#Plastic Industry

Text

#plastic industry#plastic pollution#plastic waste#environment#fossil fuel dependent#fossil fuels#single-use plastic

9 notes

·

View notes

Text

How BOROUGE RA140E is Redefining the Landscape of Polymer Science

Rapid changes are occurring in the realm of polymer research, and BOROUGE RA140E is beginning to bring about these changes. This innovative polymer, supplied by leading Virgin Polymer Suppliers in UAE, is revolutionizing the plastics industry with its remarkable properties and applications. This blog article will go over how BOROUGE RA140E is influencing polymer science and why companies that make plastic resin and polymers are opting to collaborate with it.

Expanding BOROUGE RA140E

The exceptional properties of high-performance virgin polymer resin BOROUGE RA140E are well-known. As a raw plastic material, it offers unparalleled strength, durability, and versatility. These characteristics make it a well-liked choice for numerous applications in the plastics sector. BOROUGE RA140E's advanced formulation solves a number of the shortcomings of traditional polymers, paving the way for improvements in product design and manufacturing processes.

Borouge RA140E's Advantages in Polymer Manufacturing

Enhanced Robustness and Efficiency

Because BOROUGE RA140E has superior mechanical properties, products made of it are more durable and strong. This feature is crucial for businesses that require high-performance materials that can withstand demanding conditions and heavy use.

Adaptability to Different Uses

Because of its versatility, the BOROUGE RA140E can be used in a variety of industries, including as consumer goods and automotive parts. Owing to its adaptability, it is an essential resource for companies looking to expand and broaden their product line.

The Way BOROUGE RA140E Promotes Environmentally Friendly Behavior

These days, it's becoming more and more important to use greener production techniques, and BOROUGE RA140E stands out for its contribution to this. Since it is a virgin polymer, the environmental impact of its production is minimal, in line with global efforts to reduce waste and promote recycling. Companies that employ BOROUGE RA140E are supporting ecologically beneficial business practices in addition to investing in premium plastics raw materials.

Virgin Polymer Suppliers in UAE Role

Virgin Polymer Suppliers in UAE, like Polymer in Stock, play a significant role in facilitating access to high-quality polymers like BOROUGE RA140E. These suppliers ensure that businesses receive high-quality polymer resin that fulfills their industrial needs and industry regulations. Forming ties with reputable suppliers can help companies stay ahead of industry advancements and provide a consistent source of raw plastic materials.

Future Directions in Polymer Science

As polymer science develops, BOROUGE RA140E is expected to propel innovations. Scientists and manufacturers are exploring new strategies to enhance this polymer's properties and expand its applications. It is anticipated that BOROUGE RA140E will lead the way in polymer science breakthroughs, resulting in further enhancements to material performance, sustainability, and affordability.

To sum up

BOROUGE RA140E is a force for change in the plastics industry, not just a polymer. Its innovative properties and applications are shaping the future of polymer science and opening up new avenues for growth and development. By choosing BOROUGE RA140E, businesses may enhance product performance, encourage sustainable practices, and preserve their competitiveness in a market that is evolving. For those seeking reputable vendors and high-quality virgin polymers to help them achieve their goals, Polymer in Stock is the go-to source.

0 notes

Text

Oman Plast 2024 Global Event for Plastic Industry at Muscat, Oman

The 8th edition of Oman Plast will take place at the Oman Convention & Exhibition Centre, Muscat, from 15-17 October 2024. This annual event focuses on the Plastics, Rubber, Petrochemicals, Chemicals, Fertilizers, Plastics Recycling, Printing, and Packaging industries. It aims to showcase products and services to Oman and the GCC market while fostering international trade links. The event will gather exhibitors, professionals, and industry leaders to discuss advancements, strengthen connections, and boost regional economic development, making it a key platform for innovation and networking.

WHY SHOULD YOU ATTEND EXHIBITION?

