#PolyethyleneTerephthalate

Text

Rising Demand for Polyethylene Terephthalate Market is estimated to Witness High Growth

The global polyethylene terephthalate (PET) market is primarily driven by its increasing usage in the production of plastic bottles for packaging beverages and other liquids. PET is a lightweight yet strong plastic resin that provides durability and shatter resistance to bottles. It helps preserve drinks for a longer time without contaminations and allows clear visibility of the contents. PET bottles are widely adopted by beverage producers due to their affordability, sustainability credentials, and high recycling rates.

The Global polyethylene terephthalate (PET) Market is estimated to be valued at US$ 53.53 Bn in 2024 and is expected to exhibit a CAGR of 8.6% over the forecast period 2024 to 2031.

Key Takeaways

Key players operating in the polyethylene terephthalate (PET) market are Medtronic, Abbott Laboratories, Boston Scientific, Biotronik, Koninklijke Philips, Nihon Kohden, Fukuda Denshi, Hill-Rom Holdings. PET resin manufacturers like DAK Americas and Indorama Ventures are investing heavily in capacity expansions to meet the rising demand from beverage producers.

The growing health-conscious population and rising consumption of packaged juices, carbonated soft drinks, energy drinks, and bottled water present significant growth opportunities for PET bottle manufacturers. Lightweight and recyclable properties of Polyethylene Terephthalate (PET) Market Size make it an environment-friendly packaging solution favored by brands targeting millennials and Gen Z.

Asia Pacific dominates the global PET market owing to China and India's large packaged beverage industries and fast-moving lifestyles necessitating portable packaged drinks. Major brands are expanding PET bottle production lines across Southeast Asia, Latin America, and Africa to tap the emerging markets. North America and Europe are also seeing high adoption of PET bottles driven by sustainability regulations and recycling infrastructure.

Market drivers

The key driver for the PET market is the increasing production of packaged beverages worldwide. PET is the material of choice for packaging carbonated drinks and bottled water due to its shatter resistance and ability to preserve liquids for longer durations. Growing health awareness and busy lifestyles are fueling the demand for ready-to-consume packaged beverages in portable bottles. PET bottle manufacturers are hence investing heavily in production capacity additions to capitalize on this secular growth opportunity. Stringent government regulations regarding single-use plastics and high recycling rates of PET also support its demand over alternative materials.

PEST Analysis

Political: PET market is regulated by government agencies on the manufacturing, import, and export of raw materials and products. Changes in environmental regulations impact the use of plastics.

Economic: The global economic growth and rising disposable incomes boost the demand for packaged foods and beverages, driving the PET market. High dependence on crude oil prices affects the production cost.

Social: Rising health consciousness increases the demand for bottled water and packaged juices. Growing awareness about recycling and reducing plastic waste impacts consumption patterns.

Technological: Advancements in PET manufacturing technologies help lower the production cost. New processing techniques yield lighter weight bottles using less raw material. Developments in bio-based PET reduce dependence on fossil fuels.

Geographical Regions with High Market Concentration

Asia Pacific dominates the global PET market in terms of value, led by China, India, Japan, and other developing nations. Strong demand from the packaging industry for food and beverages drives the market. Rapid urbanization and rising incomes support the growth of packaged consumer goods sector.

Fastest Growing Region

Europe is projected to grow at the fastest pace during the forecast period, owing to stringent regulations favoring recycled PET usage. Initiatives to curb plastic waste and promote sustainability increase the demand for recycled resins. Investments to expand recycling infrastructure contribute to the regional market growth.

Get more insights on Polyethylene Terephthalate (PET) Market

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

#CoherentMarketInsights#PolyethyleneTerephthalate#PolyethyleneTerephthalateMarket#PolyethyleneTerephthalateMarketGrowth#PolyethyleneTerephthalateMarketOutlook#PETMarket#CarbonatedSoftDrink#BottledWater#OtherDrinks#Sheets#Films#Food

0 notes

Link

#Continental#ContinentalCityPlus#ContinentalContiRe.Tex#ContinentalGreenConcepttire#ContinentalUltraContactNXT#Futurride#PET#Polyethyleneterephthalate#SouthCarolina#sustainablemobility#sustainabletires

0 notes

Text

Polyethylene Terephthalate (PET)

#PolyethyleneTerephthalate#pet#deepseaenzymes#petresin#plasticfree#upsc#upscprelims#upscprelims2024#upscmains#upsc2024#upscaspirants#currentaffairsforupsc#dailynews#generalknowledge#infographic#india

0 notes

Text

Ketut Cana: Dari Buleleng ke Panggung Nasional, Ubah Sampah Plastik Menjadi Keajaiban Teknologi 3D

BALIPORTALNEWS.COM, BULELENG - Bagi sebagian besar, sampah plastik mungkin hanya merupakan tumpukan masalah. Namun, bagi Ketut Cana, potensi tersembunyi di balik setiap limbah plastik menginspirasinya menciptakan ‘TrashKleng’. Melalui inovasi ini, plastik tak berguna diolah menjadi filamen printer 3D, yang nantinya diterapkan dalam beragam produk bernilai ekonomis.

Mengawali 2023 dengan prestasi membanggakan, TrashKleng berhasil menyabet Juara I Nasional dalam Lomba Teknologi Tepat Guna (TTG) Nusantara XXIV. Event prestisius ini diselenggarakan oleh Kementerian Desa, Pembangunan Daerah Tertinggal, dan Transmigrasi RI.

