#Qr Code Reader 2d

Explore tagged Tumblr posts

Text

Tripod Turnstile Overview Tripod Turnstile, Swing Turnstile, and Flap Turnstile( RS Security Co., Ltd: www.szrssecurity.com) are modern control gadgets for pedestrian passages. They are made use of in places where the entrance as well as leave of people require to be managed, such as clever areas, canteens, hotels, galleries, gyms, clubs, metros, terminals, docks, etc location. The use of Tripod Turnstile, Swing Turnstile, and also Flap Turnstile can make the circulation of people orderly. Tripod Turnstile, Swing Turnstile, Flap Turnstile are used in combination with smart cards, fingerprints, barcodes and also other identification system equipment to form an intelligent accessibility control channel control system; they are used in combination with computers, gain access to control, attendance, charging monitoring, ticket systems as well as various other software program to form a The intelligent Turnstile Gate detailed administration system can realize features such as gain access to control, participation, usage, ticketing, as well as existing limiting. This Turnstile Gate management system becomes part of the "all-in-one card" and also is installed at flows such as neighborhoods, factories, clever buildings, canteens, etc. It can complete various management features such as staff member card traveling control, attendance at leave work as well as dishes, and also dining. Tripod Turnstile system features Fast and hassle-free: read the card in and out with one swipe. Utilize the accredited IC card and wave it before the wise Tripod Turnstile visitor to complete the Tripod Turnstile gate opening as well as charge recording job. The card reading is non-directional as well as the reading and also writing time is 0.1 seconds, which is fast as well as convenient. Protection and also confidentiality: Use history or local confirmation, licensed issuance, and also distinct identity, that is, the card can only be made use of in this system, and it is personal and safe. Reliability: Card superhigh frequency induction, stable and dependable, with the ability to judge and think. Versatility: The system can flexibly set access and departure control workers authorizations, amount of time control, cardholder credibility and blacklist loss reporting, including cards and also various other features. Versatility: Through permission, the user card can be used for "one-card" monitoring such as car parking, attendance, access control, patrol, consumption, and so on, making it very easy to recognize multiple uses of one card. Simpleness: Easy to install, basic to connect, the software has a Chinese user interface as well as is simple to run. Tripod Turnstile, Swing Turnstile, and also Flap Turnstile( RS Security Co., Ltd: www.szrssecurity.com) are contemporary control tools for pedestrian flows. The use of Tripod Turnstile, Swing Turnstile, and also Flap Turnstile can make the flow of individuals organized. Use the authorized IC card as well as wave it in front of the smart Tripod Turnstile visitor to complete the Tripod Turnstile gate opening as well as charge recording work.

#Tripod Turnstile Gate#Bollard Led#Uhf Usb Reader#Loop Coil Cable#Qr Code Reader 2d#Qr Barcode Scanner#Outdoor Alpr Camera#Alpr Camera Security#Face Recognition Door#Outdoor Bollard Light

0 notes

Text

Boost Efficiency and Accuracy with Our Industrial Grade Barcode Scanner

Are you tired of slow and inaccurate barcode scanning in your warehouse or home library? Look no further! Introducing the Pro Extreme Performance Industrial Grade 1D 2D QR Barcode Scanner, a game-changing tool designed to revolutionize your scanning experience.

This powerful wired scanner comes with a convenient stand, making it hands-free and easy to use. Whether you're running a bustling warehouse or organizing your home library, this scanner is the perfect fit for Windows and Mac devices. Its drop-resistant and dustproof design ensures durability, even in the toughest environments.

With plug-and-play functionality, setting up the Pro Extreme Performance Scanner is a breeze. Say goodbye to complicated installations and hello to seamless scanning efficiency.

Get ready to take control of your inventory management and enhance productivity. Upgrade to the Pro Extreme Performance Industrial Grade 1D 2D QR Barcode Scanner today!

Hashtags: #ProExtremePerformance#BarcodeScanner#WarehouseProductivity#HandsFreeScanning#EfficientInventoryManagement#IndustrialGradeScanner#WindowsMacCompatible#DustproofDesign#DropResistantScanner#HomeLibraryOrganization

#Pro Extreme Performance Scanner#Industrial Grade Barcode Scanner#1D 2D QR Scanner#Wired Barcode Scanner#Warehouse Inventory Management#Home Library Scanning#Hands-Free Scanner#Plug and Play Scanner#Windows Mac Compatible#Heavy Duty Scanner#Dustproof Design#Drop Resistant Scanner#High-Performance Scanning#Efficient Barcode Scanning#Productivity Booster#QR Code Reader#Warehouse Efficiency#Professional Scanning Solution#Inventory Control System#Streamlined Scanning Process#Accurate Barcode Reader#Easy-to-Use Scanner#Industrial Warehouse Scanner#Barcode Technology#Advanced Scanning Solution#Reliable Barcode Scanning#Home Library Organization#Fast Scanning Speed#Rugged Barcode Scanner#Scanner Stand for Warehouse

0 notes

Text

Overcoming Traceability Challenges with the Latest Handheld Barcode Readers

In today's fast-paced manufacturing and logistics environments, traceability is essential for tracking products, ensuring quality control, and maintaining compliance with industry regulations.

However, traditional barcode scanning methods often face issues like poor readability, manual errors, and inefficiencies. With advancements in industrial automation, the latest handheld barcode readers are revolutionizing traceability, making it easier for users to scan, track, and manage data with accuracy and speed.

How Modern Handheld Barcode Readers Improve Traceability

1. High-Speed and Accurate Scanning

New-generation handheld barcode readers leverage advanced imaging technology to scan barcodes with greater precision. Unlike older models that struggle with faded, damaged, or low-contrast barcodes, these modern devices can capture even the most challenging codes instantly, reducing errors and improving traceability.

2. Seamless Integration with Industrial Automation Systems

Handheld barcode readers are now designed to seamlessly integrate with industrial automation systems, ensuring real-time data transmission across production lines and supply chains. This connectivity enhances inventory management, process tracking, and quality assurance, enabling businesses to maintain complete visibility over their operations.

3. Multi-Code Reading Capabilities

Manufacturers and logistics companies often deal with various barcode formats, from 1D barcodes to complex 2D and QR codes. The latest handheld readers support multi-code scanning, allowing workers to process different labels without switching devices, improving efficiency and reducing scanning time.

4. Wireless and Ergonomic Design for Maximum Mobility

Modern barcode readers are equipped with wireless connectivity, reducing the need for cumbersome cables and enabling users to move freely across warehouses, production floors, and distribution centers. Their ergonomic designs also ensure comfortable, fatigue-free operation, enhancing worker productivity.

5. Enhanced Data Security and Error Reduction

By directly integrating with industrial databases, the latest barcode readers help minimize manual data entry errors, ensuring secure and accurate traceability records. This is particularly crucial in industries requiring strict compliance, such as automotive, pharmaceuticals, and food processing.

Conclusion

With the latest advancements in industrial automation, handheld barcode readers are transforming traceability processes, providing fast, accurate, and effortless scanning solutions. Businesses adopting these technologies can expect improved operational efficiency, better compliance, and enhanced supply chain visibility.

0 notes

Text

RFID vs. Barcode: Which is Better for Inventory Management

Inventory management is essential for businesses to maintain optimal stock levels, reduce losses, and ensure smooth operations. Two popular technologies used for inventory tracking are Radio Frequency Identification and barcodes. While both systems help manage inventory, they differ in functionality, cost, and efficiency. This article compares RFID and barcode technologies to help you determine which is best suited for your inventory management needs.

Understanding RFID and Barcode Technologies

What is RFID?

RFID uses radio waves to automatically identify and track items. An RFID system consists of:

RFID Tags: Contain a microchip and antenna for storing data.

