#Rotary Labelling Machine

Explore tagged Tumblr posts

Text

Rotary Labelling Machine Manufacturer in India

Brothers India is a leading Rotary Labelling Machine Manufacturer, Supplier, and Exporter in India, offering high-speed, precision-driven labelling solutions for various industries. Our state-of-the-art rotary labelling machines are designed to provide efficient, accurate, and consistent labelling for bottles, jars, containers, and packaging materials.

Key Features of Our Rotary Labelling Machines

High-Speed Labelling: Designed for fast and efficient labelling, increasing production output.

Precision & Accuracy: Ensures perfect label placement without misalignment.

Versatile Applications: Compatible with round, square, and oval bottles for industries like pharmaceuticals, food, cosmetics, and beverages.

User-Friendly Interface: Equipped with advanced PLC controls for easy operation.

Durable & Robust Design: Made with high-quality stainless steel for long-term performance.

Customizable Solutions: Machines can be tailored for specific labelling needs and industry requirements.

Applications of Rotary Labelling Machines

Pharmaceutical Industry: Ideal for labelling medicine bottles and vials.

Food & Beverage Industry: Ensures precise labelling of juice, water, and dairy containers.

Cosmetic & Personal Care: Used for labelling beauty and skincare products.

Chemical & Agro Industry: Suitable for pesticide and chemical packaging.

As a trusted Rotary Labelling Machine Supplier & Exporter in India, Brothers Pharmamach (India) Pvt. Ltd. provides high-quality, efficient, and reliable labelling solutions to meet global standards. Contact us today for more details!

#Rotary Labelling Machine#Rotary Labelling Machine Manufacturer#Rotary Labelling Machine Supplier#Rotary Labelling Machine Exporter#Rotary Labelling Machine Manufacturer in India#Rotary Labelling Machine Supplier in India#Rotary Labelling Machine Exporter in India#Rotary Labelling Machine Manufacturer in Ahmedabad

0 notes

Text

Worldpack Automation Systems: Rotary Labelling Machine

The Rotary Labelling Machine from Worldpack Automation Systems is a cutting-edge solution designed for high-volume labeling of round containers. Industries such as beverages, chemicals, and pharmaceuticals benefit from the machine’s ability to apply multiple labels, including front, back, and neck labels, in a single cycle. Known for its speed and accuracy, the machine integrates advanced servo motor technology that guarantees perfect label placement every time.

At the core of Worldpack’s offerings is their commitment to engineering machines that are reliable, easy to operate, and cost-effective. Our rotary labeling machine is no exception, providing customization options for a range of production needs. With Worldpack’s state-of-the-art infrastructure and experience in delivering solutions across multiple sectors, this machine is built for durability, ensuring high performance in demanding production environments.

#rotary labelling machine#labelling machine#automatic labelling machine#beverage industry#industrial#manufacturer

0 notes

Text

From Fill to Finish: Mastering Packaging with Nichrome’s Integrated Systems

In a rapidly evolving manufacturing sector where every minute of downtime is a deal-breaker and manual processes are considered a thing of the past, integrated packaging solutions are the new superstars of the modern production line. Whether it is bottling honey, pharma-grade filling in jars or cartoning pouches for FMCG, efficiency is not just an option anymore, it is a…

#advanced bottle filling line solution#Automatic Bottle Filling Machine#Automatic Carton Box Packing Machines#automatic filling machines#automatic packaging machines#automatic filling and sealing system#•#bottle filling line solution#filling lines#High-speed labeling systems#Horizontal Flow Wrap Machines#integrated packaging solution#integrated packaging solutions#jar filling linessecondary packaging solutions#jar packaging systems#oil filling machine#packaging solutions#Pouch stacking and bundling systems#rotary capping machines#secondary packaging innovations#secondary packaging solutions#smart packaging ecosystems#tool-less changeover

0 notes

Text

High Speed Rotary Sticker Labeling Machine

A straightforward mechanism linear design machine, the High Speed Rotary Sticker Labeling Machine (bottle labeling machine) includes a bottle labeler for marking bottles, jars, cans, tins, and other containers. PET, glass, plastic, aluminum, metal, and tin containers can all be labeled with a bottle labeler. This apparatus has a cutting-edge Micro Processor Control label dispensing mechanism with a product and label detection system. Using an optional unique label sensing system, a specially built electronic and mechanical system applies transparent (No Look) labels to bottles at a very high speed. It’s interesting to note that no new format or change parts are needed to convert a bottle from one size to another.

