#Chemical Raw Material testing Lab

Text

Raw Material Testing Lab Mumbai, Pune, Nashik, Chennai, Hyderabad, India

#Plastic Raw Material Testing#Rubber Raw Material Testing Lab#Composite Raw Material Testing Lab#Chemical Raw Material testing Lab#Metallic raw material

0 notes

Photo

A stormy, active sun may have kickstarted life on Earth The first building blocks of life on Earth may have formed thanks to eruptions from our Sun, a new study finds. A series of chemical experiments show how solar particles, colliding with gases in Earth’s early atmosphere, can form amino acids and carboxylic acids, the basic building blocks of proteins and organic life. The findings were published in the journal Life. To understand the origins of life, many scientists try to explain how amino acids, the raw materials from which proteins and all cellular life, were formed. The best-known proposal originated in the late 1800s as scientists speculated that life might have begun in a “warm little pond”: A soup of chemicals, energized by lightning, heat, and other energy sources, that could mix together in concentrated amounts to form organic molecules. In 1953, Stanley Miller of the University of Chicago tried to recreate these primordial conditions in the lab. Miller filled a closed chamber with methane, ammonia, water, and molecular hydrogen – gases thought to be prevalent in Earth’s early atmosphere – and repeatedly ignited an electrical spark to simulate lightning. A week later, Miller and his graduate advisor Harold Urey analyzed the chamber’s contents and found that 20 different amino acids had formed. “That was a big revelation,” said Vladimir Airapetian, a stellar astrophysicist at NASA’s Goddard Space Flight Center in Greenbelt, Maryland, and coauthor of the new paper. “From the basic components of early Earth’s atmosphere, you can synthesize these complex organic molecules.” But the last 70 years have complicated this interpretation. Scientists now believe ammonia (NH3) and methane (CH4) were far less abundant; instead, Earth's air was filled with carbon dioxide (CO2) and molecular nitrogen (N2), which require more energy to break down. These gases can still yield amino acids, but in greatly reduced quantities. Seeking alternative energy sources, some scientists pointed to shockwaves from incoming meteors. Others cited solar ultraviolet radiation. Airapatian, using data from NASA’s Kepler mission, pointed to a new idea: energetic particles from our Sun. Kepler observed far-off stars at different stages in their lifecycle, but its data provides hints about our Sun’s past. In 2016, Airapetian published a study suggesting that during Earth’s first 100 million years, the Sun was about 30% dimmer. But solar “superflares” – powerful eruptions we only see once every 100 years or so today – would have erupted once every 3-10 days. These superflares launch near-light speed particles that would regularly collide with our atmosphere, kickstarting chemical reactions. “As soon as I published that paper, the team from the Yokohama National University from Japan contacted me,” Airapetian said. Dr. Kobayashi, a professor of chemistry there, had spent the last 30 years studying prebiotic chemistry. He was trying to understand how galactic cosmic rays – incoming particles from outside our solar system – could have affected early Earth's atmosphere. “Most investigators ignore galactic cosmic rays because they require specialized equipment, like particle accelerators," Kobayashi said. "I was fortunate enough to have access to several of them near our facilities." Minor tweaks to Kobayashi's experimental setup could put Airapatian's ideas to the test. Airapetian, Kobayashi, and their collaborators created a mixture of gases matching early Earth’s atmosphere as we understand it today. They combined carbon dioxide, molecular nitrogen, water, and a variable amount of methane. (The methane proportion in Earth’s early atmosphere is uncertain but thought to be low.) They shot the gas mixtures with protons (simulating solar particles) or ignited them with spark discharges (simulating lightning), replicating the Miller-Urey experiment for comparison. As long as the methane proportion was over 0.5%, the mixtures shot by protons (solar particles) produced detectable amounts of amino acids and carboxylic acids. But the spark discharges (lightning) required about a 15% methane concentration before any amino acids formed at all. “And even at 15% methane, the production rate of the amino acids by lightning is a million times less than by protons,” Airapetian added. Protons also tended to produce more carboxylic acids (a precursor of amino acids) than those ignited by spark discharges. All else being equal, solar particles appear to be a more efficient energy source than lightning. But all else likely wasn’t equal, Airapetian suggested. Miller and Urey assumed that lightning was just as common at the time of the “warm little pond” as it is today. But lightning, which comes from thunderclouds formed by rising warm air, would have been rarer under a 30% dimmer Sun. “During cold conditions you never have lightning, and early Earth was under a pretty faint Sun,” Airapetian said. “That's not saying that it couldn't have come from lightning, but lightning seems less likely now, and solar particles seems more likely.” These experiments suggest our active young Sun could have catalyzed the precursors of life more easily, and perhaps earlier, than previously assumed.

4 notes

·

View notes

Photo

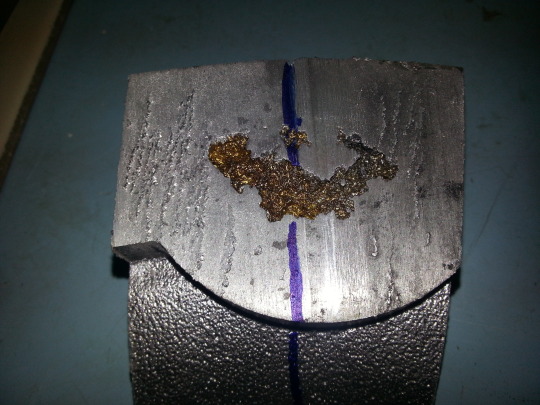

Virat Special Steels Pvt. Ltd.

AN ISO 9001:2008 CERTIFIED TRADING COMPANY

We are committed with the continuously improvement and up gradation of our infrastructure to world class standards.

