#ParamountInstruments

Text

🌟 Exciting Announcement!

We are thrilled to share that we are all set to participate in the upcoming BNI Greater Surat Business Conclave, taking place from 2nd to 4th February 2024!🚀

We are super excited to network & showcase Our Latest Cutting-Edge Innovations which we are sure you wouldn’t want to miss out on!!✨

Save the dates, mark your calendars 🗓️ and stay Tuned for More exciting updates coming your way!✨🔜

#BNISURAT#Exhibition#ParamountInstruments#BNIConclave#SuratConclave#Network#TestingEquipments#ManufacturingIndustry#SaveTheDate

0 notes

Text

Tensile Strength Tester: The Indispensable Testing Solution To Eliminate Rejections!

The Textile Industry supplies a wide array of everyday products, from clothing and household textiles to industrial materials. Among the critical tests that are required to be performed in the textile industry to ensure up to the mark quality, safety, and usage of the final products, The Tensile Strength Test is the most basic requisite as it assesses a material's ability to endure stretching forces without breaking.

Rejected items not only result in financial losses but heavily damage a company's reputation.

This is where a Tensile Strength Tester can help in not only eliminating rejections but also taking your quality control to new heights! Before talking about how the tensile strength tester makes it possible, Lets briefly understand it’s working.

What is it & Why to Use it?

The Tensile Strength Testing, also referred to as The Tension Test, is a fundamental property test that is used to determine how much force a material can withstand when subjected to a pulling or stretching force. Tensile Strength Testing provides insightful data regarding a fabric’s ability to withstand different stresses during its entire lifecycle, from the initial stages of production to the end-use consumption. Using this test, the manufacturers can gauge the following parameters -

1. Strength

2. Durability

3. Quality

4. Performance

5. Safety

And all these factors deeply contribute to ensuring that the final produced product is up to the mark in its intended use.

Now let's come to the key points of How a Tensile Strength Tester significantly helps in reducing rejections through the Tensile Strength Test by assessing the test specimen on all the vital parameters -

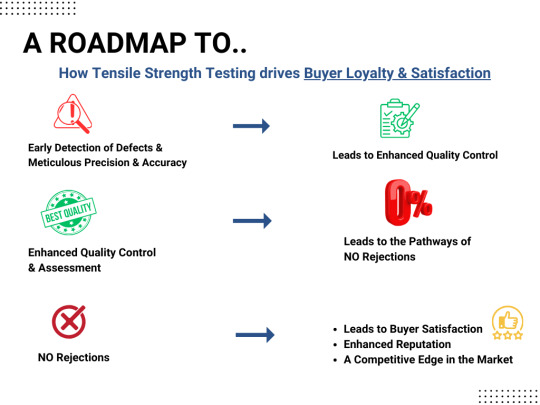

1. Timely Detection of Defects – Tensile strength testing allows manufacturers to identify material weaknesses at an early stage of the production process. This means that any issues or defects in the materials can be addressed and rectified before they progress further in the manufacturing process. This Precautionary Approach results in resolution of any issues within the materials, in detail preventing their escalation throughout manufacturing stages.

2.Meticulous Precision & Accuracy - Using Tensile Strength equipment precisely accurate measurements of a material’s ability to withstand stretching forces are calculated. With this accuracy manufacturers can rely on test results to make well-informed and thought-of decisions.

3. Enhanced Quality Control – With the Timely Detection of Defects & Meticulous Precision & Accuracy, manufacturers can be assured that the tested materials meet the required standards for durability and strength. This all in all, leads to the production lot being less likely of getting rejected!

4. Minimization of Product Rejections – Coming to the most crucial aspect of testing that is Reduced to NO Rejections. With all the above-mentioned benefits that tensile testing helps in achieving it leads to a significant reduction in the number of rejections. Fewer rejections would mean more cost savings and an overall efficient manufacturing process.

Above Highlighted, is a pictorial representation of how incorporating tensile strength testing by investing in the right tensile strength machine can help to achieve Long-Term Buyer Satisfaction & Loyalty as a result of Zero Rejections and ultimately lead to COMPLETE PEACE OF MIND!

#paramountinstruments#testingequipments#textile#qualitycontrolassessment#textileindustry#tensiletester#zerorejections#norejections#qualitytesting#qualityassurance#manufacturingindustry

0 notes

Text

IOT has been on an unstoppable rise of captivating industries from all over that are transitioning into this dynamic realm. Connected to IOT, is IIOT frequently used in industries like Manufacturing, Textiles, Automotive, and Healthcare to name a few. Check out our latest blog at

as we talk about it in detail, its benefits, and how it is transforming the Manufacturing Industry.

#ParamountInstruments#IIOT#IIOTinMachines#IOT#TextileTesting#QualityAssurance#MachineLearning#IOTTrends#SmartManufacturing#ConnectedDevices#IIoTTechnology#IndustrialInternetOfThings

0 notes

Text

Choosing the Best Textile Testing Equipment: 5 Crucial Questions to Consider

Quality Control is Paramount in any industry be it Manufacturing, Health Care or any other industry that values providing the right quality to its customers! In the Textile industry to ensure that the fabrics meet the desired specifications, choosing a reliable testing equipment for your textile lab is KEY. Sometimes choosing the testing equipment can get challenging and confusing all at the same time.

