin : Zhejiang, China

Weight : 32 KG

Warranty : 1 Year

Key Selling Points : Easy to Operate

Type : Gluing Machine

Condition : New

Application : Printing

Packaging Type : Case

Packaging Material : Wood

Automatic Grade : Semi-automatic

Driven Type : Electric

Voltage : 110V/220V

Brand Name : Befitter

Dimension(L*W*H) : 600*410*360mm

Name : Cold gluing machine for sale

Max gluing width : 380mm

Max speed : 0-26m/min

Power : 120W

Glue type : Cold glue

After Warranty Service : Video technical support

Packaging and delivery

Packaging Details : 1pc/ wooden case

Selling Units : Single item

Single package size : 60X41X36 cm

Single gross weight : 40.000 kg

Buy Now & Read More

(04) Rjs Sheet Glue Machine Paper Gluing Machine with heating

Introduction

I recently purchased the Rjs Sheet Glue Machine from COLORDOWELL for my manufacturing plant, and I am extremely satisfied with its performance. This semi-automatic gluing machine has proven to be a valuable addition to our production process, and here's why:

Versatile Application

The Rjs Sheet Glue Machine caters to a wide range of industries, making it a versatile choice for manufacturing plants, machinery repair shops, restaurants, printing shops, advertising companies, and more. Its adaptability across various sectors, including food, beverage, commodity, medical, chemical, machinery and hardware, apparel, and textiles, makes it a worthwhile investment for businesses with diverse needs.

Ease of Operation

One of the key selling points of this machine is its user-friendly interface. The easy-to-operate design simplifies the gluing process, ensuring that our team can efficiently use it without extensive training. The manual feeding feature adds an extra layer of control, allowing for precise application of glue on different materials.

Sturdy Construction

The build quality of the Rjs Sheet Glue Machine is impressive. Crafted with durability in mind, the machine boasts a robust motor as its core component, ensuring reliable and consistent performance. The machine's solid structure, weighing 65 KG, is a testament to its durability, providing stability during operation.

Adaptable Glue Type

The water-based glue used by the machine is a thoughtful choice, considering environmental concerns and safety standards. This feature aligns with our commitment to sustainable practices, making the Rjs Sheet Glue Machine an eco-friendly option.

Size and Dimensions

The compact size of the machine, with dimensions of 1060390430mm, makes it suitable for various production environments. It efficiently fits into our workspace without occupying excessive floor space.

Packaging and Delivery

The machine arrived in perfect condition, securely packaged in a wooden case. COLORDOWELL ensures that each unit is well-protected during transit, and the packaging details, including dimensions (105X52X90 cm) and gross weight (120.000 kg), reflect their commitment to delivering products in top-notch condition.

Warranty and Support

The 1-year warranty on core components, especially the motor, provides peace of mind. While we haven't encountered any issues, knowing that we have support in case of unexpected situations adds an extra layer of confidence in our purchase.

Conclusion

In conclusion, the Rjs Sheet Glue Machine from COLORDOWELL has exceeded our expectations. Its versatility, user-friendly design, and durability make it an excellent choice for businesses looking for a reliable and efficient gluing solution. I highly recommend this machine for anyone in need of a semi-automatic gluing machine with exceptional performance.

Quick Details

Applicable Industries : Machinery Repair Shops, Home Use, Retail, Printing Shops, Advertising Company

Showroom Location : None

Video outgoing-inspection : Provided

Machinery Test Report : Provided

Warranty of core components : 1 Year

Core Components : Motor

Place of Origin : Zhejiang, China

Weight : 32 KG

Warranty : 1 Year

Key Selling Points : Easy to Operate

Type : Gluing Machine

Condition : New

Application : Printing

Packaging Type : Case

Packaging Material : Wood

Automatic Grade : Semi-automatic

Driven Type : Electric

Voltage : 110V/220V

Brand Name : Befitter

Dimension(L*W*H) : 600*410*360mm

Name : Cold gluing machine for sale

Max gluing width : 380mm

Max speed : 0-26m/min

Power : 120W

Glue type : Cold glue

After Warranty Service : Video technical support

Packaging and delivery

Packaging Details : Wooden case

Selling Units : Single item

Single package size : 105X52X90 cm

Single gross weight : 120.000 kg

Buy Now & Read More

(05) A4 A3 automatic rubber machine fully automatic hot glue book Perfect glue binder book Binding machine

Introduction

In the fast-paced world of manufacturing and printing, efficiency is key. COLORDOWELL, a leading name in machinery innovation, has once again raised the bar with their A4 A3 Automatic Rubber Machine – a fully automatic hot glue book binder that promises to revolutionize bookbinding processes. Let's delve into the details of this impressive piece of equipment.

