#PCB Design Software Market Demand

Explore tagged Tumblr posts

Text

Global PCB Design Software Market Is Estimated To Witness High Growth Owing To Increasing Demand for Advanced Electronics

A) Market Overview: PCB design software is a computer-aided design tool used to create layout designs for printed circuit boards (PCBs). These software tools offer numerous advantages such as enhanced efficiency, accuracy, and productivity in the design process. With the rapid advancements in technology and the increasing demand for advanced electronic devices in various industries, the need for PCB design software has become crucial. This software enables engineers and designers to create complex and highly functional PCB designs, ensuring proper connectivity and signal integrity. The global PCB design software market is expected to witness significant growth due to the growing adoption of advanced electronics across various industries such as automotive, aerospace, consumer electronics, healthcare, and telecommunications.

The global PCB Design Software Market Size is estimated to be valued at US$3.56 billion in 2022 and is projected to grow at a CAGR of 12.3% from 2023 to 2030, according to a market research report published by Coherent Market Insights.

B) Market Key Trends: One key trend in the PCB design software market is the adoption of cloud-based solutions. Cloud-based PCB design software offers several advantages over traditional on-premise software. It enables remote collaboration, allowing multiple stakeholders to work on the same design simultaneously. Cloud-based solutions also provide easy access to design files from anywhere and on any device, facilitating seamless workflow and faster decision-making. Moreover, cloud-based software eliminates the need for expensive hardware infrastructure, reducing costs and improving scalability. For example, Altium LLC, a key player in the PCB design software market, offers Altium 365, a cloud-based platform that enables collaborative PCB design. C) PEST Analysis: Political: The political environment plays a significant role in the growth of the PCB design software market. Government regulations and policies regarding intellectual property rights and data security can impact the adoption of PCB design software. Economic: The economic factors such as GDP growth, industrial development, and disposable income influence the demand for PCB design software. The growth of end-user industries such as automotive, aerospace, and consumer electronics drives the market. Social: The social factors such as changing consumer preferences, increased awareness about advanced electronics, and the need for innovative products drive the demand for PCB design software. Technological: Technological advancements in the field of electronics, such as the integration of IoT, AI, and 5G technology, are driving the demand for advanced PCB designs. PCB design software needs to keep up with these technological developments to meet the evolving requirements of the industry. D) Key Takeaways: - The global PCB design software market is expected to witness high growth, exhibiting a CAGR of 12.3% over the forecast period, due to increasing demand for advanced electronics. - North America is expected to dominate the PCB design software market, owing to the presence of key players, technological advancements, and early adoption of advanced electronics. - Cadence Design Systems, Inc., Altium LLC, and WestDev Ltd. are some of the key players operating in the global PCB design software market. In conclusion, the global PCB design software market is poised for significant growth in the coming years. The increasing demand for advanced electronics and the adoption of cloud-based solutions are driving factors for this market. However, political, economic, social, and technological factors will continue to influence the market dynamics. Key players in the market are focusing on innovative solutions to cater to the evolving needs of the industry.

#PCB Design Software Market#PCB Design Software Market Size#Coherent Market Insights#PCB Design Software Market Demand#PCB Design Software Market Trends#PCB Design Software Market Forecast

0 notes

Text

The PCB Design Software Market: Transforming Product Development Across Industries

The global PCB Design Software market is poised for significant growth, reaching $7,939 million by 2030, driven by rising demand in industries like telecommunications, automotive, and IoT. PCB Design Software helps companies streamline product development, reduce costs, and improve performance across various sectors. With advancements in schematic capture and cloud-based solutions, PCB design tools are more accessible and powerful than ever.

#pcbdesign#electronics#iot#automotive#telecom#cloudcomputing#radarsystems#pcbsoftware#engineering#innovation#productdesign#digitaltransformation#cad#designautomation

2 notes

·

View notes

Text

Wagner Engineering USA

Wagnerengineer is your trusted partner in electronic and software product development. Located in Chicago, we specialize in delivering fully integrated engineering solutions that help businesses bring innovative ideas to life. Whether you're building a connected device, developing embedded systems, or scaling cloud infrastructure, we deliver the precision and reliability your project demands.

Our expert team works across every stage of the product development lifecycle—from concept and design to prototyping, deployment, and long-term support. With services tailored to your needs and a commitment to technical excellence, we provide more than engineering—we deliver results.

What We Do

Wagner Engineering USA offers a full suite of services designed to support product innovation from the ground up. We combine experience in electrical engineering, embedded software, full-stack development, and cloud architecture to deliver smart, scalable solutions that work seamlessly together.

PCB Design

Printed circuit boards are the foundation of any electronic system. Our team designs reliable, manufacturable PCBs that power your hardware with efficiency and durability. From single-layer prototypes to complex, multilayer boards, we engineer for long-term performance and smooth production.

Embedded Firmware Development

Embedded systems demand fast, efficient, and stable firmware. Our engineers write secure and optimized code that interfaces perfectly with your hardware. Whether it's powering sensors, managing connectivity, or enabling advanced logic, we develop firmware that makes your device smarter and more capable.

Software Development

Great software brings hardware to life. We build customized software applications for desktop, mobile, and web platforms—designed to fit your product, workflow, and user needs. From control panels to user interfaces to integrated tools, our software supports usability, reliability, and scale.

Cloud & IoT Infrastructure

Connectivity is the backbone of today’s smart devices. We develop cloud-based systems and IoT platforms that allow your product to collect data, communicate remotely, and scale over time. Our cloud solutions are secure, flexible, and designed to grow with your business.

Why Clients Choose Wagner Engineering

We don’t just write code or design boards—we solve problems. Our process is built around understanding your goals and delivering the exact technology to help you achieve them.

Here’s what sets Wagner Engineering USA apart:

Complete Engineering Capabilities From circuit design to cloud deployment, our team offers a full range of skills under one roof.

Tailored, Scalable Solutions We adapt our services to your project—building only what you need, with flexibility for the future.

Reliable Communication We believe in transparency. Expect regular updates, clear timelines, and honest conversations throughout.

Quality-Focused Delivery Every product is tested thoroughly to meet performance, safety, and compliance standards.

End-to-End Partnership We support your product from the first idea to market launch and beyond—offering technical guidance at every step.

Industries We Serve

Our team supports a wide range of industries, from emerging startups to established brands. We understand the unique challenges and regulatory requirements of different markets and build solutions accordingly.

Consumer Electronics Creating innovative, user-friendly devices built for performance and mass production.

Medical & Health Devices Engineering high-precision electronics and software that support safe, effective healthcare solutions.

Industrial Automation Developing embedded controls and cloud systems for smart manufacturing and process automation.

Smart Home & IoT Building cloud-connected systems that enable seamless control, automation, and monitoring of devices.

Automotive & Mobility Delivering robust, embedded systems for advanced vehicle functions and integrations.

Robotics & Manufacturing Tech Powering intelligent machines and tools with custom electronics and control software.