RFID Readers: Capture information from tags using radio signals.

Software Platform: Manages inventory data and provides real-time visibility.

What is a Barcode?

A barcode is a visual representation of data using lines and spaces of varying widths. It requires line-of-sight scanning and consists of:

Barcode Labels: Printed codes attached to items.

Barcode Scanners: Optical devices that read barcodes.

Inventory Software: Processes scanned data and updates records.

Benefits of RFID

Automated Inventory Management: Tracks items without manual scanning.

Real-Time Visibility: Provides instant updates on inventory levels.

High Data Capacity: Stores comprehensive product information.

Enhanced Security: Prevents theft and unauthorized access.

Efficient Bulk Scanning: Speeds up stocktaking and audits.

Benefits of Barcode

Cost-Effective: Lower initial investment and maintenance costs.

Simple and Reliable: Proven technology with widespread adoption.

Easy Integration: Compatible with most inventory management systems.

When to Choose RFID or Barcode

RFID: Ideal for large warehouses, high-value items, and automated processes.

Barcode: Suitable for small businesses with limited budgets and simple inventory needs.

Challenges of RFID and Barcode Systems

RFID Challenges

High Costs: Expensive tags, readers, and software.

Signal Interference: Metal and liquids can disrupt signals.

Complex Setup: Requires specialized expertise.

Barcode Challenges

Limited Range: Requires close proximity scanning.

Prone to Damage: Labels can tear, fade, or smudge.

Manual Effort: Slower inventory counts.

The Future of RFID and Barcode Technologies

Advancements in RFID, including integration with IoT and AI, will enhance real-time tracking and data analysis. Barcodes may evolve with 2D and QR codes offering more storage and functionality.

Conclusion

Choosing between RFID and barcode technology depends on your business needs, budget, and inventory complexity. RFID offers advanced features for real-time visibility and automation, while barcodes remain a reliable and cost-effective solution. Evaluate your requirements and invest in the right technology to streamline your inventory management.

For tailored RFID and barcode solutions, contact us today!

#real time tracking#asset management#qr code#electronic devices#rfid solutions#aidc technologies india#technology#barcode#aidc#barcode printers

0 notes

Text

The Role of Automation: How Barcode & QR Codes Boost WMS Efficiency

Introduction

With the rapidly evolving logistics and supply chain sector today, automation is an essential contributor to efficiency and productivity. Perhaps the most efficient way to automate warehouse functions is to incorporate barcode and QR code technology in a warehouse management system (WMS) .These technologies make it easier to monitor inventory, manage orders, and warehouse operations in general by reducing errors and increasing speeds. In this, we examine how WMS efficiency increases with automation using barcode and QR code technology, and how they transform the warehouse business.

Warehouse Management System (WMS)

A warehouse management system (WMS) is software that is used to automate different warehouse activities like inventory management, stock replenishment, picking, packing, and shipping. It helps the warehouse manager maintain accurate levels of inventory, automates processes, and improves productivity. With the integration of barcode and QR code technology, a WMS receives even more power, enabling it to monitor warehouse activities in real-time and automate warehouse activities.

How Barcode & QR Code Technology is Applied in WMS

Barcode Technology

Barcodes are 1D bar codes that are applied to encode product data in the form of parallel lines. Scanned and read by a barcode reader, the data is fetched directly and saved in the WMS. This facilitates quick processing of inventories and removes the need for manual entry.

QR Code Technology

QR codes are 2D codes with the ability to hold more intricate data, including product descriptions, batch numbers, expiration dates, and even URLs. QR codes are unique from barcodes as they can be read through mobile phones and are more flexible when it comes to managing data.

The Role of Automation in WMS Efficiency

Barcoding and QR code technology used in WMS automates most warehouse activities, resulting in enhanced efficiency. Some of the key ways in which automation enhances WMS functionality are explained below:

1. Improved and Streamlined Inventory Management

Existing manual tracking techniques of inventories make use of hand-held scanning as well as hand data entry and thus are easily liable to faults. Real-time updated inventory may be kept with the help of speedy barcodes as well as QR code scans by warehouse staff. This clears stock discrepancies and maintains accurate inventory up-to-date.

2. Improved Order Fulfillment Process

Order fulfillment is often the most critical warehouse management function. Barcode and QR code automation support quicker picking and packing by enabling staff to validate product details in real-time. This negates order processing errors and ensures punctual deliveries.

3. Reduction of Human Errors

Manual data entry increases the likelihood of errors in stock records, order details, and monitoring shipments. Scanners of barcodes and QR codes allow automatic data collection, minimizing manual error and increasing overall accuracy.

4. Enhanced Warehouse Productivity

Automation speeds up warehouse operations by removing redundant handoffs. Employees have less time handling paperwork and more on activities of value, such as rationalizing storage space and improving order handling.

5. Real-Time Data and Analytics

WMS integration with barcode and QR code provides warehouse managers with real-time visibility into inventory levels, shipment status, and warehouse operations. Information that helps to decide, forecast demand, and optimize warehouse planning.

6. Integration with Other Technologies

Barcodes and QR codes can further be integrated with other automated technology such as RFID, IoT sensors, and robots. It forms a networked warehouse system in which different systems are networked and they are in communication so that they enable greater efficiency.

7. Cost Savings and ROI Improvement

By automating warehouse operations, businesses are able to save labor, prevent losses due to inefficiently managed inventory, and improve overall warehouse efficiency. The initial cost of barcode and QR code technology is quickly offset by long-term cost savings and improved warehouse performance.

Implementing Barcode and QR Code Automation in WMS

Step 1: Select a Barcode/QR Code-Supported WMS

Choose a WMS that can perform barcode and QR code scanning to enable easy integration with existing warehouse operations.

Step 2: Implement Proper Labeling

Tag all inventory items, storage bins, and shelves with barcodes or QR codes so they can be scanned and monitored easily.

Step 3: Invest in Scanning Devices

Equip warehouse personnel with barcode and QR code scanners or mobile devices that can accurately capture and process data

Step 4: Train Warehouse Staff

Train personnel in the use of barcode and QR scanners for maximum return from automation.

Step 5: Monitor and Optimize Performance

Review WMS data regularly to identify where improvements can be made and optimize warehouse operations accordingly.

The Future of Automation in Warehouse

As technology advances, barcode and QR code automation will be even more sophisticated. Future trends are:

AI-Driven WMS Solutions: Artificial intelligence (AI) will augment barcode and QR code functionality by allowing predictive analytics and automated decision-making.

Cloud-Based WMS: Cloud integration will enable warehouses to operate remotely with real-time data access.

Robotic and IoT Integration: Autonomous robots and IoT-enabled devices will be used in conjunction with barcode and QR code systems to build highly efficient and automated warehouses.

Conclusion

The use of barcode and QR code technology in Warehouse Management Systems (WMS) is transforming warehouse operations. Through automated tracking of inventory, order picking, and warehouse operations, companies can greatly enhance efficiency, accuracy, and cost reduction. With further advancements in automation, barcode and QR code technology will be an integral part of contemporary warehouse management, increasing productivity and overall supply chain operations.

For businesses looking to optimize their warehouse operations, adopting barcode and QR code automation in WMS is no longer optional—it’s a necessity for staying competitive in the evolving logistics landscape. https://www.instagram.com/quickmovetechnologies/ https://youtu.be/PjDQMaFRazk?si=hGbrQasKB31iojDg

https://www.linkedin.com/company/6638777/admin/dashboard/

0 notes

Text

GTIN Barcode

Understanding GTIN Barcodes: What They Are and How They Work

In today’s fast-paced and highly interconnected global market, efficient product identification and tracking are critical. One of the most effective ways to achieve this is through the use of GTIN barcodes. These barcodes are essential for businesses to streamline operations, improve inventory management, and ensure smooth transactions across various sales channels.