So, we have listed below the 5 questions to consider when purchasing your Next Testing Equipment that can help you make an informed decision!

1. How Accurate & Precise is the Result Generation?

Accuracy & Precision are one of the most important parameters that should be considered when purchasing a testing equipment. If a machine fails to deliver accurate results, the main objective of testing is clearly unmet. Accuracy refers to how closely the measurements align with their truest values while Precision reflects on a machine’s consistency in providing identical results during multiple measurements of the same sample. If a machine is accurate and precise in result generation, it can ensure that the assessment of vital properties of the fabrics such as Tensile Strength, Color Fastness, Thickness etc. which directly impact a product’s quality is done appropriately.

Things to keep in Mind when inspecting the Instrument on Accuracy and Precision Grounds

a). Check its Specification and Technical Details

b). See the Calibration Process

c). Confirm if the equipment adheres to the Required International Testing Standards

2. Do the Equipment’s Testing Capabilities Align with your Lab/Buyer’s Specific Testing Needs?

The testing requirements of different textile labs may vary depending on the type of fabrics they work with and the industry standards they are required to meet. Therefore, it is important to choose the testing equipment that fully aligns with the lab’s specific needs. Similarly, the buyer might also have a certain set of requisites that have to be fulfilled which the testing equipment should be able to assess.

Factors to consider when evaluating the testing capabilities of an equipment -

A). Test Type — Determine and evaluate the tests that you are required to conduct. For example, if you deal with apparel fabrics, the equipment that will be needed for tests should be able to test properties like color fastness, tear strength, pilling resistance etc.

B). Sample Size — The equipment must be able to accommodate the sample size that you typically work with. This is because some instruments are designed for small swatches.

C). Test Speed — Depending on the overall efficiency and workload requirements, the testing speed of the equipment needs to be kept in mind too. If your workload is more, you would need faster machines that generate more productivity, however they come at a higher cost.

D). Automation — Automation is one feature that can substantially improve the reliability and consistency of the test results. So, make sure to look for an equipment that comes with automation features such as automatic data recording or sample feeding to eliminate any manual and redundant tasks.

3. Are Calibration & Maintenance Services readily available ?

To make sure that the test results are dependable and reliable every time, it is crucial to consistently calibrate and maintain any testing equipment. So, when choosing the equipment for your textile lab, assessing the ease of calibration and the smooth accessibility to maintenance services is important. Some equipments require built in calibration routines so that needs to be considered too. Having swift technical assistance and maintenance can reduce the overall downtime and work towards extending the lifespan of the equipment. Therefore, keeping the two in consideration when on the lookout for purchasing a testing machine is essential.

4. Is it Easy to Operate or Is Extensive Training needed?

Ease of use is another important factor when choosing a testing equipment, majorly for labs that have operators with different levels of expertise. The equipment is considered user-friendly if it features an intuitive interface and provides clear operation, setup and troubleshooting instructions.

Criteria to consider when assessing the usability aspects of an equipment -

A). Software Interface — How is the software interface like? How does it impact the overall testing efficiency? Is it smooth in navigation, and does it offer any reporting capabilities and data analysis?

B). Training and Support Provision — Are any support options and trainings provided by the manufacturer to minimize user errors and ensure accurate equipment operation.

C). Documentation — Are User Manual Guides and Technical Details provided in an easy-to-understand format to support the operators?

5. Does the Cost align well with your Company’s Budget?

Finally coming to the most pivotal decision-making factor, the Cost with the Budget Alignment. To strike a balance between Quality and Budget is very challenging and so when weighing the cost considering the following factors will make decision making easier.

A). Initial Capital — Make sure to include the upfront machine cost and any necessary add-ons in the total budget.

B). Running Costs — Assess and Evaluate any ongoing costs like maintenance, calibration, and consumables to calculate the overall total ownership expense.

C). Return on Investment (ROI) — Examine how the equipment enhances the product quality, productivity and the lab’s efficiency in terms of Output, Cost, Rejection Rate, Production.

D). Warranty & Service Support Agreements — Understand and Review the manufacturer’s service and warranty terms. Affordable service agreements and Extended warranties can help in reducing unexpected expenses.

To conclude, when buying lab testing equipment, it is important to make informed decisions based on a thorough assessment of accuracy, precision, testing capabilities, maintenance, calibration, user-friendliness, and cost.

Choosing your next equipment keeping these vital parameters in mind will help in selecting an equipment that specifically caters to your needs and ensure the high-quality of your textile products, in turn leading to Happy Buyers!

Originally Published on www.paramountinstruments.com

#paramountinstruments#qualitycontrol#testingequipments#qualityassurance#performancetesting#questionsworthasking#textiletesting#manufacturingindustry#testing#textile#qualitycontrolassessment#accuracy#precision#precisionintesting#calibration

0 notes

Text

Button Snap Pull Tester: A Comprehensive Guide for Buyers and Manufacturers

If you are in the business of producing clothing, bags, or any other textile products, you know the importance of the quality of buttons and snaps. In order to ensure that the buttons and snaps are securely attached to your products, you need a reliable tool to test them. That’s where the button snap pull tester comes into play. In this article, we will cover everything you need to know about this essential testing tool.

What is a Button Snap Pull Tester?

A button snap pull tester is a device that is used to determine the holding strength of buttons and snaps. It measures the force required to pull the button or snap off the fabric. This type of test is crucial for ensuring the durability and safety of products, particularly for items that are subjected to regular use and wear.

