#Pattern and Prototype Maker

Explore tagged Tumblr posts

Text

Q: How do I figure out how much money to spend on costume design and production?

Do you have a creative project that needs some budget numbers or estimates to help move it forward?Do you have characters that need to be designed, developed or produced?Do you have a budget, but need help deciding on how to get the most bang for your buck? Whether you’re planning a themed wedding, corporate event, stage production, parade float, film shoot, music video, photo booth experience,…

#Calulator#Corporate Events#Costume Budget#Designer Consultant#Emmy Award Winning#Entertainment#fabric sourcing#Film and Television Wardrobe#Free#Illustration#Online#Orlando Design House#Parade Costumes#Pattern and Prototype Maker#Pattern Making#Performance#Planner#Production Sewing#Show#Stage#Themed Wedding#Tool#Video#Wardrobe Budget

0 notes

Text

half a thought. the cat, "i need to know why my maker has left me here"—singular. "only to leave and make all of [you]." either:

light carved and animated the cat alone

light took all the credit and dark let him

this is soft confirmation dark ascended

jabber is the prototypal human; the brothers made him together, to "finish what the cat started." but he came out "brutal" (uncontrollable) so light decided to unmake him. dark refused. the brothers fought. jabber remained in the end—either dark won that argument or jabber returned on his own, like humans would after him.

in brother-cult doctrine, the god of darkness "forgot" the grimm after he and his brother made humans together. we know from the lost fable that this is not true, that darkness lived among his grimm, and even in the myth he refuses to destroy them and it hurts his feelings when light disdains them as creatures of pure malice. however,

that is precisely what the god of light did to his first creation: the cat figures in the blacksmith’s tale only as the inspiration for the brothers’ creation of jabber. the cat has no relevance or presence in the story after jabber is made. the god of light forgot them.

likewise the motivation ascribed to the grimm by brother-cult doctrine, that they hate humankind out of jealousy because their creator forgot about them in his fascination with humans, is the cat’s motivation exactly.

the cat is the prototypal grimm

light controlled the narrative back in the day, and the story he told about the grimm was a projection of his own failings in regard to the cat

hm. hmm. the cat–

hm. the cat "finds the broken parts of the ever after." in other words, they’re drawn to negativity. empathy. they seek out pain and offer comfort—but, but. jabber was meant to "finish what the cat started" and although he came out more "brutal" than the brothers anticipated, he was "effective" for this purpose. the cat was to find the broken parts and jabber was to act as the reaper, sending them back to the tree for ascension.

and that’s why jabber turned out wrong. the cat became a healer and the brothers created an executioner to "finish what they started," because they didn’t understand what the cat was really doing.

snaps fingers. pattern theory. the cat is untethered from the tree until they’re killed, and then they wind up in the blacksmith’s workshop. the god of light feared they had disrupted the balance and tried to destroy jabber, but darkness remade him, and jabber remained—not a monster but a creature desperate to "fix" his home.

for it is in passing we achieve immortality. fuck. we all got it backwards: ascension didn’t exist—couldn’t exist—until the brothers created HEALING and DEATH. true balance finds its own equilibrium. what was the ever after like in the very beginning? "[the brothers] were given creativity, to imagine what—and who—could replace the wilderness… the brothers built homes for them and gave them roles to play." that isn’t how ascension works! that isn’t how the ever after is anymore! the brothers were children playing with dolls until they disrupted the balance. ascension coagulated in the wake of that disruption.

oh. OH—ambrosius. destruction to clear the wilderness and creativity to replace it. that’s how light thinks it should work because that’s how it DID work before he and his brother changed things. every time they made something new they began by destroying what had been.

so– so the grimm—

hm.

like the cat, grimm are empathetic beings drawn to painful emotions. like both the cat and jabber, they’re predators. like ambrosius’ creations, they crumble into ash and smoke when they die. "you may bask in the powers of creation, but you do not own them" and "this force of pure destruction could not destroy […] so it created." their true purpose cannot be to kill humans, because they were created first; the mythical conceit that they envied humans because darkness forgot them is contradicted by the reality that he didn’t.

they are "manifestations of anonymity."

if i’m right on the origin of ascension and how the ever after worked before, then the rules the brothers set regarding life and death in their new world mimicked the original conditions of the ever after—but only imperfectly, else there would be no afterlife.

the planet’s core is liquid grimm.

the faunus came into being when salem combined the waters of life and grimm into one being and remade herself into something new. the god of darkness made the grimm to find the broken parts of this world, like the cat had done in the ever after, and then…

…either destroy or create.

the pool of grimm creates salem. or else she used it to recreate herself. either way the grimm have the capacity for it.

darkness refused to punish jabber for being what they made him. and then, in the new world he and his brother created together, he… made a new iteration of the cat with jabber’s destructive nature woven into the design and also gave humans a powerful weapon in the form of magic, protecting them from his other creations.

which sounds like a purposeful attempt to recreate the conditions that shifted the balance in the ever after, without being too obvious about it. and that tracks with what we know about him—his contributions outlined in the myth suggest that he set out to make their world into an ecosystem that could exist without them—but hm. still cooking.

42 notes

·

View notes

Text

2 confessions but somewhat related:

1. If you are going to try and charge what is equal to doll company prices for your own self-designed artist doll, most people are going to expect a certain level of quality standards beyond just saying it is 'professionally cast'. There is no aesthetic style that excuses badly designed, badly engineered dolls. Your casting company is probably going to be ok with casting whatever blob you send them as long as it doesn't have too many impossible cuts or thin spots but it's usually up to the sculptor or doll designer to have the knowledge of how to produce a functional finished doll that can handle string tension, has an acceptable range of motion, proper balance and so on. You still need to prototype all of that in cast resin in each color because the mixes have different properties. The finished resin dolls or heads are not going to behave the same way as a 3d printed prototype. Too many newer and untrained artists are trying to skip this step.

2. Also please consider at least a basic collaboration with a clothing or pattern maker and a shoe maker if your dolls fall outside of standard sizing. Over the years, we have watched even really good sculptors struggle more than they need to sometimes because they produce their unique but odd-sized dolls in a bubble and then it's really hard for owners to get any clothes or shoes for them.

~Anonymous

#BJD#ABJD#BJD Confessions#Community Confessions#BJD Sculpting#Jointing Systems#BJD Casting#BJD Fashion

25 notes

·

View notes

Note

How did you get into plushie making, and what's your favorite part of making them??

Hiya~! I guess I'd say I've always been into crafts and never really grew out of liking plush toys? So the interest was always there, but when I was a teen and discovered deviantart and all the plush makers of the time (BabyLondonStar, Usakochan, kickass-peanut, melkatsa etc.) I fell in love with their work and wanted to try it too and it just evolved from there.

