#Composite Raw Material Testing Lab

Explore tagged Tumblr posts

Text

Raw Material Testing Lab Mumbai, Pune, Nashik, Chennai, Hyderabad, India

#Plastic Raw Material Testing#Rubber Raw Material Testing Lab#Composite Raw Material Testing Lab#Chemical Raw Material testing Lab#Metallic raw material

0 notes

Note

(The one who suggested the colored hexgems)

Ah- no, I don’t believe I have.

My parents are both chemists and I do find interest in STEM but I lean towards biology, however I am occasionally inclined towards the engineering and ingenuity side of things! Unfortunately I am not much for mathematics and that is a rather key aspect of engineering and physics, I find the concepts and theoretical sides appealing though.

I hadn’t even considered the light emitting aspects of hexgems so that’s a very interesting suggestion! I was originally thinking about how you can certain minerals to refract different wavelengths of light, or with metals like bismuth and steel you can use electronic charges to shift the atomic arrangement to refract different wavelengths, though to be honest I do not have an in depth understanding of the process.

I suppose it would depend on if hexgems are structurally more similar to a crystalline form or a metal, on which method you would be able to use.. and the opacity.

Affecting the wavelength of the light actually emitted would also be very interesting to experiment with!

I suppose the simplest way would be to simply layer colored sheets of glass around the gemstones but what’s the fun in doing it the easy way? Plus the naturally blue hue would impact your color range if you’re simply layering.

If you could get it to a yellow or white, then pair it with cut gems, it would make quite the light show.

-🪡🪶

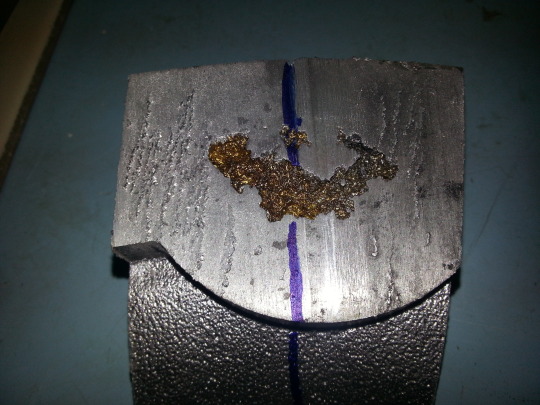

There’s a lot we still don’t understand about the gems, even with years of testing and research. They’re crystalline in structure; the closest compositional equivalent would be a form of aurichalcite though it’s not an exact match—there’s a much lower percentage of copper in the makeup, which is interesting considering the blue color is still so pronounced.

Your suggestion of shifting the atomic arrangement is an intriguing one, and something we actually use in the process of refining the raw crystalline material from the brittle, fibrous aggregate form found naturally into the denser, more stable product we use in Hextech today. It’s definitely worth further investigation! Perhaps an energy-efficient source of light to assist our miners, as another, slightly more practical use case.

You are, of course, more than welcome to visit the lab if you’d like to take a closer look at the crystals yourself. I’m admittedly no biologist and my chemistry’s a little rusty (ha…sorry, had to), and we always appreciate fresh eyes on our work. Sometimes Viktor and I both been stare at the same problem for too long and start losing our minds a little; it all just blurs together, especially if it’s been a while without sleep.

#jayce talis roleplay#jayce talis rp#arcane rp#arcane roleplay#jayvik rp#jayce talis roleplay blog#jayce talis rp blog#jayce talis ask blog#jayce talis asks#jayce rp blog#jayce roleplay#jayce rp#jayce talis arcane#arcanerp

6 notes

·

View notes

Text

How Textile Rubber Composite Testing Contributes to Sustainable Manufacturing?

Sustainability has become a critical priority for manufacturers worldwide, and the textile and rubber industries are no exception. As manufacturers strive to reduce environmental impact, textile rubber composite testing plays an essential role in supporting sustainable manufacturing practices. This testing ensures that composite materials not only meet performance and safety standards but also align with eco-friendly goals such as resource efficiency, durability, and recyclability.

In this blog, we explore how textile rubber composite testing helps manufacturers advance sustainability throughout the product lifecycle—from material selection and production to end-of-life management. Understanding the role of testing in sustainable manufacturing is vital for businesses aiming to meet growing regulatory demands and consumer expectations for green products.

What is Textile Rubber Composite Testing?

Textile rubber composites combine textile fabrics and rubber to create materials that are flexible, durable, and versatile. These composites are widely used in automotive parts, protective equipment, footwear, hoses, and industrial applications.

Textile rubber composite testing involves assessing these materials for mechanical strength, adhesion, abrasion resistance, chemical stability, and environmental durability. Testing labs use standardized procedures to ensure composites perform as expected and comply with industry regulations.

The Link Between Textile Rubber Composite Testing and Sustainability

Sustainability in manufacturing means more than just using “green” materials. It encompasses minimizing waste, reducing energy consumption, extending product life, and enabling recycling or reuse. Textile rubber composite testing supports these goals in several critical ways:

1. Ensuring Material Efficiency and Waste Reduction

Testing helps manufacturers optimize the composition and structure of textile rubber composites. By verifying properties such as tensile strength and adhesion, manufacturers can avoid over-engineering products, which reduces excess material use. Optimized composites require fewer raw materials without sacrificing quality, leading to less waste during production.

Moreover, early detection of defects or weak batches through rigorous testing reduces scrap and rework. This directly minimizes material waste and energy consumption in manufacturing processes.

2. Enhancing Durability for Longer Product Lifespans

Durability is a cornerstone of sustainable manufacturing. Textile rubber composite testing assesses resistance to abrasion, tear, heat, and chemical exposure, ensuring that products last longer under real-world conditions.

Longer-lasting products reduce the need for frequent replacement, cutting down raw material demand and waste generation. For example, automotive hoses or protective gloves that pass strict durability tests contribute to sustainability by lowering the carbon footprint associated with manufacturing replacements.

3. Supporting Use of Eco-Friendly Materials

The push towards sustainability has led to innovations such as bio-based rubbers, recycled textile fibers, and environmentally friendly adhesives. Textile rubber composite testing evaluates the performance of these new materials against established standards.

By validating eco-friendly materials’ suitability, testing labs encourage manufacturers to adopt greener alternatives without compromising quality. This accelerates the transition toward sustainable raw materials in composite manufacturing.

4. Facilitating Recycling and Circular Economy Initiatives

Testing plays a role in designing textile rubber composites that are easier to recycle or reuse. Properties like thermal stability and chemical resistance influence how materials behave during recycling processes.

Comprehensive testing helps manufacturers understand how composites break down or can be reprocessed, enabling design choices that support circular economy goals. For instance, composites that maintain integrity through multiple recycling cycles reduce landfill waste and resource depletion.

Key Textile Rubber Composite Tests That Promote Sustainability

Here are some critical tests performed to ensure composites align with sustainability objectives:

- Tensile Strength and Elongation Testing

These tests confirm that composites are strong yet flexible enough for intended applications without excessive material usage. Proper balance improves material efficiency and product longevity.

- Abrasion Resistance Testing

High abrasion resistance means composites wear slower, extending product life and reducing waste from premature failure.

- Adhesion Testing

Strong bonding between textile and rubber layers prevents delamination, reducing product rejects and extending durability.

- Thermal Aging and Chemical Resistance Tests

These evaluate composites’ stability under harsh conditions, ensuring they remain functional longer and can withstand recycling processes.

Industry Standards Supporting Sustainable Textile Rubber Composite Testing

Many global standards emphasize performance criteria that inherently promote sustainability by encouraging durability and quality:

ASTM D412 (Tensile properties of rubber)

ASTM D1171 (Abrasion resistance of rubber)

ISO 13934-1 (Tensile properties of textiles)

ISO 4649 (Abrasion resistance of rubber)

EN 388 (Protective gloves — Mechanical properties)

By adhering to these standards, manufacturers ensure that their products are robust and resource-efficient.