Oman Plast 2024 is one of the most important events in the plastics industry, attracting experts, manufacturer, Traders, Businessmen, Managing Director, Board member, Associations, Financial heads, Purchasing manager, Supervisor, Group leader, engineer. This exhibition offers numerous opportunities to learn, innovate, and connect with the global plastics community. The Exhibition also welcomes regulatory representatives, higher education institutions, and R&D institutes. The event will feature discussions on the latest trends and developments within the plastics, petrochemical, and packaging industries, offering valuable insights into market dynamics and future opportunities.

Exhibition Highlight

Exhibition Date: 15th to 17th Oct 2024

Time: 10.00 AM to 6.00 PM

Exhibition Location Address – Oman Convention & Exhibition Centre, Al Maardih St, 111 Muscat, Muscat, Oman

Entry Fees: Free Ticket for Industry Professionals on advance booking.

Estimated Visitors: 212 Exhibitors

Estimated Exhibitors: 3084 Visitors from 34 Countries

Hall No.: Exhibition Hall 3

WHO SHOULD EXHIBIT?

Oman Plast 2024 will showcase the latest machinery, technologies, and services essential for plastic and petrochemical manufacturing, offering attendees a chance to explore innovative, efficient, and sustainable solutions. It serves as a prime networking platform for exhibitors, professionals, and decision-makers to build and strengthen business relationships across regional and global markets. The exhibition will showcase the latest advancements in manufacturing machines, Chemicals, Fertilizers, Plastic Packaging Machinery, Equipment & Services, Plastic Recycling, Ancillary Equipment, packaging materials, Parts and Components, Raw materials. It serves as a catalyst for innovation and a hub for professional connections, making it an essential event in the plastics processing.

Organizer Information:

Organizer Name: Silver Star Corporation L.L.C.

Organizer Address: P.O. Box 1075, Ruwi Postal Code 112 Sultanate of Oman

Organizer Phone No.: 00 968 24788804

Organizer Email Id: [email protected]

Website: www.silverstaroman.com

Registration Link: https://www.omanplast.net/registration-contract/

Oman Plast 2024 promises to be a pivotal event for the plastics, petrochemical, and packaging industries, offering a platform for innovation, networking, and business growth. With its focus on sustainability, efficiency, and the latest trends, the exhibition will not only support regional economic development but also position Oman as a hub for industrial progress and international collaboration.

0 notes

Text

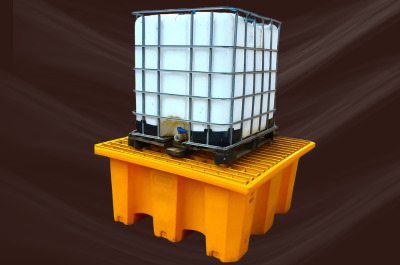

IBC Spill Containment Pallets: Best Practices for Use and Benefits

Ensuring spill control and safety is crucial in businesses handling huge amounts of hazardous liquids. These liquids are frequently transported and stored in intermediate bulk containers (IBCs), yet there is a chance of spilling. Consequently, IBC spill containment pallets are useful in this situation. Because these pallets are designed to reduce environmental damage and increase worker safety, they are crucial for following safety standards and protecting your business.

In this blog, we will discuss the use and benefits of IBC spill containment pallets.

Understanding IBC Spill Containment Pallets

Pallets designed for IBC spill containment are made especially to store liquids and stop leaks or spills. Additionally, a containment basin in robust construction collects and holds spills. This prevents them from spilling into the surrounding space and stops spills from reaching the floor. Moreover, the robust materials used to manufacture these pallets, like polyethylene, which is resistant to chemicals, ensure long-term usage and durability.

Proper Placement and Setup

Where to place: To ensure the best results with your IBC spill containment pallet, carefully place it on a flat, stable surface. Additionally, make sure the area around it is free from any obstructions and allows for easy handling and movement of your IBCs.

Leveling: Make sure the pallet is level to avoid spills brought on by tilting and uneven liquid distribution in the IBC.

Load Bearing Limits: Stick to the weight limits set by the pallet manufacturer. Overloading can compromise its integrity, resulting in spillage.

Handling and Transport

Proper Lifting: Forklifts or pallet jacks are suitable lifting equipment to use while moving IBCs onto and off the spill containment pallet. IBCs should not be dragged or dropped since this could harm the pallet as well as the container.