As for favourite part, I have a love/hate relationship with pattern drafting haha. It's often the most time consuming/frustrating part, but there's something so satisfying about figuring out the right shapes and darts to get a plush just right that sometimes once I've finished the prototyping phase I'd rather start the next pattern than work on the final plush ^^;

Thanks so much for the questions, hope you're having a lovely day/night~

11 notes

·

View notes

Text

AI in Manufacturing: Real-World Applications and Case Studies

Artificial Intelligence (AI) is revolutionizing the manufacturing industry. What was once associated mainly with robotics and automation is now transforming every stage of the production process—from supply chain optimization to predictive maintenance, and even quality assurance. As manufacturers aim for increased efficiency, reduced costs, and enhanced product quality, AI is emerging as a key enabler of the smart factory era.

In this blog, we’ll explore how AI is applied in real-world manufacturing settings and examine compelling case studies that demonstrate its impact.

The Rise of AI in Manufacturing

AI technologies such as machine learning (ML), computer vision, and natural language processing (NLP) have matured rapidly, and manufacturers are adopting them to address longstanding challenges. Traditional manufacturing systems often struggle with reactive decision-making, lack of real-time insights, and inefficiencies caused by equipment failure or supply chain disruptions.

AI brings a proactive, data-driven approach that empowers decision-makers with predictive insights and automation capabilities.

Real-World Applications of AI in Manufacturing

1. Predictive Maintenance

AI systems analyze data from sensors embedded in machines to predict failures before they occur. By continuously monitoring equipment conditions, manufacturers can schedule maintenance only when needed, reducing downtime and maintenance costs.

Example: General Motors uses AI-powered sensors and machine learning algorithms to monitor factory equipment. This approach helped GM reduce unplanned downtime by up to 50%.

2. Quality Control and Defect Detection

AI, especially computer vision, enables real-time inspection of products on the assembly line. These systems can detect defects at a scale and speed unattainable by human inspectors.

Example: BMW employs AI-based image recognition to identify surface defects on car bodies during the manufacturing process. This has improved quality control precision and reduced rework.

3. Supply Chain Optimization

AI helps manufacturers anticipate demand, optimize inventory, and manage logistics more efficiently. Machine learning algorithms analyze historical sales data, supplier performance, and external factors like weather or geopolitical events.

Example: Siemens uses AI to improve supply chain transparency and optimize inventory levels, resulting in faster production cycles and reduced stockouts.

4. Process Automation and Robotics

AI enhances traditional automation by enabling robots to learn from their environment. Collaborative robots (cobots) can adapt to complex tasks and work alongside humans safely.

Example: Fanuc, a global manufacturer of industrial robots, utilizes deep learning to improve the precision of robotic arms in real-time, allowing them to handle more intricate assembly tasks.

5. Energy Management

AI systems monitor energy consumption patterns and suggest ways to reduce waste. By optimizing usage, manufacturers lower energy costs and minimize their carbon footprint.

Example: Schneider Electric integrates AI into its energy management systems to identify inefficiencies across manufacturing facilities, achieving up to 30% energy savings.

6. Design and Product Development

AI accelerates product development by simulating performance, testing designs, and even generating prototypes based on desired criteria using generative design techniques.

Example: Airbus uses AI-driven generative design to create lighter aircraft components, reducing material costs and improving fuel efficiency.

Case Studies: AI in Action

Case Study 1: Tesla – Smart Factories and Real-Time Analytics

Tesla leverages AI extensively in its Gigafactories. Through data analytics, Tesla predicts equipment failures, optimizes production schedules, and continuously improves its autonomous manufacturing processes. Tesla’s use of AI in robotics and automation has helped it maintain high production rates with limited downtime.

Case Study 2: Bosch – AI-Driven Quality Control

Bosch has implemented AI at scale across its manufacturing operations. By using AI algorithms for anomaly detection in the production of sensors and electronic control units, Bosch has significantly decreased the rate of defective products and improved its overall production yield.

Case Study 3: Foxconn – Smart Factory Transformation

Foxconn, a major electronics contract manufacturer, has invested in AI to improve its operational efficiency. AI is used for predictive maintenance, logistics planning, and even employee safety monitoring. This has enabled Foxconn to enhance production efficiency and reduce operational costs.

The Future Outlook

As AI technologies continue to evolve, their adoption in manufacturing will become more widespread and accessible—even for small and medium enterprises (SMEs). Integration with technologies like IoT (Internet of Things), digital twins, and 5G will further accelerate the shift toward Industry 4.0.

Manufacturers that embrace AI today are not just improving efficiency—they are building resilience, agility, and innovation into their business models.

Conclusion

AI is no longer a futuristic concept AI in manufacturing—it's a present-day reality. From predictive maintenance to quality assurance and energy optimization, AI is delivering measurable results across the industry. By learning from early adopters and understanding the practical applications, manufacturers of all sizes can begin to unlock the value of AI and shape the factories of the future.

0 notes

Text

okok so I've been putting this off for ages:

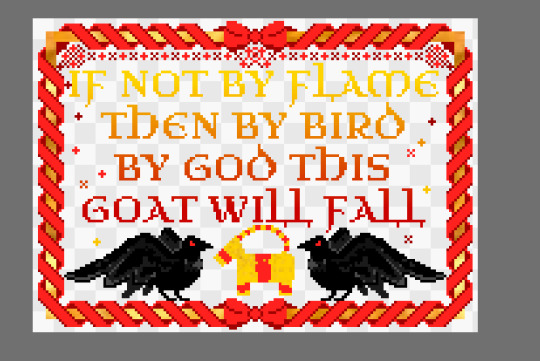

first, an update on my prototype of this pattern:

things that I have learned:

the blackish-brown and grey thread i chose to distinguish the bird wings has BARELY any contrast. the whole thing needs to be redesigned

the red and dark red on the ribbon-work doesn't contrast highly enough, it sort of just. sludges together? I need a darker red or maybe even a red-tinted brown

i'm attempting to use some of the blackish-brown as letter outlining to make up for the fact that I chose a metallic (and therefore pricier) floss

the auto-settings for uploading a cross stitch pattern based on existing art is uh, NOT GREAT

NOTES! GROUPINGS! SEPARATIONS! oh by god was it a mess. Some colours were so close I had to group them to make it make sense. others, such as the DMC 444, was trying to be both lemon yellow in the text gradient AND brownish straw in the goat itself so they needed separation.

I've remade the pattern stitch by stitch on a different maker. It's still available at the same pay-what-you-like link up there ^ but here's the NEW preview:

oh also i made the birds look more like jackdaws

me: oughghgh okay you gotta go OUT today and run errands like an adult, pick up prints, buy floss for the beans cross stitches you sell, maybe some groceries....

also me: oh 3pm's not that late! plenty of time to spend on a cross stitch project!

several hours later, it is already dark out:

me:..... shit.

(ty to @presidentdragon for a sentence that goes extremely hard)

also idk what the cheapest way to get this pattern out to yall would be is there like, a public drive folder somewhere where you can upload free pattern pdfs?

9K notes

·

View notes

Text

Why More Businesses Are Choosing Garment Manufacturers in the Philippines

In the ever-evolving world of fashion and retail, finding the right manufacturing partner can make or break a brand. With shifting consumer expectations, tighter budgets, and a growing demand for ethical sourcing, businesses are now thinking beyond the traditional manufacturing hubs. One country that’s rapidly gaining attention is the Philippines—a rising star in global apparel production. Whether you're a startup clothing brand or an established retailer looking to streamline your supply chain, there are compelling reasons to explore a garment manufacturer philippines.