The Environmental Benefits of Reliable Testing

Reliable textile rubber composite testing helps manufacturers:

Reduce Carbon Footprint: Durable, optimized composites require less frequent replacement, lowering emissions linked to production and transport.

Minimize Waste: Early quality control reduces defective batches and scrap materials.

Promote Green Innovation: Validating eco-friendly materials speeds their adoption.

Enable Responsible Recycling: Testing informs design for recyclability and material recovery.

Collectively, these benefits contribute to a greener manufacturing ecosystem.

The Role of Accredited Testing Labs in Sustainable Manufacturing

To fully realize sustainability goals, manufacturers must partner with accredited textile rubber composite testing labs. Such labs:

Follow internationally recognized standards.

Use advanced equipment to simulate real-world conditions.

Provide transparent, accurate reports for compliance and improvement.

Offer expertise in new eco-friendly material testing.

Their insights help manufacturers make informed decisions that balance performance, cost, and environmental impact.

Conclusion

Textile rubber composite testing is more than a quality assurance step — it is a vital enabler of sustainable manufacturing. Through rigorous testing, manufacturers can optimize material use, enhance durability, validate eco-friendly innovations, and design composites for recycling.

As environmental regulations tighten and consumer demand for sustainable products grows, investing in reliable textile rubber composite testing becomes essential for manufacturers committed to green practices. By partnering with expert labs and adhering to global standards, businesses can confidently produce high-quality, sustainable composites that benefit both the planet and their bottom line.

#textile rubber composite testing#textile testing#textile testing lab#testing lab near me#testing lab in delhi

0 notes

Text

Mirabegron API Uses, Benefits, and Chemox Pharma’s Quality Advantage

In the evolving world of medicinals, the demand for high- quality Active Pharmaceutical constituents( APIs) is more critical than ever. Among these, Mirabegron API stands out as a significant element in the treatment of hyperactive bladder( OAB), a condition affecting millions encyclopedically. As a trusted Mirabegron API supplier, Chemox Pharma plays a crucial part in delivering dependable and effective raw accoutrements that help ameliorate lives.

This blog explores the uses and benefits of Mirabegron, its growing significance in ultramodern drug, and why Chemox Pharma is the favored choice among pharma API manufacturers in India.

What's Mirabegron?

Mirabegron is an oral beta- 3 adrenergic agonist used primarily in the treatment of hyperactive Bladder( OAB). The medicine works by relaxing the detrusor smooth muscle during the storehouse phase of the urinary bladder filler-void cycle. This increases bladder capacity and reduces symptoms like urgency, frequent urination, and urinary incontinence.

Uses of Mirabegron API

Mirabegron is used in the expression of several tradition specifics for hyperactive Bladder( OAB) It helps control unforeseen urges to urinate and reduces the frequency of urination.

Urinary Incontinence By perfecting bladder control, it reduces leakage occurrences.

Combination remedy frequently used alongside antimuscarinic agents to enhance effectiveness in managing bladder symptoms.

With the adding frequency of OAB, especially among growing populations, the demand for high- chastity Mirabegron API is steadily rising across global pharmaceutical requests.

Request Demand and Growth Implicit

According to recent request exploration, the global OAB treatment request is anticipated to grow at a CAGR of over 3.5 in the coming times. A large part of this growth is driven by Aging populations worldwide

Increased mindfulness and opinion of OAB

Preference fornon-invasive oral treatments like Mirabegron

This makes Mirabegron API an important element in the product portfolios of general and ingrained medicine manufacturers likewise.

Why Quality Matters in API Manufacturing

When it comes to pharmaceutical product, API quality directly impacts the safety, efficacity, and nonsupervisory compliance of the final product. contaminations or inconsistent composition in the raw material can lead to failed batches, increased product costs, and indeed implicit health pitfalls to cases.

Therefore, choosing a trusted Mirabegron API supplier like Chemox Pharma becomes pivotal for pharmaceutical brands aiming for excellence.

Chemox Pharma A Trusted Mirabegron API Supplier

Chemox Pharma is a Surat- grounded pharmaceutical API manufacturer with a strong character for delivering high- chastity, lab- tested APIs encyclopedically. Then is why Chemox stands out in the competitive API manufacturing geography

WHO- GMP Compliant Manufacturing

All API manufacturing at Chemox Pharma is done under WHO- GMP pukka installations, icing transnational norms of quality, hygiene, and thickness.

High Assay chastity

Chemox Pharma’s Mirabegron API boasts> 99 chastity, meeting strict pharmacopoeial norms( USP/ EP/ JP), suitable for regulated andsemi-regulated requests.

Transparent Attestation

Every API batch is accompanied by a Certificate of Analysis( CoA), Material Safety Data distance( MSDS), and complete nonsupervisory attestation as needed by guests.

Timely Deliveries Across Global Markets

As a reputed pharma API manufacturer in India, Chemox Pharma supplies to guests across the US, Europe, Africa, and Asia, with well- established logistics networks and bulk force capability.

Competitive Pricing for Bulk Orders

Chemox offers flexible pricing for large- volume buyers, contract manufacturers, and pharmaceutical expression companies – without compromising on quality.

Operations of Chemox’s Mirabegron API

Chemox Pharma’s Mirabegron API is ideal for the expression of

Tablets( 25 mg and 50 mg boluses)

Extended Release phrasings

General medicines in Regulated requests

Custom phrasings for Clinical Trials

Whether you are a large- scale expression company or a incipiency working on bladder health specifics, Chemox can give custom batch sizes, fast reversals, and specialized support.

Final studies

The global demand for bladder complaint treatments is growing fleetly, and Mirabegron API continues to gain traction due to its effectiveness and safety profile. For pharmaceutical manufacturers, partnering with a dependable Mirabegron API supplier like Chemox Pharma ensures not only quality but also peace of mind.

With world- class installations, nonsupervisory moxie, and a devoted platoon, Chemox Pharma has sculpted a niche as a leading pharma API manufacturer in India, ready to meet the rising healthcare demands worldwide.

0 notes

Text

How Chemical Testing Labs in Ajman Facilitate Export Compliance for Local Manufacturers? | +971 554747210

In today’s globalized economy, manufacturers in Ajman are increasingly looking beyond local markets and aiming to export their products internationally. However, exporting goods is not simply about shipping items abroad; it requires strict compliance with regulatory standards set by importing countries. This is where chemical testing labs in Ajman play a pivotal role. They help local manufacturers ensure their products meet the stringent chemical safety, quality, and environmental regulations necessary for smooth entry into global markets.

In this blog, we will explore how chemical testing lab in Ajman facilitate export compliance for manufacturers by providing reliable testing services, certification support, and regulatory guidance.

The Importance of Export Compliance for Ajman Manufacturers

Export compliance refers to the adherence to laws, regulations, and standards that govern the export of goods to foreign countries. Failure to comply with these regulations can result in product rejections, costly recalls, fines, and damage to brand reputation.

For Ajman manufacturers, export compliance involves:

Meeting chemical safety standards of target markets

Providing accurate product composition data

Ensuring absence of restricted or hazardous substances

Obtaining necessary certifications and test reports

Aligning with international environmental and quality regulations

Because regulations vary across countries and industries, having access to expert chemical testing is crucial for exporters to understand and fulfill these requirements.

Role of Chemical Testing Labs in Ajman for Export Compliance

Chemical testing labs in Ajman provide manufacturers with essential laboratory services to verify and document product safety and quality. Here’s how they contribute to export compliance:

1. Comprehensive Chemical Composition Analysis

Many importing countries require detailed information on the chemical makeup of imported products, especially if they contain chemicals that may pose risks to health or the environment. Chemical testing labs analyze:

Raw materials and finished goods for chemical identity and purity

Presence of heavy metals such as lead, mercury, cadmium, and arsenic

Residual solvents, pesticides, or toxins

Additives, stabilizers, and contaminants

This data helps manufacturers certify that their products do not exceed permissible limits set by regulatory bodies like the EU REACH, FDA, or GCC technical regulations.