VIRAT SPECIAL STEELS PVT. LTD. is one of the largest Importer, Exporter and Stuckist of Die Blocks (DIN 1.2714, DB6, H13, H11), Tool Steels, Die Steels, Special Steels and Alloy Steels in various grades.

Our material stocking capacity in our 3 yards shed at different regions together is more than 3500 tons and having complete and updated infrastructure with facility of horizontal & vertical band saw cutting machines running at our different ware houses in different regions to serve the ever increasing delivery requirement of our esteemed clients.

We have our own machining shop which can help our customers with some value addition and also save their downtime with regards to raw material. Having the dedicated team strength of 50 people we can also claim to have one of the fastest responding people to the queries of our end users.

MACHINERY & EQUIPMENTS:

- 27 Bimetal Horizontal & Vertical Bandsaw Machines (Cutting capacity upto 2500mm x 1100mm)

- 14 Overhead lifting Cranes - Lifting capacity upto 20 Tons

- Lifting Magnets = 20 Nos. – Lifting capacity upto 5 Tons

- 2 Fork Lifter - Lifting capacity upto 3 Tons

- Chemical & Spectro Lab

- UT Testing Machine

- Machining Plant

- Hardness Tester

For more information visit

https://www.viratsteels.com/

#iso9001#engineering#steel#alloy steel#cold work steel#die steels#high speed steel#h13steels#toolsteel#toolsteelsupplier#viratsteels#viratsteelsindia#2714steel#db6steel#din2344#h13steel#h11

3 notes

·

View notes

Text

The Biological Sciences as a Career

The biological sciences are an excellent place to start whether you're considering career possibilities or have just begun your job hunt. The subject has many different professions, from research scientists to wildlife conservationists.

A bachelor's degree in biology, chemistry or a closely related discipline is often required for work in the biological sciences. Nevertheless, a master's or doctorate may be necessary for higher roles.

A research scientist designs and executes lab tests in a particular branch of biology. In a business or government organization, they may also help create products or procedures.

A bachelor's or master's degree in a specific subject, such as chemistry, computer science, environmental science, biology, or medicine, is usually required. They could also hold a Doctorate in the subject matter.

Some research scientists also have academic positions where they instruct future generations of scientists about a particular field of study and conduct studies.

Pharmaceuticals and medical research are two fields where research scientists are employed. The region and industry have an impact on these occupations' pay.

Medical researchers design and carry out experiments on illnesses and disorders to advance scientific understanding of issues relating to medicine and public health. Companies frequently use this research to create new medicines or healthcare items.

A bachelor's degree in a scientific discipline, such as chemistry, biology, or biomedical engineering, is required for those who want to work as medical researchers. Also, they must obtain expertise in research, grant writing, and laboratory work.

They generally then seek a Doctorate in a related branch of science. Students in these programs complete dissertations presented before a committee of experts, concentrating on laboratory work and original research.

Medical scientists can work in academic institutions or the business sector on research projects accepted by the employer after earning a Doctorate. They often need excellent oral and written communication abilities to communicate their results to doctors and other healthcare professionals.

To address issues with the production or usage of chemicals, fuels, pharmaceuticals, and food, chemical engineers employ the concepts of chemistry, biology, physics, and arithmetic. They are employed in manufacturing facilities, research labs, and pilot plant establishments.

Chemical engineering is the area of engineering that develops machinery, methods, and procedures for blending, compounding, and processing chemicals to create valuable products from raw materials. The fundamental concepts include material and energy balances, thermodynamics, fluid mechanics, separation technologies, and chemical reactor design.

Chemical engineers have a wide range of career options and can choose to work in various sectors. Examples include the production of ammonium nitrate at a fertilizer plant, converting crude oil into gasoline, jet fuel, diesel fuel, and lubricating oil in a petroleum refinery, or blending several chemicals to create shampoo or body lotion at a personal care product maker.

Biomedical engineers create and develop devices that aid doctors in patient diagnosis and treatment. Examples include medical imaging equipment and tools that enable remote medication or surgical patient treatment.

The discipline of biomedical engineering is ever-evolving, making it a great fit for those who appreciate the challenge of developing novel solutions to new issues. These advancements immediately enhance the health and quality of life of patients.

Work environments for biomedical engineers include hospitals, research centers, educational institutions, and governmental organizations. They create brand-new gadgets, evaluate their performance, and offer technical assistance for already-available goods.

3 notes

·

View notes

Text

How to decarboxylate marijuana

What It Is, Why You Need It, How To Do It

Decarboxylation. DO NOT let the long scientific name intimidate you and scare you off from reading this article. If you use cannabis and ESPECIALLY if you cook with cannabis, this tutorial on marijuana decarboxylation is vital information you need to know in order to get the most out of your cannabis.Don’t worry, I am going to break everything down in layman’s terms to make it easy to understand and do.

What is marijuana decarboxylation?

Scientifically speaking, Decarboxylation is a chemical reaction that removes a carboxyl group and releases carbon dioxide (CO2).So why the heck should cannabis users care about this? Because if you want to feel a buzz from your cannabis, you need it to be decarboxylated. Why? Because believe it or not, the raw cannabis plant contains no THC!https://youtu.be/ojMKQk9B38URaw cannabis contains the acidic form of this cannabinoid, THC-A or Tetrahydrocannabinolic Acid, which will not make you high. It takes the process of age and/or adding heat to decarboxylate the cannabis and convert the THC-A into psychoactive THC or Tetrahydrocannabinol.All the cannabinoids contained in raw cannabis flowers have an extra carboxyl ring or group (COOH) attached to their chain, so decarboxylation works with more than just THC, although this is where its effects will mostly be felt by the end cannabis consumer as the other cannabinoids don’t make you high.

Buy Better Buds!

Why do you need decarboxylation?