This article will explore what GTIN barcodes are, how they work, and why they are an essential tool for modern businesses.

What is a GTIN Barcode?

A GTIN barcode is a machine-readable representation of a Global Trade Item Number (GTIN), a unique identifier used to track and manage products. The GTIN itself is a numeric code that identifies a product or trade item, while the barcode is the visual representation of that code. The barcode can be scanned by barcode readers or mobile devices to quickly retrieve product information, such as the product’s description, price, stock level, and more.

A GTIN barcode is typically printed on product packaging or labels, making it easy for retailers, distributors, and suppliers to scan and track items throughout the supply chain.

How Does a GTIN Barcode Work?

The GTIN barcode works by encoding the unique GTIN into a machine-readable format. Here's a breakdown of the process:

GTIN Creation: The first step is the creation of a GTIN (such as GTIN-12, GTIN-13, or GTIN-14) for the product. This code can be assigned by the manufacturer or business when the product is created and registered with GS1, the global standards organization.

Barcode Generation: Once the GTIN is assigned, a GTIN barcode is generated. The barcode is a visual pattern of bars and spaces that represent the GTIN number. It can be a 1D (one-dimensional) barcode (like UPC or EAN) or a 2D (two-dimensional) barcode (such as QR codes, though less commonly used for GTINs in retail).

Barcode Printing: The generated barcode is printed on the product packaging, label, or tag. This barcode can now be scanned by devices to retrieve the product information embedded in the GTIN.

Scanning the Barcode: At the point of sale or during inventory management, the barcode is scanned. A scanner or mobile device reads the barcode and decodes the GTIN, which retrieves the relevant product data from the database, such as the product name, price, and stock level.

Types of GTIN Barcodes

There are various types of GTIN barcodes, each corresponding to a different GTIN format. The most common types of GTIN barcodes are:

UPC Barcode (GTIN-12): A 12-digit barcode used in North America. It is commonly used for retail products and is one of the most recognizable barcode formats in the world. This barcode is used for individual products that are sold directly to consumers.

EAN Barcode (GTIN-13): A 13-digit barcode primarily used outside of North America, including Europe and Asia. The GTIN-13 is used for individual consumer products, similar to the GTIN-12 but with an additional digit to accommodate international identification.

ITF-14 Barcode (GTIN-14): A 14-digit barcode used to identify trade items that are sold in bulk or in larger packaging, such as cartons or pallets. The GTIN-14 barcode is used to track large shipments and bulk products.

Why are GTIN Barcodes Important?

GTIN barcodes provide a range of benefits for businesses, retailers, and consumers:

Increased Efficiency: The use of GTIN barcodes significantly speeds up product scanning and checkout processes. Instead of manually entering product codes or prices, the barcode can be scanned, instantly retrieving product details and speeding up the entire transaction.

Accurate Product Tracking: Barcodes make it easy to track products throughout the supply chain. Each product’s barcode can be scanned at multiple points, from warehouse management to point-of-sale, ensuring accurate tracking of inventory levels, shipments, and stock.

Reduced Errors: By automating data entry through barcode scanning, the risk of human error is minimized. This ensures that the correct product details, pricing, and stock levels are always captured and updated in real time.

Global Compatibility: GTIN barcodes are recognized worldwide. Regardless of where a product is sold or distributed, a GTIN barcode ensures the product can be scanned and identified internationally. This makes it easier for businesses to sell products globally and for consumers to purchase products from different regions.

Improved Inventory Management: Businesses can use GTIN barcodes to efficiently manage inventory. Scanning barcodes allows real-time updates of stock levels, helping businesses avoid overstocking or stockouts and optimize their supply chain operations.

E-commerce Integration: Many e-commerce platforms, such as Amazon, require GTIN barcodes for product listings. Having a GTIN barcode ensures that products are properly listed and searchable on these platforms, improving visibility and sales potential.

Better Consumer Experience: For consumers, GTIN barcodes ensure faster checkouts and more accurate product information. Whether shopping in-store or online, the consistent use of GTIN barcodes helps to improve the overall shopping experience.

How to Generate and Print GTIN Barcodes

To create and print GTIN barcodes, businesses must first obtain GTINs for their products by registering with GS1. Once a GTIN is assigned to a product, businesses can generate the corresponding barcode using barcode generation software. These barcodes can be printed on product packaging, labels, or tags.

There are many online tools available, including websites like gtin.info, that can guide businesses through the process of generating GTIN barcodes and printing them correctly for their products.

Conclusion

GTIN barcodes are an essential tool for modern businesses that want to streamline operations, reduce errors, and ensure smooth product tracking throughout the supply chain. By using these barcodes, businesses can efficiently manage inventory, speed up transactions, and expand their reach in global markets. Whether you are a small retailer or a large multinational business, adopting GTIN barcodes will improve operational efficiency and enhance the customer experience. If you're ready to get started, websites like gtin.info offer valuable resources to help businesses register their products and create barcodes.

0 notes

Text

Barcode

A barcode is a graphical representation of data that can be read by machines, primarily used for identifying and tracking products, assets, or information. Barcodes are a key component of modern business operations, especially in retail, logistics, healthcare, and inventory management. They offer a fast and accurate way to store and retrieve product data, reducing the risk of human error and streamlining processes.

What is a Barcode?

A barcode is made up of black bars and white spaces, where the width of the bars and the gaps between them represent different numerical or alphanumeric data. Barcodes are typically scanned using barcode scanners or barcode readers, which decode the information embedded in the pattern and convert it into digital data that can be processed by computers.

There are several types of barcodes, including 1D barcodes (also known as linear barcodes) and 2D barcodes (also known as matrix barcodes). Each type of barcode has a specific format and use case, depending on the amount of information needed to be encoded and the industry or application.

Types of Barcodes

1D Barcodes (Linear Barcodes):

These are the most common and traditional barcodes. They consist of parallel lines (bars) of varying widths and spaces between them. Each pattern represents a specific character, usually numbers, which is why they're often used for product identification in retail.

Examples of 1D Barcodes:

UPC (Universal Product Code): Common in retail, especially in North America.

EAN (European Article Number): Used primarily outside the U.S. for retail.

Code 39: Used in various industries for inventory and tracking, able to encode both letters and numbers.

Code 128: A compact barcode used to encode all 128 ASCII characters.

2D Barcodes (Matrix Barcodes):

Unlike 1D barcodes, 2D barcodes store data both horizontally and vertically, allowing them to encode more information in a smaller space. This makes them ideal for applications that require storing more data, like product details, URLs, or even contact information.

Examples of 2D Barcodes:

QR Code (Quick Response Code): A widely recognized 2D barcode, often used in marketing, ticketing, and payments. It can store more data than a 1D barcode and is often used to link to websites or other digital content.

Data Matrix: A 2D barcode used in industries like healthcare and electronics, able to store large amounts of data in a small space.

PDF417: A barcode used for documents that store large amounts of information such as airline tickets or identification cards.

How Does a Barcode Work?

The process of how a barcode works involves scanning, decoding, and retrieving data from the barcode. Here is a simplified explanation of the process:

Scanning: A barcode scanner reads the barcode by shining a laser or LED light onto it. The light is reflected off the white spaces and absorbed by the black bars. The scanner translates the pattern of reflected and absorbed light into data.

Decoding: The scanner then decodes the data based on the width and spacing of the bars. For 1D barcodes, this typically involves converting the varying widths of the bars into numbers or characters. For 2D barcodes, the scanner reads both the horizontal and vertical patterns to extract the encoded data.

Retrieving Information: The decoded data is sent to a database or system that matches it with a product or item. This could be in retail (retrieving price information), logistics (tracking items in the supply chain), or any other industry where barcodes are used.