Secure Positioning: Make sure the IBC is steady and firmly positioned when it has been placed on the pallet. To prevent movement during handling or transportation, use straps or other fastening techniques as needed.

Load Management

Weight Limits: Observe the weight restrictions for the pallets as indicated by the manufacturer. Pallet overloading increases the chance of spills and can harm the structure.

Proper Loading: Position IBCs centrally on the pallets to ensure even weight distribution and stability. Avoid putting multiple IBCs on the same pallet unless it has been designed to handle such weights.

Benefits of Using IBC Spill Containment Pallets

1. Enhanced Safety

Swift’s IBC spill containment pallets are a game-changer for workplace safety. They offer a secure platform to store hazardous materials, giving you peace of mind. With their advanced secondary containment feature, any spills are contained, preventing them from spreading. This means a safer environment, less risk of accidents, and reduced exposure to dangerous chemicals.

2. Cost Savings

Spill and leak control may save you a lot of money. After all, spills can result in costly cleaning operations, penalties, and damage to equipment and the workplace. Therefore, investing in IBC spill containment pallets reduces these multiple costs.

3. Versatility

IBC pallets have many uses and show up in different industries such as food and drink processing, and chemical production. They can adapt to different needs, which makes them a key tool for any business working with liquids and chemicals. These pallets help keep people safe and make handling these materials more effective.

4. Easy Maintenance

These pallets are built to last and require minimal maintenance. Moreover, regular inspections and cleaning assure their longevity and efficacy, giving a long-term spill containment solution.

Conclusion

You may extend the life and efficacy of these pallets by being aware of their design and function, making sure they are positioned and set up correctly, and by following safe handling and transportation procedures.

IBC spill containment pallets have many advantages, such as improved worker safety, cost savings from spill prevention, industry adaptability, and ease of maintenance. We at Swift Technoplast are dedicated to offering IBC spill containment pallets of the finest quality that meet industry standards and support the safety of your business.

Our products are made to provide 100% Environmentally friendly, sturdy, dependable containment solutions that guarantee worker safety. Invest in Swift Technoplast IBC spill containment pallets to enhance the safety and efficiency of your facility.

#IBC Spill Containment pallet#plastic industry#plasticmanufacturer#plasticproducts#IBC pallet#spill pallets#swifttechnoplastprivatelimited#plastic product manufacturer#plastic product suppliere

0 notes

Text

Best Injection Molding Operator Jobs in Rajpur | Nearmejob

Looking for Injection Molding Operator jobs in Rajpur. Visit our site for updated listings, job details, and easy application instructions.

1 note

·

View note

Text

Creative Ways to Reduce Plastic Use in Your Daily Life

Introduction Plastic pollution is a significant environmental issue, with millions of tons of plastic waste ending up in our oceans and landfills each year. While recycling is crucial, reducing plastic use in our daily lives can make an even bigger impact. Here are some creative and practical ways to minimize plastic consumption and contribute to a healthier planet.

1. Bring Your Own Bags

Reusable Shopping Bags: Carry reusable bags when shopping to avoid using single-use plastic bags. Many stores offer discounts for bringing your own bags.

Produce Bags: Use cloth or mesh bags for fruits and vegetables instead of the plastic ones provided in stores.

2. Opt for Reusable Bottles and Cups

Water Bottles: Invest in a high-quality reusable water bottle. Not only will it reduce plastic waste, but it will also save you money in the long run.

Coffee Cups: Bring your own reusable coffee cup to your favorite café. Some places even offer a discount for using your own cup.

3. Choose Plastic-Free Packaging

Bulk Buying: Purchase items in bulk to reduce packaging waste. Use your own containers or bags when shopping at bulk stores.

Plastic-Free Products: Look for products with minimal or no plastic packaging. Opt for items packaged in glass, metal, or cardboard.

4. DIY Household Products

Cleaning Supplies: Make your own cleaning products using natural ingredients like vinegar, baking soda, and essential oils. Store them in reusable glass bottles.

