#Shaft Encoders Sector

Explore tagged Tumblr posts

Text

Shafted Hall Effect Sensors Market: Technological Advancements Reshaping Illumination Control

MARKET INSIGHTS

The global Shafted Hall Effect Sensors Market size was valued at US$ 567.8 million in 2024 and is projected to reach US$ 945.2 million by 2032, at a CAGR of 7.60% during the forecast period 2025-2032.

Shafted Hall effect sensors are compact magnetic field sensing devices with injection-molded housings designed for precision measurement in rotary and linear motion applications. These sensors operate on the Hall effect principle, where they detect changes in magnetic fields to measure position, speed, or directional movement. Their rugged construction allows operation across wide temperature ranges (-40°C to 150°C) while maintaining resistance to moisture and environmental contaminants.

The market growth is driven by increasing automation in industrial sectors and rising demand for contactless sensing solutions in automotive applications. While the industrial equipment segment currently dominates with over 45% market share, the automotive sector is witnessing accelerated adoption due to electrification trends. Recent advancements include miniaturized form factors with improved signal-to-noise ratios, enabling higher precision in tight spaces. Key players like Sensata Technologies and TE Connectivity are expanding their portfolios with IoT-enabled sensors featuring integrated diagnostics.

MARKET DYNAMICS

MARKET DRIVERS

Growing Industrial Automation to Fuel Demand for Shafted Hall Effect Sensors

The rapid expansion of industrial automation across manufacturing sectors is driving significant demand for shafted Hall effect sensors. These sensors play a critical role in position sensing, speed detection, and angular measurement in automated systems. The global industrial automation market is projected to maintain a robust growth rate, creating parallel opportunities for shafted Hall effect sensor manufacturers. Their durability, precision, and ability to operate in harsh environments make them indispensable components in modern automated production lines. Recent advancements in Industry 4.0 technologies have further intensified this demand, particularly for sensors that can deliver accurate real-time data for process optimization.

Electric Vehicle Revolution to Accelerate Market Expansion

The automotive industry’s accelerated shift toward electric vehicles presents a substantial growth opportunity for shafted Hall effect sensors. These sensors are essential components in EV powertrains, battery management systems, and motor control units. With global EV sales surpassing 10 million units annually and projected to grow exponentially, the demand for reliable position sensing solutions is reaching unprecedented levels. Major automotive manufacturers are increasingly specifying shafted Hall effect sensors for their compact size, resistance to vibration, and ability to operate in electromagnetic interference-rich environments characteristic of electric vehicles.

Furthermore, government initiatives supporting EV adoption across major economies are creating favorable conditions for sensor manufacturers:

➤ Several national policies now include stringent requirements for position sensing accuracy in EV components, directly benefiting high-performance Hall effect sensor suppliers.

MARKET RESTRAINTS

Intense Price Competition from Alternative Technologies to Limit Growth

While shafted Hall effect sensors offer numerous advantages, the market faces considerable pressure from competing technologies such as optical encoders and inductive sensors. These alternatives have seen significant price reductions in recent years, making them attractive options for cost-sensitive applications. The average selling price for standard shafted Hall effect sensors has declined steadily, squeezing profit margins for manufacturers. This pricing pressure is particularly acute in high-volume consumer applications where even marginal cost differences significantly influence purchasing decisions.

Additionally, the growing adoption of integrated sensor solutions that combine multiple sensing modalities presents a competitive challenge for standalone Hall effect sensor providers.

MARKET CHALLENGES

Complex Supply Chain Disruptions to Impact Production Capacities

The shafted Hall effect sensor market continues to grapple with multifaceted supply chain challenges that emerged following recent global disruptions. Semiconductor material shortages have particularly affected sensor production, given their reliance on specialized magnetic materials and integrated circuits. Lead times for certain critical components have extended dramatically, forcing manufacturers to either maintain larger inventories or risk production delays. These challenges are compounded by rising transportation costs and geopolitical factors affecting rare earth material supplies essential for sensor manufacturing.

Other Significant Challenges Include:

Technical Limitations in Extreme Environments While shafted Hall effect sensors perform well in most industrial conditions, their reliability can be compromised in extremely high-temperature or highly corrosive environments. This limitation restricts their applicability in certain heavy industrial and aerospace applications where alternative technologies may be preferred.

Miniaturization Demands The persistent industry trend toward smaller form factors presents engineering challenges for maintaining sensor accuracy and durability in ever-shrinking packages, requiring continuous R&D investments.

MARKET OPPORTUNITIES

Emerging IoT Applications to Create New Growth Verticals

The rapid proliferation of Industrial Internet of Things (IIoT) deployments is opening substantial new opportunities for shafted Hall effect sensor manufacturers. These sensors are increasingly being integrated into predictive maintenance systems and smart equipment monitoring solutions. The ability of Hall effect sensors to provide reliable, contactless position data makes them ideal for IIoT applications where continuous monitoring is essential. Market analysts project strong growth in this segment as industries increasingly adopt condition-based maintenance strategies that rely on real-time sensor data.

Medical Device Innovations to Drive Premium Sensor Demand

The medical equipment sector is emerging as a high-growth market for precision shafted Hall effect sensors. These components are finding increasing use in advanced imaging systems, robotic surgical equipment, and portable medical devices. The medical sensor market commands premium pricing due to stringent reliability requirements and regulatory certifications. Several leading sensor manufacturers have recently introduced medical-grade shafted Hall effect sensors with enhanced EMI resistance and sterilization capability, specifically targeting this lucrative segment.

SHAFTED HALL EFFECT SENSORS MARKET TRENDS

Automotive Electrification Drives Demand for Hall Effect Sensors

The global shafted Hall Effect sensors market is witnessing significant growth, driven primarily by the increasing electrification of automotive systems. These compact, durable sensors play a critical role in modern vehicle systems, enabling precise angular position sensing in throttle valves, pedal positions, and transmission systems. With electric vehicle production expected to grow at a CAGR of over 26% through 2030, OEMs are incorporating more Hall Effect sensors to monitor motor position and speed in electrified powertrains. The automotive sector now accounts for nearly 42% of all shafted Hall Effect sensor applications globally.

Other Key Trends

Miniaturization and IoT Integration

The demand for compact, rugged position sensors has increased across industrial automation and consumer electronics sectors. Shafted Hall Effect sensors – combining high accuracy with small form factors – are increasingly being integrated into IoT-enabled devices. Their ability to operate in harsh environments without physical contact makes them ideal for smart factory equipment, where they monitor parameters like fluid levels, valve positions, and actuator movements. The industrial segment is projected to account for over 28% of market revenue by 2030 as Industry 4.0 adoption accelerates.

Technological Advancements in Sensing Capabilities

Recent innovations are expanding the capabilities of shafted Hall Effect sensors to meet evolving industry needs. Rotary Hall Effect sensors now achieve angular resolutions below 0.1°, while linear variants offer sub-millimeter precision. Manufacturers are also developing multi-axial sensing solutions that combine position and speed measurement in single packages, reducing system complexity. These advancements are particularly valuable in medical devices and robotics, where precision motion control is critical. The integration of self-diagnostics and digital interfaces (like I²C and SPI) is further enhancing their utility in connected industrial systems.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Global Expansion Drive Market Competition

The global Shafted Hall Effect Sensors market is moderately fragmented, with established multinational corporations competing alongside specialized regional players. Sensata Technologies leads the market with its comprehensive portfolio of rugged, high-performance sensors designed for automotive and industrial applications. The company’s strong engineering capabilities and vertically integrated manufacturing give it a competitive edge in pricing and quality control.

