#PCB Design Software Market Trends

Explore tagged Tumblr posts

Text

Pcb Design Software Market Is Anticipated to Witness High Growth Owing to Growing Adoption of Advanced Electronics

Printed circuit board (PCB) design software enables engineers and designers to create schematics, perform layout planning, simulate signal integrity, and execute design rule checks for diverse electronic applications. These tools streamline the development of consumer electronics, automotive systems, aerospace hardware, and IoT devices by automating manual drafting processes, reducing design errors, and accelerating time-to-market.

Key advantages include comprehensive component libraries, real-time collaboration features, and advanced routing algorithms that enhance board density and thermal management. As product lifecycles shorten and electronic complexity rises, manufacturers increasingly rely on Pcb Design Software Market Growth solutions to achieve higher yields and lower development costs while ensuring compliance with industry standards. Moreover, integration with cloud-based platforms allows remote teams to share market insights and design data securely, supporting global expansion strategies and agile iterations. Get more insights on: Pcb Design Software Market Get This Report In Japanese Language: PCB設計ソフトウェア市場

Get This Report In Korean Language: PCB 설계 소프트웨어 시장

#Digital Transformation#PCB Design Software#PCB Design Software Market#PCB Design Software Market Insights#PCB Design Software Market Trends#Coherent Market Insights

1 note

·

View note

Text

Global PCB Design Software Market Is Estimated To Witness High Growth Owing To Increasing Demand for Advanced Electronics

A) Market Overview: PCB design software is a computer-aided design tool used to create layout designs for printed circuit boards (PCBs). These software tools offer numerous advantages such as enhanced efficiency, accuracy, and productivity in the design process. With the rapid advancements in technology and the increasing demand for advanced electronic devices in various industries, the need for PCB design software has become crucial. This software enables engineers and designers to create complex and highly functional PCB designs, ensuring proper connectivity and signal integrity. The global PCB design software market is expected to witness significant growth due to the growing adoption of advanced electronics across various industries such as automotive, aerospace, consumer electronics, healthcare, and telecommunications.

The global PCB Design Software Market Size is estimated to be valued at US$3.56 billion in 2022 and is projected to grow at a CAGR of 12.3% from 2023 to 2030, according to a market research report published by Coherent Market Insights.

B) Market Key Trends: One key trend in the PCB design software market is the adoption of cloud-based solutions. Cloud-based PCB design software offers several advantages over traditional on-premise software. It enables remote collaboration, allowing multiple stakeholders to work on the same design simultaneously. Cloud-based solutions also provide easy access to design files from anywhere and on any device, facilitating seamless workflow and faster decision-making. Moreover, cloud-based software eliminates the need for expensive hardware infrastructure, reducing costs and improving scalability. For example, Altium LLC, a key player in the PCB design software market, offers Altium 365, a cloud-based platform that enables collaborative PCB design. C) PEST Analysis: Political: The political environment plays a significant role in the growth of the PCB design software market. Government regulations and policies regarding intellectual property rights and data security can impact the adoption of PCB design software. Economic: The economic factors such as GDP growth, industrial development, and disposable income influence the demand for PCB design software. The growth of end-user industries such as automotive, aerospace, and consumer electronics drives the market. Social: The social factors such as changing consumer preferences, increased awareness about advanced electronics, and the need for innovative products drive the demand for PCB design software. Technological: Technological advancements in the field of electronics, such as the integration of IoT, AI, and 5G technology, are driving the demand for advanced PCB designs. PCB design software needs to keep up with these technological developments to meet the evolving requirements of the industry. D) Key Takeaways: - The global PCB design software market is expected to witness high growth, exhibiting a CAGR of 12.3% over the forecast period, due to increasing demand for advanced electronics. - North America is expected to dominate the PCB design software market, owing to the presence of key players, technological advancements, and early adoption of advanced electronics. - Cadence Design Systems, Inc., Altium LLC, and WestDev Ltd. are some of the key players operating in the global PCB design software market. In conclusion, the global PCB design software market is poised for significant growth in the coming years. The increasing demand for advanced electronics and the adoption of cloud-based solutions are driving factors for this market. However, political, economic, social, and technological factors will continue to influence the market dynamics. Key players in the market are focusing on innovative solutions to cater to the evolving needs of the industry.

#PCB Design Software Market#PCB Design Software Market Size#Coherent Market Insights#PCB Design Software Market Demand#PCB Design Software Market Trends#PCB Design Software Market Forecast

0 notes

Text

Global Polyurethane Foam Mattress Market Forecast (2025–2031): Growth, Trends & Strategic Insights

"

The Global Polyurethane Foam Mattress Market is projected to grow steadily from 2025 through 2031. This report offers critical insights into market dynamics, regional trends, competitive strategies, and upcoming opportunities. It's designed to guide companies, investors, and industry stakeholders in making smart, strategic decisions based on data and trend analysis.

Report Highlights:

Breakthroughs in Polyurethane Foam Mattress product innovation

The role of synthetic sourcing in transforming production models

Emphasis on cost-reduction techniques and new product applications

Market Developments:

Advancing R&D and new product pipelines in the Polyurethane Foam Mattress sector

Transition toward synthetic material use across production lines

Success stories from top players adopting cost-effective manufacturing

Featured Companies:

Tempur Sealy International

Serta Simmons Bedding

Sinomax

Sleemon

Recticel

Corsicana

MLILY

Sleep Number

Hilding Anders

Ashley

Pikolin

Derucci

King Koil

Get detailed profiles of major industry players, including their growth strategies, product updates, and competitive positioning. This section helps you stay informed on key market leaders and their direction.

Download the Full Report Today https://marketsglob.com/report/polyurethane-foam-mattress-market/1007/

Coverage by Segment:

Product Types Covered:

King Size

Queen Size

Single Size

Applications Covered:

Private Households

Hotels

Hospitals

Others

Sales Channels Covered:

Direct Channel

Distribution Channel

Regional Breakdown:

North America (United States, Canada, Mexico)

Europe (Germany, United Kingdom, France, Italy, Russia, Spain, Benelux, Poland, Austria, Portugal, Rest of Europe)

Asia-Pacific (China, Japan, Korea, India, Southeast Asia, Australia, Taiwan, Rest of Asia Pacific)

South America (Brazil, Argentina, Colombia, Chile, Peru, Venezuela, Rest of South America)

Middle East & Africa (UAE, Saudi Arabia, South Africa, Egypt, Nigeria, Rest of Middle East & Africa)

Key Insights:

Forecasts for market size, CAGR, and share through 2031

Analysis of growth potential in emerging and developed regions

Demand trends for generic vs. premium product offerings

Pricing models, company revenues, and financial outlook

Licensing deals, co-development initiatives, and strategic partnerships

This Global Polyurethane Foam Mattress Market report is a complete guide to understanding where the industry stands and how it's expected to evolve. Whether you're launching a new product or expanding into new regions, this report will support your planning with actionable insights.

" Exclusion Chromatography (SEC) HPLC Columns Cell-Site Simulators Ship Dismantling CAD/CAM Software for Sheet Metal Ship Management and Crew Management Rebar Coupler Modular Office Furniture Consumer Goods (CPG)ing Software and Platforms Energy-as-a-Service (EaaS) Glass-Melting Furnaces Vacuum Plasma Machine for Bare PCB Manufacturing Direct to Garment Printers Under Eye Gel

0 notes

Text

Reimagining Everyday Innovation: The Art of Consumer Electronics Product Design

At Avantari Technologies Pvt. Ltd., we don’t just build products—we create intelligent experiences that seamlessly integrate into people’s lives. From smart meditation wearables like the Dhyana Ring to intuitive mobile apps and IoT-enabled devices, consumer electronics product design lies at the core of what we do.