India offers an high speed rotary sticker labeling machine with a special single point synchronized speed control mechanism. We may provide specific machine models equipped with Automatic Label Length detection systems, which removes the requirement for label length data to be manually sent into memory, stored there, and then retrieved each time the label size needs to be changed or the machine needs to be restarted. As a result, the System helps to increase productivity while saving significant time by preventing machine downtime.

Additionally, the machine can be equipped with an optional Turn Table for Container Feeding, which facilitates the online movement of containers from the capping/inspection machine to the labeling station and the online transfer of labeled bottles to the packing conveyor/inspection system. This system aids in the ongoing bottle labeling process.

An optional acrylic safety cabinet or toughened (tampered) glass can be included with the machine. Devices that save time and money by having all the necessary functionality as standard fitments to meet the demands of the modern market. Adinath’s sticker labelers are suitable for attaching to the filling lines of bottles, both liquid and powder. Various names for this machine include syrup bottle sticker labeling machine, glass bottle labeler, plastic bottle labeler, and pharmaceutical labeler.

0 notes

Text

理豐智動化有限公司

LEBAL Automation Intelligence CO.,LTD

Company Overview We are a company specializing in automation equipment and technology solutions, primarily applied in beverage packaging.

Product Offerings We offer a variety of automation machines and equipment, such as hot melt glue labeling machines and self-adhesive labeling machines, incorporating Industry 4.0 and AI technology to enhance equipment intelligence.

Comprehensive Services Our services encompass design, manufacturing, installation, and maintenance, emphasizing efficiency, precision, reliability, and customization.

Service Advantages Our service advantages include a professional team, one-stop service, and continuous technological innovation, dedicated to improving production efficiency and reducing costs.

#OPP熱熔膠貼標機、#OPP貼標機、#BOPP貼標機、#環形貼標機、#貼標機、#轉塔貼標機、#旋轉式貼標機

youtube

#OPP#熱熔膠貼標機#OPP熱熔膠貼標機#OPP貼標機#BOPP貼標機#環形貼標機#貼標機#轉塔貼標機#旋轉式貼標機#OPP hot melt labeling machine#OPP labeling machine#BOPP labeling machine#ring labeling machine#labeling machine#turret labeling machine#rotary labeling machine#OPP ホットメルト ラベリング マシン#OPP ラベリング マシン#BOPP ラベリング マシン#リング ラベリング マシン#ラベリング マシン#タレット ラベリング マシン#ロータリー ラベリング マシン#Youtube

2 notes

·

View notes

Text

Elevate Your Production Standards with UV Graphic’s Expertise

Machines that cure are crucial for fast, effective hardening or drying of different materials such as inks, coatings, adhesives in various industries. Such machines cure by applying heat, UV, or other forms of energy so that they assure durability with high finish quality. These machines find extensive applications in industries printing, packaging, automobiles, and electronics.

UV Graphics-the supreme manufacturer of curing machines, produces the avant-garde products matching the expectations of the modern-day industries. The curing machines-a perfect example of precision and speed; even energy efficiency is guaranteed, every time-one can expect flawless output under flexible variable conditions. Some of the features include adjustable intensity of curing, automated controls, and adaptability to various substrates that truly define invaluable wealth to any production line.

Choosing UV Graphic means an acquisition of sophistication in technology, which is further strengthened by unmatchable support for any kind of business. It is because of innovation and quality that UV Graphic endeavors toward simplifying processes within an organization while excelling at achieving high achievements. From equipment to machines based on UV curing or rather on thermal curing systems, realize your modern machines of performance, reliability, and trusted partnership in the manufacturing sector.

#uv curing systems#curing machine manufacturer#rotary hot foil stamping#flexo printing machines manufacturer#gravure printing machines manufacturer#label punching machines manufacturer

0 notes

Text

"Empowering Excellence with Innovation in Flexographic Printing." 🔥

Exciting News from Webtech! 📣

We are thrilled to announce the finalization of yet another significant order—a 10-color Fully Servo Flexographic Printing Machine in 350 mm working width, custom-designed for lamitube substrates, for our esteemed client in Maharashtra. This client stands as a leader in the Indian market for printing lamitube substrates, and it’s an honor for us to collaborate with such a distinguished company.