Besides the fact that you need decarboxylation if you want to get high from your cannabis, it also unlocks the full medicinal potential of other cannabinoids, such as CBDs, CBNs, and CBGs. Now to be sure, the acidic form of all these cannabinoids also has important medicinal benefits, so if a high is not important to you, full decarboxylation may not be either.So what do I mean when I say “full decarboxylation?” This would mean you are converting 100% of the THC-A in your plant material into THC. This is nearly impossible for reasons I’ll discuss in the next section, but know that usually some is left unconverted.Does it matter? To a degree, yes, but in my opinion, not as much as a lot of people think it does. I say this because unless you are ultra-sensitive to THC you probably are not going to notice a few points difference. And the THC-A left unconverted is imparting health benefits, so it’s not a big loss.I also say this because, long before lab tests showed that decarboxylating before making slow cooking infusions like butter and oil increases potency, we still made some potent AF infusions. Many people still do not bother to decarboxylate before making these infusions and still get great results.That said, most people do want to get as much potency as possible from their cannabis, so they are going to want to convert as much THC-A into THC as possible, which means they are going to want to know how to decarboxylate their marijuana. And not just flowers – kief, hash, and hash oils all benefit from decarboxylation as well.

Looking for Edibles?

How to decarboxylate marijuana

Consult 10 different sources and you’ll find 10 different methods for how to decarboxylate your marijuana. I tried to get some testing labs and scientists to go on record with the best times and temperatures for decarbing and could not get a straight answer from any of them. Perhaps this is because, like so many things with cannabis, there is no one simple answer. For instance, the amount of moisture in your plants can significantly affect the time needed to decarb, with more time needed for drying, and then decarbing. Or that decarbing CBD-A takes more time than decarbing THC-A.After researching lots of methods, especially those that have been lab-tested, my own views on decarbing have evolved. While I used to recommend about 20 minutes at 220 degrees F, I now see that a much longer decarb time can achieve far greater THC conversion. So I now recommend about an hour at 240 degrees F. thanks to the fine folks at the Marijuana Growers Headquarters who did some experiments and lab testing.

Before decarbing (left) After decarboxylation (right).

Place your cannabis or cannabis concentrate in an ovenproof dish, or on a baking sheet if you are decarbing a lot of plant material. Cover with foil and place in a preheated 240-degree oven for about an hour. Your cannabis is now decarbed and ready for cooking. You will notice that it appears and smells a bit “toasty.” You may also notice that you lost a little volume. This is normal. The photo above shows the same strain and amount of cannabis after (left) and before (right) decarboxylating.

Decarboxylating CBD

Interestingly enough, the experiments done by the Marijuana Growers Headquarters did not convert much of the CBD-A to CBD. Probably because as a general rule CBD needs longer to decarboxylate.CBD concentrates or isolates may or may not be decarbed already, although most are, so check the labels to see if this step is necessary. If it lists a high CBD content (as opposed to CBD-A) it has been decarbed.According to the experts at Sensi Seeds, you should decarb high CBD cannabis strains (defined as 90% or more of total cannabinoid content) for 15 minutes at a temperature of 220°F in order to dry the plants, and then 60 minutes at 250°F. for decarboxylation. As oils and isolates don’t need drying, I would just go with the 60 minutes at 250°F. for these, if needed at all.According to Project CBD’s Martin Lee, there is no exact boiling point number for CBD, but it is in the 320°F – 338°F range, slightly higher than THC.When using the Ardent Nova Lift Decarboxylator, inventor Shanel Lindsey recommends putting the cannabis through two decarbing cycles, IF (and ONLY IF) the plant matter contains under 1% THC, otherwise decarb CBD in the same manner as THC.Keep in mind CBD, like THC, metabolizes better in the presence of fat, so it is best to use it in recipes that contain fat, or alternately consume nonfat CBD edibles accompanied by a fat-containing food or beverage.

Read the full article

3 notes

·

View notes

Text

Why Dubai is a Hub for Advanced Chemical Testing Laboratories

Dubai has emerged as a global leader in various industries, from tourism and real estate to finance and technology. One often overlooked but equally significant sector where Dubai excels is chemical testing. The city has become a hub for advanced chemical testing laboratories, attracting businesses from around the world. This blog explores why Dubai is a premier destination for chemical testing labs and how this benefits industries and consumers alike.

Strategic Location and Global Connectivity

Dubai's strategic geographical location serves as a bridge between the East and the West, making it an ideal place for international trade and commerce. This advantage extends to the chemical testing sector, where timely and efficient logistics are crucial.

Benefits:

Ease of Access: Businesses from Europe, Asia, and Africa can easily access Dubai for their testing needs.

Efficient Logistics: The city's world-class ports and airports facilitate the swift transportation of samples and materials.

Government Support and Investment

Dubai's government is committed to fostering innovation and excellence in various sectors, including chemical testing. Significant investments have been made to develop state-of-the-art laboratories and infrastructure.

Key Initiatives:

Free Zones: Areas like Dubai Science Park and Jebel Ali Free Zone offer incentives such as tax exemptions and full foreign ownership to attract scientific and technological businesses.

Regulatory Framework: Dubai's stringent regulatory standards ensure that labs operate at the highest levels of accuracy and reliability.

Cutting-Edge Technology and Innovation

Chemical testing labs in Dubai are equipped with the latest technology and instruments, ensuring precise and reliable results. The city's commitment to innovation has led to the adoption of advanced testing methodologies and practices.

Advanced Technologies:

Chromatography: Used for separating and analyzing complex mixtures.

Mass Spectrometry: Identifies compounds based on mass and charge.

Spectroscopy: Measures the interaction of light with matter to identify substances.

Research and Development:

Innovation Hubs: Dubai hosts several R&D centers that focus on developing new testing methods and improving existing ones.