In a market flooded with devices, true innovation happens when design meets purpose. So, what does it take to design consumer electronics that are not only functional but also loved by users?

Let’s dive into Avantari’s perspective on creating future-ready electronic products.

1. Design Thinking: It All Starts with the User

Successful product design begins by asking the right questions:

Who is the user?

What problem are we solving?

How can the product make their life better?

At Avantari, we adopt a design thinking methodology to understand real user pain points. By empathizing with end-users, we’re able to conceptualize devices that feel intuitive, desirable, and impactful from day one.

2. Seamless Integration of Hardware & Software

Unlike software-only products, consumer electronics require a harmonious balance of mechanical design, embedded hardware, and intelligent software. Avantari’s in-house teams work across:

PCB design

Embedded systems

Firmware development

Mobile app integration

AI/ML algorithm tuning

This end-to-end approach ensures that the product is not only technologically sound but also optimized for usability, performance, and manufacturability.

3. Prototyping & Iteration: Fail Fast, Improve Faster

A great idea is only the beginning. We rapidly prototype physical devices and test them with real users to validate design assumptions. Feedback from early prototypes is used to improve both form and function.

From ergonomics to battery life, from material choices to haptic feedback—every element is tested, refined, and perfected.

4. Miniaturization & Aesthetic Appeal

Today’s consumers expect their devices to be compact, beautiful, and wearable. Our design philosophy merges aesthetic elegance with engineering precision, ensuring that every product delivers both style and substance.

The Dhyana Ring is a great example—designed to be light, comfortable, and durable while housing sensors, Bluetooth chips, and long-lasting batteries.

5. Future-Proofing with Smart Features

Consumer electronics are no longer just tools—they’re smart companions. We embed AI-powered analytics, Bluetooth connectivity, and cloud sync capabilities to make devices smarter, more personal, and more adaptable.

Our design process considers how users will grow with the product and how it will stay relevant in a fast-evolving tech landscape.

6. Compliance, Manufacturing & Scalability

Designing for the consumer market means ensuring regulatory compliance (CE, FCC, RoHS), as well as preparing for mass production. Avantari’s team ensures that the transition from prototype to production is smooth, cost-effective, and scalable.

We collaborate with trusted manufacturing partners and provide full support in BOM optimization, component sourcing, and quality control.

7. UX/UI: Completing the Experience

A beautiful device must also offer a seamless digital experience. Whether it’s a companion app, a device dashboard, or cloud integration, our UI/UX experts craft intuitive interfaces that match the elegance of the physical product.

Conclusion: Designing for Life, Not Just the Shelf

At Avantari, consumer electronics product design isn’t about chasing trends—it’s about shaping the future. We envision, design, and engineer devices that become a meaningful part of people’s daily lives, built on a foundation of empathy, innovation, and technological excellence.

🚀 Want to bring your product idea to life?

Let’s talk about how Avantari can turn your concept into a scalable, market-ready solution.

🔗 www.avantari.org/everyday-innovation

0 notes

Text

Compact Reflow Oven Market to Reach $343.7 Million by 2035, According to DataString Consulting

The global Compact Reflow Oven market is projected to grow significantly from $205.2 million in 2024 to $343.7 million by 2035, according to the latest research by DataString Consulting. This growth is driven by expanding applications across key industries such as electronics manufacturing, automotive component production, LED lighting, aerospace, and medical device production.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/compact-reflow-oven-market-research-report

Expanding Use in Electronics and Medical Device Manufacturing

Compact Reflow Ovens are essential tools in electronics manufacturing, known for delivering precision soldering through controlled heating and cooling processes. Their compact footprint and efficiency make them ideal for mass production of printed circuit boards (PCBs), enabling companies like Samsung and IBM to maintain high throughput and consistent quality.

In the medical device sector, the need for delicate component handling has led to the adoption of compact reflow ovens. These ovens support precise soldering for devices such as digital thermometers, glucose monitors, and implantable medical equipment. Leading firms like Medtronic and Boston Scientific rely on these ovens to uphold stringent quality standards in assembling advanced healthcare devices.

Shift Toward Energy-Efficient, Software-Driven Systems

The industry is undergoing a shift toward energy-efficient models due to increased focus on sustainability and energy consumption in manufacturing operations. This trend is driving innovations in software-integrated ovens that reduce power usage and streamline workflows. Energy efficiency is now a competitive differentiator, especially in industries focused on volume production and sustainability compliance.

Strategic Initiatives from Leading Market Players

Several prominent manufacturers are pursuing specific strategies to stay competitive in the evolving Compact Reflow Oven market:

Heller Industries is investing in highly automated reflow oven systems designed to maximize performance and precision.

Manncorp focuses on advanced thermal profiling solutions for automotive electronics and small-batch manufacturing.

BTU International is known for developing ovens that support high-volume LED production with accurate temperature control.

SMT Max delivers precision ovens for complex, high-reliability circuit board assembly, particularly for aerospace applications.

These initiatives reflect the broader industry push toward automation, miniaturization, and efficiency.

Regional Insights: North America Leads with Innovation and Industrial Adoption

North America, particularly the United States, continues to lead in terms of market share and innovation. The region benefits from a robust electronics manufacturing base and a strong pipeline of technological advancements. Compact reflow ovens are increasingly being integrated into production lines to enhance productivity, reduce errors, and support high-precision tasks.

With the growing demand for high-speed, high-accuracy electronics assembly, compact reflow ovens are becoming essential tools in North American manufacturing ecosystems. The trend toward eco-friendly and energy-saving solutions is also influencing procurement decisions.

Global Market Segmentation and Growth Opportunities

The DataString Consulting research study provides a deep-dive analysis of the Compact Reflow Oven market, segmented by:

Product Type: Infrared Reflow, Vapor Phase Reflow, Hot Air Reflow

End Users: Automotive Electronics, Aerospace Engineering, Consumer Electronics, Others

Technology: Lead-based Soldering, Lead-free Soldering

Covering over 20 countries, the study highlights regional trends, market opportunities, and technological innovation areas that will shape the industry’s future.

About DataString Consulting

DataString Consulting helps organizations formulate robust strategies, expand their Total Addressable Market (TAM), diversify revenue streams, and explore new business territories. Backed by over 30 years of combined experience, the firm provides actionable market intelligence and competitor analysis, helping businesses turn complex data into strategic advantage.

With expertise spanning 15+ industries and 60+ sub-industries, DataString Consulting delivers customized business intelligence solutions tailored for both B2B and B2C enterprises.

Explore the full report: 👉 Compact Reflow Oven Market Research Report – DataString Consulting

0 notes

Text

Innovative Hardware, Software, and Marketing Services for Business Excellence

In a rapidly changing business environment, innovation is critical to staying competitive. Companies today require robust, integrated solutions that encompass hardware, software, and digital marketing to meet evolving customer demands and achieve business excellence. At Tech4Biz Solutions, we offer end-to-end services designed to drive innovation, streamline operations, and fuel long-term growth.

Cutting-Edge Hardware Solutions

At Tech4Biz Solutions, we provide customized hardware solutions that are tailored to meet specific business needs. Whether it’s designing high-performance systems or manufacturing advanced circuit boards, our hardware solutions help businesses stay ahead.

Custom Hardware Design: We develop hardware systems that are optimized for performance and tailored to fit your business workflows.

IoT-Enabled Devices: Our IoT-enabled hardware solutions enhance real-time monitoring and connectivity, empowering businesses to make data-driven decisions.

PCBA and PCB Manufacturing: Our manufacturing services ensure high-quality, reliable, and efficient production of printed circuit boards to support your products.