Personal Care: Create homemade personal care items such as shampoo bars, toothpaste, and deodorant. There are plenty of DIY recipes available online.

5. Shop at Zero-Waste Stores

Zero-Waste Shops: Visit zero-waste stores where you can buy products without packaging. Bring your own containers to fill with items like grains, spices, and liquids.

Farmers’ Markets: Buy fresh produce and other items at farmers' markets where you can often find goods without plastic packaging.

6. Use Reusable Food Storage

Beeswax Wraps: Replace plastic wrap with beeswax wraps, which are reusable and biodegradable.

Glass Containers: Store leftovers in glass containers instead of plastic ones. They are safer for your health and the environment.

7. Say No to Single-Use Plastics

Straws: Carry a reusable metal or silicone straw with you to use instead of plastic ones.

Cutlery: Bring your own reusable cutlery set when eating out or ordering takeout to avoid plastic utensils.

8. Support Sustainable Brands

Eco-Friendly Companies: Choose to support brands that prioritize sustainability and offer plastic-free products.

Ethical Shopping: Research and buy from companies that use recycled materials or have take-back programs for their packaging.

9. Participate in Plastic-Free Challenges

Monthly Challenges: Join initiatives like Plastic Free July, where you commit to reducing plastic use for a month.

Social Media Campaigns: Follow and participate in social media challenges that promote reducing plastic waste.

10. Educate and Advocate

Spread Awareness: Share information about the importance of reducing plastic use with friends and family.

Community Involvement: Get involved in local environmental groups and advocate for policies that reduce plastic waste.

Conclusion Reducing plastic use in our daily lives requires some effort and creativity, but the benefits for the environment are well worth it. By making small changes and adopting sustainable practices, we can collectively make a significant impact on reducing plastic pollution. Start implementing these creative ways to minimize plastic use today and inspire others to do the same for a healthier planet.

https://pashupatigrp.com/

0 notes

Text

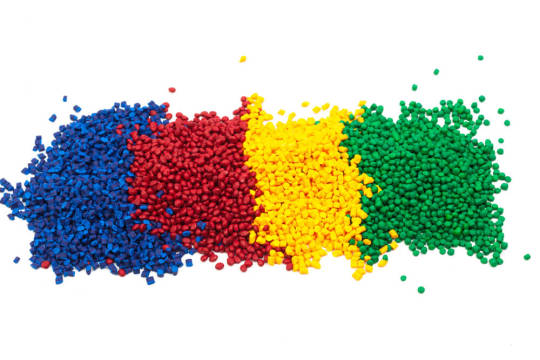

Innovations in Commodity Plastic: Advancements and Trends

Commodity plastic, long a staple of modern manufacturing, continues to evolve with new innovations, advancements, and trends shaping its usage and applications across various industries.

Biodegradable Plastics: One notable innovation in commodity plastic is the development of biodegradable plastics, which offer a more environmentally friendly alternative to traditional plastics. These plastics are designed to break down into harmless substances when exposed to natural conditions, reducing the environmental impact of plastic waste and contributing to efforts to combat plastic pollution.

Recycled Plastics: With growing concerns about plastic waste and environmental sustainability, there has been a significant focus on recycling Commodity Plastic. Innovations in recycling technologies have made it possible to transform used plastics into high-quality recycled materials that can be used to manufacture new products, reducing the need for virgin plastics and minimizing waste.

Advanced Manufacturing Techniques: Advancements in manufacturing techniques, such as 3D printing and injection molding, have revolutionized the production of commodity plastics. These techniques allow for greater precision, customization, and efficiency in the manufacturing process, enabling manufacturers to create complex shapes and designs with ease.

Enhanced Performance Properties: Another trend in commodity plastic innovation is the development of plastics with enhanced performance properties, such as increased strength, durability, and resistance to heat, chemicals, and UV radiation. These advanced plastics are finding applications in industries such as automotive, aerospace, and electronics, where demanding performance requirements must be met.