Benefits of Using Barcodes

Increased Efficiency: Barcodes make data entry faster and more accurate. Scanning a barcode is much quicker than manually entering information, reducing checkout times in retail and speeding up inventory processes.

Error Reduction: Barcodes reduce the likelihood of human error in data entry, which can be costly in industries like retail, healthcare, and manufacturing. With barcode scanning, there’s less room for mistakes since the data is automatically transferred to the system.

Cost-Effective: Implementing barcode systems is relatively inexpensive, and the return on investment is high because of the time saved in data processing, inventory tracking, and transaction handling.

Improved Inventory Control: Barcodes are essential for inventory management. By scanning products as they are received or sold, businesses can easily track stock levels, reducing the risk of overstocking or stockouts.

Space-Efficient: Barcodes, especially 2D barcodes like QR codes and Data Matrix codes, can store a large amount of information in a small space. This is particularly useful for products with limited space for labeling, such as small electronics or packaging.

Enhanced Data Management: Barcodes are an essential part of integrated systems that allow businesses to efficiently manage data related to products, orders, sales, and inventory. This integration helps in improving operational workflows and decision-making.

Applications of Barcodes

Retail: Barcodes are ubiquitous in retail environments, allowing quick identification of products at the checkout and efficient inventory management.

Logistics and Supply Chain: Barcodes are used to track products from the manufacturer to the consumer. With barcodes on packaging or pallets, businesses can monitor product movement and ensure accurate deliveries.

Healthcare: In healthcare, barcodes are used for patient identification, medication administration, and tracking medical equipment. This helps prevent errors and ensures that patients receive the right medication and treatment.

Manufacturing: Barcodes help manufacturers track products on the assembly line and manage parts and supplies in inventory. They also help with quality control by linking specific products to their manufacturing batches.

Libraries: Libraries use barcodes to track books and other media. By scanning the barcode on a book, staff can quickly check it in or out and monitor inventory.

Ticketing and Events: Barcodes are widely used in ticketing for concerts, transportation, and events. Event organizers scan tickets to confirm entry and manage seating.

How to Create and Use Barcodes

Get a Barcode Number: Businesses need a unique barcode number for each product, often obtained through registering with GS1, a global standards organization that issues company prefixes for creating unique product identifiers.

Generate the Barcode: Once you have the barcode number, use barcode generation software or online tools to create a visual barcode image. The software will encode the product number into the barcode format (e.g., UPC, EAN, QR Code, etc.).

Print the Barcode: After generating the barcode, you can print it on product packaging, labels, or tags using a barcode printer. Ensure the barcode is printed clearly and at the correct size for easy scanning.

Test the Barcode: After printing the barcode, it’s important to test it with a barcode scanner to ensure it’s readable. If the scanner has trouble reading the barcode, you may need to adjust the size, clarity, or contrast of the print.

Conclusion

A barcode is a simple yet powerful tool that plays a crucial role in modern business and technology. Whether used in retail, logistics, healthcare, or manufacturing, barcodes help streamline processes, improve accuracy, and boost efficiency. With the ability to store data compactly, barcodes enable businesses to quickly track products, manage inventory, and improve customer service.

From basic 1D barcodes like UPC and EAN to advanced 2D barcodes like QR codes, barcodes have become essential for organizing data and ensuring smooth operations across industries.

0 notes

Text

Barcode

Understanding Barcodes: The Key to Modern Inventory and Retail Management

Barcodes have become an indispensable part of our daily lives, revolutionizing how products are tracked, managed, and sold globally. From retail stores to warehouses, and healthcare facilities to logistics operations, barcodes simplify product identification, improve inventory accuracy, and enhance operational efficiency. This article dives into the fundamentals of barcodes, their types, uses, and why they remain a critical tool in modern business operations.

What is a Barcode?

A barcode is a method of representing data in a visual, machine-readable format using a combination of parallel lines, spaces, or dots. Scanners or mobile devices equipped with barcode readers decode this data and convert it into readable information, such as product details, pricing, or inventory levels.

Barcodes primarily consist of two elements:

Black Bars (or Patterns): Represent data.

White Spaces: Separate the black bars for clarity.

Each barcode contains a unique identifier that links to a database, providing details about the product, including its price, stock status, and origin.

History of Barcodes

The concept of barcoding was introduced in the 1940s by Norman Joseph Woodland and Bernard Silver. However, it wasn’t until 1974 that the first barcode was scanned on a Wrigley’s gum pack in an Ohio supermarket, marking the beginning of a technological revolution in retail and inventory management.

Types of Barcodes

There are two primary categories of barcodes: 1D (Linear Barcodes) and 2D Barcodes.

1. 1D (Linear) Barcodes:

These are the traditional barcodes with vertical black and white lines. Examples include:

UPC (Universal Product Code): Commonly used in retail stores.

EAN (European Article Number): International retail barcode.

Code 39: Used in manufacturing and military applications.

Code 128: Often found in logistics and shipping.

2. 2D Barcodes:

These barcodes store more data in both horizontal and vertical patterns. Examples include:

QR Codes (Quick Response Codes): Used in marketing, payments, and product information.

DataMatrix Codes: Common in healthcare and electronics.

PDF417: Found in shipping labels and ID cards.

How Do Barcodes Work?

Barcode Creation: A unique identification number is encoded into a barcode format.

Printing: The barcode is printed on labels or product packaging.

Scanning: A barcode scanner reads the black and white patterns.

Decoding: The scanner translates the barcode into digital data.

Database Lookup: The system retrieves product or asset details from the database.

This seamless process ensures accurate and instant information retrieval, reducing manual errors and improving efficiency.

Applications of Barcodes

Barcodes are widely used across various industries:

1. Retail:

Quick and accurate billing at checkout counters.

Improved inventory management and stock tracking.

2. Healthcare:

Tracking patient medications.

Managing medical equipment and supplies.

3. Logistics and Warehousing:

Real-time tracking of shipments.

Efficient warehouse inventory control.

4. Manufacturing:

Monitoring production lines.

Ensuring quality control through traceability.

5. Event Management:

Ticket scanning for concerts, sports events, and conferences.

Benefits of Barcodes

Accuracy: Reduces human errors in data entry.

Speed: Speeds up processes like billing, inventory checks, and shipping.

Cost-Effective: Affordable technology with significant ROI.

Inventory Control: Real-time visibility into stock levels.

Improved Traceability: Enhances product tracking across supply chains.

Data Insights: Provides accurate data for business analysis and forecasting.

Barcode Scanning Technology

Barcode scanners are devices designed to read and decode barcode information. Common types include:

Laser Scanners: Fast and accurate, commonly used in retail.

CCD Scanners (Charge-Coupled Device): Best for short-range scanning.

2D Image Scanners: Can read both 1D and 2D barcodes.

Mobile Scanners: Smartphones with barcode scanner apps for flexible use.

Barcodes vs RFID

While barcodes are widely used, RFID (Radio Frequency Identification) is emerging as an alternative technology.

Feature

Barcode

RFID

Cost

Low

Higher

Range

Short-range scanning

Long-range reading

Line of Sight

Required

Not required

Data Storage

Limited

Extensive

Both technologies have their advantages, but barcodes remain the preferred choice for cost-sensitive applications.

Challenges with Barcodes

Despite their advantages, barcodes face certain challenges:

Damage or Smudging: Barcodes may become unreadable if damaged.

Limited Data Storage: 1D barcodes can only store minimal information.

Dependency on Line of Sight: Direct scanning is necessary.

The Future of Barcodes

The future of barcoding technology is promising:

Smart Barcodes: Embedded with enhanced data storage.

Integration with IoT (Internet of Things): Enabling smarter inventory systems.

AI Integration: Improving predictive analytics for supply chains.

Blockchain Integration: Ensuring immutable traceability records.

