#tensiletesting

Explore tagged Tumblr posts

Text

Power. Precision. Performance – 1000N Bench-top Universal Testing Machine

Optimised for precise material testing, the Testron 1000N Bench-top Single Column Universal Testing Machine is the standard for quality control and R&D use. Built for automotive, aerospace, cable, plastic, rubber, and packaging companies, this state-of-the-art testing solution offers unparalleled accuracy, reliability, and efficiency.

Why Opt for Testron 1000N?

Complete Strength Analysis – Reliably measures tensile strength, yield strength, fracture strength, elasticity, and elongation.

Flexible Control Modes – Provides fixed speed, positioning shift, and load control modes.

Automatic Range Adjustment & Calibration – Maintains accuracy with auto-calibration and dynamic range adaptation.

Smooth Data Management – Batch testing and auto-data storage to avoid data loss.

Real-time Curve Analysis – Dynamic plotting of stress-strain and force-displacement curves.

Sophisticated Safety Features – Auto safety mechanisms when load crosses 2-10% capacity.

Step up your material testing productivity with Testron's state-of-the-art Universal Testing Machines.

𝗙𝗼𝗿 𝗺𝗼𝗿𝗲 𝗶𝗻𝗳𝗼𝗿𝗺𝗮𝘁𝗶𝗼𝗻:

Email: [email protected]

Product: https://testrongroup.com/product/tt-sc1000-1000n-bench-top-single-column-universal-testing-machine/

Website: https://testrongroup.com/

#UniversalTestingMachine#MaterialTesting#TensileTesting#TTSCT1000#QualityControl#BenchTopTester#StrengthTesting#SingleColumnTester#LaboratoryEquipment#TestingSolutions

0 notes

Text

The Tensile Testing Machine is a highly efficient and reliable device designed for testing the strength and durability of various materials. It is equipped with advanced technology that allows for precise and accurate measurements of tensile strength, elongation, and other mechanical properties. With its user-friendly interface and intuitive controls, this machine is suitable for both research and industrial applications. Its robust construction ensures long-lasting performance, while its versatile design allows for testing a wide range of materials including metals, plastics, textiles, and more. The Tensile Testing Machine is an essential tool for quality control, product development, and material testing in various industries.

#TensileTesting#MaterialTesting#StrengthTesting#MechanicalTesting#QualityControl#Engineering#Manufacturing#LabTesting#TensileStrength#QualityAssurance

0 notes

Text

Understanding the Universal/Tensile Testing Machine (UTM Machine): A Comprehensive Guide

mechanical properties of materials, aiding in product development, quality control, and research endeavors across various industries. In this article, we delve into the intricacies of UTM Machines, exploring their functionalities, applications, and significance in modern engineering.

What is a Universal/Tensile Testing Machine (UTM Machine)?

A Universal/Tensile Testing Machine, commonly referred to as a UTM Machine or simply a Tensile Tester, is a versatile apparatus designed to evaluate the mechanical properties of materials under tension, compression, bending, and shear forces. These machines are widely utilized in laboratories, manufacturing facilities, and research institutions to ascertain the performance characteristics of materials, ranging from metals and polymers to composites and ceramics.

Components and Working Principle:

UTM Machines consist of several key components, including a sturdy frame, a load cell or force transducer, grips or fixtures for specimen attachment, and a control system equipped with software for data acquisition and analysis. The working principle of a UTM Machine involves subjecting a specimen to controlled mechanical loads while simultaneously measuring the resulting deformation or displacement. This process allows engineers and researchers to determine essential parameters such as tensile strength, yield strength, modulus of elasticity, and elongation at fracture.

Applications:

The applications of UTM Machines span a wide array of industries and fields, including but not limited to:

Material Characterization: UTM Machines facilitate the characterization of materials by providing valuable insights into their mechanical behavior and performance under different loading conditions. This information is crucial for material selection, design optimization, and quality assurance processes.

Quality Control and Assurance: In manufacturing environments, UTM Machines are instrumental in ensuring the quality and reliability of manufactured components and products. By conducting routine tensile, compression, and flexural tests, manufacturers can identify defects, assess conformance to specifications, and uphold stringent quality standards.

Research and Development: UTM Machines play a pivotal role in research and development endeavors aimed at enhancing material properties, exploring new alloys and composites, and innovating advanced manufacturing techniques. Researchers rely on UTM data to validate theoretical models, optimize processing parameters, and drive innovation across various disciplines.

Structural Testing: UTM Machines are extensively employed in structural engineering to evaluate the strength and durability of building materials, such as concrete, steel, and timber. These tests aid in assessing the structural integrity of bridges, buildings, and other infrastructure components, thereby ensuring safety and reliability.