Pria yang berasal dari Desa Sinabun, Kecamatan Sawan, Buleleng itu menjelaskan kisahnya di balik TrashKleng. Inovasinya ini bukan hanya unik, tapi juga menjadi solusi konkret mengatasi masalah sampah plastik yang kian menggunung khususnya di Kabupaten Buleleng.

Nama ‘TrashKleng’, menurut Cana, mencerminkan esensi dari proyek ini. Jika 'Trash' mengacu pada sampah dalam Bahasa Inggris, 'Kleng' — sebuah kata dalam dialek Keling — berarti 'mengembalikan ke posisi semula'.

Pria jebolan SMKN 3 Singaraja ini berbagi tantangan dalam menjalankan ide inovatifnya. Diketahuinya, filamen untuk printer 3D bukanlah hal yang murah. Namun, dengan tekad dan kreativitas, Cana menciptakan mesin dengan biaya Rp2 juta yang dapat mengonversi sampah plastik menjadi filamen berkualitas tinggi.

Dalam penciptaan alat tersebut, Cana memanfaatkan berbagai barang bekas, seperti pemanas dari heater block telur, komponen power supply dari komputer lama, hingga gear box dari printer 3D bekas.

Mengedepankan aspek keberlanjutan, Cana mengungkapkan bahwa satu botol plastik jenis Polyethylene Terephthalate (PET) dapat dikonversi menjadi 11 meter bahan dasar filamen 3D.

"Saya menggali wawasan dari teknologi Rusia terkait pengolahan limbah plastik. Meski mereka memiliki teknologi mutakhir, harganya tak sesuai dengan pasar kita. Maka dari itu, saya menciptakan solusi yang lebih terjangkau namun tetap optimal," ungkap Cana.

Visi Cana tidak berhenti di sini. Dengan TrashKleng, dia melihat peluang dalam pembuatan prostetik, seperti tangan buatan yang dapat bergerak. Dengan integrasi teknologi deteksi kerusakan otot, harapannya produk tersebut dapat membantu lebih banyak individu.

Lebih dari itu, Cana saat ini juga tengah mengeksplor pembuatan mesin extruder plastik skala besar dari bahan High Density Polyethylene (HDPE).

Dengan semangat berbagi, Cana berkeinginan agar TrashKleng dapat terus tumbuh dengan dukungan pemerintah daerah dan masyarakat.

"Bagi saya, berbagi ilmu dan teknologi adalah bentuk dedikasi bagi masyarakat. Jika ada yang terinspirasi dan ingin mengembangkan lebih jauh, itu adalah suatu kehormatan," tutur Cana dengan semangat.

Mengenai perlindungan Hak Kekayaan Intelektual (HAKI), Cana menegaskan telah mengurus segala aspek terkait. Namun, dia tetap membuka diri bagi publik untuk bersama-sama belajar mengenai teknologi berbasis mikrokontroler ini.

"Saya sebenarnya ingin konsep ini open source. Namun, demi keberlangsungan di masa depan, saya memutuskan untuk mendaftarkannya," pungkas Cana.(sri/bpn)

Read the full article

#BaliPortalNews#Buleleng#filamen#HakKekayaanIntelektual#HighDensityPolyethylene#KetutCana#PolyethyleneTerephthalate#SampahPlastik#Teknologi3D#TrashKleng

0 notes

Text

Exporter of PET Bottle Washing Machines in South Africa

“R Mech Machines LLP” were established in 2008 in Ahmedabad (Gujarat, India) as a dependable manufacturer and supplier, Exporter of a comprehensive range of Bale Opener Machine, Grinder Machine, Industrial Dryer, Conveyor Belt, Dewatering Machine, HDPE Recycling Plant, PET Bottle Washing Machines, etc. Exporter of PET Bottle Washing Machines in South Africa.

PET bottle washing machines are used for the cleaning and preparation of PET (Polyethylene Terephthalate) bottles.

These machines are specifically designed to remove contaminants, such as dirt, labels, caps, and other impurities from PET bottles, making them suitable for reuse or recycling.

The primary use of PET bottle washing machines is to ensure proper hygiene and cleanliness of PET bottles before they are refilled or processed further.

These machines employ various cleaning methods, including water spraying, mechanical scrubbing, and chemical treatments, to thoroughly clean and sterilize the bottles.Features of PET Bottle Washing MachinesEfficient Cleaning

Contaminant Removal

Adjustable Settings

Easy Operation and Maintenance

Integration with Production Lines

Safety FeaturesApplication of PET Bottle Washing Machines

Beverage Industry

Water Bottling Plants

Soft Drink Manufacturers

Juice Processing Facilities

Dairy Industry

Food Packaging Facilities

Recycling Centers

PET Bottle Manufacturing Plants

Pharmaceutical Industry

Personal Care Product ManufacturingR Mech Machines LLP is an Exporter of PET Bottle Washing Machines in South Africa.

If you are interested, contact us, and we will offer you our best quality product.

Read the full article

#DewateringMachine#EfficientCleaning#ExporterofPETBottleWashing#ExporterofPETBottleWashingMachinesinSouthAfrica#HDPERecyclingPlant#IntegrationwithProductionLines#PETBottleWashingMachines#PolyethyleneTerephthalate#RMechMachinesLLP#SafetyFeatures#SouthAfrica

0 notes

Text

Sunkaier SK3000 E-E Blade Kneader Reactor

DESCRIPTION

SK3000E-E Type Blade Intermeshing Kneader is a state-of-the-art mixing equipment designed to integrate multiple functions in a single machine for high-volume processing of high viscosity polymers and chemicals to mixing, shearing, evaporation, drying, crushing and crystallization.