Unmatched Performance

Boasting a weight of 130 KG, the COLORDOWELL hot glue book binder is a robust machine designed for seamless operation. Its 1 Year warranty on core components, including the engine and bearing, reflects the manufacturer's confidence in the product's durability. The binding width of 320mm, binding thickness of 50mm, and a remarkable binding speed of 200 books per hour make it a standout choice for manufacturing plants, printing shops, and advertising companies.

Innovative Technology

The Automatic Grade feature ensures a hassle-free operation, making it incredibly easy to operate. With an electric-driven type and a voltage requirement of 220V, this machine aligns with modern technological standards, ensuring a smooth and reliable performance in diverse applications, from machinery and hardware to apparel.

Space-Efficient Design

Measuring at 1090mm480mm950mm, the compact design of this machine makes it ideal for various working environments. The manufacturer, COLORDOWELL, has crafted a perfect balance between functionality and space efficiency, ensuring that it seamlessly integrates into any workspace.

Quality Packaging

The attention to detail doesn't stop at the machine itself. COLORDOWELL understands the importance of secure transportation. The packaging, whether it's a carton case or wooden case, is designed to withstand the rigors of shipping, reflecting their commitment to delivering a pristine product to your doorstep.

Global Presence

With a showroom presence in Kazakhstan and Uzbekistan, COLORDOWELL has made its mark on the international stage. This signifies their commitment to providing cutting-edge machinery solutions to a global clientele.

Conclusion

In conclusion, the COLORDOWELL A4 A3 Automatic Rubber Machine is more than just a hot glue book binder; it's a testament to the future of efficient bookbinding. Whether you are running a manufacturing plant, a printing shop, or an advertising company, this machine promises to elevate your productivity to new heights. With its impressive specifications, innovative technology, and global presence, it's no surprise that COLORDOWELL stands at the forefront of the industry. Choose efficiency, choose innovation – choose COLORDOWELL.

Quick Details

Applicable Industries : Manufacturing Plant, Printing Shops, Advertising Company

Showroom Location : Kazakhstan, Uzbekistan

Video outgoing-inspection : Not Available

Machinery Test Report : Not Available

Warranty of core components : 1 Year

Core Components : Engine, Bearing

Place of Origin : Zhejiang, China

Weight : 130 KG

Warranty : 1 Year

Key Selling Points : Easy to Operate

Type : Gluing Machine

Condition : New

Application : Machinery & Hardware, APPAREL

Packaging Type : Cartons

Packaging Material : Paper

Automatic Grade : Automatic

Driven Type : Electric

Voltage : 220V

Brand Name : COLORDOWELL

Dimension(L*W*H) : 1090mm*480mm*950mm

Binding width : 320mm

Binding thickness : 50mm

Binding speed : 200 books/hour

Packaging and delivery

Packaging Details : Carton case or wooden case

Selling Units : Single item

Single package size : 115X61X103 cm

Single gross weight : 160.000 kg

Buy Now & Read More

.....................................................................................

Smeartra Amb

(Affiliated Marketing Business)

Affiliated marketer

This my blogs

Read MORE

...........................................................................................................

{Although the majority of the products are in stock, we were unable to include all of them on the website.}

Click here link and read more or buy more productsResource : Packaging Machines Buy Now & Read More

0 notes

Text

Types of Embroidery Machines and their Functions

The art of embellishing fabric or other materials with the use of thread or yarn is called embroidery. Moreover, embroidery can use other materials like sequins, beads, pearls, and quills. These days, you can see embroidery on skirts, jeans, golf shorts, caps, headgear, coats, overlays, blankets, dress shirts, and stockings. In embroidery, a vast array of colors and thread types are employed. It’s also utilized for materials for clothes and gifts. Machine embroidery is the term for the technique of creating a pattern on textile material with the use of an embroidery or sewing machine. It is mostly used for corporate advertising, uniform decoration, and product branding (logo). In the fashion sector, it’s also utilized to embellish clothing. Fanciers and craftsmen utilize machine embroidery on garments and home decor to enhance the present. Consider designing wall hangings, quilts, etc. We shall discuss all of the many kinds of embroidery machines in the below section. Additionally, there are contemporary embroidery machines. That is computer-controlled machine embroidery that has been computerized. Weavetech, being the best textile machinery manufacturer in Gujarat, delivers innovation and quality. So why look anywhere else when you can connect with us for innovation and quality.