Advantages of UTM Machines:

The versatility, accuracy, and reliability of UTM Machines offer several advantages, including:

Precise Measurement: UTM Machines are capable of delivering highly accurate and repeatable measurements, allowing for reliable characterization of material properties.

Flexibility: With the ability to perform multiple testing modes, including tension, compression, bending, and shear tests, UTM Machines offer unparalleled flexibility to accommodate diverse testing requirements.

Efficiency: Automated control systems streamline the testing process, enabling efficient data collection, analysis, and reporting, thereby saving time and resources.

Standard Compliance: UTM Machines adhere to international standards such as ASTM, ISO, and DIN, ensuring consistency and comparability of test results across different laboratories and industries.

In conclusion, Universal/Tensile Testing Machines (UTM Machines) play a vital role in material testing, quality assurance, and research endeavors across various industries. By providing valuable insights into the mechanical properties of materials, these versatile machines facilitate informed decision-making, innovation, and quality excellence. As technology continues to advance, UTM Machines are poised to remain indispensable tools in the pursuit of engineering excellence and material science innovation.

For more information and to explore our range of UTM Machines, visit Multitek.in today.

Targeted keywords are: UTM Machine, Universal Testing Machine, Tensile Testing Machine, Tensile Hardness Tester, Universal harness tester, Metallurgy, metrology, Mechanical, Commercial

0 notes

Text

youtube

Mastering Tensile Testing: Unravelling The Strength of Materials

Tensile testing is the key to understanding how materials respond to stress and strain. From engineering plastic materials to metal products, testing each and every aspect of material is important in ensuring accuracy of tensile testing results. Thus, with the Presto tensile strength testing instrument, manufacturers can easily and accurately conduct tensile tests on the materials. In this video, we break down the fundamentals of tensile testing and delve into its diverse applications across industries. Gain a deeper understanding of how this testing machine helps manufacturers in testing the integrity of materials.

#TensileTesting#MaterialStrength#EngineeringTests#MaterialsScience#QualityControl#MechanicalTesting#LabTesting#MaterialProperties#TensileStrength#MaterialTestingLab#prestogroup#Youtube

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

In our ongoing video series about the manufacturing process of Titanium bars, today we've shared the finishing steps of manufacturing. Here, we focus on chamfering and ensuring that Titanium Round Bars are of the highest quality.

Distinguishing Process Parameters:

Chamfering: Controlled feed rate Controlled cutting speed Controlled depth of cut Continuous coolant and lubrication

Quality Analysis: Material qualifications as per ASTM and ISO international specification Testing carried out as per International Testing Procedures

Distinguishing Chamfered and Tested Bars Quality:

Reduced stress concentration at both side edges Machining benefits Easy to handle Enhanced workpiece functionality Chemical analysis, Tensile testing, Ultrasonic testing, Metallurgical analysis, Dimensional analysis, and Analysis reports

Stay tuned as we take a closer look at how we make Titanium bars for medical purposes.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#Chamfering#EasytoHandle#ReduceStressConcentrations#QualityAnalysis#ISO#ASTM#Testing#MaterialQualifications#Specifications#Standards#ChemicalAnalysis#TensileTesting#UltrasonicTesting#MetallurgicalAnalysis#DimensionalAnalysis#AnalysisReports#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

How does a Tensile Tester work?

Tensile Testers are one of the most frequently used testing equipment's in the field of material testing. They play a crucial role in determining the mechanical properties of materials, such as pulling strength, elasticity, and flexibility. Understanding how a tensile tester works is essential for producing precise and trustworthy results, be it in the industrial sector or while performing research in a lab.

In this blog, we will delve deep into the working of the tensile strength tester and will also be covering the key benefits that performing a tensile test using a tensile machine offers.

Starting with the step wise process of how a tensile tester typically works:

1. Preparation of the Specimen - A small sample of the textile material is cut into a specific size and shape suitable for the tensile strength tester.

2. Mounting the Specimen - The sample is then mounted between the two jaws or grips of the tensile tester. The jaws are specifically designed to prevent any damage or slippage to the specimen (sample) during the test.

3. Testing the Specimen - A controlled force is applied at a steady rate to the specimen until the material breaks. The tensile tester then measures the amount of force applied and resulting elongation of the specimen.

4. Data Compilation - The data that is collected during the test, including the elongation at break, modulus of elasticity, and the tensile strength can then be used to assess the mechanical properties of the textile material.

5. Examination: The results of the test help to assess the performance and quality of textile material which can be used to make decisions regarding the quality control, material selection, and product design.