Why the Philippines? A Strategic Manufacturing Hub

The Philippines has a long-standing history in textile and apparel production, dating back to its colonial era. Today, it combines that rich tradition with modern capabilities, making it an attractive alternative to larger, often overcrowded manufacturing markets like China or Bangladesh.

English Proficiency and Cultural Compatibility

One of the biggest challenges brands face when outsourcing production is communication. Misunderstandings can lead to costly errors and delays. The Philippines stands out with its high level of English proficiency. In fact, it ranks among the top English-speaking countries in Asia, significantly reducing communication gaps between international clients and local manufacturers.

On top of that, Filipino culture has strong Western influences, which translates into a better understanding of international fashion trends, consumer behavior, and quality expectations. This cultural compatibility often results in smoother collaborations and faster alignment on design and production goals.

Skilled Workforce and Craftsmanship

The country boasts a labor force rich in creativity, attention to detail, and technical skills. Filipino sewers, pattern makers, and quality control specialists are known for their precision and commitment to craftsmanship. For small to mid-sized fashion brands looking to produce boutique or high-quality pieces, working with a garment manufacturer in the Philippines can offer a level of artisanal care that mass-production hubs often lack.

Moreover, many manufacturers invest in continuous staff training, ensuring teams stay up-to-date with evolving production techniques, fabric innovations, and industry best practices.

Cost-Effective Without Compromising Quality

While price shouldn’t be the sole deciding factor when choosing a manufacturer, it’s certainly important. The Philippines offers competitive labor and overhead costs, especially when compared to Western countries or even other parts of Asia. That said, the lower cost doesn’t equate to lower quality.

Many Filipino garment factories adhere to international standards, with ISO certifications and rigorous quality assurance protocols in place. Brands can achieve cost-efficiency while still maintaining high product standards—a win-win scenario.

Ethical and Sustainable Production Practices

With consumers placing more emphasis on sustainability and ethical sourcing, it’s crucial for brands to partner with manufacturers who align with these values. Many Philippine garment manufacturers emphasize fair labor practices, safe working environments, and eco-friendly production methods.

Some go the extra mile by sourcing organic or recycled fabrics, reducing water usage, and implementing waste management systems. Partnering with a responsible garment manufacturer philippines not only supports local communities but also enhances your brand's reputation among conscious consumers.

Customization and Flexibility

If you're a growing brand or launching a niche product line, flexibility in manufacturing is key. The Philippines is home to many small to mid-sized manufacturers that specialize in low to mid-volume production—ideal for businesses that need custom runs, prototyping, or varied product lines.

Unlike massive factories that often prioritize high-volume clients, Filipino manufacturers are often more accommodating to startups and SMEs. This flexibility can mean faster turnaround times, easier communication, and more collaborative design and development processes.

Proximity to Other Asian Markets

While the Philippines is a valuable market in its own right, its location also makes it a strategic point for distributing products across Asia and beyond. As a member of ASEAN (Association of Southeast Asian Nations), the country benefits from favorable trade relations with many neighboring economies. That means easier logistics and lower tariffs for brands targeting Asian markets.

Additionally, the Philippines’ major ports are well-developed, and its international shipping infrastructure is robust. Exporting finished products is generally efficient, helping brands meet tight retail deadlines without excessive transportation delays.

Real-World Success Stories

Several international brands—both mainstream and boutique—have already tapped into the Philippines’ garment manufacturing potential. From independent streetwear labels to ethical fashion startups, many have found success in working with Filipino manufacturers due to the consistent quality, dependable lead times, and collaborative relationships.

For example, a growing trend among e-commerce brands is to work with a Philippine-based manufacturer for limited-edition drops. These short production runs require attention to detail and flexibility—two things Filipino manufacturers excel at.

What to Look for in a Philippine Garment Manufacturer

When selecting a manufacturing partner in the Philippines, keep these criteria in mind:

1. Experience and Specialization

Does the manufacturer specialize in your type of apparel—sportswear, casualwear, uniforms, or fashion pieces? Look for partners with a proven track record in your niche.

2. Transparency and Communication

Strong, clear communication is crucial. Choose a factory that’s responsive, transparent about pricing and timelines, and open to feedback.

3. Certifications and Ethical Standards

Verify certifications such as ISO or WRAP to ensure the manufacturer meets international standards for quality and ethical practices.

4. Production Capabilities and Lead Times

Ask about their minimum order quantities (MOQs), production speed, and ability to scale as your brand grows.

5. Client References or Portfolio

A reputable manufacturer should be able to provide case studies, client testimonials, or sample work.

Final Thoughts

As fashion becomes more fast-paced and customer expectations rise, your supply chain needs to be agile, reliable, and aligned with your brand values. The Philippines offers a unique blend of quality craftsmanship, cost efficiency, and ethical production practices. Whether you're a boutique brand looking for small-batch production or an established label expanding into Southeast Asia, a partnership with a trusted garment manufacturer philippines could be the strategic advantage you need.

If you're ready to take the next step, explore manufacturers like Shirt City Commercial that combine years of expertise with modern innovation. In an industry where trust, quality, and flexibility are paramount, the Philippines is proving to be more than just an alternative—it’s a smart choice.

0 notes

Text

What to Expect from a Bachelor of Apparel Design Course 🎨🧵

Are you passionate about fashion, fabric, and the art of turning ideas into wearable statements? The Bachelor of Apparel Design course could be just the ticket to take off. But before you take off on your innovative journey, you have to comprehend what you will be doing.Let's unpack what to expect from this stimulating undergraduate qualification - from classroom based learning, to catwalk-ready designs.

📚 Curriculum: A Blend of Creativity & Practicality

A Bachelor of Apparel Design typically spans 3 to 4 years and is structured to give students a solid foundation in both creative design and technical know-how.

Core Subjects Include:

Fashion Illustration & Sketching

Textile Science & Fabric Studies

Pattern Making & Garment Construction

Surface Ornamentation & Embroidery

Computer-Aided Design (CAD)

Fashion History & Trends

Design Thinking & Portfolio Development

Most courses are hands-on, with practical labs, workshops, and studio-based learning at the heart of every semester.

🎓 Entrance Exams & Admissions

Admission to top design colleges usually requires clearing a design aptitude test. One such option is the All India Design Aptitude Test (AIDAT), which opens doors to several recognized fashion and design programs across India.

These tests generally assess:

Creative and visual thinking

Design and sketching ability

Logical reasoning

General awareness of fashion and culture

Some institutes may also conduct interviews or ask for a portfolio review as part of the selection process.

🧪 Labs, Workshops & Studio Time

Expect to spend a lot of time experimenting with fabrics, learning stitching techniques, and developing prototypes. Students are encouraged to test textures, patterns, and silhouettes, often under the guidance of industry-experienced faculty.