This project promises to be exceptional, featuring cutting-edge advancements in our latest generation LABELTECH S4 SERIES. We are excited to bring these innovations to life and look forward to sharing more updates on our products and services. ✨

Stay tuned for more exciting news! 📺

#label printing#flexo innovation#flexo printing machine#flexo#packaging labels#webtech#lamitube Printing#10 Colors press#label#rotary Label Printing Machine#Labeltech S4 SERIES#Fully Servo Flexo Press

0 notes

Note

how much machinegun would you need to satanize elementals anyway? Like, single transformation LAM concerns aside...

After some investigation I discovered that "satanize" is on occasion slang for "destroy, wholly obliterate", and so the question after that is how much damage does it take to kill an Elemental.

The search for an answer to this led me to seek out the most powerful weapon which could still technically be labelled as a "machine gun". My answer was found, I believe, in the Bane-7. Each arm has an HAG/40, before the pulse laser and quad ER lasers. If you cannot get your hands on that, you may instead need to resort to the most reliable way of killing an Elemental with machine guns.*

A HAG/40 is not an unkind old woman, but rather a Hyper Assault Gauss, the largest of the grade. You may know Gauss rifles as the weapons which magnetically launch lumps of metal the size of, if I have my numbers right with the listed 30cm diameter, some naval shells; the Hyper Assault Gauss actually slims down the rounds in favor of volume of fire. It could be thought of as "Gauss damage plus rotary AC fire-rate". The HAG/20 and /30 also exist; the /40 is the top of the line.

As with any Clan weapon whose mere description can ruin somebody's entire day just by the mental image stuck in their head, the HAG was, of course, designed by the Hell's Horses.

I really hope their numbering scheme on HAGs is different from autocannons, or else that means this gun fires rapid bursts of slugs in the neighborhood of a 400mm diameter, and even for the Horses, that is a disturbing thought. There will not be a target left after that. You hit somebody with that and their whole Star, sibko, bloodname House, and the last Clan they served in under bond will all feel it.

(*Drop a shipping container filled with them on top of them when they are not expecting it. Nearly 100% success rate, but very awkward to try and pull off, you need a very careful plan.)

32 notes

·

View notes

Text

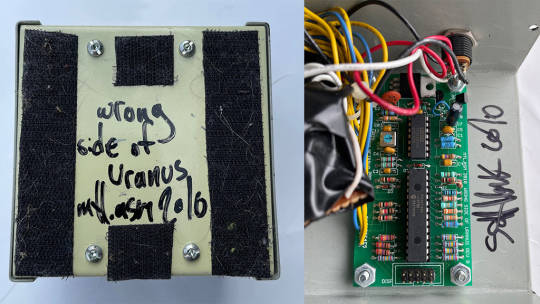

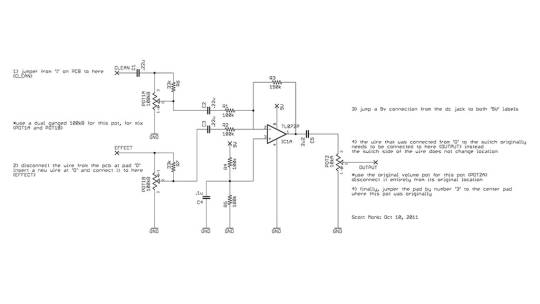

Montreal Assembly - Worng Side Of Uranus

"If you’re a regular Cabinet peruser, you’ve joined me as I waxed nostalgic for time periods I’ve never lived in, you’ve noticed me orating some company and component history, and you’ve almost certainly seen me talk about the best effects in their respective classes. And while there are plenty of classes and there is certainly enough love to go around, today I present you with my favorite pedal of all time: the Montreal Assembly Wrong Side of Uranus.

While many of you know Scott Monk and his amazing company for the Count to 5, he’s been in business for much longer than you think, and he’s made more things than most people know about. I first found out about him in 2009 while chasing wares by one of pedal history’s most sought-after builders, Etienne Blythe of Sonic Crayon.

If you were as into pedals as I was in the late-aughts… well, there’s a chance you still may never have heard of Sonic Crayon. However, at one time, Sonic Crayon’s wares were in extreme demand, with resellers ransacking the limited inventory and flipping the pedals for four times the price. His most famous may have been the Hollow Earth. His most unobtainable may have been the Anti-Nautilus. The one I wanted was the Moth.

