#Plastic Packaging Solution

Text

What Are Pet Preform Manufacturers and How Does It Work?

Pet preform manufacturers in india produce pet preforms, which are plastic containers that are used to store various products. These manufacturers use a variety of machines and techniques to produce these preforms, which are then used by companies all over the world. The process of manufacturing pet preforms begins with the raw materials.

Visit Us - https://www.nightofthelivingdeb.com/what-are-pet-preform-manufacturers-and-how-does-it-work/

0 notes

Text

#good news#science#environmentalism#environment#plastic#potential plastic alternatives#plastic pollution solutions#plastic alternatives#plastic packaging#microbes#bacteria

64 notes

·

View notes

Text

plastic bottle recycling machine in india

Diamond PET Flakes

#recycling of plastic waste in india#epr for plastic waste in india#epr plastic india#plastic waste epr india#Eco-friendly Packaging Solutions#sustainable food packaging companies#sustainable packaging for food eco friendly packaging for food#eco friendly food packaging for small business#eco friendly food packaging india#eco friendly sustainable food packaging#eco friendly food packaging companies#eco friendly plastic food packaging food packaging companies#food packaging company#waste management trash company#largest waste management companies

2 notes

·

View notes

Text

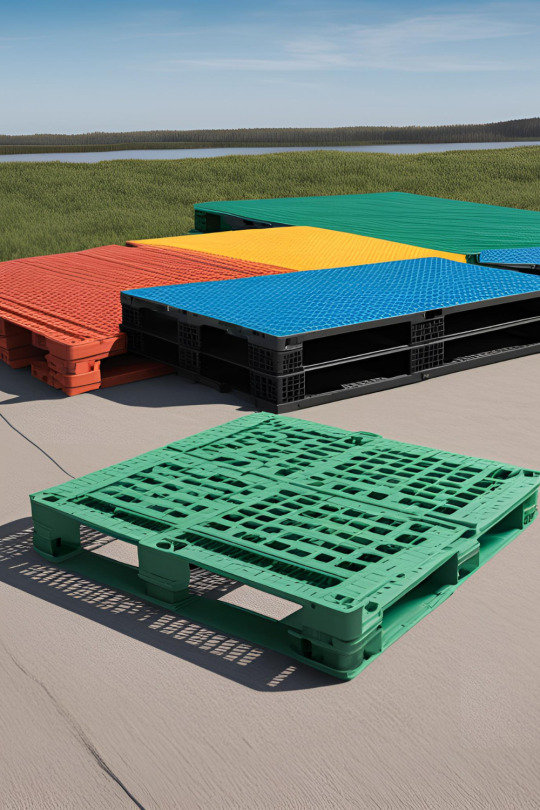

Discover durable and reusable Nilkamal Bubbleguard Returnable Pallets. Our high-quality plastic pallets offer excellent protection and are perfect for efficient supply chain management. Shop now!

#Nilkamal Bubbleguard#Returnable Pallet#plastic pallets#reusable pallets#supply chain management#logistics#warehousing#industrial packaging#durable materials#cost-effective solutions

0 notes

Text

Elevate Your Brand with Premium Cosmetic Plastic Jars from Teknobyte India

Teknobyte India Pvt Ltd is an eminent manufacturer and exporter firm in Delhi, India dealing in cosmetic plastic jars and many other types of plastic packaging products.

The company was set with operating since 1995 and becomes one of the intensive Cosmetic Plastic Jar Manufacturer in the domestic as well as the international market. Their cosmetic jars are derived from quality materials which…

#Bulk Cosmetic Jars Manufacturer#Cosmetic Cream Jar Supplier#Cosmetic Packaging Solutions India#Cosmetic Plastic Jar Manufacturer#Custom Cosmetic Jars#Eco-Friendly Cosmetic Jars#HDPE Plastic Jars for Cosmetics#Personalized Cosmetic Containers#PET Cosmetic Jars Supplier#Plastic Jar Supplier India#Plastic Jars for Lotions and Creams#Premium Cosmetic Packaging#Teknobyte India#Wholesale Cosmetic Packaging

1 note

·

View note

Text

Your Trusted Partner in Bottle Design and Blowing

At Awanti Polymoulds, we specialize in delivering complete solutions for bottle design and blowing. From concept to production, trust us to bring your packaging vision to life with precision and expertise.