Understanding the systematic process of a tensile strength tester’s working can make sure that accurate and reliable measurements are undertaken every time a test is performed.

Benefits of performing a Tensile Test using a Tensile Strength Tester :

Identifying Weaknesses at the Initial Stage: Tensile strength testing can help to identify any flaws or weaknesses in a fabric, such as areas that might be prone to breaking or tearing. By using this information, the production process can be adjusted as needed to increase the fabric's quality.

Improving Quality Control: Tensile strength testers are frequently used for quality control assessments in the textile industry. Testing the tensile strength of a fabric can help manufacturers ensure that the final product meets the required standards of durability and strength, thus increasing customer satisfaction and trust.

Cost Efficiency: Performing the tensile test can help to detect the materials that may be prone to breaking or are less durable, which can in turn lead to cost savings by eliminating the use of such damaged materials in the production process.

Assuring Safety Standards: One of the main reasons for performing the tensile test is to also ensure that the safety of fabrics and garments is ensured for end use. Using the tensile strength equipment, manufacturers can make sure that the fabrics/garments meet the required safety standards and are not prone to breaking or tearing during use.

Developing Suitability for Specific Applications: Testing the tensile strength of fabrics can also help to determine its suitability for specific end use applications like outdoor gear or heavy-duty workwear. Thus, by testing the strength of the fabric, manufacturers can make sure that it holds up under the intended use conditions.

We may assert that assessing the tensile strength of materials is important to assure their durability, quality and safety is up to the mark and is fully perfected for its end-use application.

#paramountinstruments#qualitycontrol#testingequipments#qualityassurance#performancetesting#tensilestrengthtester#tensiletesting#tensilestrength#tensilestructure

0 notes

Text

At SKG Lab, we’re more than engineers—we’re the problem solvers shaping tomorrow. 🌟 From groundbreaking research to innovative solutions, we tackle challenges head-on to create a brighter, smarter future. Whether it’s precision in tensile strength testing, accuracy in impact testing, or reliability in hardness testing, our expertise drives excellence in every project. Join us on our journey to engineer possibilities into reality. 🌍⚙️ Get in Touch: 🌐 www.skglab.com 📞 +91 22 2756 2145 📧 [email protected] 📍 Navi Mumbai

#engineeringinnovation hashtag#skglab hashtag#tensiletesting hashtag#impacttesting hashtag#hardnesstesting hashtag#civilengineeringlab hashtag#mumbai hashtag#india

0 notes

Text

Universal Tensile Testing Machine: Features, Uses, and Working Principle

When it comes to material testing, a Universal Tensile Testing Machine (UTM) plays a crucial role in evaluating the mechanical properties of different materials. Whether you are testing metals, plastics, rubber, or composites, a UTM manufactured by Effective Lab India ensures precise and reliable results. This guide will take you through its features, applications, and working principles, helping you understand why it is essential for quality control and research.

What is a Universal Tensile Testing Machine?

A Universal Tensile Testing Machine is a laboratory instrument used to measure the tensile strength, elongation, and other mechanical properties of materials. It applies a controlled force to a specimen until it breaks, helping industries determine material durability and performance under stress conditions.

Features of Universal Tensile Testing Machine by Effective Lab India

Effective Lab India’s Universal Tensile Testing Machines are designed with cutting-edge technology to ensure high accuracy, repeatability, and user-friendly operation. Here are the key features:

1. High Precision Load Cell

2. Digital Display & Software Integration

3. Robust Construction

4. Multiple Testing Modes

5. Variable Speed Control

6. Interchangeable Grips & Fixtures

7. Safety Features

Uses of a Universal Tensile Testing Machine

A Universal Tensile Testing Machine is widely used in industries such as automotive, aerospace, construction, packaging, and research laboratories. Here are some of its key applications:

1. Metal Industry

2. Plastic & Polymer Testing

3. Rubber & Elastomers

4. Textile Industry

5. Paper & Packaging Industry

6. Composite Materials

Working Principle of Universal Tensile Testing Machine

The Universal Tensile Test Machine works on a simple yet effective principle: applying force to a specimen until it deforms or breaks while recording the applied force and elongation.

Step-by-Step Working Process:

Why Choose Effective Lab India’s Universal Tensile Testing Machine?

Choosing the right UTM is crucial for accurate material testing. Effective Lab India offers:

Frequently Asked Questions (FAQs)

1. What materials can be tested with a Universal Tensile Testing Machine?

A UTM can test metals, plastics, rubber, textiles, paper, composites, and more.

2. How does a Universal Tensile Testing Machine ensure accuracy?

It uses high-precision load cells and digital software to record force and elongation data with minimal error.