The Moth was Sonic Crayon’s bitcrusher, and back in 2008 and 2009, that wasn’t an effect you could get just anywhere. However, Sonic Crayon had an old-school way of doing things: When he felt like making a batch, he did. Then he put 10 or so up for sale on his blog, and by word of mouth they’d sell out in minutes. One time, when checking his blog for a potential drop, I saw a new post where he said that if you’re tired of waiting for a Moth, there’s another Canadian guy making bitcrushers and that his were admittedly better. Who am I to argue? Let’s go.

That company was Montreal Assembly. At that time, Scott had only released two pedals, the Uranus and another insane device called Probability of a Fax Machine. When I heard the crude “basement demos,” I was sold. The problem: the sales tactics were exactly the same as Sonic Crayon—made and sold whenever. I never caught one. But my friend did.

My friend had gone off to college and left a present for me. I took a train and met their dad at a station in the suburbs, retrieved the box and opened it right there on the train. The Uranus was inside. When I got home I plugged everything I could into it. I messaged its creator, Scott, on Gmail Chat and geeked out when he answered.

I asked him if it was possible to add a mix circuit to the Uranus and Scott took time out of studying for signal processing exams to draw me up a somewhat complicated add-on schematic. Being somewhat intermediate with prototyping board, I hadn’t done a whole lot of my own stripboard layouts. Be that as it may, I cobbled it together. It worked. Now, I could blend the clean signal in with the bitcrushed one.

Despite being housed in a spray painted computer project box and featuring a barren aesthetic landscape, the Uranus is an impeccably engineered piece of sonic kit. Like most bitcrushers, there are knobs for bit rate and sample rate reduction. The third is volume. However, the bit rate knob is a pushbutton rotary encoder; as you turn it, it displays the bitrate in the seven-segment display. When the pedal is in bypass, the display flashes “bypass,” one letter at a time. Pressing down on the rotary encoder cycles through a slew of modes—ten to be exact—called things like “Dialup,” “Hostile” and more, including an incredible bitcrushed trem called “Blipo'' and a modulated sample rate mode called “Plunger.” It’s total labor-of-love stuff and I am here for it.

Mine is labeled 2010 and is one of a handful known to exist, and the only one with this mix knob. You may have seen one in a promotional photo that Strymon posted of its El Capistan being used in the studio by Godspeed! You Black Emperor, with the Uranus riding sidesaddle. Many, many people have never heard of it, and some of you may have never heard of Montreal Assembly before now. I urge you to change that.

At NAMM 2020, I actually saw Scott walking by our booth and I recognized him from some old demos. I ran down the aisle and tapped him on the shoulder. He looked right at me, then read my name badge, looked back up and said “Heyyy, Kula, how’s that bitcrusher treating you?” What a legend."

cred: catalinbread.com/blogs/kulas-cabinet/montreal-assembly-wrong-side-of-uranus

22 notes

·

View notes

Text

Loftus Bralette MK2 Go!

So the thing about the bralette pattern was that it was fiddly. There are a few seams where the seam allowance is one millimeter. That's hard to do. I am capable of that but have not the habit of the necessary carefulness. And I know a lot of the fit issues of the muslin-- which I did shorten the straps of, and put on to check the fit, and again then did not want to remove, so while it is not perfect it is currently the best bra I have (I have some decent RTW ones but forgot them at the farm so my need is dire right now). Anyway a lot of the fit issues of that could stem from careless sewing, so. I immediately cut out a second one with no alterations, just being MEGA SUPER ULTRA careful to cut EXACTLY on the lines.

I used a kit I bought from Porcelynne when I bought all the other materials. I'd meant to make a couple practice ones but then, you know, the kit wasn't that expensive and I might as well just. Do it!

It's black heavy-duty powermesh, black nylon cup lining, and pretty red lace, with black picot elastic and other findings, and then the 2" wide band elastic is metallic silver. Which is so cute and I wish I'd been able to buy just lengths of that elastic, but I wasn't able to find any on the site.

Anyway, the pattern is fiddly but not that challenging, and like 90% of the battle is remembering which way each thing goes. So I figure, if I make another one immediately I've a high chance of the best possible outcome. So here's some of that progress. Well, mostly I'm going to talk about equipment and setup.

