#Polymer Materials

Text

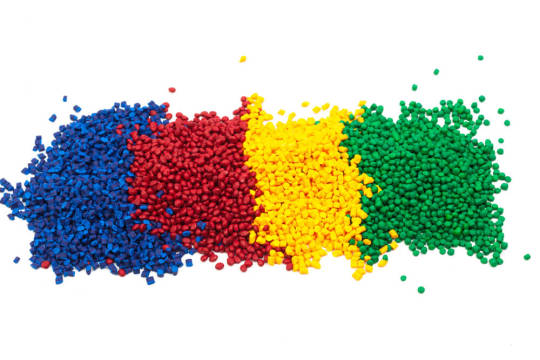

How to Choose Between Near Prime Polymer and Recycled Polymers for Your Needs

In the ever-evolving world of polymer materials, choosing the right polymer material for your application can be crucial to both cost and performance. At Polymer in Stock, we understand how important it is to select the top polymer suppliers in United Arab Emirates in order to meet your specific needs. In this blog post, we will compare and contrast Near Prime Polymers with Recycled Polymers to help you make an informed decision for your business.

How Do Near Prime Polymers Work?

Near prime polymers are premium materials that are marginally different from prime grade due to minor changes in their properties or appearance. They are often used in situations where higher standards are not required, and even with these little differences, they continue to provide outstanding performance. Crucial attributes include:

High Quality: Near prime polymers function nearly identically like prime polymers, but at a lower cost.

Cost-Effectiveness: Since they are less expensive than prime-grade polymers, they are a more cost-effective alternative for a lot of businesses.

Versatile Uses: Ideal for consumer goods, autos, and packaging, among other industries.

What Makes Recycled Polymers Necessary?

Plastic components that have been used before are processed and repurposed to make recycled polymers. They provide a sustainable option for those looking to reduce their environmental impact. Crucial attributes include:

Environmental Benefits: Recycled polymers help conserve resources and cut down on waste.

Cost Savings: They may be less expensive than virgin or Near Prime Polymers, depending on the recycling process and material quality.

Variable Quality: Disparities in quality resulting from sources and processing methods may have an effect on the performance of recycled polymers.

Choosing the Ideal Polymer for Your Needs

The particular needs of your application, your budget, and your sustainability goals should all be taken into consideration when deciding between Near Prime and Recycled Polymers. At Polymer in Stock, our team of experts can help you sort through these choices and choose the one that best meets your requirements.

Get in touch with us now

If you need help selecting the ideal polymers for your needs or are looking for a reliable Near Prime Polymer supplier in UAE, get in touch with Polymer in Stock. To meet the needs of your business, we provide an extensive range of reasonably priced, premium polymer solutions.

#polymer materials#Near Prime Polymers#Near Prime Polymers suppliers#Plastic Materials#Plastic Row materials#Recycled Polymers

0 notes

Text

Innovations in Commodity Plastic: Advancements and Trends

Commodity plastic, long a staple of modern manufacturing, continues to evolve with new innovations, advancements, and trends shaping its usage and applications across various industries.

Biodegradable Plastics: One notable innovation in commodity plastic is the development of biodegradable plastics, which offer a more environmentally friendly alternative to traditional plastics. These plastics are designed to break down into harmless substances when exposed to natural conditions, reducing the environmental impact of plastic waste and contributing to efforts to combat plastic pollution.

Recycled Plastics: With growing concerns about plastic waste and environmental sustainability, there has been a significant focus on recycling Commodity Plastic. Innovations in recycling technologies have made it possible to transform used plastics into high-quality recycled materials that can be used to manufacture new products, reducing the need for virgin plastics and minimizing waste.

Advanced Manufacturing Techniques: Advancements in manufacturing techniques, such as 3D printing and injection molding, have revolutionized the production of commodity plastics. These techniques allow for greater precision, customization, and efficiency in the manufacturing process, enabling manufacturers to create complex shapes and designs with ease.

Enhanced Performance Properties: Another trend in commodity plastic innovation is the development of plastics with enhanced performance properties, such as increased strength, durability, and resistance to heat, chemicals, and UV radiation. These advanced plastics are finding applications in industries such as automotive, aerospace, and electronics, where demanding performance requirements must be met.