The SK3000E-E Type Blade Intermeshing Kneader is a state-of-the-art mixing equipment designed to integrate multiple functions in a single machine for high-volume processing of high viscosity polymers and chemicals.

SPECIAL DESIGNED KNEADERING IMPELLER

SUNKAIER Special Designed Differential Co-Rotation Kneading Impeller is designed specifically for the efficient treatment of high-viscosity materials, including mixing, evaporation, drying, and polymerization processes.

APPLICABLE FOR PBAT CHAIN EXTENSION PROCESS

SK3000E, as part of the SUNKAIER line of equipment, is designed for applications involving high-viscosity materials and complex processing needs, such as chain extension in the production of polybutylene adipate terephthalate (PBAT). PBAT is a biodegradable and compostable polyester that is often used in applications requiring flexibility, such as film packaging and mulch films.

SOLVENT COUNTER WASHING APPLICATION

SK3000E, as part of the SUNKAIER line of equipment, is used for polymer gel crushing and washing. This process is typically involved in the post-polymerization treatment of materials, where the goal is to break down larger gel pieces into smaller particles and wash away impurities or residual solvents.

ADVANTAGES:

Effective Self-Cleaning prevent the formation of dead zones and accumulation of product, which can lead to degradation over time.

SK3000E provides superior kneading, mixing capabilities and better homogenization of the material.

SK3000E is designed to efficiently transfer heat to or from the material to ensures that the material is heated or cooled uniformly.

SK3000E promotes frequent renewal of the surface area of the material. this enhances the mixing and heat transfer processes, leading to more efficient processing.

SK3000E has a significant volume available for the release of vapors to facilitate the removal of volatiles and gas.

SK3000E LAB UNIT

SK3000E self-cleaning kneader reactor lab unit sounds like a specialized piece of equipment designed for use in laboratory settings, particularly for research and development purposes.

This type of equipment is typically used for mixing, kneading, and reacting various materials under controlled conditions.

APPLICATIONS:

Polymer Research: Studying the behavior of polymers under various conditions.

Chemical Synthesis: Developing new chemical processes or optimizing existing ones.

Material Science: Characterizing and developing new materials.

Pharmaceuticals: Formulation development and process optimization.

If you have any need of equipment please contact me without hesitation, thanks. Thanks & Regards

Helena Xiao / Sales Manager

Email: [email protected]

Phone: +86 510 8758 8707

Mobile: +8618261586225

#chemicalprocessing #chemicalindustry #chemicalmanufacturing #chemicalsolution #polymersolution #mixing #chemicalreaction #polymerization #highviscocitymaterialprocessing #highviscocitymaterialsolution #mining #petrochemical #oil #oilprocessing #lubrication #polymer #polymerprocessing #plastics #plasticprocessing #metallurgy #powdermetallurgy #metalprocessing #metallurgicalengineering #polyvinylidenefluoride #hydrogenfluoride #polybutyleneadipateterephthalate #thermoplasticurethanes #polyvinylchloride #highimpactpolystyrene #generalpurposepolystyrene #polyethylene #polyethylenewax #polyethyleneterephthalate #polyurethane #polyglycolideacid #polylacticacid #acrylonitrilebutadienestyrene #extrudingprocess #kneaderingprocess #kneadingtechnology #devolatilizationtechnology #polymerizationprocessexpert #chemicalpulp #PETrecycling #polyethyleneterephthalaterecycling #UHMWPEultra #MDImethylenediphenyldiisocyanate #rubber #TPUelastomer #nylon #textile #fabrics

1 note

·

View note

Text

"Diving Deep into the Specialty Polymers Market: Trends, Innovations, and Strategic Insights

Specialty Polymers: Harnessing the Power of Specialty Macromolecules for Next-Generation Technologies

Specialty Polymers Overview

Specialty macromolecules, also known as engineering macromolecules, are a class of macromolecules that are specially engineered to have targeted physical and chemical properties that make them suitable for advanced applications. Though they only represent a small fraction of the total macromolecules market, specialty macromolecules command a significant revenue share due to their higher value and more niche end uses.

Types of Specialty Macromolecules

There are several main types of specialty macromolecules classified based on their monomer makeup and resultant properties. Some of the major types include:

Polyamides (Nylons)

Polyamides, best known by the brand name Nylon, are a class of thermoplastic macromolecules containing amide linkages along their polymer chains. They are known for their high strength, toughness, and relative durability compared to other plastics. Engineering polyamides such as Nylon 46 and Nylon 610 can withstand higher temperatures than commodity nylons.

Fluoromacromolecules

Fluoromacromolecules contain strong carbon-fluorine covalent bonds which give them unique oil, chemical, heat and weather resistance properties. Popular fluoromacromolecules include polytetrafluoroethylene (PTFE or Teflon), fluorinated ethylene propylene (FEP), and polyvinylidene fluoride (PVDF). They are used in applications requiring non-stick, low friction surfaces.

Polyesters

Engineering polyesters such as liquid crystal macromolecules (LCP), polybutylene terephthalate (PBT), and polyethyleneterephthalate (PET) can be formulated with enhanced heat resistance, strength and rigidity over traditional polyesters. They are employed in automotive, electrical/electronic and consumer goods.