Mechanical Embroidery Machine

There are other kinds of embroidery machines, but this is the first one that functions similarly to a household sewing machine. Here, the machine uses the needle to pierce the fabric material; the real fabric, needle, and treads are not attached. This machine pulls the stretched thread through the hole to make the embroidery design over the fabric. Additionally, this machine functions just like a standard sewing machine.

Free-motion Machine Embroidery

This kind of free-motion machine embroidery uses a regular zigzag sewing machine to create embroidered motifs. This is primarily utilized for customization, meaning that it has less automation and innovation. The machine’s feeding dog was covered, and a human manipulated the cloth by hand to create a design. The running stitch will be used to make the embroidery. Thicker lines are needed for patterns so that the machine can perform a zigzag stitch. Whatever the design created for this, it is unique and cannot be duplicated exactly. Another name for it is a free-hand sewing machine. Here, visualize the needle as a pencil and use it to create the design on the fabric by moving it in the direction you want.

Cornely Hand-guided Embroidery

Hand-guided embroidery requires one human operator to control the machine’s speed and accuracy while utilizing the artistic ability of a trained embroiderer. Special chain stitch, satin stitch, long and short stitch, cording, and applique may all be produced with this machine. Interior designers are well familiar with this hand-guided needlework. The cost of the embroidered job will vary based on design times, size, intricacy, and size. Following the creation of this machine, individuals realized that more diverse embroidery machine designs were required, which led to the introduction of computer-controlled embroidery machines.

Computer-Controlled Embroidery Machines

All contemporary embroidery machines are solely computer-controlled. The devices we observed in the previous section are sewing machines that also function as embroidery machines. However, these are exclusively meant to be embroidered. With these kinds of machines, the design is pre-programmed into the machine by the program format. The fabric is then put into the hoop, which is then fastened onto the machine. At that point, the machine automatically begins to embroider in accordance with the program. This computerized embroidery machine requires a variety of inputs.

The machine’s straightforward, independent touchscreen interface will let users adjust many parameters, including design, stitch type, stitch length, and other necessary factors. This activity does not require the hiring of professional labor because the machine generates an accurate design based on input instructions. Here, all that is required is the creation of a simple pattern in software, which must then be fed into the machine interface and turned on. The machine will then automatically begin to embroider the fabric, stopping itself if a thread breaks.

1- Single-head embroidery machine: This machine has a single embroidery head, as the name would imply. The machine’s arms move in accordance with directions, and the embroidery head remains stationary. This device will have seven to fifteen needles. operating at a speed of roughly 300–1000 stitches per minute (the machine’s manufacturer may have an impact on the number of needles and stitches per minute).

2- Multi-head embroidery machine: This machine has a single embroidery head, as the name would imply. The machine’s arms move in accordance with directions, and the embroidery head remains stationary. This device will have seven to fifteen needles. operating at a speed of roughly 300–1000 stitches per minute (the machine’s manufacturer may have an impact on the number of needles and stitches per minute).

3- Schiffli embroidery machine: These devices are used in the Schiffli product line. The fabric that requires embroidery is fed into the Schiffli machines vertically, which is a unique characteristic that is achieved entirely through the use of a device. The method of stitching will be horizontal needle entry. At the same height, every needle is positioned in a straight line and simultaneously pierces the fabric. Here, the cloth is gripped, and as it moves both horizontally and vertically, a design is eventually created on the fabric. Two textiles in total can be treated. Due to the individual handling of each needle, color shift is possible. Depending on the type of machine, 2200 needles can be inserted into fabric in a single shot.

Transform your textile operations with Weavetech, your gateway to the best textile machinery in Gujarat. Elevate your production standards and efficiency. Choose Weavetech for cutting-edge technology and unmatched quality. Seize the opportunity to enhance your textile business contact us now to weave success together.

This Blog Originally Posted Here:

https://www.weavetech.com/types-of-embroidery-machines-and-their-functions/

0 notes

Text

Industrial Uses Of Enzymes

Enzymes play an amazingly vital role in business and are essential to the assembly of a lot of industrial products. Enzymes are proteins that speed up reactions and improve yield by increasing accessible precursors for downstream reactions. Perhaps the foremost obvious use for enzymes in business is the production of cheese, bread, and alcohol. In these ancient applications the enzymes are a part of microorganism machinery like bacterium or yeast. Over time scientists are ready to isolate specific enzymes and to grasp their chemical change functions to a tolerable degree to include them with or while not their microorganism hosts into a wide variety of somewhat surprising situations. For example, enzymes are used in the production of textiles, detergents, biofuels, and pharmaceutical products. Large quantities of desired enzymes are required for these applications, and they need to be available in the purest form possible. The purity of enzymes in the industry is particularly important for pharmaceutical applications where the products, as well as the process, are susceptible to review and control by regulatory associations. Batches of enzymes in business endure regular method validation to make sure batch-to-batch consistency. There are many industrial uses of enzymes across different industries such as Detergent, Pharmaceuticals, Starch, etc.