Get More Insights On This Topic: Commodity Plastic

#Commodity Plastic#Polymer Materials#Plastic Manufacturing#Plastic Industry#Petrochemicals#Plastic Production#Plastic Resins#Synthetic Polymers#Plastic Recycling

0 notes

Text

Plasticizers Market Will Reach USD 24.7 Billion By 2030

The global plasticizers market has garnered USD 17.1 billion in revenue in 2023, and it is projected to rise at the rate of 5.6% from 2023 to 2030, to capture USD 24.7 billion by 2030. Due to the high demand for flexible polymer materials like PVC, the most important end-user for those products is gradually increasing worldwide, i.e., in the construction industry.

Furthermore, the surge in the…

View On WordPress

#industrial applications#Key players#market trends#Plasticizers Market#polymer materials#Technological advancements

0 notes

Text

A new chemical process can essentially vaporize plastics that dominate the waste stream today and turn them into hydrocarbon building blocks for new plastics.

The catalytic process, developed at the University of California, Berkeley, works equally well with the two dominant types of post-consumer plastic waste: polyethylene, the component of most single-use plastic bags; and polypropylene, the stuff of hard plastics, from microwavable dishes to luggage. It also efficiently degrades a mix of these types of plastics.

Continue Reading.

137 notes

·

View notes

Text

Soft, stretchy 'jelly batteries' inspired by electric eels

Researchers have developed soft, stretchable 'jelly batteries' that could be used for wearable devices or soft robotics, or even implanted in the brain to deliver drugs or treat conditions such as epilepsy.

The researchers, from the University of Cambridge, took their inspiration from electric eels, which stun their prey with modified muscle cells called electrocytes.

Like electrocytes, the jelly-like materials developed by the Cambridge researchers have a layered structure, like sticky Lego, that makes them capable of delivering an electric current.

The self-healing jelly batteries can stretch to over ten times their original length without affecting their conductivity—the first time that such stretchability and conductivity has been combined in a single material. The results are reported in the journal Science Advances.

Read more.

#Materials Science#Science#Batteries#Flexible electronics#Electronics#Self healing#Hydrogels#Polymers#University of Cambridge

117 notes

·

View notes

Text

Some polymer clay project ideas. Some more subtle, others a little more obvious

#i was thinking keychains / charms again but technically I could also make them little collectible figurines#or the flower pots could be actual flower pots!#since I am just trying out stuff and getting familiar with the materials come talk to me and let me know what you think :D#or if you have specific ideas!#i know next tinothing about polymer clay sculpting at the moment so everything is possible 😌#bluishfrog art#dteam fanart#dream fanart#georgenotfound fanart#sapnap fanart#polymer clay art

41 notes

·

View notes

Text

if I had a nickel for every time I read a random shonen jump series with an autistic MC who I was NOT expecting at all I would have two nickels. which is not a lot but it’s weird that it happened twice (should happen more)

#one->#kagurabachi#do you see the vision on this one? like he and his dad definitely send me some brain signals in that respect#MC’s dad is presented as having an unconventional worldview#and the MC himself strikes me as the prototypical ‘not very expressive and has a straightforward personality’ guy#I like him and his goldfish. of course there’s not really a lot of material to comment on as of yet#two->#MARRIAGETOXIN#saw this dude compulsively cleaning the bathroom when stressed and was like he is so me for real#him and his water absorbing polymer truly sweep#and his DIY candy kits of course#good stuff all around. if anyone has any recommendations please enlighten me#well that’s assuming that people will see this post lolz#thinking emoji

43 notes

·

View notes

Text

What are the materials used in weapons manufacturing?

Materials used in weapons manufacturing are chosen based on their mechanical properties, durability, and suitability for specific applications. The materials used in weapons manufacturing are:

1. Alloys, including steel, aluminum, titanium, nickel, and cooper.

2. Composites, including carbon fiber, glass fiber, and kevlar.

3. Ceramics, including alumina, silicon carbide, and boron carbide.

4. Polymers, including polyamide, polycarbonate, and polyethylene.

5. Specialized Coatings and Treatments, including ceramic coatings, teflon coatings, and phosphate coatings.

6. Explosives and Propellants, including RDX (Cyclotrimethylenetrinitramine), TNT (Trinitrotoluene), and composite propellants.

7. Electronic and Semiconductor Materials, including silicon, and gallium nitride (GaN).

Alloys

High-Strength Steel - Commonly used in the manufacturing of

Barrels: The main component of a firearm, responsible for propelling projectiles.