Get More Insights On This Topic: Commodity Plastic

#Commodity Plastic#Polymer Materials#Plastic Manufacturing#Plastic Industry#Petrochemicals#Plastic Production#Plastic Resins#Synthetic Polymers#Plastic Recycling

0 notes

Text

0 notes

Text

There is an increasing demand for plastic coming from the packaging industry owing to advancements in widespread industries, such as consumer goods, automotive, electrical & electronics, and food &

beverage due to its versatility and adaptability of plastic that meets diverse packaging needs, which in turn drives the growth of the market. Moreover, the growing adoption of bioplastics that are more

sustainable alternatives to traditional plastics and made from renewable materials boosting the growth of the market.

0 notes

Text

HDPE Sprinkler Coupler Manufacturer and Exporter| ADM Engineering

0 notes

Text

Consumer Reports discovered “widespread” evidence of plastic in food

Consumer Reports found that plastics remained “widespread” in food and urged regulators to re-assess the safety of plastics coming into contact with food during production, Reuters reported.

The non-profit consumer group claimed on Thursday that 84 out of 85 recently tested supermarket food and fast-food products contain “plasticisers” known as phthalates. This chemical is used to make plastic more durable.

It also stated that 79 per cent of the food samples in its study contained bisphenol A (BPA), another chemical found in plastic, as well as other bisphenols, although the levels were lower than in tests carried out in 2009.

The group reports that none of the levels of phthalates detected exceeded the limits set by US and European regulators. However, this does not guarantee food safety. It also argues that there is no level of phthalates that scientists consider safe.

Phthalates and bisphenols are dangerous as they can interfere with the production and regulation of estrogen and other hormones, potentially increasing the risk of birth defects, cancer, diabetes, infertility, neurodevelopmental disorders, obesity and other health problems.

Read more HERE

#world news#world politics#news#global news#current events#consumer reports#consumer products#consumer goods#business#economy#plastic bag sealers#supermarket#management#sales#food#plastic industry#chemicals#disease#health news#health and wellness#public health#health

0 notes

Text

How BOROUGE RA140E Is Shaping the Future of Polymer Science

Explore how BOROUGE RA140E is transforming polymer science. Discover insights from Polymer in Stock, a top Virgin Polymer Supplier in the UAE, on its industry impact.

0 notes

Text

Fakuma 2024 Global Event for Plastics Industry at Frickenhausen

The FAKUMA 2024 trade show is considered the prime global event dedicated to the industrial plastic processing sector. This event is scheduled to take place from 15th to 19th October 2024, in Friedrichshafen, Germany. Fakuma international trade fair for plastics processing has become a prominent meeting place for the industry, with international charisma. It holds second place in the overall ranking of international trade fairs for plastics. However, because of the organization cycle, it is the principal event for the Plastic industry.

WHY SHOULD YOU ATTEND EXHIBITION?

Fakuma 2024 is one of the most important events in the plastics processing industry, attracting experts, manufacturer, supplier, Managing Director, Board member, Supervisor, Group leader, engineer. This exhibition offers numerous opportunities to learn, innovate, and connect with the global plastics community. The Exhibition also welcomes regulatory representatives, higher education institutions, and R&D institutes. This broad attendance underscores Fakuma 2024's importance as a global meeting point for the plastic Industry.

Exhibition Highlight

Exhibition Date – 15th to 19th October 2024

Time – Thursday to Friday: 9.00 am to 5.00 pm and Saturday 9.00 am to 3.00 pm

Expo Location Address – P. E. Schall GmbH & Co. KG Gustav-Werner- Strasse 6 D Frickenhausen, Germany.

Entry Fees – Free Ticket for Industry Professionals on advance booking. + Admission for one person on one day of the fair: €30

Estimated Visitors – 1636 from 40 Countries

Estimated Exhibitors – 39,343 visitors from 89 Countries

Hall No.: A1 to A7 and B1 to B5

Estimate area: 85,000 square meters

WHO SHOULD EXHIBIT?

Fakuma stands as a premier global event for industry professionals, offering unmatched opportunities for networking, innovation, and business growth. Renowned for its international reach, Fakuma provides a platform to showcase advancements, engage with thought leaders, and explore cutting-edge technologies. The exhibition will showcase the latest advancements in Injection moulding machine, extrusion, thermoforming, and 3D printing machine. It serves as a catalyst for innovation and a hub for professional connections, making it an essential event in the plastics processing.