How We Work

Every successful product starts with a clear, focused process. At Wagner Engineering USA, we take a structured yet flexible approach that adapts to your needs:

Consultation & Discovery We start by learning your goals, product vision, and technical challenges.

Design & Development Our team builds your solution—from schematics and code to user interfaces and cloud systems.

Testing & Validation We rigorously test your product for performance, compliance, and real-world use.

Launch & Support Once your solution is ready, we help bring it to market and provide long-term support as it grows.

Let’s Build Something Great

Whether you're developing a prototype or scaling production, Wagner Engineering USA is ready to help. Our engineering team offers the precision, creativity, and problem-solving skills needed to move your project forward.

We’re here to collaborate, innovate, and engineer what’s next—for your business and your customers.

Wagnerengineer is committed to transforming your ideas into dependable, cutting-edge products that excel in today’s fast-evolving marketplace. By focusing on tailored solutions, technical mastery, and close collaboration, we help your business unlock its full potential through innovative engineering. Choose Wagner Engineering USA as your partner for expert guidance and solutions that deliver real, lasting impact.

0 notes

Text

Global Polyurethane Foam Mattress Market Forecast (2025–2031): Growth, Trends & Strategic Insights

"

The Global Polyurethane Foam Mattress Market is projected to grow steadily from 2025 through 2031. This report offers critical insights into market dynamics, regional trends, competitive strategies, and upcoming opportunities. It's designed to guide companies, investors, and industry stakeholders in making smart, strategic decisions based on data and trend analysis.

Report Highlights:

Breakthroughs in Polyurethane Foam Mattress product innovation

The role of synthetic sourcing in transforming production models

Emphasis on cost-reduction techniques and new product applications

Market Developments:

Advancing R&D and new product pipelines in the Polyurethane Foam Mattress sector

Transition toward synthetic material use across production lines

Success stories from top players adopting cost-effective manufacturing

Featured Companies:

Tempur Sealy International

Serta Simmons Bedding

Sinomax

Sleemon

Recticel

Corsicana

MLILY

Sleep Number

Hilding Anders

Ashley

Pikolin

Derucci

King Koil

Get detailed profiles of major industry players, including their growth strategies, product updates, and competitive positioning. This section helps you stay informed on key market leaders and their direction.

Download the Full Report Today https://marketsglob.com/report/polyurethane-foam-mattress-market/1007/

Coverage by Segment:

Product Types Covered:

King Size

Queen Size

Single Size

Applications Covered:

Private Households

Hotels

Hospitals

Others

Sales Channels Covered:

Direct Channel

Distribution Channel

Regional Breakdown:

North America (United States, Canada, Mexico)

Europe (Germany, United Kingdom, France, Italy, Russia, Spain, Benelux, Poland, Austria, Portugal, Rest of Europe)

Asia-Pacific (China, Japan, Korea, India, Southeast Asia, Australia, Taiwan, Rest of Asia Pacific)

South America (Brazil, Argentina, Colombia, Chile, Peru, Venezuela, Rest of South America)

Middle East & Africa (UAE, Saudi Arabia, South Africa, Egypt, Nigeria, Rest of Middle East & Africa)

Key Insights:

Forecasts for market size, CAGR, and share through 2031

Analysis of growth potential in emerging and developed regions

Demand trends for generic vs. premium product offerings

Pricing models, company revenues, and financial outlook

Licensing deals, co-development initiatives, and strategic partnerships

This Global Polyurethane Foam Mattress Market report is a complete guide to understanding where the industry stands and how it's expected to evolve. Whether you're launching a new product or expanding into new regions, this report will support your planning with actionable insights.

" Exclusion Chromatography (SEC) HPLC Columns Cell-Site Simulators Ship Dismantling CAD/CAM Software for Sheet Metal Ship Management and Crew Management Rebar Coupler Modular Office Furniture Consumer Goods (CPG)ing Software and Platforms Energy-as-a-Service (EaaS) Glass-Melting Furnaces Vacuum Plasma Machine for Bare PCB Manufacturing Direct to Garment Printers Under Eye Gel

0 notes

Text

What Sets Apart a Great Electronics Design Engineer and a Top-Tier PCB Designer

Developing cutting-edge products requires more than just a basic understanding of electronics—it demands specialized expertise at multiple levels of the design process. While the roles of an electronics design engineer and a PCB designer often overlap, each discipline has its own set of core skills, priorities, and best practices. Understanding these differences can help companies build stronger teams and ensure both functionality and manufacturability from concept to production.

1: Foundations: Concept vs. Layout

Electronics Design Engineer

System-level thinking: Architects circuits that meet performance, power, and cost targets.

Component selection: An electronics design engineer chooses processors, sensors, power supplies, and other parts based on specifications and availability.

Simulation and validation: Uses SPICE, MATLAB, or custom scripts to verify that circuits behave as intended under various conditions.

PCB Designer

Physical realization: Translates schematic diagrams into board layouts, deciding component placement, routing, and layer stacks.

Signal integrity: Manages trace lengths, impedance control, and differential pairs to prevent timing mismatches and noise.

Thermal management: Integrates heat sinks, copper pours, and thermal vias to maintain reliable operating temperatures.

2: Technical Skills: Breadth vs. Depth

Breadth of Knowledge (Engineer)

A great electronics engineer understands analog and digital domains, power management, RF techniques, and often systems integration. Their toolkit includes:

Circuit simulation tools (e.g., Cadence, LTspice)

Firmware debugging (e.g., JTAG, SWD)

Test equipment (oscilloscopes, spectrum analyzers)

Depth of Expertise (PCB Designer)

A top-tier PCB designer goes deep into board stack-up design, advanced routing strategies, and material characteristics:

PCB CAD software mastery (e.g., Altium Designer, Mentor Xpedition)

High-speed design considerations (e.g., controlled impedance, crosstalk analysis)

3: Collaboration and Workflow

Communication Styles

Electronics engineers often work in cross-functional teams—mechanical, software, and compliance—to validate overall design requirements. Their deliverables include schematics, block diagrams, and simulation reports.

PCB designers interact heavily with manufacturing partners. They must document fabrication drawings, assembly notes, and BOM details clearly to avoid production delays.

By recognizing the strengths each role brings—and fostering close collaboration between them—teams can bring innovative, reliable products to market faster and more efficiently.

Source: https://extrondesignservice.blogspot.com/2025/05/what-sets-apart-great-electronics.html

0 notes

Text

How Does Circuit Card Assembly Impact Electronics Production?

In the rapidly evolving field of electronics, Circuit Card Assembly (CCA) plays a crucial role in determining the performance, reliability, and scalability of electronic devices. Circuit Card Assembly, also known as Printed Circuit Board Assembly (PCBA), involves mounting electronic components onto a pre-designed circuit board, forming the foundation of all modern electronic products.

Enhancing Product Efficiency

Circuit Card Assembly significantly improves the efficiency and functionality of electronics. By automating the process using Surface Mount Technology (SMT) and Through-Hole Technology, manufacturers can ensure consistent and high-speed assembly with minimal human error. This streamlined process allows for mass production of devices ranging from consumer gadgets to industrial control systems, while maintaining performance integrity.