Receivers: The housing for the firearm's action, holding essential components.

Slides (pistols): The moving part that houses the barrel and holds ammunition.

Frames (pistols): The base of the handgun, supporting other components.

Bolts and carriers (rifles): Components involved in the firing cycle.

Springs: Essential for firearm operation, providing recoil and return forces.

Steels like 4140, 4340, and maraging steel are known for their toughness, high yield strength, and resistance to wear.............

#science#metals#alloys#materials#materials science#materials science and engineering#composites#ceramics#polymers#engineering#firearm

10 notes

·

View notes

Text

spent some time trying to figure out how I think cass' cowl works/looks and how to do it in my style

trying to lean into the faceless/horror aspects of her design and make her facial features as hard to make out as possible without just giving her just. the agent venom mask but with stitching and ears and no eye frames

Currently indecisive on whether I think the harsh skull-like eyesockets or the shallower, less defined "eyes" work better. same for the mouth

On the one hand I think the skull eyesockets are more dramatic and mayyybe more intimidating in a "looks like she wants to kill you" sense. I also think they're better for communicating emotion and kinda look more "passively angry"

On the other hand the shallower indent-y eyesockets look more natural/realistic, and I think the clearer lack of eyes (where the skulltype obscures whether or not her eyes are just hidden in shadow) makes her look more inhuman, which maybe plays up the uncanny horror aspect more

(I did initially do a version that followed the damion scott thing of her mouth being visible under the mask but I didn't like how it turned out. looked too, uh. I dunno. personable? approachable? not scary/creepy/unnerving enough)

(I didn't, however, do a version with the lenses over her eyes because I thought it'd be bad for the creepy-horror-movie-monster-esque-aesthetic I was going for.)

Also yeah I know that logically she should be a little friendly looking or whatever what with being a superhero. and also so civilians trust/aren't afraid of her. but also uh. hehe scary cass

#cassandra cain#batgirl#digital art#robotsprinkles draws#my art#ignore the neck I'm lazy#debating whether I think cass' costume should be slick black like polished leather or have the texture of more conventional materials#or be a rough matte like some sort of polymer

96 notes

·

View notes

Text

little hobbitses magnets made out of air dry clay :)

#more crafts from this weekend :)#another first attempt!! working with clay for the first time in almost 10 years . i also sculpted these before i tried to make gandalf big#naturals. also trying out making something simplified and cutesy another thing i have no idea how to do 😭. but i had fun!!!!#i think i want to make more not that i know a bit more. and also once i get the idea how to sculpt i want to try polymer clay instead of air#dry clay bc it’s probably easier to do smaller stuff. but gotta learn some basic with the cheap stuff first even when the materials are#different but like get the sense of sculpting#my art#lotr#air dry clay#acryllic paints

18 notes

·

View notes

Text

Metamaterials are products of engineering wizardry. They are made from everyday polymers, ceramics, and metals. And when constructed precisely at the microscale, in intricate architectures, these ordinary materials can take on extraordinary properties.

With the help of computer simulations, engineers can play with any combination of microstructures to see how certain materials can transform, for instance, into sound-focusing acoustic lenses or lightweight, bulletproof films.

But simulations can only take a design so far. To know for sure whether a metamaterial will stand up to expectation, physically testing them is a must. But there’s been no reliable way to push and pull on metamaterials at the microscale, and to know how they will respond, without contacting and physically damaging the structures in the process.

Now, a new laser-based technique offers a safe and fast solution that could speed up the discovery of promising metamaterials for real-world applications.

The technique, developed by MIT engineers, probes metamaterials with a system of two lasers — one to quickly zap a structure and the other to measure the ways in which it vibrates in response, much like striking a bell with a mallet and recording its reverb. In contrast to a mallet, the lasers make no physical contact. Yet they can produce vibrations throughout a metamaterial’s tiny beams and struts, as if the structure were being physically struck, stretched, or sheared.

The engineers can then use the resulting vibrations to calculate various dynamic properties of the material, such as how it would respond to impacts and how it would absorb or scatter sound. With an ultrafast laser pulse, they can excite and measure hundreds of miniature structures within minutes. The new technique offers a safe, reliable, and high-throughput way to dynamically characterize microscale metamaterials, for the first time.

