#Commodity Plastic

Text

Understanding Commodity Plastic: Basics and Applications

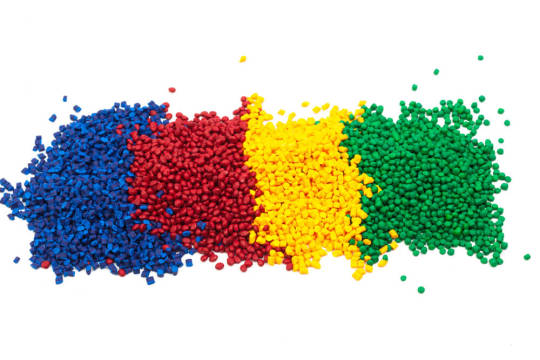

Commodity plastic is a term frequently used in the plastics industry to refer to a group of plastics that are produced on a large scale and used in a wide range of applications. Understanding the basics of commodity plastic, including its properties and applications, is essential for anyone involved in the manufacturing or use of plastic products.

Exploring the Basics of Commodity Plastic:

Definition and Characteristics: Commodity Plastic refers to a category of plastics that are produced in high volumes and have relatively low costs compared to engineering plastics or specialty plastics. These plastics are characterized by their versatility, durability, and ease of processing, making them ideal for a variety of applications.

Common Types of Commodity Plastics: Some of the most common types of commodity plastics include polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), and polyethylene terephthalate (PET). Each type of commodity plastic has its own unique properties and applications, ranging from packaging materials to consumer goods.

Applications of Commodity Plastic:

Packaging: One of the largest applications of commodity plastic is in packaging materials. Polyethylene and polypropylene, in particular, are widely used for manufacturing plastic bags, bottles, containers, and packaging films due to their excellent barrier properties and flexibility.

Consumer Goods: Commodity plastic is also commonly found in a wide range of consumer goods, including household items, toys, kitchenware, and electronics. Polystyrene, for example, is used to make disposable cups, plates, and food containers, while polyvinyl chloride is used in the production of vinyl flooring and window frames.

Construction Materials: In the construction industry, commodity plastic is used for manufacturing a variety of materials, such as pipes, fittings, insulation, and siding. PVC, in particular, is a popular choice for plumbing and drainage systems due to its corrosion resistance and affordability.

Automotive Components: Commodity plastics play a vital role in the automotive industry, where they are used for manufacturing interior and exterior components, such as dashboards, bumpers, trim panels, and seating. Polypropylene, with its lightweight and impact-resistant properties, is a common choice for automotive applications.

Commodity plastic is a versatile and widely used material that plays a crucial role in various industries and applications. Understanding the basics of commodity plastic, including its properties and applications, is essential for manufacturers, designers, and consumers alike. By recognizing the versatility and value of commodity plastic, we can continue to innovate and create sustainable solutions for the future.

Get More Insights On This Topic: Commodity Plastic

#Commodity Plastic#Polymer#Petrochemical#Packaging Material#Plastic Production#Consumer Goods#Thermoplastic#Industrial Applications

0 notes

Text

Still amused by G coming out of the storage box, triumph on his face, saying “now THIS is one box we can DEFINITELY get rid of” before proffering a box marked “plastic bags.” At which point I had to watch his face fall as I sheepishly explained that no, those ARE precious

#i use them for fibrecraft projects#and we banned plastic bags shortly before I moved to Van so at this point they’re kind of a precious commodity#i haven’t like. done a science about it but it reduces the friction vs a cloth bag#it’s also useful if im doing a self-striper or w/e to keep my colours organised#but also im sorry dude im sorry you’ve fallen into a house of insane crafters#but ALSO also it’s very nice that he didn’t argue with me or make me feel bad about it

0 notes

Text

The global Commodity Plastics Market is expected to grow at a significant rate of around 6% during the forecast period.

0 notes

Text

the way I would actually kill to read a fic in Android!Kevin's point of view...