With the rise of e-commerce and digital logistics, barcodes are evolving to meet the demands of modern supply chains.

How to Get a Barcode for Your Business

Register with GS1: GS1 is the global authority for barcode standards.

Obtain a GTIN (Global Trade Item Number): A unique identifier for your product.

Generate the Barcode: Use GS1-approved barcode creation tools.

Print and Apply: Ensure high-quality printing for accurate scanning.

Investing in barcoding systems ensures smooth operations and enhances scalability for businesses of all sizes.

Conclusion

Barcodes are far more than black lines on product packaging—they are a gateway to efficiency, accuracy, and global connectivity. From simplifying retail checkouts to ensuring supply chain transparency, barcodes have proven their value across industries.

As technology continues to advance, barcodes remain a cornerstone of effective product identification and data management, offering unparalleled benefits in a world driven by speed and precision.

0 notes

Text

Asset Tracking Systems: Revolutionizing Business Efficiency and Accountability

In today’s competitive business environment, managing resources efficiently is crucial to staying ahead. Companies across industries—whether it’s a small business or a global corporation—are constantly seeking ways to streamline operations and improve the accuracy of their asset management processes. Asset tracking systems are at the forefront of these efforts, providing businesses with a powerful solution to keep track of valuable resources.

An asset tracking system utilizes a blend of technology to monitor the location, condition, and utilization of physical assets. From tools and equipment to vehicles and IT infrastructure, the goal of asset tracking is to ensure that businesses know where their assets are, how they’re being used, and when they need maintenance or replacement.

This blog explores the ins and outs of asset tracking systems, their benefits, and how they are transforming how companies manage their resources.

What Is an Asset Tracking System?

An asset tracking system is a technology solution designed to help businesses monitor and manage physical assets, often in real-time. The system typically consists of tags or labels placed on assets, scanning devices (such as barcodes or RFID), and a software platform that compiles and analyzes the data.

The system works by providing detailed visibility into the asset’s location, condition, and usage history. Whether you’re tracking tools in a warehouse, office equipment, or machinery on a construction site, these systems help ensure your assets are being optimally utilized and not misplaced or underused.

How Asset Tracking Systems Work

At the heart of asset tracking systems is the technology used to tag and track assets. Let’s break down the main components:

1. Tagging and Labeling Assets

The first step in asset tracking is assigning a unique identifier to each asset. This identifier can be a QR code, barcode, or RFID tag. These tags are attached to the assets and serve as their "ID card."

Barcodes are scanned manually using a handheld scanner. Barcodes are best suited for stationary assets, and they require direct line-of-sight to be scanned.

RFID tags are more advanced and allow for automatic and remote scanning. RFID is great for tracking high-value or high-mobility assets. It doesn’t require direct line-of-sight and can scan multiple items at once.

QR codes, a form of 2D barcodes, can also be scanned using mobile devices, making them more versatile in terms of access and use.

2. Tracking the Assets

Once an asset is tagged, it is tracked using various technologies, including RFID readers, GPS devices, and mobile applications.

RFID readers and scanners capture information from the tags, while GPS tracking devices provide real-time location updates for mobile assets, such as vehicles and equipment.

For stationary items, tracking systems may rely on manual scans when assets are moved or checked.

3. Software Integration and Data Management

The data collected by the RFID readers, GPS devices, and barcode scanners is sent to an asset management platform. This platform stores all the information related to the assets, including location, usage, maintenance schedules, and more.

The software often integrates with existing business management systems (like Enterprise Resource Planning (ERP) or Inventory Management Software) to ensure a seamless flow of data across departments.

It also provides advanced features like real-time tracking, data analysis, alerts, and reporting, which allow businesses to make informed decisions about asset allocation, maintenance, and purchases.

The Benefits of Asset Tracking Systems

Implementing an asset tracking system brings several key advantages to businesses, regardless of size or industry. Here’s why an asset tracking system is a game-changer:

1. Enhanced Accuracy and Visibility

One of the primary challenges of traditional asset management is the risk of human error. Manual tracking methods—like spreadsheets or physical logs—are prone to mistakes, leading to inaccurate asset records.

An automated asset tracking system ensures accuracy by providing real-time updates on asset status and location. This visibility allows businesses to make data-driven decisions on resource allocation and maintenance, reducing errors and improving overall operations.

2. Improved Security and Theft Prevention

Asset theft and misplacement can be costly for businesses, especially in industries that rely on high-value or mobile assets. An asset tracking system provides real-time alerts when an asset is moved outside a designated area or is no longer where it should be.

Geofencing technology, a feature of many asset tracking systems, allows companies to define virtual boundaries. When an asset enters or exits this boundary, the system triggers an alert, reducing the risk of theft and loss.

3. Cost Savings and Resource Optimization

Many businesses are unaware of how underutilized their assets are. By tracking the usage patterns of assets, businesses can determine which ones are being overused or underused, allowing them to reallocate resources more effectively.

This optimization reduces the need for purchasing additional assets or renting equipment unnecessarily, saving businesses money in the long run.

Furthermore, knowing when assets need maintenance or replacement helps prevent costly repairs or downtime, which can disrupt operations and incur additional expenses.

4. Improved Maintenance and Longevity of Assets

Regular maintenance is key to prolonging the life of assets and preventing unexpected breakdowns. An asset tracking system can track the age, usage, and maintenance history of each asset, triggering automated alerts when maintenance is due.

This ensures that assets are serviced on time, reducing the risk of unexpected failures and increasing their lifespan.

5. Streamlined Compliance and Reporting

For many industries, asset tracking is not just a best practice—it’s a requirement. In industries like healthcare, construction, and manufacturing, strict regulatory requirements dictate how assets must be maintained and tracked.

An asset tracking system makes it easy to keep accurate records of asset movements and maintenance, simplifying compliance with industry regulations. Additionally, the system generates detailed reports that can be used for audits, helping companies stay compliant with minimal effort.

Applications of Asset Tracking Systems

Asset tracking systems have a wide range of applications across industries. Below are some examples of how different sectors benefit from asset tracking:

1. Healthcare

In hospitals and healthcare facilities, tracking medical equipment is essential for providing efficient care. Asset tracking systems ensure that critical devices, such as wheelchairs, infusion pumps, and diagnostic tools, are easy to locate when needed. Additionally, these systems help track maintenance schedules for sensitive medical equipment, ensuring it remains in working order.

2. Construction

Construction companies often operate with a wide variety of equipment and machinery spread across different job sites. Asset tracking systems provide visibility into the location and status of tools, vehicles, and heavy machinery, ensuring they are used effectively and not lost or stolen.

GPS tracking is particularly useful for monitoring large equipment across multiple sites, improving logistics, and reducing downtime.

3. Logistics and Supply Chain

In the logistics industry, asset tracking helps businesses manage their fleet of vehicles, containers, and inventory in real time. Companies can track the movement of goods, monitor the performance of delivery vehicles, and ensure that assets are properly maintained.

This level of oversight boosts operational efficiency and improves customer satisfaction by providing accurate delivery timelines.

4. Retail

Retailers use asset tracking systems to manage their inventory and stock levels. By tagging products and stock with barcodes or RFID tags, businesses can automate inventory counts and minimize human error.

The system also allows for better stock replenishment, ensuring that high-demand items are always available for customers, reducing lost sales due to out-of-stock situations.

Conclusion: The Future of Asset Management

Asset tracking systems are more than just a tool—they’re a transformative technology that helps businesses optimize their resources, improve operational efficiency, and reduce costs. As industries continue to evolve and businesses become increasingly data-driven, having a system in place to manage and track assets is essential for staying competitive.

