#PCB Design Software Market Size

Explore tagged Tumblr posts

Text

Global PCB Design Software Market Is Estimated To Witness High Growth Owing To Increasing Demand for Advanced Electronics

A) Market Overview: PCB design software is a computer-aided design tool used to create layout designs for printed circuit boards (PCBs). These software tools offer numerous advantages such as enhanced efficiency, accuracy, and productivity in the design process. With the rapid advancements in technology and the increasing demand for advanced electronic devices in various industries, the need for PCB design software has become crucial. This software enables engineers and designers to create complex and highly functional PCB designs, ensuring proper connectivity and signal integrity. The global PCB design software market is expected to witness significant growth due to the growing adoption of advanced electronics across various industries such as automotive, aerospace, consumer electronics, healthcare, and telecommunications.

The global PCB Design Software Market Size is estimated to be valued at US$3.56 billion in 2022 and is projected to grow at a CAGR of 12.3% from 2023 to 2030, according to a market research report published by Coherent Market Insights.

B) Market Key Trends: One key trend in the PCB design software market is the adoption of cloud-based solutions. Cloud-based PCB design software offers several advantages over traditional on-premise software. It enables remote collaboration, allowing multiple stakeholders to work on the same design simultaneously. Cloud-based solutions also provide easy access to design files from anywhere and on any device, facilitating seamless workflow and faster decision-making. Moreover, cloud-based software eliminates the need for expensive hardware infrastructure, reducing costs and improving scalability. For example, Altium LLC, a key player in the PCB design software market, offers Altium 365, a cloud-based platform that enables collaborative PCB design. C) PEST Analysis: Political: The political environment plays a significant role in the growth of the PCB design software market. Government regulations and policies regarding intellectual property rights and data security can impact the adoption of PCB design software. Economic: The economic factors such as GDP growth, industrial development, and disposable income influence the demand for PCB design software. The growth of end-user industries such as automotive, aerospace, and consumer electronics drives the market. Social: The social factors such as changing consumer preferences, increased awareness about advanced electronics, and the need for innovative products drive the demand for PCB design software. Technological: Technological advancements in the field of electronics, such as the integration of IoT, AI, and 5G technology, are driving the demand for advanced PCB designs. PCB design software needs to keep up with these technological developments to meet the evolving requirements of the industry. D) Key Takeaways: - The global PCB design software market is expected to witness high growth, exhibiting a CAGR of 12.3% over the forecast period, due to increasing demand for advanced electronics. - North America is expected to dominate the PCB design software market, owing to the presence of key players, technological advancements, and early adoption of advanced electronics. - Cadence Design Systems, Inc., Altium LLC, and WestDev Ltd. are some of the key players operating in the global PCB design software market. In conclusion, the global PCB design software market is poised for significant growth in the coming years. The increasing demand for advanced electronics and the adoption of cloud-based solutions are driving factors for this market. However, political, economic, social, and technological factors will continue to influence the market dynamics. Key players in the market are focusing on innovative solutions to cater to the evolving needs of the industry.

#PCB Design Software Market#PCB Design Software Market Size#Coherent Market Insights#PCB Design Software Market Demand#PCB Design Software Market Trends#PCB Design Software Market Forecast

0 notes

Text

Global Polyurethane Foam Mattress Market Forecast (2025–2031): Growth, Trends & Strategic Insights

"

The Global Polyurethane Foam Mattress Market is projected to grow steadily from 2025 through 2031. This report offers critical insights into market dynamics, regional trends, competitive strategies, and upcoming opportunities. It's designed to guide companies, investors, and industry stakeholders in making smart, strategic decisions based on data and trend analysis.

Report Highlights:

Breakthroughs in Polyurethane Foam Mattress product innovation

The role of synthetic sourcing in transforming production models

Emphasis on cost-reduction techniques and new product applications

Market Developments:

Advancing R&D and new product pipelines in the Polyurethane Foam Mattress sector

Transition toward synthetic material use across production lines

Success stories from top players adopting cost-effective manufacturing

Featured Companies:

Tempur Sealy International

Serta Simmons Bedding

Sinomax

Sleemon

Recticel

Corsicana

MLILY

Sleep Number

Hilding Anders

Ashley

Pikolin

Derucci

King Koil

Get detailed profiles of major industry players, including their growth strategies, product updates, and competitive positioning. This section helps you stay informed on key market leaders and their direction.

Download the Full Report Today https://marketsglob.com/report/polyurethane-foam-mattress-market/1007/

Coverage by Segment:

Product Types Covered:

King Size

Queen Size

Single Size

Applications Covered:

Private Households

Hotels

Hospitals

Others

Sales Channels Covered:

Direct Channel

Distribution Channel

Regional Breakdown:

North America (United States, Canada, Mexico)

Europe (Germany, United Kingdom, France, Italy, Russia, Spain, Benelux, Poland, Austria, Portugal, Rest of Europe)

Asia-Pacific (China, Japan, Korea, India, Southeast Asia, Australia, Taiwan, Rest of Asia Pacific)

South America (Brazil, Argentina, Colombia, Chile, Peru, Venezuela, Rest of South America)

Middle East & Africa (UAE, Saudi Arabia, South Africa, Egypt, Nigeria, Rest of Middle East & Africa)

Key Insights:

Forecasts for market size, CAGR, and share through 2031

Analysis of growth potential in emerging and developed regions

Demand trends for generic vs. premium product offerings

Pricing models, company revenues, and financial outlook

Licensing deals, co-development initiatives, and strategic partnerships

This Global Polyurethane Foam Mattress Market report is a complete guide to understanding where the industry stands and how it's expected to evolve. Whether you're launching a new product or expanding into new regions, this report will support your planning with actionable insights.

" Exclusion Chromatography (SEC) HPLC Columns Cell-Site Simulators Ship Dismantling CAD/CAM Software for Sheet Metal Ship Management and Crew Management Rebar Coupler Modular Office Furniture Consumer Goods (CPG)ing Software and Platforms Energy-as-a-Service (EaaS) Glass-Melting Furnaces Vacuum Plasma Machine for Bare PCB Manufacturing Direct to Garment Printers Under Eye Gel

0 notes

Text

How Does Circuit Card Assembly Impact Electronics Production?

In the rapidly evolving field of electronics, Circuit Card Assembly (CCA) plays a crucial role in determining the performance, reliability, and scalability of electronic devices. Circuit Card Assembly, also known as Printed Circuit Board Assembly (PCBA), involves mounting electronic components onto a pre-designed circuit board, forming the foundation of all modern electronic products.

Enhancing Product Efficiency

Circuit Card Assembly significantly improves the efficiency and functionality of electronics. By automating the process using Surface Mount Technology (SMT) and Through-Hole Technology, manufacturers can ensure consistent and high-speed assembly with minimal human error. This streamlined process allows for mass production of devices ranging from consumer gadgets to industrial control systems, while maintaining performance integrity.

Supporting Innovation in Design

The evolution of electronics design is deeply connected to advancements in CCA. High-density assemblies allow more complex circuits to be placed in smaller form factors. This has enabled innovations in smartphones, medical devices, and IoT products. With technologies like multi-layer boards and flexible PCBs, companies can now meet unique design challenges with customized, compact solutions.

Reducing Production Costs

Efficiency in Circuit Card Assembly directly translates to cost savings. Automated machines reduce labor costs, and precise component placement minimizes material waste. Moreover, the early detection of defects through automated optical inspection (AOI) and X-ray testing helps avoid costly recalls or field failures, improving overall quality assurance.

Improving Reliability and Lifespan

One of the key impacts of CCA is enhanced product reliability. A professionally assembled circuit card undergoes rigorous testing to ensure long-term durability, even under demanding conditions. This is especially critical in industries like aerospace, automotive, and telecommunications, where component failure can have significant consequences.

Role of Guangzhou Wangerbao Software Development Co., Ltd.