VLSI Design Services: For businesses looking for advanced integrated circuit design, our VLSI services offer innovation at every stage of product development.

By investing in advanced hardware solutions, businesses can optimize processes, enhance operational efficiencies, and scale more effectively.

Next-Level Software Development Services

In today’s digital-first world, having scalable, secure, and intuitive software is vital for business growth. Tech4Biz Solutions specializes in comprehensive software development services that address the unique challenges of businesses.

Custom Software Development: We create tailored software applications to align with your specific business goals.

Cloud Infrastructure Services: Our cloud services enable businesses to scale operations, improve data accessibility, and enhance system performance.

Process Automation: We develop automation solutions to streamline repetitive tasks, reduce operational costs, and improve accuracy.

Application Modernization: Tech4Biz Solutions also helps businesses update legacy systems to more modern, efficient, and secure platforms.

With our software development services, businesses can increase agility, improve customer experiences, and unlock new opportunities for growth.

Data-Driven Digital Marketing Solutions

Building a strong online presence is essential for companies aiming for long-term business success. At Tech4Biz Solutions, our digital marketing services are designed to boost visibility, enhance engagement, and convert prospects into loyal customers.

Search Engine Optimization (SEO)

Our SEO experts optimize your website to improve search engine rankings and drive organic traffic. We employ a data-driven approach to ensure sustainable growth and increased visibility.

Social Media Marketing

We craft social media strategies that increase brand awareness, drive engagement, and foster a loyal community across platforms like Facebook, Instagram, LinkedIn, and more.

Content Marketing

Content plays a crucial role in establishing authority and building trust with potential customers. Our content marketing services help businesses tell their story and position themselves as thought leaders.

Pay-Per-Click (PPC) Campaigns

Our targeted PPC campaigns are designed to maximize conversions and deliver a high return on investment. By leveraging audience insights and market trends, we create ads that resonate with your target customers.

Email Marketing

Tech4Biz Solutions also helps businesses stay connected with their audience through email marketing. Our personalized email campaigns nurture leads and encourage repeat business.

With our marketing services, businesses can harness the power of digital channels to enhance brand awareness and drive sustained growth.

Integration for Seamless Business Operations

One of the key advantages of working with Tech4Biz Solutions is our integrated approach to hardware, software, and marketing. By aligning all aspects of your business’s digital strategy, we ensure that operations run smoothly and that data-driven decisions are made with confidence.

End-to-End Integration: We create a unified experience across hardware, software, and marketing systems.

Data Insights: Leveraging insights from multiple sources, we help businesses make informed decisions and improve customer satisfaction.

Operational Efficiency: Our solutions reduce redundancies, streamline processes, and improve the overall effectiveness of your business.

Tailored Solutions for Every Industry

At Tech4Biz Solutions, we understand that every industry has its unique set of challenges. That’s why we offer tailored solutions for businesses across sectors.

Small Businesses: For startups and small enterprises, we offer scalable solutions that help accelerate growth.

Medium Enterprises: We provide customized services to help medium-sized businesses expand their reach and improve operational efficiencies.

Large Corporations: Our enterprise-level services cater to complex business needs, driving large-scale digital transformation.

Why Choose Tech4Biz Solutions?

Choosing Tech4Biz Solutions means partnering with a company committed to delivering business excellence. Here are a few reasons why businesses trust us:

Innovation-focused: We stay on top of industry trends and emerging technologies to ensure our clients remain competitive.

Client-centric approach: We put your business goals at the forefront, ensuring that every solution we provide aligns with your vision.

End-to-End Support: From concept to implementation and beyond, we offer comprehensive support at every stage of your project.

Holistic Solutions: By offering hardware, software, and marketing services under one roof, we create seamless, integrated solutions for business success.

Empower Your Business with Tech4Biz Solutions

Tech4Biz Solutions is dedicated to helping businesses achieve excellence through innovation and collaboration. Our comprehensive range of services is designed to drive growth, optimize operations, and improve customer engagement.

Ready to take your business to the next level? Visit our website at Tech4Biz Solutions to learn more about how our innovative hardware, software, and marketing services can fuel your business growth.

0 notes

Text

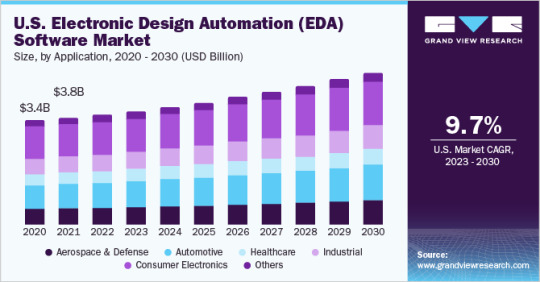

Electronic Design Automation Software Market Size And Share Report, 2030

Electronic Design Automation Software Market Growth & Trends

The global electronic design automation software market size is anticipated to reach USD 22.21 billion by 2030, expanding at a CAGR of 9.1% from 2023 to 2030, according to a new study by Grand View Research Inc. The growing usage of advanced electronic components across different areas of healthcare, automotive, and consumer electronic sectors is driving Electronic Design Automation (EDA) software market growth. Apart from this, the proliferation of the Internet of Things (IoT) and connected devices further promotes EDA software market advancement.

Miniaturization of devices and chips is expected to create lucrative opportunities for EDA software. This software assists chipmakers in lowering the errors in Integrated Circuit (IC) and chips, thereby driving the electronic design automation software industry growth. The exponential growth of the integrated circuits market is driving the need for electronic design automation software. The software is increasingly being adopted for designing electronic systems such as printed circuit boards and integrated circuits, supporting the growth of the EDA market.

Furthermore, developments in technology, growing digitization, growth of the electronics manufacturing industry, and increasing adoption of advanced rendering & simulation tools by hardware designers are expected to positively influence the electronic design automation software industry growth over the forecast period. Furthermore, the increasing acceptance and awareness of smart fitness devices are factors enabling electronic design companies to invest in innovative design software tools for designing enhanced & compact products, thereby propelling the EDA software market growth over the forecast period.

Growing demand for EDA software is encouraging various market players to adopt various business strategies to achieve higher profitability in the market for electronic design automation software. Market players are unveiling new solutions by partnering with technology providers to improve their brand identity, propelling the EDA software market growth. For instance, in January 2022, Altium LLC announced a partnership with MacroFab, Inc., a U.S.-based cloud platform provider for electronic production, to launch “Altimade.” The new solution combines elastic manufacturing capabilities and real-time supply chain data, available on the Altium 365 electronic design platform. Altimade empowers customers to request instant quotes and place orders for manufacturing their PCB assembly without exiting the design environment.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/electronic-design-automation-eda-software-market

Electronic Design Automation Software Market Report Highlights

The services segment is expected to register a CAGR of 10.6% from 2023 to 2030. The segment growth can be attributed to the increasing proclivity of OEMs to outsource their design needs. Furthermore, electronic circuit boards are in high demand in the industry due to their increasing importance in a variety of vital electronic products such as mobile phones and tablets

The cloud segment is expected to register a CAGR of 10.8% from 2023 to 2030. Cloud-based deployment allows for faster distribution, less maintenance, lower costs, and more scalability

The healthcare segment is expected to register a CAGR of 11.5% from 2023 to 2030. The segment growth can be attributed to the benefits of EDA software in healthcare, such as lower costs, improved patient outcomes, faster design & development, enabled regulatory compliance of medical devices, and simulation and testing of medical equipment

The microprocessors & controllers segment is expected to register a CAGR of 9.5% from 2023 to 2030. The increased use of microprocessors in consumer devices such as smartphones, personal computers (PCs), and laptops is expected to drive global demand for the segment