Enzymes area unit generally isolated from microorganism, animal, or plant sources. Microbial sources are particularly useful because they can be quickly grown into large colonies and are easy to store in vats prior to isolation. The separation and purification of enzymes require multiple separation steps involving filtration, centrifugation, chromatography, and more frequently bio-magnetic separation. The ability to use bio-magnetic separation for large volumes is a relatively new development in the field. Modern bio-magnetic separation racks that provide homogeneous magnetic force throughout the working volume are a drastic improvement over traditional setups and have made it possible to scale up the technique for use with large production volumes. This in-batch consistency is also important for process validation to ensure that products are reliable and safe for consumption.

Some Examples Of Industrial Uses Of Enzymes:

Rennin for coagulation of milk to make cheese.

Invertase from yeast and lactase in the food industry.

Cellulase and amylase to remove waxes, oils, and starch coatings on fabrics and to improve the look of the final product.

Amylase and protease for baking.

Lipases in fruit juices to break down cell walls for increased yield.

Proteases, lipases, amylases, oxidases, peroxidases, and cellulases in detergents to help break down stains and chemical bonds.

Carbohydrase to convert starch into corn syrup.

Zymase to convert carbohydrates into ethanol in alcoholic beverages.

Cellulases are used to convert cellulose into glucose to improve biofuel yield.

Lipase and phospholipase are used in the production of biodiesel by converting free fatty acids to fatty acid methyl esters.

Phytases to improve agricultural feed efficiency.

Applications Of Enzymes

The biocatalysts (enzymes and cells) are used in multifarious ways in a different field. They grouped the applications into four broad categories: (i) therapeutic uses, (ii) analytical uses, (iii) manipulative uses, and (iv) industrial uses of enzymes.

Therapeutic Uses Of Enzymes

Enzymes are used for this purpose where some inborn errors of metabolism occur due to missing of an enzyme where specific genes are introduced to encode specific missing enzymes. However, in most cases, certain diseases are treated by administering the appropriate enzyme. For example, virilisation of disease developed due to loss of hydroxylase enzyme from adrenal cortex and introduction of the hydroxyl group (-OH) on 21-carbon of the ring structure of steroid hormone. Steroids are compounds having a common skeleton in the form of perhydro-1, 2-cyclo-pentano-phenanthrene. The missing enzyme synthesises aldosterone (male hormone) in excess leading to masculinization of female baby and precocious sexual activity in males in about 5-7 years.

Similarly, treatment of leukaemia (a disease in which leukemic cells require exogenous asparagine for their growth) could be done by administering asparaginase of bacterial origin.

Analytical Uses Of Enzymes

Use of enzymes for analytical purposes is also important. Generally, endpoint and kinetic analysis are possible. Endpoint analysis refers to the total conversion of substrates into products in the presence of enzymes in a few minutes while kinetic analysis involves the rate of reaction and substrate/product concentration. Moreover, the analysis of antibodies, immuneglobins, necessary for human use poses a great promise. The usable enzymes are alkaline phosphatase, b-galactosidase, b-lactamase, etc. Another use of enzyme is in biosensor, device of biologically active material displaying characteristic specificity with chemical or electronic sensor to convert a biological compound into an electronic signal. It is constructed to measure almost anything from blood glucose. A simple carbon electrode, an ion-sensitive electrode, oxygen electrode or a photocell, maybe a sensor.

Manipulative Uses Of Enzymes

A variety of enzymes isolated from different sources are nowadays applied in genetic engineering as one of the biological tools.

Industrial Uses Of Enzymes

Enzymes are used in industries in different ways.

In Dairy industry

For a long time, the dairy enzyme calf rennet has been used in the dairy industry. In recent years, calf rennets are replaced by microbial rennets (e.g. Mucor michei). They are acid aspartate proteases. They slightly differ from calf rennets as they depend for reaction with casein on Ca++, temperature, pH, etc.

Lactase (produced by Bacillus stearothermophilus) is used for hydrolysis of lactose in whey or milk, and lipase for flavour development in special cheeses.

