#Rubber Raw Material Testing Lab

Explore tagged Tumblr posts

Text

Raw Material Testing Lab Mumbai, Pune, Nashik, Chennai, Hyderabad, India

#Plastic Raw Material Testing#Rubber Raw Material Testing Lab#Composite Raw Material Testing Lab#Chemical Raw Material testing Lab#Metallic raw material

0 notes

Text

How Textile Rubber Composite Testing Contributes to Sustainable Manufacturing?

Sustainability has become a critical priority for manufacturers worldwide, and the textile and rubber industries are no exception. As manufacturers strive to reduce environmental impact, textile rubber composite testing plays an essential role in supporting sustainable manufacturing practices. This testing ensures that composite materials not only meet performance and safety standards but also align with eco-friendly goals such as resource efficiency, durability, and recyclability.

In this blog, we explore how textile rubber composite testing helps manufacturers advance sustainability throughout the product lifecycle—from material selection and production to end-of-life management. Understanding the role of testing in sustainable manufacturing is vital for businesses aiming to meet growing regulatory demands and consumer expectations for green products.

What is Textile Rubber Composite Testing?

Textile rubber composites combine textile fabrics and rubber to create materials that are flexible, durable, and versatile. These composites are widely used in automotive parts, protective equipment, footwear, hoses, and industrial applications.

Textile rubber composite testing involves assessing these materials for mechanical strength, adhesion, abrasion resistance, chemical stability, and environmental durability. Testing labs use standardized procedures to ensure composites perform as expected and comply with industry regulations.

The Link Between Textile Rubber Composite Testing and Sustainability

Sustainability in manufacturing means more than just using “green” materials. It encompasses minimizing waste, reducing energy consumption, extending product life, and enabling recycling or reuse. Textile rubber composite testing supports these goals in several critical ways:

1. Ensuring Material Efficiency and Waste Reduction

Testing helps manufacturers optimize the composition and structure of textile rubber composites. By verifying properties such as tensile strength and adhesion, manufacturers can avoid over-engineering products, which reduces excess material use. Optimized composites require fewer raw materials without sacrificing quality, leading to less waste during production.

Moreover, early detection of defects or weak batches through rigorous testing reduces scrap and rework. This directly minimizes material waste and energy consumption in manufacturing processes.

2. Enhancing Durability for Longer Product Lifespans

Durability is a cornerstone of sustainable manufacturing. Textile rubber composite testing assesses resistance to abrasion, tear, heat, and chemical exposure, ensuring that products last longer under real-world conditions.

Longer-lasting products reduce the need for frequent replacement, cutting down raw material demand and waste generation. For example, automotive hoses or protective gloves that pass strict durability tests contribute to sustainability by lowering the carbon footprint associated with manufacturing replacements.

3. Supporting Use of Eco-Friendly Materials

The push towards sustainability has led to innovations such as bio-based rubbers, recycled textile fibers, and environmentally friendly adhesives. Textile rubber composite testing evaluates the performance of these new materials against established standards.

By validating eco-friendly materials’ suitability, testing labs encourage manufacturers to adopt greener alternatives without compromising quality. This accelerates the transition toward sustainable raw materials in composite manufacturing.

4. Facilitating Recycling and Circular Economy Initiatives

Testing plays a role in designing textile rubber composites that are easier to recycle or reuse. Properties like thermal stability and chemical resistance influence how materials behave during recycling processes.

Comprehensive testing helps manufacturers understand how composites break down or can be reprocessed, enabling design choices that support circular economy goals. For instance, composites that maintain integrity through multiple recycling cycles reduce landfill waste and resource depletion.

Key Textile Rubber Composite Tests That Promote Sustainability

Here are some critical tests performed to ensure composites align with sustainability objectives:

- Tensile Strength and Elongation Testing

These tests confirm that composites are strong yet flexible enough for intended applications without excessive material usage. Proper balance improves material efficiency and product longevity.

- Abrasion Resistance Testing

High abrasion resistance means composites wear slower, extending product life and reducing waste from premature failure.

- Adhesion Testing

Strong bonding between textile and rubber layers prevents delamination, reducing product rejects and extending durability.

- Thermal Aging and Chemical Resistance Tests

These evaluate composites’ stability under harsh conditions, ensuring they remain functional longer and can withstand recycling processes.

Industry Standards Supporting Sustainable Textile Rubber Composite Testing

Many global standards emphasize performance criteria that inherently promote sustainability by encouraging durability and quality:

ASTM D412 (Tensile properties of rubber)

ASTM D1171 (Abrasion resistance of rubber)

ISO 13934-1 (Tensile properties of textiles)

ISO 4649 (Abrasion resistance of rubber)

EN 388 (Protective gloves — Mechanical properties)

By adhering to these standards, manufacturers ensure that their products are robust and resource-efficient.

The Environmental Benefits of Reliable Testing

Reliable textile rubber composite testing helps manufacturers:

Reduce Carbon Footprint: Durable, optimized composites require less frequent replacement, lowering emissions linked to production and transport.

Minimize Waste: Early quality control reduces defective batches and scrap materials.

Promote Green Innovation: Validating eco-friendly materials speeds their adoption.

Enable Responsible Recycling: Testing informs design for recyclability and material recovery.

Collectively, these benefits contribute to a greener manufacturing ecosystem.

The Role of Accredited Testing Labs in Sustainable Manufacturing

To fully realize sustainability goals, manufacturers must partner with accredited textile rubber composite testing labs. Such labs:

Follow internationally recognized standards.

Use advanced equipment to simulate real-world conditions.

Provide transparent, accurate reports for compliance and improvement.

Offer expertise in new eco-friendly material testing.

Their insights help manufacturers make informed decisions that balance performance, cost, and environmental impact.

Conclusion

Textile rubber composite testing is more than a quality assurance step — it is a vital enabler of sustainable manufacturing. Through rigorous testing, manufacturers can optimize material use, enhance durability, validate eco-friendly innovations, and design composites for recycling.

As environmental regulations tighten and consumer demand for sustainable products grows, investing in reliable textile rubber composite testing becomes essential for manufacturers committed to green practices. By partnering with expert labs and adhering to global standards, businesses can confidently produce high-quality, sustainable composites that benefit both the planet and their bottom line.

#textile rubber composite testing#textile testing#textile testing lab#testing lab near me#testing lab in delhi

0 notes

Text

What Makes a Great Cogged Belt Manufacturer? A Guide for Industrial Buyers

When it comes to industrial power transmission, cogged belts are a vital component that often operates behind the scenes but plays a central role in ensuring machinery runs efficiently and reliably. Unlike standard V-belts, cogged belts offer improved flexibility, better heat dissipation, and higher power transmission capacity — making them a popular choice in demanding environments.

But not all cogged belts are created equal, and the same goes for their manufacturers. If you're an industrial buyer looking to source durable, high-performance cogged belts, choosing the right manufacturer is crucial. Here’s a guide to what separates great cogged belt manufacturers from the rest.

1. Material Quality and Engineering Precision

A great manufacturer prioritizes the use of high-grade rubber compounds, fiber reinforcements, and advanced manufacturing techniques. The consistency and quality of raw materials determine the belt's resistance to heat, oil, and abrasion — all critical in industrial environments.

What to Look For:

Use of synthetic rubber (like chloroprene or EPDM)

Fiberglass or aramid cord reinforcement

ISO or BIS certifications for raw material quality

2. In-House Testing and Quality Control

Top-tier manufacturers conduct rigorous testing on their cogged belts for tensile strength, elongation, temperature resistance, and dynamic performance. This ensures each batch meets the required performance standards.

Key Indicators:

Presence of a dedicated quality control lab

Testing reports or certificates available upon request

Compliance with international standards like ISO 9001, IS 2494, or DIN 2215

3. Customization and Product Range

The needs of industries vary widely. A great manufacturer offers more than just standard sizes — they provide custom solutions tailored to specific applications, from HVAC to heavy machinery.