“We need to find quicker ways of testing, optimizing, and tweaking these materials,” says Carlos Portela, the Brit and Alex d’Arbeloff Career Development Professor in Mechanical Engineering at MIT. “With this approach, we can accelerate the discovery of optimal materials, depending on the properties you want.”

Portela and his colleagues detail their new system, which they’ve named LIRAS (for laser-induced resonant acoustic spectroscopy) in a paper appearing today in Nature. His MIT co-authors include first author Yun Kai, Somayajulu Dhulipala, Rachel Sun, Jet Lem, and Thomas Pezeril, along with Washington DeLima at the U.S. Department of Energy’s Kansas City National Security Campus.

Keep reading.

Make sure to follow us on Tumblr!

16 notes

·

View notes

Text

Choosing the Right Polymer Supplier in UAE

Find the best polymer supplier in UAE with our expert guide. Discover key considerations and best practices for selecting a reliable, high-quality polymer suppliers.

0 notes

Text

Commodity Plastic: An Essential Component of Everyday Products

Commodity plastic is an indispensable material in our daily lives, found in a multitude of products that we use regularly. Understanding its significance and widespread applications sheds light on its vital role in modern society.

Exploring the Versatility of Commodity Plastic:

Ubiquitous Presence: Commodity Plastic is ubiquitous, seamlessly integrated into a vast array of everyday products. From packaging materials to household items, consumer electronics to automotive components, its versatility knows no bounds.

Diverse Range of Types: Commodity plastic encompasses a diverse range of types, each with its own unique properties and applications. Polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), and polyethylene terephthalate (PET) are among the most commonly used types of commodity plastics.

Applications of Commodity Plastic:

Packaging Solutions: One of the primary applications of commodity plastic is in packaging solutions. Plastic bags, bottles, containers, and films are ubiquitous in grocery stores, households, and industries worldwide, thanks to the durability, flexibility, and cost-effectiveness of commodity plastics.

Household Items: Commodity plastics are found in numerous household items, including kitchenware, storage containers, and cleaning products. Their lightweight nature, durability, and ease of cleaning make them ideal for everyday use.

Get More Insights On This Topic: Commodity Plastic

#Commodity Plastic#Plastic Industry#Packaging Solutions#Household Items#Consumer Electronics#Automotive Components#Polymer Materials#Plastic Manufacturing

0 notes

Text

newest hyperfix hobby: jewelry making! made a werewolf-y inspired necklace inspired by the red moon pendant i found in my childhood home + some matching bracelets for me and my partner

#art tingz#handmade jewelry#diy jewelry#last winter i did a weird wire project and while it was kind of awful and bad i really enjoyed working with the material#also made super cute fish earrings out of polymer clay w my bestie last year and have been wanting to make more wearables since#so this felt like a natural evolution of both things!#when i get back to REDACTED i wanna see if i can make electronic jewelry wearables….. i wonder if my supplies are conductive at all lol

4 notes

·

View notes

Text

Imagine if physicians could capture three-dimensional projections of medical scans, suspending them inside an acrylic cube to create a hand-held reproduction of a patient's heart, brain, kidneys, or other organs. Then, when the visit is done, a quick blast of heat erases the projection and the cube is ready for the next scan.

A report in the journal Chem by researchers at Dartmouth and Southern Methodist University (SMU) outlines a technical breakthrough that could enable such scenarios, and others with widespread utility.

Continue Reading.

86 notes

·

View notes

Text

Which packaging type for a 12-ounce, single-serve container of orange juice would you choose as the most sustainable option:

1. Aluminum/canned, made with recycled material;

2. Carton, described as biodegradable/compostable;

3. Glass, 100% recyclable; or

4. Plastic, described as biodegradable/compostable?

If you were like the U.S. consumers surveyed by food scientists in a University of Massachusetts Amherst study, you'd prefer glass and believe it was the most sustainable choice. And you all would be mistaken.

"Glass was the most sought-after and most highly esteemed packaging type," says Nomzamo Dlamini, lead author of the paper recently published in the journal Sustainability. Dlamini, a food science Ph.D. candidate, was a recent visiting Fulbright scholar from the University of Pretoria in South Africa studying in the UMass Amherst lab of senior author Alissa Nolden, assistant professor of food science. "But it turns out, glass is actually among the least sustainable if you look at the whole packaging lifecycle," Dlamini added.

Read more.

81 notes

·

View notes