0 notes

Link

Textile Machinery Spare Parts Manufacturer like Stenter and Jigger Machine spare parts, Cloth Guider, Textile Rotary Printing Machine Spares form India. Over Feed for Stenter Machine. In the Textile Machinery, we manufacture, export & supply Stenter Machine, Chain Link Bottom Parts, Jigger Machine, Cloth Guider, Folding Machine, Rotary Printing Machine Parts, Bowl Mangle & Drying Range, Gear Set, Spinning & Weaving Machine, Rubber Rollers, and Rubber Fillet from India. We have been successfully manufacturing, exporting & supplying all types of above Textile machinery. We always have following Spares of Spinning & Weaving Machine readily available from Stock Heald Frames and Heald Frame Accessories, Reeds, Healds and Drop Pins, Temple Cylinder and Rings, Airjet. Rubber Roller, Wrinkle Removing Rolls, Banana Roller, Bow Roll, Metal Rolls, Metal Bow Expander Roll, Industrial Rollers, Hard Chrome Plated Rolls etc. Spares for Rotary Screen Printing Machine Like Printing Unit Lifting Bevel Box, Hand Wheel, Screen drive Gear Shaft, Screen Drive gear, Fork Assembly, Muff Coupling, Eccentric Type, Bearing, Rollers MS.

#Textile Machinery Spares Manufacturer#Textile Spare parts#Textile Machinery Spare Parts#Spare Parts of Textile Machine#Stenter Machine#Over Feed for Stenter Machine#Textile Rotary Printing Machine#Spinning and Weaving Machine#Wrinkle Removing Rolls#Metal Bow Expander Roll#Industrial Rollers#Banana Roller#Textile Spare Parts Suppliers

0 notes

Link

Over Feed Part Manufacturer, Exporter and Supplier, All type of Stenter Machine Parts, Textile Machinery Spare Parts like, Stenter Clip, Pin Block, Pin Bar. We maintain a comprehensive range of Stenter part of textile machinery. Genuine Overfeed with highly efficient quality, offering high reliability and optimum results and maximum output. All type of equipment manufacturer for flexible packaging, and textile processing machines like Rubber Roller, Air Shaft, Bow Roll and many more.

#Over Feed Part#Over Feed Part Manufacturer#Stenter Machine Over Feed#Textile Machinery Spares#Textile Machinery Spares parts#Stenter Clip#Stenter Machine Clip#Stenter Pin bar#Stenter Machine Pin bar#Stenter Machine Spare#Stenter Machine Spare parts#Stenter Machine Clips#Textile Machinery Parts

0 notes

Text

My river is thirsty! Feed it with Mercy!

My river is thirsty! Feed it with Mercy!

Introduction

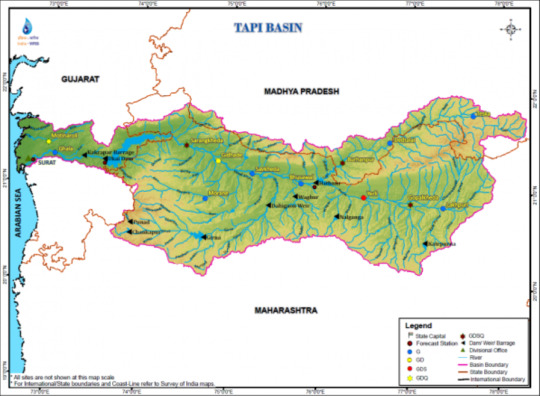

The Tapti river, more commonly known as the Tapi river is a water body that provides for all of us. This river flows from the hills of south-central Madhya Pradesh, making its way from Maharashtra, Surat Gujarat, and finally to the Gulf of Khambhat and into the Arabian sea.

Being the 2nd largest river in India, it provides water to 3 major states, Gujrat, Maharashtra, and Madhyapradesh, and is also given great importance in Hindu and Muslim religions, based on its history of it, and is also worshiped on numerous occasions, by thousands of people.

Even though, with its importance and how essential it is, the river has gone through a lot in the past decade.

The Problem

With the increased development and globalization, heavy industrialization, and increased usage of plastic, we have forgotten what has quenched our thirst over the years. More and more plastic is being dumped into the river, along with the industrial waste. The Central pollution board has also classified the Tapi-river as moderately polluted, as the water hardness, cleanliness, and overall quality have started to deplete over the past few years.

A lot of sewage has gathered in several places, near the river and its bank, and is affecting all the marine and terrestrial around it. Many times fishes are also found on the river banks, during summers and monsoon seasons, the river also occurs to be brown occasionally during the winters. Surat, Madhyapradesh, and Nasik are known for their industries in India for manufacturing and textile purposes, and the byproducts of production are also introduced to freshwater steam.