What to Ask:

Do they offer custom belt profiles or lengths?

Can they support OEM requirements or private labeling?

Are specialized belts (oil-resistant, anti-static, etc.) part of their catalog?

4. Strong Distribution and After-Sales Support

Cogged belts may be small, but delays in procurement can shut down entire production lines. A reliable manufacturer ensures timely delivery through a strong distribution network and provides technical support when needed.

What Sets Them Apart:

Wide dealer or distributor network, especially in industrial zones

Stock availability and fast turnaround times

Responsive customer service and field support

5. Reputation and Industry Presence

Word of mouth still matters in the industrial sector. Manufacturers who consistently deliver value build strong reputations over time. Ask peers or look for reviews and testimonials.

Signs of a Reputable Manufacturer:

Long-standing presence in the market (10+ years)

Partnerships with major OEMs or MNCs

Exhibitor at industry expos like IMTEX, Auto Expo, or Hannover Messe

Conclusion: Choose Wisely, Perform Better

As an industrial buyer, your choice of cogged belt manufacturer impacts not just component reliability but also equipment uptime and maintenance costs. A great manufacturer is more than just a supplier — they are a technical partner who understands your operational needs and delivers consistent quality.

Whether you’re sourcing belts for a textile plant, a food processing unit, or an automotive assembly line, taking the time to evaluate manufacturers on these five fronts can help ensure long-term value and peace of mind.

0 notes

Text

How to Evaluate Quality Standards When Choosing a China Clay Manufacturer in India

When sourcing raw materials like china clay for industrial or commercial use, quality assurance is paramount. With a multitude of china clay manufacturers in India, it becomes critical for buyers to understand how to differentiate between vendors who merely supply and those who uphold world-class standards. This article outlines a comprehensive framework for evaluating quality standards when choosing the right manufacturer, while also shedding light on china clay properties and the role of a reliable mineral mining company in consistent supply chains.

Understanding China Clay and Its Industrial Significance

China clay, also known as kaolin, is a soft white clay rich in kaolinite. It’s prized for its physical and chemical characteristics that make it suitable for industries such as ceramics, paper, rubber, paints, plastics, and pharmaceuticals. The china clay properties that most influence its quality include:

Brightness and whiteness

Particle size and distribution

Plasticity and viscosity

Moisture content

Impurity levels (e.g., iron, titanium)

These properties must be consistent across batches to ensure quality end-products, making the choice of a manufacturing partner crucial.

Why Quality Standards Matter in China Clay Procurement

In industries like paper and ceramics, even slight deviations in china clay properties can result in defective products, cost overruns, and brand damage. Here’s why adherence to quality standards is non-negotiable:

Operational Consistency: Uniformity in clay composition helps streamline downstream processes.

Regulatory Compliance: Especially in pharma and food packaging, materials must meet safety benchmarks.

Cost Efficiency: Low-grade clay may require additional processing or result in high rejection rates.

Customer Satisfaction: High-quality raw materials result in better product finish and customer experience.

Step-by-Step Guide to Evaluating Quality Standards

1. Verify the Manufacturer’s Certifications

When assessing china clay manufacturers in India, start with their certifications. The most reputable players hold:

ISO 9001 (Quality Management System)

ISO 14001 (Environmental Management System)

OHSAS 18001 (Occupational Health and Safety)

REACH Compliance for export to European markets

These certifications reflect a commitment to quality control, traceability, and environmental responsibility.

2. Review the Source of Raw Material

A trustworthy mineral mining company will either directly own or have long-term access to kaolin deposits. Ask the manufacturer:

Where is your clay sourced from?

Are your mines audited for environmental and labor compliance?

How do you maintain geological consistency?

A direct link between the china clay manufacturers in India and a reputed mineral mining company ensures better oversight and accountability.

3. Inspect Laboratory Testing Facilities

State-of-the-art labs are a strong indicator of quality commitment. Look for capabilities in:

XRF and XRD Analysis: For elemental composition

Sedimentation Tests: To check particle size

Brightness Meter Testing

Moisture Analysis

Microscopic Examination

Reputable manufacturers will not only have these facilities but will also provide Certificate of Analysis (COA) for every batch.

4. Examine Batch-to-Batch Consistency

Batch uniformity is one of the most overlooked aspects. Inquire about:

Process Control Measures during milling, sieving, and drying

Storage Conditions that prevent contamination or degradation

Internal Quality Audits before dispatch

A premium mineral mining company often implements traceability from pit to product, ensuring higher batch consistency.

5. Request for Technical Data Sheets and Samples

Any competent china clay manufacturer in India should provide:

Detailed TDS (Technical Data Sheets)

MSDS (Material Safety Data Sheets)

Free Samples with full lab analysis

These documents allow you to perform your own validations or third-party testing.

6. Evaluate Customization Capabilities

Every industry may require specific grades of china clay with tailored china clay properties. For example:

High plasticity and low shrink-swell ratio for ceramics

Ultra-fine particle size for paint and coatings

Low iron content for paper and pharma

Reliable china clay manufacturers in India should offer product customization based on end-use requirements.

7. Assess Manufacturing Infrastructure

A visit or virtual audit of the manufacturing facility will reveal:

Kiln Types (rotary, flash dryers, etc.)

Automated Handling Systems

Real-time Quality Monitoring Sensors

Dust and Effluent Control Units

These indicators reflect whether the manufacturer is truly committed to producing high-quality china clay.

8. Ask About Supply Chain Reliability

Even the best product is of no use if it doesn’t arrive on time. Check:

Inventory Management Systems

Logistics Partnerships (domestic and export)

Backup Mines or Plants for supply assurance

Some top-tier china clay manufacturers in India function as vertically integrated operations with their own mineral mining company, processing units, and export capabilities.

9. Review Case Studies or Client Testimonials

Look for real-world case studies showcasing:

Industries Served (paint, rubber, pharma, etc.)

Problem Solving Examples (e.g., color consistency issues, impurities, etc.)

Global Reach or OEM partnerships

Social proof goes a long way in narrowing down reliable china clay manufacturers in India.

10. Prioritize Long-Term Partnership Potential

Finally, the relationship should be more than transactional. Ask:

Do you offer volume discounts or annual contracts?

Is there a technical support team available?

Can you co-develop product grades based on feedback?

A manufacturer that values long-term relationships will also consistently uphold their quality standards.

Red Flags to Watch Out For

Here are some warning signs that a manufacturer might not meet the quality standards expected:

Lack of certifications or out-of-date documents

Inability to provide third-party lab reports

Unclear sourcing of raw material

Limited documentation or vague specifications

Refusal to provide samples or references

Steering clear of such suppliers helps mitigate the risk of receiving sub-par material.

Conclusion: Make Quality Your Core Selection Metric

Choosing among the many china clay manufacturers in India is not just about cost—it’s about quality, consistency, and long-term reliability. Whether you’re sourcing for ceramics, pharmaceuticals, or rubber manufacturing, prioritizing high china clay properties ensures your end products perform as intended.

By focusing on technical documentation, certifications, sourcing transparency, and lab testing capabilities, buyers can confidently select a mineral mining company or manufacturing partner that aligns with their operational needs and quality benchmarks.

If your business relies on high-purity, customizable china clay, it pays to do the due diligence upfront—because quality clay is not a commodity, it’s a competitive advantage.

0 notes

Text

What Is Material Testing?

Material testing is the process of checking how strong, safe, and good-quality your raw materials are, whether it’s metal, concrete, plastic, soil, or water. In a growing industrial area like Palakkad, where factories, construction companies, and manufacturers are booming, this testing becomes even more important.

At STS Lab, we support local industries with complete material testing services. We are a trusted material testing lab in Palakkad helping you make better decisions about the materials you use every day.

1. Detect Problems Before They Get Big

A material might look fine to the eye, but it can still fail when used. For example, a metal sheet might rust easily, or a cement sample might not hold the proper weight. Through metal testing lab in Palakkad, you can avoid costly damages and ensure long-term performance.