Guangzhou Wangerbao Software Development Co., Ltd. is at the forefront of providing software solutions that optimize Circuit Card Assembly processes. Their intelligent software platforms integrate with production lines to manage real-time monitoring, defect tracking, and process control. By using data analytics and automation tools, Wangerbao helps manufacturers ensure precision and efficiency across the assembly lifecycle.

Wangerbao’s solutions are particularly valuable for small to medium-sized enterprises (SMEs) seeking to adopt smart manufacturing practices. Their platforms support traceability, resource planning, and predictive maintenance, which are critical to maintaining competitiveness in global electronics production.

Enabling Scalable Manufacturing

With growing demand for custom electronics and rapid prototyping, scalable CCA processes are essential. Modular assembly lines, supported by smart software from companies like Wangerbao, allow manufacturers to shift quickly from prototyping to full-scale production. This flexibility enables businesses to meet market demands faster while maintaining quality.

Conclusion

Circuit Card Assembly is a foundational element of modern electronics manufacturing, influencing everything from design innovation to production cost and product reliability. With the support of advanced software systems developed by Guangzhou Wangerbao Software Development Co., Ltd., manufacturers can optimize their processes and stay ahead in a competitive, technology-driven market. As electronics continue to evolve, so too will the role and impact of intelligent, efficient circuit card assembly.

0 notes

Text

GOOD EVENING, NAUGHTY CHILDREN. IT'S ENGINEERING STORY TIME.

Today I might have gotten someone in India written up and also gave several engineers and a program manager heart palpitations

Context: The primary program I support has 9 different circuit cards, one of which is called the Processor card. As you might imagine, it has the processor, the memory that our software is loaded on and runs from, etc. Processors, memory chips, data registers, etc. are hellishly proprietary. If I design a board to use the TX38Q processor from Semiconductors R Us, I cannot swap in something similar from MacroCircuits Inc without redesigning half the board.

In 2018, we updated the processor card to use a new Flash memory chip, because the old one was obsolete and we could not get more for love or money. The pre-2018 memory chip will be called AML, because that's the beginning of its part number and the only part of that number I can be bothered to remember. The post-2018 memory chip will be called WHE-T, because that's the end of its part number and also the only part I can be bothered to remember. Every six months or so, program leadership will request an obsolescence scrub from an engineering team based out of India. They use the documented parts list, a private database of part numbers, and several tools to determine if parts are still available on the market or if we're skating close to the edge.

Today, the program manager was suddenly up in arms because we couldn't buy more AMLs. The general response from the engineering team was "yeah, and?" but because I am thorough, I went ahead and checked to see what we were using on the current design. WHE-Ts. Cool. Pulled up a side-by-side comparison to see if we could maybe just… swap them? No. Not just no, but hell no. They're completely different sizes, both physically and in terms of memory allocation and organization. Can't be done. The software engineers would riot and the PCB designers would murder me.

But while I was checking to see whether WHE-Ts were interchangeable with AMLs, I discovered that WHE-Ts are marked as obsolete. That's funny. I don't remember them coming up in a scrub before, but I'm sure they must have and our very responsible program leadership would have done the responsible thing and ordered a butt ton of them, to tide us over on production until the next redesign. Right?

Right??

No.

Over the summer, the company that makes WHE-Ts lost the capacity to manufacture the core of the part. I don't know if there was a horrible accident at their chip manufacturer and all the dies were shattered or what, but they can't make them anymore. Industry standard for announcing end of life for a part is to give 6 months notice. August 1st, they announced that the part should be listed as End Of Life effective immediately, last purchase orders were due by September 15th, and last shipments would be completed by December 31st. The entire product line is finito.

Also over the summer, my site's obsolescence manager quit, so no one was watching the Change Notices as closely as they should have been. We missed the deadline to order more parts.

If that was the end of the story, the engineer and project manager heart palpitations would be explained, and no one in India would be getting in trouble.

In mid-January, one of the chief engineers requested an obsolescence scrub. On January 27th, someone in India said that they had talked to the manufacturer of WHE-Ts, and they'd said the part was active with no plans to obsolete it.

A part that hadn't been available anywhere, for any price, for four weeks.

So now, with zero warning and a looming contract, we get to redesign the most complex circuit card.

7 notes

·

View notes

Text

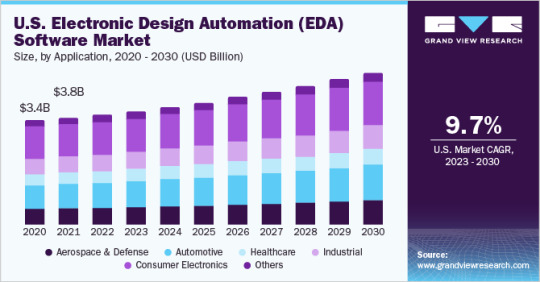

Electronic Design Automation Software Market Size And Share Report, 2030

Electronic Design Automation Software Market Growth & Trends

The global electronic design automation software market size is anticipated to reach USD 22.21 billion by 2030, expanding at a CAGR of 9.1% from 2023 to 2030, according to a new study by Grand View Research Inc. The growing usage of advanced electronic components across different areas of healthcare, automotive, and consumer electronic sectors is driving Electronic Design Automation (EDA) software market growth. Apart from this, the proliferation of the Internet of Things (IoT) and connected devices further promotes EDA software market advancement.

Miniaturization of devices and chips is expected to create lucrative opportunities for EDA software. This software assists chipmakers in lowering the errors in Integrated Circuit (IC) and chips, thereby driving the electronic design automation software industry growth. The exponential growth of the integrated circuits market is driving the need for electronic design automation software. The software is increasingly being adopted for designing electronic systems such as printed circuit boards and integrated circuits, supporting the growth of the EDA market.

Furthermore, developments in technology, growing digitization, growth of the electronics manufacturing industry, and increasing adoption of advanced rendering & simulation tools by hardware designers are expected to positively influence the electronic design automation software industry growth over the forecast period. Furthermore, the increasing acceptance and awareness of smart fitness devices are factors enabling electronic design companies to invest in innovative design software tools for designing enhanced & compact products, thereby propelling the EDA software market growth over the forecast period.

Growing demand for EDA software is encouraging various market players to adopt various business strategies to achieve higher profitability in the market for electronic design automation software. Market players are unveiling new solutions by partnering with technology providers to improve their brand identity, propelling the EDA software market growth. For instance, in January 2022, Altium LLC announced a partnership with MacroFab, Inc., a U.S.-based cloud platform provider for electronic production, to launch “Altimade.” The new solution combines elastic manufacturing capabilities and real-time supply chain data, available on the Altium 365 electronic design platform. Altimade empowers customers to request instant quotes and place orders for manufacturing their PCB assembly without exiting the design environment.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/electronic-design-automation-eda-software-market

Electronic Design Automation Software Market Report Highlights

The services segment is expected to register a CAGR of 10.6% from 2023 to 2030. The segment growth can be attributed to the increasing proclivity of OEMs to outsource their design needs. Furthermore, electronic circuit boards are in high demand in the industry due to their increasing importance in a variety of vital electronic products such as mobile phones and tablets

The cloud segment is expected to register a CAGR of 10.8% from 2023 to 2030. Cloud-based deployment allows for faster distribution, less maintenance, lower costs, and more scalability

The healthcare segment is expected to register a CAGR of 11.5% from 2023 to 2030. The segment growth can be attributed to the benefits of EDA software in healthcare, such as lower costs, improved patient outcomes, faster design & development, enabled regulatory compliance of medical devices, and simulation and testing of medical equipment

The microprocessors & controllers segment is expected to register a CAGR of 9.5% from 2023 to 2030. The increased use of microprocessors in consumer devices such as smartphones, personal computers (PCs), and laptops is expected to drive global demand for the segment