Asia Pacific is anticipated to emerge as the fastest-growing region over the forecast period at a CAGR of 9.6%. A surge in demand for electronic devices together with the prevalence of key electronic component manufacturers in Greater China is expected to drive regional growth

Electronic Design Automation Software Market Segmentation

Grand View Research has segmented the global electronic design automation software market based on product, deployment, application, end-use, and region:

Electronic Design Automation (EDA) Software Product Outlook (Revenue, USD Billion, 2018 - 2030)

Computer-aided Engineering (CAE)

IC Physical Design and Verification

Printed Circuit Board and Multi-chip Module (PCB and MCM)

Semiconductor Intellectual Property (SIP)

Services

Electronic Design Automation (EDA) Software Deployment Outlook (Revenue, USD Billion, 2018 - 2030)

Cloud

On-premise

Electronic Design Automation (EDA) Software Application Outlook (Revenue, USD Billion, 2018 - 2030)

Aerospace and Defense

Automotive

Healthcare

Industrial

Consumer Electronics

Others

Electronic Design Automation (EDA) Software End-use Outlook (Revenue, USD Billion, 2018 - 2030)

Microprocessors & Controllers

Memory Management Unit (MMU)

Others

Electronic Design Automation (EDA) Software Regional Outlook (Revenue, USD Billion, 2018 - 2030)

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

List of Key Players in the Electronic Design Automation Software Market

Advanced Micro Devices, Inc.

Aldec, Inc.

Altair Engineering Inc.

Altium LLC

Autodesk, Inc.

ANSYS, Inc.

Cadence Design Systems, Inc.

eInfochips

EMA Design Automation, Inc.

Keysight Technologies

Microsemi

Synopsys, Inc.

Silvaco, Inc.

The MathWorks, Inc.

Vennsa Technologies

Zuken

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/electronic-design-automation-eda-software-market

#Electronic Design Automation Software Market#Electronic Design Automation Software Market Size#Electronic Design Automation Software Market Share

0 notes

Text

Exploring Electronics and Communication Engineering in Hyderabad: Education, Careers, and Opportunities

Electronics and Communication Engineering (ECE) has emerged as one of the most sought-after fields of study and employment in India, and Hyderabad stands out as a premier destination for aspiring engineers. Known for its thriving IT industry, top-notch educational institutions, and innovation-driven ecosystem, Hyderabad offers an ideal environment for ECE enthusiasts to grow and excel. To explore more about ECE programs, visit HITAM’s Electronics and Communication Engineering page.

Why Choose Hyderabad for Electronics and Communication Engineering?

Hyderabad, often referred to as India’s “Cyber City,” boasts a unique blend of traditional educational values and cutting-edge technology advancements. Here are a few reasons why it is a hub for ECE aspirants:

Top-Notch Educational Institutions: Hyderabad is home to prestigious engineering colleges such as the Indian Institute of Technology Hyderabad (IIT-H), Jawaharlal Nehru Technological University Hyderabad (JNTUH), and Osmania University. These institutions offer state-of-the-art infrastructure, experienced faculty, and industry-focused curricula that equip students with theoretical and practical knowledge. HITAM is another institution that provides excellent opportunities for ECE students.

Industry Ecosystem: The city houses numerous tech parks, multinational companies, and startups in electronics, telecommunications, and software industries. Companies like Qualcomm, Intel, and TCS have a significant presence here, providing ample internship and employment opportunities.

Emerging Startup Culture: Hyderabad’s startup culture is thriving, particularly in areas like IoT, robotics, and embedded systems. This opens doors for ECE graduates to work on innovative projects and develop entrepreneurial skills.

Affordable Living: Compared to other metro cities, Hyderabad offers a relatively low cost of living, making it an attractive destination for students and young professionals.

Scope of Electronics and Communication Engineering in Hyderabad

ECE encompasses a vast array of specializations, including telecommunications, embedded systems, VLSI design, signal processing, and networking. Here are some career pathways for ECE professionals in Hyderabad:

Telecommunications: With the growing demand for 5G technology, companies like Airtel and Reliance Jio frequently hire ECE professionals for roles in network design, testing, and optimization.

Embedded Systems: Hyderabad’s IT ecosystem supports embedded technology development, offering roles in hardware and firmware design.

Software Development: ECE graduates with programming skills can find opportunities in software development, especially in companies focusing on real-time applications.

Research and Development: Hyderabad’s research institutions and private labs frequently hire ECE graduates for cutting-edge research projects.

Tips for Aspiring ECE Students and Professionals

Focus on Practical Skills: Gain hands-on experience through internships, workshops, and project-based learning. Knowledge of tools like MATLAB, LabVIEW, and PCB design software can be a significant advantage.

Keep Updated with Trends: Stay informed about industry trends such as IoT, AI, and 5G to align your skills with market demands.

Build a Strong Network: Attend tech meetups, hackathons, and seminars in Hyderabad to connect with industry professionals and peers.

Leverage Online Resources: Platforms like Coursera, edX, and Udemy offer specialized courses that can enhance your expertise in niche ECE areas.

Conclusion

Electronics and Communication Engineering in Hyderabad offers a promising blend of quality education, robust industry exposure, and dynamic career opportunities. Whether you are an aspiring student or a professional looking to advance your career, Hyderabad provides the perfect ecosystem to thrive in the field of ECE. Start exploring your options today and become a part of this ever-evolving technological revolution. Learn more about ECE programs and opportunities at HITAM’s official page.

1 note

·

View note

Text

Turn key model

Unconventional Approaches in Embedded Hardware Design: What’s Really Changing?

The field of embedded hardware design has long been seen as highly specialized, with a focus on optimizing performance, reducing power consumption, and ensuring reliability. Traditionally, engineers followed well-established patterns, adhering to industry standards for board layout, component selection, and interfacing with software. However, in recent years, unconventional approaches are emerging, driven by new technology requirements and the need for more efficient, scalable, and adaptive systems. These shifts are not only reshaping the way we think about embedded systems but also pushing embedded hardware design companies to rethink their development strategies.

Rethinking Form Factors and Materials

One of the key areas where embedded hardware is evolving is in its physical form. Conventional designs have often been constrained by the standard dimensions of printed circuit boards (PCBs) and the limitations of traditional materials. However, advances in flexible and stretchable electronics are enabling entirely new possibilities for embedded hardware design projects.

These developments involve materials such as flexible substrates, which allow circuits to bend, twist, or fold without breaking. This can be crucial for applications in wearables, medical devices, and even certain aerospace technologies, where space and adaptability are critical. With these new form factors, embedded hardware becomes more versatile, accommodating designs that fit seamlessly into the human body, vehicles, or cramped industrial environments.

For embedded hardware design services, this shift means thinking beyond the rigidity of conventional components and adapting to a world where hardware needs to conform to increasingly demanding applications.

Open Hardware Platforms: A New Path Forward

Another significant trend shaping the embedded hardware design & development process is the adoption of open-source hardware platforms. While software development has seen a surge in open-source projects, hardware has been slower to embrace this trend. However, the growing interest in platforms like Arduino, Raspberry Pi, and BeagleBone is changing that landscape.

Open hardware platforms provide pre-designed, modular systems that can be customized for specific applications. This shift is lowering the barrier to entry for startups and smaller embedded hardware design companies, which may not have the resources to develop systems from scratch. By using open hardware, developers can quickly prototype ideas, reducing time to market while ensuring flexibility.

AI and Machine Learning at the Hardware Level

Artificial intelligence (AI) and machine learning (ML) are usually discussed in the context of software, but they are starting to play a role in embedded system hardware design as well. Traditionally, embedded systems relied on predefined algorithms for data processing. But with the integration of AI, hardware is becoming more adaptive, capable of adjusting itself in real-time based on environmental conditions or operational feedback.