Types of Button Snap Pull Testers

There are two main types of button snap pull testers: manual and digital.

Manual Button Snap Pull Tester

A manual button snap pull tester is a basic, handheld device that relies on the user’s strength to pull the button or snap from the fabric. It consists of a calibrated spring, a hook to hold the button or snap, and a gauge to display the force measurement. Manual testers are suitable for small-scale production or for occasional use.

Digital Button Snap Pull Tester

A digital button snap pull tester is a more advanced and accurate device that uses an electronic sensor to measure the force applied to the button or snap. The results are displayed on a digital screen, making it easier to read and record. Digital testers are ideal for high-volume production or for frequent use.

Key Features to Consider When Buying a Button Snap Pull Tester

When choosing a button snap pull tester, there are several key features to consider:

Capacity

The capacity of a button snap pull tester refers to the maximum force that it can measure. Make sure to choose a tester with a capacity that is suitable for the types of buttons and snaps that you will be testing.

Accuracy

The accuracy of a button snap pull tester refers to how closely the measurements match the actual force applied. Look for a tester with a high level of accuracy to ensure reliable results.

Speed

The speed of a button snap pull tester refers to how quickly the device can perform a test. If you need to test large volumes of buttons or snaps, look for a tester with a fast speed.

Ease of Use

Make sure to choose a button snap pull tester that is easy to operate and user-friendly. Look for features such as simple controls, clear instructions, and a straightforward setup.

Benefits of Using a Button Snap Pull Tester

Using a button snap pull tester offers several benefits for both manufacturers and buyers:

Ensures Quality and Safety

By testing buttons and snaps with a pull tester, manufacturers can ensure that their products meet quality and safety standards. This helps to prevent accidents and increases customer satisfaction.

Saves Time and Money

Testing buttons and snaps with a pull tester can help to identify defects early on in the production process. This can save manufacturers time and money by avoiding costly rework or recalls.

Increases Efficiency

Using a button snap pull tester can increase the efficiency of the production process by providing fast and accurate measurements. This helps manufacturers to identify any issues and make necessary adjustments quickly.

Conclusion

A button snap pull tester is an essential tool for anyone involved in the production of textile products. By choosing the right tester and using it regularly, manufacturers can ensure that their products are of the highest quality and meet safety standards. Buyers can also benefit from testing buttons and snaps to ensure that they are purchasing durable and safe products.

#paramountinstruments#testingequipments#qualityassurance#buttonsnaptester#buttonsnap#qualitycontrol#qualitycontrolassessment#qualitytesting

0 notes

Text

IOT has been on an unstoppable rise of captivating industries from all over that are transitioning into this dynamic realm. Connected to IOT, is IIOT frequently used in industries like Manufacturing, Textiles, Automotive, and Healthcare to name a few. Check out our latest blog at Paramount Instruments as we talk about it in detail, its benefits, and how it is transforming the Manufacturing Industry.

#ParamountInstruments#IIOT#IIOTinMachines#IOT#TextileTesting#QualityAssurance#MachineLearning#IOTTrends#SmartManufacturing#ConnectedDevices#IIoTTechnology#IndustrialInternetOfThings

0 notes

Text

Predictive Maintenance in the Manufacturing Industry

In the ever-evolving landscape of the manufacturing industry, where the downtime can easily translate to resulting in heavy financial losses, predictive maintenance has emerged and now become a groundbreaking solution with many industries including manufacturing industries that are seamlessly transitioning to embrace its significantly valuable advantages.

So, What is Predictive Maintenance?

Predictive Maintenance is a strategic and proactive approach to any equipment’s maintenance that uses advanced and high-end technologies as well as data analytics to predict when the testing machinery is likely to fail, therefore allowing for timely interventions and reducing the risk of disruptions in the production processes.

Why is Predictive Maintenance Important?

The importance of Predictive Maintenance lies in the valuable benefits that it offers starting with: -

1. Avoiding Unplanned Downtime

Predictive Maintenance helps in utilizing real-time data and condition monitoring to predict potential issues before they even escalate into critical and damaging failures. This anticipation helps manufacturers to schedule and plan maintenance during planned downtimes, avoiding any costly disruptions to occur during production processes.

2. Streamlining Asset Performance

With the continuous assessment and monitoring of the condition of the manufacturing equipment, predictive maintenance makes sure that the assets operate at their peak efficiency. This not only helps to extend the lifespan of the machinery but also fully maximizes the production output as well as reduces the unnecessary energy consumption.

3. Cost Efficiency

The ability to timely navigate and address issues before they result in major breakdowns drastically minimizes repair and replacement costs. This cost-effective and efficient approach to maintenance is one of the driving reasons for its widespread adoption, especially in the manufacturing sector.

4. Enhanced Quality Control

Predictive Maintenance plays an important role in enhancing quality control, especially within the textile industry by proactively managing the performance and health of the machinery. Fully utilizing the real-time data and advanced analytics, predictive maintenance helps in ensuring that the manufacturing equipment operates under the desired optimal conditions. This proactive approach makes sure that the corrective measures are taken well in advance, to avoid any escalation of problems and fully safeguard the overall quality of the manufactured textiles.