Asia Pacific is anticipated to emerge as the fastest-growing region over the forecast period at a CAGR of 9.6%. A surge in demand for electronic devices together with the prevalence of key electronic component manufacturers in Greater China is expected to drive regional growth

Electronic Design Automation Software Market Segmentation

Grand View Research has segmented the global electronic design automation software market based on product, deployment, application, end-use, and region:

Electronic Design Automation (EDA) Software Product Outlook (Revenue, USD Billion, 2018 - 2030)

Computer-aided Engineering (CAE)

IC Physical Design and Verification

Printed Circuit Board and Multi-chip Module (PCB and MCM)

Semiconductor Intellectual Property (SIP)

Services

Electronic Design Automation (EDA) Software Deployment Outlook (Revenue, USD Billion, 2018 - 2030)

Cloud

On-premise

Electronic Design Automation (EDA) Software Application Outlook (Revenue, USD Billion, 2018 - 2030)

Aerospace and Defense

Automotive

Healthcare

Industrial

Consumer Electronics

Others

Electronic Design Automation (EDA) Software End-use Outlook (Revenue, USD Billion, 2018 - 2030)

Microprocessors & Controllers

Memory Management Unit (MMU)

Others

Electronic Design Automation (EDA) Software Regional Outlook (Revenue, USD Billion, 2018 - 2030)

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

List of Key Players in the Electronic Design Automation Software Market

Advanced Micro Devices, Inc.

Aldec, Inc.

Altair Engineering Inc.

Altium LLC

Autodesk, Inc.

ANSYS, Inc.

Cadence Design Systems, Inc.

eInfochips

EMA Design Automation, Inc.

Keysight Technologies

Microsemi

Synopsys, Inc.

Silvaco, Inc.

The MathWorks, Inc.

Vennsa Technologies

Zuken

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/electronic-design-automation-eda-software-market

#Electronic Design Automation Software Market#Electronic Design Automation Software Market Size#Electronic Design Automation Software Market Share

0 notes

Text

Key Factors to Consider When Choosing an X-Ray Inspection System

X-ray inspection systems have become indispensable in industries like manufacturing, electronics, food processing, and aerospace, offering unparalleled accuracy in detecting defects and ensuring quality control. However, selecting the right X-ray inspection system can be a challenging task, given the variety of options available in the market. Choosing the wrong system can lead to inefficiencies, higher costs, and potential risks to your production process. To help you make an informed decision, this article outlines the key factors to consider when selecting an X-ray inspection system for your needs.

1. Industry-Specific Requirements

Different industries have unique demands when it comes to X-ray inspection. The system you choose should be tailored to the specific requirements of your sector.

Food Industry: Systems must detect foreign objects like metal, glass, and bone while meeting strict regulatory standards.

Electronics: High-resolution systems are essential for inspecting solder joints, PCBs, and micro-components.

Aerospace and Automotive: Systems need to detect internal cracks or voids in critical components to ensure safety.

Understanding your industry’s specific requirements will help you narrow down options and select the most suitable system.

2. Inspection Resolution and Sensitivity

The resolution and sensitivity of an X-ray inspection system determine its ability to detect small or subtle defects. High-resolution systems are crucial for industries like electronics and aerospace, where even minute defects can have significant consequences.

Key Considerations:

Check the resolution of the detector and the size of defects the system can identify.

Ensure the system provides consistent sensitivity across varying materials and densities.

Higher resolution often comes with a higher price tag, so balance your needs with your budget.

3. System Throughput and Speed

For industries with high production volumes, the speed and throughput of the X-ray system are critical. A slower system can create bottlenecks, impacting overall efficiency.

Key Considerations:

Evaluate the inspection speed and whether it aligns with your production line’s output.

Check if the system can handle batch or continuous inspections without compromising accuracy.

Some systems are designed for high-speed applications, making them ideal for industries like food processing and packaging.

4. Ease of Integration and Scalability

The X-ray inspection system should integrate seamlessly into your existing production line or workflow. Additionally, it should offer scalability to accommodate future growth or changes in production demands.

Key Considerations:

Ensure the system supports easy integration with current conveyor belts, robotic arms, or other automated systems.

Look for modular designs that allow upgrades or expansion without replacing the entire system.

Seamless integration reduces downtime and ensures smooth operations.

5. Software Capabilities

Modern X-ray systems are equipped with advanced software for analysis, reporting, and automation. The right software can enhance functionality and usability.

Key Features to Look For:

User-friendly interface and intuitive controls.

Automated defect detection using AI or machine learning.

Real-time monitoring and data analysis capabilities.

Compatibility with your existing quality management systems.

Advanced software can significantly reduce human error and improve inspection accuracy.

6. Regulatory Compliance

In industries like food and pharmaceuticals, compliance with regulatory standards is non-negotiable. The X-ray system you choose must meet these standards.

Key Considerations:

Verify that the system adheres to industry-specific regulations such as FDA, HACCP, or ISO certifications.

Ensure it has features like contaminant detection or radiation shielding to meet safety requirements.

Compliance ensures smooth audits and avoids potential legal issues.

7. Maintenance and Support

An X-ray inspection system is a long-term investment that requires regular maintenance and support to perform optimally.

Key Considerations:

Evaluate the manufacturer’s service offerings, including maintenance contracts and warranty terms.

Check for the availability of spare parts and the ease of replacing them.

Ensure the system comes with robust technical support and training resources.

Reliable maintenance and support minimize downtime and extend the system’s lifespan.

8. Cost and Return on Investment (ROI)

While cost is a significant factor, it’s essential to assess the value the system brings to your operations rather than focusing solely on the initial price.

Key Considerations:

Compare the system’s cost with the benefits it offers, such as improved accuracy, reduced waste, and enhanced quality control.

Calculate the potential ROI by factoring in productivity gains, reduced defect rates, and customer satisfaction.

Investing in a high-quality system may involve higher upfront costs but can lead to substantial savings over time.

9. Radiation Safety

X-ray systems emit radiation, which can pose risks if not properly contained. Ensuring the system meets safety standards is vital for protecting operators and complying with regulations.

Key Considerations:

Check for shielding features that minimize radiation exposure.

Ensure the system complies with radiation safety standards such as ANSI or CE certifications.

Proper safety measures create a secure working environment and build trust with employees.

Conclusion

Choosing the right X-ray inspection system is critical for ensuring the efficiency and safety of your production processes. By considering factors such as industry requirements, resolution, throughput, integration, software capabilities, compliance, and cost, you can make an informed decision that aligns with your business needs. Investing in the right system not only improves product quality but also enhances your brand reputation and operational efficiency. Take the time to evaluate your options, and you’ll find an X-ray inspection system that delivers long-term value.

0 notes

Text

0 notes

Text

SINAMICS V90: Future-Proofing Your Automation System

Automation systems are central to achieving heightened efficiency, precision, and scalability across various sectors. However, as important as these systems are, they face significant challenges—complex installation processes, integration issues with existing technologies, and a constant need for upgrades to handle evolving industrial demands.

A good example of this technological breakthrough is the Siemens SINAMICS V90 servo drive system, which provides a reliable solution suited to modern industrial requirements. This article explores how the SINAMICS V90 not only enhances current operational capabilities but also ensures businesses are equipped for future challenges, setting a new standard in automation excellence.

What is SINAMICS V90?

The SINAMICS V90 is a highly optimized servo drive system designed to meet the versatile demands of motion control applications. This system, comprising the Siemens V90 servo drive and the SIMOTICS S-1FL6 servo motor, is engineered for a wide range of applications, making it a cost-effective solution that enhances the competitive edge of businesses by reducing time-to-market.

Performance: With features like a 1 MHz pulse train setpoint and 20-bit encoder resolution, the system achieves high positioning accuracy, essential for precision-driven processes. The drive and motor offer a 300% overload capacity, which, along with fast acceleration and braking capabilities, significantly boosts productivity.