You’ll learn how to:

Handle different types of fabrics

Operate sewing and digital embroidery machines

Create customized garments from scratch

Develop your own design collections

💡 Industry Exposure & Internships

The fashion world thrives on real-time experience. Reputed programs include internships, fashion shows, buyer meets, and industry visits as part of the curriculum. Some colleges also have guest speakers and workshops with industry experts and alumni, allowing for more career-focused, dynamic education and many more.

🧑🎓 Life Beyond the Classroom

Throughout the course, you’ll build a professional portfolio showcasing your designs, sketches, concepts, and photoshoots.

You'll also have the chance to:

Organize or participate in annual fashion shows

Compete in national design competitions

Attend design expos and textile fairs

💼 Career Possibilities After Graduation

Once you complete your degree, you can explore roles like:

Fashion Designer

Apparel Product Developer

Pattern Maker or Technical Designer

Fashion Illustrator

Textile or Print Designer

Costume Designer

Entrepreneur (start your own label or boutique)

For those who want to further specialize, options like Master’s in Fashion Design, MBA in Fashion Management, or short-term certifications in styling, merchandising, or fashion tech are also available.

🌟 Conclusion

Whether you dream of working for a fashion label, launching your own brand, or making costumes for cinema, this course equips you with the tools to make it happen.

👉 Ready to take the first step? Explore entrance exam details and top design courses at AIDAT’s official website and start your journey into the world of fashion and design.

0 notes

Text

Bringing manufacturing back to America, one fab lab at a time

New Post has been published on https://sunalei.org/news/bringing-manufacturing-back-to-america-one-fab-lab-at-a-time/

Bringing manufacturing back to America, one fab lab at a time

Reindustrializing America will require action from not only businesses but also a new wave of people that have the skills, experience, and drive to make things. While many efforts in this area have focused on top-down education and manufacturing initiatives, an organic, grassroots movement has been inspiring a new generation of makers across America for the last 20 years.

The first fab lab was started in 2002 by MIT’s Center for Bits and Atoms (CBA). To teach students to use the digital fabrication research facility, CBA’s leaders began teaching a rapid-prototyping class called MAS.863 (How To Make (almost) Anything). In response to overwhelming demand, CBA collaborated with civil rights activist and MIT adjunct professor Mel King to create a community-scale version of the lab, integrating tools for 3D printing and scanning, laser cutting, precision and large-format machining, molding and casting, and surface-mount electronics, as well as design software.

That was supposed to be the end of the story; they didn’t expect a maker movement. Then another community reached out to get help building their own fab lab. Then another. Today there are hundreds of U.S. fab labs, in nearly every state, in locations ranging from community college campuses to Main Street. The fab labs offer open access to tools and software, as well as education, training, and community to people from all backgrounds.

“In the fab labs you can make almost anything,” says Professor and CBA Director Neil Gershenfeld. “That doesn’t mean everybody will make everything, but they can make things for themselves and their communities. The success of the fab labs suggests the real way to bring manufacturing back to America is not as it was. This is a different notion of agile, just-in-time manufacturing that’s personalized, distributed, and doesn’t have a sharp boundary between producer and consumer.”

Communities of makers

A fab lab opened at Florida A&M University about a year ago, but it didn’t take long for faculty and staff to notice its impact on their students. Denaria Pringley, an elementary education teacher with no experience in STEM, first came to the lab as part of a class requirement. That’s when she realized she could build her own guitar. In a pattern that has repeated itself across the country, Pringley began coming to the lab on nights and weekends, 3D-printing the body of the guitar, drilling together the neck, sanding and polishing the finish, laser engraving pick guards, and stringing everything together. Today, she works in the fab lab and knows how to run every machine in the space.

“Her entire disposition transformed through the fab lab,” says FAMU Dean of Education Sarah Price. “Every day, students make something new. There’s so much creativity going on in the lab it astounds me.”

Gershenfeld says describing how the fab labs work is a bit like describing how the internet works. At a high level, fab labs are spaces to play, create, learn, mentor, and invent. As they started replicating, Gershenfeld and his colleague Sherry Lassiter started the Fab Foundation, a nonprofit that provides operational, technical, and logistical assistance to labs. Last year, The Boston Globe called the global network of thousands of fab labs one of MIT’s most influential contributions of the last 25 years.

Some fab labs are housed in colleges. Others are funded by local governments, businesses, or through donations. Even fab labs operated in part by colleges can be open to anyone, and many of those fab labs partner with surrounding K-12 schools and continuing education programs.

Increasingly, corporate social responsibility programs are investing in fab labs, giving their communities spaces for STEM education, workforce development, and economic development. For instance, Chevron supported the startup of the fab lab at FAMU. Lassiter, the president of the Fab Foundation, notes, “Fab labs have evolved to become community anchor organizations, building strong social connections and resilience in addition to developing technical skills and providing public access to manufacturing capabilities.”

“We’re a community resource,” says Eric Saliim, who serves as a program manager at the fab lab housed in North Carolina Central University. “We have no restrictions for how you can use our fab lab. People make everything from art to car parts, products for their home, fashion accessories, you name it.”

Many fab lab instructors say the labs are a powerful way to make abstract concepts real and spark student interest in STEM subjects.

“More schools should be using fab labs to get kids interested in computer science and coding,” says Scott Simenson, former director of the fab lab at Century College in Minnesota. “This world is going to get a lot more digitally sophisticated, and we need a workforce that’s not only highly trained but also educated around subjects like computer science and artificial intelligence.”

Minnesota’s Century College opened its fab lab in 2004 amid years of declining enrollment in its engineering and design programs.

“It’s a great bridge between the theoretical and the applied,” Simenson explains. “Frankly, it helped a lot of engineering students who were disgruntled because they felt like they didn’t get to make enough things with their hands.”

The fab lab has since helped support the creation of Century College programs in digital and additive manufacturing, welding, and bioprinting.

“Working in fab labs establishes a growth mindset for our community as well as our students,” says Kelly Zelesnik, the dean of Lorain County Community College in Ohio. “Students are so under-the-gun to get it right and the grade that they lose sight of the learning. But when they’re in the fab lab, they’re iterating, because nothing ever works the first time.”

In addition to offering access to equipment and education, fab labs foster education, mentorship, and innovation. Businesses often use local fab labs to make prototypes or test new products. Students have started businesses around their art and fashion creations.

Rick Pollack was a software entrepreneur and frequent visitor to the fab lab at Lorain County Community College. Pollack became fascinated with 3D printers and eventually started the additive manufacturing company MakerGear after months of tinkering with the machines in the lab in 2009. MakerGear quickly became one of the most popular producers of 3D printers in the country.

“Everyone wants to talk about innovation with STEM education and business incubation,” Gershenfeld says. “This is delivering on that by filling in the missing scaffolding: the means of production.”

Manufacturing reimagined

Many fab labs begin with tiny spaces in forgotten corners of buildings and campuses. Over time, they attract a motley crew of people that have often struggled in structured, hierarchical classroom settings. Eventually, they become hubs for people of all backgrounds driven by making.

