#Warehouse Automation System

Explore tagged Tumblr posts

Text

AI Solutions for Automated Pallet Counting - Innodatatics

A cutting-edge technical tool called the Automated Pallet Counting System was created to improve and expedite inventory management in warehouses and distribution facilities. With the use of advanced algorithms and cutting-edge imaging technology, this system counts pallets precisely in real-time, eliminating the need for manual labor and decreasing human error. It easily interfaces with the current warehouse management systems, offering real-time information and comprehensive reports that support accurate stock control, enhanced operational effectiveness, and storage space optimization.

#inventory counting#inventory counting services#warehouse counting#counting boxes on a pallet#automated warehouse management system#automated pallet counting system#warehouse automation#warehouse automation system#Automation#Warehousing#InventoryManagement#SupplyChain#Automated Pallet Counting System#Pallet Counting System#Automated Pallet Counting System In Hyderabad#Innodatatics Analytics Services#Innovation data analytics#Innodatatics#Innodatatics Internship

0 notes

Text

How To Deploy Warehouse Automation System?

Warehouse automation is a solution advised for firms aiming to increase logistics productivity, maximize storage space, and enhance the safety of their personnel, goods, and storage systems. But how exactly does one go about automating a warehouse? What steps should people take? In this blog, let’s discuss the steps to implement warehouse automation.

Rising R&D spending, high labor costs, a shortage of qualified workers, and increasing public awareness of the benefits of the market. Thus, these elements are predicted to boost market growth. In addition, according to a research report by Astute Analytica, the global Warehouse Automation Market is likely to grow at a compound annual growth rate (CAGR) of 15% over the projection period from 2023 to 2031.

Follow This Step-By-Step Guide To Get Started With Warehouse Automation:

Create a committee to oversee the implementation

Create a committee of internal stakeholders with knowledge of current warehouse capabilities, performance, and challenges, as well as an understanding of existing technology gaps; consider bringing in third-party experts who are knowledgeable about supply chain automation and have knowledge of industry and warehouse operations.

Collect essential information

Effective warehouse automation is dependent on data from a person’s existing supply chain and business-critical warehouse operations. Before deploying new automation technology, assess the present data collection method and infrastructure. They should delegate data migration responsibility to qualified IT stakeholders.

Examine inventory controls

Inventory control is crucial to warehouse operations. Determine or refine people inventory control standard operating procedures (SOPs) before using warehouse automation technology. Include standard operating procedures for shipping, purchasing, customer satisfaction, receiving, and inventory loss.

Define the key performance indicators (KPIs) that will be used to assess the effectiveness of automated inventory control procedures and processes. Evaluate the current inventory accounting method (for instance, perpetual or periodic systems) and how automation may affect it.

Set up partnerships with stakeholders

Supply chains can be fairly complicated because they are made up of numerous distinct links. It is beyond a doubt one of the most crucial elements to consider when automating the warehouse because the person must guarantee that the appropriate resources have been engaged.

This entails establishing collaborations with firm stakeholders, who range from funders to technicians, and from their technical assistance team to operations managers. Bringing everyone’s skills and experience together will aid in identifying obstacles, opportunities, and crucial issues at the beginning of the automation process.

Establish a warehouse management system (WMS)

WMS systems include software modules that aid in the control and tracking of inventory, the management of warehouse operations, the reduction of wages associated with manual duties, and the improvement of customer service. A new WMS should aid mobile devices and be compatible with their current enterprise software.

Determine the type of warehouse automation required

Person’s intention to employ automation to cut labor expenses related to back-office warehousing operations and accounting? Or, are they growing their warehouse footprint or opening new locations and believing it’s time to implement advanced physical process automation, like robots and GTP systems? It is critical to identify the type of warehouse automation that corresponds with goals and consumer demand.

Source: How To Deploy Warehouse Automation System?