Design: The robust design of the Siemens V90 includes PCB coating and high-quality bearings, enhancing the system's reliability even in harsh environmental conditions. Integrated safety functions like STO (Safe Torque Off) provide additional security, preventing unexpected motor movement and ensuring the safety of both machinery and operators.

Ease of Use: Commissioning the SINAMICS V90 is straightforward, thanks to the SINAMICS V-Assistant, a standalone graphic configuration software that simplifies setting parameters, jogging, troubleshooting, and monitoring. This user-friendly approach ensures quick setup and minimal downtime.

SINAMICS V90 Servo Drive Capabilities

The V90 servo drive system, designed for optimal performance and easy operation, includes a range of features tailored for efficient automation. Below is a table highlighting key attributes and capabilities of the system:

Feature

Description

Power Range

0.05 to 7.0 kW, accommodating both single and three-phase networks.

Motor Compatibility

Specifically paired with SIMOTICS S-1FL6 servo motors for enhanced performance.

Communication Interfaces

Multiple options including PTI, PROFINET, USS, or Modbus RTU for versatile integration.

Drive Sizes

Available in eight converter frame sizes and seven motor shaft heights to suit various applications.

Cooling

Designed to operate without external cooling; heat dissipation through the motor surface.

Installation

Features quick-release connectors for fast and straightforward installation.

Overload Capability

Capable of handling a threefold overload, ensuring robust operation under demanding conditions.

Commissioning

Plug-and-play setup with minimal configuration needed for quick commissioning.

Control Compatibility

Integrates seamlessly with Siemens SIMATIC PLC control systems for streamlined automation.

Application Across Industries

The Siemens V90 is suitable for diverse applications such as pick & place, labeling, horizontal packaging, and printing. Its ability to manage both simple and complex motion control tasks makes it a preferred choice for industries looking for a reliable and efficient automation solution.

Coupled with the SIMOTICS S-1FL6 servo motor, the V90 servo drive system showcases its flexibility and efficiency across a broad spectrum of industries.

Manufacturing and Production Control In the manufacturing sector, the Siemens V90 drive system is frequently utilized for precise position and speed control, essential for assembly lines and automated production processes. The integration with SIMATIC S7-1200 and S7-1500 PLCs via PROFINET enhances its functionality, allowing for seamless communication and synchronization of complex manufacturing operations.

Packaging and Assembly: For industries focused on packaging and assembly, the SINAMICS V90 motor provides reliable solutions for conveyor systems and automated assembly lines. The drive's ability to perform with high dynamic responses ensures that operations are not only fast but also accurate, which is crucial for maintaining throughput and reducing downtime.

Robotics and CNC Machines: The adaptability of the V90 extends to robotics and computer numerical control (CNC) machining. Here, the drive system excels in applications requiring complex motion sequences and high precision, such as in robotic arm positioning and CNC machining centers.

Material Handling: The v90 also finds its application in material handling systems, where smooth and controlled motion is necessary. Its robust design supports the demands of applications like cranes and lifting equipment, providing the necessary control to handle materials safely and efficiently.

Textile and Woodworking: These industries require precise control for processes like weaving, cutting, and engraving. The V90's ability to handle complex motion sequences makes it a valuable asset, improving productivity and product quality.

Benefits of the SINAMICS V90

The SINAMICS V90 servo drive system, integral to Siemens' SINAMICS product line, delivers notable advantages across a range of industrial applications. Here are some key benefits detailed through real-world use cases and statistical data:

Energy Efficiency and Cost Savings: The Siemens v90 motor is designed to optimize energy use, particularly in applications like pumps, fans, and compressors. By transitioning from mechanical control systems to variable-speed drives, the V90 significantly reduces power consumption, especially under partial load conditions. This shift can result in up to 70% savings on energy costs, making a substantial economic impact for businesses focused on sustainability and efficiency.

Scalability and Flexibility: With a broad spectrum of power ratings (0.05 to 7.0 kW) and the ability to operate across single and three-phase networks, the Siemens V90 offers remarkable scalability. This flexibility is further enhanced by its compatibility with various communication interfaces such as PTI, PROFINET, USS, and Modbus RTU, allowing seamless integration into existing automation systems.

Operational Efficiency: The SINAMICS V90 system is known for its quick commissioning features and high reliability, which significantly reduce downtime and maintenance costs. The drive system is not only easy to install but also ensures continuous, trouble-free operation across diverse environmental conditions.

Diverse Industrial Applications: From manufacturing and robotics to packaging and material handling, the Siemens V90 motor proves its versatility. For example, in manufacturing, it facilitates precise control over machinery, enhancing product quality and production rates. In material handling, it provides the necessary control to manage operations smoothly and safely.

Integration in Automation Systems: As part of Siemens' Totally Integrated Automation (TIA) philosophy, the v90 drive system works cohesively within a larger automation framework. This integration capability allows for centralized control and management of various drive tasks, streamlining operations and reducing complexity.

Conclusion: Your Next Steps with Naksh Technology

Naksh Technology Solutions LLP is committed to driving innovation and efficiency in automation through the SINAMICS V90 and its comprehensive suite of automation solutions. As industries evolve, partnering with a leader like Naksh ensures that your automation systems are not only up to date but also future-proof. For more information or to schedule a consultation, explore our website and discover how we can make a significant impact on your operational success.