I cut out all the materials while on a Zoom call with friends-- someone I know started hosting weekly Zooms to "meet up" with friends and work on crafts sometime during the pandemic I think, and I joined in somewhere in that time. That person has since become my sister's roommate so sometimes I go over there and participate in person, LOL. Anyway I set up my computer at the kitchen counter, got out my little cutting mat and rotary cutter, and just spent two full hours very carefully cutting out pieces and this time I labeled them with the tape before I even cut them out.

The red lace won't take a mark from anything but a Sharpie, which won't wash out, so I wasn't able to mark notches. So I just carefully stacked every copy of the pieces on top of the paper pattern piece, and put them into a baggie that way. I was so so so so careful to get the fabric cut right on the cutting lines, because the sewing lines are marked but I can't transfer those marks, and I discovered sewing the muslin that I can't sew on a line like that anyway (and often it was on the wrong side of the fabric for me to see.)

I'm home alone for two or three days, so I've taken over the living areas of the house to work in. This involved setting up a spare sewing machine on the absolutely-not-for-sewing desk that Dude uses to wfh, temporarily. I had forgotten I owned this machine, and it is a more modern one than the ten-stitch mechanical Kenmore that's my primary axe these days. This one is a Singer 6235 from the 80s, one of the most sophisticated mechanical ones they made before computerized machines were introduced; it's not high in resale value because some of the gears are nylon, but this particular individual one has clearly not been used much. It has wildly nonstandard bobbins, but I got a baggie of like twelve of them with it.

[image description: a Singer 6235 sewing machine, made of beige plastic and beige-enameled metal with black control panels, sits on a wooden desktop. In the background is a framed photo of a pink Easter bunny and a girl in a blue shirt, this is me and Dude from 2007. He rented that costume and wore it to a roller derby bout and got his ass grabbed SO much by many many people who absolutely did not suss that he was a dude in there. But the fluffy tail, he says, protected him.]

And when I opened the top, I found every single accessory lovingly stored there, including the package of needles it came with, still all in their package. So.

[Image description: looking down into the top of the sewing machine, which is molded plastic and has a number of esoteric plastic and metal items carefully stowed within custom-shaped cradles, with a letter key on top which is useless without a manual to decode it but good news I found a PDF copy of the manual on Al Gore's Blessed Internet so all is well.]

The single accessory I'm most excited about, however, is the reason I'm telling you all about all of this, which is otherwise not particularly relevant-- you can sew this bra on any machine that can do a zig-zag, and most of it is constructed with straight stitch because it is almost entirely non-stretch, you just need the zig-zags for the elastic attachments. It is:

A SEAM GUIDE. Which i cannot BELIEVE is no longer standard with sewing machines. It's in the above photo at top right, a metal thing with a knob in the middle. It screws into a hole in the machine bed and then you position it to hold your fabric as you sew, to make sure you do not stray over too far.

[Image description: a view through the sewing machine's active area, showing the presser foot down, the needle in some sheer black fabric, and the little metal item in question screwed into place with the metal arm of it pushed all the way over, actually touching the presser foot, holding the fabric at a 1/4" seam allowance.]

Indispensible. Though, I should have switched presser feet, because when the seam guide touches the edge of this presser foot it's actually slightly over 1/4". Just a fraction, so I've let it be because at least it's consistent and it's better than i was doing in the previous version.

so. This machine is needlessly complicated but works pretty darn well so I'm going to keep using it at least until dude gets back from his work trip on friday night.

I'm a bunch of the way through assembling the second bralette, but I think I'll talk about that in its own post, this has descended into sewing machine wittering. Suffice to say, knowing what i'm doing and what to expect means I'm doing a lot better. I'm also doing all the fiddly shit like pressing seams, and let me tell you, ironing synthetics is pointless LOL, so I'm just topstitching everything. I stopped for the day because the bobbin ran out, it was 9pm, and I looked it up and the way you wind the bobbin on this machine is by keeping the whole thing threaded including the needle and just winding it inside the bobbin case, which is So wild I definitely did not want to attempt it at 9pm after a long day. So, tomorrow I will actually talk about sewing this bralette.

But, I did have one more thing to show off-- I actually have purchased an after-market, universally-compatible seam guide that can just magnet itself to the throat plate of any machine, and was fully intending to use it on this project.