5. Data-Driven Decision Making

Textile Manufacturers can fully harness the valuable insights derived from predictive maintenance data to enhance overall productivity and efficiency. This obtained information can act as a strategic asset, empowering manufacturers to make better and well-informed decisions that can minimize downtime, optimize the overall operations, and elevate the productivity of manufacturing processes.

6. Ensuring Operational Safety

Predictive Maintenance also helps in ensuring operational safety as the machines operating at their highest performance levels are not only efficient but even less likely to malfunction unexpectedly. This optimization is important in creating a safe and sound working environment where the equipment behaves and functions predictably, thus reducing any chances of accidents that could be caused by unforeseen technical errors.

7. Achieving a Competitive Edge

Manufacturers that are leveraging the power of predictive maintenance also gain a strong strategic advantage over their competitors as this systematic approach helps in achieving efficient textile production at a much lower cost compared to their counterparts.

Essential Components in Predictive Maintenance

Presented below are the 3 Vital components that help in creating a robust framework for enabling industries to predict, prevent, monitor, assess, and optimize equipment performance.

a). Smart Sensing Solutions

The Advanced Sensor Technology integrated in the system allows to collect real-time data on various aspects of the machinery such as vibration, lubrication, and temperature to name a few. These sensors serve as integral components by providing important data inputs to enhance the observational capabilities of the predictive maintenance systems.

b). Advanced Analytics and Machine Learning

Cutting-edge algorithms assess and analyze the data collected by sensors to identify patterns that indicate any potential equipment failures. Machine learning models constantly work to improve predictive capabilities with more data, thus refining the accuracy and precision of maintenance predictions over time.

c). Condition Monitoring

Consistent Monitoring of the machine conditions allows the manufacturers to move from planned maintenance to condition-based maintenance. This shift minimizes unnecessary interventions making sure that the maintenance activities are performed accurately when required.

All in all, Predictive Maintenance holds significant importance in the Manufacturing industry as it reduces unnecessary costs, minimizes downtime, enhances the product quality, and helps in improving the overall operational efficiency. The use of data and technology in the predictive maintenance structure ensures that the manufacturing equipment runs smoothly, which is very important in a cutting-edge and competitive industry like the Textile industry as Product Quality and Efficiency are key factory for Success and providing the Right value to the Customers.

#paramountinstruments#qualitycontrol#qualityassurance#qualitycontrolassessment#iiot#predictive maintenance#technology#software#machine learning

0 notes

Text

Is Switching to IOT a Trend or Need of the Hour?

The BUZZWORDS: IOT & IIOT

IOT, or the Internet of Things has been on an unstoppable rise of captivating industries from all over that are transitioning into this dynamic realm. Connected to IOT, is IIOT which is the Industrial Internet of Things more frequently used in industries like Manufacturing, Textiles, Automotive, Healthcare to name a few. This Industrial Internet of Things is a groundbreaking technological framework that uses the integration of machines, physical devices, software systems, and sensors within the industrial settings.

The sole purpose of it is to provide seamless communication and data exchange between the components that are interconnected. In generic terms, the implementation of IIOT refers to employing smart devices and sensors across diverse industrial sectors that carefully monitor equipment performance, environmental conditions, and many other vital parameters that then transmit data to centralized computer systems for in-depth analysis.

Is it a trend or Pre-Requisite in Today’s Time?

At first, IOT and IIOT truly felt like those popular lingo terms that were discussed in every industry event, conferences, and even got media coverage, seemingly everywhere. However, it was only later that when people began to understand the vital significance this advancement holds today with the benefits it was offering it started getting adopted. This realization prompted industries worldwide, including manufacturing, healthcare, education, and more, to embrace and adopt these technologies. Enforcing IOT into functioning has given businesses a competitive edge to get access to and harness data-driven insights for enhanced decision making. So, what started as a Market Buzz has become a Pre-Requisite for industries who want to take their businesses to the next level!

Now that we know that having IIOT can enhance the overall productivity of a business let's move to throwing some light on highlighting the key benefits that it offers.

Benefits of IIOT

Enhanced Efficiency – IIOT helps in integrating devices, sensors and data analytics that fully optimize the industrial processes. It effectively works towards automating mundane tasks, reducing the human intervention and errors.

Real-Time Data Monitoring – One of the biggest perks of implementing the IOT framework is the real-time data monitoring and assessment with the help of which any inefficiencies can be mitigated and opportunities for improvement can be identified. Therefore, streamlining the operations, improving productivity and lowering the downtime.

Insights Driven by Data – IIOT also helps in generating vast amounts of valuable data using the sensors and devices. Once this data is processed, it can be thoroughly analysed to provide valuable insights. Using this data, well-informed decisions can be made by businesses allowing them to respond to changing conditions proactively.

Predictive Maintenance – Another key advantage that IIOT offers is the ability to provide data for predictive maintenance. This is a risk-avoidant maintenance strategy that uses heavy-centric data analytics to predict when a machinery or equipment is likely to fail so that its required maintenance can be performed just in time.

Cost Savings – This benefit is the result of the predictive maintenance that IIOT provides. With the prospective opportunity areas and elimination of problems or issues navigated beforehand it helps to avoid any costly machine breakdowns and repairs.

Quality Improvement – With the monitoring of vital parameters in real-time, manufacturers can now easily identify the deviations from the required standards and parameters if any and take corrective measures and actions promptly thus resulting in providing high-quality products and services to the end consumers

Along with all the above-mentioned benefits, having IIOT instruments also gives a competitive edge in the market producing well-researched, efficient, standard-stringent customer centric end products!