0 notes

Text

0 notes

Text

How to Choose the Best PCB Design Tool for Your Project

Printed Circuit Board (PCB) design tools are crucial for electronic engineers and designers. They facilitate the creation, modification, and validation of circuit boards, making the design process efficient and error-free. However, selecting the right PCB design tools is challenging, given the wide variety of options available in the market. This article will guide you through the factors to consider when choosing the best PCB design tool for your project, ensuring you make an informed decision that meets your needs. Choosing The Best PCB Design Tool for Your Project Understand Your Project Requirements The first step in selecting a PCB design tool is to evaluate the specific needs of your project. Not all tools offer the same features, so understanding your project's demands is crucial. - Complexity: Is your design simple with a single-layer PCB, or does it involve multiple layers with complex circuits? - Type of Components: Are you working with analogue, digital, or mixed-signal designs? Some tools specialize in one or the other. - Size of the Project: How many components are involved, and how large will your PCB be? If you are working on large-scale projects, you’ll need software that supports complex designs. Ease of Use The learning curve of PCB design software can vary significantly. If you are a beginner, look for user-friendly tools with intuitive interfaces. On the other hand, if you are an experienced engineer, more advanced features might be a priority, even if they come with a steeper learning curve. - Interface Design: A well-designed interface with easy-to-navigate menus, drag-and-drop functionality, and visual aids like real-time 3D previews can significantly improve your workflow. - Tutorials and Documentation: Ensure that the software you choose offers comprehensive tutorials, user guides, and forums to help you understand the tool’s functionality. This is particularly important if you are new to PCB design. Key Features to Look For Modern PCB design tools come with a variety of features. Here's what you should prioritize: - Schematic Capture: A good PCB design tool should have an efficient schematic capture feature, allowing you to create and modify circuit diagrams before starting the actual PCB layout. - Layout Editor: Look for software that includes a powerful layout editor. Features like routing automation, design rule checking (DRC), and constraint management are essential. - Component Library: An extensive, customizable component library is vital for streamlining the design process. Some tools allow you to import new components, saving time and effort. - 3D Visualization: Many modern PCB design tools offer 3D views of your design, enabling you to inspect the layout from different angles and catch potential errors early in the process. - DRC and ERC (Electrical Rule Check): Design Rule Checking ensures that your PCB adheres to manufacturing requirements, while Electrical Rule Checking ensures that your circuits are functional and error-free. Both features are must-haves for any severe PCB designer. - Auto-Routing: This feature automatically connects all your components based on the schematic. While manual routing offers more control, auto-routing can save significant time on less critical areas of the design. Compatibility and Integration When selecting a PCB design tool, consider how well it integrates with other software and hardware you are using: - File Format Compatibility: Ensure the software supports standard formats like Gerber, DXF, or ODB++. This ensures that you can easily export and share your designs with manufacturers. - Integration with Simulation Tools: If you are working with circuit simulations (e.g., SPICE), check if the design tool supports simulation integration. This allows you to simulate the behaviour of your circuits before committing to a final design. - Collaboration Features: If your project involves teamwork, look for tools that offer collaboration features, such as version control, shared libraries, and cloud-based storage. Cost and Licensing Options Budget is another critical factor to consider when choosing a PCB design tool. Both free and paid options are available, and the cost typically reflects the functionality and complexity of the tool. - Free Tools: If you're working on a small project or learning PCB design, free tools like KiCAD, EasyEDA, and Fritzing may be sufficient. However, these may lack advanced features like multi-layer design, auto-routing, and extensive component libraries. - Paid Tools: For professional projects, consider investing in paid software like Altium Designer, OrCAD, or Eagle. While these tools come with higher price tags, they offer advanced features, better support, and regular updates. - Subscription vs. One-Time Purchase: Some PCB design tools operate on a subscription model, while others require a one-time purchase. Evaluate which model makes sense for your project and your long-term needs. Platform Compatibility Ensure that the software you choose is compatible with your operating system. Most PCB design tools are compatible with Windows, but not all support macOS or Linux. Check if the software has a web-based version, which could offer cross-platform flexibility without installation. Community and Support Access to an active user community and technical support can make a significant difference, especially when facing a complex design problem. - User Forums and Online Communities: Active forums or user groups can be a goldmine for troubleshooting, sharing design tips, and exploring advanced features. - Technical Support: Look for software providers that offer robust customer support, including live chat, email support, or even personalized training sessions. This is particularly important for professional projects where deadlines matter. Manufacturer Compatibility Before finalizing a PCB design tool, consider the manufacturer's compatibility. Some PCB design tools have built-in integrations with specific manufacturers, allowing you to upload your designs for prototyping and production directly. This feature can save you time and reduce the chances of errors during manufacturing. Future Scalability While your current project may be small or mid-sized, it's worth considering whether your chosen tool can scale with your future needs. If you plan to work on more complex, high-layer, or multi-board designs, you’ll want software that can handle the additional complexity without requiring you to switch platforms. Top PCB Design Tools to Consider Here’s a quick overview of some of the top PCB design tools based on the factors discussed above: - Altium Designer - Best For Professionals working on complex, multi-layer designs. - Key Features: Advanced schematic capture, PCB layout, 3D visualization, and collaboration features. - Price: Paid, premium option. - Eagle (by Autodesk) - Best For Small to medium-sized projects with a focus on flexibility. - Key Features: Schematic editor, auto-routing, comprehensive component library. - Price: A free version is available, but paid plans offer more features. - KiCAD - Best For: Open-source enthusiasts or those working on small projects. - Key Features: Multi-layer design, extensive component libraries, schematic capture. - Price: Free. - OrCAD - Best For: Large, enterprise-level projects. - Key Features: Advanced simulation, schematic capture, high-speed PCB design. - Price: Paid, with a focus on enterprise users. - EasyEDA - Best For: Beginners and hobbyists. - Key Features: Web-based tool with integrated PCB manufacturing options. - Price: Free with paid manufacturing options. Conclusion Choosing the best PCB design tool for your project depends on several factors, including complexity, ease of use, features, and budget. By carefully evaluating your requirements and the features of available tools, you can find the one that best fits your needs and ensures a smooth and efficient design process. Whether you’re a hobbyist or a professional, the right PCB design software will significantly affect your workflow and the quality of your final product. Read the full article

0 notes

Text

Today’s world is moving rapidly towards Industry 4.0, which requires a strong collaboration of electronics, software, and manufacturing. PCBs are the game changer in this aspect. As per market forecast, the PCB market will grow from 86.76 billion USD in 2024 to 152.46 billion USD by 2033, marking a CAGR of 5.8% [1]. By reducing the manufacturing cost, you can be more market competitive. This blog will discuss the specifics of cost-effective PCB assembly, which will help you make wise decisions. Knowing PCB Assembly Costs

Let’s understand the factors that affect PCB assembly costs. Below are some important considerations:

Board complexity and design: The cost of your PCB can be determined by the number of layer counts. Though they cost more than simpler, single-layer, or double-layer boards, multilayer boards give more design freedom. The board size is also equally important. Larger boards are capable of handling more components, which can translate to more material and fabrication expenses. Furthermore, higher component density and complicated circuit designs will increase assembly time and drive up costs. Types of Components Used: Through-hole technology calls for human or semi-automated assembly of components, which costs more than surface-mount technology (SMT). In SMT, automation is used to assemble components at a fast pace. Often requiring specialist handling, ball grid arrays (BGAs) and other sophisticated components increase the assembly cost. Technology Used in Assemblies: Your board design and component type will determine which type of technology, among SMT, through-hole, or mixed assembly approaches, is to be used. Every technique has financial implications; however, working with a reputed and experienced PCB assembly company can help you choose the most affordable solution for your requirements. Order Quantity: PCB assembly works through economies of scale. Usually, you can negotiate better in case of higher volume orders and reduce per-unit costs. Lead time constraints: Tighter deadlines and expedited assembly result in extra costs. To mitigate the short project schedule, you need to buy components at a higher price and modify the manufacturing schedule. Optimizing Profit and Cost Knowing the cost drivers now will help you investigate ways to simplify your PCB manufacturing process and maintain control of expenses: Design for Manufacturability (DFM): Incorporate DFM ideas from the very beginning. It helps reduce the number of layers as much as possible, using standard parts and ensuring that the spacing between parts is right for automated placement.

Strategic Component Selection: Whenever possible, standardize component packages to simplify the assembly. Look at easily available, reasonably priced components that meet your PCB performance needs. Leverage Technology: Most advanced PCB assembly companies use modern automated inspection systems to guarantee quality and eliminate human error. This increases efficiency as well as the quality of products, which helps to save money. Strong Communication and Collaboration: Always keep the lines of communication open with your PCB assembly partner. Communicate your design objectives and financial limitations at the outset. You can benefit from their knowledge and insight as they point out ways to cut costs and propose new strategies. PCB Power is one of the leading PCB assembly companies, with strong knowledge and commitment. For any type of assistance, you can always approach our experts. Do Market Analysis Do in-depth market analysis on component pricing and assembly cost and ask for estimates from several reliable PCB manufacturers. This lets you evaluate pricing schemes and, depending on cost, capacity, and lead times, determine which best fits your project. Smart Tips: Consider prototyping: Invest in low-volume prototypes to validate your idea before deciding on a high-volume manufacturing run. Long-term partnerships: Strong relationships with a trustworthy PCB assembly partner can be quite advantageous over the long run. Final Thoughts: Increasing selling costs is not the right approach to making profits. You must think of reducing production costs and avoid rework and rejections. These strategic techniques can help you reduce PCB assembly expenses and improve general project efficiency. To learn more about the efficient PCB assembly process and other insights, connect with PCB Power. Email us at [email protected] or call us at +1(818) 886 8900.

Read More:- The Definitive Guide to Reducing PCB Assembly Costs and Enhancing Efficiency

0 notes

Text

0 notes

Text

Field Programmable Gate Array (FPGA) Market - Forecast(2024 - 2030)

The FPGA market was valued at USD 4.79 Billion in 2017 and is anticipated to grow at a CAGR of 8.5% during 2017 and 2023. The growing demand for advanced driver-assistance systems (ADAS), the growth of IoT and reduction in time-to-market are the key driving factors for the FPGA market. Owing to benefits such as increasing the performance, early time to market, replacing glue logic, reducing number of PCB spins, and reducing number of parts of PCB, field programmable gate arrays (FPGA’s) are being used in many CPU’s. Industrial networking, industrial motor control, industrial control applications, machine vision, video surveillance make use of different families of FPGA’s.