#Bottle Design#Bottle Blowing#Packaging Solutions#Plastic Moulding#Custom Bottles#Manufacturing Partner

0 notes

Text

How to Start a Biodegradable Plastic Bags Manufacturing Business

Want to turn your passion for sustainability into a thriving business? 🌍💼 Learn how to launch a biodegradable plastic bags manufacturing business and make a positive impact on the planet! #BiodegradableBags #sustainablebusiness #ecofriendlybusiness

The biodegradable plastic bag industry aims to create eco-friendly substitutes for conventional plastic bags. Biodegradable plastic bags are made to degrade more quickly in natural environments than ordinary plastics, which can take hundreds of years to break down. Usually composed of plant-based materials like sugarcane or cornstarch, these bags have a smaller environmental impact because they…

#biodegradable plastic bags#biodegradable plastic bags business#biodegradable products#biodegradable products industry#eco-conscious entrepreneurship#eco-friendly business opportunities#eco-friendly manufacturing#environmental business opportunities#green business ideas#green technology business#how to start a biodegradable plastic bags business#manufacturing green products#new business ideas 2024#plastic alternatives#profitable green business#profitable manufacturing business#profitable small business ideas#start a business#sustainable entrepreneurship#sustainable packaging#sustainable packaging solutions#sustainable startup

0 notes

Text

Flexible Plastic Packaging: Market Trends for 2024-2032

According to Triton Market Research, the global flexible plastic packaging market report is sectioned by Application (Pharmaceutical, Food & Beverage, Cosmetics & Toiletries, Other Applications), Product (Bags, Films & Wraps, Rollstock, Pouches, Other Products), Printing Technology (Digital Printing, Rotogravure, Flexography, Other Printing Technologies), Material Type (Aluminum Foils, Plastics, Other Material Types), and Regional Outlook (Europe, Asia-Pacific, Middle East and Africa, North America, Latin America).

The report highlights the Market Summary, Industry Outlook, Impact Analysis, Porter’s Five Forces Analysis, Market Attractiveness Index, Regulatory Framework, Key Buying Impact Analysis, Supply Chain Analysis, Key Market Strategies, Market Drivers, Challenges, Opportunities, Analyst Perspective, Competitive Landscape, Research Methodology and scope, Global Market Size, Forecasts & Analysis (2024-2032).

Triton’s research analysis suggests that the global flexible plastic packaging market is expected to advance at a CAGR of 3.80% during the forecast period 2024-2032.

Flexible plastic packaging consists of materials that conform to the shape of their contents, such as bags, pouches, and wraps. These items are designed to be adaptable and versatile. They are cost-effective, lightweight, and help extend shelf life by shielding products from pollutants, moisture, and air.

Factors such as technological advancements and increased demand from the e-commerce industry are expected to create lucrative opportunities for the flexible plastic packaging market. As e-commerce continues to expand globally, driven by increasing consumer reliance on online shopping, the need for durable, lightweight, and customizable packaging solutions is rising. Flexible plastic packaging, known for its versatility and ability to protect products during transit, is well-suited to meet these demands. Additionally, advancements in manufacturing technologies are enabling the production of flexible packaging with enhanced barrier properties, sustainability features, and innovative designs.

However, issues arising in recycling plastic packaging products and high operational costs limit the expansion of the studied market.

Globally, the Asia-Pacific is anticipated to become the fastest-growing region over the forecast period. Countries such as China, India, and Southeast Asian nations are experiencing significant industrialization and expansion of the retail sector, fueling the need for efficient and sustainable packaging solutions. The region’s growing middle class and changing consumer preferences toward convenient and lightweight packaging are further accelerating this trend.