2. Testing for Restricted Substances and Hazardous Chemicals

Many international markets restrict or ban certain substances in consumer products, industrial materials, and packaging. Chemical testing labs in Ajman conduct:

Screening for restricted chemicals under global regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals)

Verification of volatile organic compounds (VOCs) emissions

Tests for phthalates, formaldehyde, and other hazardous substances

This ensures that products comply with export market restrictions, reducing the risk of shipment rejection.

3. Certification Support with Accredited Testing

Exporters must submit test reports from accredited labs to prove compliance. Ajman’s chemical testing labs typically hold ISO/IEC 17025 accreditation, ensuring their test results are internationally recognized and accepted by customs and regulatory agencies worldwide.

By partnering with these labs, manufacturers obtain valid test certificates that support customs clearance and market access.

4. Customized Testing for Industry-Specific Standards

Different industries have specific chemical testing requirements. For example:

Food and beverage exporters need pesticide residue and contaminant analysis.

Pharmaceutical manufacturers require purity and stability testing.

Cosmetics exporters need heavy metals and allergen screening.

Textile producers must comply with chemical safety norms like OEKO-TEX.

Construction material suppliers need tests on hazardous substances and durability.

Ajman chemical testing labs offer tailored services aligned with these standards to help manufacturers meet exact export criteria.

5. Supporting Sustainable and Eco-Friendly Exports

With growing global emphasis on sustainability, many importing countries enforce strict environmental regulations. Chemical testing labs assist Ajman manufacturers by analyzing:

Environmental impact of products and packaging

Compliance with eco-labels and green certifications

Presence of biodegradable or recyclable materials

This not only aids export compliance but also enhances brand reputation in environmentally conscious markets.

Benefits for Ajman Manufacturers Using Local Chemical Testing Labs

Choosing chemical testing labs in Ajman offers several advantages for manufacturers aiming to export:

Proximity for Faster Turnaround

Local labs reduce logistical challenges by enabling quick sample delivery and faster report generation. This helps manufacturers meet tight export deadlines without delays.

Cost-Effective Testing Solutions

Ajman labs offer competitive pricing compared to overseas testing facilities, lowering overall export compliance costs while maintaining high quality standards.

Expert Guidance on Export Regulations

Many chemical testing labs in Ajman provide consulting services to help exporters understand complex international chemical regulations and prepare accurate documentation.

Trusted and Accredited Testing Services

ISO/IEC 17025 accreditation ensures that Ajman labs provide precise, reproducible, and globally accepted test results, crucial for customs and regulatory approval.

Common Export Challenges Solved by Chemical Testing Labs

Manufacturers often face challenges such as:

Lack of clarity on chemical compliance requirements

Variability in product quality leading to failed tests

Delays due to non-availability of accredited local labs

Difficulty obtaining internationally recognized certifications

Chemical testing labs in Ajman address these by offering comprehensive testing packages, regulatory insights, and certified documentation to smooth the export process.

How to Choose the Right Chemical Testing Lab in Ajman for Export Needs

To maximize export compliance benefits, manufacturers should consider the following when selecting a chemical testing lab:

Accreditation and certifications: Ensure the lab is ISO/IEC 17025 accredited.

Range of testing services: Choose a lab that covers the specific tests required for your product and export market.

Turnaround time: Fast and reliable testing to meet export schedules.

Technical expertise: Experienced analysts familiar with industry and regulatory standards.

Customer support: Lab should provide clear reporting and compliance advice.

Reputation and references: Positive track record with exporters in Ajman.

Conclusion

Exporting goods from Ajman to international markets is an excellent growth opportunity for local manufacturers. However, navigating complex chemical regulations and ensuring compliance is a significant hurdle. Chemical testing labs in Ajman are indispensable partners in this journey, providing essential analytical services, accredited certification, and regulatory guidance.

By leveraging the expertise of chemical testing labs, manufacturers can:

Confirm chemical safety and product quality

Comply with international regulations like REACH, RoHS, FDA, and GCC standards

Avoid costly export delays or product rejections

Gain credibility and trust in global markets

Support sustainable and eco-friendly business practices

#chemical testing lab#chemical testing#chemical testing services#testing lab near me#testing lab uae

0 notes

Text

How Chemical Testing Labs in Abu Dhabi Contribute to Sustainable Industrial Practices? | +971 554747210

As the world moves towards more sustainable industrial practices, the role of chemical testing labs has become increasingly significant. In Abu Dhabi, a city that is rapidly evolving as a hub for industry and innovation, chemical testing labs play a crucial role in helping businesses align with environmental sustainability goals. These labs provide vital services that ensure industries minimize their ecological footprint while maintaining high standards of quality and safety.

This blog will explore how chemical testing lab in Abu Dhabi contribute to sustainable industrial practices and why partnering with these labs is essential for industries committed to environmental responsibility.

The Growing Importance of Sustainability in Abu Dhabi's Industrial Sector

Abu Dhabi’s vision for sustainable development is embedded in its economic and environmental policies. The emirate is committed to reducing carbon emissions, managing natural resources efficiently, and promoting green technologies across various sectors including oil and gas, manufacturing, food processing, and construction.

Industries face increasing pressure from regulators, consumers, and global markets to adopt sustainable practices. Chemical testing labs serve as critical partners by providing accurate data and insights needed to monitor, evaluate, and improve environmental performance.

What Are Chemical Testing Labs and Their Core Functions?

Chemical testing labs are specialized facilities equipped with advanced instruments and expert personnel who analyze substances for their chemical composition, contamination levels, and compliance with regulatory standards. Their services include:

Testing raw materials and finished products.

Detecting hazardous substances and pollutants.

Monitoring emissions and waste quality.

Verifying compliance with environmental and safety regulations.

In Abu Dhabi, many chemical testing labs hold ISO/IEC 17025 accreditation, ensuring their testing processes meet international standards for reliability and accuracy.

How Chemical Testing Labs Support Sustainable Industrial Practices

1. Monitoring and Reducing Industrial Pollution

One of the key contributions of chemical testing labs is the continuous monitoring of pollutants released into the air, water, and soil by industrial activities. Through detailed chemical analyses, labs detect the presence of harmful substances such as heavy metals, volatile organic compounds (VOCs), and persistent organic pollutants (POPs).

By identifying pollutants and their concentrations, industries can take corrective actions to reduce emissions, implement cleaner production techniques, and minimize environmental contamination. For example:

Testing wastewater before discharge ensures harmful chemicals are removed or treated.

Air quality monitoring detects industrial emissions, allowing for mitigation strategies to be deployed.

This proactive pollution management supports Abu Dhabi’s environmental regulations and helps industries reduce their ecological footprint.

2. Ensuring Compliance with Environmental Regulations

Abu Dhabi’s government enforces stringent environmental regulations to protect natural resources and public health. Chemical testing labs assist industries in meeting these requirements by providing:

Accurate and timely test results required for regulatory submissions.

Verification that raw materials, intermediates, and final products comply with chemical safety limits.

Documentation and certification for environmental audits and permits.

By ensuring compliance, labs help companies avoid fines, legal issues, and reputational damage, while promoting responsible industrial practices aligned with Abu Dhabi’s sustainability goals.

3. Supporting Waste Management and Recycling Initiatives

Effective waste management is a cornerstone of sustainable industry. Chemical testing labs analyze industrial waste streams to:

Characterize chemical composition and toxicity.

Identify recyclable components or hazardous fractions requiring special handling.

Monitor landfill leachate to prevent soil and groundwater contamination.

Such insights enable industries to optimize waste segregation, enhance recycling efforts, and implement safer disposal methods—key actions that reduce environmental impact and resource consumption.

4. Promoting Green Chemistry and Sustainable Product Development

Chemical testing labs play a vital role in the research and development of eco-friendly products and processes. They evaluate:

The chemical safety and environmental impact of new materials.

The effectiveness of green alternatives to hazardous chemicals.