Edge computing is a perfect example of where this trend is having a significant impact. Instead of sending all data to the cloud for processing, embedded systems can now handle complex AI tasks locally, thanks to more intelligent hardware architectures. These architectures are optimized to run AI models efficiently, without the need for heavy computational resources.

Power Efficiency Through Energy Harvesting

Embedded systems have always been designed with power efficiency in mind, particularly for applications where changing batteries frequently isn’t practical, such as remote sensing, medical implants, or IoT devices. Traditional power optimization strategies focus on minimizing energy consumption through low-power states or more efficient algorithms.

However, energy harvesting is emerging as a game-changer for embedded hardware design. By capturing energy from ambient sources like light, heat, or motion, devices can potentially operate indefinitely without external power sources. This capability drastically reduces maintenance costs and extends the operational life of embedded systems in remote or inaccessible locations.

Energy harvesting technology is still evolving, but it holds great promise. As more embedded hardware design companies integrate this technology into their designs, it could fundamentally change the way we think about powering devices in the future.

The Rise of Custom Silicon

Custom silicon, particularly application-specific integrated circuits (ASICs), is gaining traction in the embedded hardware design & development world. Instead of relying on general-purpose processors or microcontrollers, more companies are designing custom chips tailored to their specific needs. This approach allows for greater optimization, both in terms of performance and power efficiency, as the chip is designed precisely for the intended use case.

This trend is particularly evident in high-performance applications such as cryptocurrency mining, AI acceleration, and telecommunications, where standard off-the-shelf components can’t deliver the required performance. Custom silicon can also improve security, as companies can integrate hardware-level protections directly into the chip.

Cross-Disciplinary Collaboration

As embedded systems become more complex, embedded hardware design projects are increasingly benefiting from collaboration across multiple disciplines. Mechanical engineers, material scientists, software developers, and electrical engineers are working together more closely than ever before. This interdisciplinary approach allows teams to tackle problems holistically, considering all aspects of the system, from the physical constraints of the hardware to the software that drives it.

Cross-disciplinary collaboration also opens the door to more innovative solutions, as professionals from different fields bring unique perspectives and expertise to the table. This trend will continue to drive forward the capabilities of embedded hardware design, enabling more sophisticated and integrated systems.

Conclusion,

The embedded hardware design industry is undergoing a transformation as new materials, open platforms, AI integration, energy harvesting, custom silicon, and cross-disciplinary collaboration reshape the field. These unconventional approaches are pushing the boundaries of what embedded systems can achieve, offering more efficiency, adaptability, and intelligence. For companies involved in embedded hardware design services, staying ahead means embracing these changes and rethinking traditional approaches to meet the demands of future applications.

For more information on embedded product design companies in usa subscribe to our blog. For sales queries, contact us at +1 (775) 404-5757 or email [email protected]. We are here to assist you.

0 notes

Text

0 notes

Text

Field Programmable Gate Array (FPGA) Market - Forecast(2024 - 2030)

The FPGA market was valued at USD 4.79 Billion in 2017 and is anticipated to grow at a CAGR of 8.5% during 2017 and 2023. The growing demand for advanced driver-assistance systems (ADAS), the growth of IoT and reduction in time-to-market are the key driving factors for the FPGA market. Owing to benefits such as increasing the performance, early time to market, replacing glue logic, reducing number of PCB spins, and reducing number of parts of PCB, field programmable gate arrays (FPGA’s) are being used in many CPU’s. Industrial networking, industrial motor control, industrial control applications, machine vision, video surveillance make use of different families of FPGA’s.

North America is the leading market for field programmable gate arrays with U.S. leading the charge followed by Europe. North America region is forecast to have highest growth in the next few years due to growing adoption of field programmable gate arrays.

What is Field Programmable Gate Arrays?

Field Programmable Gate Arrays (FPGAs) are semiconductor devices. The lookup table (LUT) is the basic block in every FPGA. Different FPGAs use variable sized LUTs. A lookup table is logically equivalent to a RAM with the inputs being the address select lines and can have multiple outputs in order to get two Boolean functions of the same inputs thus doubling the number of configuration bits. FPGAs can be reprogrammed to desired application or functionality requirements after manufacturing. This differentiates FPGAs from Application Specific Integrated Circuits (ASICs) although they help in ASIC designing itself, which are custom manufactured for specific design tasks.

In a single integrated circuit (IC) chip of FPGA, millions of logic gates can be incorporated. Hence, a single FPGA can replace thousands of discrete components. FPGAs are an ideal fit for many different markets due to their programmability. Ever-changing technology combined with introduction of new product portfolio is the major drivers for this industry.

Request Sample

What are the major applications for Field Programmable Gate Arrays?

FPGA applications are found in Industrial, Medical, Scientific Instruments, security systems, Video & Image Processing, Wired Communications, Wireless Communications, Aerospace and Defense, Medical Electronics, Audio, Automotive, Broadcast, Consumer Electronics, Distributed Monetary Systems, Data and Computer Centers and many more verticals.

Particularly in the fields of computer hardware emulation, integrating multiple SPLDs, voice recognition, cryptography, filtering and communication encoding, digital signal processing, bioinformatics, device controllers, software-defined radio, random logic, ASIC prototyping, medical imaging, or any other electronic processing FGPAs are implied because of their capability of being programmable according to requirement. FPGAs have gained popularity over the past decade because they are useful for a wide range of applications.

FPGAs are implied for those applications in particular where the production volume is small. For low-volume applications, the leading companies pay hardware costs per unit. The new performance dynamics and cost have extended the range of viable applications these days.

Market Research and Market Trends of Field Programmable Gate Array (FPGA) Ecosystem

FPGA As Cloud Server: IoT devices usually have limited processing power, memory size and bandwidth. The developers offer interfaces through compilers, tools, and frameworks. This creates effectiveness for the customer base and creates strong cloud products with increased efficiency which also included new machine learning techniques, Artificial Intelligence and big data analysis all in one platform. Web Service Companies are working to offer FPGAs in Elastic Compute Cloud (EC2) cloud environment.

Inquiry Before Buying

Artificial Intelligence: As an order of higher magnitude performance per Watt than commercial FPGAs and (Graphical Processing Unit) GPUs in SOC search giant offers TPUs (Google’s Tensor Processing Units). AI demands for higher performance, less time, larger computation with more power proficient for deep neural networks. Deep neural network power-up the high-end devices. Google revealed that the accelerators (FGPAs) were used for the Alpha GO systems which is a computer developed by Google DeepMind that plays the board game Go. CEA also offers an ultra-low power programmable accelerator called P-Neuro.

Photonic Networks for Hardware Accelerators: Hardware Accelerators normally need high bandwidth, low latency, and energy efficiency. The high performance computing system has critical performance which is shifted from the microprocessors to the communications infrastructure. Optical interconnects are able to address the bandwidth scalability challenges of future computing systems, by exploiting the parallel nature and capacity of wavelength division multiplexing (WDM). The multi-casted network uniquely exploits the parallelism of WDM to serve as an initial validation for architecture. Two FPGA boarded systems emulate the CPU and hardware accelerator nodes. Here FPGA transceivers implement and follow a phase-encoder header network protocol. The output of each port is individually controlled using a bitwise XNOR of port’s control signal. Optical packets are send through the network and execute switch and multicasting of two receive nodes with most reduced error

Low Power and High Data Rate FPGA: “Microsemi” FPGAs provides a non-volatile FPGA having 12.7 GB/s transceiver and lower poor consumption less than 90mW at 10 GB/s. It manufactured using a 28nm silicon-oxide-nitride-oxide-silicon nonvolatile process on standard CMOS technology. By this they address cyber security threats and deep submicron single event upsets in configuration memory on SRAM-based FPGA. These transceivers use cynical I/O gearing logic for DDR memory and LVDS. Cryptography research provides differential power analysis protection technology, an integrated physical unclonable function and 56 kilobyte of secure embedded non-volatile memory, the built-in tamper detectors parts and counter measures.