Organizer Information:

Organizer Name: P. E. Schall GmbH & Co.KG

Organizer Address: Gustav-Werner-Strasse 6, D Frickenhausen, Germany

Organizer Phone No.: 49-7025-9206-650

Organizer Email Id: [email protected]

Website: www.schall-messen.de

Registration Link: https://obs.schall-messen.de/Members/Login.aspx

Fakuma 2024 underscored the industry's commitment to innovation in sustainable plastics, showcasing a range of new materials, advanced manufacturing techniques, and comprehensive services aimed at reducing the environmental footprint of plastic Industry.

#plastic industry#plastic exhibition#plastic expo#plastic packaging industry#plastic product#plastic industry raw materials#injection moulding#plastic and packaging#3d printing#3d printing machine#raw materials#injection moulding machine#P4t

0 notes

Text

How to Reduce Product Damage in the Warehouse with Plastic Pallets

How to Reduce Product Damage in the Warehouse? Every warehouse manager knows the pain of seeing damaged goods. It causes lower profits, slows operations, and can even harm your reputation in the market. But this damage can be managed simply by using the right plastic pallets.

Plastic pallets offer a major advantage over traditional wooden pallets when protecting your products. Here’s how they can significantly reduce damage in your warehouse:

In the dynamic world of warehouse management, minimizing product damage is key to sustained success. Plastic pallets offer a modern solution many facilities embrace, effectively reducing damage and enhancing efficiency. Let’s explore how plastic pallets are used with their durability and functional versatility to improve warehouse operations and protect valuable goods.

Check The Merits of Plastic Pallets

Plastic pallets have become a preferred choice in warehouses for transportation and storage due to several advantages. These include Reduced product damage, Ease of cleaning, customizable designs, and enhanced durability with reinforced steel rods, these factors help businesses to reduce product damage.

Plastic Pallets are highly Durable

Plastic pallets are durable and don’t break during their movement while in transportation and storage. They won’t splinter, split, or break under heavy loads, ensuring your products stay safe during handling and transportation. With its durable nature pallets can resist the harsh conditions of warehouse settings, such as frequent handling, and make your transportation operation smooth.

Maintain Proper Hygiene

Plastic pallets are especially useful in areas like food and pharmaceutical sectors that have strict hygiene rules. Plastic pallets are beneficial in this sector because they are so easy to clean and wash and easy to maintain hygiene.

Lightweight Construction of Pallets

Lightweight Plastic pallets making them simpler to handle and decreasing warehouse worker accidents. Despite their low weight, they are extremely durable, providing a dependable storage solution for a wide range of products.

Enhanced Stability

Plastic pallets excel in offering superior stability owing to their uniform construction and interlocking design. This stability mitigates the risk of pallets tipping over or collapsing, thereby preventing products from shifting or falling during transportation.

Impact Resistance

Designed to withstand impacts and rough handling, plastic pallets remain resilient without sustaining damage. They absorb shocks and evenly distribute weight, This feature is particularly beneficial for fragile items or goods that are sensitive to vibrations and shocks, such as electronics, glassware, or pharmaceutical products.

Moisture Resistance

Plastic pallets do not absorb moisture or hold humidity, they are the perfect option for storing goods in moist or humid conditions while maintaining product quality.

Cleanliness

The plastic pallets are not complex in cleaning and washing to minimize dirt and dust. It helps keep the items safe at the warehouse.

Customization Options

Plastic pallets offer flexibility in design and customization. They can be tailored to specific industry requirements, such as reinforced corners and anti-slip surfaces giving a personal touch to meet your specific transportation and storage needs. These modifications not only improve pallet performance but also reduce the risk of product damage, allowing for smooth operations and peace of mind.

Conclusion

plastic pallets present a robust solution for minimizing product damage in warehouse operations. Swift’s Plastic pallets are the better option, especially when it comes to less product damage in the warehouse. Their hygienic qualities, stability, longevity, and customization possibilities make them valuable resources for companies looking to boost productivity and protect expensive stock. Warehouses may successfully reduce product damage, and speed up processes.