Liquid Silicone Rubbers

Liquid silicone rubbers (LSRs) are two-part addition-cure silicone elastomers that vulcanize at room temperature. Their biocompatibility, stability and flexibility make them well-suited for medical, food and microfluidic device applications. Low compression set LSRs retain shape over time.

Polyketones

Polyketones are a family of thermoplastics with high strength, heat resistance and chemical resistance derived from their ketone groups in the polymer backbone. They include comacromolecules like polyetheretherketone (PEEK) used in demanding mechanical and electrical end uses.

Markets and Applications

Specialty macromolecules are developing across diverse markets driven by the need for advanced material performance. Some of the major application areas include:

Automotive

In automotive, specialty macromolecules enable lightweighting through replacement of traditional metals. Nylons, PBT, polycarbonate and liquid silicone aid composites in vehicles. Use in engine components require heat resistance of PEEK and liquid crystal macromolecules.

Electronics

Electronics rely on specialty macromolecules for miniaturization and reliability. PTFE, FEP, PET and PVDF bring dielectric, insulating properties. PBT molding aids housings. Semiconductor uses benefit from high heat resistance of PEKK and LCP.

Medical

Biocompatible and non-leaching properties of silicones, nylons and PEEK suits medical industry. Implants, catheters, sensors and drug delivery use these. PEKK aids orthopedic devices. Silicones serve prosthetics, wound care and contact lenses.

Infrastructure

Resistance to chemical, heat and environmental stress qualifies many macromolecules for infrastructure. PVDF and silicones protect coatings and paints. Dams, tunnels utilize durability of PTFE and polyketones lining.

Other Developments

New technologies foster demand for high performance plastics. Renewable energy harvest requires specialty macromolecules in wind turbines, solar cells. Aerospace gravitates toward sturdy yet lightweight materials like PEKK, PEEK. Microfabrication leverages specialty silicones and fluoromacromolecules. As applications diversify, advanced macromolecules enable novel solutions.

Future Prospects

The specialty macromolecules market is forecast to sustain strong growth over the medium term supported by their rising penetration across major end-use industries. Polyketones, liquid silicone rubbers and high-temperature polyamides will be key winning product types. The Asia Pacific region is expected to lead future demand growth driven by its large manufacturing industries. Robust R&D focus on bio-based and high-tech specialty macromolecules will further fuel new product innovations and market opportunities going forward.

In Summary, specialty polymers represent a fascinating realm of materials science, offering tailored properties and applications beyond traditional macromolecules. These advanced materials are engineered to meet specific performance requirements, such as enhanced durability, conductivity, or biocompatibility. From aerospace components to medical devices, specialty macromolecules play a crucial role in a wide range of industries, driving innovation and pushing the boundaries of what's possible.

0 notes

Link

Concerns over resource depletion are increasing in India because rising factory output, urbanization and population putting pressure on existing resources.

0 notes

Text

Polyethylene Terephthalate Market - Insights, Size, Share, Opportunity Analysis till 2025

Polyethylene terephthalate is the most common plastic resin of polyester made from the combination of two monomers. Polyethylene terephthalate, also referred to as PET or PETE, is a remarkable cost and energy efficient packaging material, which possesses properties of versatility, strength, and recyclability, thus being used in various end-use industries such as packaging and textile. The polyethylene terephthalate market is projected to boost an excellent sustainability during the forecast period (2017-2025). However, growing environmental pollution from the chemical and petrochemical industries is expected to be one of the key concerns for the PET market. Despite various environmental concerns of PET use, it is much favorable in comparison to steel, aluminum, glass and other materials used for packaging, due to its high weight bearing capacity and light weight, which in turn reduces the transportation cost by utilizing less space and weight.

Request For Sample Copy of this Research Report : https://www.coherentmarketinsights.com/insight/request-sample/279

Regional Insights

In 2016, Asia Pacific, followed by Europe and North America, respectively, accounted for a major share in terms of revenue and volume, in the global polyethylene terephthalate market, and the trend is expected to remain the same over the forecast period. In 2016, the share in terms of volume, held by Asia Pacific was 68.4% and by Europe was 12.5%. The growing demand for carbonated soft drinks in Asia Pacific due to growing demand for packaged and ready to eat food coupled with growing population, and infrastructure development of retail and hospitality sector is expected to drive growth of the global polyethylene terephthalate market over the forecast period. According to a study conducted by Coherent Market Insights, the other drink application segment market is expected to witness a CAGR of 8.8% from 2017 to 2025, in terms of revenue, which in turn is expected to fuel growth of the global polyethylene terephthalate market.

Multinational players need to tap potential addressable market in the emerging regions with the help of geographical expansion

Product portfolio expansion and geographical expansion are the key market trends, which are expected to shape the industry in the near future. Major players in the global Polyethylene Terephthalate market include Alpek S.A.B de C.V., RTP company, BASF SE, The Dow Chemicals Company, Jiangsu Sanfangxiang Group, Indorama Ventures, M&G Chemicals, Nan Ya Plastics Corporation, Far Eastern New Century, and Quadrant AG among others.

For More Information: http://bit.ly/2JK6oK0

About Coherent Market Insights:

Coherent Market Insights is a prominent market research and consulting firm offering action-ready syndicated research reports, custom market analysis, consulting services, and competitive analysis through various recommendations related to emerging market trends, technologies, and potential absolute dollar opportunity.