How IIOT is transforming the Manufacturing Industry?

IIOT has been significantly impacting many industries including the Manufacturing industries in various ways. Along with providing the quintessential benefits that it already does like improved operations, heightened productivity, superior product quality it also actively works towards employee safety which is extremely vital especially in factories. The workplace accidents in the manufacturing industry are quite common but with IOT-based connected devices any hazards and potential risks can be detected easily to take immediate actions for improving the safety measures for the employees. Another big challenge that IOT-based devices can work towards eliminating is the accurate maintaining of the supply on the shelves as usually the stock is low or is over-stocked. Using the RFID sensors that can help in tracing the exact movement, status and location of the supply this reoccurring issue can be easily brought under control. Furthermore, an estimation of the arrival of materials, availability of existing materials can be fully traced thus optimizing the supply chain by many folds.

Conclusion

In the end, it can be firmly said that Industrial Internet of things isn’t just a buzzword but a fundamental shift that is truly reshaping the landscape of many industries along with manufacturing. If embraced fully in today’s time, can ensure that the manufacturers continue to remain competitive, adaptable and are equipped for any opportunities or challenges that lie ahead.

#paramountinstruments#qualitycontrol#testingequipments#textileindustry#iot#iiot#industrial internet of things#industrialinnovation#testing

0 notes

Text

Conformance is a term that is frequently used in the textile testing industry by manufacturers, suppliers, and buyers to set their products or services apart from others. Check out our latest blog at https://paramountinstruments.com/blog-detail/does-conformance-really-matter-in-textile-testing as we talk about it in detail and the vital importance it holds in the Textile testing Industry.

#paramountinstruments#qualitycontrol#testingequipments#qualityassurance#performancetesting#qualitycontrolassessment

0 notes

Text

How does a Tensile Tester work?

Tensile Testers are one of the most frequently used testing equipment's in the field of material testing. They play a crucial role in determining the mechanical properties of materials, such as pulling strength, elasticity, and flexibility. Understanding how a tensile tester works is essential for producing precise and trustworthy results, be it in the industrial sector or while performing research in a lab.

In this blog, we will delve deep into the working of the tensile strength tester and will also be covering the key benefits that performing a tensile test using a tensile machine offers.

Starting with the step wise process of how a tensile tester typically works:

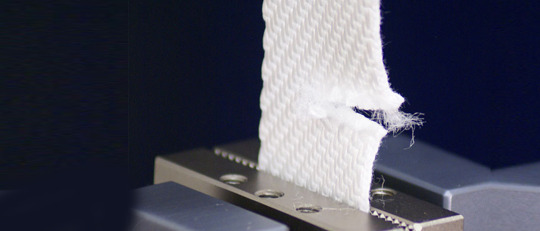

1. Preparation of the Specimen - A small sample of the textile material is cut into a specific size and shape suitable for the tensile strength tester.

2. Mounting the Specimen - The sample is then mounted between the two jaws or grips of the tensile tester. The jaws are specifically designed to prevent any damage or slippage to the specimen (sample) during the test.

3. Testing the Specimen - A controlled force is applied at a steady rate to the specimen until the material breaks. The tensile tester then measures the amount of force applied and resulting elongation of the specimen.

4. Data Compilation - The data that is collected during the test, including the elongation at break, modulus of elasticity, and the tensile strength can then be used to assess the mechanical properties of the textile material.

5. Examination: The results of the test help to assess the performance and quality of textile material which can be used to make decisions regarding the quality control, material selection, and product design.

Understanding the systematic process of a tensile strength tester’s working can make sure that accurate and reliable measurements are undertaken every time a test is performed.

Benefits of performing a Tensile Test using a Tensile Strength Tester :

Identifying Weaknesses at the Initial Stage: Tensile strength testing can help to identify any flaws or weaknesses in a fabric, such as areas that might be prone to breaking or tearing. By using this information, the production process can be adjusted as needed to increase the fabric's quality.

Improving Quality Control: Tensile strength testers are frequently used for quality control assessments in the textile industry. Testing the tensile strength of a fabric can help manufacturers ensure that the final product meets the required standards of durability and strength, thus increasing customer satisfaction and trust.

Cost Efficiency: Performing the tensile test can help to detect the materials that may be prone to breaking or are less durable, which can in turn lead to cost savings by eliminating the use of such damaged materials in the production process.

Assuring Safety Standards: One of the main reasons for performing the tensile test is to also ensure that the safety of fabrics and garments is ensured for end use. Using the tensile strength equipment, manufacturers can make sure that the fabrics/garments meet the required safety standards and are not prone to breaking or tearing during use.

Developing Suitability for Specific Applications: Testing the tensile strength of fabrics can also help to determine its suitability for specific end use applications like outdoor gear or heavy-duty workwear. Thus, by testing the strength of the fabric, manufacturers can make sure that it holds up under the intended use conditions.

We may assert that assessing the tensile strength of materials is important to assure their durability, quality and safety is up to the mark and is fully perfected for its end-use application.