[img description: my hand holding a little metal gizmo with some arcane writing on the front; it's a square with a solid longer piece coming off the top, angled down on both sides.] This one came from Madam Sew or something, and comes with a plastic ruler with holes in it, and the idea is you put the ruler down, put your needle down so it goes through the hole marked at the distance you want, put your presser foot down to hold it, and then snap this magnetic guide at the edge of the plastic, and then it's foolproof. The thing is it doesn't work great at 1/4" either because again, that's where the presser foot is. So. I can't find the plastic ruler currently either because I am a disaster. But if your machine doesn't have a seam guide you can buy one of these and then you have a seam guide. I recommend it 100%; learning to sew a straight line is one thing, learning to follow a seam allowance is another, and you can improve your sewing immensely by taking the easy approach to it. You have to remove the guide for things like topstitching or other fiddly things, but for the vast majority of seams, including curved ones, this works a treat, makes it so you basically don't have to think, and just-- well, as long as your cutting-out was precise, you're guaranteed to get an accurate fit if you just use this kind of dealie to be precise about seam allowances.

The free version is that you get a piece of masking tape, put it down on your throat plate, and mark in Sharpie exactly where your seam should go, a big thick bold line as long as you can get it. That helps a ton too. Cashmerette's knit patterns all have 3/8" SAs, which aren't a standard marking on throat plates, and their wovens are all 1/2" instead of 5/8", so that's *also* not a standard marking, so I have long ago put the masking tape on but sometimes I also just use the seam guide because then I don't have to keep paying attention.

18 notes

·

View notes

Text

So one of the standard things you can make with an old rotary phone dial is an audio interruptor — run a signal through the wires that would connect to the hook switch and dial in your temporary tremolo. And since I had my soldering iron out and an empty box of oats, I figured I'd build one.

The dial is just set into the plastic lid, and the cylinder of the box is cut down to a couple of inches high, with two sizes of phone jacks (in parallel) on each side, so I can use this for guitar effects or in Eurorack. (It doesn't really matter which side is input and which is output, so I haven't bothered labeling.)

Of course, this is a nice vintage dial and I didn't want to damage it by cutting the wires; I'd like to be able to restore the phone to its original state if I decide to do so. So I dealt with the forked terminals on the dial in what seemed like the most straightforward way: I soldered the jacks' tip lugs to nuts and tightened machine screws through them to cinch the terminals in place.

3 notes

·

View notes

Text

Designed a telephone network for Omuin (continent of Ubos I'm working on). Lore undercut. (Uxder model)

Missive-Bulletin Networks (or M-B Networks for short) were designed by the Oxevia Empire after the fall of the Gamaian Empire. Nations required a way to communicate quickly through cities that didn't rely on a Hivemind, so magic was infused into wires, able to connect households and other buildings all across the city. These wires would return to a relay station, where a green light flashes to indicate an incoming call so an operator could connect them to their destination using a large switchboard. Each point of origin has its own plug-in, so the plug receiving the connection request is slotted into the correct plug-in, and the message is carried out until one of the callers hangs up. When a hang-up occurs, a red light flashes so the operator can disconnect the call. Callers are required to know the number of the person they're attempting to contact, as plug-ins are labelled by registered numbers rather than names.

If a call is unable to reach its recipient, a message will be left on the recipient's machine. This message can be replayed at any time, as well as deleted, as message boxes can only hold 100 messages at a time.

An additional function exists which allows for mass communication. A mass plug-in is located at the top of all switchboards, which opens broadcasting lines to all members of the M-B Network. This is typically reserved for diplomatic announcements

Repeating messages or recorded broadcasts are also used to convey information such as local news, weather, or other broadcasts. There are many stations callers can tune into as well, which broadcast to frequencies rather than specific plug-ins. Smaller devices, known as radios, can be used to tune into these broadcasting frequencies. These devices are separate from M-B Network communicators (coms or communicators or M-Bs for short), allowing for a call to be made while the radio is playing. Radios have a variety of different programs, such as audio dramas, music stations, news stations and religious stations. Radio stations exist all across the continent, allowing residents to tune into frequencies from other nations or even independent stations. Mass communication announcements will interrupt all broadcasts for their duration.