#Warehouse Automation System#Warehouse Automation Market#Warehouse Automation#WarehouseAutomation#SupplyChainTech#LogisticsSolutions#OperationsManagement#IndustrialEngineering#ManufacturingTech#RoboticsIntegration#BusinessAutomation#TechnologyDeployment#EfficientWarehousing#ProcessOptimization#SmartWarehousing#InventoryManagement#DistributionCenter#AutomatedLogistics

0 notes

Text

5G-Powered Drones: Ericsson, Qualcomm And Dronus Collaboration In Developing Autonomous Drone Solutions

5G mmWave technology for industrial use. Ericsson, Qualcomm, and Dronus Collaboration in developing autonomous drone solutions. The world of industrial automation is on the cusp of a revolution, and at the forefront is a powerful combination, of 5G technology and autonomous drones. A recent collaboration between Ericsson, Qualcomm Technologies, Inc., and Dronus provides a glimpse into this exciting future.

#5G drones#Industrial automation#Indoor drone applications#Warehouse inventory management#mmWave 5G technology#Autonomous drones#Industry 4.0#5G smart factory#(PoC)#Qualcomm QRB5165 processor#Telit Cinterion#mmWave#Industrial M.2 data card#5G Modem-RF System#Native mmWave connectivity#High-performance 5G connection#Bandwidth-intensive industrial operations#drone

2 notes

·

View notes

Text

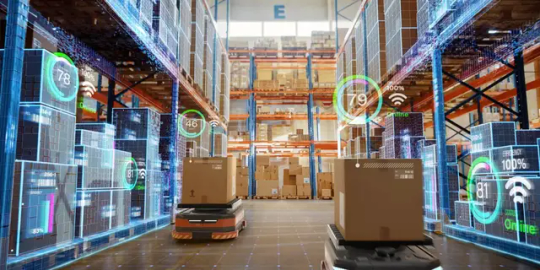

Meet the AMR Robot: The Smart Teammate Revolutionizing Warehouses

In today’s hyperconnected, fast-paced world of e-commerce and just-in-time manufacturing, warehouses have evolved into strategic nerve centers. No longer just spaces to stash goods, they’re critical hubs that can make or break a business’s ability to deliver quickly, efficiently, and profitably. At the heart of this warehouse revolution stands a sleek, smart, and tireless teammate: the AMR robot, or Autonomous Mobile Robot.

The Rise of the AMR

Gone are the days of bulky machines tied to rails or conveyor belts. Today’s AMRs are nimble, autonomous, and surprisingly intelligent. Using a mix of advanced sensors, real-time mapping, and onboard AI, these robots can independently navigate complex warehouse layouts. They can identify and avoid obstacles, reroute in case of congestion, and reach their destinations without needing fixed paths or constant human intervention.

Think of them as the self-driving cars of the warehouse world—only quieter, more efficient, and trained to never break the speed limit.

A New Age of Warehouse Handling Equipment

When it comes to warehouse handling equipment, the AMR robot is a category-defining marvel. Traditionally, equipment like forklifts, conveyor systems, and pallet jacks required skilled operators and constant supervision. That meant higher labor costs, increased chances of human error, and limitations in scaling during peak demand seasons.

Enter the Autonomous Mobile Robot—a compact, battery-powered solution that works 24/7 without fatigue. Whether it’s moving raw materials to production lines, picking customer orders from shelves, or transporting finished goods to loading docks, AMRs handle it all with unshakable precision.

The result? Fewer mistakes, faster cycle times, and more efficient warehouse operations.

A Teammate, Not a Replacement

A big concern with automation has always been the fear of replacing human workers. But the beauty of AMRs lies in their collaborative nature. These robots are designed to work alongside people, not in place of them. While the AMR robot tackles repetitive, physically taxing, and time-consuming tasks, human workers can focus on strategic responsibilities—like quality control, equipment maintenance, or optimizing processes.

This collaboration between humans and machines boosts morale at work in addition to productivity. No more exhausting journeys via enormous warehouses or back-breaking lifting. Workers instead take on the role of overseers of efficiency and operators of intelligent systems.

The reasons everyone is discussing AMRs

AMRs are receiving a lot of attention in the industrial and logistics industries for a reason. They are enticing to contemporary businesses because of the following main advantages:

Adaptability: AMRs are easily reconfigurable, in contrast to typical automation systems that need established infrastructure. With minimal downtime, you may scale operations, modify workflows, and adjust to new layouts.

Rapid Deployment: Since AMRs are not reliant on predetermined routes or tracks, they may be deployed rapidly. This is very helpful for businesses that are seasonal or growing rapidly.