Plastic usage over the past decades has been increasing exponentially, the waste plastic which is leftover from food items, packaging materials, waste polyester, stationeries, and old parts from electronics machinery, is sometimes dumped into the riverfront or its bank. This is due to it is not easily recyclable and requiring a lot of money, so the easier option becomes to dump it into the river or the ocean. Back in the day, this wasn’t such big of an issue but over the past decade, our usage of plastic and other waste materials has increased and is starting to become a big issue and needs to be addressed quickly.

One more factor causing this problem to still exist is loose regulations and norms or people taking advantage of the government/system, for river water usage and waste management, which is why Tapi among many rivers in the world is suffering from it.

Although industrial waste and plastic are one of the largest contributors to Tapti river pollution, other miscellaneous factors are also responsible for the same, such as religious practices, fishing, boating, trade, and heavy rains are also responsible for the same.

Effect and impact on other sectors

Plastic is a material used all over the world, but only recyclable in some places, because the land has strict norms for waste and has landfills everywhere, is not presentable and also expensive, people generally resort to dumping waste into the river nearby, although other factors like loose regulation and illiteracy add to this problem and contribute equally.

Consequently, a lot of marine life and water quality depletes day by day, and at the end of the day, we as citizens have to spend more amount of money on water purification in our homes, or on a local level(in form of taxes).

Industrial waste has been a problem that has high severity, day by day our river has increased contamination and the number of minerals present inside it is increasing day by day.

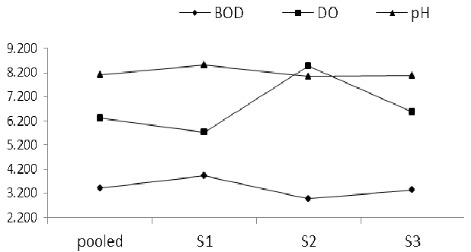

(Data from 2013)

The concentration of minerals like Ammonia, Phosphate, Potassium, and even the Ph value of water is not in the recommended range, and the maximum values of data collected are also well over the limit. While parameters like dissolved oxygen concentration in water, sodium concentration, fluoride concentration, Nitrate concentration, Nitride concentration, conductivity, alkalinity, and even temperature is lesser than of what it should be. This doesn’t allow marine life and other organisms to survive in the river. Continuation of this can also cause severe issues and damage to the ecosystem.

From physics, we know that “For every action, there is an equal and opposite reaction”, which is true in our case (at least analogically). River pollution has its impact not just on us or the marine life but on a variety of places, and sectors.

First of all, being the most obvious is us humans and marine life and the health sector, river pollution leads to several diseases, such as skin irritation and allergies, and consumption can lead to cancer, impotence, sterility in women, and other major health concerns, this is because water can be a source for pathogens, and lead to biomagnification in other organisms, if the river pollution is long term and goes unnoticed it can lead to a disaster (for example Minamata case) and have an impact on future generations, which is why it is such a large issue and globally discussed, also it has increased the average hospital occupancy by 3%.

River pollution can have an impact on the economic sector too because there is demand for freshwater from all over the world, river pollution can hamper fresh water supplies over the world, and companies like Kinley make use of water extracted from rivers located in Gujrat, Kolkata, etc… Due to high river pollution in India, some countries have banned the fresh water supply from Indian rivers.

It can also have an impact on the farming industry, this is because salty water is not good for crops, farms resort to taking their fresh water supply from rivers, and due to the water being contaminated with chemicals and plastic waste, it can affect the crops that grow, or result in an unhealthy or a low yield, often because the yield is bad/unhealthy or there is too much crop residue, farmers tend to burn it, causing air pollution, and due to this, there is a 9% growth loss in our GDP growth rate, in the past decade.

Too much pollution in the river can also cause water clogging, which can affect our local freshwater supply too.

One hot example of the impact on the economic sectors is the way SMC has used Tapi river pollution to its advantage by setting up sewage treatment plants, selling fresh water to local industries and other states, and generating a lot of revenue.

Another sector being affected by Tapi river pollution is Climate change, when evaporating processes are naturally occurring, pollution of plastic and industrial waste can lead to the mixing of toxic and greenhouse gas into the same, causing changes in rain cycle, extreme heat/cold, abnormal water levels, and extreme weather conditions, in the long run.

Sustainability issues that arise due to this

Sustainability isn't just about the environment, it also includes environmental and social aspects to it. And river pollution as highlighted above affects all three of them causing tension and issues towards sustainability.

River pollution impacts and contributes to a lot of SDGs, such as 3. Good health and well-being, 12. Responsible consumption and production, 14. Life below water, and most importantly 6. Clean water and sanitation. Because these SDGs are being affected, other SDGs also come into inclusion such as good health and well-being, industry innovation and infrastructure, and climate action.