3. Can I perform different tests on the same UTM?

Yes, with interchangeable grips and fixtures, you can perform tensile, compression, flexural, and shear tests.

4. What industries use a Universal Tensile Testing Machine?

Industries like automotive, aerospace, packaging, textiles, and research laboratories rely on UTMs for material testing.

5. Where can I buy a Universal Tensile Testing Machine in India?

You can purchase a high-quality UTM from Effective Lab India, a leading manufacturer of reliable testing equipment.

Conclusion

A Universal Testing Machine is an essential tool for evaluating the strength and durability of materials. Whether for quality control, research, or product development, a UTM from Effective Lab India ensures high accuracy, efficiency, and reliability. With its advanced features, diverse applications, and user-friendly operation, it is a must-have for industries that demand superior material performance.

If you’re looking for a trusted tensile testing machine manufacturer in India, Effective Lab India provides top-quality equipment tailored to your needs.

#UTM #utmmachine #tensiletestingmachine #universaltensiletestingmachine #effectivelabindia #utmtesting #testingmachine #testinginstruments #tensiletester

0 notes

Text

Accuracy. Consistency. Performance – 500N Bench-top Universal Testing Machine

In industries that require precision testing, the Testron 500N Bench-top Single Column Universal Testing Machine provides top-performing material testing and quality control. The advanced system is intended for the aerospace, automotive, plastic, rubber, cable, and packaging markets and provides accurate and repeatable test results for a wide range of applications.

Key Components:

Advanced Material Testing – Accurately records tensile strength, yield strength, fracture strength, elasticity, and elongation.

Multi-Control Mode – Provides fixed speed, position shift, and fixed load operating modes for multifaceted uses.

Auto-Calibration & Auto-Range – Increases accuracy with auto-range measurement adjustment.

Batch Testing & Data Storage – Supports smooth multi-test operation with data security storage.

Real-time Display & Curve Analysis – Offers real-time visualisation of stress-strain, force-displacement, and other vital parameters.

Advanced Safety Mechanisms – Auto safety mechanisms kick in when the load exceeds 2-10% of capacity.

Elevate your quality control with Testron's state-of-the-art Universal Testing Machines.

𝗙𝗼𝗿 𝗺𝗼𝗿𝗲 𝗶𝗻𝗳𝗼𝗿𝗺𝗮𝘁𝗶𝗼𝗻:

Email: [email protected]

Product: https://testrongroup.com/product/tt-sc0500-500n-bench-top-single-column-universal-testing-machine/

Website: https://testrongroup.com/

#UniversalTestingMachine#MaterialTesting#QualityControl#LabEquipment#TensileTesting#CompressionTesting#TestronGroup#SingleColumnTester#TestingEquipment#BenchTopTester

0 notes

Text

Best Tensile Testing Laboratory in Chennai-Kiyo R&D Center and Laboratory

#kiyor&dcenterandlaboratory #tensiletesting

Ensuring Material Excellence: KIYO R&D Lab's Premier Tensile Testing Services in Chennai

Introduction

In the dynamic fields of engineering and manufacturing, the integrity and performance of materials are paramount. Tensile testing is a critical method used to assess these properties, providing essential data for material selection and product development. Chennai’s KIYO R&D Lab, located in Chitlapakkam, is at the forefront of delivering superior tensile testing services. Here's why KIYO R&D Lab is the go-to choice for material testing.

Cutting-Edge Testing Equipment

KIYO R&D Lab boasts an array of modern tensile testing machines designed to handle a variety of materials, including metals, plastics, and composites. The lab ensures that all testing equipment is frequently updated and rigorously calibrated to maintain the highest standards of accuracy.

Experienced and Skilled Team

The success of KIYO R&D Lab is driven by its team of experienced professionals. The engineers and technicians possess a deep knowledge of material science and testing methodologies, ensuring that every test is conducted with precision and expertise. Their dedication to quality results in reliable and insightful data for clients.

Comprehensive Material Testing

Beyond tensile testing, KIYO R&D Lab offers a full suite of material testing services. This includes hardness testing, impact testing, and fatigue testing, among others. By providing a comprehensive range of tests, KIYO R&D Lab ensures that clients gain a complete understanding of their materials' performance under various conditions.

Quality Assurance and Standards

KIYO R&D Lab is committed to delivering the highest quality testing services. The lab adheres to international standards and follows stringent quality control measures to ensure the accuracy and repeatability of test results. This commitment to quality makes KIYO R&D Lab a trusted partner for material testing.