Supporting Innovation in Design

The evolution of electronics design is deeply connected to advancements in CCA. High-density assemblies allow more complex circuits to be placed in smaller form factors. This has enabled innovations in smartphones, medical devices, and IoT products. With technologies like multi-layer boards and flexible PCBs, companies can now meet unique design challenges with customized, compact solutions.

Reducing Production Costs

Efficiency in Circuit Card Assembly directly translates to cost savings. Automated machines reduce labor costs, and precise component placement minimizes material waste. Moreover, the early detection of defects through automated optical inspection (AOI) and X-ray testing helps avoid costly recalls or field failures, improving overall quality assurance.

Improving Reliability and Lifespan

One of the key impacts of CCA is enhanced product reliability. A professionally assembled circuit card undergoes rigorous testing to ensure long-term durability, even under demanding conditions. This is especially critical in industries like aerospace, automotive, and telecommunications, where component failure can have significant consequences.

Role of Guangzhou Wangerbao Software Development Co., Ltd.

Guangzhou Wangerbao Software Development Co., Ltd. is at the forefront of providing software solutions that optimize Circuit Card Assembly processes. Their intelligent software platforms integrate with production lines to manage real-time monitoring, defect tracking, and process control. By using data analytics and automation tools, Wangerbao helps manufacturers ensure precision and efficiency across the assembly lifecycle.

Wangerbao’s solutions are particularly valuable for small to medium-sized enterprises (SMEs) seeking to adopt smart manufacturing practices. Their platforms support traceability, resource planning, and predictive maintenance, which are critical to maintaining competitiveness in global electronics production.

Enabling Scalable Manufacturing

With growing demand for custom electronics and rapid prototyping, scalable CCA processes are essential. Modular assembly lines, supported by smart software from companies like Wangerbao, allow manufacturers to shift quickly from prototyping to full-scale production. This flexibility enables businesses to meet market demands faster while maintaining quality.

Conclusion

Circuit Card Assembly is a foundational element of modern electronics manufacturing, influencing everything from design innovation to production cost and product reliability. With the support of advanced software systems developed by Guangzhou Wangerbao Software Development Co., Ltd., manufacturers can optimize their processes and stay ahead in a competitive, technology-driven market. As electronics continue to evolve, so too will the role and impact of intelligent, efficient circuit card assembly.

0 notes

Text

Compact Reflow Oven Market to Reach $343.7 Million by 2035, According to DataString Consulting

The global Compact Reflow Oven market is projected to grow significantly from $205.2 million in 2024 to $343.7 million by 2035, according to the latest research by DataString Consulting. This growth is driven by expanding applications across key industries such as electronics manufacturing, automotive component production, LED lighting, aerospace, and medical device production.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/compact-reflow-oven-market-research-report

Expanding Use in Electronics and Medical Device Manufacturing

Compact Reflow Ovens are essential tools in electronics manufacturing, known for delivering precision soldering through controlled heating and cooling processes. Their compact footprint and efficiency make them ideal for mass production of printed circuit boards (PCBs), enabling companies like Samsung and IBM to maintain high throughput and consistent quality.

In the medical device sector, the need for delicate component handling has led to the adoption of compact reflow ovens. These ovens support precise soldering for devices such as digital thermometers, glucose monitors, and implantable medical equipment. Leading firms like Medtronic and Boston Scientific rely on these ovens to uphold stringent quality standards in assembling advanced healthcare devices.

Shift Toward Energy-Efficient, Software-Driven Systems

The industry is undergoing a shift toward energy-efficient models due to increased focus on sustainability and energy consumption in manufacturing operations. This trend is driving innovations in software-integrated ovens that reduce power usage and streamline workflows. Energy efficiency is now a competitive differentiator, especially in industries focused on volume production and sustainability compliance.

Strategic Initiatives from Leading Market Players

Several prominent manufacturers are pursuing specific strategies to stay competitive in the evolving Compact Reflow Oven market:

Heller Industries is investing in highly automated reflow oven systems designed to maximize performance and precision.

Manncorp focuses on advanced thermal profiling solutions for automotive electronics and small-batch manufacturing.

BTU International is known for developing ovens that support high-volume LED production with accurate temperature control.

SMT Max delivers precision ovens for complex, high-reliability circuit board assembly, particularly for aerospace applications.

These initiatives reflect the broader industry push toward automation, miniaturization, and efficiency.

Regional Insights: North America Leads with Innovation and Industrial Adoption

North America, particularly the United States, continues to lead in terms of market share and innovation. The region benefits from a robust electronics manufacturing base and a strong pipeline of technological advancements. Compact reflow ovens are increasingly being integrated into production lines to enhance productivity, reduce errors, and support high-precision tasks.

With the growing demand for high-speed, high-accuracy electronics assembly, compact reflow ovens are becoming essential tools in North American manufacturing ecosystems. The trend toward eco-friendly and energy-saving solutions is also influencing procurement decisions.

Global Market Segmentation and Growth Opportunities

The DataString Consulting research study provides a deep-dive analysis of the Compact Reflow Oven market, segmented by:

Product Type: Infrared Reflow, Vapor Phase Reflow, Hot Air Reflow

End Users: Automotive Electronics, Aerospace Engineering, Consumer Electronics, Others

Technology: Lead-based Soldering, Lead-free Soldering

Covering over 20 countries, the study highlights regional trends, market opportunities, and technological innovation areas that will shape the industry’s future.

About DataString Consulting

DataString Consulting helps organizations formulate robust strategies, expand their Total Addressable Market (TAM), diversify revenue streams, and explore new business territories. Backed by over 30 years of combined experience, the firm provides actionable market intelligence and competitor analysis, helping businesses turn complex data into strategic advantage.

With expertise spanning 15+ industries and 60+ sub-industries, DataString Consulting delivers customized business intelligence solutions tailored for both B2B and B2C enterprises.

Explore the full report: 👉 Compact Reflow Oven Market Research Report – DataString Consulting

0 notes

Text

What to Look for in a Trusted PCB Fabrication Company

Choosing a PCB fabrication company is a crucial step in the process of developing high-performance electronic products. Whether you're building prototypes or preparing for full-scale production, the reliability and expertise of the fabrication partner can directly influence the quality, performance, and success of your final product.

With so many options available, knowing what to look for in a trusted provider can help you avoid costly delays, product flaws, or missed market opportunities. Here are the key factors to consider when selecting a PCB fabrication company.

1. Proven Track Record and Industry Experience

Experience matters when it comes to PCB fabrication. A company with a long-standing presence in the industry has likely dealt with a wide range of design complexities and fabrication challenges. Look for a PCB fabrication company with a proven track record in delivering reliable and innovative solutions for industries such as telecommunications, automotive, healthcare, aerospace, and consumer electronics.

Client testimonials, portfolio case studies, and positive reviews are excellent indicators of a company’s credibility and reliability.