2. Improve Safety at the Workplace

Regular testing reduces the risk of structural failures, broken machinery, and workplace injuries. Safe materials mean a safer workplace for your team, and that can improve your overall productivity too.

3. Save Money in the Long Run

Many businesses skip testing to save a small amount of money. But when poor-quality materials lead to rework, breakdowns, or recalls, it ends up costing a lot more. Testing materials at a certified testing lab in Palakkad, like STS Lab helps avoid those costly issues.

4. Stay Compliant with Laws and Standards

Authorities like BIS, IS, ISO, and ASTM require you to meet specific standards. Failing to meet them may result in rejected products or legal issues. Our laboratory in Palakkad helps you ensure your materials are tested as per these standards.

5. Gain Customer Trust and Brand Value

If you want to grow your business, earning customer trust is key. Using tested materials proves that your company cares about quality. This builds brand value and helps you stand out from competitors.

Why STS Lab?

STS Lab is one of the leading material testing labs in Palakkad offering:

Metal & tensile testing

Soil and rock testing

Cement and concrete testing

Water quality testing

Rubber & plastic testing

Oil and food testing

We use modern technology, follow international standards, and explain results in a clear, easy way so that even small businesses can understand what to do next.

Let’s Work Together

If you’re an industry leader or just starting out, regular material testing is your best investment in quality, safety, and growth. Connect with STS Lab Testing Lab in Palakkad today and let’s build a better future, one test at a time.

Why should industries in Palakkad invest in regular material testing?

1 note

·

View note

Text

Signifying Nothing (ILM prequel: opening snippet)

.

.

There was an awful stench in the air, a kind of rot that wasn’t easy to recognize. A little like the smell of a dead mouse left for too long under a house, or a discarded deer carcass. It wasn’t either of those things though. It was something much worse. ‘Putrid’ wasn’t a word naturally occurring in anyone’s internal dialogue, but for once it would have been. The smell was overwhelming, and it was coming from everything.

A scuffed black shoe that used to shine with its polish set down on a few small shards of broken glass and the quiet crack made the wearer pause.

The shoes belonged to a man, fairly average in height but with a light build, dark skin, and darker hair that fell into his face. Even stained as it was from hard wear, his white lab coat stood out against the grimy grey and brown walls covered in blood spatter and soot stains and something orange and rotting.

The man stepped further into the room, carefully stepping over the larger chunks of glass and torn metal and rubble that littered the floor. He reached the center of the room and made a slow circle, taking everything in.

Anyone watching would have been able to tell two things at a glance. One, that the man was being cautious and two, that he wasn’t being as cautious as he should have been. He stood out against his surroundings as much as the lab coat did, scanning the walls and leftover carnage more like a tourist at an art gallery than a tattered man in a ransacked laboratory.

Floor to ceiling, the lab around him looked like the aftermath of a horror film. Most of the tables had been flipped, some broken, and writings and beakers and broken glass littered the floor. The room’s one window was busted halfway up and a ragged panel of glass still half-hung in the pane, like a waiting guillotine. Both doors had been torn from the walls. One had fallen into the doorway; the other was in shreds around the room, solid oak torn apart like tissue paper. One small chunk of it still hung from a hinge where it had been broken through, and long, deep scratches ran up it. A large, menacing chandelier hung from its chain in the center of the room weakly, likely to go at any moment. The other lamps were on the ground, and there were still scorch marks around a particularly large one showing where it had caught fire to the research materials around it. Even some of the walls were in pieces, laying rubble around the room amidst tables and test tubes. More noticeable than the state of the room itself was the blood. It was everywhere, reds and browns of various ages flung across the walls and the floor and the implements scattered among the debris, but no bodies. There was an overwhelming smell of corpses, and no corpse.

The man kept walking. He stopped by a pool of ink which had a book floating in it. He knelt, almost reverently, and touched the cover with a finger. There were many things a book could recover from. Soaking in a pile of ink was not one of them.

He stood then, using his forearm to push his hair out of his eyes, and took a small pair of glasses out of his pocked and put them on, blinking as his eyes adjusted to the magnification.

Everything around him was still. A crime scene the day after, a battlefield after even the medics and grave diggers had gone.

The man with glasses took a large messenger bag off of his shoulder and set it on a table. He opened it and rummaged around inside for a few seconds, then froze. Something behind him in the far corner of the room had moved.

Ever so slowly, the man turned to look, eyes unblinking, fixed on where he’d caught movement.

There was nothing.

Very quietly, the man took a syringe out of the bag and readied it like a knife. Slowly, he walked towards the corner of the room. If he’d been careful before, now he was being meticulous. A large broken piece of metal, sharp and jagged on the end that had snapped when it was torn from a lamp and laying a few feet away caught his eye, and he stooped to pick it up.

Still cautious in his approach, the man’s footsteps on the stone floor were the only sound as he got close to the pile of rubble he’d seen movement by, jagged hunk of metal at his side and syringe at the ready in his left hand, and then in one quick, practiced motion the man moved beside the wall to see behind the chunks of stone. He immediately gagged and stumbled back, trying to fight the intense urge to vomit. He failed. The man turned to the side, leaning on a still upright lab table for support and wretched until his body was just dry-heaving. It took him almost twenty seconds to stop. Finally, the man managed to weakly push himself back upright, using one forearm to push his curly hair out of his face, and with his other shaking hand he took a little cloth out of his pocked and used it to wipe his mouth.

It hadn’t just been the sight—he was used to seeing things most people couldn’t begin to imagine. It had been the smell, up close and all at once. It had caught him off guard. Face resigned and exhausted, the bags under his eyes appearing even deeper and his face more gaunt than when he first entered thee room, the man took a breath and went to look at the body again.

Gods have mercy on us all, he thought absently. He didn’t mean it. At this point, that thought was more like a sick joke than anything, but it had become automatic.

The man walked over and knelt down to get a better look at the corpses. He hadn’t even realized at first that there were two of them. The smell that came from the oozing, pussy, decaying mass of mutilated flesh and growths that covered the scarred victims was almost unbearable on a physical level, and he had to keep his forearm over his mouth and nose, trying to filter out some of the smell.

One of the bodies was smaller than him and shrunken. It had cuts all over its still form which oozed an orange substance he was all too familiar with—that disgusting puss secreted by the spirit whose world they were trapped in. He’d seen the nectar before many times. Once every year, when it purged. It was the only genuinely reliable marker that existed to keep track of the passage of time. God, did they use just the raw materials? And so much of it. What is this? It smells like the usual rot, but burned. The thought was a little more olfactorily descriptive than he meant, and his body tried to gag again, but there was nothing left in his stomach to come up. Steeling himself, the man put his syringe in a breast coat pocket, pulled a hard-worn pair of rubber gloves from a back pocket, and pulled them on. From his messenger bag, he took out an empty vial. Leaning over the smaller body, he scraped some of the puss from one of its arms and closed it in his little glass jar, inspecting the sample carefully before placing it in his sack. He shifted then, and used the blunt end of his broken piece of metal to poke at the figure a little, moving one of the arms which covered its chest to get a better look at its torso. Absently, his free hand reached into a pocket and took out a clunky old pocket recorder, marked simply by the initial “C” and hit record.

“Multiple injection marks,” he said to the recorder, eyes fixed on the corpse as he tried to get a better angle on it, “all up and down the ribcage, as if whoever did this was attempting to get it into the bone marrow itself. The subject is young—thirties at the oldest. I don’t recognize the body.”

Gentle as he was going, his metal rod accidentally took off a chunk of flesh the size of a napkin, peeling back and sloughing off the side to reveal mucus and bone and clotted blood, thick with orange lumps. The man gagged again and took a deep breath to steel himself.