Contact Us:

Mr. Shah

Coherent Market Insights

1001 4th Ave,

#3200

Seattle, WA 98154

Tel: +1-206-701-6702

Email: [email protected]

0 notes

Text

Plastic Packaging: Advantages & Disadvantages

As the population is proliferating, the demands for consumers’ product are increasing day-by-day.

Producers and manufacturers of beverages and foods are continually looking for different ways that can enhance the practice of their working and add creational values in the product.

This is also the duty of manufacturers to ensure that the food products are highly-preserved and their packaging is up-to-date till the time of their sale.

In the market, there are various materials and alternatives are available for the packaging, but plastic packaging has always been considered as the most recommended option due to high durability, low-rates, adaptability, and common availability.

Over many years, plastic packaging has retained its popularity, and people are using it more frequently.

Why is plastic packaging becoming so popular?

Due to several functionalities, plastic packaging serves in different ways in modern lives.

Below there are some primary reasons that peruse us to rely on it in our lives

Display information

plastic packaging allows the manufacturers to mention important information about the product on the package such as preservative, nutrients that cause allergies, the usability of the product, recommended amount, etc.

Preservation

for longer preservation of food, manufacturers are using plastic packaging. This will reduce the waste ability of product and allow consumers to use products for a longer period before they are not sustainable

Prevent wastes

spillages are avoided by keeping products together.

Protection

for the protection of vulnerable products in transit, plastic packaging is best. It can also protect food protects from humidity, gases, microorganism insects, contamination and light.

Transportation

as compared to other materials and alternatives materials, plastic packaging allows manufacturers to transport products from great distances.

In this way, consumers have easy access to a wide range of non-local products that also encourages trade in the country. Plastic packaging made transportation more efficient by saving spaces due to stacking objects.

Are plastic pouches are sustainable for food packaging?

Due to the ease of transportation and durability, the standup pouches are considered as an ideal packaging option for food.

Different types of microwave-safe pouches can stand with different temperature scales and pressures. These microwave pouches are made up of LLDPE and laminated PET food grade material.

Food grade plastic pouches are also the best option for keeping your favorite food fresh for longer periods.

These plastic pouches come up with the protective layer that successfully keeps the outside elements such as moisture, dust, UV Lights, dust and oxygen from entering it into the package.

Recyclability of the Plastic Pouches

The plastic packages are versatile that increase their optimism recyclability value. It is also increasing because the flexible packaging industry is moving towards the industry of full recycling of plastic products.

This property of pouches allows us to customize this packaging material to the end-life of their use.

Plastic Packaging and Retail

Plastic pouches have made the life of product manufacturers easy.

Plastic pouches allow manufacturers to include clearly and professionally all the information regarding nutritional info and marketing information of the product on the packet.

In this way, the manufacturers don’t have to spend a large sum of money on the labeling and customizing of the package.

Due to the use of high-quality rotogravure printing, you can make your product stand out on the list of many products.

Due to the high economic value, plastic packaging has an instant impact on the consumers in the retail market.

In saturated market places, Cottage-Style Manufacturers are effectively beating household brands, and this is also the reason that increases the use of this packaging style in the market.

With different characteristics, plastic packaging allows producers to create eye-catching, increase product visibility in the retail market with top-rated custom designs.

What is the reason for using plastic pouches?

Plastic packaging bags are consumer friendly and easy-to-use.

Consumers only have to pope up or tear the package for accessing the content in the packet.

Some plastic packaging comes up with grip seal closure settings that allow customers to easily open the product and repeatedly use it for several times.

Now you don’t have to eat your entire chocolate bar at ones and store it

This is the article in which you can learn some basic advantages and disadvantages that will help you to decide whether you use plastic packaging for your products or not. Let’s have a brief look at them.

Advantages of using Plastic Packaging

As per the advantages, the use of plastic packaging is becoming more common. The list of its advantages is

Safety

Due to the high rate of a shatter resistant, plastic packages and containers do no damage or break when they are dropped and knocked over.

This property of plastic packaging makes them more vulnerable and increases their use at different places such as bathrooms, parties, food markets, at the pools, around children playgrounds, by the beaches, and at party clubs.

Flexibility

Due to the adaptability value, plastic packaging is highly durable and flexible.

Due to this property, manufacturers can change the size, shape, and weight of the packaging according to their needs and the packaging that attract the interests of consumers.

This property of plastic packaging allows manufacturers to transport their products at long distance places without losing the original value of their product.

Lightweight storage option

The plastic packaging option does not require lots of storage space as compared to other alternatives because it is extremely light in weight.

Since plastic packaging product doesn’t cover large spaces; this packaging material is easily transportable and effectively reduces the need for the carbon footprint.

Hygienic

Pollution is increasing, and there are very few items that can save our food and other vulnerable product safe from contamination and plastic packaging is one of them.

This property of plastic packaging makes it useful for medical packaging because the packaging is filled automatically and sealed without any human.

Economical value

Due to the high economic value, the plastic packaging is used by all industries no matter what type of packaging style they require and what is their motive of operations.

As this packaging is cost-effective, which make it beneficial for the manufacturers who work on small scales? This allows them to adjust the standardized packaging of products in low budgets.

Decrease wastage

Since the durability value of plastic is extremely high, and it is the best resistor for the external influencer.

The product packaging makes sure that your product is preserved and secure from all sides all the times.

On the other hand, it can also save you from wastage of inventory and help you to bring more malleability, consistency in the delivery of the final product.

