#Samarium Cobalt magnets

Text

Loss of Permanent Magnet Magnetization Due to Cold Temperatures Exposure

Loss of Permanent Magnet Magnetization Due to Cold Temperatures Exposure

Loss of magnetization due to cold temperatures exposure is a phenomenon that occurs in various types of materials, particularly in magnetic materials. This phenomenon is commonly known as the “superparamagnetic effect” or “temperature-dependent magnetization.” It results from the thermal agitation of the atomic spins in the…

View On WordPress

#ceramic ferrite magnets#Ferrite Magnets#Ferrite Magnets Applications#hard ferrite magnet#High Temperature Resistance Magnet#high temperature resistant magnet#Magnet Magnetization#Magnet Raw Material#Magnetic Materials#magnetic properties#magnetic strength#magnetization#Neodymium rare earth magnets#permanent magnet demagnetization#Permanent rare earth magnets#Rare Earth Magnets#raw magnets#raw material price#samarium cobalt#Samarium Cobalt Magnets#Samarium Cobalt Rare Earth Magnets#Sintered Ferrite magnets#sintered hard ferrite magnets#Sintered rare earth magnets#Sintered Samarium Cobalt Magnets#SmCo#SmCo magnets

3 notes

·

View notes

Text

Working With Magnets in High or Low Temperatures

Working With Magnets in High or Low Temperatures

The ambient temperature surrounding your magnets during work impact their strength significantly, but each magnetic material is different. Which magnet works best in your conditions?

High or Low Temperatures | Get the Right Magnets for Your Application in High or Low Temperatures

Temperature and magnetic strength have a turbulent relationship.

Some…

View On WordPress

#Alnico magnets#Ceramic Ferrite Magnets#Ceramic magnets#electromagnets#ferrite magnets#General Questions#licensed neodymium magnets#magnet question#magnetic domains#neodymium iron boron#Neodymium magnets#permanent magnets#Protect Magnets#rare earth magnets#Rare Earths#Samarium Cobalt magnets#Stainless Steel Case Magnets#Stainless Steel Magnetic

0 notes

Text

High Performance SmCo Magnet Manufacturers

Sm2Co17-based magnets are still playing an irreplaceable role in the permanent magnet industry due to its unique high temperature magnetic properties and superior magnetic stability, then it always serving to the high-speed motors, electronic communication, and aerospace. High energy product magnets are the important basis to accelerate miniaturization and high efficiency of the device. Thus, obtain high performance SmCo magnet has always been a goal since the advent of Sm2Co17.

Although the remanence and magnetic energy product of high-performance samarium cobalt (XGS33H and XGS35H) are lower than the N42EH and N38AH grades of neodymium iron boron at lower temperatures, their remanence and magnetic energy product are significantly higher at higher temperatures than the N42EH and N38AH grades of neodymium iron boron. With the increase of temperature, the remanence and magnetic energy product of N42EH and N38AH grades of neodymium iron boron deteriorate rapidly, especially the coercivity. However, high-performance samarium cobalt still retains high magnetic properties and exhibits excellent thermal stability.

0 notes

Text

Innovative Solutions in Magnetic Assemblies: Comprehensive Services for Precision and Performance

Magnetstek Engineering is one of the leading global suppliers of magnetic assemblies and manufacturers specialising in permanent magnets and rare earth magnetic products. Serving various industries such as wind power, medical technology and audio systems, we offer a wide range of products including neodymium magnets, samarium-cobalt, alnico and advanced magnetic assemblies. With more than two decades of industry experience, our professional team, including Ph.D. experts, provides unparalleled R&D support. We pride ourselves on our fast production times, high-performance materials and strict quality standards, ensuring our customers receive top-notch products designed to meet the exact requirements of their application.

For more information about Magnetic Assemblies click on this link: https://magnetstek.com/magnetic-assemblies/

2 notes

·

View notes

Text

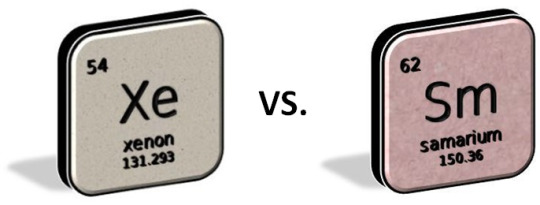

Periodic Table Championship:

Round 1, Day 4, Xenon vs. Samarium

The second match of day 4 has element 54, xenon, competing against element 62, samarium.