Smart Navigation: AMRs navigate through dynamic environments, including those shared with people and forklifts, with confidence by utilising technology such as LiDAR, SLAM (Simultaneous Localisation and Mapping), and obstacle recognition.

Data-Driven Operations: AMRs produce a lot of data, including route efficiency and journey times. This knowledge can enhance overall operational effectiveness and optimize warehouse layouts.

Safety First: With sensors and integrated safety procedures, AMRs lower the possibility of mishaps, making them a reliable component of contemporary warehouse handling machinery.

Not only for storage facilities

Autonomous Mobile Robots are becoming more and more popular in a wide range of other settings, even though they excel in warehouses. They deliver lab samples and medications to hospitals. They manage security and baggage at airports. They oversee the replenishment of goods in shop backrooms. Because of their versatility, they can be used in any facility that has to move items precisely and repeatedly.

Bottom-Line Enhancers

Although the technology is impressive, what about the ROI?

AMRs save money over time in a number of ways. They minimise downtime from fatigue or absence and reduce workforce expenses by minimising reliance on human labour. Their accuracy reduces order errors and product damage. Additionally, businesses benefit from improved service levels and quicker turnaround times due to their ability to work continuously.

Determine the difference between AMR and AGV

AMRs and AGVs (Automated Guided Vehicles) are frequently confused in the automation field. Although they are both utilised for material transportation, their navigational strategies differ significantly.

AGVs are dependent on fixed pathways, such as implanted wires, magnetic strips, or QR codes. They halt and wait for anything to move out of their way. AMRs, however, are more intelligent. They avoid obstacles, adjust to shifting conditions, and plot routes dynamically using onboard intelligence.

Because they offer flexibility and scalability that conventional automated guided vehicles just cannot, AMRs are sometimes regarded as the next generation of AGVs.

What will happen to AMRs next?

The capabilities of the AMR robot will advance in tandem with advancements in robotics, artificial intelligence, and warehouse management systems. Better object detection, collaborative arms for choosing, and even machine learning-based route optimisation are possible features of future versions.

And we may anticipate seeing these robots in mid-sized and even small businesses, not just the major players, as they become more widely available and reasonably priced.

It could be time to consider when, rather than if, you will implement AMRs if you work in manufacturing, logistics, or any other industry that requires moving materials. Because neither your customers nor the future are waiting.

0 notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes

Text

Truck Loading Conveyor Manufacturers in Faridabad: Leaders in Innovation

Looking for cutting-edge truck loading conveyor solutions? Discover why Faridabad is the heart of conveyor manufacturing in India. Home to industry-leading companies, Faridabad-based manufacturers are known for their technological innovation, customized designs, and cost-effective solutions for modern logistics and warehousing.

From telescopic conveyors to hydraulic truck loaders, these manufacturers are empowering India’s supply chains with faster, safer, and more efficient material handling systems. Whether you're in e-commerce, FMCG, agriculture, or manufacturing, these conveyors are engineered to deliver unmatched performance.

#truck loading conveyor#Faridabad manufacturers#conveyor systems India#telescopic conveyor#hydraulic loading conveyor#material handling India#warehouse automation#belt conveyor#loading solutions India

0 notes

Text

Top 5 Benefits of Warehouse Automation for Safer and Faster Operations

Nowadays, many organizations use warehouse automation systems to make their tasks easier and complete on time. With rising demand and growing online shopping, more businesses use automation to stay competitive.

It helps companies work better by saving time, reducing errors and improving supply chain efficiency. Let's explore the main benefits of warehouse automation and how custom software can help improve your logistics and warehouse operations.

Promotes Safety:

Safety is necessary in every industry. Every organization wants to keep their employees and businesses safe from harmful attacks. It reduces the danger in risky jobs like reaching high shelves, working in busy areas, lifting heavy pallets, or handling harmful products like chemicals.

Drive Sustainability:

If you want to make your brand sustainable, choosing warehouse automation solutions is a great choice. It provides optimized space usage, better control of resources, follows green practices and more in an organization. So, you can have rational support for your company. Opt for these solutions from a professional brand and enjoy the best and most reliable results.

Boost Efficiency:

One major benefit of warehouse automation is that it helps your business run more smoothly. It makes tasks like picking, sorting, and packing much faster. It also reduces delays, speeds up the whole order process and helps everything work in an organized way.