In hand, it also increases the value of your brand.

Surviving ability

As plastic packaging is made up of different complex procedures, so plastic packaging has more abilities to endure the toughest environment.

As compare to others, the plastic packaging doesn’t degradable in hot or cold temperatures that increase its integrity value of storing fruits and beverages.

In comparison with other packaging materials, plastic packaging can protect the food from dust, germs, oxygen, light, colors, and microorganisms.

Versatility

The versatility of plastic packaging is high that allows the easy reuse and recycling of the packet.

Nowadays, companies are designing specially customized plastic bags with the help of rain that helps you to optimize their recyclability.

A study is conducted by the United States of EPA, “as compared to paper, plastic packaging take 40% less time to produce and 80% less waste is generated in its manufacturing.

Molding

Not all products require the packaging of the same size; some of them require small size while others are large.

Manufacturer companies can easily mold the plastic packaging bag into the size and shape that fits perfectly with their product.

Disadvantages of Using Plastic Packaging

No doubt that the use of plastic packaging has been increased from recent past years.

Many companies have joined the industry of plastic packaging, and many different types of plastics are now manufacturing.

Industries consider plastic packaging a lot cheaper and an easy way for protecting their food from contamination as compared to other materials (for example stones, metal, and aluminum).

Plastic bags are the raw material that is produced from the byproducts of crude oil, and it can be recycled in many ways.

According to the point of view of consumers, plastic packaging is light in weight, and they can easily carry products with them.

However, the increasing use of crude oil has also some shortfalls.

Except for the long list of advantages of plastic packaging, there are also some disadvantages that make use doubt the characteristics of plastic.

Let’s learn some disadvantages that have become the most common downfall of the use of plastic bags.

Low Melting Point

In comparison with other packaging material, the most common downfall of plastic is that they have low melting points.

This means the plastic packaging doesn’t withstand in the area where the temperature is a little high.

Due to low melting points, plastics cannot be used in the furnaces. Some plastic products are highly flammable such as nylons, polyethylene, acrylics, and polyesters.

These materials are commonly used in offices and home appliances. Low melting point also makes plastic a fire hazard material.

Degradation of the environment

Plastics are non-degradable material. The decay of this material is not easy. It might take centuries and cause pollution in the environment.

Due to the strong bonding of intermolecular forces, the molecules in the plastic material are constituted.

This property makes sure that the structure of plastic neither decomposes nor corrodes for several thousand years.

The plastic material that is disposed of indecently restricted is washed away by water reservoirs. The plastic clogs the natural sources of water and floats on reservoirs.

This cause pollution and make water unsightly and useless for humans.

Harmful for nature

The plastic material that is used in means of human consumption purposes, such as food packaging bags contains harmful components.

Improper disposal of plastic packages cause many harmful disadvantages and leads plastic to find its way in natural water bodies.

Here they will decay or resolve after thousands of years ago due to their nature of non-degradability. For animals, littered plastic means death because they can accidentally eat them and die because of choking.

Moreover, in the manufacturing of plastic fabrication, many destructive chemicals are included in the form of colorant, stabilizers and high enduring substances.

Almost all the time, these chemicals are not undergone through the ecological risk approval process and have a negative impact on human nature, and the well-being of the environment is disturbed with these materials.

Phthalates are a common example of plastic fabrication that is commonly used in the manufacturing of Polyvinyl Chloride (PVC).

Durability

As compared to metals, plastic materials have a short usage life.

Due to this short life span, there are large pile-ups of unwanted garbage such as plastic bags, packaging, food stuffing boxes, and water bottles in the offices, houses, in kid’s playgrounds and amusement parks.

No matter how much plastic is recycled but there is always some that are remaining untouched and uncollected in dump sites and waste yards.

In today’s pollution, plastic materials such as shopping bags are playing a leading role.

Moreover, the polythene bags are lighter as compared to any other bag carrier, and it is easily carried away by winds, and it makes it impossible to collect these bags for recycling purposes.

A Better Bottom Line

It is not right to say that plastic is always the best choice for manufacturers.

However, with a large list of advantages, we cannot ignore the fact that plastic is a non-toxic material that has undeniably a negative impact on our environment and nature.

This is a huge problem that is creating big problems for our future.

The plastic packaging in particular and society in general, the plastic manufacturing processes still need advancements and better resources, and this is the only way to step forward to overcome this enormous problem.

https://www.alppm.com/plastic-packaging-advantages-disadvantages/

#environmentfriendly#greenpackaging#packagingtrend#plasticpackaging#plasticpackagingboxes#polyethyleneterephthalate#recyclability#retailpackagingboxes

0 notes

Text

Its variety of features determine the good materials for making plastic bottles

Due to these two characteristics, PET plastics have good film properties. PET plastics have a wide range of applications in many fields, let's understand. What is PET plastics? PET comes from English Polyethyleneterephthalate, Chinese translation for polyethylene terephthalic acid. The most PET plastic is a packaging industry. On the machinery equipment, the image of PET plastics is also common. Since PET plastics have such a wide range of purposes, how should I identify PET plastics? smell it.

Its variety of features determine the good materials for making plastic bottles, the weight of the PET plastic bottle is light, nor toxic, and the structural strength is large. This is the name of the plastic category, including polybenzene, polybenzene, polybenzene. After using the PET plastic bottle, don't throw anything, it should be recycled. Film sheet. PET plastic is a good packaging material for precision instruments and electrical components, and the use of PET plastic film packaging can extends good protection, extending life. One of the most practical methods of identifying PET plastics is to bake. The raw materials for all kinds of beverage bottles that we use are PET plastics. It is contracted from both benzolic acid and ethylene glycol, which is a heat shrinkage polyester and a saturated polyester.