M-B Network Communicators consist of a receiver in the shape of a hand, which rests on a metal bar on a round M-B box when not in use. M-Bs also have a rotary dial, allowing the caller to dial a known number for another's M-B (an operator will connect the call without needing to be asked). Otherwise, the Caller can dial 000-000-000 to reach the operator, who can connect them to the correct M-B. M-Bs have a speaker underneath the "skin" of the palm and a microphone underneath the "skin" of the thumb-tip. There is also a speaker in the pointer-finger tip for when the M-B rings. M-B receivers can be worn on the side of the head, hands free, allowing the Caller to preform tasks within the range of the M-B's cord. The average cord length is fifteen feet when fully stretched out. When resting, the cord is tightly coiled together, with the majority inside the phone. When the receiver rings, the pointer-finger lifts up to identify the M-B. To put the M-B on speaker, simply turn the receiver around so the speaker is facing outward.

4 notes

·

View notes

Text

and just to illustrate this a little further:

Your Jeans are sewn together by people working with sewing machines. The pieces fabric pieces for your jeans are cut out by a person, often with a saw that can cut through 500 layers of fabric at once, which means they're prone to hurt themselves due to lack of safety standards. The distressing on your Jeans is done by people, often with a dremel (one of those small rotary tools that cosplayers often use to detail foam), or with sandpaper, or with sandblasting. In some cases they use laser technology, but that is expensive, and no middle man buying product for a clothing company wants to pay a cent more than they have to, because those cents go in their own pocket. Yes, even the expensive brand jeans you bought, those are usually made in the same places, they just use slightly different fabrics (like 100% cotton instead of blends) and slap on a label, but the working conditions stay the same.

"crochet can't be made by machines" went from being a cool fun fact to being a call to action of "so if you see mass manufactured crochet in Target, that was made by a person and they were underpaid and you should boycott it" which is true, it was made by a person, but EVERY item of clothing you own (that you did not purchase from a company using ethical labor) was made by a person being underpaid (at *best*.)

Sewing machines are operated by *people*. Knitting machines are operated by *people*. Yes lots of the process is automated but you cannot tell a machine "make me a t-shirt" or "make me a knit cardigan".

Higher awareness of fast fashion, and the true human labor and abuse behind it, is GREAT, but let's not pretend that the crochet hat in target is THE problem. Every article of clothing in target is the problem. "All clothes are made by people" is the jumping off point here into understanding this issue it's not just crochet it's the whole thing ahhhhHHHHHHHHHH

28K notes

·

View notes

Text

Automatic High Speed Ampoule Vial Combo Sticker Labeling Machine

High Speed Ampoule Vial Combo Sticker Labeling Machine or ampoule vial combi labeler is uses to label filled & sealed ampoules. Contemporary ampoule and vial filling calls for high-end machines and our automatic high speed ampoule labeling machine does exactly that. This machine is harnessed to label ampoules and vials of diverse shapes at high speeds. This rotary labeling machine has an exclusive system comprising mechanical and electronic system to apply even transparent or no look labels. It also features a synchronized speed control system. Machine suitable to label ampoule as well as vials, so called combo labeler machine.

If you are looking for a machine that helps you achieve high production targets with no errors and no machine downtime, our high speed ampoule vial labeling machine is the right pick for you. It is capable of labeling up to 600 products in just one minute. It has a unique feeding device that is used for feeding ampoules or vials and labeled ampoules or vials can be collected from the trays. Ampoule feeding and labeling doesn’t require disruption in the operation as the operator doesn’t need to stop the machine for either of these tasks. Besides, no damage is caused to vials and ampoules which is another prime reason; this machine is quite sought after.

For more information about our high speed ampoule vial labeling machine made of stainless steel, feel free to drop us a line. If you are looking for an obligation free quote for automatic high speed ampoule-vial combo sticker labeling machine, we will be more than happy to help you with that as well.

#Ampoule Vial Combo Sticker Labeling Machine#High Speed Ampoule Vial Combo Sticker Labeling Machine#high speed ampoule vial labeling machine#rotary labeling machine

0 notes

Text

What You Need to Know Before Buying a Liquid Filler

The Essential Role of Liquid Filling Machines in the Pharmaceutical Industry

In the pharmaceutical industry, precision, hygiene, and efficiency are not just desired—they are mandatory. Every stage of pharmaceutical production is held to the highest standards to ensure product quality, patient safety, and regulatory compliance. Among these stages, the filling process—particularly for liquid medications—is one of the most critical. This is where Liquid filling machines come into play.

What Are Liquid Filling Machines?