Xenon is a dense, colorless gas belonging to the group of noble gases on the periodic table and existing in the Earth's atmosphere only in trace amounts. While extremely nonreactive, alongside the other noble gases, xenon was the first of this group to be synthesized in a compound, xenon hexafluoroplatinate. It is known for its applications in lighting, lasers, and as a general anesthetic. Its name comes from the Greek for foreigner, stranger, or guest.

Samarium is a hard, silvery, rare earth metal and lanthanide that crystalizes in the rhombehedral system at room temperature. It has one of the largest atomic radii of any element (only five elements are larger), and its known for its magnetic properties. Samarium-cobalt magnets aren't as well known as neodymium magnets, but can withstand higher temperatures and can be used in specialized applications. The name comes from the mineral samarskite, which was itself named for Vassili Samarsky-Bykhovets, making samarium the first element to be named after a person, albeit indirectly.

11 notes

·

View notes

Text

China says it can keep F-35 fighters on the ground without firing any missiles

Fernando Valduga By Fernando Valduga 11/10/2022 - 08:14in Military

F-35A fighter takes off from Hill Air Base. (Photo: George Frey/Getty Images)

As the United States authorized the use of rare alloys of Chinese origin in pieces of F-35 fighter fighter, orders have grown in China to apply stricter export controls for its superligas, without which the American jet could be grounded.

The aircraft manufacturer, Lockheed Martin, is one of the American weapons companies sanctioned by China for selling weapons and equipment to Taiwan. However, its auxiliary power unit manufacturer, Honeywell, in which the rare earth magnet of Chinese origin is found, is not among the sanctioned companies.

The Pentagon suspended deliveries of the F-35 fighter in September after it discovered that the aircraft's engine manufactured by Honeywell uses a magnet that includes a cobalt and samary alloy, which does not comply with U.S. purchasing laws, according to reports.

However, it allowed the resumption of deliveries of the Lockheed Martin F-35 jet under an exemption allowing Chinese alloys to enter a part of the engine, Reuters said citing the Pentagon on Saturday.

With the resignation, the Pentagon will accept all aircraft under the contract, currently projected for October 2023, Reuters reported. "The magnet does not transmit information or harm aircraft and that there are no safety risks involved," he noted.

An alternative source for metal will be found and used in the future, the report said, citing the F-35 Joint Program Office, the Reuters report said. However, he did not specify the alternative source.

Main suppliers of rare earth alloys for the US. (Infographic: Bloomberg)

Chinese experts believe it is not possible to remove China from the rare alloy supply chain. “The U.S. attempt to remove imports of Chinese alloys from military equipment is almost impossible, as China has an advantage in the production of rare earth magnets from extraction to refining,” said Yang, manager of a state-owned rare league company in Ganzhou, as quoted by the Global Times on Sunday.

China is the only country in the world that has developed the ability to extract samary and cobalt metals from rare earths. It also accounts for more than 70% of the final product of the samarium-cobalt rare earth magnet. “How can Washington remove Chinese rare earth products from its jets in such a scenario?” Yang wondered.

According to Yang, neodymium magnets made in China - another main type of rare earth magnets widely used in electrical machines for a series of electronic products - also represent 85% of the global share.

Research and development, as well as the production of many weapons and advanced equipment, cannot be done without these rare components, Wei Dongxu, Beijing military expert, told the Global Times.

With the U.S. using rare earth alloys of Chinese origin in military aircraft that can harm China's sovereignty, Wei said China should consider applying stricter export controls of rare earth products, which are resources of strategic value.

Tags: Military AviationChinaF-35 Lightning IIHoneywellLockheed MartinUSAF - United States Air Force / US Air Force

Previous news

Sierra Nevada takes over Voly's Volansi military UAV series

Next news

American Airlines makes investment in hydrogen distribution company

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. It has works published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

MILITARY

NAVAIR progresses in converting E-3D former RAF to U.S. Navy E-6B

11/10/2022 - 11:00

MILITARY

Sierra Nevada takes over Voly's Volansi military UAV series

11/10/2022 - 07:54

MILITARY

VIDEO: Saab highlights Gripen E capabilities and successful partnership with the Swedish Air Force

10/10/2022 - 19:07

ROSY smokescreen launched from the H145M helicopter. (Photo: German Ministry of Defense)

HELICOPTERS

Germany completes "world's first test" of a smokescreen launched by helicopter

10/10/2022 - 16:00

Aeronaves P-72A.