#plastic pallets#rackable plastic pallets#plastic industry#plasticmanufacturer#plasticpallets#plasticproducts#hdpepallets#hdpeplastic#swifttechnoplast#swifttechnoplastprivatelimited#plastic pallets manufacturer#plastic pallet supplier#warehouse safety#HDPE plastic pallets#plastic pallets near me#pallets near me#export pallets

0 notes

Text

Premier Position for Senior Production Engineer | Apply Now

Transform your career with our thrilling Senior Production Engineer role. Lead innovative production processes and join a dynamic team. Apply today

1 note

·

View note

Text

Revolutionizing Healthcare: The Synergy of 2K Injection Molding and Medical Advancements

In the dynamic realm of medical manufacturing, innovation is a constant driver of progress. One such technological marvel making waves is 2K injection molding, a process revolutionizing the creation of intricate and functional medical components. This article explores the transformative impact of 2K injection molding and its applications in advancing the landscape of the medical industry.

Demystifying 2K Injection Molding:

2K injection molding, or two-shot molding, represents a cutting-edge manufacturing process where two different materials are injected into a single mold to craft a unified, integrated part. This sophisticated technique empowers the medical industry to engineer complex and multifaceted components with unparalleled precision.

youtube

Unveiling the Potential in Medical Applications:

1. Precision in Medical Devices:

- Intricate Designs: 2K injection molding facilitates the creation of medical devices with intricate designs, elevating their functionality and overall performance.

- Material Fusion: The seamless integration of different materials enables the production of medical devices with customized material combinations for specific medical needs.

2. Innovative Drug Delivery Systems:

- Compact Complexity: Drug delivery systems benefit from 2K molding's ability to consolidate multiple components into a single, streamlined unit, enhancing precision and ease of medication administration.

3. Elevating Diagnostic Equipment:

- Functional Finesse: Components for diagnostic equipment harness the versatility of 2K molding, integrating materials with diverse properties to improve functionality and accuracy.

4. Advancements in Surgical Instruments:

- Ergonomic Excellence: Surgical instruments take a leap forward with improved ergonomics and functionalities, achieved through the integration of materials with varying textures and hardness levels.

Advantages of 2K Injection Molding in Medical Manufacturing:

1. Simplified Assembly Processes:

- Integration of multiple materials in a single molding cycle reduces the intricacies of assembly, minimizing errors and enhancing overall efficiency.

2. Optimized Product Performance:

- The combination of materials with distinct properties empowers the creation of medical components with heightened durability, flexibility, and resistance to environmental factors.

3. Long-Term Cost-Efficiency:

- Despite initial setup costs, the streamlined production process and reduced assembly complexities contribute to long-term cost-effectiveness.

4. Tailored Solutions for Patients:

- 2K molding enables the customization of medical components, catering to the unique needs of patients and healthcare providers.

Challenges and Considerations:

1. Material Compatibility Prowess:

- Rigorous assessment of material compatibility is imperative to ensure the seamless integration of different materials without compromising the overall integrity of medical components.

2. Precision and Stringent Tolerances:

- Achieving precise tolerances in 2K molding demands meticulous engineering and manufacturing processes to meet the rigorous standards set by the medical industry.

Looking Ahead:

As the medical field continues its forward march, 2K injection molding is poised to play an increasingly integral role. The capability to fashion complex, integrated components with enhanced functionality aligns seamlessly with the industry's commitment to delivering cutting-edge solutions for patient care.

Conclusion: Embracing a Future of Healthcare Innovation:

2K injection molding emerges as a catalyst for transformative change in medical manufacturing, ushering in a new era of possibilities for precision and customization. As medical device manufacturers embrace this groundbreaking technology, the potential to create innovative, patient-centric solutions becomes boundless. With its capacity to enhance functionality, simplify assembly processes, and deliver cost-effective solutions, 2K injection molding is at the forefront of reshaping the future of medical components, contributing to the ongoing evolution of healthcare worldwide.

0 notes