This not only causes, a lot of people to suffer but our goals are being delayed. And it is really important to remember that “Thinking someone else will solve the problem will not help it”. The more delayed and more intense the problem gets, it will get more difficult for us to repair the damage we have done. And Inorder to become sustainable, we have to solve this issue.

Although Tapi river pollution hasn��t become very severe, we have already started facing problems like lack of clean water and sanitation and life below water, for our holy river. Continuation of these practices can lead to other issues and delay our achievement of the SDGs, moreover can impact the population both local and global.

Steps have already been taken (big and small)

Because this is not a recent problem and has been observed by local authorities and globally steps have already been taken to minimize the effect and for the betterment of our river.

→ Tapti river Bank cleanup movement: This movement has been organized by the local authorities, private NGOs, and other organizations with the help of SMC, to gather as many people as possible for the clean-up purpose of the Tapti river.

Back in 2018, efforts from SMC, under our ex-Chief minister Vijay Rupani had Organized an Rs. 941 crore cleanup plan 2018 and is still in progress, however, the importance and progress have depleted since COVID-19.

Apart from SMC and other big organizations, small NGOs, institutions, schools, colleges and many other organizations have put in efforts for our river recovery, although their contribution is very little, it has a huge impact on others.

Steps that can be taken by us!

If you are someone who can’t make a huge difference, just making small changes to your lifestyle can also help the situation, because remember, to climb a mountain you have to take small steps.

Here are some tips and tricks from my end that can help you reduce your contribution to river pollution and help reduce the damage being done.

Tip1: Note what chemicals you use: Most chemicals nowadays contain some amount of minerals such as phosphorus, arsenic, and sometimes even ammonia, which can be harmful to the water quality of the river you live nearby, so instead of using basins or toilets to drain our these chemicals you use, instead use to dustbin or drainage bags to do so.

Tip2: Use less plastic: Although it is quite hard to avoid plastic because most of the things you make use of are made of plastic, try and consume it less, resume the bottle you bought from the store, avoid plastic packaging, and try to recycle and resume what you consume.

Tip3: Don’t litter around, instead use the dustbin: Using the dustbin to throw out the trash is important because many times the thrash you throw around doesn’t end up where it is supposed to, also producing less waste can also help the cause, instead of buying from supermarkets, choose for local stores, this helps the economy and also helps the environment and reduce waste.

Tip4: Spread awareness, a lot of people nowadays have access to social media and the internet, and it is really important for people to know how severe the Tapi river conditions are, and is important for a lot of people to know and help our cause.

Tip5: Clean nearby river banks, or donate some money to do so, organizations like Rivers of the world foundation, The Nature Conservancy, or the Environmentalist Foundation of India help clean rivers and maintain their water quality, donating to these organizations or participating in the campaigns organized by them can help clean the river a lot.

Conclusion

At the end of the day, our Tapti river has suffered a lot and this needs to be changed. Join in the movement and help make a difference, make changes to your lifestyle, not for you, not for all of us, but for our river.

Citation:

"Tapi River | Tapi River Map, System, Pollution, History And Importance". NCERT Books, 2022, https://www.ncertbooks.guru/tapi-river/. Accessed 9 July 2022.

"Arabian Sea - Economic Aspects". Encyclopedia Britannica, 2022, https://www.britannica.com/place/Arabian-Sea/Economic-aspects. Accessed 9 July 2022.

"River Water Pollution In India: It’S Causes And Impact". Youth Ki Awaaz, 2018, https://www.youthkiawaaz.com/2018/11/the-rising-pollution-of-rivers-in-india-what-might-be-the-consequences/. Accessed 9 July 2022.

Intechopen.Com, 2022, https://www.intechopen.com/chapters/58138. Accessed 9 July 2022.

https://www.conserve-energy-future.com/causes-effects-of-industrial-pollution.php

News, City, and surat News. "Massive Campaign To Clean Up Tapi River Begins On May 1 | Surat News - Times Of India". The Times Of India, 2022, https://timesofindia.indiatimes.com/city/surat/massive-campaign-to-clean-up-tapi-river-begins-on-may-1/articleshow/63964494.cms. Accessed 9 July 2022.

2022. [online] Available at: [Accessed 10 July 2022].

2022. [online] Available at: [Accessed 16 July 2022].

4 notes

·

View notes

Text

Extrusion and Thermoplastics

In a thermoplastic extrusion, the material is first softened by heating so that it can be shaped. This process is performed by the extruder, or extrusion machine. This heat softening is referred to by different names, such as ‘thermal softening’, ‘plasticization’, or ‘plastication’.