“The smell is worse than normal,” he continued, clearing his throat to try and bite back the urge to gag, “Could be due to the natural composition of the body, combined with heavy injections. Decay level of the tissue is low, maybe a week at most, but the chemicals seem to have altered body chemistry heavily, greatly lowering the integrity of the skin. That, or it’s been here a long time and the serum did the opposite,” he added as an afterthought. “Unlikely, though.”

He moved a little, crouch-walking to save time, and leaned over the body again at a new angle. “There are skin lacerations around the subject’s wrists and neck. Not deep, but pre-mort…” Shackles, he realized, glancing instinctively to look for the objects. Had it broken free and been killed? There was no wound he had seen that would have caused death, but he’d only just started. As he looked down, he realized that one of the ankles was still cuffed to a heavy chain embedded in the wall. “It was shackles,” he continued, remembering the recorder, “one is still connecting the subject to the wall. The others seem to have been removed.” He clicked the recorder off, then after a second held the record button down again. “Something has completely trashed my lab, but left the bodies. No recent signs of a presence here either. Everything is at least half a week old, going by blood. Maybe five days. But before that, somebody got very, very busy with my research notes.” He released the button.

I wasn’t gone from the lab that long was I? A few months? What the hell happened here? The man looked at the small, shriveled corpse beneath his feet. Female. About my age, weren’t you? Who were you before this? How long did it take for them to kill you?

He had only given the larger figure a casual glance so far. It was slumped against the wall, half-sitting. He turned his attention to it now, clicking the recorder back on.

“The second body I’ve found is larger and more deformed. There are no puss sacs or growths like seem to have killed the first subject, but the chemical seems to have been altered on this one to include organic compounds from the area. There are sharp vines coming out of its shoulders and arms, covering its head, with large growths above its skull. It looks almost like a stag.” The man clicked the recorder off again and got closer, looking the body in front of him up and down. It was like a tree had overgrown a person, seeping into their body, symbiosis. There were little dark slits on the thing’s head where eyes would have been, and horns made of rotting wood rested above its expressionless face. A huge chunk was missing from its chest, leaving what was left of its ribcage bare and exposing the remaining organs inside. He raised the recorder again and continued his analysis. “Exposed chest wound, including major bone damage to the ribcage which leaves the heart partially exposed. Possibly—”

Again, the man had the impression that something had moved, and he froze. –There it was again!

He squinted, leaning in closer to the figure in front of them. It had come from inside the thing’s chest. Insects, rats? Why the hell—there aren’t naturally occurring animals here, so why would a…

His eyes were only a few inches from the corpse’s chest when he saw it for real, as clear as the vines digging into the thing’s lungs. The exposed heart beat.

In an explosion of movement, the monster’s arm swung out and caught him in the chest, throwing him backwards into the pile of rubble behind him with enough force to knock the breath out of him.

He didn’t even have time to connect the pain in the back of his shoulder and down his arm with the blood dripping onto his fingers before it was on him, lunging for his throat, and the man scrambled backwards, toppling over the pile of rubble blindly as the thing crawled after him, roaring like a beast.

“Oh fucking shit!” the man yelled, his brain’s first attempt to give him a rational response or solution to the situation. He crawled backwards, trying to move faster than the thing was crawling towards him, which was physically impossible. It lunged at him and he rolled out of the way, leaving a smear of blood as he crawled beneath a table and came up stumbling to his feet on the opposite side of it.

In the half-second of safety the metal table offered he got a good look at the monster in its entirety. Horns included, the thing towered over him by a good two feet, head tilted and gold-orange puss dripping from its cuts and wounds and mouth and eyes. If you could call them eyes—they were something anyway, a flickering white-blue light coming from where there had been nothing but darks slits on its face for eyes before, and the lights stayed trained on him as it moved impossibly fast and flung the metal table between them across the room in one swift motion. He could hear the table crashing into a wall as the beast leapt for him, its arm catching hold of his hair and taking a handful as the man tore himself free and threw himself to the ground underneath its arms and past its legs, twisting as he hit the ground, snatching at the syringe in his breast coat pocket and digging its needle into the popliteal artery at the back of the monster’s knee, driving his thumb against the plunger, and emptying the container of pentobarbital into the monster’s leg. It spun with him, just as fast, and swung at him again, its hand catching him in the cheek and sending him skidding along the floor backwards into the same pile of rubble he’d been bashed against before.

Without hesitation, the horned beast came at him with a fury, but it stumbled, and the man rolled out of the way and watched it crash into the rocks it had knocked him against moments before. It shook its head like it was trying to clear it and took another step towards him, and then a much slower, more shaky step, and began to sway. It tried to grab a nearby gurney for support and it fell, taking the stretcher with it as it collapsed onto its side

The man sat were he’d rolled, breathing hard, arms still poised to help him crawl backwards quickly if he had to, eyes fixed on the monster in front of him.

It twitched and made an agonized sound and tried to pull itself back up and failed, and tried again, and again its shoulders gave out. It turned its head towards him and he saw a shudder run down its whole body, and the lights beneath the slits on its face flickering. The golden-orange liquid drained from it more slowly now, as the beast excruciatingly dug its fingers into the stone floor and tried to crawl towards the fallen gurney.

The man got to his feet shakily and blinked in surprise at the blood dripping down his arm. Choosing to ignore the wound for now in favor of more present danger, though, he turned his attention back to the creature on the floor and realized for the first time that this second test subject had been shackled too—was still shackled. Its left leg was connected to the wall by a long tether which had almost reached its length. As he watched, the beast dragged itself over to the fallen stretcher and tried again and again to pull itself up from its prone position. With each attempt he could see it getting weaker as the drug took hold.

Noticing his piece of torn lamp pole from before laying by the rock heap where he’d lost it when he took the first hit, the man in the lab coat walked over and reclaimed his weapon, then crossed purposefully to the creature on the floor.

As he neared it, he could see from the slow, ragged rise and fall of its chest and the slow flickering on and off of the lights that seemed to be its eyes that it was fighting to stay awake. As he got close to it, it swung a hand weakly at him twice before its strength gave out and the arm dropped to the ground.

After waiting a few seconds to make sure the drug had worked its way deep enough into the thing’s system, the man knelt by the monster and leveled his piece of metal. He saw it move its shoulder, trying to will an arm up to defend itself from him, but the drug had set in in earnest now and it had seconds before it was dead to the world completely. He looked from its throat to its exposed heart, trying to decide how to deal with the thing. After a second, he decided on the heart and the man placed one hand on its chest to steady his aim, and then he raised his jagged piece of metal over its exposed heart and it made a sound almost like a whimper.

He hesitated then, looking down at the thing beneath him. The lights behind the slits of its wooden face were fading out, but its chest still rose and fell. He knew it was looking at him as it lost consciousness, and he felt it shudder under the hand he had on its chest. Its breath was coming in quick and shallow, even with the sedative seeping through its veins, and he realized suddenly that it was scared of him and scared to die.

The lights behind its eye slits went out and the creature’s head lulled to the side as it lost consciousness and the man raised his makeshift weapon again. Then he stopped.

Instead, he moved his hand to the thing’s face and felt the rough wooden surface. There was a crack over the left side, which spiderwebbed out from near its ear. Gingerly, the man followed the crack down the monster’s cheekbone to a place where a small chunk about the size of a fingernail had broken off the wood. He let his fingertip rest on the spot, and felt the sticky-warm of fresh blood, and the rough-soft of damaged human skin beneath the wood.

He let the chunk of metal fall from his hand then and collapsed back onto the floor and sat there, staring at the thing in front of him. Out of the corner of his eye the bright red button on his tape recorder caught his eye. It had landed by an overturned table about fifteen feet away, miraculously intact. For some reason the sight reassured him, and the adrenaline drained from his system as he calmed down and it left him exhausted. He brushed his hair out of his eyes and took a deep breath, thinking hard.

After a second, he pulled himself unsteadily to his feet, crossed to the recorder and slumped to the ground beside it, leaning his back leaning against the pile of rubble like it was an easy chair. He picked the dented machine up and pressed record.