TE Connectivity and Amphenol Corporation maintain significant market positions due to their extensive distribution networks and ability to provide customized sensor solutions. These companies have strategically expanded their production facilities in Asia to capitalize on growing demand from China’s automotive sector.

Several European manufacturers like Gefran and Elen srl have carved out strong niches in precision industrial applications. Their expertise in developing sensors that operate reliably in harsh environments has made them preferred suppliers for heavy machinery and automation systems.

Meanwhile, DiscoverIE Plc and Novotechnik are investing heavily in next-generation Hall Effect technologies that integrate digital interfaces and IoT capabilities. These enhancements allow for predictive maintenance features – a key value proposition for industrial customers looking to minimize downtime.

List of Key Shafted Hall Effect Sensor Manufacturers

Sensata Technologies (U.S.)

TE Connectivity (Switzerland)

Amphenol Corporation (U.S.)

Gefran (Italy)

Elen srl (Italy)

Servotech Instrumentation (India)

P3 America (U.S.)

Novotechnik (Germany)

Vishay (U.S.)

DiscoverIE Plc (U.K.)

Segment Analysis:

By Type

Rotary Hall Effect Sensor Segment Leads Due to Wide Industrial and Automotive Applications

The market is segmented based on type into:

Rotary Hall Effect Sensor

Linear Hall Effect Sensor

By Application

Industrial Equipment Segment Dominates Market Owing to Automation and Process Control Requirements

The market is segmented based on application into:

Industrial Equipment

Automotive

Telecommunications Equipment

Others

By End-User

Manufacturing Sector Holds Major Share Due to Precision Measurement Needs

The market is segmented based on end-user into:

Manufacturing Industries

Automotive OEMs

Telecom Providers

Consumer Electronics

Others

Regional Analysis: Shafted Hall Effect Sensors Market

North America The North American market for shafted Hall effect sensors is driven by strong demand from the industrial automation and automotive sectors, particularly in the U.S. and Canada. The U.S. accounts for the majority of the regional market due to heavy investments in Industry 4.0 adoption, with leading manufacturers such as Sensata Technologies and TE Connectivity headquartered here. Stringent safety regulations in automotive applications, particularly in electric vehicles (EVs), further boost demand. However, the market faces challenges from increasing competition from alternative sensing technologies and supply chain disruptions.

Europe Europe remains a key market for shafted Hall effect sensors, driven by advancements in industrial automation and strong automotive manufacturing activities in Germany, France, and Italy. The EU’s focus on precision engineering and energy-efficient solutions supports sensor adoption in high-performance applications. Market leaders like Gefran and Novotechnik have capitalized on the region’s emphasis on quality-controlled manufacturing. However, strict regulatory compliance and elevated production costs compared to Asian manufacturers present constraints for market expansion.

Asia-Pacific The Asia-Pacific region dominates global consumption of shafted Hall effect sensors, primarily due to rapid industrialization in China, Japan, and India. China, being a manufacturing powerhouse, leads in both production and utilization of these sensors across automotive and telecommunications sectors. Cost-effectiveness and scalability of local suppliers such as Vishay and Servotech Instrumentation fuel market growth. Meanwhile, Japan’s precision manufacturing industry and India’s expanding automation sector contribute significantly. Though price sensitivity remains a challenge, increasing investments in smart manufacturing are expected to sustain demand.

South America Market growth in South America is gradual, influenced by Brazil’s and Argentina’s emerging industrial sectors. While adoption of shafted Hall effect sensors is primarily seen in automotive manufacturing, economic instability limits widespread industrial automation. Local players face competition from imported products, yet the growing focus on upgrading manufacturing facilities hints at untapped potential. Regulatory gaps and limited R&D investments hinder faster technological adoption despite the expanding market.

Middle East & Africa This region shows moderate demand, primarily driven by industrial and automotive applications in GCC countries such as Saudi Arabia and the UAE. Investments in smart infrastructure and gradual industrial diversification are creating opportunities for sensor integration. However, the market’s growth remains constrained by reliance on imports and limited local manufacturing capabilities. Though still nascent, strategic collaborations with international players like Amphenol Corporation could enhance market penetration in the long term.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Shafted Hall Effect Sensors markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Shafted Hall Effect Sensors market was valued at USD 260 million in 2024 and is projected to reach USD 380 million by 2032, growing at a CAGR of 4.8%.

Segmentation Analysis: Detailed breakdown by product type (Rotary Hall Effect Sensor, Linear Hall Effect Sensor), application (Industrial Equipment, Automotive, Telecommunications Equipment), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (USD 85 million in 2024), Europe, Asia-Pacific (fastest growing at 6.2% CAGR), Latin America, and Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including Sensata Technologies (12% market share), TE Connectivity, Amphenol Corporation, and Vishay, covering product portfolios, R&D investments, and strategic developments.

Technology Trends & Innovation: Assessment of miniaturization trends, integration with IoT systems, and advancements in magnetic sensing technologies.

Market Drivers & Restraints: Evaluation of factors including industrial automation growth, automotive electrification trends, and challenges related to raw material pricing volatility.

Stakeholder Analysis: Strategic insights for sensor manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

Understanding the Role of Hollow Shaft Rotary Encoders in Modern Robotics

Introduction to Rotary Encoders in Robotics

Rotary encoders are fundamental components in robotic systems, serving as critical feedback devices that measure the rotation, position, and direction of motor shafts. These sensors translate mechanical motion into electrical signals, which control systems then interpret to ensure precise movement. Among the various types of rotary encoders, hollow shaft rotary encoders have emerged as a key player due to their compact design, ease of integration, and high reliability. As robotics continues to permeate sectors like manufacturing, healthcare, logistics, and consumer electronics, understanding the specific contributions of hollow shaft rotary encoders becomes vital. Their importance lies not only in their functional capabilities but also in how they influence design flexibility and performance optimization in robotic applications. By integrating seamlessly into existing architectures, these encoders reduce mechanical complexity while improving feedback accuracy. This comprehensive examination will explore how these components are revolutionizing modern robotics, from their design advantages to their roles in various robotic subsystems.

Evolution of Rotary Encoders and Robotic Needs

The development of rotary encoders parallels the evolution of robotics itself. Early robotic systems relied on open-loop controls, often leading to inaccuracies and inefficiencies. As the demand for precision and repeatability grew, rotary encoders became indispensable. Initially, these sensors were bulky and susceptible to environmental interference. Over time, however, innovations in materials, signal processing, and miniaturization led to more robust and compact designs. Hollow shaft rotary encoders, in particular, emerged as a response to the need for space-saving yet highly accurate feedback devices. Robotics has evolved from simple pick-and-place machines to complex, autonomous entities requiring precise coordination across multiple axes. This shift necessitated encoders capable of delivering consistent, high-resolution feedback without contributing to design bulk. In mobile robots, surgical devices, and industrial arms, space is a premium commodity. Hollow shaft encoders allow engineers to route cables or mechanical shafts through the encoder's center, optimizing spatial configuration and reducing wear on moving parts. This evolution marks a significant turning point in the interplay between sensor technology and robotic capability.