The major companies in the flexible plastic packaging market are CCL Industries Inc, Sealed Air Corporation, DS Smith, Amcor Plc, Berry Global Group Inc, Constantia Flexibles, Sonoco Products Company, Coveris, Mondi Group, Glenroy Inc, Huhtamaki OYJ, Proampac, Graphic Packaging International LLC, Printpack, and Sigma Plastics Group.

The threat of new entrants in the flexible plastic packaging market is moderate due to several factors. On one hand, the industry is characterized by relatively low capital requirements and the increasing demand for sustainable packaging solutions, which can attract new players. However, established competitors possess significant advantages, including economies of scale, well-established distribution networks, and long-standing customer relationships.

#Flexible Plastic Packaging#sustainable packaging solutions#triton market research#market research reports

0 notes

Text

Returnable Container Solutions | Nilkamal Bubbleguard

#Returnable Containers#Reusable Containers#Packaging Solutions#Supply Chain Optimization#Nilkamal Bubbleguard#Plastic Containers#Eco-Friendly Packaging#Sustainable Packaging#Industrial Packaging#Logistics

0 notes

Text

Precision at its Finest: The Benefits of Using CNC Machines in Mold Manufacturing

In Today’s rapidly growing manufacturing sector, the use of computerized numerical control (CNC) machinery has led to changes in accuracy, speed, efficiency and flexibility in various manufacturing processes One area where CNC machinery has had a significant impact and pottery making. The use of CNC machines offers plastic injection molding manufacturer many advantages that increase both productivity and efficiency. This blog explores the benefits of using CNC machinery in injection molding solutions and sheds light on the transformative potential of this technology.

Understanding CNC Technology

A CNC machine, short for computer numerical control machine, is a manufacturing machine that uses computer software to control machining speed and production It uses pre-programmed instructions to cut, manufacture and shape machine parts a it is accurate and high precision CNC machine works on many different axes. These technologies have transformed industries by vastly improving productivity, reducing human error and enabling robust custom designs.

How CNC machines work in mold manufacturing

In mold manufacturing, CNC machines play an important role in mold making and machining due to their high accuracy and efficiency. These devices follow a step-by-step process to turn a digital photo or image into a physical mold. First, the molds are fabricated using computer-aided design (CAD) software. The CAD file is then converted to a format that CNC machines can understand. The CNC machine uses this information to control various cutting tools such as cutting machines and grinding machines to create the molds. The machines are guided by pre-programmed instructions, ensuring accurate and consistent machining. The result is a high-quality mold that matches the specifications of the digital design, ready to be used in a variety of production applications. CNC machines eliminate the need for manual operations, reduce errors, and dramatically improve the speed and quality of mold production.

Advantages of CNC Machining in mold manufacturing

1. Accuracy Accuracy includes:

CNC machines ensure exceptional accuracy and precision in mold production. Computer-aided design (CAD) software is used to create detailed digital drawings, which are then converted into CNC machining instructions. This eliminates crafting errors, resulting in high-quality, accurately sized molds.

2. Speed and efficiency:

CNC machines dramatically increase the speed and efficiency of mold production. With automation, CNC machines can complete complex machining tasks faster than traditional methods. In addition, the ability to handle complex design means that molds can be produced with intricate details and fine finishes that would be difficult to produce by hand

3. Costs:

Despite the initial investment associated with CNC machines, they offer long-term cost benefits in mold manufacturing. CNC machines provide better material handling, saving waste. Furthermore, labor costs are reduced as fewer employees are required to maintain the machines. This increases productivity and ultimately reduces production costs.

4. Modifications and modifications:

CNC machines offer unparalleled flexibility and scalability. They can easily make a variety of pots, from small to large. Furthermore, setup and turnaround times are significantly reduced compared to traditional manufacturing methods, allowing for flexibility in adapting to customer needs and changing demands.