By providing real-time visibility, improving asset security, and ensuring assets are maintained properly, these systems empower businesses to make smarter, more informed decisions. Whether you’re in healthcare, logistics, construction, or retail, an asset tracking system is a must-have solution that pays dividends in the form of reduced costs, improved productivity, and long-term asset durability.

In the ever-changing landscape of modern business, an investment in an asset tracking system is an investment in the future success of your organization.

0 notes

Text

NFC vs. QR Code Business Cards: Which One is Right for You?

In a world where networking is vital, digital business cards have become a game-changer. NFC (Near Field Communication) business Cards and QR Code business cards are two popular options for quickly sharing contact information and other digital content. Each has its strengths, but how do you choose the one that best suits your needs? Here’s a straightforward comparison of NFC vs. QR Code business cards, highlighting their key differences, ease of use, and features to help you make an informed decision.

Understanding NFC Business Cards

NFC (Near Field Communication) is a wireless technology that enables devices to communicate when they are nearby, usually within a few centimeters. NFC business cards have embedded chips that store data, which can be read by tapping a smartphone against the card.

Key Features of NFC Business Cards:

Ease of Use: NFC cards are incredibly easy to use. With a simple tap, users can instantly share contact information, social media profiles, websites, or other digital content without the need to open any apps.

Technology Integration: NFC business cards leverage advanced technology, offering a seamless experience for users with modern smartphones.

Customization: Data on NFC chips can be updated or customized to meet various needs, such as sharing a portfolio or sending users to a specific website.

Speed: NFC technology allows for almost instantaneous data transfer, making it faster than scanning a QR code.

Professional Appeal: NFC cards feel modern and tech-savvy, making them ideal for industries where innovation is key.

However, NFC business cards do have some limitations. Not all smartphones are equipped with NFC readers, especially older models. Additionally, these cards can be more expensive to produce compared to traditional QR code cards.

Understanding QR Code Business Cards

QR (Quick Response) codes are 2D barcodes scannable by smartphones. When scanned, the code directs users to a website, social media page, or other digital content.

Key Features of QR Code Business Cards:

Wide Compatibility: Almost all smartphones come with built-in QR code scanners, either within the camera or through a downloadable app, making it highly accessible.

Cost-Effective: QR code business cards are generally cheaper to produce than NFC cards. You only need to print the QR code on the card, and it can be scanned multiple times.

No Additional Tech Required: Since scanning QR codes requires no special hardware, it can be used by a broader audience, including those without NFC-enabled phones.

Customizable: Just like NFC cards, QR codes can be linked to various forms of content, such as websites, portfolios, or social media profiles.

Printable: QR codes can be added to any material, whether it’s a business card, a flyer, or even a product package.

However, QR codes have some downsides. They require users to open their phone’s camera or an app, which might take slightly longer than NFC’s tap-and-go functionality. Additionally, scanning QR codes in low light or from a damaged surface can be tricky.

A Side-by-Side Comparison

Feature NFC Business Cards QR Code Business Cards

Ease of Use - Tap to transfer information instantly - Requires opening camera to scan code

Cost - Higher due to NFC chip production - Lower, simply print the QR code

Speed - Instantaneous data transfer - Slight delay due to the scanning process

Customization - Easily programmable and updatable - Customizable but fixed once printed

Compatibility - Limited to NFC-enabled devices - Works with nearly all smartphones

Durability - Chip could wear over time - QR codes can be damaged or faded

Which is Best for Your Business?

Choosing between NFC and QR code business cards depends on your business needs, audience, and budget.

NFC Cards: These are ideal if you want to present yourself as cutting-edge and tech-savvy. If your audience is likely to have modern smartphones and you’re looking for an easy, fast, and seamless way to share data, NFC cards are a great option. Industries like tech, marketing, and startups may benefit from the professional appeal of NFC business cards.

QR Code Cards: If you’re looking for a cost-effective solution that can reach a broader audience, QR code business cards are a solid choice. They work with nearly any smartphone and don’t require special hardware, making them more accessible to people who may not have the latest technology. They are also perfect for mass distribution, especially in industries like retail, events, or hospitality.

Final Thoughts

Both NFC and QR code business cards have their unique benefits and challenges. NFC cards provide a sleek, modern approach to networking but come with higher costs and limited compatibility. QR code cards are highly accessible and affordable but may not offer the same speed or ease of use as NFC cards. By considering your target audience, business goals, and budget, you can decide which type of digital business card will best suit your needs.

#NFC Cards#Business Cards#QR Code Business Cards#NFC Business Cards#NFC Technology#RFID Technology#Near Field Communication#NFC Reader

0 notes

Text

Android 12/8.1 3G 4G Handheld POS Terminal With 58mm Thermal Printer 1D 2D Bar Code QR Scanner NFC Reader optional Mobile Device

Scanning Light Source: Natural Light Novelty: New Product Type: Bar Code Scanner Model Number: GZPDA06/PDA15 Colour Depth: 32 Bit Scan Breadth: A6 Type: Barcode Scanner Interface Type: USB Scan Element Type: CCD Scan Speed: 100 scans/second Optical Resolution: 600*1200 Brand Name: KMZONE Origin: Mainland China Certification: CE System: Android 12/ Android…

0 notes

Text

Overcoming Traceability Challenges with the Latest Handheld Barcode Readers

In today's fast-paced manufacturing and logistics environments, traceability is essential for tracking products, ensuring quality control, and maintaining compliance with industry regulations.

However, traditional barcode scanning methods often face issues like poor readability, manual errors, and inefficiencies. With advancements in industrial automation, the latest handheld barcode readers are revolutionizing traceability, making it easier for users to scan, track, and manage data with accuracy and speed.

How Modern Handheld Barcode Readers Improve Traceability

1. High-Speed and Accurate Scanning

New-generation handheld barcode readers leverage advanced imaging technology to scan barcodes with greater precision. Unlike older models that struggle with faded, damaged, or low-contrast barcodes, these modern devices can capture even the most challenging codes instantly, reducing errors and improving traceability.

2. Seamless Integration with Industrial Automation Systems

Handheld barcode readers are now designed to seamlessly integrate with industrial automation systems, ensuring real-time data transmission across production lines and supply chains. This connectivity enhances inventory management, process tracking, and quality assurance, enabling businesses to maintain complete visibility over their operations.

3. Multi-Code Reading Capabilities

Manufacturers and logistics companies often deal with various barcode formats, from 1D barcodes to complex 2D and QR codes. The latest handheld readers support multi-code scanning, allowing workers to process different labels without switching devices, improving efficiency and reducing scanning time.

4. Wireless and Ergonomic Design for Maximum Mobility

Modern barcode readers are equipped with wireless connectivity, reducing the need for cumbersome cables and enabling users to move freely across warehouses, production floors, and distribution centers. Their ergonomic designs also ensure comfortable, fatigue-free operation, enhancing worker productivity.

5. Enhanced Data Security and Error Reduction

By directly integrating with industrial databases, the latest barcode readers help minimize manual data entry errors, ensuring secure and accurate traceability records. This is particularly crucial in industries requiring strict compliance, such as automotive, pharmaceuticals, and food processing.

Conclusion

With the latest advancements in industrial automation, handheld barcode readers are transforming traceability processes, providing fast, accurate, and effortless scanning solutions. Businesses adopting these technologies can expect improved operational efficiency, better compliance, and enhanced supply chain visibility.

0 notes

Text

Cutting-Edge Barcode Technology for Modern Business Operations

Introduction to Barcode Systems

A barcode is a machine-readable representation of data that encodes information about an object using a sequence of lines, squares, or patterns. These codes enhance operational efficiency by enabling seamless tracking, identification, and management of assets.

Barcodes are widely utilized across various industries, including retail, logistics, healthcare, manufacturing, and document management, ensuring accurate and fast data retrieval.