Anatomy of a Hollow Shaft Rotary Encoder

At its core, a hollow shaft rotary encoder consists of a rotor, stator, and signal processing circuitry housed in a compact unit. What distinguishes it from other encoder types is the central hollow section through which a shaft or cabling can pass. This seemingly simple design offers substantial advantages. The rotor attaches directly to the rotating shaft, while the stator remains fixed to the structure. As the shaft turns, the encoder senses the angular displacement and transmits corresponding electrical signals. These signals may be digital or analog, depending on the encoder type and application. Typically, hollow shaft encoders utilize optical, magnetic, or capacitive technologies to detect movement. Optical encoders, for instance, use a light source and a photo-detector array to interpret interruptions in a coded disc. This method provides high-resolution data, essential for robotic operations requiring micrometer-level precision. Additionally, many hollow shaft encoders incorporate features like integrated bearings, multi-turn tracking, and error correction protocols, ensuring they maintain accuracy even under high-speed or high-vibration conditions.

Integration in Robotic Joint Systems

One of the primary applications of hollow shaft rotary encoders in robotics is within joint systems. Whether in humanoid robots or articulated industrial arms, joint movement must be monitored and controlled with utmost precision. Hollow shaft encoders facilitate this by being mounted directly onto the joint actuators, enabling real-time position feedback. Their hollow design allows power and data cables to pass through the joint axis, reducing external cabling and potential points of failure. This configuration not only enhances the mechanical efficiency of the joint but also simplifies maintenance and design. In collaborative robots, or cobots, where safety and fluid motion are paramount, these encoders help ensure smooth articulation and responsive behavior. They support closed-loop control systems that adjust motor output dynamically based on encoder feedback. This loop is crucial for tasks like pick-and-place operations, precision welding, or surgical manipulations, where even millimeter-level deviations can compromise functionality or safety. By offering a balance of compactness, accuracy, and reliability, hollow shaft rotary encoders are central to robotic articulation systems.

Enhancing Mobility in Autonomous Robots

Autonomous mobile robots (AMRs) require robust sensory systems to navigate complex environments accurately. Hollow shaft rotary encoders play an essential role in this context by providing reliable feedback on wheel or track rotation. Unlike incremental encoders that only track changes in position, absolute feedback systems offer the advantage of positional memory. This becomes crucial in navigation, where knowing the robot's exact orientation at any given time determines path planning and obstacle avoidance efficacy. In differential drive systems, for instance, encoders mounted on each wheel shaft measure relative speeds and directions, allowing for accurate steering and speed control. The compact nature of hollow shaft encoders is especially beneficial in mobile platforms, where every millimeter of space impacts battery size, payload capacity, or sensor load. Their integration also enhances durability since fewer external mechanical parts mean less exposure to dust, moisture, or mechanical wear. This synergy of design efficiency and functional robustness makes hollow shaft encoders indispensable in robotic mobility subsystems.

Role in Precision Tasks and Fine Manipulation

Modern robotics increasingly involves tasks requiring fine motor control, such as electronic assembly, 3D printing, and medical interventions. In these scenarios, the encoder’s resolution and responsiveness directly impact task accuracy. Hollow shaft rotary encoders contribute significantly by enabling micro-adjustments based on real-time positional data. In robotic arms used for electronic manufacturing, for instance, components must be placed with sub-millimeter accuracy. The encoder's feedback ensures that the tool tip follows the programmed path without deviation. Similarly, in 3D printing, layer consistency and nozzle positioning depend heavily on precise rotary feedback. Medical robotics, particularly in minimally invasive surgery, represents another frontier where precision is non-negotiable. Here, hollow shaft encoders are used in tool actuation systems, allowing surgeons to perform complex procedures remotely with high confidence in the robot's positional accuracy. The encoders’ inherent design also aids in sterilization and integration within tight surgical tool assemblies. Thus, their role extends from mechanical feedback to enabling new capabilities in high-precision robotic tasks.

Environmental Robustness and Industrial Viability

Robotic systems often operate in harsh environments—factories, outdoor settings, or hazardous locations. Devices integrated into such systems must exhibit resilience to temperature fluctuations, vibrations, dust, and moisture. Hollow shaft rotary encoders are increasingly engineered with these challenges in mind. Manufacturers offer variants with IP-rated enclosures, corrosion-resistant materials, and sealed optical systems. This robustness allows them to function reliably in automotive assembly lines, mining robots, or agricultural drones. In temperature-controlled warehouse automation, for example, encoders must perform consistently despite frequent exposure to cold or variable humidity levels. The absence of exposed cables and the encoder’s enclosed design minimize contamination risks and mechanical wear. These features contribute to lower maintenance demands and longer operational lifespans, which are critical in high-throughput industrial settings. Moreover, their compatibility with various communication protocols—such as EtherCAT, CANopen, and SSI—ensures that they can be integrated into diverse control architectures without extensive modification. This adaptability further cements their place in modern industrial robotics.

Supporting Safety and Redundancy Mechanisms

Safety is a fundamental concern in robotics, particularly in collaborative or human-facing environments. Encoders play a vital role in ensuring operational safety by providing accurate position feedback for motion verification and error detection. Hollow shaft rotary encoders are especially suited for redundant systems, where multiple sensors verify each other's outputs. This redundancy ensures that if one sensor fails, the system can continue operating safely or shut down in a controlled manner. In safety-rated robotic arms, encoders are often employed in tandem with other sensors to monitor limits and ensure compliance with predefined safety envelopes. Their high resolution and low latency make them ideal for such critical feedback loops. Additionally, their compact form factor allows for integration into secondary safety circuits without adding bulk. The feedback from these encoders also enables soft-limit programming, which prevents actuators from moving beyond safe zones. In service robots or exoskeletons, where human safety is paramount, this encoder-driven feedback becomes essential for real-time decision-making and reactive control.

Future Outlook: Smart Integration and Predictive Maintenance

As robotics evolves towards greater autonomy and intelligence, the role of feedback devices like hollow shaft rotary encoders is also transforming. Modern encoders are increasingly being equipped with smart features such as self-diagnostics, condition monitoring, and real-time data streaming. These capabilities feed into predictive maintenance systems, helping operators detect wear or misalignment before it causes failure. For example, by monitoring signal consistency or rotational anomalies, the encoder can alert the system to potential mechanical issues. This proactive approach reduces downtime and extends the life of robotic assets. Furthermore, as artificial intelligence becomes integral to robotics, encoder data can be used to train machine learning models for movement optimization and adaptive control. Smart encoders also support advanced communication standards that facilitate seamless integration into IoT-enabled infrastructures. This trend indicates a shift from passive sensing to active data contribution, where encoders not only report motion but also enhance system intelligence. Such evolution positions hollow shaft rotary encoders as foundational components in next-generation robotic ecosystems.

Precision Engineering Meets Practical Application

The intersection of precision engineering and practical robotic application is where hollow shaft rotary encoders demonstrate their full potential. As manufacturing tolerances tighten and robotic roles diversify, the demand for encoders that can deliver high-resolution feedback in compact, rugged packages continues to grow. These devices are not only vital for motion tracking but also contribute to reducing system complexity, enhancing safety, and enabling adaptive control. Their utility spans industries and use-cases, from autonomous warehouse robots to robotic-assisted surgery. As designers push the boundaries of what robots can achieve, they increasingly turn to encoders that offer a balance of size, accuracy, and integration flexibility. Among these, the hollow shaft rotary encoder stands out for its ability to combine mechanical elegance with technical performance. Its role in facilitating the compact, precise, and reliable movement is central to the continued advancement of robotics.