The stability and degradation of biodegradable and sustainable materials.

This support accelerates innovation toward sustainable manufacturing and product lines, helping Abu Dhabi industries meet global demand for greener goods.

5. Facilitating Energy Efficiency Through Material Testing

Sustainable industry also means improving energy efficiency. Chemical testing labs analyze materials used in industrial equipment and processes to:

Assess properties that affect durability and performance.

Recommend materials that reduce energy loss or improve process efficiency.

For example, testing insulation materials or chemical catalysts helps industries optimize energy use, lowering greenhouse gas emissions and operational costs.

6. Assisting in Carbon Footprint Reduction Efforts

Many industries in Abu Dhabi aim to reduce their carbon footprint in alignment with national climate goals. Chemical testing labs contribute by:

Measuring greenhouse gas emissions from industrial processes.

Testing fuels, lubricants, and other inputs to ensure cleaner combustion.

Monitoring carbon sequestration materials and technologies.

Accurate data from chemical testing is critical for tracking progress and implementing effective carbon reduction strategies.

Technologies Used by Chemical Testing Labs for Sustainable Industrial Testing

Chemical testing labs in Abu Dhabi employ cutting-edge technologies to deliver precise and comprehensive environmental analyses:

Gas Chromatography (GC) and Mass Spectrometry (MS) for detecting trace organic pollutants.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) for measuring heavy metals at ultra-trace levels.

Fourier Transform Infrared Spectroscopy (FTIR) to identify chemical bonds and molecular structures.

Atomic Absorption Spectroscopy (AAS) for rapid metal analysis in waste and emissions.

Water and air sampling systems integrated with laboratory analysis for real-time environmental monitoring.

These technologies provide the backbone for effective sustainability assessment and continuous improvement.

Why Choosing an Accredited Chemical Testing Lab in Abu Dhabi Matters

To truly benefit from chemical testing in advancing sustainability, partnering with an accredited lab is crucial. Accreditation, such as ISO/IEC 17025, ensures:

High standards of accuracy, repeatability, and impartiality in test results.

Competence of technical staff and validation of testing methods.

Recognition of test reports by regulatory authorities locally and internationally.

Choosing the right lab means reliable data that empowers industries to make informed decisions toward sustainability.

Future Trends: Chemical Testing Labs and Sustainable Industry in Abu Dhabi

Looking ahead, chemical testing labs will continue evolving to meet Abu Dhabi’s ambitious sustainability agenda. Emerging trends include:

Integration of digital technologies and IoT for real-time environmental monitoring.

Development of rapid on-site chemical testing to minimize delays.

Expansion of testing services for emerging contaminants such as microplastics and nanomaterials.

Increased collaboration with industries for customized sustainability solutions.

These advancements will further solidify the critical role of chemical testing labs in driving sustainable industrial transformation.

Conclusion

Chemical testing labs in Abu Dhabi are indispensable partners in the journey toward sustainable industrial practices. Through meticulous monitoring, compliance support, waste management, and green innovation, these labs help industries minimize environmental impact while maintaining quality and safety.

For businesses in Abu Dhabi aiming to embed sustainability into their operations, leveraging the expertise and advanced testing capabilities of accredited chemical testing labs is not just a regulatory necessity but a strategic advantage. Together, they contribute to a cleaner, greener, and more sustainable future for the emirate and beyond.

#chemical testing lab#chemical testing#chemical testing services#testing lab near me#testing lab uae

0 notes

Text

QC in Pharmaceutical Industry – The Frontline of Drug Quality Assurance

Quality Control (QC) in pharmaceutical industry refers to a comprehensive system of tests, checks, and validation procedures that ensure medicines are safe, pure, and effective. It is the frontline defense against contamination, inconsistencies, and regulatory non-compliance. In simpler terms, QC guarantees that every dose of medicine—from the first pill to the last—is manufactured to the same high-quality standard. As global demand for pharmaceuticals grows, so does the need for more rigorous and reliable QC practices. Without them, the industry risks product recalls, regulatory violations, and most importantly, patient harm.

What QC Stands for in the Pharmaceutical Industry?

In the pharmaceutical world, QC stands for Quality Control. It’s a vital set of protocols that verify the quality of materials, processes, and final products through scientifically validated testing methods. These processes involve chemical, physical, and microbiological testing to ensure that each product conforms to preset standards. QC is different from QA (Quality Assurance), which focuses on the system and processes. QC is the "doer" of testing, while QA is the "planner" ensuring the system is effective. QC in pharmaceutical industry is not an option—it’s a regulatory requirement that companies must meet to legally manufacture and sell drugs.

The Scope of QC in Pharmaceutical Industry

The scope of QC in pharmaceutical industry is extensive. It spans every stage of the drug production lifecycle. QC is applied:

During raw material intake to verify identity, purity, and composition.

Throughout formulation and manufacturing, ensuring consistency and accuracy.

On packaging materials to protect product stability and sterility.

In environmental monitoring of cleanrooms and lab spaces.

This wide reach makes QC not just a step in the process but a continuous system embedded in every layer of pharmaceutical operations.

The QC Laboratory – Where Science Meets Safety

At the heart of QC in pharmaceutical industry is the laboratory. It is here that rigorous analyses are performed using state-of-the-art technology. Each lab is equipped with validated instruments and staffed by highly trained scientists. They perform various tests such as:

Assay tests to determine potency.

Dissolution testing to assess drug release.

Microbial limit testing to check for contamination.

Physical tests like hardness and friability for tablets.

The QC lab functions like the final checkpoint before a drug is deemed safe to ship. Any failures in this phase are escalated immediately, and the batch is held back for investigation.

QC in Pharmaceutical Industry and Regulatory Compliance

QC in pharmaceutical industry isn’t just about safety—it’s about compliance. Regulatory agencies across the globe have strict guidelines on how QC must be implemented. Agencies like:

The FDA in the United States

The EMA in Europe

The MHRA in the UK

The WHO globally

All enforce standards around documentation, lab practices, and testing protocols. Companies must maintain detailed QC records, known as batch records, which inspectors can review at any time. Non-compliance not only risks product seizure or recalls but can also lead to shutdowns and legal consequences.

Real-Time QC – Making Decisions as Products are Made

Traditional QC is post-production, but modern systems use real-time QC. This involves in-line sensors and software that monitor quality during manufacturing. With this approach:

Errors are detected instantly.

Adjustments are made before a problem escalates.

Batch release times are reduced.

Real-time QC in pharmaceutical industry is revolutionizing how companies manage risk and improve efficiency.

Challenges Faced in QC Implementation

While QC is crucial, it’s not without challenges:

Resource Intensiveness: Advanced equipment and skilled professionals are expensive.

Volume Pressure: As demand grows, so does the volume of tests to be run.

Sample Management: Storing, tracking, and disposing of samples can become complex.

Ever-Evolving Regulations: Keeping up with regional and international guidelines requires constant training.

Still, companies must prioritize QC investment as an essential part of long-term success and patient trust.

Training and Skillset Required in QC Teams

Personnel working in QC labs must be well-versed in:

Analytical chemistry

Microbiology

Pharmacopoeial standards (USP, BP, JP, etc.)

GMP documentation practices

They must also possess soft skills like attention to detail, critical thinking, and adaptability, especially when dealing with new drug formats or testing methods.

The Role of Technology in Enhancing QC

Technology is changing the game in QC. Software and instruments now help automate:

Data collection and logging

Sample identification using barcodes and RFID

Out-of-specification (OOS) investigations

Trend analysis and report generation

Instruments integrated with Laboratory Information Management Systems (LIMS) are reducing human error and boosting efficiency. The digital transformation of QC in pharmaceutical industry is streamlining workflows and improving data integrity.

Quality Control and Public Health

Ultimately, QC in pharmaceutical industry serves public health. From ensuring insulin vials are contaminant-free to confirming the potency of cancer medications, QC is the unsung hero that makes modern medicine reliable. Every successful treatment outcome is backed by thousands of lab hours and careful scrutiny. It reinforces the invisible trust between a patient and the pharmaceutical product they consume.