North America is the leading market for field programmable gate arrays with U.S. leading the charge followed by Europe. North America region is forecast to have highest growth in the next few years due to growing adoption of field programmable gate arrays.

What is Field Programmable Gate Arrays?

Field Programmable Gate Arrays (FPGAs) are semiconductor devices. The lookup table (LUT) is the basic block in every FPGA. Different FPGAs use variable sized LUTs. A lookup table is logically equivalent to a RAM with the inputs being the address select lines and can have multiple outputs in order to get two Boolean functions of the same inputs thus doubling the number of configuration bits. FPGAs can be reprogrammed to desired application or functionality requirements after manufacturing. This differentiates FPGAs from Application Specific Integrated Circuits (ASICs) although they help in ASIC designing itself, which are custom manufactured for specific design tasks.

In a single integrated circuit (IC) chip of FPGA, millions of logic gates can be incorporated. Hence, a single FPGA can replace thousands of discrete components. FPGAs are an ideal fit for many different markets due to their programmability. Ever-changing technology combined with introduction of new product portfolio is the major drivers for this industry.

Request Sample

What are the major applications for Field Programmable Gate Arrays?

FPGA applications are found in Industrial, Medical, Scientific Instruments, security systems, Video & Image Processing, Wired Communications, Wireless Communications, Aerospace and Defense, Medical Electronics, Audio, Automotive, Broadcast, Consumer Electronics, Distributed Monetary Systems, Data and Computer Centers and many more verticals.

Particularly in the fields of computer hardware emulation, integrating multiple SPLDs, voice recognition, cryptography, filtering and communication encoding, digital signal processing, bioinformatics, device controllers, software-defined radio, random logic, ASIC prototyping, medical imaging, or any other electronic processing FGPAs are implied because of their capability of being programmable according to requirement. FPGAs have gained popularity over the past decade because they are useful for a wide range of applications.

FPGAs are implied for those applications in particular where the production volume is small. For low-volume applications, the leading companies pay hardware costs per unit. The new performance dynamics and cost have extended the range of viable applications these days.

Market Research and Market Trends of Field Programmable Gate Array (FPGA) Ecosystem

FPGA As Cloud Server: IoT devices usually have limited processing power, memory size and bandwidth. The developers offer interfaces through compilers, tools, and frameworks. This creates effectiveness for the customer base and creates strong cloud products with increased efficiency which also included new machine learning techniques, Artificial Intelligence and big data analysis all in one platform. Web Service Companies are working to offer FPGAs in Elastic Compute Cloud (EC2) cloud environment.

Inquiry Before Buying

Artificial Intelligence: As an order of higher magnitude performance per Watt than commercial FPGAs and (Graphical Processing Unit) GPUs in SOC search giant offers TPUs (Google’s Tensor Processing Units). AI demands for higher performance, less time, larger computation with more power proficient for deep neural networks. Deep neural network power-up the high-end devices. Google revealed that the accelerators (FGPAs) were used for the Alpha GO systems which is a computer developed by Google DeepMind that plays the board game Go. CEA also offers an ultra-low power programmable accelerator called P-Neuro.

Photonic Networks for Hardware Accelerators: Hardware Accelerators normally need high bandwidth, low latency, and energy efficiency. The high performance computing system has critical performance which is shifted from the microprocessors to the communications infrastructure. Optical interconnects are able to address the bandwidth scalability challenges of future computing systems, by exploiting the parallel nature and capacity of wavelength division multiplexing (WDM). The multi-casted network uniquely exploits the parallelism of WDM to serve as an initial validation for architecture. Two FPGA boarded systems emulate the CPU and hardware accelerator nodes. Here FPGA transceivers implement and follow a phase-encoder header network protocol. The output of each port is individually controlled using a bitwise XNOR of port’s control signal. Optical packets are send through the network and execute switch and multicasting of two receive nodes with most reduced error

Low Power and High Data Rate FPGA: “Microsemi” FPGAs provides a non-volatile FPGA having 12.7 GB/s transceiver and lower poor consumption less than 90mW at 10 GB/s. It manufactured using a 28nm silicon-oxide-nitride-oxide-silicon nonvolatile process on standard CMOS technology. By this they address cyber security threats and deep submicron single event upsets in configuration memory on SRAM-based FPGA. These transceivers use cynical I/O gearing logic for DDR memory and LVDS. Cryptography research provides differential power analysis protection technology, an integrated physical unclonable function and 56 kilobyte of secure embedded non-volatile memory, the built-in tamper detectors parts and counter measures.

Schedule a Call

Speeds up FPGA-in-the-loop verification: HDL Verifier is used to speed up FPGA-in-the-loop (FIL) verification. Faster communication between the FPGA board and higher clock frequency is stimulated by the FIL capabilities. This would increase the complexity of signal processing, control system algorithms and vision processing. For validation of the design in the system context simulate hardware implementation on an FPGA board. HDL Verifier automates the setup and connection of MATLAB and Simulink test environments to designs running on FPGA development boards. The R2016b has been released that allows engineers to specify a custom frequency for their FPGA system clock with clock rates up to five times faster than previously possible with FIL. This improves faster run-time. From MATLAB and Simulink is an easy way to validate hardware design within the algorithm development environment

Xilinx Unveils Revolutionary Adaptable Computing Product Category: Xilinx, Inc. which is leader in FGPAs, has recently announced a new product category which is named as Adaptive Compute Acceleration Platform (ACAP) and has the capabilities far beyond of an FPGA. An ACAP is a highly integrated multi-core heterogeneous compute platform that can be changed at the hardware level to adapt to the needs of a wide range of applications and workloads. ACAP has the capability of dynamic adaption during operation which enables it to deliver higher performance per-watt levels that is unmatched by CPUs or GPUs.

Lattice Releases Next-Generation FPGA Software for Development of Broad Market Low Power Embedded Applications: Lattice Semiconductor, launched its FPGA software recently. Lattice Radiant targeted for the development of broad market low power embedded applications. Device’s application expands significantly across various market segments including mobile, consumer, industrial, and automotive due to is rich set of features and ease-of-use, Lattice Radiant software’s support for iCE40 Ultra plus FPGAs. ICE40 Ultra Plus devices are the world’s smallest FPGAs with enhanced memory and DSPs to enable always on, distributed processing. The Lattice Radiant software is available for free download.

Who are the Major Players in market?

The companies referred in the market research report include Intel Inc, Microsemi, Lattice Semiconductor, Xilinx, Atmel, Quick Logic Corp., Red Pitaya, Mercury Computer, Nallatech Inc., Achronix Semiconductor Corporation, Acromag Inc., Actel Corp., Altera Corp.

Buy Now

What is our report scope?

The report incorporates in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and its impact during the forecast period 2017-2023.

All our reports are customizable to your company needs to a certain extent, we do provide 20 free consulting hours along with purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

Key Takeaways from this Report

Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level – for product types, end use applications and by different industry verticals.

Understand the different dynamics influencing the market – key driving factors, challenges and hidden opportunities.

Get in-depth insights on your competitor performance – market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

Analyze the sales and distribution channels across key geographies to improve top-line revenues.

Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

Get a quick outlook on the market entropy – M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than top 20 countries globally for the market.