MILITARY

Malaysia will acquire P-72A aircraft and TAI Anka drones

10/10/2022 - 15:00

ARMAMENTS

New AGM-114 R-4 Hellfire extended range is tested from the Reaper drone

10/10/2022 - 14:00

homeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

2 notes

·

View notes

Text

The global permanent magnet market is valued at USD 53.5 billion in 2024 and is projected to reach USD 80.4 billion by 2029, growing at 8.5% CAGR from 2024 to 2029.

1 note

·

View note

Text

0 notes

Text

Master Magnetics Inc., based in Castle Rock, Colorado, has been a magnet industry leader since 1976, operating under The Magnet Source® brand. The company boasts over 20 million magnets in stock, ensuring quick and affordable delivery across North America. Their standout samarium cobalt magnets are renowned for their durability, temperature stability, and resistance to corrosion and demagnetization. Available in multiple forms, these samarium magnets serve various industrial applications. Master Magnetics also provides top-notch customer support for custom magnetic solutions.

1 note

·

View note

Text

Alnico Magnets: High Strength and Stability from Master Magnetics

Since its founding in 1976 in Castle Rock, Colorado, Master Magnetics Inc. has excelled in the magnet industry, focusing on the creation and distribution of magnets and magnetic devices for various sectors. Under our renowned brand, The Magnet Source®, we deliver top-tier quality, expertise, and exceptional customer service. With over 20 million magnets in our inventory and strategically located production and distribution centers, we guarantee fast and economical delivery across North America. Our extensive product range makes us a premier choice in the magnetic industry.

Our alnico magnets, a key product line, consist mainly of aluminum, nickel, cobalt, copper, iron, and sometimes titanium. They come in cast or sintered forms and undergo rigorous processes to ensure superior performance. Cast alnico is melted, molded, and heat-treated, often within a magnetic field, to enhance magnetization. Sintered alnico involves pressing a powdered mix into a die, sintering in a hydrogen atmosphere, and cooling with or without a magnetic field. Despite being brittle and prone to demagnetization, alnico magnets are essential due to their high magnetic strength and stability.

At Master Magnetics, we cater to the specific needs of different applications by offering specialized services like grinding and cutting for alnico materials. Whether for complex industrial uses or consumer products, our expertise and resources are available to you. Compare our Permanent Magnet Materials to see if alnico suits your project. For further help, contact us via our website, email, or phone to learn how our superior samarium cobalt magnets can benefit your work.

1 note

·

View note

Text

Loss of Permanent Magnet Magnetization Caused by Heat Exposure

Loss of Permanent Magnet Magnetization Caused by Heat Exposure

Loss of Magnetization Caused by Heat Exposure – Exposing a magnet to high temperatures can decrease its strength or permanently damage its structure. Usually this happens at very high temperatures, but for certain neodymium magnets this can happen as low as 60°C.

Magnets are characterized by two temperature thresholds: the working…

View On WordPress

#ceramic ferrite magnets#Ferrite Magnets#Ferrite Magnets Applications#hard ferrite magnet#High Temperature Resistance Magnet#high temperature resistant magnet#Magnet Magnetization#Magnet Raw Material#magnetic properties#magnetic strength#magnetization#Neodymium rare earth magnets#permanent magnet demagnetization#Permanent rare earth magnets#Rare Earth Magnets#raw magnets#raw material price#samarium cobalt#Samarium Cobalt Magnets#Samarium Cobalt Rare Earth Magnets#Sintered Ferrite magnets#sintered hard ferrite magnets#Sintered rare earth magnets#Sintered Samarium Cobalt Magnets#SmCo#SmCo magnets#Vehicle Magnets

3 notes

·

View notes

Text

How Magnets Work

How Magnets Work

You probably know that magnets attract specific metals and they have north and south poles. Opposite poles attract each other while like poles repel each other. Magnetic and electrical fields are related, and magnetism, along with gravity and strong and weak atomic forces, is one of the four fundamental forces in the universe.