Minimize Risks:

To minimize risk in your business, having a good automation system is crucial. It can identify potential risks in your system and provide you with the best possible solutions to reduce risks.

Plus, the professionals at these firms have all the required tools and technologies, which can be used to access real-time insights and data. By using these data, they can deliver proactive decisions, resulting in a better system.

Offer Scalability and Future Growth:

As the business grows, the need for warehousing and distribution also increases. That is why having a scalable and reliable automated solution is crucial. Unlike traditional methods, automated warehousing solutions offer more robustness. Plus, they also ensure long-term ROI, seamless integration and flexible layouts.

About Primus:

Primus is a popular firm known for its smart warehousing solutions. It has an expert team of professionals who specialize in the field. This company offer many services, including front-end services, design-build construction, thermal envelope, construction management and more. You can choose the one tailored to your needs and budget.

To get more details, visit https://www.primusbuilders.com/

Original Source: https://bit.ly/3F6hTel

0 notes

Text

Revolutionize Logistics: Explore Warehouse Management Software Benefits

In the ever-evolving landscape of supply chain logistics, businesses are constantly looking for smarter ways to optimize their warehouse operations. Enter the game-changing technology of Warehouse Management Software (WMS). These digital tools are reshaping how warehouses operate, bringing enhanced efficiency, precision, and cost savings. If your logistics system still relies heavily on manual tracking or fragmented tools, it’s time to explore the full spectrum of Warehouse Management Software Benefits.

A major advantage of warehouse management software is its ability to provide real-time inventory tracking. Gone are the days of paper logs and spreadsheets. With WMS, you can monitor inventory levels, shipments, and stock movement as they happen. This visibility not only improves operational planning but also minimizes the risk of overstocking or stockouts.

Operational efficiency is another key benefit. WMS automates processes such as picking, packing, and shipping, drastically reducing the time required to fulfill orders. This directly leads to faster delivery times and improved customer satisfaction. Businesses that adopt these systems often see a measurable boost in productivity within weeks of implementation.

In terms of cost reduction, WMS can streamline labor allocation, ensuring your workforce is always focused on high-priority tasks. The software's built-in analytics help managers identify bottlenecks and areas where time and resources are being wasted. This allows for informed decisions that enhance performance and profitability.

Accuracy is critical in warehousing. By integrating technologies like barcode scanning and RFID tagging, WMS significantly lowers the risk of human error during inventory counts and order fulfillment. These features help ensure that your records are accurate and your customers receive the right products on time.

On a broader scale, WMS acts as the digital backbone of a smart supply chain. It integrates with ERP systems, eCommerce platforms, and transportation management systems, creating a seamless flow of data across your business operations.

The bottom line? The Warehouse Management Software Benefits are far too impactful to ignore. Whether you're running a small storage facility or a large distribution center, adopting WMS could be the key to staying competitive in an increasingly fast-paced market.

Take the first step toward a more agile, data-driven warehouse today—and watch your supply chain transform from a cost center into a value-driving asset.

#inventory control system#warehouse automation#logistics optimization#real-time inventory#supply chain software#barcode scanning#stock management.

0 notes

Text

#Top challenges DMS#Recover DMS#Advanced DMS#DMS in AI#Ditribution automation#Heerasoftware#inventory system#warehouse management#wholesale management#distribution product management#supply chain management#sales management#Sales automation#Fmcg distribution#CPg distribution

0 notes

Text

Automated Pallet Counting AI Solutions - Innodatatics

A sophisticated technical tool known as an automated pallet counting system is employed in warehouses and distribution centers to enhance and expedite inventory management procedures. Pallet counting, a laborious task, is precisely and efficiently automated by this system through the utilization of advanced sensors, cameras, and software algorithms. This automation not only reduces manual errors but also conserves critical time and resources, providing rapid visibility into inventory levels through real-time data collection. The solution seamlessly integrates with existing inventory management systems, facilitating easy data synchronization and analysis

#inventory counting#inventory counting services#warehouse counting#counting boxes on a pallet#automated warehouse management system#automated pallet counting system#warehouse automation#warehouse automation system#Automation#Warehousing#InventoryManagement#SupplyChain#Automated Pallet Counting System#Pallet Counting System#Automated Pallet Counting System In Hyderabad#Innodatatics Analytics Services#Innovation data analytics#Innodatatics#Innodatatics Internship

0 notes

Text

Discover how wireless asset tracking revolutionizes retail operations by offering real-time data, improved security, and scalable efficiency. This article explores advanced tracking technologies and future trends that position wireless systems as the top choice for retail asset management.