“Fab labs provide access to tools, but what’s really driving their success is the culture of peer-to-peer, project-based learning and production,” Gershenfeld says. “Fab labs don’t separate basic and applied work, short- and long-term goals, play and problem solving. The labs are a very bottom-up distribution of the culture at MIT.”

While the local maker movement won’t replace mass manufacturing, Gershenfeld says that mass manufacturing produces goods for consumers who all want the same thing, while local production can make more interesting things that differ for individuals.

Moreover, Gershenfeld doesn’t believe you can measure the impact of fab labs by looking only at the things produced.

“A significant part of the benefit of these labs is the act of making itself,” he says. “For instance, a fab lab in Detroit led by Blair Evans worked with at-risk youth, delivering better life outcomes than conventional social services. These labs attract interest and then build skills and communities, and so along with the things that get made, the community-building, the knowledge, the connecting, is all as important as the immediate economic impact.”

0 notes

Text

How Can a STEM Lab in Ahmedabad Schools Boost Computational Thinking?

https://makersmuse.in/wp-content/uploads/2025/03/STEM-Labs-in-Ahmedabad-1.jpg

With the creation of STEM Labs in Ahmedabad schools, the city, which is renowned for its inventiveness and educational excellence, is setting the path for the upcoming generation of thinkers and innovators. These labs are more than just learning environments; they are a learning revolution that instills students with the ability to think computationally and solve problems.

Because they serve a diverse student body, Ahmedabad schools are uniquely positioned to revolutionize education through the STEM Lab Program. As the city continues to expand its foothold in industries like technology, manufacturing, and engineering, there is an ever-growing demand for a workforce equipped with critical thinking and technical expertise. This is where STEM education plays a pivotal role.

The introduction of STEM Lab Solution in Ahmedabad School helps align education with the city’s aspirations. By integrating science, technology, engineering, and mathematics into hands-on learning, these labs ensure students can turn abstract theories into tangible solutions. Want to explore more about Stem Lab in Ahmedabad? Join makers’ muse!

What is computational thinking, and why is it crucial in the STEM Lab Solution in Ahmedabad School’s?

Computational thinking forms the foundation of innovation. At its core, it is about analyzing problems systematically, identifying patterns, and developing logical solutions. However, it extends far beyond just coding or software development. Computational thinking can be applied to a range of real-world scenarios, equipping students with the mindset needed to approach complex challenges.

Ahmedabad Schools , through their robust STEM Lab Solution in Ahmedabad Schools, offers students innovative tools and resources to develop computational thinking in engaging and interactive ways:

Hands-On Robotics Projects: Students design and build robots, which nurtures creativity and engineering knowledge.

Problem-Centric Coding Challenges: These allow students to solve real-world issues through programming.

Practical Engineering Prototypes: This fosters an understanding of physics, mechanics, and design thinking.

Benefits of STEM Labs Tailored to Ahmedabad’s Context

The benefits of the STEM Lab Program in Ahmedabad schools are not limited to academic growth but extend to personal and professional development. Here’s how these labs can specifically impact Ahmedabad’s educational ecosystem:

City-Specific Challenges: STEM labs can incorporate local themes, such as environmental sustainability, water management, or urban planning, into student projects.

Preparation for Growing Industries: Ahmedabad’s strong presence in the technology and textile sectors requires a future workforce that is adaptable and skilled in STEM.

Cultural Innovation: By combining traditional learning with modern tools, STEM labs balance heritage with progress, mirroring the city’s identity.

Student-Centric Growth: By fostering creativity, collaboration, and critical thinking, these labs prepare students for dynamic futures.

Preparing Students for a Competitive World with STEM Lab Program in Ahmedabad School

Ahmedabad School is nurturing a generation that can compete on a global stage. The STEM Lab Program in Ahmedabad School doesn’t just aim to teach technical skills but ensures holistic development. Students gain teamwork, communication, and decision-making abilities through collaborative projects and group activities.

Encouraging Educator and Parent Involvement in the STEM Lab Program in Ahmedabad School

The success of the STEM Lab Program in Ahmedabad School depends heavily on the involvement of educators and parents. Teachers are trained not only to use the latest tools but also to guide students in applying their knowledge creatively. By fostering a collaborative approach between schools and families, students are motivated to explore STEM with enthusiasm.

Moreover, partnerships with organizations specializing in STEM resources can ensure these labs remain cutting-edge. Ahmedabad schools can also collaborate with local industries to provide students with exposure to real-world applications of their learning.

Shaping Tomorrow: The Future Vision for STEM Labs in Ahmedabad and How You Can Contribute

Looking ahead, the potential for a STEM Lab in Ahmedabad schools is immense. Schools can explore integrating advanced technologies like artificial intelligence, virtual reality, and 3D printing to make the learning process even more engaging and futuristic.

If you’re an educator, policymaker, or parent in Ahmedabad, now is the time to invest in the future of education. Advocate for the expansion of STEM labs in schools, support initiatives that foster computational thinking and innovation, and help shape a generation of young problem-solvers. Join our community for the best STEM lab setup in your school! our students—and our city.

Ahmedabad’s potential to become a hub for education and technology is limitless, and STEM labs are the stepping stones to achieving this vision. Let’s collaborate and make it happen! Connect us!

0 notes

Text

Designing a garment

Garment design includes components of "color, texture, space, lines, pattern, silhouette, shape, proportion, balance, emphasis, rhythm, and harmony". All of these elements come together to design a garment by creating visual interest for consumers.

Fashion designers work in various ways, some start with a vision in their head and later move into drawing it on paper or on a computer, while others go directly into draping fabric onto a dress form, also known as a mannequin. The design process is unique to the designer and it is rather intriguing to see the various steps that go into the process. Designing a garment starts with patternmaking. The process begins with creating a sloper or base pattern. The sloper will fit the size of the model a designer is working with or a base can be made by utilizing standard size charting.

Three major manipulations within patternmaking include dart manipulation, contouring, and added fullness. Dart manipulation allows for a dart to be moved on a garment in various places but does not change the overall fit of the garment. Contouring allows for areas of a garment to fit closer to areas of the torso such as the bust or shoulders. Added fullness increases the length or width of a pattern to change the frame as well as fit of the garment. The fullness can be added on one side, unequal, or equally to the pattern.

A designer may choose to work with certain apps that can help connect all their ideas together and expand their thoughts to create a cohesive design. When a designer is completely satisfied with the fit of the toile (or muslin), they will consult a professional pattern maker who will then create the finished, working version of the pattern out of paper or using a computer program. Finally, a sample garment is made up and tested on a model to make sure it is an operational outfit. Fashion design is expressive, the designers create art that may be functional or non-functional.

Technology within fashion

Over the years, there has been an increase in the use of technology within fashion design. Iris van Herpen, a Dutch designer, incorporated 3D printing in her Crystallization collection.

Software can aid designers in the product development stage. Designers can use artificial intelligence and virtual reality to prototype clothing. 3D modeling within software allows for initial sampling and development stages for partnerships with suppliers before the garments are produced.