....maybe I should write one

#kevin day made to be second best#kevin day who became the best anyway by his own design#kevin day who's always a commodity. always cold. plastic and metal and mechanical perfection#never real. never alive. never truly in control.#you get me??#he rules the court and yet had no power over it until he got to palmetto#kevin breaking against the programming that force him to obey#riko who broke him like a favoured toy that night. a machine rendered defective for being too alive too real too good.#neil catching glimpses of kevin's personality slipping through the cracks as kids. too bright too brilliant and stubborn to be restrained#andrew catching those same glimpses i. plametto

1 note

·

View note

Text

youtube

EPE Sheet Production line machine Laxmi Enterprises [email protected]

Polyethylene foam sheet(film),also named as pearl cotton, is a kind of new-type packing material with the features of dampproof, shockproof, sound insulation, heat preservation and good plasticity . It is an ideal substitute of traditional packing materials and used widely in the packing of electronic product, commodity, glass, pottery, electrical household appliances, spraying, furniture, hardware product, toy, etc.

#Polyethylene foam sheet(film)#also named as pearl cotton#is a kind of new-type packing material with the features of dampproof#shockproof#sound insulation#heat preservation and good plasticity . It is an ideal substitute of traditional packing materials and used widely in the packing of electr#commodity#glass#pottery#electrical household appliances#spraying#furniture#hardware product#toy#etc.#Youtube

0 notes

Text

#Commodity Plastic Market Growth#Commodity Plastic Market Analysis#Commodity Plastic Market Insight#Commodity Plastic Market Forecast#Commodity Plastic Market Index#Commodity Plastic Market Trends

0 notes

Text

I've walked past the Barbie branded selfie booth, sat through the reel of old commercials that precede the previews, and watched Margot Robbie learn to cry, and I’m still not sure what “doing the thing and subverting the thing,” which Greta Gerwig claimed as the achievement of Barbie in a recent New York Times Magazine profile, could possibly mean. This was the second Gerwig profile the magazine has run. I wrote the first one, in 2017, which in hindsight appears like a warning shot in a publicity campaign that has cemented Gerwig’s reputation as so charming and pure of heart that any choice (we used to call them compromises) she makes is justified, a priori, by her innocence. This is a strange position for an adult to occupy, especially when the two-hour piece of branded content she is currently promoting hinges on a character who discovers that her own innocence is the false product of a fallen world. But—spoiler alert!—the point of Barbie’s “hero’s journey” is less to reconcile Barbie to death than to reconcile the viewer to culture in the age of IP.

“Doing the thing and subverting the thing”: I haven’t finished working out the details, but I think the rough translation would be Getting rich and not feeling feel bad about it. (Or, for the viewer: Having a good time and not feeling bad about it.) One must labor under a rather reduced sense of the word “subvert” to be impressed with poking loving fun at product misfires such as Midge (the pregnant Barbie), Tanner (the dog who poops), and the Ken with the earring, especially given that the value of all these collectors’ items has, presumably, not decreased since the film opened. Barbie may feature a sassy tween sternly informing Robbie’s Stereotypical Barbie that the tiny-waisted top-heavy billion-dollar business she represents has made girls “feel bad” about themselves, but if anyone uttered the word “anorexia,” I missed it. (There was a reason Todd Haynes told the story of Karen Carpenter’s life and death with Barbies, and it wasn’t because an uncanny piece of molded plastic has the magical power to resolve the contradictions of girlhood and global capitalism.) There’s a bit about Robbie going back into a box in the Mattel boardroom, but Barbies aren’t made in an executive suite; they come from factories in China. On the one hand, it’s weird for a film about a real-world commodity to unfold wholly in the realm of ideas and feelings, but then again, that’s pretty much the definition of branding. Mattel doesn’t care if we buy Barbie dolls—they’re happy to put the word “Barbie” on sunglasses and T-shirts, or license clips from the movie for an ad for Google. OK, here’s my review: When Gerwig first visited Mattel HQ in October 2019, the company’s stock was trading at less than twelve dollars a share. Today the price is $21.40.

Christine Smallwood, Who Was Barbie?

8K notes

·

View notes

Text

Innovations in Commodity Plastic: Advancements and Trends

Commodity plastic, long a staple of modern manufacturing, continues to evolve with new innovations, advancements, and trends shaping its usage and applications across various industries.

Biodegradable Plastics: One notable innovation in commodity plastic is the development of biodegradable plastics, which offer a more environmentally friendly alternative to traditional plastics. These plastics are designed to break down into harmless substances when exposed to natural conditions, reducing the environmental impact of plastic waste and contributing to efforts to combat plastic pollution.