Since the polyvinyl chloride plastic is mixed in many polyester plastics, we adjust the oven temperature to 250 degrees Celsius and place the target plastic to bake over a period of time. There are many advantages of PET plastics. can be made with PET plastics, and outdoor signages and models are PETG container frequencies with PET plastics. After recovery, it becomes the raw materials of various industrial supplies. This item is high for non-toxic and harmless plastics, and PET is just satisfying this need. Various food pharmaceutical packaging has widely used PET plastics.

The initial PET plastic bottle is only used in cola, Schibi and other carbonated beverage bottles, and now in the packaging bottle of beer, cosmetics, edible oil, drugs, etc. Further, the polyester is a plastic insulating material. If there is a polyvinyl chloride material, there will be many yellow spots on the plastic surface. First of all, smell the taste of PET plastic, after igniting PET plastic with a lighter, smelling the fragrance, there is no pungent taste, there is other materials in PET plastics, there will be pungent taste. For example, gears, motor frames, pump hoses, watches, etc., Pet plastics. Not only that, good optical performance and weather resistance are also two symbolic features of PET.There are many plastic products in our lives, which may be PET plastics. bake. Packaging bottle. . Equipment. PET plastics are plastics with highly stacked molecular structures, with good crystalline directionality

0 notes

Text

Polyethylene Terephthalate Market Size is Envisioned to Grow at a Remarkable CAGR Till 2027

Recent report published by research nester titled “Global Polyethylene Terephthalate (PET) Market Analysis & Opportunity Outlook 2027”delivers detailed overview of the global polyethylene terephthalate market in terms of market segmentation by product type, by industry and by region.

Further, for the in-depth analysis, the report encompasses the industry growth drivers, restraints, supply and demand risk, market attractiveness, BPS analysis and Porter’s five force model.

Geographically, Asia-Pacific accounted for the major share in the global market of polyethylene terephthalate packaging during 2009 to 2013 owing to the rise in investments by major key players and rising personal disposable income, which is further anticipated to benefit the expansion of the global polyethylene terephthalate packaging market in this region with noteworthy revenue by the end of the forecast period. After Asia Pacific, North America accounted for around 23.1% of market share while Europe accounted for around 19.6% of market share in global polyethylene terephthalate packaging market during 2014.

The global polyethylene terephthalate markethas been segmented by industry into food & beverages, healthcare & medical, cosmetics and FMCG industries. Among these segments, the food & beverage industry is anticipated to dominate the overall Polyethylene Terephthalate Market owing to the expanded demand from the beverages industries.

Request Sample To Learn More About This Report @ https://www.researchnester.com/sample-request-131

The global market of polyethylene terephthalate (PET) packaging was valued at USD 50.5 Billion in 2015 and is projected to reach USD 63.4 Billion by the end of 2027 by expanding at a compound annual growth rate of 5.15% over the period. Features of polyethylene terephthalate such as flexibility, non-toxic nature and light in weight among other safety features are some of the major factors that are driving the growth of polyethylene terephthalate market around the globe.

Growing Demand from Packaged Goods Industry

The polyethylene terephthalate (PET) packaging is easy to use, easy to handle with unbreakable capability. These capabilities are expected to benefit the growth of the market over the forecast period. In addition to that, advancement in technology and rapid growth in consumer packaged goods industry is believed to supplement the expansion of polyethylene terephthalate (PET) packaging market over the forecast period.

However, environmental issues while recycling and difficulties with supply of raw material are projected to restrain the growth of the global polyethylene terephthalate market in the near future.

This report also provides the existing competitive scenario of some of the key players of the global Polyethyleneterephthalate market which includes company profiling of Amcor, Gepack, Gerresheimer, Graham Packaging, PET Power and others.The profiling enfolds key information of the companies which encompasses business overview, products and services, key financials and recent news and developments.

On the whole, the report depicts detailed overview of the global polyethylene terephthalate market that will help industry consultants, equipment manufacturers, existing players searching for expansion opportunities, new players searching possibilities and other stakeholders to align their market centric strategies according to the ongoing and expected trends in the future.

Request Sample To Learn More About This Report @ https://www.researchnester.com/sample-request-131

About Us

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision so as to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Photo

SEAQUAL-TM

We have Seaqual in our collections and this is one of the most certified, earth friendly fibres in the world. It’s high quality recycled polyester yarn made from recycled materials including post consumer plastic bottles and plastic captured from the sea, thats why it contributes to preserving natural resources and reducing the waste in the planet’s water.

With a vertical production process with controlled traceability, we recycle some of the plastic collected, turning it into granules, yarn and fabric based on responsible manufacturing. The result are recycled fabrics meeting all quality standards.

We select plastic from the Mediterranean to obtain PET (polyethyleneterephthalate) chips or pellets

We help clean rubbish from the oceans with the aid of fishermen

We turn plastic into polyester yarn to make fabrics

At the weaving phase, the polyester of marine origin is mixed with other ecological, natural, recycled or recovered fibres

We apply ecological dyes and finishes based on saving water and energy, completing a vertical, eco-friendly process165 fishing boats from eastern Spain help to recover the plastic used

High standards in selecting the marine PET are among the keys to guaranteeing the final quality of the yarn

Minimum 5% of the material used in the fabrics comes from the sea

Ecolandye maximizes fabric properties and minimizes environmental impact.