Collaborations: Labs often collaborate with universities and research institutions to stay at the forefront of technological advancements.

Diverse Range of Services

Dubai's chemical testing laboratories offer a broad spectrum of services to cater to various industries. This diversity makes it a one-stop destination for businesses with multiple testing needs.

Services Offered:

Pharmaceutical Testing: Ensures the safety and efficacy of drugs and medical devices.

Food and Beverage Testing: Verifies nutritional content and detects contaminants.

Environmental Testing: Analyzes air, water, and soil samples for pollutants.

Material Testing: Assesses the quality and durability of construction materials.

Industry Applications:

Manufacturing: Ensures that raw materials and finished products meet quality standards.

Healthcare: Verifies the safety and efficacy of pharmaceuticals and medical devices.

Agriculture: Tests soil and water quality to ensure optimal crop production.

Accreditation and Standards

Dubai's chemical testing labs adhere to international standards, ensuring high levels of accuracy, reliability, and trustworthiness. Accreditation from global bodies like ISO/IEC 17025 is common, reinforcing the credibility of the labs.

Accreditation Bodies:

ISO/IEC 17025: Specifies the general requirements for the competence of testing and calibration laboratories.

Dubai Accreditation Center (DAC): Provides accreditation to labs in compliance with international standards.

Quality Assurance:

Regular Audits: Labs undergo frequent audits to ensure compliance with international standards.

Certification Programs: Continuous certification and recertification processes maintain high-quality standards.

Skilled Workforce

The availability of a highly skilled workforce is another reason why Dubai is a hub for advanced chemical testing laboratories. The city attracts top talent from around the world, ensuring that labs are staffed with experienced and knowledgeable professionals.

Education and Training:

Universities and Colleges: Dubai is home to several institutions that offer specialized courses in chemistry, biotechnology, and related fields.

Professional Development: Continuous training and development programs ensure that lab personnel stay updated with the latest advancements in the field.

Expertise:

Experienced Chemists: Many labs employ chemists with extensive experience in various industries.

Multidisciplinary Teams: Teams often comprise experts from different fields, providing a comprehensive approach to testing.

Economic Stability and Business Environment

Dubai's economic stability and favorable business environment make it an attractive destination for investment in advanced chemical testing laboratories. The city's robust economy provides a stable platform for businesses to thrive.

Business-Friendly Policies:

Ease of Doing Business: Dubai ranks high on the global Ease of Doing Business index, with streamlined processes for setting up and operating businesses.

Tax Benefits: Free zones offer tax exemptions and other financial incentives to attract foreign investment.

Economic Diversification:

Growing Sectors: Industries such as healthcare, pharmaceuticals, and manufacturing are rapidly growing in Dubai, increasing the demand for chemical testing services.

Sustainability Initiatives: Dubai's focus on sustainability and environmental protection drives the need for advanced environmental testing services.

Case Studies: Leading Chemical Testing Labs in Dubai

Dubai Central Laboratory (DCL)

Operated by Dubai Municipality, DCL is renowned for its comprehensive range of testing services. Equipped with advanced technology, DCL provides reliable and accurate results across various sectors.

METS Laboratories

A global leader in laboratory services, METS Laboratories has a significant presence in Dubai. The lab offers specialized testing services, leveraging its global expertise and advanced technology.

SGS Gulf Limited

Part of the SGS Group, SGS Gulf Limited provides a wide range of chemical testing services. Known for its rigorous quality control standards, SGS is a trusted partner for businesses in Dubai.

Intertek

Intertek's innovative testing methods and commitment to quality make it a prominent player in Dubai's chemical testing industry. The lab offers a variety of services, including regulatory compliance testing and material analysis.

Bureau Veritas

With a global reputation for excellence, Bureau Veritas offers comprehensive chemical testing services in Dubai. The lab's stringent quality control processes ensure that products meet the highest safety and quality standards.

Conclusion

Dubai's strategic location, government support, advanced technology, diverse services, international accreditation, skilled workforce, and favorable business environment collectively make it a hub for advanced chemical testing lab. These factors not only attract businesses from around the world but also ensure that they receive reliable, accurate, and high-quality testing services. As Dubai continues to grow and diversify its economy, the importance of chemical testing labs in maintaining safety, quality, and regulatory compliance will only increase, further solidifying the city's position as a global leader in this essential sector.

0 notes

Text

Types Laboratory Glassware Manufacturer For a School Science Classroom

Laboratory Glassware Ambala, a prominent laboratory glassware manufacturer in India, specializes in supplying high-quality glass adapters and other scientific laboratory glassware. Our products are essential academic resources, widely used in science laboratories across colleges worldwide. As leading glass adapter exporters, we have earned a global reputation for excellence and reliability in the industry

A wide range of objects are utilized in laboratory investigations, which is known as laboratory glassware manufacturing. Slides for microscopic examination, funnels, burettes for precise liquid measurements, and reagent bottles for chemical storage are examples of laboratory glassware manufactured in laboratories. Superior borosilicate glass is used in the production of laboratory glassware. It has undergone extensive testing to withstand high temperatures and chemical exposure without breaking down. Moreover, easily customisable goods allow experienced scientific glassblowers to quickly produce customized objects made especially for studies.

We manufacture high quality laboratory glassware with the use of supreme quality raw materials from the trusted sources. Our laboratory glassware is used in various educational institutes, testing & research centers, forensic labs, microbiology, biotechnology, pharmaceutical labs around the world.

Few of our laboratory glasswares are beaker low form, beaker tall form, flask erlenmeyer, flask round bottom, flask flat bottom, flask, flask distillation, flask filtration, flask conical, weighing bottles, aspirator bottle with screw type etc.