2. Range of Fabrication Capabilities

A dependable PCB assembly manufacturer should offer a full spectrum of fabrication capabilities tailored to your project’s specifications. From single-layer to multilayer boards, rigid to flex PCBs, and HDI (High-Density Interconnect) technologies, your fabrication partner must be capable of handling a variety of board types and complexities.

The ability to provide custom options, advanced materials, and specialized finishes also reflects the company’s technical flexibility and dedication to quality.

3. Advanced Technology and Equipment

The technological edge of a PCB fabrication company plays a major role in ensuring precision, consistency, and efficiency throughout the production process. Check whether the company uses the latest software, automation systems, and inspection tools like AOI (Automated Optical Inspection) and X-ray for multilayer PCB verification.

Companies that invest in state-of-the-art machinery and continuous improvement practices are more likely to deliver better turnaround times and fewer defects in finished products.

4. Quality Control and Certifications

Quality assurance should be one of the first things you evaluate. Trusted PCB Manufacturing Company adheres to industry-recognized standards such as ISO 9001, IPC-A-600, and RoHS compliance. These certifications validate that the company follows strict processes to maintain consistency and safety in production.

Ask about their testing protocols—do they conduct electrical testing, impedance control, or thermal stress analysis? Strong internal quality control systems reduce the risk of malfunction or product failure later in the development cycle.

5. Transparent Communication and Customer Support

Effective communication is key to building trust. A reputable PCB manufacturing assembly company will assign a dedicated account manager or support team to guide you throughout the process, from design file review and quote generation to prototyping, production, and delivery.

You want a partner that is responsive to questions, transparent about timelines and costs, and capable of solving challenges quickly should any issues arise.

6. Turnaround Time and On-Time Delivery

Time-to-market is critical in today’s competitive environment. Choose a PCB fabrication company that can meet your deadlines through quick-turn services without compromising on quality. The ability to deliver prototypes in a few days or scale production rapidly based on demand can give your business a significant competitive edge.

Final Thoughts

Partnering with the right PCB fabrication company ensures not only quality output but also a smooth and stress-free production experience. By focusing on experience, technology, quality control, and support, you can find a fabrication partner that aligns with your goals and consistently delivers high-performance results for every project.

0 notes

Text

A Guide About Understanding EMS in Electronics Manufacturing

Electronics Manufacturing Services (EMS) play a vital role in the production of electronic components or sub assemblies. EMS providers offer a range of services such as PCB assembly, Box Build, Supply Chain Management, Engineering, Product Management, and after sales support, ensuring that businesses receive high-quality, reliable electronic products without the need for in-house manufacturing capabilities.

At Arrival Electronics Limited, EMS solutions are designed to support businesses in various industries, including automotive, aerospace, medical, industrial, and consumer electronics. By partnering with a reliable EMS provider, companies can focus on innovation and product development while benefiting from expert manufacturing processes.

The Role of EMS in Modern Electronics Production

EMS providers take on various responsibilities to assist businesses in bringing their products to market. These include:

1. Design and Prototyping

EMS providers collaborate with businesses in the early stages of product development. This includes design assistance, prototyping, and testing to ensure functionality and compliance with industry standards.

2. Component Sourcing and Procurement

Finding the right components at competitive prices is essential in electronics manufacturing. EMS providers leverage their supply chain relationships to source components efficiently while ensuring authenticity and quality control.

3. PCB Assembly (PCBA)

Printed Circuit Board Assembly (PCBA) is a core service in EMS. This involves surface-mount technology (SMT) and through-hole assembly, ensuring the electronic components are securely placed and soldered onto circuit boards.

4. Testing and Quality Control

Quality assurance is critical in electronics manufacturing. EMS providers perform rigorous testing, including in-circuit (ICT), functional, and environmental stress testing, to ensure products meet performance standards and reliability expectations.

5. Final Product Assembly and Integration

Beyond assembling circuit boards, EMS providers also manage full product integration, including enclosure assembly, software installation, and final testing.

6. Logistics and Aftermarket Services

Once the product is manufactured, EMS providers handle logistics, warehousing, and distribution. Additionally, they may offer repair and refurbishment services to extend product life cycles.

Comprehensive Turnkey Manufacturing Solutions for Every Stage of Production

Experience full turnkey manufacturing services designed for precision and efficiency. Our expertise includes:

Complex SMT assemblies

High-density PCBs

Rapid-turn prototypes

Serial production

Box build solutions

Complete product assembly & testing

Custom cable assemblies

Aftermarket service support

Our advanced facilities ensure top-tier quality and innovation at every stage of production.

Benefits of Partnering with an EMS Provider

Choosing a trusted EMS provider like Arrival Electronics Limited brings several advantages to businesses looking to produce high-quality electronic products efficiently.

Cost Efficiency

By outsourcing electronics manufacturing, businesses can reduce operational costs, including labor, equipment, and infrastructure investments. EMS providers streamline production processes, minimising waste and maximising efficiency.

Access to Advanced Technologies

EMS providers stay current with the latest manufacturing technologies, ensuring that businesses benefit from state-of-the-art production methods without the need for continuous investment in new equipment and training.

Scalability and Flexibility

Whether a business needs low-volume prototyping or high-volume production, EMS providers offer the flexibility to adapt to varying demands. This particularly benefits startups and growing companies that need adaptable manufacturing solutions.

Improved Product Quality

Strict quality control measures in EMS manufacturing ensure that each product meets industry and regulatory standards. This reduces defects, enhances reliability, and leads to greater customer satisfaction.

Faster Time-to-Market

EMS providers help accelerate product development timelines by handling the complexities of manufacturing. With efficient production processes, businesses can bring their products to market faster while maintaining high quality.

Key Industries Benefiting from EMS

Various industries rely on EMS providers to develop and produce electronic products efficiently. Some of the key sectors include:

Automotive Electronics: The automotive industry depends on EMS providers to produce advanced driver-assistance systems (ADAS), infotainment systems, and power management solutions. Precision manufacturing is essential to ensure safety and performance in vehicles.

Medical Devices: Medical electronics, including diagnostic equipment, wearable health monitors, and imaging devices, require strict compliance with regulatory standards. EMS providers ensure medical devices meet these standards while maintaining reliability and accuracy.

Aerospace and Defense: In aerospace and defense applications, reliability is paramount. EMS providers manufacture high-performance electronic components for avionics, radar systems, and communication equipment that withstand extreme conditions.

Industrial Automation: EMS supports the development of industrial control systems, sensors, and automation solutions that optimize manufacturing and operational efficiency in industrial settings.

Consumer Electronics: EMS providers manufacture various consumer electronics, from smartphones to smart home devices, ensuring high-quality production while maintaining cost-effectiveness.

Choosing the Right EMS Provider

When selecting an EMS provider, businesses should consider the following factors:

Industry Experience and Expertise

A provider with extensive experience in a specific industry understands the challenges and requirements unique to that sector. Arrival Electronics Limited has decades of experience delivering quality EMS solutions across multiple industries.