0 notes

Text

Saudi Arabia Warehouse Automation Market Share, Size, Technologies, Growth Strategy, Challenges and Future Competition Till 2033: SPER Market Research

Warehouse automation encompasses the implementation of technology and systems designed to enhance and optimize various operations within a warehouse, such as inventory management, order fulfilment, and material handling. This automation can range from basic conveyor systems to sophisticated robotics and software solutions that manage tasks with limited human involvement. The main objective is to improve operational efficiency, lower labour expenses, and increase accuracy in the handling of goods. Automated Storage and Retrieval Systems (AS/RS) are vital in facilitating the swift storage and retrieval of items. As e-commerce continues to expand, the importance of warehouse automation grows, becoming critical for satisfying consumer demands and sustaining competitive advantages in supply chain management.

According to SPER Market Research, ‘Saudi Arabia Warehouse Automation Market Size- By Type, By End User - Regional Outlook, Competitive Strategies and Segment Forecast to 2033' states that the Saudi Arabia Warehouse Automation Market is estimated to reach XX Billion by 2033 with a CAGR of XX %.

DRIVERS:

The swift growth of the e-commerce industry serves as a significant catalyst, driving the demand for effective storage and distribution systems to satisfy the rising consumer expectations for prompt delivery and efficient inventory management. Persistent labour shortages are compelling organizations to implement automated solutions to sustain productivity while decreasing dependence on human labour. The escalating requirement for cold storage facilities, especially within the food and pharmaceutical industries, is generating prospects for specialized automated solutions. Advancements in automation technologies, including robotics, artificial intelligence (AI), and cloud-based warehouse management systems, are enhancing operational efficiency and lowering expenses. A surge in the e-commerce sector is significantly driving the demand for warehouse automation. The warehouse automation market is marked by a highly competitive environment.

RESTRAINTS:

The initial capital needed for warehouse automation technologies, including robotics and automated systems, can be considerable. This financial hurdle may discourage smaller enterprises from embracing these solutions, thereby constraining overall market expansion. There exists a notable demand for skilled individuals who can operate and maintain sophisticated automation systems. The existing shortage of qualified personnel in Saudi Arabia presents a challenge for organizations aiming to implement these technologies successfully. Additionally, employees and management may be hesitant to shift from conventional manual processes to automated systems due to concerns about job security or a lack of familiarity with new technologies. Addressing this resistance necessitates the implementation of effective change management strategies and comprehensive employee training.

Request a Free Sample Report: https://www.sperresearch.com/report-store/saudi-arabia-warehouse-automation-market.aspx?sample=1

The rise of e-commerce during the pandemic prompted a need for enhanced operational efficiency within warehouses. Organizations pursued automation solutions to handle the surge in order volumes and to satisfy consumer demands for quicker delivery times, thereby propelling growth in the warehouse automation industry. The pandemic also resulted in significant disruptions to global supply chains, impacting the availability of essential components and materials required for the implementation of automation technologies. Consequently, businesses aiming to automate their operations faced project delays and increased costs. Although the long-term prospects of warehouse automation remain promising, certain companies displayed hesitance in capital investments due to economic uncertainties and a decline in consumer spending during the pandemic.

The market for Saudi Arabia warehouse automation is dominated by Eastern region because of its support in industrial activities and logistics operations, contributing to the overall growth of the market. Some of its key players are- ABB Ltd, Vanderlande, Toyota Industries Corporation, Murata Machinery, Honeywell International Inc.