Schedule a Call

Speeds up FPGA-in-the-loop verification: HDL Verifier is used to speed up FPGA-in-the-loop (FIL) verification. Faster communication between the FPGA board and higher clock frequency is stimulated by the FIL capabilities. This would increase the complexity of signal processing, control system algorithms and vision processing. For validation of the design in the system context simulate hardware implementation on an FPGA board. HDL Verifier automates the setup and connection of MATLAB and Simulink test environments to designs running on FPGA development boards. The R2016b has been released that allows engineers to specify a custom frequency for their FPGA system clock with clock rates up to five times faster than previously possible with FIL. This improves faster run-time. From MATLAB and Simulink is an easy way to validate hardware design within the algorithm development environment

Xilinx Unveils Revolutionary Adaptable Computing Product Category: Xilinx, Inc. which is leader in FGPAs, has recently announced a new product category which is named as Adaptive Compute Acceleration Platform (ACAP) and has the capabilities far beyond of an FPGA. An ACAP is a highly integrated multi-core heterogeneous compute platform that can be changed at the hardware level to adapt to the needs of a wide range of applications and workloads. ACAP has the capability of dynamic adaption during operation which enables it to deliver higher performance per-watt levels that is unmatched by CPUs or GPUs.

Lattice Releases Next-Generation FPGA Software for Development of Broad Market Low Power Embedded Applications: Lattice Semiconductor, launched its FPGA software recently. Lattice Radiant targeted for the development of broad market low power embedded applications. Device’s application expands significantly across various market segments including mobile, consumer, industrial, and automotive due to is rich set of features and ease-of-use, Lattice Radiant software’s support for iCE40 Ultra plus FPGAs. ICE40 Ultra Plus devices are the world’s smallest FPGAs with enhanced memory and DSPs to enable always on, distributed processing. The Lattice Radiant software is available for free download.

Who are the Major Players in market?

The companies referred in the market research report include Intel Inc, Microsemi, Lattice Semiconductor, Xilinx, Atmel, Quick Logic Corp., Red Pitaya, Mercury Computer, Nallatech Inc., Achronix Semiconductor Corporation, Acromag Inc., Actel Corp., Altera Corp.

Buy Now

What is our report scope?

The report incorporates in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and its impact during the forecast period 2017-2023.

All our reports are customizable to your company needs to a certain extent, we do provide 20 free consulting hours along with purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

Key Takeaways from this Report

Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level – for product types, end use applications and by different industry verticals.

Understand the different dynamics influencing the market – key driving factors, challenges and hidden opportunities.

Get in-depth insights on your competitor performance – market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

Analyze the sales and distribution channels across key geographies to improve top-line revenues.

Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

Get a quick outlook on the market entropy – M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than top 20 countries globally for the market.

#field programmable gate array market#field programmable gate array market report#field programmable gate array market research#field programmable gate array market size#field programmable gate array market shape#field programmable gate array market forecast#field programmable gate array market analysis#Image processing#Wave form generation#Partial reconfiguration#Wired Communications#Optical Transport Network

0 notes

Text

The Role of PCB Design Services in Danbury and PCB Prototyping in Dallas, Texas

In the dynamic landscape of electronics manufacturing, the journey from concept to market ready product begins with PCB Design Services Danbury and PCB Prototype Dallas Texas. Danbury, Connecticut, and Dallas, Texas, serve as epicenters of innovation in this field, offering specialized services that bridge the gap between imagination and realization. As technological advancements continue to reshape industries, the importance of efficient and reliable PCB Design Services Danbury and PCB Prototype Dallas Texas becomes increasingly apparent.

Danbury, nestled in Fairfield County, Connecticut, boasts a thriving community of PCB Design Services Danbury renowned for their expertise and precision. Leveraging cutting-edge software and industry-leading practices, these design firms collaborate closely with clients to translate ideas into tangible circuit board layouts. From intricate multilayer designs to high-frequency applications, PCB Design Services Danbury excel in delivering solutions tailored to the unique requirements of diverse industries, including aerospace, telecommunications, and medical devices.

What sets PCB Design Services Danbury apart is their unwavering commitment to quality and innovation. By staying abreast of emerging technologies and industry trends, these firms continually push the boundaries of possibility, pioneering new techniques and methodologies to optimize PCB performance and reliability. Moreover, their collaborative approach fosters a spirit of partnership, enabling clients to actively participate in the design process and iterate upon concepts until they achieve optimal outcomes.

Meanwhile, in the bustling metropolis of Dallas, Texas, PCB Prototype Dallas Texas facilities play a pivotal role in transforming design concepts into physical prototypes ready for testing and validation. Equipped with state-of-the-art equipment and staffed by skilled technicians, these facilities offer rapid turnaround times and unmatched precision, enabling clients to accelerate product development cycles and gain a competitive edge in the market.

PCB Prototype Dallas Texas cater to a wide range of needs, from single-layer prototypes for proof-of-concept testing to complex multilayer boards for full-scale production. With a focus on efficiency and cost-effectiveness, these facilities leverage advanced manufacturing techniques such as automated assembly and surface-mount technology to streamline the prototyping process without compromising on quality or reliability.

Furthermore, Dallas's proximity to major transportation hubs and logistics networks ensures seamless integration with global supply chains, facilitating expedited delivery of prototype boards to clients worldwide. This strategic advantage positions Dallas as a preferred destination for companies seeking agile and responsive PCB Prototype Dallas Texas solutions to meet their evolving needs.

The synergy between PCB Design Services Danbury and PCB Prototype Dallas Texas facilities drives innovation and propels technological advancements across industries. By fostering collaboration, embracing emerging technologies, and prioritizing customer satisfaction, these entities play a crucial role in bringing ideas to life and ushering in a future where connectivity knows no bounds.

As the pace of technological innovation accelerates, the demand for reliable and efficient PCB Design Services Danbury and PCB Prototype Dallas Texas will only continue to grow. In

Danbury and Dallas, the legacy of excellence established by these entities ensures that they remain at the forefront of the electronics manufacturing industry, driving progress and shaping the future of technology, one circuit board at a time.

0 notes

Text

The Role of PCB Design Services in Danbury and PCB Prototyping in Dallas, Texas

In the dynamic landscape of electronics manufacturing, the journey from concept to market ready product begins with PCB Design Services Danbury and PCB Prototype Dallas Texas. Danbury, Connecticut, and Dallas, Texas, serve as epicenters of innovation in this field, offering specialized services that bridge the gap between imagination and realization. As technological advancements continue to reshape industries, the importance of efficient and reliable PCB Design Services Danbury and PCB Prototype Dallas Texas becomes increasingly apparent.

Danbury, nestled in Fairfield County, Connecticut, boasts a thriving community of PCB Design Services Danbury renowned for their expertise and precision. Leveraging cutting-edge software and industry-leading practices, these design firms collaborate closely with clients to translate ideas into tangible circuit board layouts. From intricate multilayer designs to high-frequency applications, PCB Design Services Danbury excel in delivering solutions tailored to the unique requirements of diverse industries, including aerospace, telecommunications, and medical devices.

What sets PCB Design Services Danbury apart is their unwavering commitment to quality and innovation. By staying abreast of emerging technologies and industry trends, these firms continually push the boundaries of possibility, pioneering new techniques and methodologies to optimize PCB performance and reliability. Moreover, their collaborative approach fosters a spirit of partnership, enabling clients to actively participate in the design process and iterate upon concepts until they achieve optimal outcomes.