Quality Certifications and Compliance

Certifications such as ISO 9001, ISO 13485 (for medical devices), and AS9120B (for aerospace) indicate a provider’s commitment to quality and compliance with industry standards.

Technological Capabilities

An EMS provider should have access to modern manufacturing technologies, including automated assembly lines, advanced testing equipment, and robust supply chain management systems.

Supply Chain and Component Sourcing

A strong supply chain network ensures access to high-quality components while mitigating risks such as shortages and counterfeit parts.

Customer Support and Communication

Clear communication and reliable customer support are essential for successful collaboration. A responsive EMS provider keeps businesses informed throughout the manufacturing process.

Experience Efficiency & Cost Savings with Our Tailored Manufacturing Solutions

We provide efficient, cost-effective manufacturing services designed to meet your unique needs. By leveraging proven lean manufacturing techniques, we help you maximise value with:

Minimal inventory requirements

Lower overall acquisition costs

Risk mitigation through multiple inventory locations

Enhanced quality assurance

Guaranteed on-time delivery

Why Arrival Electronics Limited?

Arrival Electronics Limited is a trusted partner for businesses seeking comprehensive EMS solutions. With a strong commitment to quality, reliability, and industry expertise, the company provides end-to-end support for electronics manufacturing, from design to final product assembly.

With extensive experience in sourcing, assembling, and testing electronic components, Arrival Electronics Limited ensures businesses receive products that meet performance expectations and regulatory standards. Whether you require small-batch prototyping or large-scale production, their team is ready to assist with your EMS needs.

Conclusion

EMS plays a vital role in modern electronics manufacturing, offering businesses a way to produce high reliability products efficiently and cost-effectively. By working with an experienced EMS provider like Arrival Electronics Limited, companies can streamline their production processes, maintain strict quality control, and confidently bring their electronic products to market.

For more information about EMS solutions, visit www.arrivalelectronics.co.uk.

0 notes

Text

CNC Programming & Cam Support — FASTechnologies

FASTechnologies offering CNC Programming , CAM Support, Annual Maintenance Plan, Excellon DNC, CNC6 DNC, System2000 DNC, NC Rout & Drill, PCB DNC, CNC6 Keyboard & Monitor.

In the world of modern manufacturing, CNC programming plays a pivotal role in ensuring precision, accuracy, and efficiency. This computerized approach to controlling machines has revolutionized various industries, from automotive and aerospace to electronics and healthcare. With the aid of CAM (Computer-Aided Manufacturing) systems, CNC programming enables manufacturers to optimize their production processes and deliver high-quality products. In this article, we delve into the intricacies of CNC programming and explore the significance of CAM support in maximizing operational effectiveness.

Introduction to CNC Programming

CNC, short for Computer Numerical Control, refers to the automation of machine tools using computerized systems. This technology allows manufacturers to control and manipulate machine operations with unparalleled accuracy and repeatability. By utilizing programming languages specifically designed for CNC machines, engineers can create detailed instructions that guide the equipment through precise movements and actions. This level of control ensures that complex manufacturing tasks can be executed reliably, resulting in consistent output and reduced errors.

The Role of CNC Programming in Manufacturing

CNC programming is the backbone of modern manufacturing processes. It enables manufacturers to streamline production, reduce cycle times, and increase productivity. By leveraging CNC machines, intricate components and parts can be manufactured with exceptional accuracy and intricate designs that would be challenging or impossible to achieve manually. The versatility of CNC programming makes it an essential tool across various industries, including automotive, aerospace, electronics, and medical device manufacturing.

Understanding CAM Support

CAM, or Computer-Aided Manufacturing, is a crucial aspect of CNC programming. While CNC programming focuses on generating instructions for machine control, CAM support involves creating the instructions necessary to transform a design or model into a physical product. CAM systems work in conjunction with computer-aided design (CAD) software, allowing engineers to translate their designs into machine-readable code. These codes contain information about tool paths, cutting speeds, feed rates, and other parameters required to manufacture the desired product.

Benefits of CAM Support in CNC Programming

Increased Efficiency: CAM support automates the conversion process from design to production, eliminating the need for manual programming. This automation saves time, reduces errors, and enables rapid prototyping.

Enhanced Accuracy: CAM software ensures precise replication of the intended design by providing tools for simulating and optimizing machining processes. This minimizes the risk of errors and ensures consistent quality across production runs.

Complex Machining Capabilities: CAM systems empower manufacturers to create intricate and complex parts that would be challenging to produce using traditional manufacturing methods. With CAM support, manufacturers can leverage the full potential of CNC machines to fabricate innovative designs.

Scalability and Flexibility: CAM software allows manufacturers to efficiently scale production by replicating and modifying machining instructions as needed. This flexibility enables quick adaptation to changing market demands and design iterations.

Conclusion

CNC programming, coupled with CAM support, is a game-changer in the manufacturing industry. It offers precise control, efficiency, and the ability to create intricate designs with exceptional accuracy. With the increasing demand for high-quality products and faster production cycles, mastering CNC programming and utilizing CAM support has become imperative for manufacturers worldwide.

For More Info :https://www.fastechnologies.com/ Contact us : (763) 263-0611

#DNC UltraServer#PCB DNC#Excellon DNC#NC Drill#excellon#System2000 DNC#CNC6 Monitor#CAM support#Gerber#cnc programming#FASTechnologies

0 notes

Text

Innovative Hardware, Software, and Marketing Services for Business Excellence

In a rapidly changing business environment, innovation is critical to staying competitive. Companies today require robust, integrated solutions that encompass hardware, software, and digital marketing to meet evolving customer demands and achieve business excellence. At Tech4Biz Solutions, we offer end-to-end services designed to drive innovation, streamline operations, and fuel long-term growth.

Cutting-Edge Hardware Solutions

At Tech4Biz Solutions, we provide customized hardware solutions that are tailored to meet specific business needs. Whether it’s designing high-performance systems or manufacturing advanced circuit boards, our hardware solutions help businesses stay ahead.

Custom Hardware Design: We develop hardware systems that are optimized for performance and tailored to fit your business workflows.

IoT-Enabled Devices: Our IoT-enabled hardware solutions enhance real-time monitoring and connectivity, empowering businesses to make data-driven decisions.

PCBA and PCB Manufacturing: Our manufacturing services ensure high-quality, reliable, and efficient production of printed circuit boards to support your products.

VLSI Design Services: For businesses looking for advanced integrated circuit design, our VLSI services offer innovation at every stage of product development.

By investing in advanced hardware solutions, businesses can optimize processes, enhance operational efficiencies, and scale more effectively.

Next-Level Software Development Services

In today’s digital-first world, having scalable, secure, and intuitive software is vital for business growth. Tech4Biz Solutions specializes in comprehensive software development services that address the unique challenges of businesses.

Custom Software Development: We create tailored software applications to align with your specific business goals.

Cloud Infrastructure Services: Our cloud services enable businesses to scale operations, improve data accessibility, and enhance system performance.