Customized Testing Solutions

Understanding that each project has unique requirements, KIYO R&D Lab offers customized testing solutions tailored to meet specific client needs. The lab’s team collaborates closely with clients to understand their objectives and deliver testing services that provide actionable insights, driving innovation and quality assurance.

Conclusion

For businesses and researchers in Chennai seeking reliable tensile testing services, KIYO R&D Lab in Chitlapakkam is the premier choice. With advanced testing equipment, a skilled team, and a commitment to quality, KIYO R&D Lab ensures that you receive precise and dependable results. Whether you are in the process of developing new materials or validating the performance of existing ones, trust KIYO R&D Lab to provide the essential insights needed for success. Visit KIYO R&D Lab today and discover the excellence in material testing that sets them apart.

To Know More Info About Best Tensile Testing Laboratory in Chennai, Kiyo R&D Center and Laboratory, Best Tensile Testing Laboratory in Chitlapakkam, Top Laboratory Testing For Tensile Strength in Chennai, Tensile Testing Lab in Chennai — Kiyo R&D, Top Lab Testing For Tensile Test in Chennai, Tensile Testing

0 notes

Text

Tensile Testing FAQs

Read the full article

0 notes

Text

The Significance of Product Testing for a Smooth Release?

Ensure a flawless product release with comprehensive testing. Discover the significance of product testing for a seamless launch.

0 notes

Photo

Computerized UTM with Various load capacities to suit your specific application - For More information - https://www.flexitest.in/universal-materials-testing-machine-QC-501M2F-502M2F-503M2F-engineering For any questions, please feel free to contact us by email - at [email protected] Or Call - +91-8291971983

#universaltestingmachine#utm#materialtesting#tensiletest#compressiontest#bendingtest#peeltest#flexitest

0 notes

Text

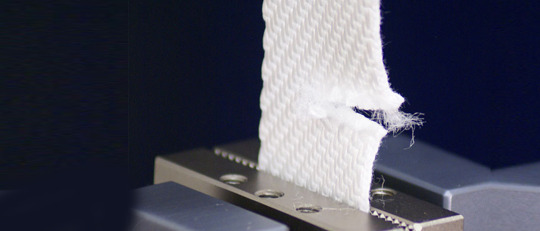

Tensile Testing

Tensile Testing to failure (Ultimate Tensile) is usually more of a shear test than a tensile test. Tensile Testing rips rather than pulls the strands apart. Depending on the configuration of the product, pulling the mesh may actually change it from one form to another.

For more details, click below: goo.gl/BxVFHP

0 notes

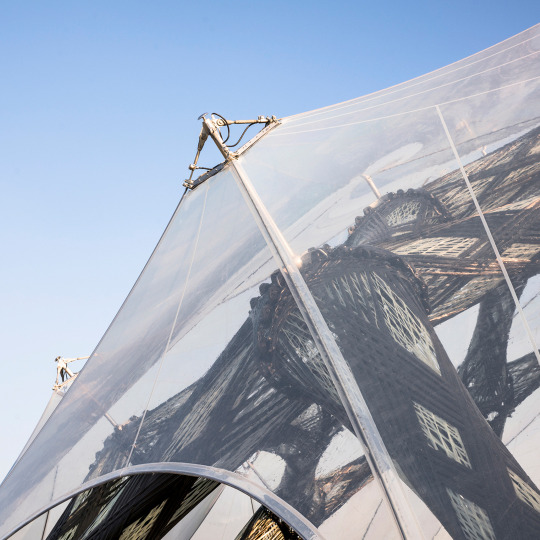

Photo

Tensile structures are made of cables, fabric, or metal grids that are suspended from an overhead support system. #structure #architecture #architecturedesign #creative_architecture #structures #steelstructure #architecturedetails #amazingarchitecture #architecturedose #contemporaryarchitecture #architecturelove #tensile #tensilearchitecture #tensilemembrane #tensilestructures #tensilefabric #tensilemembranearchitecture #tensileengineering #tensiletest #tensile_structure #structuredesign #tensilemesh #tensileshade #tensiledesign #tensileroofing #tensilefabrics #tensileroof #tensilestrength — view on Instagram https://scontent-ort2-2.cdninstagram.com/v/t51.2885-15/279205292_353304200167102_4357044226666148039_n.jpg?_nc_cat=110&ccb=1-5&_nc_sid=8ae9d6&_nc_ohc=98dSW_REUOQAX_YWtPd&_nc_ht=scontent-ort2-2.cdninstagram.com&edm=ANo9K5cEAAAA&oh=00_AT9gJtuW9VFjRq-5JbqXrXCvdmwTeKzdwXQ-lEah3aw_CA&oe=626F7D22

0 notes