Laboratory Glassware Ambala have been in the education and laboratory instruments business for 40 years with all products made in India. Since its incorporation, it is operated by veterans who have been in this industry for over 45 years. Our team has been and will continue to be committed to the educational science industry to provide quality products at competitive prices to our clients all over the world.

Our Products

We at Laboratory Glassware Ambala provide a wide selection of glassware for laboratories that is intended to satisfy the different requirements of scientists, educators, and researchers working in different sectors. Among our product offerings are:

Beakers

Flasks (Round Bottom, Erlenmeyer, Conical)

Condensers

Pipettes (Volumetric, Graduated)

Burettes

Measuring Cylinders

Desiccators

Test Tubes

Petri Dishes

And More!

We offer a wide range of laboratory glassware made from borosilicate glass, known for its:

Excellent chemical resistance

High thermal endurance

Superior clarity

Our Commitment to Quality:

We use only premium-grade borosilicate glass to ensure the durability and accuracy of our products.

Our manufacturing processes adhere to strict quality control standards.

Many of our products are ISI marked, signifying their compliance with Indian safety and quality benchmarks.

We cater to the needs of various sectors, including:

Educational Institutions (Schools & Universities)

Research Laboratories (Government & Private)

Pharmaceutical Companies

Chemical Industries

Food & Beverage Industry

0 notes

Text

GOA Pharma Jobs: VerGo Pharma Research Laboratories Hiring in Multiple Departments

VerGo Pharma Research Laboratories Pvt. Ltd., a leading Contract Development and Manufacturing Organization (CDMO) based in Verna, Goa, is currently seeking qualified candidates for various positions in Manufacturing, Analytical Development, Quality Control, and Engineering. If you have the relevant experience and qualifications, this is an excellent opportunity to advance your career in the pharmaceutical industry.

Job Location: Verna, Goa

About VerGo Pharma Research Laboratories: VerGo Pharma is renowned for its commitment to quality and innovation in pharmaceutical research and development. The company is expanding its team and looking for talented professionals to join their dynamic workforce.

Available Positions and Qualifications

1. Analytical Development

Qualification: MSc/B.Pharm/M.Pharm

Experience: 2-3 years in Analytical Development and Validation

Responsibilities:

Conduct analytical method development and validation.

Perform stability testing and document results.

Ensure compliance with regulatory standards.

2. Engineering

Qualification: Diploma or BE in Electrical Engineering

Experience: 2-5 years in pharma documentation, validation, and protocol execution

Responsibilities:

Oversee electrical systems and ensure their proper functioning.

Validate and execute engineering protocols.

Maintain detailed documentation of engineering processes.

3. Quality Control (QC)

Qualification: B.Sc/M.Sc/B.Pharm

Experience: 2-3 years in HPLC analysis, RS analysis, and chemical analysis

Responsibilities:

Conduct routine and non-routine analysis of raw materials and finished products.

Utilize HPLC and other analytical techniques.

Maintain accurate and detailed documentation.

4. Manufacturing

Qualification: B.Pharm/M.Pharm

Experience: 2-4 years in Granulation, Compression, Coating

Responsibilities:

Oversee manufacturing processes such as granulation, compression, and coating.

Ensure compliance with GMP standards.

Maintain detailed records of production activities.

[caption id="attachment_49509" align="aligncenter" width="930"] Vergo Pharma Research Labs Goa Hiring For Production Executive[/caption]

How to Apply

Interested candidates are invited to send their CVs to [email protected]. Ensure to include details of your current CTC and notice period.

0 notes

Text

From Design to Delivery: The Journey of a Forged Product

Forging is a centuries-old manufacturing process that involves shaping metal using compressive forces. From the initial design phase to the final delivery of the product, the journey of a forged item is a fascinating process that requires precision, expertise, and careful attention to detail. In this blog, we'll delve into each stage of this journey, exploring the intricate steps involved in bringing a forged product to life.

Journey of Forged Product-

The journey of a forged product is a meticulous process, ensuring the highest quality and precision. Here's a detailed look at each stage of this journey:

1. Covered Raw Material Yard

The journey begins in the covered raw material yard, where raw materials are stored under optimal conditions. This step ensures that the raw materials remain free from contaminants and are ready for processing.

2. Billet Cutting Section

Next, the raw materials move to the billet cutting section. Here, the materials are cut into smaller, manageable pieces called billets. Precision cutting is crucial to ensure the billets are of the exact size required for forging.

3. Metallurgical Testing Lab

Quality control is key, so the billets undergo rigorous testing in the metallurgical testing lab. This stage involves analyzing the chemical composition and mechanical properties to ensure they meet the required standards.

4. Forging

The core of the process is forging. In this step, the billets are heated to high temperatures and shaped into the desired form using powerful forging presses and hammers. This process enhances the material's strength and durability.

5. Controlled Cooling

After forging, the products undergo controlled cooling. This step is crucial to relieve internal stresses and refine the material's structure, ensuring uniformity and stability in the final product.

6. Heat Treatment

Heat treatment follows, where the forged products are subjected to precise temperature cycles to enhance their mechanical properties. This process improves hardness, strength, and toughness, making the products suitable for demanding applications.

7. Machining

Once heat-treated, the products move to the machining section. Here, they are precisely shaped and finished to meet exact specifications. Machining ensures that the products have the correct dimensions and surface finish.

8. Standard Room

In the standard room, the products undergo thorough inspections using high-precision measuring instruments. This step ensures that the products comply with all dimensional and geometric tolerances.

9. Final Inspection

A comprehensive final inspection is conducted to verify the overall quality of the forged products. This includes visual checks and functional tests to ensure the products meet all quality standards and customer requirements.