#field programmable gate array market#field programmable gate array market report#field programmable gate array market research#field programmable gate array market size#field programmable gate array market shape#field programmable gate array market forecast#field programmable gate array market analysis#Image processing#Wave form generation#Partial reconfiguration#Wired Communications#Optical Transport Network

0 notes

Text

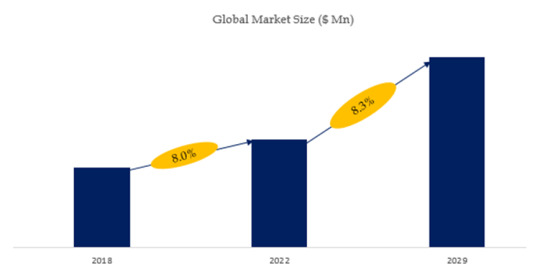

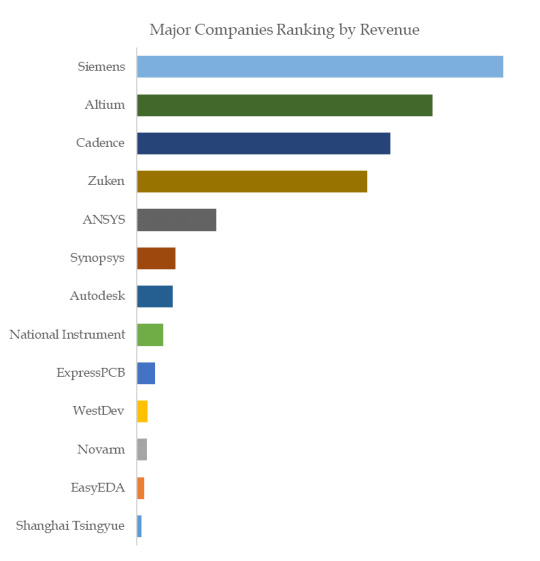

Global Top 5 Companies Accounted for 83% of total PCB Software market (QYResearch, 2021)

PCB design software aids electronic engineers in designing layouts for printed circuit boards. Engineers leverage the software to collaborate on the design process, pull previously used circuit board component designs from PCB libraries, and verify circuit schematic designs. PCB design software is most often used by engineering firms and teams that may be involved with product development. PCB design software is often implemented as a part of other design software systems such as product and machine design software and general-purpose CAD software.

The PCB Software industry can be broken down into several segments, On Premises, Cloud Based.

Across the world, the major players cover Siemens, Altium, etc.

According to the new market research report “Global PCB Software Market Report 2023-2029”, published by QYResearch, the global PCB Software market size is projected to reach USD 1.82 billion by 2029, at a CAGR of 8.3% during the forecast period.

Figure. Global PCB Software Market Size (US$ Million), 2018-2029

Figure. Global PCB Software Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of PCB Software include Siemens, Altium, Cadence, Zuken, ANSYS, Synopsys, Autodesk, National Instrument, ExpressPCB, WestDev, etc. In 2021, the global top five players had a share approximately 83.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Unveiling the Excellence of PCB Manufacturing in Toronto with Crimp Circuits

Introduction: In the bustling hub of technological innovation that is Toronto, Canada, Crimp Circuits stands as a beacon of excellence in the realm of PCB manufacturing. With a rich history spanning over four decades, Crimp Circuits has established itself as a leader in the industry, delivering cutting-edge solutions to clients across a diverse range of sectors. In this blog, we'll delve into the world of PCB manufacturing in Toronto and shed light on how Crimp Circuits continues to set the standard for excellence in the field.

A Legacy of Innovation: Since our inception, Crimp Circuits has been at the forefront of technological innovation, pushing the boundaries of what's possible in PCB manufacturing. Our state-of-the-art facility, located in the heart of Toronto, boasts advanced equipment, experienced personnel, and a commitment to excellence that sets us apart from the competition. From concept to completion, we pride ourselves on delivering superior PCB solutions that meet and exceed the expectations of our clients.

Precision Engineering and Design: At Crimp Circuits, precision is our watchword. Our team of skilled engineers and designers leverage the latest technology, including Eagle software, to create PCB designs that are optimized for performance, reliability, and efficiency. Whether it's a simple two-layer board or a complex multilayered design, we have the expertise and experience to bring your vision to life with unparalleled precision and accuracy.

Diverse Range of Offerings: Crimp Circuits offers a comprehensive suite of PCB manufacturing services to meet the diverse needs of our clients. From printed circuit board design and prototyping to full-scale production and assembly, we have the capabilities and resources to handle projects of any size or complexity. Whether you're a startup looking to bring a new product to market or a large corporation in need of high-volume production, Crimp Circuits has you covered.

Quality Assurance and Compliance: Quality is ingrained in everything we do at Crimp Circuits. We adhere to stringent quality control measures at every stage of the manufacturing process to ensure that our clients receive PCBs of the highest quality and reliability. Additionally, we maintain compliance with industry standards and regulations, giving our clients peace of mind knowing that their products meet all necessary requirements.

Customer-Centric Approach: At Crimp Circuits, we understand that our success is directly tied to the success of our clients. That's why we take a customer-centric approach to every project, prioritizing open communication, collaboration, and responsiveness. We work closely with our clients to understand their unique needs and requirements, ensuring that we deliver solutions that not only meet but exceed their expectations.

Conclusion: In conclusion, PCB manufacturing in Toronto is synonymous with excellence, innovation, and reliability, thanks to companies like Crimp Circuits. With our state-of-the-art facilities, experienced team, and commitment to quality, we continue to set the standard for PCB manufacturing in the region and beyond. Contact us today to learn more about how Crimp Circuits can meet your PCB manufacturing needs.For more details visit our website: www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

0 notes

Text

Gaming Keyboards for Big Hands

Gaming Keyboards for Big Hands Choosing the right gaming keyboard is crucial for gamers with big hands. The market offers a variety of options designed to provide comfort and improve gaming performance. A keyboard with larger keys, ample space between keys, and an ergonomic design can significantly enhance gaming sessions. It's important to consider the switch type, keycap size, and wrist support features. We explore a selection of keyboards that stand out for their suitability for gamers with big hands. alt="A gaming keyboard illuminated with LED lights" src="https://ae01.alicdn.com/kf/S613be4247adc4ef68d308139a2dd06a7I.jpg" />

Top Picks for Gamers with Big Hands

Extra-Large Mechanical Keyboards Find More > Keyboards with Adjustable Key Spacing Explore Options > Ergonomic Designs for Comfortable Use Learn More > Keyboards with Programmable Keys View Products > Durable Keyboards for Intense Gaming Sessions Check Availability > LED Backlit Keyboards for Night Gamers Discover Selection >

class="o-ProductRoundup--image-advanced" src="https://ae01.alicdn.com/kf/Sf75d6305d8124ec2a247b8d59d1385a7O.jpg" alt="68 Keys Gaming Keyboard" /> 68 Keys Gaming Keyboard USB Wired Portable 20 RGB Backlight Keyboard for Windows Laptops Computer > class="o-ProductRoundup--review-advanced" href="#product-4597d76a-c8c3-4ab7-a0c2-e089db5fedce" > src="https://ae01.alicdn.com/kf/H0f7f283a5527481a8018a3e58624cdd31.png" alt="English Laptop keyboard for Asus TUF Gaming" /> For ASUS TUF Gaming Series English Laptop keyboard for Asus TUF Gaming FX505 - US Backlit > href="#product-4597d76a-c8c3-4ab7-a0c2-e089db5fedce" > src="https://ae01.alicdn.com/kf/S639501bbf5c7405c923aa3eb093ec230b.jpg" alt="CSTC40 40% Mechanical Keyboard PCB" /> CSTC40 RGB 40% Mechanical Keyboard Hot Swappable PCB Programmed with VIA & VIAL software > href="#product-4597d76a-c8c3-4ab7-a0c2-e089db5fedce" > src="https://ae01.alicdn.com/kf/S5bc818ca10e14a6287d0a7d5f96d2f33b.jpg" alt="AULA F2088 Mechanical Gaming Keyboard" /> AULA F2088 Keyboard Full Key Programmable Macro Keyboard for Vast Gaming Experience > href="#product-4597d76a-c8c3-4ab7-a0c2-e089db5fedce" > src="https://ae01.alicdn.com/kf/S613be4247adc4ef68d308139a2dd06a7I.jpg" alt="VIAL Programmable 42 Key Mechanical Split Keyboard Gaming DIY Kit" /> VIAL Programmable 42 Key Keyboard Programmable Mechanical Split Keyboard Gaming DIY Based on QMK Hot swaps RGB Backlit Keypad Kit > href="#product-4597d76a-c8c3-4ab7-a0c2-e089db5fedce" > src="https://ae01.alicdn.com/kf/Sdbfdc5b053ea4e41ac05e6098a7e87d4s.jpg" alt="Gaming Keyboard Russian EN Keyboard RGB Backlight" /> Gaming Keyboard for Big Hands 104 Keys USB Wired Gamer Keyboard with RGB Backlight for Tablet Desktop > href="#product-4597d76a-c8c3-4ab7-a0c2-e089db5fedce" > src="https://ae01.alicdn.com/kf/S613be4247adc4ef68d308139a2dd06a7I.jpg" alt="VIAL Keyboard Programmable 42 Key Mechanical Split Keyboard" />