Meanwhile, in the bustling metropolis of Dallas, Texas, PCB Prototype Dallas Texas facilities play a pivotal role in transforming design concepts into physical prototypes ready for testing and validation. Equipped with state-of-the-art equipment and staffed by skilled technicians, these facilities offer rapid turnaround times and unmatched precision, enabling clients to accelerate product development cycles and gain a competitive edge in the market.

PCB Prototype Dallas Texas cater to a wide range of needs, from single-layer prototypes for proof-of-concept testing to complex multilayer boards for full-scale production. With a focus on efficiency and cost-effectiveness, these facilities leverage advanced manufacturing techniques such as automated assembly and surface-mount technology to streamline the prototyping process without compromising on quality or reliability.

Furthermore, Dallas's proximity to major transportation hubs and logistics networks ensures seamless integration with global supply chains, facilitating expedited delivery of prototype boards to clients worldwide. This strategic advantage positions Dallas as a preferred destination for companies seeking agile and responsive PCB Prototype Dallas Texas solutions to meet their evolving needs.

The synergy between PCB Design Services Danbury and PCB Prototype Dallas Texas facilities drives innovation and propels technological advancements across industries. By fostering collaboration, embracing emerging technologies, and prioritizing customer satisfaction, these entities play a crucial role in bringing ideas to life and ushering in a future where connectivity knows no bounds.

As the pace of technological innovation accelerates, the demand for reliable and efficient PCB Design Services Danbury and PCB Prototype Dallas Texas will only continue to grow. In

Danbury and Dallas, the legacy of excellence established by these entities ensures that they remain at the forefront of the electronics manufacturing industry, driving progress and shaping the future of technology, one circuit board at a time.

0 notes

Text

Laser Cutting Machines Market Forecast and Analysis Report (2023-2032)

The global demand for laser cutting machines was valued at USD 5681.20 million in 2023 and is expected to reach USD 12338.96 million in 2032, growing at a CAGR of 9.00% between 2024 and 2032.

The laser cutting machines market is experiencing robust growth, driven by advancements in technology, increasing industrial applications, and the demand for precision cutting across various sectors. Laser cutting machines utilize a focused laser beam to cut, engrave, or mark materials with high accuracy and speed, making them indispensable in industries such as automotive, aerospace, electronics, and metalworking. The adoption of laser cutting technology is propelled by its advantages over traditional cutting methods, including superior precision, reduced material waste, lower operational costs, and the ability to cut complex shapes and patterns without the need for tool changes.

One of the key factors contributing to the market's expansion is the continuous innovation in laser technologies. Developments in fiber lasers, CO2 lasers, and solid-state lasers have enhanced the efficiency and versatility of laser cutting machines, enabling them to handle a wide range of materials, from metals and plastics to ceramics and composites. Fiber lasers, in particular, are gaining popularity due to their high power output, energy efficiency, and ability to cut reflective materials like aluminum and copper with minimal maintenance.

The automotive and aerospace industries are significant drivers of the laser cutting machines market. In the automotive sector, laser cutting is used for precision manufacturing of components, body panels, and intricate parts, ensuring high-quality finishes and reducing production time. In aerospace, the demand for lightweight and durable materials necessitates the use of laser cutting for precision fabrication of aircraft components. Additionally, the growing trend of electric vehicles (EVs) and the need for advanced battery manufacturing processes further boost the demand for laser cutting machines.

The laser cutting machines market is poised for significant growth, driven by a multitude of opportunities across various industries and technological advancements. One of the primary growth drivers is the increasing adoption of automation and Industry 4.0 technologies. As industries move towards smart manufacturing, the integration of laser cutting machines with automation systems and advanced software solutions enhances operational efficiency, precision, and productivity. This trend is particularly evident in sectors like automotive, aerospace, and electronics, where high precision and rapid production cycles are crucial.

The automotive industry presents substantial growth opportunities for laser cutting machines. With the rising demand for electric vehicles (EVs) and lightweight automotive components, manufacturers are increasingly relying on laser cutting technology to achieve precise and efficient production processes. Laser cutting is essential for the fabrication of complex components, battery modules, and lightweight materials, contributing to the overall performance and efficiency of EVs.

In the aerospace sector, the need for high-precision cutting of advanced materials such as titanium, carbon composites, and aluminum alloys drives the demand for laser cutting machines. The ability of laser cutting technology to produce intricate and precise parts with minimal material wastage is critical in this industry, where safety and performance are paramount.

The electronics industry also offers significant growth potential. As the demand for miniaturized and high-performance electronic devices continues to rise, laser cutting machines are increasingly used for the precision cutting and engraving of components such as printed circuit boards (PCBs), semiconductors, and microelectronic devices. The capability to perform fine cuts and produce intricate designs with high accuracy makes laser cutting indispensable in electronics manufacturing.

Additionally, the medical device industry is emerging as a lucrative market for laser cutting machines. The growing demand for minimally invasive surgical instruments, implants, and other medical devices necessitates precise and sterile manufacturing processes. Laser cutting technology provides the accuracy and cleanliness required for medical device production, supporting the industry's stringent quality and safety standards.

Key Players:

TRUMPF

Tanaka Holdings Co., Ltd.

Bystronic Group

Koike Aronson, Inc.

Amada Co., Ltd.

Yamazaki Mazak Corporation

Salvagnini Italia S.p.A.

Prima Power

Messer Cutting Systems

Mitsubishi Electric Corporation

More About Report- https://www.credenceresearch.com/report/laser-cutting-machines-market

The future dynamics of the laser cutting machines market are shaped by several key trends and factors that will drive its growth and evolution. One of the foremost dynamics is the continuous advancement in laser technology. Innovations such as high-power fiber lasers, ultrafast lasers, and hybrid laser systems are expected to significantly enhance the capabilities of laser cutting machines. These advancements will lead to improved cutting speeds, higher precision, and the ability to process a wider variety of materials, including those that are traditionally difficult to cut.

The integration of automation and artificial intelligence (AI) into laser cutting systems is another critical dynamic. As industries increasingly adopt Industry 4.0 practices, the demand for smart, automated laser cutting machines will rise. These machines will be equipped with AI-driven features such as real-time monitoring, predictive maintenance, and adaptive control systems, which optimize cutting processes, reduce downtime, and enhance overall productivity. The ability to integrate laser cutting machines with other automated systems and robotics will further streamline manufacturing operations.

Sustainability and energy efficiency are also becoming significant factors influencing the future of the laser cutting machines market. As environmental regulations tighten and companies strive to reduce their carbon footprints, there will be a growing demand for laser cutting machines that offer higher energy efficiency and utilize eco-friendly technologies. This trend will drive manufacturers to develop and market machines that consume less power and produce minimal waste, aligning with global sustainability goals.

The rise of additive manufacturing, or 3D printing, is another dynamic that will intersect with the laser cutting machines market. Hybrid manufacturing solutions that combine additive and subtractive processes are gaining traction. Laser cutting machines, equipped with additive manufacturing capabilities, will enable manufacturers to perform complex tasks, such as cutting, welding, and adding material, in a single machine setup. This convergence will expand the application scope of laser cutting technology and create new opportunities for manufacturers.

Customization and flexibility in manufacturing are becoming increasingly important, driven by the demand for personalized products and shorter product life cycles. Laser cutting machines offer the versatility to quickly adapt to different materials, designs, and production requirements. This flexibility will be crucial in industries such as automotive, aerospace, and consumer electronics, where rapid prototyping and small-batch production are essential.