Conclusion

QC in pharmaceutical industry is the critical process that upholds the safety, effectiveness, and regulatory compliance of every drug. It encompasses everything from raw material testing to the final evaluation of finished products. It’s deeply embedded in the operations of pharmaceutical companies and ensures public confidence in the medications they depend on. As technology advances, QC is becoming faster, smarter, and more reliable—continuing to be the bedrock of modern drug manufacturing.

FAQs

Q1: What does QC stand for in pharmaceutical industry? QC stands for Quality Control, which involves testing and verifying pharmaceutical products to ensure they meet safety and regulatory standards.

Q2: How is QC different from QA in pharma? QC focuses on product testing, while QA (Quality Assurance) ensures the systems and processes are designed to prevent quality issues.

Q3: Why is QC essential in pharmaceuticals? QC ensures drugs are safe, effective, and consistent, protecting public health and meeting legal regulations.

Q4: What types of tests are done in QC labs? Tests include assay, dissolution, microbial limits, and physical evaluations such as tablet hardness and weight.

Q5: Who sets the guidelines for QC in pharmaceutical industry? Regulatory agencies like the FDA, EMA, WHO, and MHRA set the standards companies must follow.

Q6: What qualifications are needed for QC professionals? A background in pharmaceutical sciences, chemistry, or microbiology along with knowledge of regulatory practices is essential.

Q7: How does technology help QC operations? It automates testing, improves data tracking, enhances accuracy, and speeds up batch release processes.

Q8: What is real-time QC? Real-time QC involves monitoring and adjusting product quality during manufacturing rather than after it's completed.

Q9: What happens if a product fails QC? The batch is held back, investigated, and only released if re-tested and compliant. Otherwise, it is rejected.

Q10: How is QC evolving in modern pharma? With AI, automation, and digital systems, QC is becoming more efficient, predictive, and integrated into production.

#health#pharmaceutical industry#quality control in pharmaceutical industry#QC in pharmaceutical industry#quality control

0 notes

Text

Melt Flow Index Tester Uses

Source of Info: https://www.perfectgroupindia.co.in/blog/melt-flow-index-tester-uses

Introduction

Melt Flow Index Tester is one of the best instruments to analyze thermoplastic polymer flow features. It is important for maintaining continuous material quality in the quickly changing plastic and polymer industry. This tool is important for research, product development and quality control processes. It is also known as an MFI tester. We at Perfect Group India offer high performance testing equipment that follow the global standards, guaranteeing reliability and durability in each measurement.

Study About Melt Flow Index Tester

A Melt Flow Index Tester is a piece of equipment used in laboratories for measuring how quickly thermoplastic polymers flow under pressure and heat. The outcome is measured in grams per ten minutes and is referred to as the Melt Flow Index. This test helps to measure the material's thickness which has an impact on how it processes and performs in the end. In order to compare batches of the same material then verify material grades and make sure a polymer is suitable for specific processing methods like injection molding, extrusion and blow molding MFI values are necessary for manufacturers.

Key Uses of this Testing Equipment

Let's analyze the different industries that use the Melt Flow Index Testing equipment:

1. Quality Control in Manufacturing

A Melt Flow Index Tester is mostly used in quality control facilities of plastic manufacturing companies. Before any processing it helps with checking whether the raw materials meet the required standards. Manufacturers can maintain product quality and cut waste by making sure melt flow levels are stable.

2. Material Grade Verification

The MFI values for different polymer grades differentiate. Manufacturers can confirm whether the material they get is of the right grade by using a tester. For example, low MFI materials perform better in extrusion while high MFI polymers are more suitable for injection molding. Manufacturers can effectively categorize and verify materials using Perfect Group India's MFI testers by guaranteeing the correct polymer is being used for the purpose it was designed for.

3. Research and Product Development

The Melt Flow Index Tester is a required tool in research and development labs. It helps researchers and engineers to analyze the effects of adjustments to polymer compositions such as the addition of chemicals, colorants or fillers on melt flow characteristics. In order to help achieve faster product innovation cycles, Perfect Group India provides research and development facilities with reliable and simple to use Melt Flow Index Testing instruments that provide quick and accurate results.

4. Comparison of Polymer Blends

In order to achieve the desired qualities manufacturers often combine polymers. The Melt Flow Index Tester helps in measuring the behavior of different polymer mixes under pressure and heat. Incompatibilities or incorrect mixing could be indicated by a noticeable change in MFI. At Perfect Group India our MFI testers are continually and accurately built to provide detailed data for blend optimization.

5. Troubleshooting Processing Issues

MFI testing helps in discovering the true cause of flaws that occur during plastic production such as warping, short shoots or unequal wall thickness. An MFI result that separates from the usual range could be a sign of pollution, batch change or thermal breakdown. Manufacturers can reduce downtime and save time by properly solving such issues with the help of Perfect Group India's dependable Melt Flow Index Tester.

6. Regulatory Compliance and Certifications

Strict international standards like ASTM D1238 or ISO 1133 must be met by plastic products especially those used in food packaging, automotive and healthcare industries. Test labs must have a Melt Flow Index Tester in order to receive authorization from regulators. For approved testing environments, Perfect Group India provides MFI testers that follow international testing standards.

Why Choose Perfect Group India?

We at Perfect Group India are well aware of how important accurate testing equipment is for business success. The purpose of our Melt Flow Index Tester is to:

High Accuracy: Precise temperature and weight control.

User Friendly Interface: Digital displays for easy operation.

Durability: Strong construction for long term industrial use.

Compliance: Follows ASTM and ISO standards.

Customization: Available in manual with semi automatic and fully automatic models.

The most suitable MFI testing solution is available from Perfect Group India whatever your size from small producers to massive polymer manufacturing facilities.

Applications Across Industries

The Melt Flow Index Tester is used across a wide array of industries, including:

Automotive: To guarantee that the thermoplastic materials used for interiors and parts are of good quality.

Medical: For confirming the safe polymer flow characteristics that are used in medical equipment.

Packaging: In the production of bottles, films and containers to maintain uniformity and performance.

Consumer Electronics: For materials used in casings and insulating components.

Construction: To validate pipes, profiles and sheets used in infrastructure projects.

You can take any test with assurance if you work with Perfect Group India. Your products will meet the highest quality standards thanks to our skill in creating accurate testing equipment.

Conclusion

The Melt Flow Index Tester is a valuable instrument for guaranteeing polymer quality and performance but it is more than a testing tool. It performs a variety of important functions that have a direct impact on customer happiness and reliability of goods from production to research and development. In order to improve your quality assurance methods Perfect Group India offers advanced testing instruments that offer reliability, conformance and unmatched value. Join together with us to get the perfect solution for all of your testing requirements.

0 notes

Text

Key Factors to Consider When Choosing Ready Mix Concrete in Pakistan

In today’s fast-paced construction environment, where precision, strength, and efficiency are non-negotiable, Ready Mix Concrete (RMC) has emerged as a vital material for modern building projects. In Pakistan, the demand for this pre-mixed, high-quality concrete solution is growing rapidly across residential, commercial, and infrastructure sectors. As a top choice among construction professionals, Ready Mix Concrete in Pakistan offers unmatched consistency, strength, and convenience. However, not all RMC providers are created equal. Selecting the right supplier involves more than just comparing prices—it’s about ensuring long-term durability, compliance with engineering standards, and timely delivery to your site. This is where Allied Materials stands out. As one of the most trusted names in the industry, Allied Materials offers premium-grade RMC backed by advanced technology, strict quality control, and professional service. In this guide, we will explore the key factors to consider when choosing Ready Mix Concrete in Pakistan, and why Allied Materials should be your go-to partner.

What is Ready Mix Concrete?

Ready Mix Concrete is a manufactured concrete that is batched in a central plant under controlled conditions and delivered to the construction site in specialized mixer trucks. Unlike traditional concrete mixed on-site, RMC guarantees consistency in quality, composition, and performance.