#paramountinstruments#qualitycontrol#testingequipments#qualityassurance#performancetesting#tensilestrengthtester#tensiletesting#tensilestrength#tensilestructure

0 notes

Text

The Paramount Martindale Abrasion Tester i9™, equipped with 9 stations, is a state-of-the-art instrument for evaluating abrasion and pilling in a wide range of materials, including knitted, woven, non-woven, leather, and coated fabrics. This versatile equipment enables multiple abrasion and pilling tests, offering efficiency and ease of use with its advanced touch screen interface.

#paramountinstruments#qualitycontrol#testingequipments#abrasion&pillingtester#abrasiontester#pillingtester#textileindustry#performancetesting#martindale abrasion tester

0 notes

Text

The i10™ Tensile Strength Tester from Paramount is an advanced piece of equipment, embodying the most up-to-date technology by employing the Constant Rate of Elongation (CRE) principle. It seamlessly integrates with sophisticated software provided with the equipment via the included laptop.

#paramountinstruments#qualitycontrol#textile#textileindustry#qualitycontrolassessment#tensile strength#tensile strength tester#elongation#seam- slipage#tear

0 notes

Text

The Importance of Martindale Abrasion and Pilling Tester in Textile Testing

The Martindale abrasion and pilling tester is one of the key testing instruments in the textile industry. Below, we will be outlining why it is so important in the textile testing industry.

1. Ensures Durability: Through testing the abrasion and pilling properties of the fabrics by subjecting them to mechanical wear and tear it helps to ensure that the fabric can easily withstand repeated washing and use without losing its performance or quality.

2. Product Development: The martindale abrasion tester is used in product development to test new materials and fabrics for quality and durability. This plays a key role in helping textile manufacturers to develop new products that meet the needs of their customers as well as stay competitive in the market.

3. Adherence to Standards: Fabrics are tested for compliance with industry laws and standards, such as ISO and ASTM standards, using the martindale abrasion machine. This makes it easier to guarantee that textile products are trustworthy and safe for consumers to use.

4. Cost Savings: Fabrics that are not strong enough to be used in products can be identified using the martindale abrasion and pilling tester. Textile manufacturers can save money in the long term and prevent expensive production mistakes and delays by recognising these textiles early on.

5. Quality Assurance: The martindale abrasion tester is also used in quality control to ensure that the fabric meets the required industry standards for strength, durability, and pilling resistance. This helps to ensure that the fabric will meet the needs of the consumer and is of premium quality.

In conclusion, the martindale abrasion and pilling tester is a crucial testing instrument for assessing textiles. Durability, Quality Control, Product Development, Compliance to standards, and Cost Savings for textile producers are all aided by it.

By using this testing instrument, textile manufacturers can create high-quality textile products that satisfy client expectations and maintain market competitiveness.

#paramountinstruments#testingequipments#qualityassurance#textileindustry#qualitycontrolassessment#pilling#pillingtesting#abrasiontesting#martindale abrasion tester

0 notes

Text

Why Lab Testing Instrument is Crucial for Textile Industry?

The textile industry is one of the most important industries in the world. It is an industry that involves the production of fabrics and garments, which are used by people all over the world. The industry is constantly evolving and growing, with new technologies and materials being introduced all the time. One of the most important aspects of the textile industry is lab testing instruments.

In this blog, we will discuss why lab testing instruments are crucial for the textile industry.

1. Quality Control

Quality control is one of the most important aspects of the textile industry. The industry produces millions of garments every year, and it is important to ensure that each garment meets certain quality standards. Lab testing instruments are crucial for quality control. These instruments can test the quality of fabrics, dyes, and other materials used in garment production. They can detect any defects or flaws in the materials, which can be corrected before the garment is produced.

Lab testing instruments can also test the durability of fabrics and garments. They can simulate wear and tear and test the fabrics and garments to see how they hold up under different conditions. This helps to ensure that the garments produced are of high quality and will last a long time.

2. Compliance with Standards

The textile industry is subject to several different standards and regulations. Lab testing instruments are crucial for ensuring compliance with these standards. For example, the industry must comply with standards for flammability, chemical content, and other safety standards. Lab testing instruments can test fabrics and garments to ensure that they meet these standards.

Lab testing instruments can also test for the presence of harmful substances in fabrics and garments. This is particularly important in the production of children's clothing. Many countries have strict regulations on the use of certain substances in children's clothing, such as lead and phthalates. Lab testing instruments can test fabrics and garments to ensure that they are free of these substances.

3. Product Development

Lab testing instruments are also crucial for product development in the textile industry. Before a garment is produced, it must be designed and tested. Lab testing instruments can test fabrics and garments to determine their properties, such as their tensile strength, elasticity, and water resistance. This information is then used to design garments that meet specific requirements.

Lab testing instruments can also be used to test new materials and technologies. For example, new fabrics may be developed that have special properties, such as antimicrobial properties or moisture-wicking properties. Lab testing instruments can test these fabrics to ensure that they meet the required standards.

4. Environmental Sustainability

The textile industry has a significant impact on the environment. Industry uses large amounts of water and energy and produces a lot of waste. Textile testing instruments can help to reduce the environmental impact of the industry by testing fabrics and garments to ensure that they are produced in an environmentally sustainable way.

For example, textile testing instruments can test fabrics to determine their water usage. This information can then be used to develop fabrics that use less water in their production. Lab testing instruments can also test fabrics to determine their biodegradability. This information can then be used to develop fabrics that are more environmentally friendly.