Modern Western fashion design is often considered to have started in the 19th century with Charles Frederick Worth who was the first designer to have his label sewn into the garments that he created. Before the former draper set up his maison couture (fashion house) in Paris, clothing design and creation of the garments were handled largely by anonymous seamstresses. At the time high fashion descended from what was popularly worn at royal courts. Worth's success was such that he was able to dictate to his customers what they should wear, instead of following their lead as earlier dressmakers had done. The term couturier was in fact first created in order to describe him. While all articles of clothing from any time period are studied by academics as costume design, only clothing created after 1858 is considered fashion design.

It was during this period that many design houses began to hire artists to sketch or paint designs for garments. Rather than going straight into manufacturing, the images were shown to clients to gain approval, which saved time and money for the designer. If the client liked their design, the patrons commissioned the garment from the designer, and it was produced for the client in the fashion house. This designer-patron construct launched designers sketching their work rather than putting the completed designs on models.

Types of fashion

Garments produced by clothing manufacturers fall into three main categories, although these may be split up into additional, different types.

Haute couture

Main article: Haute couture

Until the 1950s, fashion clothing was predominately designed and manufactured on a made-to-measure or haute couture basis (French for high-sewing), with each garment being created for a specific client. A couture garment is made to order for an individual customer, and is usually made from high-quality, expensive fabric, sewn with extreme attention to detail and finish, often using time-consuming, hand-executed techniques. Look and fit take priority over the cost of materials and the time it takes to make.[8][9] Due to the high cost of each garment, haute couture makes little direct profit for the fashion houses, but is important for prestige and publicity.[10]

Ready-to-wear (prêt-à-porter)

[edit]

Main article: Ready-to-wear

Ready-to-wear, or prêt-à-porter, clothes are a cross between haute couture and mass market. They are not made for individual customers, but great care is taken in the choice and cut of the fabric. Clothes are made in small quantities to guarantee exclusivity, so they are rather expensive. Ready-to-wear collections are usually presented by fashion houses each season during a period known as fashion week or fashion month. This takes place on a citywide basis and occurs twice a year. The main seasons of Fashion Week include spring/summer, fall/winter, resort, swim, and bridal.

Half-way garments are an alternative to ready-to-wear, "off-the-peg", or prêt-à-porter fashion. Half-way garments are intentionally unfinished pieces of clothing that encourage co-design between the "primary designer" of the garment, and what would usually be considered, the passive "consumer". This differs from ready-to-wear fashion, as the consumer is able to participate in the process of making and co-designing their clothing. During the Make{able} workshop, Hirscher and Niinimaki found that personal involvement in the garment-making process created a meaningful "narrative" for the user, which established a person-product attachment and increased the sentimental value of the final product.

Otto von Busch also explores half-way garments and fashion co-design in his thesis, "Fashion-able, Hacktivism and engaged Fashion Design".

Mass market

Main article: Mass market

Currently, the fashion industry relies more on mass-market sales. The mass market caters for a wide range of customers, producing ready-to-wear garments using trends set by the famous names in fashion. They often wait around a season to make sure a style is going to catch on before producing their versions of the original look. To save money and time, they use cheaper fabrics and simpler production techniques which can easily be done by machines. The end product can, therefore, be sold much more cheaply.

There is a type of design called "kutch" originated from the German word kitschig, meaning "trashy" or "not aesthetically pleasing". Kitsch can also refer to "wearing or displaying something that is therefore no longer in fashion".

Income

The median annual wages for salaried fashion designers was $79,290 in May 2023, approximately $38.12 per hour. The middle 50 percent earned an average of 76,700. The lowest 10 percent earned $37,090 and the highest 10 percent earned $160,850. The highest number of employment lies within Apparel, Piece Goods, and Notions Merchant Wholesalers with a percentage of 5.4. The average is 7,820 based on employment. The lowest employment is within Apparel Knitting Mills at .46% of the industry employed, which averages to 30 workers within the specific specialty. In 2016, 23,800 people were counted as fashion designers in the United States.

Geographically, the largest employment state of Fashion designers is New York with an employment of 7,930.New York is considered a hub for fashion designers due to a large percentage of luxury designers and brands.

Fashion today is a global industry, and most major countries have a fashion industry. Seven countries have established an international reputation in fashion: the United States, France, Italy, United Kingdom, Japan, Germany and Belgium. The "big four" fashion capitals of the fashion industry are New York City, Paris, Milan, and London.

0 notes

Text

How Shoes Are Made In The Shoe Factory 101

How Shoes Are Made In The Shoe Factory 101

Curious about how footwear is brought to life, especially for Portugal shoe brands and Portuguese shoes? here’s a breakdown of the entire process:

1. Management Office

Key Roles: Owner, factory manager, business manager, and footwear developers.

Responsibilities: Scheduling, procurement, and overseeing design specifications.

2. Development Room

Purpose: First stop for new designs.

Tasks: Skilled stitchers, pattern makers, and sample cutters create prototypes for shoes and more.

3. Warehouse & Materials Handling

Inventory: Leather, textiles, rubber, and outsole components.

Quality Control: Inspecting raw materials upon arrival.

4. Cutting Department

Function: Precision cutting of leather, textiles, etc., using advanced machinery.

Process: Components are cut, stacked, and labeled for organization.

5. Preparation Department

Role: Prepares upper pieces with logos, stitching guides, and skiving.

Outcome: Assembled kits for the stitching team.

6. Stitching Department

Operations: Stitchers handle specific tasks in assembly lines.

Equipment: Includes traditional and automated stitching machines.

7. Outsole Preparation (Stock Fitting)

Procedure: Gluing and assembling outsole parts.

Outcome: Ready-to-attach outsoles for the main assembly.

8. Assembly Line

First Step: Lasting the shoe’s upper.

Assembly: Priming, cementing, and pressing the upper and outsole together.

9. Final Touches & Quality Control

Chilling: Sets the glue in place.

De-lasting: Removing the last from the shoe.

Packing: Final inspection, lacing, packing, and labeling.

Production Timelines

Factories can produce hundreds to thousands of shoes daily, based on complexity and style. Efficient scheduling ensures seamless transitions from cutting to final assembly, essential in high-quality Portugal shoes brands.

ConclusionFrom design to production, each phase is essential for delivering premium footwear. Addvance Studio takes pride in working on industry-standard quality, ensuring every pair reflects the highest standards in Portuguese shoes.

Website: https://addvance.pt/ Address: Rua Nicolau Coelho, Nº1858 — Felgueiras Portugal Phone: (+351) 255 166 235

0 notes

Text

Top 3D Rendering and Visualization Services in Kolkata

3d rendering services in Kolkata has seen a surprising ascent, because of the flourishing land area, item configuration needs, and developing imaginative businesses. Whether it's a great structure's outside, mind boggling insides, or vivid walkthrough movements, 3D delivering organizations in Kolkata offer state of the art arrangements. In this article, we investigate the wide range of administrations given by 3D delivering studios in Kolkata and their importance in different businesses.