“Okay. Well. The big one wasn’t dead. It attacked me, but I was able to inject it with a high dose of pentobarbital. Nice to know some things still work on creatures under effects of the serum,” he said, then released the record button to take a shaky breath, eyes on the unconscious monster about ten feet away. He hit record again. “Unsure how to proceed now. I have to do something fast. It’s still breathing, and I don’t think the OD is going to kill it,” he paused, watching the thing’s heart beating weakly in its open chest cavity. “But uh,” he continued half-automatically after a second, “I think it might be salvageable. Yeah. Yeah, I might have to see what I can do. It, uh…” He ran his fingers through the curly hair that hung in his face. “When it couldn’t defend itself anymore, that thing looked…it acted an awful lot like a regular human being. It, uh…” He looked at the thing’s slumped form. It seemed so much less tall now, less imposing. The yellowed ichor that had been pumped into its veins was slowly dripping from where its ears should have been, leaking down its collarbone and seeping past vines into its chest. “Yeah, I might have to see what I can find out.”

The man released the button and set down the recorder, then he slowly slid the rest of the way down the rock until he was laying on his back on the ground. He put his hands over his face and groaned. “Fuuuuck.”

#In Living Memory#In Living Memory (fic)#as promised! Here is the opening scene to Signifying Nothing. Hope you enjoy it and a look at my boy#writing#dead by daylight#Vigo#dbd Vigo#This takes place not too long after OG Hallowed Blight event#but that's all I'm gonna say ; )#hope you enjoy

21 notes

·

View notes

Text

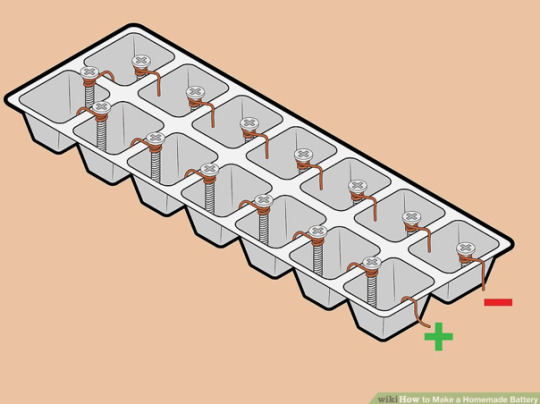

OEM Bussiness

OEM Bussiness

Tianning provides customized home decor service. Our OEM work start from materials and than finishes, crafts, texture, all of the perception views, and finally reach to the certain design language or style base on our product.

1. Customer inquiry and select the samples to/from Tianning.

2. Agreements on Sales Contract and Agreement.

3. Client’s order forwarding to Engineering & Production Dept.

4. Production Dept produce sample with required specifications.

5. Clients confirm the specifications of sample products.

6. Tianning prepare BOM order and mass production.

7. Client nominate third-party to do Interim inspection & Lab Test.

8. Final sample test and arrange delivery.

Pine Wood

Pinewood is an inexpensive lightweight and widely available type. Pine has very good structural strength and featured with yellowish, whitish tune, brown knot texture and would be perfect for interior design and decorating, pinewood brings a unique aroma into homes and create warm and cozy rooms.

Oak Wood

Oak wood is a highly durable wood type that is used widely in furniture and flooring. Even though there are more than 60 varieties of oak types worldwide, the most common choices are white and red oak. White oak has light beige to brown hues while red oak tends to be pinkish and reddish. The prominent ring of oak gives a coarse texture.

Beech Wood

Beechwood is a mainstay and widely-used hardwood which is typically in creamy yellow and yellowish-brown hues. As shown in the picture, the straight grain varies from fine to medium texture. Mainly used for veneer, flooring furniture, cabinetry, instruments, plywood, etc.

Rubber Wood

Rubberwood is regarded as one of the finest furniture-making hardwood. It’s a moisture absorbent that can only be kept in a less humid environment. Rubberwood is mostly seen as a light blonde tint and would likely turn darker after being exposed to the light. The advantage of rubberwood compare to other natural wood is its durability. The shrinkage and cracking of rubberwood are minimum after years of usage.

Poplar Wood

Poplar wood has white/ivory color tone with green or brown streaks. It’s a very popular material for making the frame of the furniture. The common use for poplar also includes wood pallets, storage, and shipping crates because of their good strength and durability.

MDF

MDF is engineered wood made up of small wood fibers. It’s an inexpensive and fairly durable material compared to natural wood. The most common reason to choose MDF as furniture components is the easily painting because of the smooth surface.

Back to the design perspective, wood finishes are compatible with any kind of interior style. Walnut and oak tunes fit naturally in both country manor and modern apartments. Reclaimed wood and bleached pine work fine for Scandinavian decor, urban loft, townhouse, etc. The codes for this type of aesthetic are mixture and contrast, raw timber mixed with rugged metal, pale wood furniture in contrast with contemporary architectural bones, antique furniture meet with a new pieces that is how to design style comes out.

https://www.tianningwood.com/chinese-home-decor-items-oem-business/

1 note

·

View note

Text

How COVID-19 Impacted on Material Testing in Chemicals & Materials Industry ?

COVID-19 Impact on Material Testing in Chemicals and Materials Industry

Materials testing are the study of the properties and Behaviour of materials such as metals, ceramics, and polymers under a variety of situations. The information gained can be used to specify material appropriateness for a variety of applications, such as building or aircraft construction, machinery, or packaging. It is possible to test a full-scale or small-scale model of a proposed machine or structure.

Categories for Materials testing:-

· Mechanical Testing;

· Testing for Thermal Properties

· Testing for Electrical Properties

· Testing for Resistance to Corrosion, Radiation, and Biological Deterioration

· Nondestructive Testing

Materials testing are a well-known and well-respected technique for determining the physical and mechanical properties of raw materials and components. It may be used to analyse a wide range of materials, including human hair, steel, ceramics, and composites.

Materials testing machines are perfect for use in manufacturing, quality control, education, research, and laboratories. These devices can be employed in a wide range of applications on account of their vast testing capabilities.

Chemical analysis for medical components provides you with the assurance that your components are proper, clean, and safe for use by the general public. Metals, plastics, polymers, powdered metals, ores, ferroalloys, composites, and ceramics are among the materials we test. FT-IR surface analysis is a useful method for ensuring that your medical devices and packaging components are free of contaminants.

Before being released for public use or sale, any pharmaceutical product or medical device must be approved by the State FDA and the Central Drugs Standards Control Organization (CDSCO).Material analysis, DSC analysis, chemical tests, physical characterization, NMR testing, FTIR testing, and other tests can be performed by testing laboratories, all in accordance with the standards and in a safe manner.

Traditionally, raw material testing and reports have been performed by chemical testing laboratories to verify their quality and appropriateness for use in pharmaceutical drug formulations. They have the necessary equipment to carry out the complex operations required for raw material testing.

Effective materials testing is critical whether you need to validate material attributes for application trials, find faults, evaluate failures, improve novel materials, or conduct basic research on the theoretical strength of materials

Materials testing Applications:-

· Electronics

· Automotive

· Paper and Board

· Medical

· Building Materials

· Metals

· Plastics

· Textiles

· Rubber

· Packaging

· Pharmaceuticals

· Wood

COVID-19 IMPACT ON MATERIALS TESTING IN CHEMICALS AND MATERIALS INDUSTRY

Material Testing is commonly used by mask manufacturers and other producers of Personal Protective Equipment to undertake physical strength tests to evaluate material and functionality performance. Masks are made of paper or other non-woven materials and are tension tested until they tear. The ear-loop straps' attachment to the mask is tested to ensure that it is sturdy enough to endure repeated use without breaking. Peel-testing is done on sterile packaging to ensure that it may be opened easily while still maintaining its protective barrier properties. Physical strength testing is also performed on disposable face masks used with manual and automatic resuscitators and ventilators. The torque required to match effectively with connectors is measured by testing the check valves that limit airflow.