It is ideal for time-sensitive projects, large-scale constructions, and any application where structural integrity is critical. The rise of Ready Mix Concrete in Pakistan reflects a shift toward efficiency, quality assurance, and adherence to international construction standards.

Why Choosing the Right Ready Mix Concrete Matters

Concrete is the foundation of any structure. A poor-quality mix can lead to costly repairs, structural failures, or project delays. Therefore, selecting a reliable RMC supplier is a crucial step that can directly affect the success of your project.

Let’s examine the most important factors that should influence your decision:

1. Quality of Materials

The first and most vital aspect of any concrete mix is the quality of raw materials used—cement, aggregates, water, and admixtures. These elements must meet specific standards for strength, durability, and safety.

Allied Materials sources only certified, high-grade raw materials and subjects them to rigorous lab testing to ensure every batch meets or exceeds required specifications. Their in-house laboratory performs compressive strength tests, workability evaluations, and consistency checks to maintain exceptional standards.

Poor-quality materials can lead to shrinkage, cracks, or reduced load-bearing capacity—issues that Allied Materials helps you avoid.

2. Batching Plant Technology

The technology and automation level of the batching plant significantly affects the accuracy of mix proportions and overall quality. Advanced batching systems can control water-cement ratios and reduce human error. Allied Materials operates state-of-the-art automated batching plants that maintain precision at every stage of production. These plants are designed to produce large volumes without compromising consistency. This precision ensures you get the same strength and quality—whether you’re pouring the first slab or the hundredth.

3. Mix Design Flexibility

Not all concrete is created equal. Different projects have different needs—residential slabs, commercial foundations, industrial flooring, or infrastructure works like flyovers.

Your RMC supplier should be able to provide customized mix designs that align with your structural and environmental requirements. Allied Materials offers a wide range of concrete grades and tailor-made solutions, including:

High-performance concrete

Early setting mixes

High-strength mixes

Eco-friendly/low-carbon options

Waterproof or self-compacting concrete

Their experienced engineers work closely with clients to create the most suitable mix for each project.

4. Timely Delivery and Logistics

Time is money in the construction business. Delayed concrete deliveries can bring your project to a halt, especially for high-rise or sequential slab casting.

A dependable logistics and fleet management system is critical for any RMC provider.

Allied Materials operates a large fleet of GPS-enabled transit mixers and concrete pumps, ensuring on-time delivery across Karachi and beyond. Their dispatch team coordinates seamlessly with your site schedule to avoid bottlenecks or idle labor.

Whether your site is in Clifton, Korangi, Gulshan, or outskirts like Gadap, Allied gets your concrete there—fast and fresh.

5. On-Site Technical Support

The best Ready Mix Concrete providers don’t just drop off the concrete—they stay involved.

Site supervision, pour monitoring, and technical support are crucial to ensuring that the concrete is placed, compacted, and cured correctly.

Allied Materials provides trained engineers and support teams who assist with:

Slump tests at site

Pouring technique optimization

Curing advice

Adjustments for weather conditions

Their proactive engagement minimizes errors and maximizes performance.

6. Compliance and Certification

Construction projects in Pakistan are increasingly subject to compliance with local and international standards. Whether you’re building under DHA guidelines or working on a government tender, your concrete supplier must meet specific ISO and PSQCA standards.

Allied Materials is fully compliant with:

Pakistan Standards and Quality Control Authority (PSQCA)

ISO 9001: Quality Management

ASTM Standards for Mix Design and Testing

Choosing a certified supplier like Allied minimizes risk and ensures project approval.

7. Sustainability and Environmental Practices

In an era of environmental awareness, green construction practices are gaining traction. Concrete manufacturing can be resource-intensive, but progressive RMC providers are adopting eco-friendly technologies.

Allied Materials is committed to sustainability through:

Recycling wastewater used in batching

Dust control systems at their plants

Low-carbon cement alternatives

Efficient fleet fuel usage

By partnering with Allied, you contribute to a more sustainable construction industry in Pakistan.

8. Transparent Pricing and Value

Cost is always a factor, but it shouldn't be the only one. The cheapest concrete may come at the cost of quality, leading to costly rework or structural issues later.

Allied Materials offers competitive pricing with complete transparency. They provide detailed quotations, break down costs, and help clients assess the total value of the mix—not just the upfront price.

Investing in high-quality Ready Mix Concrete in Pakistan from Allied Materials means fewer headaches, faster completion, and long-term savings.

9. Proven Track Record and Customer Feedback

Nothing speaks louder than real-world results. Allied Materials has delivered concrete for hundreds of successful projects across Karachi and beyond, ranging from residential villas and plazas to factories and infrastructure works.

They are known for their professionalism, consistency, and strong customer relationships. Testimonials from contractors, architects, and developers confirm their position as a market leader in RMC.

10. Ease of Ordering and Communication

Allied Materials simplifies the process of placing an order through:

Online booking options

Dedicated customer service

Technical consultancy

Flexible delivery scheduling

Conclusion

The construction industry in Pakistan is evolving—and so should your choice of materials. Choosing the right Ready Mix Concrete in Pakistan is not just a matter of cost but a strategic decision that affects the entire lifecycle of your project. With a strong emphasis on quality, innovation, logistics, and customer satisfaction, Allied Materials stands out as a trusted name in the ready-mix industry. Whether you're constructing a home, an office complex, or an industrial facility, Allied delivers more than just concrete—they deliver confidence. Make the smart choice. Choose Allied Materials for your next project and build with strength, precision, and peace of mind.

In today’s fast-paced construction environment, where precision, strength, and efficiency are non-negotiable, Ready Mix Concrete (RMC) has emerged as a vital material for modern building projects. In Pakistan, the demand for this pre-mixed, high-quality concrete solution is growing rapidly across residential, commercial, and infrastructure sectors. As a top choice among construction professionals, Ready Mix Concrete in Pakistan offers unmatched consistency, strength, and convenience. However, not all RMC providers are created equal. Selecting the right supplier involves more than just comparing prices—it’s about ensuring long-term durability, compliance with engineering standards, and timely delivery to your site. This is where Allied Materials stands out. As one of the most trusted names in the industry, Allied Materials offers premium-grade RMC backed by advanced technology, strict quality control, and professional service. In this guide, we will explore the key factors to consider when choosing Ready Mix Concrete in Pakistan, and why Allied Materials should be your go-to partner.

What is Ready Mix Concrete?

Ready Mix Concrete is a manufactured concrete that is batched in a central plant under controlled conditions and delivered to the construction site in specialized mixer trucks. Unlike traditional concrete mixed on-site, RMC guarantees consistency in quality, composition, and performance.

It is ideal for time-sensitive projects, large-scale constructions, and any application where structural integrity is critical. The rise of Ready Mix Concrete in Pakistan reflects a shift toward efficiency, quality assurance, and adherence to international construction standards.

Why Choosing the Right Ready Mix Concrete Matters

Concrete is the foundation of any structure. A poor-quality mix can lead to costly repairs, structural failures, or project delays. Therefore, selecting a reliable RMC supplier is a crucial step that can directly affect the success of your project.

Let’s examine the most important factors that should influence your decision:

1. Quality of Materials

The first and most vital aspect of any concrete mix is the quality of raw materials used—cement, aggregates, water, and admixtures. These elements must meet specific standards for strength, durability, and safety.

Allied Materials sources only certified, high-grade raw materials and subjects them to rigorous lab testing to ensure every batch meets or exceeds required specifications. Their in-house laboratory performs compressive strength tests, workability evaluations, and consistency checks to maintain exceptional standards.

Poor-quality materials can lead to shrinkage, cracks, or reduced load-bearing capacity—issues that Allied Materials helps you avoid.