But none of those facts answers the most basic…

View On WordPress

#Alnico magnets#Ceramic magnets#Ferrites magnets#Industrial Magnetics#Magnet Strength#magnetic materials#magnetic performances#Magnetics technology#Making Magnets#Neodymium magnets#permanent magnet materials#permanent magnetic materials#permanent magnets#powerful magnets#regular magnets#Samarium Cobalt magnets#Shipping Magnets

0 notes

Text

SMCO MAGNET-Grade28-R77×R70×17.94°×L66-Ni Coating

High-performance SMCO (Samarium Cobalt) permanent magnets, with specifications of 28 grades - R77×R70×17.94°×L66, are designed for high-demand application scenarios. The magnet adopts advanced manufacturing technology to ensure excellent and stable magnetic properties, and is covered with a layer of high-quality nickel coating on the surface, which effectively improves its corrosion resistance and environmental adaptability and extends its service life.

Grade and specification: Grade 28, the diameter gradually changes from R77mm to R70mm, the angle is accurate to 17.94°, and the length reaches L66mm. The size is precise and meets the needs of precision assembly.

Material characteristics: High-purity Samarium Cobalt material is selected, which has high remanence, high coercivity and excellent temperature stability. It can maintain stable magnetic properties even in high temperature environments and is suitable for a variety of extreme working environments.

Surface treatment: The surface is treated with precision nickel coating, which is not only beautiful, but also greatly enhances the anti-oxidation and anti-corrosion capabilities, and is suitable for long-term use in outdoor or humid environments.

Application fields: Widely used in high-tech fields such as motors, sensors, instruments and meters, medical equipment, aerospace, etc., it is a key component to improve equipment performance and ensure stable operation.

0 notes

Text

Small magnets - Supreme Magnets

Despite their small size, small magnets are powerful magnets. Several materials are used for the construction of these miniature marvels, including neodymium, ferrite, and samarium cobalt. Having small magnets in your arsenal is a fun and versatile tool. Small magnets are perfect for crafting, organizing, and just enjoying their magnetic properties. Visit us: https://suprememagnets.com/products/powergrind-round

#magnet ring#electropermanent magnet#neodymium magnets#small magnets#n52 magnets#super strong magnets#small round magnets#pot magnets#cube magnets#singapore#magnet balls#spherical magnets#flexible magnets#magnet sheets

0 notes

Text

Innovative Magnetic Solutions for Industrial Applications

Since time immemorial, magnets have been an essential commodity in different industries as they provide multiple applications to increase production, creativity, and efficacy. From the multiple magnetic technologies in the market, countersunk magnets, magnetic assemblies, AlNiCo magnets, SmCo magnets as well as other custom or specialty solutions have become almost essential in fulfilling the various industrial requirements. These targeted magnet solutions offer specific advantages for the production sector up to electronics.

Industrial Precision and Custom countersunk Magnets

Custom Countersunk Magnets are products that are critical to uses that involve accurate fixing. These magnets have a countersunk hole, so they can be easily attached to wooden, plastic, or metallic substrates using screws. They can be used in mounting, holding, and joining applications, and they are suitable for construction, automobile, and electronic industries. Custom countersunk magnets are specifically useful in improving stability and performance in numerous assemblies because of the assurance of firm grip and proper alignment.

Increase of Efficiency of Industrial Systems with the Use of Magnetic Assemblies

For more complex applications, Magnetic Assemblies provides a turnkey solution to the customer. These assemblies unite various magnetic components in a single system, which helps to improve the efficiency of machines and devices. It is applied in fields such as automation technologies, robotics, energy industries, and others in which high stability, tight tolerance, and higher performance are required.

Here are some of the benefits that are associated with the Custom AlNiCo and SmCo Magnets:

Custom AlNiCo magnetic and SmCo magnetic are used in several high-performance applications because of their properties and flexibility. AlNiCo magnets also called aluminum nickel cobalt magnets are very stable at high temperatures and highly resistant to demagnetization. These characteristics make AlNiCo magnets suitable for sensors, motors, and loudspeakers where stable magnetic indications are required.

On the other hand, Custom SmCo magnets or Samarium Cobalt are highly appreciated for their strong magnetic field and their relatively high levels of durability against corrosion as well as oxidation. These features make them suitable for many applications in hostile environments including aerospace applications, military, and applications in the medical devices industry. Special SmCo magnets also have the property of possessing high Curie temperature, this means that the magnets can handle high temperatures in a way that other magnets cannot.

Conclusion

Custom AlNiCo magnets and Custom SmCo magnets are produced and can be made to order in the required shapes, sizes, and magnetic properties. Whether it is required for an application that operates

0 notes