IMPACT OF COVID-19 ON SUPPLY CHAIN

The supply chain has an effect on not only manufacturers, distributors, and customers, but also impact on lab testing .Production of various plants was decreased, stopped, or temporarily halted as a result of workers who were found to be COVID-19 positive. Covid-19 has impacted the supply chain the most as due to the lock down in the several countries the import and export activities became difficult and also the demand has reduced which has impacted the materials testing market. Several plant implementations have gone on hold and also transportation of the materials testing from one nation to another is very difficult due to such a situation.

CONCLUSION

The upcoming few months and years does not look much fruitful for the businesses in the construction industry. The impact of COVID-19 will affect all players. Material testing provides job to millions of people in many countries. Thus the development of employment will depend on for the speed of recovery and the duration of crises. To avoid any mass layoffs, most of the firms are now looking for short-work schemes.

Today the spread of the novel coronavirus has triggered significant market damage across the world. Most businesses have stopped immediately and the effect of the pandemic on all industries such as Electronics, Automotive, Paper and Board, Medical, Building Materials, Metals, Plastics and among others is not yet clear. The towns are closed down, and social distancing has become a modern norm.

Government along with the private sector can play a vital role in reviving the sector. The government is attending the large financing needs arising from COVID-19, the private sector can take care of large investments and expertise required in developing countries. Apart from this, strong engagement with governments and local stakeholders will continue to contribute significantly to the development of the sector.

Several manufactures closed the factory due to heavy losses. Companies are making the strategic action to increase the demand of the testing materials in the market and to increase their revenue. Government has also introduced many polices and initiatives which would help manufactures to maintain stable growth in current dynamic situation.

#Material Testing Market Size +#Material Testing Market by Type#Material Testing Market Future Innovation

0 notes

Link

#plastic raw material testing#rubber raw material testing lab#composite raw material testing lab#chemical raw material testing lab#metallic raw material#mechanical testing

0 notes

Text

How Textile Rubber Composite Testing Supports Quality Control in Manufacturing?

In modern manufacturing, quality control is a critical component that ensures products meet stringent performance, safety, and durability standards. When it comes to textile rubber composites—a unique combination of textile fibers and rubber compounds used across industries such as automotive, aerospace, construction, and consumer goods—robust quality control is essential to guarantee reliability and customer satisfaction.

This is where textile rubber composite testing comes into play. Testing these composites helps manufacturers maintain high-quality standards, optimize production processes, and ensure that end products meet regulatory and market demands. In this blog, we’ll explore how textile rubber composite testing supports quality control in manufacturing, its key benefits, and the most relevant testing methods used by labs worldwide.

Understanding Textile Rubber Composites in Manufacturing

Textile rubber composites combine the structural strength and stability of textiles with the flexibility, elasticity, and chemical resistance of rubber. This hybrid material is used in applications such as conveyor belts, automotive components, protective gear, hoses, seals, and vibration dampers.

Due to the complex nature of these composites, ensuring consistent quality is challenging. Variations in raw materials, production conditions, and bonding processes can affect the final product’s mechanical properties, durability, and safety. Hence, rigorous quality control through testing is mandatory to uphold manufacturing excellence.

Why Quality Control Matters in Textile Rubber Composite Manufacturing

Quality control in textile rubber composite manufacturing impacts several critical areas:

Product Performance: High-quality composites withstand mechanical stresses, environmental exposure, and chemical contact without failing. Poor quality can lead to premature wear, safety hazards, or operational inefficiencies.

Regulatory Compliance: Many industries require products to meet international standards and certifications. Testing validates compliance, avoiding costly recalls or legal penalties.

Customer Satisfaction: Reliable, durable products build brand reputation and foster customer trust.

Cost Efficiency: Early detection of defects through testing reduces waste, rework, and warranty claims, saving money in the long term.

How Textile Rubber Composite Testing Supports Quality Control

1. Verification of Raw Material Quality

Testing starts at the raw material stage. Textile fabrics and rubber compounds are examined for consistency, purity, and performance attributes. For example, textile fiber tensile strength and rubber compound hardness are tested to ensure materials meet required specifications before production.

2. Process Monitoring and Optimization

During manufacturing, testing samples from production batches helps monitor key parameters such as:

Bond Strength: Ensures the adhesion between textile and rubber layers is strong enough to withstand operational stresses. Poor bonding can cause delamination and product failure.

Thickness and Weight Consistency: Uniform thickness and weight guarantee consistent performance and prevent weak spots.

Physical Properties: Regular tensile strength, elongation, tear resistance, and abrasion resistance tests help monitor whether the manufacturing process produces composites with expected mechanical properties.

Identifying deviations early enables manufacturers to adjust processing parameters such as temperature, pressure, and curing time, enhancing overall product consistency.

3. Performance Testing Under Simulated Conditions

Textile rubber composites often operate in harsh environments. Testing simulates conditions such as:

Thermal Aging: To verify the material’s resistance to heat over time, important for automotive or industrial applications.

Ozone and UV Exposure: Ensures composites resist cracking or degradation when exposed to ozone or sunlight.

Chemical Resistance: Testing exposure to oils, solvents, and chemicals confirms that the composite maintains integrity in contact with harsh substances.

These tests guarantee that the composite will maintain its properties throughout its service life.

4. Final Product Inspection and Certification

Before shipment, manufacturers perform comprehensive testing on finished products to verify compliance with client specifications and industry standards such as ISO and ASTM.

Certified testing labs often provide:

Detailed Test Reports: Documenting results for tensile strength, tear resistance, abrasion resistance, chemical resistance, and more.

Certifications: Demonstrating conformity to international standards like ISO 4649 (abrasion resistance) or ASTM D412 (tensile properties).

These documents support quality assurance processes and provide customers with confidence in the product’s reliability.

Key Testing Methods for Textile Rubber Composite Quality Control

Here are some of the essential tests performed on textile rubber composites to support quality control:

Tensile Strength and Elongation Testing: Measures the maximum load a composite can bear before breaking and its ability to stretch without failure.

Tear Resistance Testing: Determines how well the composite resists propagation of tears and cuts.

Abrasion Resistance Testing: Simulates wear caused by friction, predicting product lifespan in abrasive environments.

Bond Strength Testing: Assesses the adhesion between textile and rubber layers using peel tests or shear strength measurements.

Hardness Testing: Measures the rubber compound’s resistance to indentation, impacting flexibility and durability.

Thermal Aging Tests: Samples are exposed to elevated temperatures to evaluate changes in mechanical properties over time.

Chemical Resistance Tests: Evaluate the composite’s stability and integrity after exposure to oils, solvents, acids, or alkalis.

Ozone and UV Resistance Testing: Simulates exposure to environmental factors that cause cracking and degradation.

Benefits of Partnering with Accredited Testing Labs

Manufacturers benefit immensely by partnering with accredited textile rubber composite testing labs that:

Use internationally recognized standards ensuring accurate and repeatable results.

Possess state-of-the-art testing equipment and expert technicians.

Provide quick turnaround times to avoid production delays.

Offer consulting on improving product design and manufacturing processes.

Help in obtaining necessary certifications for local and international market access.

Real-World Applications of Textile Rubber Composite Testing in Quality Control

Automotive Industry: Conveyor belts, gaskets, and vibration dampers made from textile rubber composites must meet strict mechanical and environmental resistance standards. Testing ensures safety and performance in vehicles.

Industrial Manufacturing: Conveyor belts and hoses used in factories undergo regular testing to withstand abrasion, chemical exposure, and mechanical loads, preventing costly downtime.

Protective Equipment: Gloves and safety gear with textile rubber composites are tested for tear resistance and chemical protection to safeguard workers.

Consumer Goods: Footwear and sports equipment manufacturers test composites to ensure comfort, durability, and safety.