Enhancing Control Through Advanced Feedback Systems

In many robotic systems, especially those with complex kinematics, advanced feedback is necessary to synchronize multiple actuators. Here, the absolute rotary encoder proves instrumental. By providing unique position values that do not require recalibration after power loss, these encoders enhance system reliability and responsiveness. This becomes particularly valuable in automated systems that must resume operation immediately after interruptions. Their use simplifies control algorithms and reduces computational overhead, which in turn allows for more fluid and responsive robotic behavior. From industrial automation lines to mobile robotic platforms, absolute encoders bring consistency and predictability, even under dynamic load changes or complex trajectories. When integrated with real-time control loops, they enable smoother transitions, better torque management, and reduced mechanical stress. These benefits contribute to more agile and longer-lasting robotic systems.

Meeting Modern Demands with Cutting-Edge Solutions

The robotic landscape is shifting rapidly, driven by needs for flexibility, scalability, and intelligence. In this context, the absolute position encoder emerges as a critical component, especially in scenarios where exact positioning is non-negotiable. Whether it’s aligning robotic cameras, controlling prosthetic limbs, or managing the angular position of robotic grippers, these encoders deliver the granularity required for high-precision tasks. They also facilitate seamless feedback for AI-driven decisions, particularly in adaptive robotics that interact with unpredictable environments. The encoder's ability to provide exact position data without drift ensures consistent performance across repetitive tasks. In emerging sectors like robotics-as-a-service or modular robotics, where plug-and-play compatibility is essential, these encoders ensure that new modules or replacements can integrate smoothly and function reliably. As expectations for precision, speed, and autonomy grow, so too does the importance of dependable, high-performance feedback systems like the absolute position encoder.

0 notes

Text

Pepperl Fuchs | Incremental Rotary Encoder 14143613600Y47043

The Pepperl+Fuchs Incremental Rotary Encoder 14143613600Y47043 is a high-performance, reliable device designed to provide precise and accurate rotational measurements in industrial automation systems. As part of Pepperl+Fuchs' renowned series of sensors, this incremental rotary encoder plays a critical role in monitoring and controlling rotational movements in machinery, robotics, and other applications where position feedback is essential.

This particular model is designed with a robust construction, ensuring durability and long-lasting performance even in demanding environments. It uses incremental encoding technology to detect the angular position of a rotating shaft and convert it into an electrical signal that can be easily interpreted by control systems and machinery. The encoder produces a series of pulses, which represent the rotational movement, allowing precise speed and position control.

Key Features:

Incremental Output: The encoder provides incremental signals, typically in quadrature format, which are used to measure both rotational speed and position. This makes it ideal for applications requiring continuous feedback and motion control.

High Precision and Accuracy: Designed to meet high standards of precision, the encoder ensures accurate measurements of rotational movements. It is suitable for applications that demand high resolution and repeatability, such as industrial automation, robotics, and CNC machinery.

Durable and Robust Design: The Pepperl+Fuchs Incremental Rotary Encoder is built to withstand harsh conditions, including vibration, dust, moisture, and temperature fluctuations. Its sturdy housing ensures reliable performance in tough environments.

Versatile Mounting Options: With flexible mounting and connection options, this encoder can be easily integrated into a variety of machines and equipment, making it a versatile choice for OEMs and system integrators.

Wide Range of Applications: This model is ideal for use in applications where rotational position feedback is essential, including in conveyor systems, motors, actuators, pumps, and more. It can also be used in packaging, automotive, and material handling industries.

Easy Installation and Integration: The encoder is designed for quick and easy integration into existing systems, with minimal setup required. Its compatibility with a wide range of control systems makes it a convenient option for a variety of industrial sectors.

Specifications:

Model Number: 14143613600Y47043

Type: Incremental Rotary Encoder

Resolution: Offers high-resolution pulse output for detailed position feedback.

Electrical Interface: Typically available in standard formats like TTL or HTL, ensuring compatibility with various control systems.

Shaft Diameter: Available in different shaft sizes to meet specific mechanical requirements.

Power Supply: The encoder operates on a wide range of supply voltages, ensuring flexibility for various setups.

The Pepperl+Fuchs 14143613600Y47043 Incremental Rotary Encoder is a reliable and cost-effective solution for applications that require precise motion control. Whether in a factory automation system, a robotics project, or an industrial machine, this encoder delivers dependable performance, ensuring smooth operation and optimal productivity. Its high accuracy, robust construction, and easy integration make it a top choice for professionals in industrial and automation fields.

1 note

·

View note

Text

Main classification and function of stepper motor encoders

1.What is a stepper motor encoder? A stepper motor encoder is a device used to feedback the motion state and position of a stepper motor. It senses the motor's rotor motion, determines the motor's position and direction, and feeds this information back to the controller so that the controller can control the motor's motion. Stepper motor encoders can accurately measure motor motion and improve the accuracy and reliability of the control system.

2.Main classification of stepper motor encoders 1.Incremental encoders: Incremental encoders output three sets of square wave pulses A, B and Z phases through the principle of photoelectric conversion. The phase difference between the A and B groups of pulses is 90 degrees, which is used to determine the direction of rotation, while the Z phase is one pulse per revolution, which is used for reference point positioning. Its advantages are simple principle and structure, long average mechanical life, strong anti-interference ability, and suitable for long-distance transmission. The disadvantage is that it cannot output the absolute position information of the shaft rotation. 2.Absolute encoders: Absolute encoders directly output digital signals. There are several concentric code disks on the circular code disk, and there are light-transmitting and light-impermeable sectors on each track. When the code disk is in different positions, the photosensitive element converts the corresponding level signal according to whether it is illuminated or not, forming a binary number. Its characteristic is that there is no need for a counter, and a fixed digital code can be read at any position of the rotating shaft, which is suitable for applications that require high-precision positioning. 3.Hybrid absolute encoder: This encoder outputs two sets of information, one for detecting the magnetic pole position, with absolute information function; the other is completely the same as the output information of the incremental encoder. This encoder combines the advantages of incremental and absolute types and is suitable for occasions that require high-precision and absolute position information.

3.Main functions of stepper motor encoders 1.Measuring position: The stepper motor encoder can accurately measure the position of the motor. By processing the photoelectric signal, the encoder can calculate the rotation angle of the motor and thus determine the current position of the motor. This function is very important for applications that require high-precision positioning. 2.Measuring speed: The encoder can measure the speed of the motor by calculating the position change of the motor at each moment. This is particularly important for applications such as high-precision positioning, motion control and adaptive control, and can help the system adjust the control parameters in real time to improve motion accuracy and positioning accuracy. 3.Improve motion control accuracy: By providing deterministic feedback signals, the encoder can ensure accurate position control and eliminate errors caused by load changes or environmental factors. In addition, the encoder can provide more accurate speed feedback information, improve the motor's motion performance, and reduce noise and vibration. 4.Improve system stability and achieve closed-loop control: The encoder can monitor the motor's operating status in real time, such as speed, torque and other parameters. When the motor is abnormal, the controller can take timely measures, such as reducing the speed or stopping the operation, to protect the motor. In addition, the encoder is used in combination with the controller to achieve closed-loop control and improve the system's response speed, stability and accuracy. 5.Prevent overshoot and undershoot: Through the actual speed information provided by the encoder, the controller can effectively adjust the motor's operation to avoid overshoot or undershoot, thereby improving the system's operating performance.