How Barcode Technology Works

Barcodes encode data in a visual format that can be scanned and translated into digital information by barcode readers or mobile scanning devices. The scanning device captures the barcode, deciphers the encoded information, and transmits it to a central database for processing.

There are two primary types of barcodes:

1D (Linear) Barcodes: Consist of vertical black lines that store alphanumeric data, commonly used in retail and inventory systems.

2D Barcodes: Include QR codes and Data Matrix codes, capable of storing more complex data and being scanned from multiple angles for versatile applications.

Essential Components of a Barcode System

A robust barcode system integrates several key elements for efficient operation:

Barcode Labels: Unique identification codes affixed to products, documents, or assets for tracking.

Barcode Scanners: Optical devices that read and interpret barcode data.

Barcode Software: Systems that manage, analyze, and store barcode-related information.

Database Management System: A structured data repository that ensures secure storage and easy access to barcode data.

Applications of Barcode Technology Across Industries

1. Retail & Inventory Management

Retailers depend on barcodes to streamline product tracking, maintain accurate stock levels, and accelerate checkout processes. Barcode scanning enhances pricing accuracy and inventory visibility.

2. Logistics & Supply Chain Optimization

Barcodes play a critical role in logistics, enabling businesses to track shipments, monitor warehouse stock, and ensure efficient deliveries. Each package is assigned a barcode for real-time location tracking.

3. Healthcare & Pharmaceuticals

The healthcare sector uses barcodes for tracking medications, managing patient records, and ensuring proper specimen identification. This reduces medical errors and enhances regulatory compliance.

4. File & Document Management

Businesses and government institutions utilize barcode systems to organize, track, and retrieve important documents securely. Barcode-based filing systems reduce misplacement and improve workflow efficiency.

5. Manufacturing & Asset Tracking

Manufacturers use barcode technology to monitor production stages, raw materials, and finished goods. Barcode-based asset tracking prevents losses and ensures proper equipment management.

Benefits of Barcode Implementation

Increased Accuracy: Minimizes manual errors in data entry and tracking.

Enhanced Productivity: Reduces scanning time, improving operational efficiency.

Real-Time Inventory Monitoring: Provides instant updates on stock levels and product locations.

Cost Savings: Lowers labor costs and eliminates paperwork inefficiencies.

Strengthened Security: Prevents unauthorized access and improves asset management.

Conclusion

Barcode technology is a game-changer for businesses looking to optimize workflow, enhance security, and improve productivity. Whether applied in retail, logistics, healthcare, or document management, barcode systems provide an innovative and cost-effective approach to data tracking and asset management.

By integrating barcode solutions, organizations can achieve seamless operations, real-time monitoring, and data-driven decision-making for sustained success.

#real time tracking#qr code#rfid solutions#asset management#aidc technologies india#electronic devices#barcode

0 notes

Text

The Role of Automation: How Barcode & QR Codes Boost WMS Efficiency

Introduction

With the rapidly evolving logistics and supply chain sector today, automation is an essential contributor to efficiency and productivity. Perhaps the most efficient way to automate warehouse functions is to incorporate barcode and QR code technology in a warehouse management system (WMS) .These technologies make it easier to monitor inventory, manage orders, and warehouse operations in general by reducing errors and increasing speeds. In this, we examine how WMS efficiency increases with automation using barcode and QR code technology, and how they transform the warehouse business.

Warehouse Management System (WMS)

A warehouse management system (WMS) is software that is used to automate different warehouse activities like inventory management, stock replenishment, picking, packing, and shipping. It helps the warehouse manager maintain accurate levels of inventory, automates processes, and improves productivity. With the integration of barcode and QR code technology, a WMS receives even more power, enabling it to monitor warehouse activities in real-time and automate warehouse activities.

How Barcode & QR Code Technology is Applied in WMS

Barcode Technology

Barcodes are 1D bar codes that are applied to encode product data in the form of parallel lines. Scanned and read by a barcode reader, the data is fetched directly and saved in the WMS. This facilitates quick processing of inventories and removes the need for manual entry.

QR Code Technology

QR codes are 2D codes with the ability to hold more intricate data, including product descriptions, batch numbers, expiration dates, and even URLs. QR codes are unique from barcodes as they can be read through mobile phones and are more flexible when it comes to managing data.

The Role of Automation in WMS Efficiency

Barcoding and QR code technology used in WMS automates most warehouse activities, resulting in enhanced efficiency. Some of the key ways in which automation enhances WMS functionality are explained below:

1. Improved and Streamlined Inventory Management

Existing manual tracking techniques of inventories make use of hand-held scanning as well as hand data entry and thus are easily liable to faults. Real-time updated inventory may be kept with the help of speedy barcodes as well as QR code scanss by warehouse staff. This clears stock discrepancies and maintains accurate inventory up-to-date.

2. Improved Order Fulfillment Process

Order fulfillment is often the most critical warehouse management function. Barcode and QR code automation support quicker picking and packing by enabling staff to validate product details in real-time. This negates order processing errors and ensures punctual deliveries.

3. Reduction of Human Errors

Manual data entry increases the likelihood of errors in stock records, order details, and monitoring shipments. Scanners of barcodes and QR codes allow automatic data collection, minimizing manual error and increasing overall accuracy.

4. Enhanced Warehouse Productivity

Automation speeds up warehouse operations by removing redundant handoffs. Employees have less time handling paperwork and more on activities of value, such as rationalizing storage space and improving order handling.

5. Real-Time Data and Analytics

WMS integration with barcode and QR code provides warehouse managers with real-time visibility into inventory levels, shipment status, and warehouse operations. Information that helps to decide, forecast demand, and optimize warehouse planning.

6. Integration with Other Technologies

Barcodes and QR codes can further be integrated with other automated technology such as RFID, IoT sensors, and robots. It forms a networked warehouse system in which different systems are networked and they are in communication so that they enable greater efficiency.

7. Cost Savings and ROI Improvement

By automating warehouse operations, businesses are able to save labor, prevent losses due to inefficiently managed inventory, and improve overall warehouse efficiency. The initial cost of barcode and QR code technology is quickly offset by long-term cost savings and improved warehouse performance.

Implementing Barcode and QR Code Automation in WMS

Step 1: Select a Barcode/QR Code-Supported WMS

Choose a WMS that can perform barcode and QR code scanning to enable easy integration with existing warehouse operations.

Step 2: Implement Proper Labeling

Tag all inventory items, storage bins, and shelves with barcodes or QR codes so they can be scanned and monitored easily.

Step 3: Invest in Scanning Devices

Equip warehouse personnel with barcode and QR code scanners or mobile devices that can accurately capture and process data

Step 4: Train Warehouse Staff

Train personnel in the use of barcode and QR scanners for maximum return from automation.

Step 5: Monitor and Optimize Performance

Review WMS data regularly to identify where improvements can be made and optimize warehouse operations accordingly.

The Future of Automation in Warehouse

As technology advances, barcode and QR code automation will be even more sophisticated. Future trends are:

AI-Driven WMS Solutions: Artificial intelligence (AI) will augment barcode and QR code functionality by allowing predictive analytics and automated decision-making.

Cloud-Based WMS: Cloud integration will enable warehouses to operate remotely with real-time data access.

Robotic and IoT Integration: Autonomous robots and IoT-enabled devices will be used in conjunction with barcode and QR code systems to build highly efficient and automated warehouses.

Conclusion

The use of barcode and QR code technology in Warehouse Management Systems (WMS) is transforming warehouse operations. Through automated tracking of inventory, order picking, and warehouse operations, companies can greatly enhance efficiency, accuracy, and cost reduction. With further advancements in automation, barcode and QR code technology will be an integral part of contemporary warehouse management, increasing productivity and overall supply chain operations.