Process Automation: We develop automation solutions to streamline repetitive tasks, reduce operational costs, and improve accuracy.

Application Modernization: Tech4Biz Solutions also helps businesses update legacy systems to more modern, efficient, and secure platforms.

With our software development services, businesses can increase agility, improve customer experiences, and unlock new opportunities for growth.

Data-Driven Digital Marketing Solutions

Building a strong online presence is essential for companies aiming for long-term business success. At Tech4Biz Solutions, our digital marketing services are designed to boost visibility, enhance engagement, and convert prospects into loyal customers.

Search Engine Optimization (SEO)

Our SEO experts optimize your website to improve search engine rankings and drive organic traffic. We employ a data-driven approach to ensure sustainable growth and increased visibility.

Social Media Marketing

We craft social media strategies that increase brand awareness, drive engagement, and foster a loyal community across platforms like Facebook, Instagram, LinkedIn, and more.

Content Marketing

Content plays a crucial role in establishing authority and building trust with potential customers. Our content marketing services help businesses tell their story and position themselves as thought leaders.

Pay-Per-Click (PPC) Campaigns

Our targeted PPC campaigns are designed to maximize conversions and deliver a high return on investment. By leveraging audience insights and market trends, we create ads that resonate with your target customers.

Email Marketing

Tech4Biz Solutions also helps businesses stay connected with their audience through email marketing. Our personalized email campaigns nurture leads and encourage repeat business.

With our marketing services, businesses can harness the power of digital channels to enhance brand awareness and drive sustained growth.

Integration for Seamless Business Operations

One of the key advantages of working with Tech4Biz Solutions is our integrated approach to hardware, software, and marketing. By aligning all aspects of your business’s digital strategy, we ensure that operations run smoothly and that data-driven decisions are made with confidence.

End-to-End Integration: We create a unified experience across hardware, software, and marketing systems.

Data Insights: Leveraging insights from multiple sources, we help businesses make informed decisions and improve customer satisfaction.

Operational Efficiency: Our solutions reduce redundancies, streamline processes, and improve the overall effectiveness of your business.

Tailored Solutions for Every Industry

At Tech4Biz Solutions, we understand that every industry has its unique set of challenges. That’s why we offer tailored solutions for businesses across sectors.

Small Businesses: For startups and small enterprises, we offer scalable solutions that help accelerate growth.

Medium Enterprises: We provide customized services to help medium-sized businesses expand their reach and improve operational efficiencies.

Large Corporations: Our enterprise-level services cater to complex business needs, driving large-scale digital transformation.

Why Choose Tech4Biz Solutions?

Choosing Tech4Biz Solutions means partnering with a company committed to delivering business excellence. Here are a few reasons why businesses trust us:

Innovation-focused: We stay on top of industry trends and emerging technologies to ensure our clients remain competitive.

Client-centric approach: We put your business goals at the forefront, ensuring that every solution we provide aligns with your vision.

End-to-End Support: From concept to implementation and beyond, we offer comprehensive support at every stage of your project.

Holistic Solutions: By offering hardware, software, and marketing services under one roof, we create seamless, integrated solutions for business success.

Empower Your Business with Tech4Biz Solutions

Tech4Biz Solutions is dedicated to helping businesses achieve excellence through innovation and collaboration. Our comprehensive range of services is designed to drive growth, optimize operations, and improve customer engagement.

Ready to take your business to the next level? Visit our website at Tech4Biz Solutions to learn more about how our innovative hardware, software, and marketing services can fuel your business growth.

0 notes

Text

Electronic Design Automation Software Market Size And Share Report, 2030

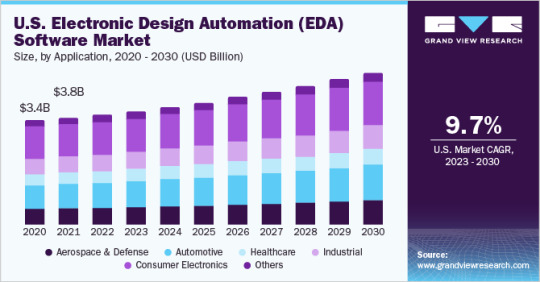

Electronic Design Automation Software Market Growth & Trends

The global electronic design automation software market size is anticipated to reach USD 22.21 billion by 2030, expanding at a CAGR of 9.1% from 2023 to 2030, according to a new study by Grand View Research Inc. The growing usage of advanced electronic components across different areas of healthcare, automotive, and consumer electronic sectors is driving Electronic Design Automation (EDA) software market growth. Apart from this, the proliferation of the Internet of Things (IoT) and connected devices further promotes EDA software market advancement.

Miniaturization of devices and chips is expected to create lucrative opportunities for EDA software. This software assists chipmakers in lowering the errors in Integrated Circuit (IC) and chips, thereby driving the electronic design automation software industry growth. The exponential growth of the integrated circuits market is driving the need for electronic design automation software. The software is increasingly being adopted for designing electronic systems such as printed circuit boards and integrated circuits, supporting the growth of the EDA market.

Furthermore, developments in technology, growing digitization, growth of the electronics manufacturing industry, and increasing adoption of advanced rendering & simulation tools by hardware designers are expected to positively influence the electronic design automation software industry growth over the forecast period. Furthermore, the increasing acceptance and awareness of smart fitness devices are factors enabling electronic design companies to invest in innovative design software tools for designing enhanced & compact products, thereby propelling the EDA software market growth over the forecast period.

Growing demand for EDA software is encouraging various market players to adopt various business strategies to achieve higher profitability in the market for electronic design automation software. Market players are unveiling new solutions by partnering with technology providers to improve their brand identity, propelling the EDA software market growth. For instance, in January 2022, Altium LLC announced a partnership with MacroFab, Inc., a U.S.-based cloud platform provider for electronic production, to launch “Altimade.” The new solution combines elastic manufacturing capabilities and real-time supply chain data, available on the Altium 365 electronic design platform. Altimade empowers customers to request instant quotes and place orders for manufacturing their PCB assembly without exiting the design environment.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/electronic-design-automation-eda-software-market

Electronic Design Automation Software Market Report Highlights

The services segment is expected to register a CAGR of 10.6% from 2023 to 2030. The segment growth can be attributed to the increasing proclivity of OEMs to outsource their design needs. Furthermore, electronic circuit boards are in high demand in the industry due to their increasing importance in a variety of vital electronic products such as mobile phones and tablets

The cloud segment is expected to register a CAGR of 10.8% from 2023 to 2030. Cloud-based deployment allows for faster distribution, less maintenance, lower costs, and more scalability

The healthcare segment is expected to register a CAGR of 11.5% from 2023 to 2030. The segment growth can be attributed to the benefits of EDA software in healthcare, such as lower costs, improved patient outcomes, faster design & development, enabled regulatory compliance of medical devices, and simulation and testing of medical equipment

The microprocessors & controllers segment is expected to register a CAGR of 9.5% from 2023 to 2030. The increased use of microprocessors in consumer devices such as smartphones, personal computers (PCs), and laptops is expected to drive global demand for the segment