2. Batching Plant Technology

The technology and automation level of the batching plant significantly affects the accuracy of mix proportions and overall quality. Advanced batching systems can control water-cement ratios and reduce human error. Allied Materials operates state-of-the-art automated batching plants that maintain precision at every stage of production. These plants are designed to produce large volumes without compromising consistency. This precision ensures you get the same strength and quality—whether you’re pouring the first slab or the hundredth.

3. Mix Design Flexibility

Not all concrete is created equal. Different projects have different needs—residential slabs, commercial foundations, industrial flooring, or infrastructure works like flyovers.

Your RMC supplier should be able to provide customized mix designs that align with your structural and environmental requirements. Allied Materials offers a wide range of concrete grades and tailor-made solutions, including:

High-performance concrete

Early setting mixes

High-strength mixes

Eco-friendly/low-carbon options

Waterproof or self-compacting concrete

Their experienced engineers work closely with clients to create the most suitable mix for each project.

4. Timely Delivery and Logistics

Time is money in the construction business. Delayed concrete deliveries can bring your project to a halt, especially for high-rise or sequential slab casting.

A dependable logistics and fleet management system is critical for any RMC provider.

Allied Materials operates a large fleet of GPS-enabled transit mixers and concrete pumps, ensuring on-time delivery across Karachi and beyond. Their dispatch team coordinates seamlessly with your site schedule to avoid bottlenecks or idle labor.

Whether your site is in Clifton, Korangi, Gulshan, or outskirts like Gadap, Allied gets your concrete there—fast and fresh.

5. On-Site Technical Support

The best Ready Mix Concrete providers don’t just drop off the concrete—they stay involved.

Site supervision, pour monitoring, and technical support are crucial to ensuring that the concrete is placed, compacted, and cured correctly.

Allied Materials provides trained engineers and support teams who assist with:

Slump tests at site

Pouring technique optimization

Curing advice

Adjustments for weather conditions

Their proactive engagement minimizes errors and maximizes performance.

6. Compliance and Certification

Construction projects in Pakistan are increasingly subject to compliance with local and international standards. Whether you’re building under DHA guidelines or working on a government tender, your concrete supplier must meet specific ISO and PSQCA standards.

Allied Materials is fully compliant with:

Pakistan Standards and Quality Control Authority (PSQCA)

ISO 9001: Quality Management

ASTM Standards for Mix Design and Testing

Choosing a certified supplier like Allied minimizes risk and ensures project approval.

7. Sustainability and Environmental Practices

In an era of environmental awareness, green construction practices are gaining traction. Concrete manufacturing can be resource-intensive, but progressive RMC providers are adopting eco-friendly technologies.

Allied Materials is committed to sustainability through:

Recycling wastewater used in batching

Dust control systems at their plants

Low-carbon cement alternatives

Efficient fleet fuel usage

By partnering with Allied, you contribute to a more sustainable construction industry in Pakistan.

8. Transparent Pricing and Value

Cost is always a factor, but it shouldn't be the only one. The cheapest concrete may come at the cost of quality, leading to costly rework or structural issues later.

Allied Materials offers competitive pricing with complete transparency. They provide detailed quotations, break down costs, and help clients assess the total value of the mix—not just the upfront price.

Investing in high-quality Ready Mix Concrete in Pakistan from Allied Materials means fewer headaches, faster completion, and long-term savings.

9. Proven Track Record and Customer Feedback

Nothing speaks louder than real-world results. Allied Materials has delivered concrete for hundreds of successful projects across Karachi and beyond, ranging from residential villas and plazas to factories and infrastructure works.

They are known for their professionalism, consistency, and strong customer relationships. Testimonials from contractors, architects, and developers confirm their position as a market leader in RMC.

10. Ease of Ordering and Communication

Allied Materials simplifies the process of placing an order through:

Online booking options

Dedicated customer service

Technical consultancy

Flexible delivery scheduling

Conclusion

The construction industry in Pakistan is evolving—and so should your choice of materials. Choosing the right Ready Mix Concrete in Pakistan is not just a matter of cost but a strategic decision that affects the entire lifecycle of your project. With a strong emphasis on quality, innovation, logistics, and customer satisfaction, Allied Materials stands out as a trusted name in the ready-mix industry. Whether you're constructing a home, an office complex, or an industrial facility, Allied delivers more than just concrete—they deliver confidence. Make the smart choice. Choose Allied Materials for your next project and build with strength, precision, and peace of mind.

0 notes

Text

Best Quality Brass Sheets Manufacturers in India

Best Quality Brass Sheet Manufacturers in India – A Focus on KWM India

India has long been recognized for its robust metal manufacturing industry, and among the various metals produced, brass holds a unique place. Known for its durability, corrosion resistance, and attractive finish, brass is widely used across industries ranging from construction and architecture to electronics, art, and decorative items. When it comes to brass sheet manufacturing, Indian companies are making a significant impact in both domestic and global markets. Among these, KWM India stands out as one of the most reputed names, delivering exceptional quality and reliability in brass sheet production.

The Growing Demand for Brass Sheets

Brass sheets manufacturers are alloy products primarily composed of copper and zinc. Their properties can be tailored by varying the composition, making them suitable for numerous applications. From precision components in machinery to electrical terminals, nameplates, kitchenware, and even musical instruments, brass sheets serve as a versatile material. With growing industrialization and infrastructure development in India and abroad, the demand for high-quality brass sheets has surged.

Why Quality Matters in Brass Sheets

When it comes to brass sheets, quality is paramount. High-quality brass sheets exhibit superior malleability, consistent thickness, uniform surface finish, and enhanced corrosion resistance. These attributes are critical, especially for industries like aerospace, electrical engineering, and architecture, where performance and safety cannot be compromised.

Choosing a trusted manufacturer ensures that the brass sheets meet international quality standards, are tested for durability, and come with a guarantee of performance. This is where companies like KWM India play a crucial role.

KWM India – A Trusted Name in Brass Manufacturing

KWM India, headquartered in Jamnagar, Gujarat — the brass manufacturing hub of India — has earned a stellar reputation for its dedication to quality, innovation, and customer satisfaction. With decades of experience in the non-ferrous metal industry, KWM India specializes in manufacturing and exporting premium-grade brass sheets and allied products.

What sets KWM India apart is its meticulous approach to production and quality control. The company uses top-grade raw materials sourced from trusted suppliers and employs state-of-the-art manufacturing processes to ensure consistency in product output. Their brass sheets manufacturers are available in various grades and thicknesses to meet the diverse needs of clients across industries.

Quality Certifications and Standards

KWM India adheres strictly to international quality standards, and its manufacturing facilities are ISO-certified. Their in-house testing labs are equipped with advanced instruments for checking chemical composition, tensile strength, and other mechanical properties. Each brass sheet undergoes rigorous quality checks before being dispatched to customers, ensuring reliability and performance.

Moreover, the company emphasizes sustainability and environmentally conscious manufacturing practices. Their recycling processes help reduce waste, and their energy-efficient production methods align with global efforts toward green manufacturing.

Applications of KWM India’s Brass Sheets

KWM India's brass sheets find use in numerous applications, such as:

Electrical connectors and terminals

Decorative architectural panels

Precision automotive parts

Marine hardware and plumbing components

Musical instruments and artistic décor items

Their ability to supply customized brass sheets as per client requirements has made them a preferred partner for many OEMs and industrial suppliers both in India and internationally.

Customer-Centric Approach

Another significant advantage of working with KWM India is their strong customer focus. The company maintains transparent communication, prompt delivery timelines, and flexible order quantities to cater to businesses of all sizes. Their experienced technical support team assists clients in selecting the right grade and specification, ensuring optimal performance for the end application.

Conclusion

India's brass sheet manufacturing industry is flourishing, with companies like KWM India leading the way through quality, innovation, and customer commitment. For businesses looking to source reliable, high-grade brass sheets, KWM India represents a trusted and proven choice. Their legacy of excellence, combined with a modern approach to manufacturing, ensures that clients receive products that meet the highest industry standards — time after time.