10. Packaging and Delivery:

Once the product has passed all quality checks, it is carefully packaged to protect it during transportation. We utilize industry-standard packaging materials and techniques to safeguard the integrity of the product. Whether it's a single component or a batch of products, each item is labeled and tracked to ensure timely delivery to our customers. Our logistics team works closely with trusted shipping partners to coordinate delivery schedules and optimize efficiency.

Conclusion

The journey of a forged product is a testament to the skill, precision, and dedication of everyone involved in the manufacturing process. From the initial design phase to the final delivery, each step is carefully orchestrated to ensure the highest quality and performance standards are met. At Happy Forging Ltd., we take pride in our commitment to excellence and customer satisfaction. With state-of-the-art facilities, experienced professionals, and a relentless pursuit of innovation, we are your trusted partner for all your forging needs. Experience the difference with Happy Forging Ltd. today!

0 notes

Text

Chemical Testing Service in New Jersey

Chemical testing services in New Jersey provide precise analysis suited to particular requirements and applications, serving a wide range of industries. These laboratories offer specialised testing protocols and state-of-the-art instrumentation to deliver accurate and dependable results, whether the clients are pharmaceutical companies looking to validate the purity and potency of drug formulations, food manufacturers ensuring the safety and authenticity of their products, or environmental agencies monitoring the quality of the air and water.

In sectors ranging from manufacturing and environmental protection to healthcare and food production, regulatory compliance is essential to quality assurance. Chemical testing services in New Jersey assist companies in navigating intricate regulatory environments and guarantee that laws and industry standards are followed.

In determining how chemicals affect the environment and encouraging sustainable practices, chemical testing services in New Jersey are essential. These services guarantee compliance with environmental laws and aid in conservation efforts by identifying and measuring pollutants in soil, water, and air samples. Chemical testing laboratories help to preserve New Jersey's natural resources and develop eco-friendly products by offering precise data on the chemical composition of the environment.

Beyond the cliché of a lab coat and boiling beakers, chemical testing services in New Jersey serve a wide range of purposes. Here's an overview of the various topics they focus on:

Guardians of the Environment: Analysing samples of soil, water, and air to detect pollutants and guarantee that environmental laws are being followed.

Champions of quality control: describing materials, whether raw and finished, to confirm their characteristics and composition, making sure they adhere to certain requirements.

Forensic Warriors: Supporting criminal investigations by examining evidence to check for the existence of illicit substances.

Pharmaceutical protectors: Ensuring the efficacy, purity, and safety of drugs during the development and production stages, protecting the general public's health.

Food Safety Defenders: Keeping people safe by spotting dangerous germs, allergies, and other pollutants in food goods.

#Chemical Testing Service in New Jersey#new jersey#usa#pharmacy#research and development center in new jersey#medicine#chemistry#chemical reactions

0 notes

Text

Pioneering Cyclopropyl Magnesium Bromide Manufacturing Excellence

In the realm of organic chemistry, Cyclopropyl Magnesium Bromide stands as a versatile and indispensable reagent, facilitating the synthesis of a wide array of complex organic molecules. As the demand for this specialized compound continues to escalate, the need for reliable and innovative manufacturers becomes increasingly paramount. In this landscape, Symax Labs emerges as a beacon of excellence, revolutionizing Cyclopropyl Magnesium Bromide manufacturing standards with its unwavering commitment to quality, innovation, and customer satisfaction.

A Legacy of Excellence:

With a rich history of chemical expertise and a relentless pursuit of excellence, Symax Labs has earned its reputation as a trailblazer in the chemical manufacturing industry. Founded on principles of integrity, precision, and innovation, the company has consistently delivered top-tier products and services to clients across various sectors.

Unveiling the Manufacturing Process:

At the heart of Symax Labs' success lies its cutting-edge manufacturing facility, meticulously engineered to uphold the highest standards of quality and efficiency in Cyclopropyl Magnesium Bromide production. Armed with state-of-the-art technology and manned by a team of seasoned professionals, the facility ensures every stage of the manufacturing process is executed with meticulous precision and adherence to strict quality control protocols.

From sourcing the finest raw materials to the synthesis and purification of Cyclopropyl Magnesium Bromide, Symax Labs leaves no stone unturned in its quest for excellence. Each batch undergoes rigorous testing and analysis to guarantee purity, consistency, and efficacy, thereby instilling confidence in clients regarding the reliability and performance of the product.

Driving Innovation Forward:

Innovation lies at the core of Symax Labs' ethos, propelling the company to continually push the boundaries of Cyclopropyl Magnesium Bromide manufacturing. With a dedicated team of researchers and chemists, Symax Labs remains at the forefront of scientific exploration, constantly exploring novel synthetic methodologies, optimizing reaction conditions, and expanding the application scope of Cyclopropyl Magnesium Bromide.

By fostering a culture of experimentation and collaboration, Symax Labs empowers researchers and industries alike with groundbreaking solutions and cutting-edge technologies. Whether it's streamlining production processes, enhancing reagent stability, or developing customized formulations, Symax Labs remains committed to driving innovation forward and shaping the future of organic synthesis.

Embracing Sustainability:

As stewards of the environment, Symax Labs is deeply committed to promoting sustainability and minimizing its ecological footprint. Through the implementation of eco-friendly practices, resource optimization strategies, and waste reduction initiatives, the company strives to operate in harmony with nature while meeting the demands of a rapidly evolving market.

By prioritizing sustainability in its operations, Symax Labs not only fulfills its corporate responsibility but also sets a benchmark for the industry to follow. From energy-efficient manufacturing processes to responsible waste management practices, Symax Labs demonstrates its unwavering commitment to environmental stewardship in every facet of its operations.