Limitations and Challenges

While CNC machinery offers many advantages in mold manufacturing, it is important to acknowledge its limitations and challenges. One limitation is the complexity of some mold designs that may require complexity definitions and tight tolerances. CNC machines can struggle to handle these issues, resulting in lower accuracy or longer machine times. Another challenge is the initially high cost of acquiring CNC machines, the need for skilled workers to design and operate them efficiently In addition, the production of large molds may be restricted due to CNC machine size limitations therefore, limiting mold size. Material selection is also a consideration, as some parts can be difficult to machine using CNC technology. Despite these limitations, continuous improvements in CNC technology and design optimization are alleviating these challenges, making CNC machining a more viable option in mold manufacturing

Advancements in CNC technology

Advances in CNC machining technology continue to push the boundaries of accuracy, efficiency and materials in manufacturing. A key development is the integration of artificial intelligence (AI) and machine learning algorithms into CNC machines. This allows real-time monitoring and adaptive control, optimizing the machine settings and adjusting parameters to achieve the best results. Furthermore, advances in sensor technology enable more accurate measurements and feedback, improving the accuracy and quality of all machined parts Furthermore, advances in automation has simplified planning and changeover time, reducing downtime and increasing productivity. The combination of advanced software and communication techniques also enables seamless communication with other systems, enables data exchange and simplifies manufacturing processes These advances in CNC technology continue to innovate and evolve products around the world.

Conclusion

CNC machines have revolutionized mold making. The precision, speed, efficiency, cost effectiveness, flexibility and flexibility offered by CNC machines have changed the industry. By adopting this technology, an injection molding maker can stay ahead of the competition, produce superior plastic chocolate molds, and meet ever-changing market trends As CNC machines continue to evolve, the potential to transform overall production becomes more promising.

#MOULDING-INJECTION#best injection molding company#cheap injection molding#custom injection mould manufacturer#injection molding maker#injection molding solutions#plastic injection molding manufacturer#plastic chocolate molds#cheap plastic injection mold#plastic injection mold design#plastic injection mould manufacturer#plastic molds for chocolate making#plastic moulding manufacturers#injection frisbee#chocolate packaging belgium#chocolate packaging manufacturer.

0 notes

Text

Airen International - A Profound Manufacturer And Supplier Of A Quality Range Of Woven Packaging Solutions

To satisfy the needs of its customers, Airen International provides its products at reasonable costs. Additionally, the items are tailored to meet the needs and specifications of the customers. Leno bags, BOPP bags, FIBC bags, HDPE/PP woven sacks, and PP (polypropylene) woven sacks make up the complete range.

#airen international#packaging solution#durable packaging#bulk packaging#leno bags#mesh bags#woven sacks#pp bags#plastic polythene

0 notes

Text

Best Place to Buy Edible Oil Bottles Perform Manufacture.

There are many factors to consider while buy edible oil bottle preform manufacturer delhi. In this blog post, we will help you narrow down your search by providing a list of the best places to buy edible oil bottle preform manufacturer delhi. We have considered various factors such as price, quality, durability, and customer service while compiling this list.

Visit Us - https://elmercadodelavivienda.com/best-place-to-choose-edible-oil-bottles-preform-manufacturer/

0 notes

Text

Revolutionizing Sustainability: The Era of Biodegradable Plastic

In a world grappling with environmental crises, the rise of biodegradable plastic heralds a new dawn for sustainability. With its eco-friendly composition and innovative properties, biodegradable plastic offers a viable solution to the detrimental effects of traditional plastics on our planet.

Understanding Biodegradable Plastic: A Breakthrough in Green Technology

Biodegradable plastic, unlike its conventional counterpart, possesses the remarkable ability to decompose naturally when exposed to environmental conditions. Derived from renewable sources such as corn starch, vegetable oil, or pea starch, this revolutionary material mitigates the persistent pollution caused by traditional plastics.

The Environmental Impact of Traditional Plastics: A Looming Crisis

Traditional plastics, notorious for their non-biodegradable nature, inflict irreversible harm on ecosystems worldwide. From clogging waterways to endangering marine life, the detrimental effects of plastic pollution are undeniable. However, the advent of biodegradable plastic offers a glimmer of hope in combating this pressing environmental threat.