4.Maintenance methods for stepper motor encoders 1.Regularly check the mechanical part: Check the mechanical part of the encoder every month to ensure that the mechanical connection points are not misaligned or loose, and maintain their stability. 2.Keep the cable connection in good condition: Check the status of the encoder connection cable regularly to ensure that the cable is not broken, short-circuited or in poor contact. If these problems are found, replace the cable or connector in time, and ensure that the cable is firmly fixed to avoid open welding or broken circuit caused by looseness. 3.Power supply voltage management: Ensure that the power supply voltage of the encoder is within the specified range, usually not less than 75V. If the power supply voltage is too low, it is necessary to repair the power supply or replace the cable. 4.Battery replacement and maintenance: For absolute encoders, check the battery voltage regularly, replace low-power batteries in time, and ensure that the reference point position memory is not lost. 5.Shielded wire grounding: Ensure that the shielded wire of the encoder cable is reliably welded and properly grounded to reduce the introduction of interference signals, ensure waveform stability and communication accuracy. 6.Prevent loose installation: Check the installation status of the encoder regularly to ensure that it is stable and reliable, and avoid reduced position control accuracy or servo system overload alarm due to loose installation. 7.Clean the grating: Clean the grating regularly to avoid grating contamination affecting the signal output amplitude. You can use cotton wool dipped in anhydrous alcohol to gently wipe off the oil on the grating. 8.Professional maintenance: Since the encoder is a precision instrument, its maintenance and care should be performed by professionals. Non-professionals should not operate or adjust the encoder and its related equipment without authorization.

Source:https://community.networkofcare.org/blogs/randy/archive/2025/03/03/main-classification-and-function-of-stepper-motor-encoders.aspx

0 notes

Text

SINAMICS V90: Future-Proofing Your Automation System

Automation systems are central to achieving heightened efficiency, precision, and scalability across various sectors. However, as important as these systems are, they face significant challenges—complex installation processes, integration issues with existing technologies, and a constant need for upgrades to handle evolving industrial demands.

A good example of this technological breakthrough is the Siemens SINAMICS V90 servo drive system, which provides a reliable solution suited to modern industrial requirements. This article explores how the SINAMICS V90 not only enhances current operational capabilities but also ensures businesses are equipped for future challenges, setting a new standard in automation excellence.

What is SINAMICS V90?

The SINAMICS V90 is a highly optimized servo drive system designed to meet the versatile demands of motion control applications. This system, comprising the Siemens V90 servo drive and the SIMOTICS S-1FL6 servo motor, is engineered for a wide range of applications, making it a cost-effective solution that enhances the competitive edge of businesses by reducing time-to-market.

Performance: With features like a 1 MHz pulse train setpoint and 20-bit encoder resolution, the system achieves high positioning accuracy, essential for precision-driven processes. The drive and motor offer a 300% overload capacity, which, along with fast acceleration and braking capabilities, significantly boosts productivity.

Design: The robust design of the Siemens V90 includes PCB coating and high-quality bearings, enhancing the system's reliability even in harsh environmental conditions. Integrated safety functions like STO (Safe Torque Off) provide additional security, preventing unexpected motor movement and ensuring the safety of both machinery and operators.

Ease of Use: Commissioning the SINAMICS V90 is straightforward, thanks to the SINAMICS V-Assistant, a standalone graphic configuration software that simplifies setting parameters, jogging, troubleshooting, and monitoring. This user-friendly approach ensures quick setup and minimal downtime.

SINAMICS V90 Servo Drive Capabilities

The V90 servo drive system, designed for optimal performance and easy operation, includes a range of features tailored for efficient automation. Below is a table highlighting key attributes and capabilities of the system:

Feature

Description

Power Range

0.05 to 7.0 kW, accommodating both single and three-phase networks.

Motor Compatibility

Specifically paired with SIMOTICS S-1FL6 servo motors for enhanced performance.

Communication Interfaces

Multiple options including PTI, PROFINET, USS, or Modbus RTU for versatile integration.

Drive Sizes

Available in eight converter frame sizes and seven motor shaft heights to suit various applications.

Cooling

Designed to operate without external cooling; heat dissipation through the motor surface.

Installation

Features quick-release connectors for fast and straightforward installation.

Overload Capability

Capable of handling a threefold overload, ensuring robust operation under demanding conditions.

Commissioning

Plug-and-play setup with minimal configuration needed for quick commissioning.

Control Compatibility

Integrates seamlessly with Siemens SIMATIC PLC control systems for streamlined automation.

Application Across Industries

The Siemens V90 is suitable for diverse applications such as pick & place, labeling, horizontal packaging, and printing. Its ability to manage both simple and complex motion control tasks makes it a preferred choice for industries looking for a reliable and efficient automation solution.

Coupled with the SIMOTICS S-1FL6 servo motor, the V90 servo drive system showcases its flexibility and efficiency across a broad spectrum of industries.

Manufacturing and Production Control In the manufacturing sector, the Siemens V90 drive system is frequently utilized for precise position and speed control, essential for assembly lines and automated production processes. The integration with SIMATIC S7-1200 and S7-1500 PLCs via PROFINET enhances its functionality, allowing for seamless communication and synchronization of complex manufacturing operations.

Packaging and Assembly: For industries focused on packaging and assembly, the SINAMICS V90 motor provides reliable solutions for conveyor systems and automated assembly lines. The drive's ability to perform with high dynamic responses ensures that operations are not only fast but also accurate, which is crucial for maintaining throughput and reducing downtime.

Robotics and CNC Machines: The adaptability of the V90 extends to robotics and computer numerical control (CNC) machining. Here, the drive system excels in applications requiring complex motion sequences and high precision, such as in robotic arm positioning and CNC machining centers.

Material Handling: The v90 also finds its application in material handling systems, where smooth and controlled motion is necessary. Its robust design supports the demands of applications like cranes and lifting equipment, providing the necessary control to handle materials safely and efficiently.

Textile and Woodworking: These industries require precise control for processes like weaving, cutting, and engraving. The V90's ability to handle complex motion sequences makes it a valuable asset, improving productivity and product quality.

Benefits of the SINAMICS V90

The SINAMICS V90 servo drive system, integral to Siemens' SINAMICS product line, delivers notable advantages across a range of industrial applications. Here are some key benefits detailed through real-world use cases and statistical data:

Energy Efficiency and Cost Savings: The Siemens v90 motor is designed to optimize energy use, particularly in applications like pumps, fans, and compressors. By transitioning from mechanical control systems to variable-speed drives, the V90 significantly reduces power consumption, especially under partial load conditions. This shift can result in up to 70% savings on energy costs, making a substantial economic impact for businesses focused on sustainability and efficiency.

Scalability and Flexibility: With a broad spectrum of power ratings (0.05 to 7.0 kW) and the ability to operate across single and three-phase networks, the Siemens V90 offers remarkable scalability. This flexibility is further enhanced by its compatibility with various communication interfaces such as PTI, PROFINET, USS, and Modbus RTU, allowing seamless integration into existing automation systems.

Operational Efficiency: The SINAMICS V90 system is known for its quick commissioning features and high reliability, which significantly reduce downtime and maintenance costs. The drive system is not only easy to install but also ensures continuous, trouble-free operation across diverse environmental conditions.

Diverse Industrial Applications: From manufacturing and robotics to packaging and material handling, the Siemens V90 motor proves its versatility. For example, in manufacturing, it facilitates precise control over machinery, enhancing product quality and production rates. In material handling, it provides the necessary control to manage operations smoothly and safely.

Integration in Automation Systems: As part of Siemens' Totally Integrated Automation (TIA) philosophy, the v90 drive system works cohesively within a larger automation framework. This integration capability allows for centralized control and management of various drive tasks, streamlining operations and reducing complexity.