Partnering for Progress:

In addition to its dedication to quality and innovation, Symax Labs places great emphasis on fostering strong partnerships and collaborations within the industry. By forging strategic alliances with academic institutions, research organizations, and industry stakeholders, Symax Labs facilitates knowledge exchange, drives collaborative research initiatives, and accelerates innovation across the board.

Moreover, Symax Labs remains deeply rooted in the communities it serves, actively contributing to local development initiatives, education programs, and environmental conservation efforts. Through its commitment to corporate social responsibility, Symax Labs aims to create a positive impact that transcends business boundaries and fosters sustainable growth and prosperity.

Charting a Course for the Future:

As Symax Labs looks ahead, it remains steadfast in its commitment to excellence, innovation, and sustainability in Cyclopropyl Magnesium Bromide manufacturing. With a clear vision and unwavering determination, the company is poised to continue setting new benchmarks of success, driving progress, and shaping the future of the chemical industry.

Through its relentless pursuit of quality, its passion for innovation, and its dedication to customer satisfaction, Symax Labs stands ready to meet the evolving needs of clients and lead the way towards a brighter, more sustainable future. As the demand for Cyclopropyl Magnesium Bromide continues to soar, Symax Labs remains at the forefront, pioneering manufacturing excellence and driving progress for generations to come.

0 notes

Link

#Corrosion Testing#Corrosion Product Powder Testing lab#Chemical Analaysis#Failure Analysis#Raw Material Testing

0 notes

Text

In 1902, the British Medical Journal reported an unusual case of rapid hair whitening.

A 22-year-old woman “witnessed a tragedy of a woman’s throat being cut and the victim falling dead at her feet,” according to a physician at the London Temperance Hospital. The next day, the right side of her pubic hair turned white, while the left half remained black.

This historic case study makes for a terribly weird (and rapid) example of an otherwise common occurrence: gray hairs seem to accumulate when we’re stressed. And it’s not just random violence that sends people’s pigment running—college exams, children, and work pressure appear to change our coloring, too. But for millennia, scholars have been relying mostly on anecdotal proof and intuition to rationalize this phenomenon. In the absence of clear evidence, many scientists did not believe stress could turn hair snow white, instead arguing the change must be triggered by chemicals or strange immune system behavior. Rare cases where doctors observed the rapid whitening—like in the 1902 BMJ study—were a source of endless consternation.

A 2020 paper, published in the journal Nature, may put some of these arguments to rest. In the study, stem cell and regenerative biologists from the United States and Brazil reported that stress can indeed cause hair to lose its pigment—and they identified a cellular pathway by which it can occur.

To study this vexing relationship, the researchers created an elaborate animal model, which basically involved trying to turn black-haired rats white with lab-made stressors. They tried three different tactics: restraint stress, chronic unpredictable stress, and nociception-induced stress, which is caused by physical pain (or the threat of it). Each successfully turned the rat’s hair white. Perhaps unsurprisingly, nociception-induced stress, which the scientists stimulated by injecting the rats with resiniferatoxin, an analogue of the chili pepper compound capsaicin, worked best and fastest.

Having identified the optimal way to make a rat panic, the team began searching for corresponding changes in the physiological pathways that give rise to coat color. They were particularly interested in the behaviors of two types of cells: differentiated melanocytes, which produce pigment in the hair and skin, and melanocyte stem cells, the raw material from which melanocytes develop. To observe each one independently, the researchers injected their tiny test subjects with the hot pepper-like substance when the rats’ fur was actively growing. At that point in the hair growth cycle, differentiated melanocytes naturally cluster in the hair bulb, while melanocyte stem cells gather together in a separate space called the bulge.

For five days after the injection, the rats’ coats remained black. The differentiated melanocytes in the hair bulb continued to pump out color. But in many follicles, the overtaxed melanocyte stem cells were “completely lost,” the researchers report. Pushed by a flood of noradrenaline, a neurotransmitter that surges in response to stress, the existing stem cells proliferated so quickly that they completely disappeared from their niche. The next time the rats’ coat grew, there were no melanocyte stem cells in these damaged follicles, so white hairs sprouted.

“In just a few days, the reservoir of pigment-regenerating stem cells [was] depleted,” Ya-Chieh Hsu, a professor of stem cell and regenerative biology at Harvard and the study’s senior author, told PopSci in an email. The loss was permanent. “And once they’re gone, pigment cannot be generated anymore.”

“This is an exquisitely elegant paper unrevealing an important mechanism of hair graying,” Alexey Terskikh, who researches development, aging, and regeneration at the Sanford Burnham Prebys Medical Discovery Institute, wrote via email.

But there are many other ways hair can lose its color. A 2018 paper suggested an overactive immune response can also destroy melanocytes and melanocyte stem cells in rats, bleaching their coat. Certain skin cancer drugs turn some patients’ hair transparent. Doctors think it’s a sign their bodies are responding positively to the drug. Genetic pathways, environmental pathways, and mutations can also play a role, according to Terskikh.

Hair still holds many secrets. We don’t know why hair loss plays out differently on someone’s scalp than on their face or, for that matter, their back. And, unfortunately for the anonymous Englishwoman with world-famous pubes, doctors still don’t agree about canities subita, the contested phenomenon where hair blanches seemingly overnight. But, in many cases, scientists are narrowing in on answers. In recent years, there’s been a surge in research and development for anti-balding solutions—and many of them show promise. Terskikh, for his part, is working on regenerating hair from scratch using things like pluripotent stem cells. If it works, we’ll have an unlimited supply of hair—presumably in every shade.

#hair color#science#gray hair#health#stress#Having identified the optimal way to make a rat panic :((((#imagine if they did this to people

0 notes

Photo

Virat Special Steels Pvt. Ltd. #ViratSpecialSteel

AN ISO 9001:2008 CERTIFIED TRADING COMPANY

We are committed with the continuously improvement and up gradation of our infrastructure to world class standards.