Conclusion

Quality control in manufacturing is vital to delivering reliable, durable, and safe textile rubber composite products. Textile rubber composite testing plays a pivotal role in this process by verifying raw materials, monitoring production quality, simulating real-world conditions, and certifying finished goods. By adhering to standardized testing protocols and partnering with accredited labs, manufacturers can optimize their processes, reduce risks, comply with regulations, and ultimately meet or exceed customer expectations.

#textile rubber composite testing#textile testing#textile testing lab#testing lab near me#testing lab in delhi

0 notes

Text

Effect of Operational Conditions on Performance of Deep Sand Filter in Turbidity Removal

Abstract

In this study, laboratory pilot plant was constructed to study the performance of deep sand filter in water treatment. Sand was used as a filtration media under different filtration rates ranged from 4 m/hr to 8 m/hr. Down flow was applied to the filter through sand media with size of 0.7-1.0 mm, while sand depth was changed from 80 cm to 140 cm. The used synthetic turbid water was prepared in different turbidity levels varying from 10 to 30 NTU. Aluminum sulfate (alum) was used as coagulant in different doses varied from 20 to 40 mg/l. Turbidity removal and head loss were investigated as functions of sand depth, filtration rate, alum dose and influent turbidity. From analysis of the experimental results, it was found that the changing of operational conditions (changing media depth, filtration rate, alum dose and influent turbidity) have significant impact on the turbidity removal efficiency, head loss and ripening period. Also, the effective depth of media is influenced by operational conditions and its value was obtained in this paper.

Keywords: Deep sand filter; Effective depth; Filtration rate; Head loss; Turbidity removal

Introduction

With an exponentially increasing of population, better and more economical water treatment methods and strategies have become the need of the hour. One such sustainable water treatment method is using deep bed filters which has great potential for treating of contaminants in drinking water [1-3].

Deep bed filtration is an effective process in removing particles from water. This is achieved by passing the suspension through a deep layer (usually between 0.5 m and 2.0 m depth) of granular material, typically sand. The suspension particles are retained within the depth of the filter media. This removal may be achieved by different mechanisms [4-6].

In filtration process, there are different stages, ripening, working, and breakthrough stage [7]. The removal efficiency during ripening stage increases, while this efficiency is nearly constant during working stage. Then the removal starts to deteriorate in breakthrough stage [8]. During ripening period, the effluent turbidity is relatively high. It takes some minutes to be allowable [9]. The effluent water during this period is mostly wasted thus this period has significant effect on the quantity of water. This period has been studied in many researches [10-13], but the effect of different operational conditions on this period was not clear. So, this paper will study that effect.

Numerous empirical equations, which are used to predict initial filter head loss, have been developed. Some commonly used equations are Carmen-Kozeny, Ergun, Fair-Hatch, Hazen, Rose, and Gregory equations [14,15]. These equations may be unacceptable for specific types of media such as crumb rubber. it was found that Both the Kozeny and Ergun equations were unacceptable for clean-bed head loss prediction in crumb rubber filters [16]. A neuro-fuzzy model was conducted to estimate head loss in dirty sand filters. Hydraulic loading rate, influent iron concentration, bed porosity, and operating time were selected as input variables [17].

Many researchers studied the deep bed filter and its performance. One of these studies showed that the removal efficiency during the ripening stage of filtration can be improved significantly by increasing the ionic strength of the water to be treated [18]. In addition, the structure of porous media (i.e., pore size distribution) has a clear effect on deep bed filter performance [19]. Moreover, impact of backwash procedures on deep bed filtration productivity in drinking water was presented [20]. From modeling point of view, many models were introduced to explain the efficiency and performance of deep bed filters, [21-25].

Through deep bed filters, not all used media depth is effective in turbidity removal but there is an effective depth which give the required or permissible limit. The effective depth for media from burned oil palm shell granular has been obtained [26]. Moreover, knowing the effective depth of turbidity removal will assist in identifying depth of the sand during filter design.

Using granular sand filters has a limitation of influent quality. When it used with drastic influent quality with small depth it don’t give the required quality. Therefore, another technique is required such as using deeper filter. The main objectives of this study is to investigate the effect of operational conditions on the performance of deep sand filter and to determine the effective depth for turbidity removal.

Materials and Methods

For this study, a Laboratory pilot plant was designed and constructed in the laboratory of sanitary engineering in the faculty of engineering – El- Mansoura University, Egypt. Figure 1 shows the schematic diagram of the laboratory pilot plant.

Experimental set up description

It consisted of the following main parts: -

a. Feeding tanks: The synthetic turbid (raw) water was prepared in four plastic feeding tanks. The four tanks divided into two groups each group consist of two tanks. The capacity of each tank was about 250 liters.

b. Feeding pump: The synthetic turbid water was transported from feeding tanks to a constant head tank by feeding pump. The horsepower of pump were 0.45 HP (Discharge 0.45 m3/hr).

c. Constant head tank: The raw water has been fed from the feeding tanks to the sand filter via a constant head tank. The capacity of constant head tank was 45 liters and has dimensions of 30 * 30 * 50 cm. Constant head tank has confirmed a constant discharge to the plant whatever the difference in water levels before and after it.

d. Filtration column: The major part of the laboratory pilot plant was the filtration column. The filtration column was made from galvanized steel with height 2.5 meters. The column consists of two parts each part 1.25 m height and it has square cross section (20 *20 cm). The filtration column has one glass face to allow monitoring what is inside the column. Along the filtration column several connection points were fixed each 20 cm as samples ports.

e. Backwash Pumps: Two pumps were used for backwashing. The horsepower of each pump were 0.45 HP (Discharge of each pump 0.45 m3/hr).

f. Piezometers: Manometer tubes installed behind filtration column to determine the head loss through the filtration media depth at different times.

g. Fittings and Plastic connecting pipes: There were different service connections such as elbow, tee, reducer and connecting pipes with different diameters due to its location and use.

Filter media

In this study, the filtration media was uniform sand media rested on the gravel layer. The sand depth in the filtration column was changed from 80cm to 140cm with size of 0.7- 1.0mm and its porosity was 0.38. The dry density of the sand was 1.65 gm/cm3 and its specific gravity was 2.55. The gravel depth under the sand was about 20cm with different sizes ranged from 2.0mm to 9.0mm. The gravel layer is located immediately below the filter sand media to separate the filter media from the underdrain system, to prevent media particles from clogging the underdrain orifice, and to dissipate the backwash water jets from the orifice of the underdrain system [27,28].

Synthetic raw water

By using fine clay soil and tap water it was able to achieve the synthetic raw water which can be used in the experimental work. The raw water was prepared by dispersing fine clay, having a size less than 0.074mm, in tap water. In this research, the synthetic raw water turbidity was ranged up to 30 NTU which is a suitable range in the River Nile and its branches in Egypt.

Laboratory pilot plant operation

This study has been extended to cover the various operation conditions for the sand bed filter. In present research, different positions for Aluminum sulfate (alum) feeding were tested as a coagulation process. it was found that feeding alum dose in feeding tanks gives high filtration efficiency with doses varied from 20 to 40mg/l. The operation of the laboratory pilot plant was controlled by 12 valves (shown in Figure 1). These valves facilitate two modes of filter operation (down flow filtration mode and filter backwash mode).

a. Filtration mode: The experimental runs were conducted under the conditions of a direct constant filtration rate. The operated filtration rate was changed from 4m/hr to 8m/hr (suitable for rapid sand filter). The effluent turbidity was measured at different depths each 1 minute for the first 30 minutes (to assess the ripening period) then it was measured each one hour throughout the remaining part of the run. The turbidity of influent and effluent water was measured by using turbidimeter in Nephelometric Turbidity Unit (NTU). Its model is Orbeco TB300-IR Lab Turbidimeter. In addition, the head loss through sand media was measured by Piezometers each one hour. The effluent turbidity measurements at different depths will help in determining of effective sand depth and developing of simplified model for filter efficiency.

b. Backwash mode: The end of filtration run was considered when effluent turbidity started to increase (turbidity breakthrough) or head loss reaches the maximum value or the run length reaches defined period (in this research, one day). Once either of this condition was reached, the filter run was terminated and the filter needs to backwash mode to remove the accumulated solids inside its bed [29,15]. Water only with high rate (50m/hr) was used as a backwash method [30]. The backwash period was extended to 18minutes and during this period, the wasted backwash water turbidity was measured each 1 minute to appraise the required backwash duration.