Advantages of Biodegradable Plastic Over Conventional Plastics

Environmental Friendliness: Biodegradable plastic undergoes decomposition through natural processes, significantly reducing its environmental footprint compared to conventional plastics.

Renewable Sources: Unlike fossil fuel-based plastics, biodegradable plastic is sourced from renewable materials, ensuring sustainability and reducing reliance on finite resources.

Reduced Pollution: By breaking down into harmless compounds, biodegradable plastic minimizes pollution and mitigates the adverse impact on ecosystems and wildlife.

Applications of Biodegradable Plastic: From Packaging to Fashion

The versatility of biodegradable plastic extends across various industries, revolutionizing traditional practices with sustainable alternatives.

Packaging Solutions: Biodegradable plastic offers a viable alternative to conventional packaging materials, reducing waste and fostering eco-conscious consumerism.

Textile Industry: With the emergence of biodegradable fabrics, such as PLA-based textiles, the fashion industry embraces sustainable practices while reducing its carbon footprint.

Food Service: Biodegradable utensils and food packaging enable establishments to prioritize sustainability without compromising on functionality or hygiene.

Challenges and Future Outlook

While the potential of biodegradable plastic is undeniable, challenges persist in scaling up production and overcoming cost barriers. However, ongoing research and technological advancements hold promise for addressing these hurdles, paving the way for widespread adoption and a more sustainable future.

Conclusion: Embracing the Green Revolution

In conclusion, the advent of biodegradable plastic marks a pivotal moment in the quest for environmental sustainability. By embracing innovative solutions and transitioning towards eco-friendly alternatives, we can mitigate the detrimental impact of plastic pollution and safeguard the planet for future generations. Together, let us champion the green revolution and pave the way for a cleaner, greener tomorrow.

#biodegradable plastic#market#sustainability#eco-friendly#renewable sources#environmental impact#packaging solutions#textile industry#food service#green technology#pollution mitigation#sustainable future

0 notes

Text

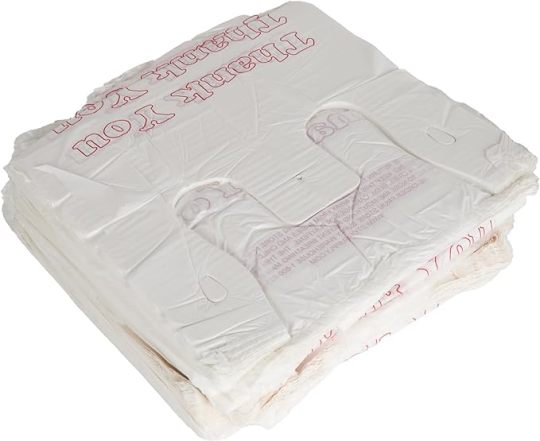

SSWBasics' white thank you bags

SSWBasics' white thank you bags, crafted from 0.48 mil HDPE plastic, bring durability and resilience to your business's daily operations. Designed to meet a wide range of needs, these bags are ideal for businesses that require reliable packaging solutions that won't fail under the weight of heavier contents. Their sturdy build ensures that they can handle the rigors of daily use without compromise.

These bags are offered in bulk quantities, making them a cost-effective choice for businesses big and small. By purchasing in large volumes, companies can reduce per-unit costs while ensuring they always have enough bags on hand to meet customer demand. This bulk option is particularly beneficial for high-volume retailers and food service businesses looking to manage costs while maintaining supply.

Versatility is a key advantage of these white thank you bags. Whether used in a grocery setting, a restaurant for takeout, or a retail shop, they adapt seamlessly to various environments. This flexibility allows businesses to streamline their packaging process using a single, reliable product for multiple types of transactions.

The bags are user-friendly, designed for ease of handling and efficiency. They are lightweight, which makes them simple to carry and distribute, yet they maintain the robustness needed to transport items securely. Their design also facilitates quick and easy storage, as well as hassle-free dispensing during busy times at checkout counters.

An elegant white color enhances the visual appeal of the bags, while a printed 'Thank You' message on each one adds a personal touch that resonates with customers. This design element not only beautifies the packaging but also serves as a subtle tool for reinforcing brand recognition and customer appreciation.