3D Outside Delivering Administrations in Kolkata

Draftsmen and land engineers depend vigorously on 3D outside delivering administrations in Kolkata to rejuvenate their dreams. These administrations change building plans into photorealistic pictures, empowering partners to envision the last result before development starts. From private edifices to business structures, a 3D outside delivering organization could exhibit many-sided subtleties at any point like surfaces, lighting, and finishing.

3D Inside Representation Administrations in Kolkata

Planning insides that are both useful and stylishly satisfying can challenge. This is where 3D inside perception administrations in Kolkata become possibly the most important factor. Inside originators, draftsmen, and property designers benefit significantly from these administrations, which permit them to introduce point by point visuals of spaces like lounges, kitchens, and office arrangements.

3D Item Representation Administrations in Kolkata

For organizations engaged with item assembling and retail, 3D item representation administrations in Kolkata have turned into a unique advantage. These administrations permit organizations to make exact computerized portrayals of their items, which can be utilized for showcasing, prototyping, and introductions. 3D item delivering in Kolkata empowers makers to feature mind boggling subtleties of their items, like surface, finish, and usefulness, without requiring actual models.

3D Walkthrough Activity Administrations in Kolkata

With regards to introducing enormous scope projects like private edifices or business structures, nothing catches consideration better than a 3D walkthrough movement. A few 3D walkthrough liveliness studios in Kolkata work in making vivid encounters that permit clients and partners to basically "stroll through" a property before it's fabricated.

These livelinesss exhibit everything about, the stupendous passages to the comfortable insides, giving a feeling of scale and mood. Whether you are a land engineer hoping to pitch your venture or a draftsman introducing your plan, 3D walkthrough liveliness administrations in Kolkata can raise your show to a higher level.

Why Pick 3D Delivering Studios in Kolkata?

Kolkata is home to a developing number of talented experts and 3D delivering studios that proposition first class benefits at serious costs. These studios utilize progressed instruments and programming to convey excellent results custom fitted to meet different client needs. From 3D outside delivering to 3D inside perception benefits, the city's delivering specialists guarantee exactness, imagination, and effectiveness in each undertaking.

In addition, Kolkata's imaginative experts comprehend the significance of remaining refreshed with worldwide patterns. Whether it's taking on the most recent delivering methods or giving custom arrangements, 3D delivering administrations in Kolkata are intended to take care of a great many businesses, including engineering, land, item plan, and publicizing.

3D exterior rendering services Kolkata

As innovation keeps on advancing, the extent of 3D delivering administrations in Kolkata is extending. Arising patterns like computer generated simulation (VR) and increased reality (AR) are preparing for more intelligent and vivid representation encounters. For example, VR-empowered walkthroughs are turning out to be progressively famous, offering clients a constant encounter of unbuilt spaces.

0 notes

Text

The Business of Fashion Design: From Sketch to Runway

Fashion design is an exciting and multifaceted field that blends creativity with business acumen. Turning an idea into a finished garment on the runway requires a structured process, a team of skilled professionals, and a strong understanding of the industry’s commercial aspects. At Suryadatta Institute of Fashion Technology (SIFT), students learn not only the creative aspects of design but also the business principles that turn a vision into a viable product. Here’s an in-depth look at the journey from sketch to runway and the essential business side of fashion design.

Introduction to the Fashion Design Process

The fashion design process is an intricate journey where imagination meets reality. Starting with a concept, designers create a piece that resonates with their brand and audience. Each stage in the design process—from sketching initial ideas to seeing the garment walk down the runway—requires careful planning, precision, and teamwork. At SIFT, students are trained to master each phase, learning how to blend their creativity with practical skills to bring their visions to life. The ultimate goal is to produce garments that make a statement and meet industry standards for quality and marketability.

Step-by-Step Breakdown: From Concept, Sketch, and Fabric Choice to Runway

Concept Development: Every collection starts with a concept, often inspired by art, nature, cultural themes, or social issues. This concept guides the entire design process and sets the tone for the collection’s style, color palette, and mood.

Sketching: Once the concept is clear, designers translate their ideas into sketches, visualizing their designs on paper or digitally. Sketching is a critical stage where designers experiment with silhouettes, details, and garment structures.

Fabric Selection: Choosing the right fabric is essential, as it impacts both the garment’s look and function. Designers at SIFT are taught to select materials that align with their concept and meet practical needs, whether it's luxurious silk for evening wear or durable cotton for everyday pieces.

Pattern Making and Prototyping: After finalizing the sketches, designers create patterns, which serve as templates for cutting fabric. Prototyping follows, where the first sample of the garment is created to assess fit, structure, and overall aesthetic.

Fitting and Adjustments: The prototype is fitted on a model to evaluate how the garment looks and feels. Necessary adjustments are made to ensure the final product meets the designer’s vision.

Final Production: Once all adjustments are complete, the garment goes into production, with pieces crafted for retail or runway. Quality control is critical at this stage to maintain high standards.

Runway Show: The final stage is the runway show, where the collection is showcased to buyers, fashion editors, and industry influencers. Runway presentations are essential for creating a buzz around the collection and establishing the designer’s brand image.

Key Roles in the Fashion Design Pipeline

The journey from sketch to runway involves a variety of professionals, each contributing unique expertise:

Fashion Stylists: Stylists ensure each look is presented cohesively, coordinating accessories, makeup, and hairstyles to bring out the collection’s essence.

Pattern Makers and Seamstresses: These professionals are responsible for transforming designs into tangible garments, ensuring every detail aligns with the designer’s vision.

Merchandisers: Merchandisers help identify which pieces in a collection will likely sell well, guiding the production process to maximize profitability.

Fashion Show Producers: Producers organize the runway shows, handling everything from logistics to lighting and music, creating an immersive experience that captures the collection’s theme.

Public Relations (PR) Teams: PR professionals handle marketing and publicity, ensuring the collection receives media attention and reaches a wider audience.

Understanding the Business Aspects (Pricing, Marketing, Branding)

Fashion is not just about design; it’s also about business. Pricing, marketing, and branding are essential to making a collection profitable and establishing a brand’s identity.

Pricing: Pricing involves understanding costs, profit margins, and the target market’s spending capacity. Setting the right price is essential to balancing accessibility with exclusivity.

Marketing: Marketing efforts, including social media campaigns, influencer partnerships, and press releases, help promote the collection. SIFT teaches students how to develop marketing strategies that attract attention and drive sales.

Branding: A strong brand identity is crucial in a competitive industry. From logos and color schemes to brand messages, branding communicates what the designer stands for and builds customer loyalty.

How Aspiring Designers Can Make an Impact in the Industry

Breaking into the fashion industry can be challenging, but with the right strategies, aspiring designers can make a mark. Here are some tips:

Find a Unique Voice: Designers should focus on developing a distinctive style that reflects their personality and vision. A unique perspective sets a brand apart and attracts a dedicated audience.

Network: Building connections within the industry is crucial. Attending events, connecting with mentors, and collaborating with other creatives can open doors to new opportunities.

Stay Adaptable: The fashion industry is fast-paced and competitive. Being adaptable and open to change is essential for growth and longevity.