Various runs were conducted under different operational conditions (varying the media depth, filtration rate, influent turbidity and alum dose) to study the performance and get the effective depth for deep bed sand filter.

Results and Discussions

Ripening period

In this study, the effluent turbidity within the first 30 minutes was measured at each of tested filtration rates (4, 5, 6, and 8m/hr) and through the different media depths (80, 100, 120, and 140cm). The results were obtained with 3 different influent turbidity (10, 20, and 30 NTU). The coagulation process was done by using alum with different doses (20, 30, and 40mg/l). the effluent turbidity was observed until it reaches the acceptable limit in the Egyptian drinking water code (1 NTU) to obtain the ripening period. Figure 2 shows the effect of increasing media depth on the ripening period for 10 NTU influent turbidity and alum dose of 40mg/l. As shown in that figure, the effluent turbidity in the beginning of filtration run was nearly 1 NTU and this turbidity was due to the remaining backwash water in the underdrainage system. The turbidity increases over few period of time nearly 4minutes. This increase was due to not removed particles that were dislodged from the media during backwash [10]. At nearly 4 to 5 minutes the effluent turbidity reaches its maximum values and these values vary according to the filter media depth. The reason for increasing turbidity to this degree is that influent water enters the filter and mixes with the backwash remnant water in the upper region of the filter. This is consistent with the results in paper for Colton et al. [31] which showed that the collapse pulsing duration was 4minutes. Then the effluent turbidity decreases until it nearly becomes constant where the media is able to capture newly influent particles [32].

From Figure 2, it was obvious that the effluent turbidity reaches 1 NTU after 12minutes when the sand media depth was 80cm. If the sand media increased to 140cm, the ripening period will be virtually 7 minutes. This means that increasing sand depth from 80cm to 140cm reduced the ripening period by 42%. So, it help in increasing of water treatment plant production. The effluent turbidity was influenced by increasing filtration rate as shown in Figure 3. When the filtration rate increased to 5m/hr the required ripening period increased. At sand depth of 140cm the required ripening period was 10minutes, while depth of 80cm gives the required turbidity after 32minutes. In addition, the ripening period in case of 100cm depth was 18minutes but in case of 120cm depth the ripening period becomes 13minutes. Increasing filtration rates may result in an inability to use a small depths as shown in F igure 3 . A t f iltration r ate o f 6m/hr t he e ffluent t urbidity reaches the acceptable limit after nearly 18, 25 and 40minutes with sand depths of 140, 120 and 100cm respectively. But depth of 80cm can’t be used due to its ripening period. This is due to increasing filtration rates resulted in greater shearing actions within the media pores, which enhanced the transport of deposited turbidity matters through the filter bed. With increasing filtration rate to 8m/hr, media depth of 100cm can’t give acceptable effluent turbidity. Figure 3 summarizes the required ripening period for each sand depth at different filtration rates. Also, this figure shows that the influent turbidity has significant effect on the ripening period. Figure 3 show great effect of operational conditions on ripening periods, so it could be guided in determining either ripening periods thus the productivity of treatment plant or required media depth at different filtration rates and influent turbidity.

Head loss through filter run

Head loss is a loss of pressure (also known as head) by water flowing through the filter media. In the current study, the head loss through filter media depth was measured for different filtration rates and various influent turbidity with alum doses 20, 30, and 40mg/l. Figure 4 shows the variation of head loss along run time at filtration rate of 5m/hr and alum dose of 40mg/l for different depths of sand media. It was noticed that the observed head loss values were close to the calculated head loss from Hazen equation and Kozeny equation for sand depth from 80cm to 140cm. It was noted from the experimental observations that the alum dose variation has not vital effect on the initial head loss at the same depth and filtration rate. but it has significant effect on the increasing rate of head loss with run time. Further, increasing filtration rate increases the increasing rate of head loss. From Figure 4, the head loss value after 24hours of run was nearly 110cm at sand depth of 140cm and filtration rate of 5m/hr. This means that using deep sand filter up to 140cm have not a critical impact on head loss value.

Figure 5 shows the observed head loss at specific time (24 hr) for sand depth of 100cm at different filtration rates. It also shows the effect of changing alum dose and influent turbidity on head loss values. It was noticed that the head loss increased from 58.7 cm to 72.9cm by increasing alum dose from 20mg/l to 40mg/l at filtration rate and influent turbidity of 4m/hr and 10 NTU respectively after 24hours of run. In addition, at filtration rate 8m/hr, increasing alum dose from 20mg/l to 40mg/l increased the head loss from 112.4cm to 129.5cm. Thus, the effect of increasing alum dose on head loss at high rates is more obvious than low rates. Figure 5 shows also the impact of raw water characteristics which represented in influent turbidity on head loss. It was noted that increasing influent turbidity from 10 NTU to 30 NTU increased head loss from 81cm to 102.5cm at filtration rate of 5m/hr and alum dose of 40mg/l. This is due that raw water with high turbidity which contains larger number of suspended particles leads to increasing of shear action when flowing through sand grains. This shear action increases with increasing filtration rate so the effect of influent turbidity on head loss at high rates is more significant than at low rates as shown in Figure 5.

Turbidity removal efficiency and effective depth

Deep bed sand filter is usually characterized by filtration efficiency, which determines the level of removal of particles from influent water. The turbidity removal efficiency was measured in the present study under various operational conditions. Figure 6 shows the turbidity removal efficiency with depth at different rates. The removal efficiency was measured as the following equation:

Figure 6 shows the removal efficiency with alum dose 20 mg/l through different sand depths at 4, 5, 6 and 8m/ hr filtration rates. It was clear that increasing media depth increases the removal efficiency where at 20cm depth the removal ratio was 78.4% while at 140 cm depth the ratio of removal increased to 94.7%.

Increasing filtration rate decreases the turbidity removal efficiency, where at 20cm depth, the removal percents for 4, 5, 6 and 8m/hr were 78.4, 75.35, 71.43 and 66.3% respectively. If the depth of media equals 140cm, the removal percents will be 94.7, 92.36, 89.72 and 87.41% at the previous rates respectively. It was also noticed that sand depths less than 100 cm have drastic variation in turbidity removal efficiency, while depths more than 100cm have slightly variation in removal efficiency at low filtration rates.

Increasing alum dose from 20mg/l to 40mg/l has significant impact on the percent of removal. Figure 7 show the removal efficiency at alum dose 40mg/l with different sand depths at 4, 5, 6 and 8m/hr filtration rates. This figure also confirms that the efficiency of removal increased by increasing sand depth and decreasing filtration rate. The removal efficiency at 20cm depth was 78.4% with alum dose of 20mg/l but 82.7% with alum dose 40mg/l. In case of depth 140cm, the efficiency was 94.7% with alum dose 20mg/l but 97.9% with alum dose of 40mg/l. This means that increasing alum dose enhanced the coagulation process so it increases the percent of removal, but it occurs at a certain limit of alum. After this limit, any increasing of dose has no effect.

After knowing turbidity values at different depths with various rates and various influent turbidity, effective depth of sand could be determined. The effective depth is the smallest sand depth which give the allowable limit of turbidity (>1 NTU). The effective depth is determined as shown in Figure 8 as following:

1. Plotting the average turbidity at different depths for each filtration rate.

2. Identify the permissible or required limit of effluent turbidity (1 NTU).

3. The intersection points at each rate could give the effective depth.

Figure 9 summarizes the effective depth for each rate with influent turbidity 10, 20, and 30 NTU. The results in the figure were obtained when the alum dose was 40mg/l, which gives high removal efficiency.