Asia Pacific is anticipated to emerge as the fastest-growing region over the forecast period at a CAGR of 9.6%. A surge in demand for electronic devices together with the prevalence of key electronic component manufacturers in Greater China is expected to drive regional growth

Electronic Design Automation Software Market Segmentation

Grand View Research has segmented the global electronic design automation software market based on product, deployment, application, end-use, and region:

Electronic Design Automation (EDA) Software Product Outlook (Revenue, USD Billion, 2018 - 2030)

Computer-aided Engineering (CAE)

IC Physical Design and Verification

Printed Circuit Board and Multi-chip Module (PCB and MCM)

Semiconductor Intellectual Property (SIP)

Services

Electronic Design Automation (EDA) Software Deployment Outlook (Revenue, USD Billion, 2018 - 2030)

Cloud

On-premise

Electronic Design Automation (EDA) Software Application Outlook (Revenue, USD Billion, 2018 - 2030)

Aerospace and Defense

Automotive

Healthcare

Industrial

Consumer Electronics

Others

Electronic Design Automation (EDA) Software End-use Outlook (Revenue, USD Billion, 2018 - 2030)

Microprocessors & Controllers

Memory Management Unit (MMU)

Others

Electronic Design Automation (EDA) Software Regional Outlook (Revenue, USD Billion, 2018 - 2030)

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

List of Key Players in the Electronic Design Automation Software Market

Advanced Micro Devices, Inc.

Aldec, Inc.

Altair Engineering Inc.

Altium LLC

Autodesk, Inc.

ANSYS, Inc.

Cadence Design Systems, Inc.

eInfochips

EMA Design Automation, Inc.

Keysight Technologies

Microsemi

Synopsys, Inc.

Silvaco, Inc.

The MathWorks, Inc.

Vennsa Technologies

Zuken

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/electronic-design-automation-eda-software-market

#Electronic Design Automation Software Market#Electronic Design Automation Software Market Size#Electronic Design Automation Software Market Share

0 notes

Text

Key Factors to Consider When Choosing an X-Ray Inspection System

X-ray inspection systems have become indispensable in industries like manufacturing, electronics, food processing, and aerospace, offering unparalleled accuracy in detecting defects and ensuring quality control. However, selecting the right X-ray inspection system can be a challenging task, given the variety of options available in the market. Choosing the wrong system can lead to inefficiencies, higher costs, and potential risks to your production process. To help you make an informed decision, this article outlines the key factors to consider when selecting an X-ray inspection system for your needs.

1. Industry-Specific Requirements

Different industries have unique demands when it comes to X-ray inspection. The system you choose should be tailored to the specific requirements of your sector.

Food Industry: Systems must detect foreign objects like metal, glass, and bone while meeting strict regulatory standards.

Electronics: High-resolution systems are essential for inspecting solder joints, PCBs, and micro-components.

Aerospace and Automotive: Systems need to detect internal cracks or voids in critical components to ensure safety.

Understanding your industry’s specific requirements will help you narrow down options and select the most suitable system.

2. Inspection Resolution and Sensitivity

The resolution and sensitivity of an X-ray inspection system determine its ability to detect small or subtle defects. High-resolution systems are crucial for industries like electronics and aerospace, where even minute defects can have significant consequences.

Key Considerations:

Check the resolution of the detector and the size of defects the system can identify.

Ensure the system provides consistent sensitivity across varying materials and densities.

Higher resolution often comes with a higher price tag, so balance your needs with your budget.

3. System Throughput and Speed

For industries with high production volumes, the speed and throughput of the X-ray system are critical. A slower system can create bottlenecks, impacting overall efficiency.

Key Considerations:

Evaluate the inspection speed and whether it aligns with your production line’s output.

Check if the system can handle batch or continuous inspections without compromising accuracy.

Some systems are designed for high-speed applications, making them ideal for industries like food processing and packaging.

4. Ease of Integration and Scalability

The X-ray inspection system should integrate seamlessly into your existing production line or workflow. Additionally, it should offer scalability to accommodate future growth or changes in production demands.

Key Considerations:

Ensure the system supports easy integration with current conveyor belts, robotic arms, or other automated systems.

Look for modular designs that allow upgrades or expansion without replacing the entire system.

Seamless integration reduces downtime and ensures smooth operations.

5. Software Capabilities

Modern X-ray systems are equipped with advanced software for analysis, reporting, and automation. The right software can enhance functionality and usability.

Key Features to Look For:

User-friendly interface and intuitive controls.

Automated defect detection using AI or machine learning.

Real-time monitoring and data analysis capabilities.

Compatibility with your existing quality management systems.

Advanced software can significantly reduce human error and improve inspection accuracy.

6. Regulatory Compliance

In industries like food and pharmaceuticals, compliance with regulatory standards is non-negotiable. The X-ray system you choose must meet these standards.

Key Considerations:

Verify that the system adheres to industry-specific regulations such as FDA, HACCP, or ISO certifications.

Ensure it has features like contaminant detection or radiation shielding to meet safety requirements.

Compliance ensures smooth audits and avoids potential legal issues.

7. Maintenance and Support

An X-ray inspection system is a long-term investment that requires regular maintenance and support to perform optimally.

Key Considerations:

Evaluate the manufacturer’s service offerings, including maintenance contracts and warranty terms.

Check for the availability of spare parts and the ease of replacing them.

Ensure the system comes with robust technical support and training resources.

Reliable maintenance and support minimize downtime and extend the system’s lifespan.

8. Cost and Return on Investment (ROI)

While cost is a significant factor, it’s essential to assess the value the system brings to your operations rather than focusing solely on the initial price.

Key Considerations:

Compare the system’s cost with the benefits it offers, such as improved accuracy, reduced waste, and enhanced quality control.

Calculate the potential ROI by factoring in productivity gains, reduced defect rates, and customer satisfaction.

Investing in a high-quality system may involve higher upfront costs but can lead to substantial savings over time.

9. Radiation Safety

X-ray systems emit radiation, which can pose risks if not properly contained. Ensuring the system meets safety standards is vital for protecting operators and complying with regulations.

Key Considerations:

Check for shielding features that minimize radiation exposure.

Ensure the system complies with radiation safety standards such as ANSI or CE certifications.

Proper safety measures create a secure working environment and build trust with employees.

Conclusion

Choosing the right X-ray inspection system is critical for ensuring the efficiency and safety of your production processes. By considering factors such as industry requirements, resolution, throughput, integration, software capabilities, compliance, and cost, you can make an informed decision that aligns with your business needs. Investing in the right system not only improves product quality but also enhances your brand reputation and operational efficiency. Take the time to evaluate your options, and you’ll find an X-ray inspection system that delivers long-term value.

0 notes

Text

Electronic Manufacturing Services Danbury and PCB Design Services Boston: Expert Solutions by Microart Services

In the fast-evolving world of electronics, reliable and precise manufacturing services are essential to bring innovative products to life. At Microart Services, we offer specialized Electronic Manufacturing Services Danbury and PCB Design Services Boston to support companies in every stage of the electronics production process. From initial design to full-scale manufacturing, our services provide the high standards of quality, reliability, and speed that businesses need to stay competitive and responsive to market demands.