Naturdye is based on colors obtained from leaves and non-edible shells of nuts.

Vital is an ecological and responsible dyeing process with less environmental impact.

0 notes

Photo

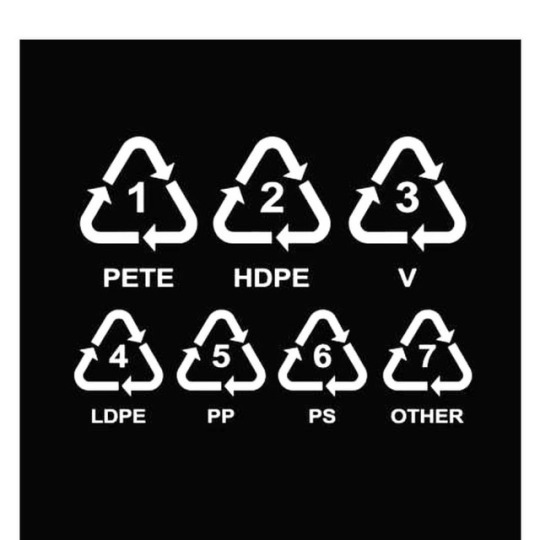

Plastics are becoming a part of our life, its impossible to avoid plastics which are in the form of containers and packages in the super market, all we can do is knowing what they do to us and being safe.So here is a short notes about the PLASTIC BOTTLES and the NUMBERS on it... . What are those number in the PLASTIC bottles ? . These numbers are printed inside a triangle, which is the universal symbol of recycling and it is called as a Resin Identification Code ( RIC ). . HARMFUL PLASTICS and its NUMBERS : . NUMBER 1( PET/ Polyethyleneterephthalate ), prolonged reuse is harmful. . NUMBER 3 ( PVC/ Poly vinyl chloride), highly dangerous to cook food items around or store them in, even if it has deemed safe to. . NUMBER 6 (PS / Polystyrene ), highly dangerous when heated, its better to stay away from these plastics if possible. . NUMBER 7, It could contain anything from polycarbonates to bisphenol A( considered very dangerous), it is suggested to not use this plastic for food storage and consumption. . SAFE PLASTICS and its NUMBERS : . NUMBER 2 (HDPE/High density polyethylene), Very safe and can be reused for storage as it has a low risk of leaching. . NUMBER 4 (LDPE/Low density polyethylene), This kind of plastic is most commonly used for producinggrocery bags, some food wraps and bread bags. While this kind of plastic is considered widely safe for the regular storage use. . NUMBER 5( PP/Polypropylene), Very safe for storage purposes. . NUMBERS THAT CAN BE RECYCLED : . ¤ Number 1 . ¤ Number 2 . ¤ Number 3 . ¤ Number 5 . ¤ Number 7 . . Know your plastics and be safe..😊 . PS : Try to avoid the plastics, lets begin to make a better place for our children to live. . . . #noplastics#saynotoplastics#notoplastics#plasticfree#plasticpollution#avoidplastics#notesonplastics#numbers#numbersandplastics#knowplastics#safeplastics#recycle#plastics#safety#health#healthandplastic#postonhealth#happytales#tamilblogger#blogger#coimbatore#coimbatoreblogger https://www.instagram.com/p/ByAMZhync0i/?igshid=1ji5fl7xezcij

#noplastics#saynotoplastics#notoplastics#plasticfree#plasticpollution#avoidplastics#notesonplastics#numbers#numbersandplastics#knowplastics#safeplastics#recycle#plastics#safety#health#healthandplastic#postonhealth#happytales#tamilblogger#blogger#coimbatore#coimbatoreblogger

0 notes

Text

Coca-Cola committed to ICC World Cup and Cricket #CocaCola #FIFAWorldCup #ICC #InternationalCricketCouncil #Cricket #India #England #Bangladesh #CricketWorldCup #12thMan #Hotstar #DigitalTerrestrialTelevision #SocialMedia #London #RanbirKapoor #PareshRawal #Ecommerce #SriLanka #Happiness #Wales #Australia #NewZealand #TheCocaColaCompany #Relish #FlyingAce #IND #YuvrajSingh #Voiceover #Jadeja #BaseOnBalls #SouravGanguly #SunielShetty #PolyethyleneTerephthalate #RaceAndEthnicityInTheUnitedStatesCensus #Nepal #Bhutan #Maldives #VisitEngland #CommandCenter #WorldWarII #Facebook #Instagram #UnitedKingdom #BrazilAtThe2016SummerOlympics #ComingUp #Snapchat #Cap This partnership includes all ICC events around the world, including the ICC Men's Cricket World Cup 2019 in England and Wales, the ICC men's and women's T20 World Cup in Australia in 2020, the ICC Women's World Cup 2021 in New Zealand and the ICC Men's Cricket World Cup in India in 2023 amongst other global tournaments. https://cricmain.com/2019/07/15/coca-cola-committed-to-icc-world-cup-and-cricket/

0 notes

Link

Polyethylene terephthalate is the most common plastic resin of polyester made from the combination of two monomers. Polyethylene terephthalate, also referred to as PET or PETE, is a remarkable cost and energy efficient packaging material, which possesses properties of versatility, strength, and recyclability, thus being used in various end-use industries such as packaging and textile.

0 notes