Most extruders are single screw machines. The screw is what forces the material towards, and then through, the die. Shape is imparted by the die, and/or by post-extrusion forming, and the product is then set to shape by cooling while maintaining its shape. The equipment used to perform this process is known as the post extrusion equipment, while the entire system is known as an extrusion line. In addition, there are food extruder machine and feed extruder machine.

Extruder Classification

Extruders may be categorized by three figures, for instance, 1-60-24. The first number specifies the amount of screws the machine has, the second number indicates the screw diameter in millimeters (mm), and the third number indicates the effective screw length as a multiple of the screw diameter. Therefore, in the given example, a single screw machine is being described that has a screw diameter of 60 mm and a length of 24 (i.e., a L/D ratio of 24/1).

Machine Construction

Figure 1 shows a cut-away diagram of a simple single screw machine. This diagram shows the arrangement the different parts of the machine. The two units - screw and barrel - interact together to convey the plastic material, melt the material, and then push it through the die.

The screw is rotated at a predetermined speed with the electric motor drive unit and gearbox. Temperature controllers are connected to heating/cooling elements on the barrel to maintain the temperature at the set-point temperatures.

The capability of the screw and barrel assembly to extrude a given material is based on the characteristics or construction of the barrel and screw, the characteristics of the plastics material, and the circumstances under which the system is operated.

Post Extrusion Equipment

When the extrudate leaves the die, it can either be set to the desired shape or its shape can be altered and then set to shape. The equipment that performs this process is known as the ‘post extrusion equipment’ or the ‘haul off’, and in terms of size, it is generally much larger than that of the extruder. This is because plastics take a considerable amount of time to cool, and this cooling process determines the speed the line will operate.

Pet Feed Machinery

The growing demands of today’s pet food market require increasingly specialized knowledge combined with advanced processing technologies. As a longtime partner to hundreds of premium pet food producers worldwide, we provides comprehensive processing solutions and aftermarket services to keep your operations ahead of the curve. All to guarantee easy, safe, and efficient operations that can quickly adapt to the next market trend.

We offers a full range of pet feed machinery – from raw material intake to finished feed bagging – as single unit or complete plant solution. The individual process machines offered are selected from the standardized and proven range of product families.

A wide variety of food products is produced worldwide on our complete twin screw extrusion processing lines to answer increasing consumers demands : cereals, snacks, crispy breads and crackers, baby food, textured proteins and food ingredients.

At the same time, we also offer pasta machinery and couscous turn-key processing lines integrating our specific design Rotante hot air drying technology.

To enable our partners in the Food industry to gain market shares and leveradge their brands, our expert teams are continuously innovating to develop and produce high-quality food products with new flavors and taste combinations.

Pasta Production Line

Over 50 years, pasta production line has offered complete production solutions for a wide range of typical short-cut pasta shapes. Over the years, Clextral experts have continuously refined every component in the production process, building high-performance lines to customer specifications, including its exclusive VHT (Very High Temperature) drying system. Clextral short pasta extruders are particularly adapted to the modern requirements of production in terms of cost-effectiveness, flexibility, ease of use, hygiene and maintenance.

HOW IS PASTA MADE ?

The raw materials are mixed with a precise dosing mechanism to maintain constant flow and obtain homogenous dough in the pasta extruder. The pressing phase is carried out with a single screw system specially designed to ensure optimal semolina hydration, mixing, compression and extrusion. Once the dough is kneaded to the required consistency it is put through fitted dies to produce the required shapes and cut to length. Drying is achieved in two phases : first, the pre-drying Trabatto is used to crust the dough surface in order to avoid sticking. The second phase is done on Rotante drying units which include a VHT (Very High Temperature) drying system, which offers several advantages, including faster pasta producton, heightened quality of the final product (especially for pasta made with soft wheat), reduced product loss, short changeover times and very hygienic processing. After drying, the pasta is cooled and stabilized in the industrial pasta machine and then transported to storage or packaged directly.

STATE-OF-THE-ART PRODUCTION OF PASTA

Clextral pasta extruders are designed and manufactured to strict production standards ensuring:

Quality construction and superior hygienic standards – stainless steel parts, easy cleaning, low loss of raw materials, etc.

Quick and easy on-site assembly – modular pre-mounted parts

End-to-end process control – full automation to guarantee product consistency

Flexibility – quick changeover, easy shape changes and adjustment of production parameters, capacity varies from 1,500kg to 6,000kg/h

Efficient maintenance – standardized extrusion and drying parts, easy access for servicing