For More Information, refer to below link: –

Saudi Arabia Warehouse Automation Market

Related Reports:

Flying Car Market Size- By Product, By Capacity- Regional Outlook, Competitive Strategies and Segment Forecast to 2034 Spark and Glow Plugs Market Growth, Size, Trends Analysis - By Vehicle Type, By Fuel Type, By Spark Plug Type, By Aftertreatment System, By Technology- Regional Outlook, Competitive Strategies and Segment Forecast to 2034

Follow Us –

LinkedIn | Instagram | Facebook | Twitter

Contact Us:

Sara Lopes, Business Consultant — USA

SPER Market Research

+1–347–460–2899

#Automated Sortation Systems Supplier in KSA#Automated Technology in Warehousing KSA#Competitors in KSA Warehouse Automation Industry#Emerging Companies in Warehouse Automation KSA#International Domestic Freight Forwarders in KSA#KSA automated technology software Market#KSA Automatic Guided Vehicle Market#KSA Logistics and Warehouse Automation Market#KSA Logistics and Warehouse Automation Market Report#KSA Logistics and Warehouse Automation Market Share#KSA Logistics and Warehouse Automation Market Trends#KSA Warehouse Automation Industry#KSA Warehouse Automation Industry Analysis

0 notes

Text

3 Common Logistics Pain Points (and Modern Solutions)

The logistics industry seems to be facing complications on all sides. Whether that’s navigating regulatory changes or avoiding resource-related bottlenecks, it’s crucial that those involved make use of the modern solutions we now have access to.

Luckily, these solutions are becoming increasingly competent at preventing or at least fixing all sorts of issues. From using AI to improve prediction models to improving order fulfilment accuracy, here are three modern solutions that you need to keep in mind over the coming year.

1. Lack of foresight

One of the main issues in logistics lies in attempting to predict the future. This is a double-edged sword, involving both trying to predict future demand and trying to assess which suppliers will be able to meet those demands. When this goes wrong, issues can arise like bottlenecks or having much too much stock to fit in a warehouse.

A modern solution that’s risen to prominence in recent years is to use AI-powered data analysis tools to make these predictions. Combined with human insight, it’s often possible to sift through vast amounts of information and pick out trends that would otherwise go unnoticed.

2. Inefficient warehouse management

Warehouses are the beating hearts of the logistics industry. There’s so much going on in these kinds of environments that it can be a huge struggle to keep everything moving, let alone keep things running in a highly efficient manner.

One of the single most effective ways of improving warehouse management efficiency is to implement some kind of automated system. Services such as Joloda Hydraroll specialise in designing and installing automated warehouse solutions, one of which might be perfect for your specific needs.

At the very least, it’s worth having an assessment carried out, to see if there’s a solution that might suit you well. Automated warehouse solutions may seem expensive at first, but they can often end up paying for themselves entirely in just a few years.

3. Order fulfilment accuracy

Lastly, decreasing the number of incorrectly fulfilled orders is an issue that remains as relevant now as ever before. While the number of items being sent out every day is likely at a historic high, we now have access to so many technologies and tools that it’s relatively easy to get fulfilment rates to the levels you need.

This will often mean implementing a range of technological solutions like RFID tags, scanners, and warehouse management software and then integrating it all into a single management system. This allows you to keep track of everything from a single location, making it much less likely that orders go missing or get lost somewhere.

These pain points are felt across the logistics sector, and will often raise their heads in subtly different ways. By taking the time to work out how the issues you’re experiencing have arisen, you can decide whether solutions like these might provide you with an easy and convenient fix. Don’t just let them accumulate to a worrying state - constantly work on optimising your set up, and don’t allow yourself to fall behind.

Pin or save this post for later!

Share in the comments below: Questions go here

#logistics#solutions#bottleneck#warehouse management#management efficiency#automated system#fulfilment rates

0 notes

Text

0 notes

Text

#Truck loading conveyor system manufacturer#Vertical lift for material handling manufacturer#Flow wrap machine for FMCG packaging manufacturer#Vertical reciprocating conveyor (VRC) manufacturer#Goods lift manufacturer India#Industrial conveyors for packaging lines manufacturer#End-of-line packaging solutions manufacturer#Smart packaging and conveyor integration manufacturer#Heavy-duty goods lifts manufacturer#Automated truck loading and unloading system manufacturer#Conveyor belt manufacturer#Horizontal flow wrap machine India manufacturer#Horizontal packaging machine for high-speed wrapping manufacturer#Industrial palletizing and packaging line manufacturer#Intralogistics solutions manufacturer#Telescopic boom conveyor manufacturer#Telescopic conveyor for truck loading manufacturer#Warehouse automation manufacturer#FMCG packaging machinery manufacturer

0 notes