Conclusion

In conclusion, lab testing instruments are crucial for the textile industry. They are used for quality control, compliance with standards, product development, and environmental sustainability. Without lab testing instruments, the textile industry would not be able to produce high-quality garments that meet the required standards. As the industry continues to evolve and grow, lab testing instruments will become even more important for ensuring that the industry is sustainable and produces garments that are safe, high-quality, and environmentally friendly.

#qualitycontrol#paramountinstruments#qualityassurance#testing#qualitycontrolassessment#textileindustry#textile#testingequipments

0 notes

Text

Martindale Abrasion and Pilling Tester - Everything You Need to Know

Durability, Functionality and Quality is the essence of every product performing to its best capacity. To make sure that the products meet the required quality and durability, a martindale abrasion tester is used in the textile industry. In this article, we will be covering all you need to know about the Martindale Abrasion and Pilling Tester, its history, working and how it benefits the garment and textile industry.

What is a Martindale Abrasion and Pilling Tester?

Martindale abrasion and pilling tester is a testing instrument that simulates the wear and tear of fabrics due to frequent usage. The martindale abrasion machine is a combination of two tests Martindale Abrasion Test and Martindale Pilling Test. This circular testing machine is used to determine how long fabrics will last by subjecting them to regulated abrasion forces. It is named after its inventor, Dr. James Graham Martindale.

The History of Martindale Abrasion and Pilling Tester

Martindale Abrasion and Pilling Tester that is used to test the abrasion and pilling properties of a fabric dates back to the early 1900. The Martindale abrasion test was developed in the early 1900s by Frank F. Martindale, a British engineer and member of the Society of Dyers and Colourists. The original version of the Martindale abrasion tester was a manually operated device that could test the abrasion resistance of fabrics. Over the years, the instrument underwent several improvements and modifications, and electronic versions were introduced in the 1950s, making testing more accurate and efficient.

The Martindale pilling test, on the other hand, was developed in the 1960s by Harold Francis, another British textile engineer. This test is used to determine the tendency of fabrics to form pills, or small balls of tangled fibres, due to wear and friction. The original version of the Martindale pilling tester was also a manually operated device, but electronic versions were later introduced, making testing more accurate and efficient.

Today, the Martindale Abrasion and Pilling tester is a highly advanced and efficient testing instrument that combines the Martindale Pilling test and the Martindale Abrasion test into one single instrument.

How Does a Martindale Abrasion and Pilling Tester Work?

Below, is a step by step working of a Digital Martindale Abrasion and Pilling Tester -

1. Preparation of the Sample: The fabric sample that is to be tested is prepared according to the desired shape and size.

2. Placing the Sample: The sample is subsequently clamped into place on the tester's testing platform.

3. Abrasion Test: The Martindale abrasion test, which gauges the fabric's abrasion resistance, makes up the first portion of the test. A set of abrasive felt on the tester rub against the fabric in a circular motion. Depending on the demands of the test, the operator sets the number of rubs, which can range from a few hundred to tens of thousands. The apparatus also gauges the sample's weight loss throughout the experiment.

4. Pilling Test: The Martindale pilling test, which is the second component of the test, gauges the fabric's propensity to create pills. A series of rotating brushes in the tester rub against the fabric in a circular motion. Depending on the demands of the test, the operator sets the number of rubs, which can range from a few hundred to tens of thousands. The equipment accurately counts the number of rubs required to form the pills on various types of fabrics.

5. Result Analysis: The Martindale abrasion machine gives a digital readout of the sample weight loss during the abrasion test, the number of pills generated during the pilling test, and other pertinent information when the test is over. This information is used to assess the fabric's strength and quality, as well as whether it complies with specific industry requirements.

The Benefits of Using a Martindale Abrasion and Pilling Tester

Martindale abrasion machine is a widely used testing instrument because of the numerous benefits it offers. Some of these benefits include -

It helps to evaluate the quality and durability of fabrics.

It is useful to determine the pilling tendency of fabrics.

It can be used to predict the fabric's behaviour during regular usage.

It identifies the abrasion resistance of fabrics.

It adheres to the required and necessary industry standards.

Overall, the martindale abrasion tester is an essential testing instrument in the textile industry to determine the longevity and quality of textiles.

#qualitycontrol#qualityassurance#martindale#abrasiontesting#pillingtesting#qualitycontrolassessment#testingequipments#performancetesting#paramountinstruments

0 notes

Text

Is it Really Important to Use a Colour Matching Booth?

A widely used testing equipment in the Textile Industry is a Colour Matching booth also known as a Colour Matching Cabinet or LightBox. It creates a specialized viewing environment that is used to assess and compare colors accurately. These cabinets are frequently used by textile industry professionals to conduct color assessment, color matching, and quality control processes.

In this blog post, we will briefly discuss about the Colour Matching Cabinet, its application, the industries where it is commonly used and the benefits it has. So, lets dive into it!

What is a Colour Matching Booth?

A Colour Matching Booth/Cabinet that is used to perform colour matching or colour assessments consists of a light source, viewing area, and standardized lighting conditions. The light source is carefully calibrated to provide specific colour temperatures such as F11 (store lighting) or D65 (daylight) that are frequently used in the industry. With the help of these standardized lighting conditions textile professionals can assess colours under reproducible and consistent illumination, omitting the variability caused by various lighting environments. The design structure of the viewing area in the colour matching cabinet is designed to reduce external light interference, that ensures to provide a regulated environment for colour evaluation. The interior walls and surfaces are usually made of neutral grey or other non-reflective materials to prevent colour distortion.