Segmentation

By technology

CO2 Lasers

Fiber Lasers

Solid-State Lasers

Others

By Application

Metal Cutting

Non-Metal Cutting

Drilling & Micromachining

By End-User Industry

Automotive

Aerospace & Defense

Electronics & Semiconductor

Medical Devices

Construction & Architecture

Browse the full report – https://www.credenceresearch.com/report/laser-cutting-machines-market

Browse Our Blog: https://www.linkedin.com/pulse/laser-cutting-machines-market-insights-comprehensive-tnrif

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Taiwan's Tech Haven - Decoding Circuit Board Manufacturing.

Manufacturing advanced circuit boards requires precision, expertise, and cutting-edge technology. In Taiwan, a global leader in electronics manufacturing, the process is taken to a whole new level. As a hub of innovation and technology, Taiwan has become synonymous with top-notch circuit board production. Pcb-togo.com stands out as a key player in this landscape, providing insight and solutions for circuit board manufacturing that meet the highest industry standards. Let's explore into the intricate world of circuit board manufacturing in Taiwan and uncover the secrets behind this tech haven.

Taiwan's Rise to Tech Prominence

Historical Development of Taiwan's Tech Industry

A pivotal moment in Taiwan's tech industry can be traced back to the 1960s when the government prioritized investing in education and infrastructure, laying the groundwork for a future tech powerhouse. With a strong focus on engineering and innovation, Taiwan began producing its first electronic components, paving the way for the development of a robust circuit board manufacturing sector.

Policy and Government Support for Tech Growth

Government policies played a crucial role in nurturing Taiwan's tech industry. By offering incentives, subsidies, and a conducive regulatory environment, the government encouraged both local and foreign investment in the sector. This support not only fueled the growth of existing tech companies but also attracted new players to establish a presence in Taiwan, solidifying its position as a global tech hub.

Taiwan's proactive approach in providing comprehensive support for tech growth has yielded impressive results. The government's continuous efforts in fostering innovation, providing research and development grants, and promoting collaborations between academia and industry have contributed significantly to the country's tech prominence on the world stage.

Circuit Board Manufacturing in Taiwan

The Basics of Circuit Board Production

For those unfamiliar with the intricacies of circuit board production, it involves a complex process of designing, prototyping, and manufacturing intricate electronic circuits on a board made of non-conductive material. This includes printing conductive pathways, soldering components, and testing for functionality.

Pcb-togo.com's Role in the Ecosystem

An integral player in Taiwan's thriving tech ecosystem, Pcb-togo.com specializes in providing high-quality circuit boards with quick turnaround times. With a focus on customer satisfaction and cutting-edge technology, they cater to the diverse needs of businesses ranging from small startups to large corporations.

Circuit board manufacturing in Taiwan has evolved to meet the demands of the rapidly growing tech industry. With a combination of advanced technologies, skilled workforce, and efficient processes, Taiwan has solidified its reputation as a global hub for electronics manufacturing. Pcb-togo.com's commitment to quality and innovation further enhances Taiwan's position as a leader in the field.

Innovations and Advancements

Cutting-Edge Technologies and Techniques

To stay on the forefront of circuit board manufacturing, companies like Pcb-togo.com are leveraging cutting-edge technologies and techniques. From advanced computer-aided design (CAD) software to state-of-the-art automated assembly lines, these innovations are revolutionizing the industry. Not only do these advancements improve efficiency and precision, but they also allow for the production of more complex and compact circuit boards that are necessary for today's electronic devices.

How Pcb-togo.com Stays Ahead of the Competition

An integral part of Pcb-togo.com's success lies in their ability to stay ahead of the competition. By continuously investing in research and development, they are able to adopt the latest technologies and optimize their manufacturing processes. Stays abreast of market trends and customer demands, Pcb-togo.com ensures that they are always one step ahead in delivering high-quality circuit boards that meet the evolving needs of their clients.

Navigating the Market with Pcb-togo.com

Understanding the Global Supply Chain

Once again, in the competitive landscape of circuit board manufacturing, understanding the global supply chain is crucial. With Pcb-togo.com, you can navigate the intricate web of suppliers and manufacturers effortlessly, ensuring a smooth and efficient production process.

Custom Solutions and Service Excellence

On the forefront of technology, Pcb-togo.com offers custom solutions tailored to meet your specific requirements. Their commitment to service excellence guarantees a seamless experience from design to delivery, making them the go-to choice for all your circuit board needs.

This dedication to custom solutions and service excellence sets Pcb-togo.com apart from the competition. Their team of experts works closely with clients to understand their unique needs and deliver quality products on time and within budget. With a focus on innovation and customer satisfaction, Pcb-togo.com ensures that every project is a success.

Summing up

Now, after decoding the intricacies of circuit board manufacturing in Taiwan, provided by Pcb-togo.com, it is evident that Taiwan's tech industry has solidified its position as a global tech haven. The expertise, efficiency, and advanced technology showcased in the process highlights Taiwan's commitment to innovation and precision. Partnering with a reputable company like Pcb-togo.com ensures the highest quality circuit boards for a wide range of applications. As technology continues to advance, Taiwan's tech sector remains at the forefront, setting the standard for excellence in manufacturing.

Original Sources: https://themediumblog.com/taiwans-tech-haven-decoding-circuit-board-manufacturing/

0 notes

Text

B.Tech Electronics & Communication Engineering Graduates Job Outlook

The discipline of electronics and communication engineering (ECE) has enormous potential for development and innovation in today's quickly changing world. Graduates of the B.Tech in Electronics and Communication Engineering are well-prepared with the skills and knowledge required to succeed in the employment market.

The job market forecast for B.Tech. Graduates in Electronics and Communication Engineering are examined in this article, which also discusses career options, market trends, and in demand abilities.

Introduction To Electronics And Communication Engineering

Electronics and communication engineering involve studying, developing, and applying electronic devices, communication systems, and information processing methods.

Graduates with a B.Tech in ECE are highly knowledgeable in the foundational engineering concepts and have a specialised understanding of analogue and digital electronics, telecommunications, embedded systems, and signal processing.

They have the knowledge and abilities needed to build, design, and troubleshoot electronic systems.

Technologies That Are Emerging And Industry Trends

Electrical and computer engineering (ECE) has seen considerable advancements thanks to new technologies.

There is significant adoption of 5G networks, the creation of intelligent cities and IoT-enabled technology, and the use of AI and machine learning in several applications. The growth of autonomous systems and robotics is one noteworthy recent trend.

A Career In ECE Is Available To B.Tech Graduates

Graduates of the B.Tech. Programme in Electronics and Communication Engineering can choose from various jobs in both the public and private sectors. Electronics and Communication Engineering (ECE) B.Tech graduates have different professional options.

Electronics, communications, signal processing, embedded systems, and other fields are all included in the field of ECE. B.Tech graduates with ECE experience can work as follows:

1. Electronics Engineer

Designing, creating, and testing electronic systems and components are all part of this position. Circuit design, PCB layout, and troubleshooting are all tasks performed by electronics engineers. They can work in the healthcare, consumer electronics, telecommunications, and aerospace sectors.

2. Communication Engineer

Wireless networks, satellite systems, and fibre optics are a few examples of communication systems that communication engineers specialise in creating and optimising. They work on network protocols, data transmission, and signal processing. Communication engineers hold one of the top-paying jobs in ECE and can find employment prospects in research institutions, networking companies, and telecommunications companies.

3. Embedded Systems Engineer

Engineers specialising in embedded systems are highly sought after due to the rising need for smart devices and Internet of Things (IoT) applications. They create and programme embedded systems, which are computers integrated into other hardware or software. Opportunities for embedded systems engineers can be found in sectors like automotive, robotics, and home automation.

4. Network Engineer