SSWBasics, headquartered in St. Louis, is committed to supporting small businesses by providing products that exceed the typical demands of retail environments. Their focus on crafting solutions tailored for retailers ensures that each product, like their thank you bags, not only meets but surpasses the expectations of business owners, operators, and their customers.

Customers frequently praise the portability, size, and overall quality of these bags. They find them convenient for carrying various items, from light groceries to heavier goods. The handles are particularly appreciated for their strength and comfort, which enhance the user experience significantly.

However, some feedback points to concerns about the thickness and sturdiness of the bags when tasked with carrying particularly heavy or sharp items. While generally satisfactory, improving the material's density could address these concerns, making the bags even more reliable under all conditions.

A slight musty smell is sometimes noted by new users of the bags, likely due to storage conditions prior to use. This issue is quickly resolved by airing out the bags before they are put into circulation, a minor step that can greatly improve the initial customer impression.

The bags' longevity is often highlighted in customer reviews. They are praised for their ability to be reused multiple times, which not only provides better value for the consumer but also aligns with environmentally conscious practices by reducing the need for single-use plastics.

For businesses considering a re-order of these thank you bags, the lasting quality and consistent performance make them a sound investment. Their reliability makes them a mainstay for operations that require durable, dependable packaging that reflects well on the business.

Retailers and restaurant owners alike find these bags indispensable for their operations. They contribute to efficient service delivery, ensuring that products are transported safely and stylishly from the point of sale to the customer's home.

Ongoing dialogue with customers about their experiences with these bags is vital. It helps in making iterative improvements that enhance functionality and customer satisfaction. Listening to user feedback is essential for maintaining the quality and relevance of the product in a competitive market.

In conclusion, the white thank you bags from SSWBasics offer a practical, attractive, and reliable solution for a variety of business packaging needs. Their robust design, combined with thoughtful features like the 'Thank You' message, makes them a favored choice for businesses aiming to enhance customer satisfaction while managing operational efficiency.

Businesses that choose these bags will find that they not only meet everyday requirements but also support broader goals of cost management, customer retention, and environmental responsibility. Their continued use across different sectors underscores their effectiveness as a versatile packaging solution.

#white thank you bags#HDPE plastic bags#bulk quantity bags#retail packaging solutions#eco-friendly packaging#custom thank you bags#business supply essentials

0 notes

Text

Returnable Pallet: Durable, Reusable, and Eco-Friendly

#Nilkamal Bubbleguard#returnable pallet#material handling#durable#reusable#eco-friendly#plastic pallet#industrial packaging#supply chain#logistics#transportation#packaging solutions

0 notes

Text

Commodity Plastic: An Essential Component of Everyday Products

Commodity plastic is an indispensable material in our daily lives, found in a multitude of products that we use regularly. Understanding its significance and widespread applications sheds light on its vital role in modern society.

Exploring the Versatility of Commodity Plastic:

Ubiquitous Presence: Commodity Plastic is ubiquitous, seamlessly integrated into a vast array of everyday products. From packaging materials to household items, consumer electronics to automotive components, its versatility knows no bounds.

Diverse Range of Types: Commodity plastic encompasses a diverse range of types, each with its own unique properties and applications. Polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), and polyethylene terephthalate (PET) are among the most commonly used types of commodity plastics.

Applications of Commodity Plastic:

Packaging Solutions: One of the primary applications of commodity plastic is in packaging solutions. Plastic bags, bottles, containers, and films are ubiquitous in grocery stores, households, and industries worldwide, thanks to the durability, flexibility, and cost-effectiveness of commodity plastics.

Household Items: Commodity plastics are found in numerous household items, including kitchenware, storage containers, and cleaning products. Their lightweight nature, durability, and ease of cleaning make them ideal for everyday use.

Get More Insights On This Topic: Commodity Plastic

#Commodity Plastic#Plastic Industry#Packaging Solutions#Household Items#Consumer Electronics#Automotive Components#Polymer Materials#Plastic Manufacturing

0 notes