Visit:- https://www.kmwindia.com/brass-sheets.html

0 notes

Text

Caltron Clays Powers Pharma with Natural Strength – Oyster Shell Calcium Powder Manufacturer and Supplier in India

Introduction: Caltron Clays & Chemicals – Leading Oyster Shell Calcium Powder Manufacturer and Supplier in India

In the competitive and ever-evolving world of pharmaceutical manufacturing, Caltron Clays & Chemicals has established itself as the most trusted Oyster Shell Calcium Powder manufacturer and supplier in India. Our commitment to innovation, consistency, and quality ensures that pharmaceutical companies receive only the finest, pharma-grade natural calcium.

Backed by over three decades of experience in the mineral and pharmaceutical raw material sector, Caltron Clays & Chemicals delivers scientifically formulated, sustainably sourced, and performance-driven Oyster Shell Calcium Powder that fits the dynamic needs of B2B clients across India and globally.

Why Oyster Shell Calcium Powder is a Game-Changer in Pharma

Harnessing Nature's Power with Advanced Formulation Support

Natural calcium sources are gaining momentum across global pharmaceutical industries. Caltron's Oyster Shell Calcium Powder is developed using 100% natural oyster shells, carefully processed to deliver unmatched purity and bioavailability. Our powder is an ideal fit for multiple pharma formulations, offering cleaner labels and superior results.

pharma-grade calcium powder, natural calcium source for supplements, calcium for bone health, mineral supplement manufacturer India.

Core Benefits:

High elemental calcium (~38%)

Derived from purified, sun-dried oyster shells

Non-toxic, safe, and well-absorbed

Compliant with IP, USP, and EP standards

Easy integration in nutraceuticals and pharmaceuticals

Caltron Clays & Chemicals: Synonymous with Quality and Compliance

Delivering Regulatory-Ready, High-Purity Raw Materials

At Caltron, we ensure our Oyster Shell Calcium Powder consistently meets the rigid quality standards demanded by national and international pharmaceutical clients. Every batch undergoes stringent lab testing, validating parameters like particle size distribution, heavy metal content, microbial load, and elemental calcium composition.

calcium supplement manufacturers, pharma raw material supplier India, GMP-compliant manufacturer, Indian pharmacopoeia-grade calcium.

Our facilities are equipped with:

ISO-certified processing units

In-house R&D and QA labs

State-of-the-art milling and micronization

From formulation to final packaging, pharma manufacturers rely on Caltron for hassle-free integration into their production pipeline.

Application Spectrum: Where Caltron's Oyster Shell Calcium Powder Performs Best

Multi-Segment Suitability for Health and Wellness Formulations

Our Oyster Shell Calcium Powder is not just a bone health ingredient it serves a wide array of therapeutic and preventive health applications.

Common Uses Include:

Bone and Joint Health Tablets: Strengthens bone mineral density and joint mobility

Pediatric Syrups and Drops: Supports healthy growth and development

Women’s Health Supplements: Crucial for prenatal, postnatal, and menopausal phases

Elderly Nutrition: Supports osteoporotic care with easily absorbable calcium

Antacid Preparations: Natural buffering agent for gastric issues

calcium for geriatrics, natural calcium source for tablets, bioavailable calcium for supplements, pharma excipients supplier.

Precision Processing: Technology Meets Traditional Mineral Wisdom

From Shell to Shelf: Our Scientific Processing Protocol

Caltron leverages industry-leading purification and processing methods to deliver functional, clean, and safe Oyster Shell Calcium Powder:

Thermal Pre-treatment: Eliminates organic residue

Calcination: Stabilizes the structure of calcium

Sterile Grinding: Achieves desired mesh and uniformity

Micronization: Boosts dissolution and absorption in the body

Each step is validated by Caltron's experienced quality control team to ensure pharma-grade consistency, traceability, and safety.

micronized calcium powder, natural antacid base, pharma excipient processor, bone health formulation supplier.

Sustainable Sourcing with Environmental Responsibility

Ethical Calcium, Engineered with Care

Caltron Clays & Chemicals upholds its commitment to sustainability by adhering to eco-conscious practices in both sourcing and processing:

Eco-Friendly Collection: Oyster shells sourced without disturbing marine ecosystems

Zero Waste Operations: By-products reused in construction and agriculture

Energy-Efficient Units: Reduced carbon emissions during calcination

eco-friendly calcium supplier, marine-derived calcium manufacturer, sustainable mineral sourcing India.

Customized Grades for Pharmaceutical Formulators

Built for Flexibility, Designed for Innovation

Pharma clients often have distinct formulation challenges. Caltron addresses them through tailored calcium grades:

Particle Size Customization: 100 mesh, 200 mesh, and micro-fine grades

Moisture-Proof Packaging: Available in 25kg HDPE bags or custom packaging

Formulation Support: Application recommendations and samples for R&D trials

formulation-ready calcium powder, pharmaceutical excipient solutions, bulk calcium supplier for pharma.

Whether you're developing tablets, capsules, suspensions, or food supplements, our Oyster Shell Calcium Powder adapts to your technical and regulatory needs seamlessly.

Why Caltron Stands Out in the B2B Pharmaceutical Industry

Your Strategic Calcium Partner, Not Just a Supplier

Caltron isn’t just a vendor. We collaborate with your product development, procurement, and compliance teams to ensure:

End-to-End Technical Support

Real-Time Batch Consistency Reports

Pan-India and Export Logistics

Our mission is to streamline your supply chain and maximize formulation efficiency while boosting your product credibility.

calcium powder supplier for pharma, pharmaceutical ingredient sourcing, calcium for healthcare manufacturers.

The Global Pharma Shift to Natural Minerals – Be Part of It with Caltron

Future-Forward Formulations with Caltron Calcium

Pharma trends show a growing demand for natural calcium ingredients with traceable origins and transparent sourcing. Caltron's Oyster Shell Calcium Powder directly supports this shift by offering:

Natural source appeal

Enhanced bioavailability vs. synthetic alternatives

Alignment with clean-label product trends

clean label pharma ingredients, calcium carbonate from marine shells, organic calcium supplementation.

As health-conscious end-users demand better ingredients, Caltron is here to supply the raw materials that power better outcomes.

Partner with Caltron Clays & Chemicals Today

India's Most Reliable Oyster Shell Calcium Powder Manufacturer for Pharma

If you're a pharmaceutical manufacturer seeking a reliable, scalable, and consistent calcium powder supplier, Caltron Clays & Chemicals offers unmatched value.

Industry-respected for quality

Preferred by leading supplement brands

Trusted by global export houses

Make your next formulation count with Caltron's pharma-grade Oyster Shell Calcium Powder.

Explore more Pharmaceutical Raw materials: Egg Membrane Powder Caltron’s MCHC Powder Ossein

Experience the Caltron Advantage Today!

Visit: Caltron Clays & Chemicals Office: 210 & 211, Level 2, Orbit Premises, Mind Space, Chincholi, Malad (West), Mumbai – 400064, India Email: [email protected] | [email protected] Tel: +91-22- 3571 9844 / +91-22-4010 6828 Google Maps: Caltron Location

Caltron Clays & Chemicals – Redefining trust, purity, and performance as the leading Oyster Shell Calcium Powder manufacturer and supplier in India.

0 notes

Text

How Textile Rubber Composite Testing Supports Quality Control in Manufacturing?

In modern manufacturing, quality control is a critical component that ensures products meet stringent performance, safety, and durability standards. When it comes to textile rubber composites—a unique combination of textile fibers and rubber compounds used across industries such as automotive, aerospace, construction, and consumer goods—robust quality control is essential to guarantee reliability and customer satisfaction.

This is where textile rubber composite testing comes into play. Testing these composites helps manufacturers maintain high-quality standards, optimize production processes, and ensure that end products meet regulatory and market demands. In this blog, we’ll explore how textile rubber composite testing supports quality control in manufacturing, its key benefits, and the most relevant testing methods used by labs worldwide.

Understanding Textile Rubber Composites in Manufacturing