Conclusion: Your Next Steps with Naksh Technology

Naksh Technology Solutions LLP is committed to driving innovation and efficiency in automation through the SINAMICS V90 and its comprehensive suite of automation solutions. As industries evolve, partnering with a leader like Naksh ensures that your automation systems are not only up to date but also future-proof. For more information or to schedule a consultation, explore our website and discover how we can make a significant impact on your operational success.

0 notes

Text

Shaft Encoders Market Trends and Forecasts 2018-2025 Scrutinized in New Research

Shaft Encoders Market Trends and Forecasts 2018-2025 Scrutinized in New Research

The Shaft Encoders market is valued at XX million USD in 2017 and is expected to reach XX million USD by the end of 2025, growing at a CAGR of XX% between 2017 and 2025. China plays an important role in global market, with market size of xx million USD in 2017 and will be xx million USD in 2025, with a CAGR of xx%. This report studies the Shaft Encoders development status and future trend in…

View On WordPress

#Shaft Encoders Shaft Encoders 2018 Report#Shaft Encoders Application#Shaft Encoders Industry#Shaft Encoders Market#Shaft Encoders Market analysis#Shaft Encoders Market growth#Shaft Encoders Research Report#Shaft Encoders Sales#Shaft Encoders Sector#Shaft Encoders Technology

0 notes

Text

Everything To Know About Incremental Shaft Encoders

Having a proper idea about the incremental shaft encoders is very important before starting work with such components. With a proper idea of the components, one would know how it works and where would be it’s ideal usage. Here it must be kept in mind that the incremental encoders fall undr the group of rotary shaft encoders. Hence, it can easily collect data and even offer feedback depending on the object rotation of a device.

What Are The Encoder Types?

Most of us might be aware of the fact that encoders are usually classified into four types, such as optical to magnetic, and mechanical to electromagnetic. All these types of encoders are usually available with the magnetic encoder distributors.

Shaft Encoders: Incremental

As we are well-aware of the fact that Rotary Encoders are often stated as Shaft Encoders. Also, Rotary Shaft Encoders are often referred to as Incremental Shaft Encoders. They can be used in a wide range of applications. But their main task is that they can easily measure speed, distance, and even the position.

However, one should keep in mind that the incremental encoders are able to offer information related to angle, position, as well as, on the rotation counts. The resolution gets defined as per the number of lines or even the pulses for every rotation. It must be kept in mind that the current position can be established by the control unit by taking help of the pulses.

Why Is It Referred To As Shaft Encoder?

In case, you are wondering why an incremental encoder is called as a shaft encoder then this post is right for you. For this style of encoder, the disk is usually mounted on the rotating shaft. The disk consists of a pattern of opaque as well as transparent sectors. As and when the disk starts tobrotate, the patterns will interrupt the light that gets emitted upon the photo detector. Thus, generating a pulse signal output.

Working Principle

Before consulting any magnetic encoder distributors for getting hold of any type of encoders, having an idea regarding the working principle of the encoders is important. For instance, the incremental encoder works as and when there is a change in the position of the shaft’s angular position into digital signal via the optical disk.

Hopefully, once you have a proper idea of the incremental shaft encoders, working with the component would be very easy one. But make sure the incremental encoder should meet the application device.

0 notes

Text

Basics of Encoder and Orthogonal Coding

1. Basics of Encoder

Encoder is a kind of electromechanical equipment, which can be used to measure the movement of machinery or the target position of machinery. Most encoders use optical sensors to provide electrical signals in the form of pulse sequences, which can be converted into motion, direction or position information in turn.

1.1 Encoder Types

Classification Mode

Type

Mechanical Movement Mode

Rotary Encoder

Linear Encoder

Read-out Mode

Contact Encoder

Non Contact Encoder

Principle of Operation

Incremental Encoder

Absolute Encoder

Table 1: Different types of encoders classified by different movement, read, and work principle.

1.2 Rotary Encoder vs. Linear Encoder

Rotary encoder can convert the rotation position or rotation amount into analog (such as analog quadrature signal) or digital (such as USB, 32-bit parallel signal or digital quadrature signal) electronic signal, which is generally installed on the rotating object, such as motor shaft. Rotary encoder is a device that converts the shaft, or the angular position or movement of the shaft into analog code or digital code. There are two types of rotary encoders as shown in the table below.

Types of Rotary Encoder

Features

Absolute Rotary Encoder

* The absolute rotary encoder outputs a digital code corresponding to the rotation angle.

* There is no need to calculate pulses to know the position of the motor shaft. You only need to read the digital output of the encoder.

Incremental Rotary Encoder

* Incremental rotary encoders only output pulses when the motor is rotating.

* To use an incremental encoder to determine the axis position, you must know the starting position and use an external circuit to calculate the number of output pulses.

Table 2: Rotary encoders are divided into absolute encoders and incremental encoders.

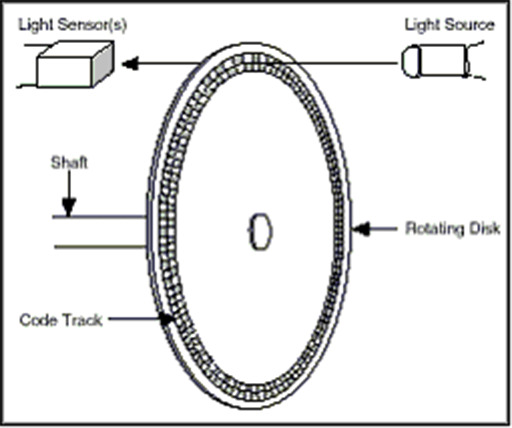

The rotary encoder can be used to measure the rotational motion of the shaft. The figure below shows the basic components of the rotary encoder, including a light emitting diode (LED), a code disk and a light sensor on the back of the code disk. The code disk is arranged on the rotating shaft, and the sector areas of opaque and transparent are arranged on the code disk according to a certain coding form. When the code disk rotates, the opaque sector can block light, while the transparent sector allows light to pass through. In this way, a square wave pulse is generated, which can be compiled into the corresponding position or motion information.

Figure 1: Rotary encoder is composed of light sensor, shaft, floating disk and code track.

A linear encoder is a sensor, transducer or reading-head linked to a scale that encodes position. The sensor reads the scale and converts position into an analog or digital signal that is transformed into a digital readout. Movement is determined from changes in position with time. The encoder is usually divided into 100 to 6000 sectors per revolution. This shows that the 100 sector encoder can provide 3.6 degrees of accuracy, while the 6000 sector encoder can provide 0.06 degrees of accuracy.

2. Orthogonal Coding

2.1 Quadrature Output of Incremental Transmitter

Orthogonal coding is an incremental signal. Here we can talk a little about what the incremental signal is. Two kinds of square wave outputs A and B can be produced after the incremental encoder is rotated. These signals constitute the quadrature output of the incremental encoder. For most encoders, these square waves A and B are out of phase by 90 degrees. By observing the changing state of a and B output, the direction of encoder can be determined. There are two channels: channel A and channel B.

More information please visit https://okmarts.com/

OKmarts.com Online Store | We provide leading brands of refrigeration compressors, servo motors, Air cylinder and more all over the world.