Recycled Plastics: With growing concerns about plastic waste and environmental sustainability, there has been a significant focus on recycling Commodity Plastic. Innovations in recycling technologies have made it possible to transform used plastics into high-quality recycled materials that can be used to manufacture new products, reducing the need for virgin plastics and minimizing waste.

Advanced Manufacturing Techniques: Advancements in manufacturing techniques, such as 3D printing and injection molding, have revolutionized the production of commodity plastics. These techniques allow for greater precision, customization, and efficiency in the manufacturing process, enabling manufacturers to create complex shapes and designs with ease.

Enhanced Performance Properties: Another trend in commodity plastic innovation is the development of plastics with enhanced performance properties, such as increased strength, durability, and resistance to heat, chemicals, and UV radiation. These advanced plastics are finding applications in industries such as automotive, aerospace, and electronics, where demanding performance requirements must be met.

Get More Insights On This Topic: Commodity Plastic

#Commodity Plastic#Polymer Materials#Plastic Manufacturing#Plastic Industry#Petrochemicals#Plastic Production#Plastic Resins#Synthetic Polymers#Plastic Recycling

0 notes

Text

Commodity Plastics Market to Exhibit Fastest Growth in Future Scope 2022-2032 | ExxonMobil Corporation, LG Chem, Sumitomo Chemical Co. Ltd

Commodity Plastics Market to Exhibit Fastest Growth in Future Scope 2022-2032 | ExxonMobil Corporation, LG Chem, Sumitomo Chemical Co. Ltd

This report estimates the growth rate and the market value based on industry dynamics and growth driving factors. While preparing this Global Commodity Plastics market research report, a few of the attributes that have been adopted include updated domain performance. The report offers wide-ranging statistical analysis of the market’s continuous developments, capacity, production, production…

View On WordPress

#Commodity Plastics#Commodity Plastics manufacturing Vendors#Commodity Plastics market#Commodity Plastics market share#Commodity Plastics market size#Commodity Plastics market SWOT analysis#Future Trends of Commodity Plastics industry#Scope of Commodity Plastics industry

0 notes

Text

Plastic Commodity Mold

Plastic Commodity Mold

A Plastic Commodity Mold is a tool that can be used for different kinds of plastic products. It can be customized to the exact specification of a specific product. It is usually used in the manufacturing of daily necessities like plastic pipe fittings, packaging boxes, barrels, and pallets. A Plastic Commodity Mold can be used for various types of applications, and can reduce mold costs.

Custom manufacturers of plastic commodity molded parts provide their customers with solutions for every manufacturing need. They can provide prototypes, small and large production runs, and secondary services such as hot stamping, heat staking, sonic welding, assembly, and cleaning. These products can be used in a wide range of industries, from aerospace to agriculture.

Commodity resins are readily available, inexpensive, and easy to process. Their low cost makes them popular in a wide variety of products, from household appliances to medical trays. Because of their low cost, most consumers use commodity plastics in everyday items. They are generally not highly engineered, but do have specific mechanical and thermal properties. The majority of thermoplastic injection molding is done with these types of resins, which are used in most consumer goods.

Custom molded plastic components can be molded using different techniques, including injection molding and compression molding. There is also the option of overmolding. Some custom-made plastic Plastic Commodity Mold commodity molds are made using fluoropolymer materials and meet military specifications. These plastic components are often used for electronics and electrical products. They can meet ANSI and ASTM standards and are available in small to high production volumes.

ABS is another widely used plastic material and is the standard for plastic mold making. It is easy to work with, is inexpensive, and exhibits good toughness. These qualities make ABS an ideal commodity-level thermoplastic polymer. It is used in a variety of industries, including the electronics industry, automotive industry, and many more.

Styrene is another common material and is used in a variety of consumer products. It is used in plastic cups, foam cushioning, CD cases, and many other items. It is also widely used in the building industry, for example, as a material for siding and insulation foam. It can also be used to make bath and shower units, and other fixtures.

Polypropylene is another popular and affordable plastic. It is easy to mold, has a low melt viscosity, and is cheap to manufacture. It can also be reinforced with glass fiber and mineral. Its properties make it ideal for many consumer products, including toys and storage containers. It is also a good choice for medical applications and is very versatile.