Our material stocking capacity in our 3 yards shed at different regions together is more than 3500 tons and having complete and updated infrastructure with facility of horizontal & vertical band saw cutting machines running at our different ware houses in different regions to serve the ever increasing delivery requirement of our esteemed clients.

We have our own machining shop which can help our customers with some value addition and also save their downtime with regards to raw material. Having the dedicated team strength of 50 people we can also claim to have one of the fastest responding people to the queries of our end users.

MACHINERY & EQUIPMENTS:

- 27 Bimetal Horizontal & Vertical Bandsaw Machines (Cutting capacity upto 2500mm x 1100mm)

- 14 Overhead lifting Cranes - Lifting capacity upto 20 Tons

- Lifting Magnets = 20 Nos. – Lifting capacity upto 5 Tons

- 2 Fork Lifter - Lifting capacity upto 3 Tons

- Chemical & Spectro Lab

- UT Testing Machine

- Machining Plant

- Hardness Tester

For more information visit

www.viratsteels.com

Email us: [email protected]

Call Us Now: +91-9814021775

#iso9001#engineering#toolsteel#toolsteelsupplier#die steels#moldsteel#viratsteelindia#viratsteels#viratspecialsteels#db6steel#h13steel#2714steel#din2714#mouldsteelstockist#gurugram#ludhiana#gurgaon#pune#india

2 notes

·

View notes

Text

Ensure Consistent Quality HDPE Granules for Pipe Production: Building Trust, One Pipe at a Time

High-density polyethylene (HDPE) pipes are the workhorses of modern infrastructure. Their durability, flexibility, and cost-effectiveness make them the go-to choice for transporting essential resources like clean water, gas, and even hazardous materials. However, the success of any HDPE pipe production process rests on a crucial foundation: consistent quality HDPE granules.

The Domino Effect of Inconsistent Quality

Imagine a house of cards — each card carefully placed, relying on the one below it for stability. Just like the house of cards, HDPE pipe production is a delicate balance. Each granule acts as a building block and any inconsistency in quality can have a cascading effect:

· Structural Weaknesses: Inconsistent granules can lead to weak spots in the final pipe, compromising its ability to withstand pressure and external forces. Leaks, bursts and even catastrophic infrastructure failures can potentially occur.

· Performance Fluctuations: Inconsistent granules can lead to inconsistencies in the pipe’s performance characteristics. Pressure rating, chemical resistance and even UV resistance may be compromised, jeopardizing the pipe’s suitability for its intended application.

· Reduced Lifespan: Pipes constructed with inconsistent granules may have a shorter lifespan. This translates to premature replacement needs, driving up overall infrastructure costs.

· Brand Reputation at Risk: Inconsistent pipe quality can erode a manufacturer’s reputation. Customers prioritize reliability and unreliable pipes can damage trust and brand image.

Choosing the Right HDPE Pipe Grade: It’s All About Specific Needs

Not all HDPE pipes are created equal. Different grades offer varying properties designed for specific applications. Here’s a breakdown of some common HDPE pipe grades:

· PE100: The gold standard for high-pressure applications like gas and water distribution due to its exceptional strength and pressure rating.

· PE80: A cost-effective option for non-pressurized drainage and sewage systems, balancing performance with affordability.

· PE32: Ideal for low-pressure applications like irrigation and electrical conduits, providing a lightweight and flexible solution.

Selecting the appropriate HDPE pipe grade based on project requirements is crucial. Consistent quality within the chosen grade ensures each granule contributes equally to the pipe’s overall integrity and performance.

Ensuring Consistent Quality: A Multi-Layered Approach

Maintaining consistent quality HDPE granules goes beyond simply choosing a reliable supplier. Here’s a multifaceted approach to achieving consistent quality:

· Partner with Reliable Suppliers: Seek out reputable HDPE pipe raw material suppliers who prioritize stringent quality control measures throughout their operations. This includes raw material selection, processing techniques and final product testing. Look for suppliers with demonstrating their commitment to quality management systems.

· Clear Communication is Key: Open communication channels are essential. Discuss your specific quality needs with your supplier and request detailed information on their quality control procedures. This allows you to understand their testing methods and ensure they align with industry standards.

· Rigorous Material Testing: Implement a robust material testing program. Evaluate the HDPE granules for key properties like melt flow index, density, and mechanical strength. This ensures the granules meet the specifications of the chosen HDPE pipe grade and industry standards. Consider partnering with independent testing labs to add a layer of objectivity to the process.

· Statistical Process Control (SPC): Implement SPC techniques to monitor your manufacturing process continuously. SPC allows for early detection of any inconsistencies in the pipe’s properties, enabling timely adjustments to maintain consistent quality. By tracking trends and identifying potential issues early on, you can prevent defective pipes from reaching the final stage of production.

Building Trust and Value: Benefits of Consistent Quality HDPE Granules

Consistent quality HDPE granules offer far more than just structural integrity and performance. They bring a host of benefits to manufacturers:

· Reduced Costs: Consistent quality translates to fewer defects and production delays. This minimizes manufacturing costs and waste, leading to long-term cost savings. By reducing the need for rework and scrap, manufacturers can optimize their production budgets.

· Enhanced Brand Reputation: Consistently delivering high-quality HDPE pipes allows manufacturers to build a reputation for reliability. This fosters trust within the market and can lead to repeat business and referrals. A strong brand reputation can also open doors to new business opportunities and partnerships.

· Streamlined Operations: With consistent quality granules, manufacturers can streamline production processes, resulting in improved efficiency and increased productivity.

#Hdpepipemanufacturing#Plasticrawmaterials#Viztaarmarketplace#Pipegradegranules#Sustainable Manufacturing

0 notes