Gain Business Knowledge: Creativity alone isn’t enough in the fashion world. Aspiring designers should understand the business side of fashion, including financial planning, branding, and consumer behavior. SIFT offers courses that equip students with this business knowledge, ensuring they are well-prepared to succeed.

The journey from sketch to runway is filled with creativity, challenges, and triumphs. For students at Suryadatta Institute of Fashion Technology (SIFT), understanding the entire process—from concept development to production and marketing—is essential for success. By combining artistry with business acumen, aspiring designers can bring their visions to life, creating collections that make a statement and resonate with audiences.

Fashion is an industry where dreams become reality, one stitch at a time. With determination, skill, and a deep understanding of the creative and business sides, designers can build a lasting impact in the world of fashion. SIFT prepares students for this journey, guiding them from the initial sketch to the thrill of seeing their work on the runway, ready to inspire the world.

0 notes

Text

Fashion Design the Fabric Evolution

About Fashion design Fashion trend is self-expression that constantly adapts and evolves, showcasing its ever-changing nature. It is a mirror that reflects the pulse of society, capturing the zeitgeist and translating it into wearable art. Fashion reinvents itself, redefining beauty standards, pushing boundaries, and challenging norms. Basics of Fashion Design Fashion designing is a creative field that depends on the creativity of the designer, yet there are certain principles that guide the designer throughout and help them make their designs more appealing to the public. Here are a few principles of fashion design that every aspiring designer must know: Creativity and innovation are the sole ingredients of fashion design, which helps the designers create ground breaking designs, but while designing, the functionality and practicality of the design must also be kept in mind so that the design is wearable and comfortable along with being stylish. The field of fashion design stands on the foundation of certain elements such as colour, line, shape, texture, balance, proportion, space, rhythm, movement, etc.

The Process of Fashion Designing The process of designer clothes involves several stages that designers go through to bring their ideas to life. It starts with research and inspiration gathering, followed by sketching and creating the initial designs that they thought of. It is followed by fabric selection, pattern-making, and garment construction. Developed prototypes are refined through fittings and adjustments. After the final design is determined, production and manufacturing processes begin, including sourcing materials, cutting, sewing, and finishing. In the final step, the finished garments are presented through fashion shows, exhibitions, or retail channels. Throughout the designing process, the designers collaborate with various professionals, including pattern makers, seamstresses, and stylists, in order to ensure their vision is translated into a tangible and marketable fashion product.

Everything in fashion creation begins with the inspiration and the thing is, we can’t get inspired whenever we wanted. Fashion collection inspiration is an ongoing process that we need to train our mind to collect ideas and store it in a place where we can use whenever we need especially when creating a fashion line. Often designers travel around the world to get their eyes on new places and gather inspiration. You can be inspired by anything and everything you see, unless you store them every time, you are gonna forget it and stare at the blank paper when you need. Importance of Fabric Knowledge Knowledge of fabric is crucial for fashion design as it directly impacts the appearance, drape, and functionality of garments. Factors such as texture, weight, stretch, and durability influence how a fabric interacts with the body and affect the overall fit and comfort of the garment. Understanding different types of fabrics enables designers to make informed decisions about which material will fit their design vision the best. The knowledge of fabric enhances the overall quality of the design. Since the right fabric is used for the right occasions, it will meet the desired aesthetic and all the requirements of the envisioned design.

How to Become a Fashion Designer?

Becoming a fashion designer requires a combination of creativity, technical skills, industry knowledge, and a passion for fashion. It is a competitive field, but with dedication, continuous learning, and a strong portfolio, aspiring designers can carve their path in this exciting and dynamic industry. Education and Training creative Skills Fashion Knowledge and Trend Awareness Business Acumen Communication and Collaboration Conceptualization of design ideas Creation of sketches and technical drawings of designs Selection of fabrics, colors, and materials for production Participating in fashion shows and representations to showcase designs Researching fashion trends and consumer preferences Collaborating with clients, manufacturers, and retailers to meet design objectives How ASD Innovation makes Fashion Trends? ASD Innovation, the modern fashion industry has an expert resource of fashion designer, fabric selector forecasting high fashion end. It has a well established system of fashion making from design selection to product launch. ASD follows strict quality measures to full the customer satisfaction.

1 note

·

View note

Text

What are some inspiring examples of STEAM classroom innovation in schools?

https://makersmuse.in/wp-content/uploads/2024/11/DSC_5360.NEF_-scaled.jpg

Imagine a classroom buzzing with creativity, where art blends seamlessly with technology and science sparks innovation. Welcome to the world of STEAM education an approach that integrates Science, Technology, Engineering, Arts, and Mathematics to prepare students for a dynamic future. Schools worldwide are adopting STEAM principles to nurture problem-solving skills and creativity. Let’s explore some inspiring examples of how classrooms are redefining education with STEAM innovation.

1. Building Sustainable Cities with LEGO Robotics

In a school in Denmark, students use LEGO robotics kits to design eco-friendly cities. They learn about renewable energy, coding, and urban planning, bringing their models to life through interactive projects.

Impact: Enhances teamwork, critical thinking, and environmental awareness.

2. Art Meets Engineering: The STEAM Gallery Project

A middle school in the USA integrates art and engineering by challenging students to create kinetic sculptures powered by simple machines. This hands-on activity bridges artistic creativity and mechanical knowledge. Learn more

Impact: Encourages innovative thinking and a deeper appreciation for interdisciplinary skills.

3. Virtual Reality for History and Science Exploration

A UK-based STEAM program uses virtual reality to transport students to historical landmarks or inside a human cell. By merging technology with curriculum content, students gain immersive learning experiences.

Impact: Improves engagement, retention, and understanding of complex concepts.

4. Coding Drones for Social Good

In Australia, students are coding drones to assist in community service projects, such as delivering supplies to remote areas. This initiative combines coding skills with real-world problem-solving.

Impact: Teaches practical applications of technology for humanitarian purposes.

5. STEAM Maker Spaces: Innovation Hubs for Young Creators

Many schools now feature maker spaces equipped with 3D printers, laser cutters, and coding tools. Students can prototype inventions, fostering an entrepreneurial mindset.

Impact: Builds confidence and promotes creativity in solving real-world challenges.

6. Biomimicry: Nature-Inspired Solutions

In Japan, students study the behavior of animals and plants to design innovative solutions, such as energy-efficient buildings inspired by termite mounds.

Impact: Fosters curiosity about nature and sustainable design thinking.

7. STEAM Music Labs: Creating Digital Symphonies

In Brazil, students compose music using coding software, combining mathematics and creativity. They learn to visualize sound patterns and create harmonious compositions.

Impact: Enhances both analytical and artistic skills, offering a unique learning experience.

Ready to make STEAM innovation a part of your child’s journey?

STEAM education is revolutionizing classrooms, making learning both fun and impactful. By integrating diverse disciplines, students develop skills that empower them for future challenges. Discover tools and resources that bring STEAM to life! Engage your audience with the wonders of STEAM education and inspire the next generation to dream big and think creatively!

0 notes