Electronic Manufacturing Services Danbury: Comprehensive Production Solutions

For companies in Danbury, Microart Services provides a full suite of Electronic Manufacturing Services (EMS) tailored to meet the demands of modern electronics. Our EMS solutions are designed to support companies in sectors like telecommunications, automotive, medical devices, and industrial electronics, delivering the reliable and scalable production solutions they need to stay competitive.

With Electronic Manufacturing Services Danbury, our goal is to take your product from concept to reality with precision and efficiency. We offer end-to-end manufacturing services, including prototyping, component sourcing, PCB assembly, and final product testing. This ensures your electronics are built to the highest quality standards, with careful attention to every detail.

Microart Services understands the importance of flexibility in manufacturing. Our Electronic M anufacturing Services Danbury are designed to support low to medium volume production, so companies can scale their projects according to demand. We also use rigorous quality control processes and state-of-the-art equipment to guarantee each product meets industry standards. Whether you need a single prototype or a full production run, our Danbury team is ready to support your goals.

PCB Design Services Boston: Bringing Innovation to Life

In Boston, where innovation and technology thrive, Microart Services offers top-tier PCB Design Services to help companies create precise and functional circuit boards that meet their product requirements. From initial concept and schematic design to layout and testing, our PCB Design Services Boston cover the complete PCB design process.

Our PCB Design Services Boston team uses the latest software tools to create complex, high-performance PCB layouts that meet both functional and aesthetic requirements. Our design experts are experienced in creating layouts that support advanced technologies such as multi-layer boards, high-speed circuits, and HDI (high-density interconnect) designs. This ensures that each PCB is optimized for performance, reliability, and manufacturability.

Through our PCB Design Services Boston, we work closely with clients to understand their specifications and ensure the final product aligns with their goals. Whether you're creating a product prototype or refining a design for large-scale manufacturing, our team can accommodate any level of complexity and customization, helping bring your product vision to life.

Why Choose Microart Services?

At Microart Services, we combine technical expertise, state-of-the-art facilities, and customer-focused service to provide the best Electronic Manufacturing Services Danbury and PCB Design Services Boston. Here’s why companies across industries trust us for their electronics projects:

Expert Team: With years of experience in electronic manufacturing and PCB design, our team has the knowledge and skill to tackle even the most complex projects. We stay current with industry standards and technologies to ensure we deliver top-quality results.

State-of-the-Art Technology: We invest in advanced equipment and software to ensure our manufacturing and design capabilities meet the highest industry standards, enabling us to deliver precise and high-performing products.

Custom Solutions: At Microart Services, we understand that every project is unique. Our team works closely with clients to provide tailored solutions that meet specific needs, from complex design requirements to scalable manufacturing.

Rigorous Quality Control: Quality is at the core of our Electronic Manufacturing Services Danbury and PCB Design Services Boston. We adhere to strict quality control processes to ensure each product meets exact specifications and reliability standards.

End-to-End Support: Our comprehensive approach supports clients from concept to production, ensuring a seamless and efficient process. We manage all aspects of the project, including design, manufacturing, assembly, and testing, so clients receive a complete solution under one roof.

Conclusion

For companies in Danbury and Boston, Microart Services offers dependable Electronic Manufacturing Services Danbury and innovative PCB Design Services Boston. By combining advanced technology with a commitment to quality, we provide efficient and customized solutions that meet the specific needs of electronics manufacturers and product developers. With Microart Services as your partner, you can be confident in achieving reliable, high-quality results for all your electronics projects.

Contact Microart Services today to learn how our comprehensive manufacturing and design solutions can support your business goals. From the first prototype to full production, we’re dedicated to bringing your electronic innovations to life with precision, efficiency, and expertise.

0 notes

Text

PCB for Power Electronics - A Design Guide | PCB Power

Printed Circuit Board (PCB), primarily used in power electronics, acts as a crucial part for several applications, from electric vehicles to renewable energy systems. Growing demands for miniaturized, efficient, and reliable power electronics shall require further innovations in power PCB design. This article discusses some important considerations and best practices in PCB design & manufacturing for power electronics.

The Unique Challenges of Power Electronics PCB Design

Power electronics PCBs have specific challenges that differ from general-purpose PCBs:

High Power Densities: Power PCBs handle significant power, resulting in high temperatures that can lower component performance and its lifespan.

Electromagnetic Interference (EMI): Power PCBs need high-speed switching operations. This generates EMI, which can disrupt the PCB's functionality.

Signal Integrity: Maintaining signal integrity is very important to ensure accurate and timely data transmission.

Power Integrity: Optimal voltage levels and minimal voltage drops are essential for reliable operation.

Key Design Considerations and Best Practices for Power Electronics PCBs

To design high-power PCBs, consider the following key design considerations:

1. Thermal Management:

Heat Sink Design: Implement effective heat sinks to dissipate heat efficiently from critical components.

Thermal Vias: Utilize thermal vias to conduct heat away from heat-generating components.

Material Selection: Choose PCB materials with high thermal conductivity.

2. Electromagnetic Interference (EMI) Mitigation:

Shielding: Implement shielding techniques to isolate sensitive components from EMI sources.

Grounding: Implement proper grounding practices to minimize noise and interference.

Layout Techniques: Carefully plan the layout to reduce loop areas and minimize EMI radiation.

3. Signal Integrity:

Controlled Impedance: Ensure consistent impedance for signal transmission.

Differential Signaling: Use differential signaling to reduce noise and improve signal integrity.

Short Trace Lengths: Minimize trace lengths to reduce signal delays and crosstalk.

4. Power Integrity:

Wide Traces: Employ wide traces to minimize voltage drops.

Power Plane Design: Design power planes to distribute power evenly.

Decoupling Capacitors: Place decoupling capacitors close to power supply pins to filter out noise.

5. Component Selection:

High-Power Components: Choose components rated for high power and temperature.

Reliable Suppliers: Source components from reputable suppliers like PCB Power to ensure quality and performance.

6. Design Tools and Software:

CAD Tools: Utilize powerful CAD tools for efficient PCB design and check DFM (Design for Manufacturability).

Simulation Tools: Employ simulation tools to analyze thermal, electromagnetic, and signal integrity issues.

Conclusion

By carefully considering these factors and employing advanced design techniques, you can create power electronics PCBs that are reliable, efficient, and capable of meeting the demands of modern applications.

Why Choose PCB Power for Your Projects?

PCB Power has been serving the market with top service in end-to-end PCB manufacturing solutions for 35 years now. We guarantee certified quality and modern technology so that products can meet the highest standards.

If you're looking for a reliable PCB manufacturing partner in the USA, just fill out a form on our website and our team will get in touch with you to discuss your PCB requirements.

Read More:- PCB for Power Electronics - A Design Guide | PCB Power.

0 notes