VIAL Keyboard Programmable 42 Key Programmable Mechanical Split Keyboard Gaming DIY Based on QMK Hot swaps RGB Backlit Keypad Kit

View More Product Features: 42 Key Programmable Layout ideal for gamers with big hands Mechanical switches for precision and durability RGB Backlit for gaming in low light conditions Possible Cons: Might be too large for those with smaller hands Programming knowledge needed for full functionality Designed for expert gamers and DIY enthusiasts, this VIAL keyboard boasts a 42 key programmable layout, mechanical switches for increased longevity and precision, and customizable RGB backlighting. Its split design is aimed at offering ergonomic benefits, potentially making it a solid choice for gamers with big hands looking for comfortable gaming keyboards. Connectivity: Wired (USB) Compatibility: PC, Mac, Linux Programmable: Yes, via QMK software src="https://ae01.alicdn.com/kf/Sf75d6305d8124ec2a247b8d59d1385a7O.jpg" alt="68 Keys Gaming Keyboard" />

68 Keys Gaming Keyboard USB Wired Portable 20 RGB Backlight Keyboard for Windows Laptops Computer

View More Product Highlights Portable 68-Key Design perfect for gamers with big hands 20 RGB Backlight Modes to enhance your gaming experience USB Wired for fast, reliable connections Considerations May not be suitable for users who prefer wireless keyboards Limited key count might not be ideal for users requiring dedicated macro keys This 68 Keys Gaming Keyboard is designed keeping in mind the needs of users with big hands, featuring a compact yet spacious layout that provides comfort during long gaming sessions. The vibrant 20 RGB backlight settings not only give it a stylish look but also ensure that the keys are visible in low light, enhancing the overall gaming atmosphere. USB wired connection guarantees minimal latency, making it a reliable option for competitive gaming. Key Count 68 Backlight 20 RGB Modes Connection Type USB Wired src="https://ae01.alicdn.com/kf/S639501bbf5c7405c923aa3eb093ec230b.jpg" alt="CSTC40 40% hot Swappable Mechanical Keyboard RGB" />

CSTC40 40 RGB 40% hot Swappable Mechanical Keyboard PCB Programmed VIA VIAL software Macro Firmware rgb switch type c planck

View More Product Highlights 40% compact layout RGB backlighting Hot swappable switches Considerations Might be too small for users with large hands Requires getting used to the compact layout The CSTC40 40 RGB Mechanical Keyboard is an excellent choice for gamers with big hands looking for a compact option without sacrificing performance. Its hot swappable feature and RGB backlighting not only provide flexibility but also add a stylish look to any gaming setup. However, it's crucial to note that the 40% compact layout might require some adjustment time for those not used to smaller keyboards. Type Mechanical Keyboard PCB Compatibility Hot Swappable switches Software Programmed VIA VIAL src="https://ae01.alicdn.com/kf/Sdbfdc5b053ea4e41ac05e6098a7e87d4s.jpg" alt="Gaming Keyboard Russian EN Keyboard RGB Backlight" />

Gaming Keyboard Russian EN Keyboard RGB Backlight Keyboard 104 Keys USB Wired Gamer Keyboard for Tablet Desktop

View More Key Features RGB Backlight for enhanced experience 104 Keys for full control USB Wired for reliable connectivity Cons Might be large for users with smaller hands Russian EN layout may require adaptation for some users Designed with gamers in mind, this RGB Backlight Keyboard combines functionality and style. Its full 104 keys ensure you have every command at your fingertips, while the USB wired connection offers uninterrupted gaming sessions. Ideal for users with big hands, its ergonomic design provides comfort during extended use. However, its large size and Russian EN layout might require some adjustment for certain users. Connection Type USB Wired Layout Russian EN Backlight RGB src="https://ae01.alicdn.com/kf/H0f7f283a5527481a8018a3e58624cdd31.png" alt="English Laptop keyboard for Asus TUF Gaming FX Series" />

English Laptop keyboard for Asus TUF Gaming FX505 FX505G FX505D FX505GD FX505GE FX505GM FX505DY FX505DV fx505dt US Backlit

View More Details Pros of English Laptop Keyboard for Asus TUF Gaming Backlit for ease of use in low light conditions Designed specifically for Asus TUF Gaming FX series laptops US layout ideal for English-speaking users Cons of English Laptop Keyboard for Asus TUF Gaming May not be compatible with non-Asus laptops or other Asus models Limited color options available This backlit English laptop keyboard is specifically designed for Asus TUF Gaming FX series, providing an optimal gaming experience for English-speaking users with big hands. The backlit feature makes it easy to use in various lighting conditions, enhancing your gaming setup's aesthetics and functionality. Compatibility Asus TUF Gaming FX505, FX505G, FX505D, FX505GD, FX505GE, FX505GM, FX505DY, FX505DV, fx505dt Layout US Feature Backlit src="https://ae01.alicdn.com/kf/S5bc818ca10e14a6287d0a7d5f96d2f33b.jpg" alt="AULA F2088 Mechanical Gaming Full Key Programmable Macro Keyboard" />

AULA F2088 Mechanical Gaming Full Key Programmable Macro Keyboard

View more details Key Features Full key programmable via macro Anti-ghosting technology for better gaming experience Wire mixed light for an immersive gaming atmosphere Cons Might be bulky for users with smaller desks Customization software may have a learning curve The AULA F2088 Mechanical Gaming Keyboard is designed for gamers with large hands, offering a comfortable and responsive typing experience with its full key programmable macro keys and anti-ghosting switches. Its mixed light feature adds to the gaming mood, making it a great addition to any gaming setup. Switch Type Mechanical Lighting Mixed RGB Keycap Material Korea Russian Arabic cap > Gaming Keyboards for Big Hands Finding the right gaming keyboard when you have big hands can be a bit of a challenge. Most keyboards seem to be designed with a one-size-fits-all approach, which doesn’t always work for those with larger hand sizes. The key to comfort and improved gaming performance for people with big hands is in the size of the keys, the spacing between them, and the overall design and ergonomics of the keyboard. In this guide, we’ll highlight some of the best gaming keyboards that cater specifically to gamers with big hands, ensuring a more comfortable and efficient gaming experience. Keyboards with adjustable key sizes and spacing for custom comfort Ergonomic designs that reduce strain during long gaming sessions Models featuring mechanical keys for better tactile feedback and durability Keyboards with programmable macros for enhanced gaming efficiency Options that include backlit keys for late-night gaming sessions It’s important to try out different keyboards to find what works best for your hand size and gaming style. Look for keyboards that offer a good balance between responsiveness and comfort. Many manufacturers are now recognizing the need for more inclusive designs, so there are plenty of options available on the market. Remember, investing in the right gaming keyboard can not only improve your gaming experience but also help prevent potential strain and fatigue, making it a crucial accessory for gamers with big hands. Read the full article

0 notes