1 note

·

View note

Text

Incremental Encoders Market to Witness Increasing Revenue Growth during the Forecast Period 2021 to 2031

Incremental Encoders Market Introduction

Incremental Encoders is a type of encoder which converts angular position or motion of a shaft into an analog or digital code to identify motion or position. An incremental encoder helps in measuring the change in position but not the absolute position. An incremental encoder offers excellent speed and distance feedback and as there are some sensors included the system is both inexpensive and simple.

Incremental Encoders Market Forecast and CAGR

According to latest research, Incremental Encoders market is estimated to grow with a expected CAGR of 12%. The adoption of advance motion control system and demand for excellent assertion in surface mount technology placement processes are major factors driving the growth of incremental encoders.

To remain ‘ahead’ of your competitors, request for a sample here@ https://www.persistencemarketresearch.com/samples/32844

What is Driving Demand for Incremental Encoders?

For improving the operations reliability manufacturers are integrating advanced signal-processing algorithms and embedded microprocessors incremental encoders. This helps in reducing the mechanical complexity and vulnerability of conventional absolute optical encoders while using in harsh environment.

Additionally, microprocessor-based instruments help engineers to modify the measurement characteristics by using various software like, zero-point location and measurement direction, update resolution without making any physical or mechanical modification.

Evaluation of various encoder products and solutions, which offers better services and products in detail to help users to take decision regarding the adoption of different encoder technology. Encoder products are expected to witness substantially high demand during the forecast period due to its advantages including ease of operation and growing awareness among the manufacturing industry regarding surface mount technology.

To receive extensive list of important regions, ask for Table of Content here@ https://www.persistencemarketresearch.com/toc/32844

Advanced motion control systems are increasingly being adopted in various sectors, including construction machinery, offshore equipment, military & aerospace equipment, automotive and alternative energy systems. This may help them increase their customer base and sales revenue.

New generation incremental encoders are being as solid-state electronics instead of delicate mechanical systems in order to cater to the rising demand for application in these sectors and industries. Due to this the adoption of incremental encoder for advanced control system is increasing.

Pre-Book Right Now for Exclusive Analyst Support @ https://www.persistencemarketresearch.com/checkout/32844

0 notes

Text

Covid-19 Outbreak: Encoder Market 2020 – Company Business Overview, Sales, Revenue And Gross Margin, Recent Development 2027

Global Encoder Market: Overview

Encoders are used as a digital signal to translate rotary or linear movements. Almost every electronic device that communicates uses encoders that generate high demand worldwide. This usually is intended for tracking or controlling motion parameters such as direction, rate, position, direction, or distance. Two different types of encoders are available: rotative and linear. A linear encoder responds to a path movement, while a rotary encoder responds to movement. The optimum model selection and configuration is critical to success when implementing encoders.

Encoders help industry to find the exact location of any object and the angle of placement for certain pieces of equipment to get the desired results. The encoders provide accuracy in workflow, speed in operation and proper process control. It also supports the performance of high feeding tasks in manufacturing industries and the manufacture of machine tools that meet the demand for high productivity.

This report offer an exhaustive analysis of the global encoder market, focusing on market trends and limitations, along with the leading factors driving the market.

Interpret a Competitive outlook Analysis Report with PDF Brochure – https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=65150

Global Encoder Market: Notable Developments

Prominent developments that could impact the global encoder market are:

High Adoption in Advanced Automotive Systems

The growing number of cars and the increase in the production of car parts are key factors that drive the encoder market growth. Automakers incorporate Bluetooth and other cellular technology into their vehicles to meet the increasing demand for consumers to remain connected while on the go. Since the automotive sector uses several encoders to produce digital position and motion information for shaft rotations, growth in the automotive industry has a direct effect on demand for encoders.

Automated Vehicles

The automation of vehicles is developing rapidly every day to improve the experience for customers. New-age cars are equipped with such technologies as speech recognition, IC integrated LED lighting and compatibility between video and image. In automotive automation, encoders play an important role and are increasingly used in car manufacturing by automakers. This is likely to boost revenues in the global encoder market.

Leading players in the global encoder market are Panasonic Corporation, Rockwell Automation, FAULHABER Drive Systems, Dynapar Corp, and Omron Corporation.

Global Encoder Market Dynamics

Governments are strongly involved in production activities and take proactive steps to reduce regulatory compliance complexities. The main objective of this step is to improve the efficiency of manufacturers. The rise of the intelligent city concept across important regional pockets further contributes to the progress of the linked infrastructure, the growth of the market for semiconductors and auxiliary components. As a result of this rapid growth in the global manufacturing sector, demand for encoders is growing.

Technological developments are being witnessed in the in the textiles and press industry and in the coming years the usage of encoders is expected to rise in this sector. In the global market for encoders, the textile and printers industry should be the most lucrative vertical sector.

Request for Custom Research at - https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=65150

At the same time, the Electronics application will provide the encoder market vendors in the near future with potential revenue opportunities. Advanced innovations and technology developments are taking place in the electronic industry. The electronics sub-segment supports the growth of the global encoder market because of these factors.

Asia Pacific Shows Promising Growth Supported by India and China

The global encoder market is expected to be led by North America, owing to progress in U.S. and Canada's new technologies. The provision of enhanced production capacity is expected to boost the North American encoder market. Furthermore, the manufacture and extensive use of new technology encoders in the region will also boost market growth in the next few years.

This study by TMR is all-encompassing framework of the dynamics of the market. It mainly comprises critical assessment of consumers' or customers' journeys, current and emerging avenues, and strategic framework to enable CXOs take effective decisions.

Our key underpinning is the 4-Quadrant Framework EIRS that offers detailed visualization of four elements:

Customer Experience Maps

Insights and Tools based on data-driven research

Actionable Results to meet all the business priorities

Strategic Frameworks to boost the growth journey

The study strives to evaluate the current and future growth prospects, untapped avenues, factors shaping their revenue potential, and demand and consumption patterns in the global market by breaking it into region-wise assessment.

The following regional segments are covered comprehensively:

North America

Asia Pacific

Europe

Latin America

The Middle East and Africa

Related Reports Press-Release –

https://www.prnewswire.com/news-releases/innovations-in-manufacturing-industry-to-boost-conveyor-system-market-to-us-6-31-bn-by-2025—tmr-300855827.html

https://www.prnewswire.com/news-releases/driving-footwear-market-to-be-worth-us3-087-9-mn-by-2026-due-to-high-demand-for-comfort-wear-noted-tmr-300804008.html

About Us

Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.

Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with your aims. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information, we offer customized solutions through adhocreports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.

TMR believes that unison of solutions for clients-specific problems with right methodology of research is the key tohelp enterprises reach right decision.”

Contact

Transparency Market Research

State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Website: https://www.transparencymarketresearch.com

0 notes

Text

The Science Behind Hollow Shaft Rotary Encoders: Torque, Speed, and Accuracy

In the landscape of modern automation, sensors and feedback mechanisms are crucial for maintaining the precision and efficiency of machinery. One of the most indispensable devices in this category is the rotary encoder, especially the hollow shaft rotary encoder. These devices provide real-time data on angular position, velocity, and direction, enabling refined control over dynamic systems. Their unique hollow shaft design offers numerous advantages, particularly when integrating with rotating shafts and assemblies in compact or sensitive environments. This article delves into the scientific underpinnings of these encoders, examining how they measure torque, speed, and accuracy in industrial and robotic applications.