Liquid filling machines are specialized equipment designed to accurately dispense and fill various types of liquid products into containers such as vials, bottles, ampoules, and syringes. These machines are engineered to handle a wide range of viscosities, volumes, and formulations, making them ideal for pharmaceutical applications.

Why Liquid Filling Machines Are Crucial in Pharmaceutical Manufacturing

1. Precision and Accuracy

In pharmaceuticals, even a slight variation in dosage can lead to serious consequences. Liquid filling machines ensure highly accurate and repeatable fills, reducing the risk of underfilling or overfilling. Modern machines use technologies such as servo-driven pistons, peristaltic pumps, and volumetric or gravimetric controls to deliver precise results every time.

2. Enhanced Efficiency

Manual filling is time-consuming and prone to error. Liquid filling machines significantly increase production speed and throughput, making them essential for large-scale pharmaceutical manufacturing. liquid filling machines manufacturer High-speed models can fill hundreds or even thousands of containers per hour, boosting productivity without compromising on quality.

3. Hygiene and Contamination Control

Maintaining sterility is paramount in pharmaceutical production. Liquid filling machines are often built to comply with GMP (Good Manufacturing Practices) and are designed for cleanroom environments. They feature clean-in-place (CIP) and sterilize-in-place (SIP) systems, ensuring that the product remains uncontaminated throughout the process.

4. Versatility and Customization

Pharmaceutical companies manufacture a wide variety of liquid products, from oral syrups to injectables. Liquid filling machines can be customized to handle different container types, fill volumes, and product viscosities. Some advanced systems also integrate capping, labeling, and inspection, providing a complete packaging solution.

5. Regulatory Compliance

Liquid filling systems are designed to meet stringent regulatory standards set by agencies like the FDA, EMA, and WHO. Accurate documentation, batch tracking, and integration with quality management systems ensure that the production process remains transparent and auditable.

Types of Liquid Filling Machines Used in Pharmaceuticals

Volumetric Fillers – Dispense a fixed volume of liquid using pistons or rotary pumps.

Peristaltic Pump Fillers – Ideal for sterile or sensitive liquids; easy to clean and maintain.

Vacuum Fillers – Suited for low-viscosity liquids; often used in bottling.

Time-Pressure Fillers – Use consistent pressure and time intervals to fill containers.

Aseptic Fillers – Specialized machines designed for sterile filling of injectables and biologics.

Key Features to Look for in a Pharmaceutical Liquid Filling Machine

High filling accuracy

Cleanroom compatibility

Ease of cleaning and sterilization

Scalability and modular design

User-friendly interface and automation

Validation and compliance documentation

Future Trends in Liquid Filling Technology

With the growing demand for personalized medicine, biologics, and sterile drug delivery systems, the need for advanced liquid filling solutions is increasing. Future machines will likely feature AI-driven quality checks, IoT integration for real-time monitoring, and greater automation, allowing for smart manufacturing with minimal human intervention.

Conclusion

In pharmaceutical manufacturing, the importance of a reliable and accurate liquid filling machine cannot be overstated. It is the cornerstone of safe, efficient, and compliant production processes for liquid medications. Investing in the right liquid filling system not only enhances operational efficiency but also ensures patient safety and regulatory approval.

As the industry continues to evolve, liquid filling technology will remain a critical component in delivering high-quality pharmaceutical products to the global market.

0 notes

Text

Maximize Your Label Production Efficiency with UV Graphic

Punching machines are used to create high-quality labels and shapes needed in industries such as packaging, retail, and logistics. They cut a variety of materials into perfect labels, ensuring that applications, including branding and product identification, will always have a consistent finish.

UV Graphic is one of the well-known companies in the printing and converting industry. It manufactures state-of-the-art label punching machines. These are designed with advanced technology in them which throws unique precision and speed, making them very well-suited for high-volume production lines. The machines support many materials including paper, film, and metallic foils as per the need of diversified industries.

The Label punching machines from UV Graphic are loaded with automated operation, easy setting, and low maintenance features which ensure the least possible downtime and maximized productivity for businesses. The solutions range from short runs to bigger projects as they cater for all sizes.

With UV Graphic, you are assured of state-of-the-art technology and service. The best quality and innovation are put in to see that the production process runs well in the current competitive market.

#curing machine manufacturer#gravure printing machines manufacturer#uv curing systems#rotary hot foil stamping#Label Punching Machines Manufacturer

0 notes