Commodity plastics are commonly used in everyday life and are used in high volumes. Although these plastics are low-quality, they are affordable and widely used.

0 notes

Text

i think a sufficient way to describe the relationship between meat animals and the average american is that the animal is more like the mascot for the meat rather than the source. as in like the beef in your $6 burger is a cow themed commodity that is produced similarly to plastic

821 notes

·

View notes

Text

I think buccal fat removal in a young person is a great way to create a returning customer. It’s like adding planned obsolescence into a face. Without the support of this fat, your face and jowls will sag and your face will (according to your plastic surgeon and your insta friends and your shitty woman hating boyfriend) NEED more surgeries.

Making an adjustment to someone’s face (for money) that will all but guarantee this person’s cascading self-esteem and “need” for more plastic surgeries (for money) is just doctors being hip to capitalism.

Elective plastic surgery will always be a tool of capitalism, because the most resellable commodity is always your dream self. They create more false standards of femininity, they charge you to meet them, then they change them, then they charge you to meet them again.

But don’t worry! Capitalism also teaches Market Segmentation. You know, how they figured out that aggressively gendering toys and selling separate fantasies to male and female children resulted in greater revenue?

Huh, I wonder how you create market segmentation when it comes to profiting off of bodies? Oh of course, you create new identities with new surgeries and new clothes and new makeup looks and new hair products and pins, and suddenly you have a whole new market.

You know ow what private medical practice is like, right? You have to drum up patients somehow! You can see them on TikTok, telling us which celebrities would look “better” with which products, telling us which random person in a video would look “better” with thousands of dollars worth of medical treatment.

And people die!! Under the knife or from infections, these are REAL surgeries. Can you imagine wiping out the rest of your life because some man said you had chubby cheeks? Because somebody told you your breasts were wrong? Because your thighs committed the sin of touching? You really want to meet your ancestors because the vibes were off on your boobs???

None of us are immune to propaganda. But we can try our hardest not to constantly consume it!! Find women you know and look for their histories in their faces. Romanticize everything that makes you unique. REJECT THE NOTION THAT FACES AND BODIES CAN GO OUT OF FASHION. That is just some male garbage made up to steal our fucking money, time, and energy.

Plastic surgery is about fear of life and of ourselves.

737 notes

·

View notes

Text

The global commodity plastics market size is projected to grow from USD 468.3 billion in 2020 to USD 596.1 billion by 2025, at a CAGR of 6.0% between 2020 and 2025. The major driving factors of the market include growing packaging industry, increased disposable income generating high demand for consumer goods, growing production of lightweight electric vehicles and increasing metal prices.

Packaging plays a vital role in keeping the product fresh, damage-proof, and acts as an efficient marketing tool. The most common commodity plastics are polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and poly (methyl methacrylate) (PMMA). Acrylonitrile butadiene styrene (ABS) and polyethylene terephthalate (PET) are also considered commodity plastics. These plastics are increasingly replacing metals due to their high tensile strength, low cost, high availability, and easy processing properties.

The key players in the commodity plastics market are Exxon Mobil (US), LG Chem (South Korea), Sumitomo Chemical (Japan), The Dow Chemical Company (US), SABIC (Saudi Arabia), BASF SE (Germany), LyondellBasell (Netherlands), Sinopec (China), Ineos (Switzerland), Formosa Plastics (Taiwan), Mitsubishi Chemical (Japan), Borealis AG (Austria), Chevron Phillips Chemical (US), ENI SpA (Italy), Reliance Industries (India), Braskem (Brazil), Hanwha Chemical (South Korea), Lotte Chemical (South Korea), Indian Oil (India), Haldia Petrochemicals (India), Nova Chemicals (Canada), Qenos Pty (Australia), Qatar Petroleum (Qatar), Westlake Chemical (US), and PTT Global Chemical (Thailand).

#Commodity Plastics#Commodity Plastics market#COVID 19 Impact on Commodity Plastics market#Global Commodity Plastics market#Commodity Plastics Market Overview#Commodity Plastics Research Report#Commodity Plastics research insights#Commodity Plastics business research report#Commodity Plastics Industry Trends#Commodity Plastics market Share#Commodity Plastics market Analysis#Commodity Plastics market growth#Commodity Plastics Market Growth#Commodity Plastics Market Research#Commodity Plastics Market Revenue

0 notes