Basics of Rotary Encoders

Rotary encoders translate rotational motion into digital signals. They are broadly categorized into absolute and incremental types. Absolute encoders deliver a unique position value, whereas incremental encoders provide relative motion data. Hollow shaft rotary encoders, a sub-type of these devices, allow the shaft of the motor or machinery to pass through the encoder. This design minimizes axial load, reduces mechanical complexity, and facilitates easier installation. The hollow shaft construction is particularly beneficial in applications where space is limited or where quick replacement and alignment are essential. These encoders are primarily used in robotics, CNC machinery, elevators, and energy sector equipment.

Working Principle of Hollow Shaft Rotary Encoders

Hollow shaft rotary encoders typically use optical, magnetic, or capacitive sensing methods. Optical encoders employ a light source and photodetector array to read patterns on a rotating disk. Magnetic encoders detect changes in magnetic fields using Hall-effect sensors or magnetoresistive elements. Capacitive encoders utilize variations in capacitance caused by changes in geometry as the shaft rotates. Each method has its advantages in terms of resolution, durability, and environmental robustness. The hollow shaft design does not alter the fundamental sensing mechanism but allows the encoder to be mounted directly over a rotating shaft without additional couplings. This direct interface helps reduce backlash and enhances accuracy.

Measuring Torque with Hollow Shaft Rotary Encoders

Torque is the rotational analog of linear force. Although rotary encoders are not traditionally used as torque sensors, they play a significant role in torque estimation. By precisely measuring angular displacement and speed, and knowing the system's moment of inertia, torque can be inferred. In applications where torque sensors are either too bulky or expensive, high-resolution encoders serve as a cost-effective alternative. The key lies in correlating the angular velocity and acceleration data provided by the encoder with the mechanical characteristics of the system. For dynamic torque measurement, especially in systems with varying load conditions, encoders offer real-time feedback that can be analyzed via control algorithms to maintain performance consistency.

Speed Detection in Dynamic Systems

Speed detection is a primary function of rotary encoders. Incremental hollow shaft rotary encoders are particularly adept at delivering high-fidelity speed data. They generate pulses for every increment of rotation, which are counted over time to calculate speed. Higher pulse counts per revolution (PPR) mean greater resolution and more accurate speed readings. In applications like conveyor systems, turbines, or robotic joints, this level of speed precision ensures smoother operation and reduces wear and tear. Encoders are also favored for their minimal latency, allowing near-instantaneous speed adjustments. Furthermore, their digital output can be seamlessly integrated into programmable logic controllers (PLCs) or microcontrollers for real-time processing and control.

Ensuring Accuracy and Resolution

Accuracy in rotary encoders refers to the degree to which the measured position matches the actual position. Resolution, on the other hand, is the smallest change in position that the encoder can detect. High-resolution encoders are essential for systems requiring fine control, such as semiconductor manufacturing or surgical robotics. Hollow shaft rotary encoders often offer both high resolution and excellent accuracy due to their ability to directly interface with the rotating element. This reduces mechanical errors associated with couplings or misalignment. Optical encoders typically offer the highest resolution, while magnetic and capacitive types provide better resilience in harsh environments. Calibration and alignment during installation also play critical roles in maintaining accuracy.

The Importance of Zero Backlash

Backlash is the slight movement that occurs when direction is reversed in a mechanical system. This can cause significant errors in position sensing. Hollow shaft encoders help minimize backlash by allowing direct mounting onto the shaft, thereby eliminating intermediate couplings or gears that can introduce slack. Zero backlash is particularly critical in high-precision applications like robotics and CNC machining, where even minor errors can lead to defective outcomes. By integrating the encoder directly onto the shaft, manufacturers can achieve tighter control loops, reduced error margins, and more reliable performance. This direct integration also facilitates better synchronization between motor movement and feedback, enhancing overall system stability.

Environmental and Structural Considerations

Industrial environments often expose equipment to dust, moisture, temperature fluctuations, and vibrations. Hollow shaft rotary encoders are designed to withstand these conditions through robust housing, sealed bearings, and non-contact sensing technologies. Magnetic and capacitive encoders are particularly well-suited for such environments due to their resistance to contaminants and mechanical wear. Structural considerations also include the material of the encoder’s housing and shaft, which must align with the application’s requirements for durability and weight. The hollow shaft itself can be designed to accommodate different shaft diameters, increasing its adaptability across multiple systems. Proper installation and maintenance further ensure the encoder's longevity and consistent performance.

Integration into Closed-Loop Systems

Hollow shaft rotary encoders play a pivotal role in closed-loop control systems, where feedback is used to adjust and correct motion in real time. These systems require high-resolution and low-latency feedback to maintain accuracy and efficiency. The encoder sends position and speed data to a controller, which then adjusts the motor’s operation accordingly. This continuous feedback loop allows for precise control even in variable load conditions. Integration into such systems requires compatibility with control hardware, appropriate signal output formats, and real-time data processing capabilities. Encoders that support multiple output protocols, such as quadrature, SSI, or BiSS, offer greater flexibility in system design.

Case Study: Hollow Shaft Encoders in Robotic Arms

Robotic arms require exceptional precision and agility, often functioning in environments that demand both speed and safety. Hollow shaft rotary encoders enable these capabilities by offering accurate position and velocity feedback without adding bulk to the joints. Their compact design fits seamlessly into tight spaces, while their direct shaft interface ensures minimal mechanical error. For example, in medical robotics, where minute movements can have significant consequences, the encoder's resolution and accuracy become critical. Additionally, their ability to function reliably in varying environmental conditions makes them suitable for both cleanrooms and industrial settings. This case study illustrates how the theoretical benefits of hollow shaft encoders translate into practical performance gains.

Comparing Hollow Shaft and Solid Shaft Encoders

Solid shaft encoders require couplings or adapters for installation, which can introduce alignment issues and mechanical play. Hollow shaft encoders bypass these challenges by mounting directly onto the shaft, thereby reducing complexity and improving measurement fidelity. While solid shaft designs may offer slightly more mechanical robustness, they often necessitate more space and careful alignment. Hollow shaft encoders, by contrast, are easier to install and replace, which is beneficial in systems where downtime must be minimized. The choice between the two often comes down to the specific application requirements, including available space, desired precision, and environmental factors. Ultimately, hollow shaft models offer a compelling mix of convenience and performance.

Market Trends and Future Outlook

The market for rotary encoders is evolving rapidly, driven by advancements in automation, robotics, and smart manufacturing. Hollow shaft rotary encoders are gaining traction due to their compact design and enhanced integration capabilities. Innovations such as wireless data transmission, miniaturization, and improved environmental resistance are expanding their application scope. Additionally, the incorporation of edge computing and AI into encoder systems is enabling predictive maintenance and smarter feedback mechanisms. As industries continue to push for higher efficiency and precision, the demand for reliable and versatile encoders will only increase. In this context, the hollow shaft encoder emerges as a key component in future-ready systems.

Conclusion

The science behind hollow shaft rotary encoders encompasses a multidisciplinary understanding of mechanics, electronics, and systems engineering. Their ability to provide accurate, real-time data on torque, speed, and position makes them invaluable in a wide array of industrial and robotic applications. Their unique hollow design simplifies installation and enhances performance by reducing mechanical errors. From aiding in torque estimation to ensuring zero backlash and high-resolution feedback, these encoders are tailored for precision-driven environments. As technological advancements continue to refine their capabilities, the hollow shaft rotary encoder is poised to remain a cornerstone of intelligent motion control systems across industries.

0 notes

Text

Magnetic Absolute Encoders Market Augmentation and Improvement (2019-2025) | HENGSTLER, Baumer Group, Pepperl+Fuchs