Key Industries where a Colour Matching Booth is Used

Below, are the major industries where a Colour Matching Booth is widely used:

Textile Industry

Leather Products Industry

Fashion Institutes

Footwear Industry

Dye House Testing Industry

Printing Testing Industry

About Paramount’s Colour Matching Booth – The SPECTRAVISION™ i9 6L (Digital)

Paramount SPECTRAVISION™ i9 6L (Digital) is a Next-Generation colour matching booth used to evaluate colours with most advanced features. It provides standardized and controlled environment for visual assessment of colour adhering to British/European norms. It is suitable for all applications where there is a requirement to maintain colour consistency and ensure high-quality standards.

It allows a person to evaluate colour samples under different light sources such as: -

• Artificial Daylight (D-65) / D-50 (Graphic) / F-10

• Cool White Light (CWF) / F-2

• TL-84 Light - Tri phosphor fluorescent Light (Point of Sale) / F-11

• Tungsten Filament Light (Domestic Light Matching) / A

• Ultraviolet Black Light (For Whites & Fluorescent Dyes)

Salient Features of the SpectraVision™ i9 6L (Digital)

Next Generation Colour Matching Booth to evaluate colours in Textile/ Leather/ Artificial Leather/ Toys/ Automotive/ Inks/ Cosmetics/ Paper & Packaging Industry

Has 6 standardized light sources: D-65, CWF, LED POS 4000K, TL-84, UVB, INCA

Latest Microprocessor based Programmable Controller with Feather Touch Controls

Auto sequencing of Lights for hands-free operation

Individual Hour meter for each light with Auto Message for Servicing

Interior Colour Neutral Grey (Munsell N7) meets all International Standards

Supplied Complete with a fixed table with 45° observation angle

Complete with 4 Grey Magnets for fixing samples

Supplied complete with Inspection & Calibration Certificate (Traceable to NPL)

Accurate & Repeatable Results and Adherence to National & International Standards

Technical Specifications of the SpectraVision™ i9 6L (Digital)

A. LIGHT SOURCES (ILLUMINANTS)

1. Artificial Daylight Lamps (D-65) : 2 No.

2. Tungsten Filament Lamps (Inc A Lamps): 1 No.

3. Cool White Fluorescent Lamp (CWF): 1 No.

4. Tri phosphor Fluorescent Lamp (TL-84): 1 No.

5. Ultra-Violet Black Lamp: 1 No.

6. Ultra Lume – 3000 (U-30) (TL-83): 1 No.

B. COLOR TEMPERATURE (ILLUMINANTS)

1. D-65 LIGHT: 6500 K (Average North Sky Day Light)

2. CWF LIGHT: 4150 K (Typical Store/Office Lighting) (Wide Band Fluorescent) USA

3. TL-84 LIGHT: 4100 K (Commercial Fluorescent) EUROPE

4. INCA LIGHT: 2856 K (Typical Home / Accent Lighting) UK/FRANCE)

5. U.V.B. LIGHT: Ultra -Violet Black Light (UV)

6. U-30 LIGHT: 3000 K (Commercial Fluorescent) USA

C. SPECIFICATIONS

1. Mains Supply: 220V, 50 Hz (Single phase)

2. Hour Totalizer: 9999.59 Hours, L/C: 1min

3. Overall Dimensions: 1190 mm x 970 mm x 670 mm, 27 Inch x 22.5 Inch x 22.5 Inch

4. Net Weight of the Instrument: 23 kg (50.6 Lb)

To know more about Paramount’s SpectraVision ™ i9 6L click here.

Benefits of using the Paramount’s SPECTAVISION ™ i9 6L

The benefits of using Paramount’s SPECTRAVISION™ i9 6L (Digital) are listed below:

1. Precise Colour Assessment: It provides a regulated environment with standardised lighting conditions, eliminating any external factors that can distort colour perception. This allows accurate colour assessment and ensures consistent results across different lighting conditions.

2. Quality Control: With the help of the Spectravision™ i9 6L, textile manufacturers can ensure that the colour of their products meet the specific requirements and standards.

3. Cost Efficiency: Using this lightbox enables more efficient and faster colour evaluation by eliminating the need for recurring colour adjustments, thus saving time and minimizing production costs. By detecting colour discrepancies at an early stage, textile manufacturers can eliminate expensive errors and reduce unwanted waste.

4. Colour Uniformity: It also facilitates accurate colour matching, which is vital when manufacturing products that require consistency. This further makes sure that the colours are unvarying across different materials, batches, or production locations, reducing the risk of any colour variations that could be unacceptable to customers.

5. Enhanced Customer Satisfaction: The implementation of precise colour assessment, quality control and colour uniformity that can be achieved using this Spectravision equipment can in turn result in improved and great level of customer satisfaction.

6. Compliance with Standards: Many industries such as food, textile, automotive, footwear, and pharmaceuticals have rigid regulations regarding colour consistency and product labelling. Using the Colour matching cabinet helps manufacturers to comply with these strict regulations and avoid any legal issues.

The benefits outlined above clearly illustrate the key importance that using a colour matching booth holds.

#color matching cabinet#color matching booth#color assessment#color evaluation#spectravision#qualityassurance#testingequipments#paramountinstruments

0 notes