For businesses looking to optimize their warehouse operations, adopting barcode and QR code automation in WMS is no longer optional—it’s a necessity for staying competitive in the evolving logistics landscape. https://www.instagram.com/quickmovetechnologies/ https://youtu.be/PjDQMaFRazk?si=hGbrQasKB31iojDg https://www.linkedin.com/company/6638777/admin/dashboard/

0 notes

Text

gs1 barcode

A GS1 barcode is a globally recognized and standardized barcode system that allows businesses to uniquely identify products and services throughout the supply chain. Managed by GS1, a not-for-profit organization, these barcodes are used by millions of businesses worldwide to streamline processes such as inventory management, point-of-sale transactions, and logistics. The GS1 barcode system ensures that businesses can efficiently and accurately track products, whether in retail, manufacturing, or other sectors.

What is a GS1 Barcode?

A GS1 barcode is a visual representation of a Global Trade Item Number (GTIN), which uniquely identifies a product. The barcode contains data that can be read by a scanner, allowing businesses to track and manage products across the supply chain. The GTIN embedded in the barcode typically represents a product’s identifier, linking it to the business’s inventory management system, product database, and sales records.

GS1 barcodes are used in various industries, including retail, healthcare, food, pharmaceuticals, and logistics, to manage product information efficiently.

Key Components of a GS1 Barcode

GS1 Company Prefix: A unique identifier assigned to each business by GS1. This prefix forms the starting part of the barcode and ensures that each company can be uniquely identified in the global supply chain.

Product Identifier (GTIN): The Global Trade Item Number (GTIN) is the unique identifier for each product. It could be a 12-digit UPC, 13-digit EAN, or 14-digit GTIN-14, depending on the product and market requirements. The GTIN provides businesses and consumers with detailed product information.

Check Digit: A single digit that helps verify the accuracy of the barcode. It is calculated using a mathematical algorithm based on the other digits in the barcode. The check digit ensures that the barcode is scanned correctly and avoids errors during transactions.

Additional Data: In some cases, additional information such as batch numbers, serial numbers, or expiration dates can be encoded into the barcode, especially for industries like healthcare, food, and pharmaceuticals.

Types of GS1 Barcodes

There are several types of GS1 barcodes, each designed for different use cases:

UPC (Universal Product Code): Used primarily in the United States and Canada, the UPC is a 12-digit barcode that uniquely identifies retail products. It consists of the GS1 Company Prefix, product identifier, and a check digit.

EAN (European Article Number): This is a 13-digit barcode used mainly in Europe and other international markets. It’s similar to the UPC but includes an additional digit to accommodate European retail standards.

GTIN-14: A 14-digit barcode used for trade items such as shipping containers, pallets, or cases containing multiple individual products. It is commonly used in logistics and supply chain management to identify bulk packaging or multi-unit items.

GS1 DataBar: A compact barcode that can encode more information than the traditional UPC or EAN barcodes. It is commonly used for small items, such as fresh produce or items with limited space for labeling.

GS1-128: A 1D barcode used in logistics, healthcare, and shipping. It is highly versatile and can store additional data such as batch numbers, expiration dates, and serial numbers.

QR Code: A 2D barcode that can store large amounts of information in both horizontal and vertical directions. It is used in various sectors, such as marketing, product information sharing, and digital transactions.

How GS1 Barcodes Work

The GS1 barcode functions by encoding product information into a machine-readable format, which can be scanned by barcode readers. When a barcode is scanned, the system decodes the information into a unique identifier (GTIN) that is cross-referenced with a product database, retrieving information such as the product name, price, manufacturer, and stock quantity.

Barcode Creation: A business must first register with GS1 to obtain a GS1 Company Prefix. Once the prefix is assigned, the business can generate GTINs for their products. Each GTIN corresponds to a specific product.

Barcode Generation: Once the GTIN is assigned, the business uses barcode generation tools or services provided by GS1 to generate the actual barcode (e.g., UPC or EAN). The barcode visually represents the GTIN as a series of black bars and white spaces, which a scanner can read.

Scanning: At the point of sale (POS) or during inventory management, a barcode scanner reads the barcode, decodes the GTIN, and retrieves the corresponding product information from a database.

Product Information: The product’s details—such as the name, price, description, and stock level—are displayed on the system, helping businesses manage inventory and process transactions quickly and accurately.

Benefits of GS1 Barcodes

Global Standardization: GS1 barcodes are used worldwide, making it easy to trade and track products internationally. No matter where a product is sold, the GS1 barcode ensures it can be easily identified, whether in retail, logistics, or e-commerce.

Efficiency and Speed: Barcodes speed up the scanning and checkout process in retail environments, reducing the time spent on manual data entry and minimizing errors. This leads to faster transactions and a better customer experience.

Improved Inventory Management: GS1 barcodes make inventory tracking easier by allowing businesses to track product movement in real-time. This reduces the risk of stockouts, overstocking, and product loss, and helps ensure accurate stock levels.

Accurate Data: By automating product identification through barcodes, businesses reduce the likelihood of errors that can occur with manual data entry. This leads to more accurate product information and fewer discrepancies between sales and inventory.

Traceability and Transparency: GS1 barcodes provide detailed traceability for products across the supply chain. This is especially important in industries like food and pharmaceuticals, where tracking the origin, batch number, and expiration date of a product is critical.

Compliance: Many retailers, government agencies, and industry regulators require products to be barcoded in compliance with GS1 standards. Using GS1 barcodes ensures that products meet regulatory requirements and retailer specifications.

How to Apply for a GS1 Barcode

To get a GS1 barcode for your product, follow these steps:

Register with GS1: Visit the official GS1 website in your region (e.g., GS1 US, GS1 UK, or GS1 International) and sign up as a member. You’ll be issued a GS1 Company Prefix.

Assign Product Numbers (GTINs): Once you have your GS1 Company Prefix, assign a unique GTIN to each of your products. The GTIN can be 12 digits (UPC), 13 digits (EAN), or 14 digits (GTIN-14), depending on the type of product and the market.

Generate the Barcode: Using your GTIN, you can generate the corresponding barcode. You can use barcode generation software or services provided by GS1 or other third-party providers.

Print the Barcode: Print the barcode onto your product packaging or labels. Make sure that the barcode is clear, scannable, and placed in a prominent area on the packaging.

Test the Barcode: Before distributing your product, test the barcode with a barcode scanner to ensure that it is correctly formatted and scannable.

Conclusion

A GS1 barcode is a critical tool for product identification and tracking in today’s global supply chain. Whether you're in retail, logistics, or healthcare, GS1 barcodes help streamline operations, improve inventory management, and ensure compliance with international standards. By registering with GS1, obtaining a Company Prefix, and assigning GTINs to your products, you can generate the necessary barcodes that make your products easily identifiable in stores and online.

0 notes

Text

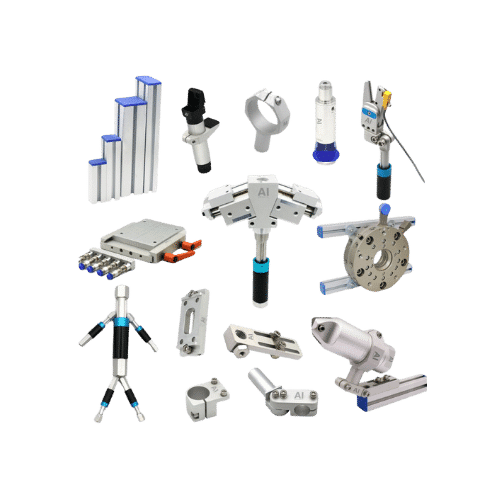

2D Barcode Reader Manufacturing Plant Setup

The 2D barcode reader, often referred to as a QR or quick response code scanner, has become an indispensable tool in numerous industries across the globe.

0 notes