#Shaft Encoders Technology

Explore tagged Tumblr posts

Text

Shafted Hall Effect Sensors Market: Technological Advancements Reshaping Illumination Control

MARKET INSIGHTS

The global Shafted Hall Effect Sensors Market size was valued at US$ 567.8 million in 2024 and is projected to reach US$ 945.2 million by 2032, at a CAGR of 7.60% during the forecast period 2025-2032.

Shafted Hall effect sensors are compact magnetic field sensing devices with injection-molded housings designed for precision measurement in rotary and linear motion applications. These sensors operate on the Hall effect principle, where they detect changes in magnetic fields to measure position, speed, or directional movement. Their rugged construction allows operation across wide temperature ranges (-40°C to 150°C) while maintaining resistance to moisture and environmental contaminants.

The market growth is driven by increasing automation in industrial sectors and rising demand for contactless sensing solutions in automotive applications. While the industrial equipment segment currently dominates with over 45% market share, the automotive sector is witnessing accelerated adoption due to electrification trends. Recent advancements include miniaturized form factors with improved signal-to-noise ratios, enabling higher precision in tight spaces. Key players like Sensata Technologies and TE Connectivity are expanding their portfolios with IoT-enabled sensors featuring integrated diagnostics.

MARKET DYNAMICS

MARKET DRIVERS

Growing Industrial Automation to Fuel Demand for Shafted Hall Effect Sensors

The rapid expansion of industrial automation across manufacturing sectors is driving significant demand for shafted Hall effect sensors. These sensors play a critical role in position sensing, speed detection, and angular measurement in automated systems. The global industrial automation market is projected to maintain a robust growth rate, creating parallel opportunities for shafted Hall effect sensor manufacturers. Their durability, precision, and ability to operate in harsh environments make them indispensable components in modern automated production lines. Recent advancements in Industry 4.0 technologies have further intensified this demand, particularly for sensors that can deliver accurate real-time data for process optimization.

Electric Vehicle Revolution to Accelerate Market Expansion

The automotive industry’s accelerated shift toward electric vehicles presents a substantial growth opportunity for shafted Hall effect sensors. These sensors are essential components in EV powertrains, battery management systems, and motor control units. With global EV sales surpassing 10 million units annually and projected to grow exponentially, the demand for reliable position sensing solutions is reaching unprecedented levels. Major automotive manufacturers are increasingly specifying shafted Hall effect sensors for their compact size, resistance to vibration, and ability to operate in electromagnetic interference-rich environments characteristic of electric vehicles.

Furthermore, government initiatives supporting EV adoption across major economies are creating favorable conditions for sensor manufacturers:

➤ Several national policies now include stringent requirements for position sensing accuracy in EV components, directly benefiting high-performance Hall effect sensor suppliers.

MARKET RESTRAINTS

Intense Price Competition from Alternative Technologies to Limit Growth

While shafted Hall effect sensors offer numerous advantages, the market faces considerable pressure from competing technologies such as optical encoders and inductive sensors. These alternatives have seen significant price reductions in recent years, making them attractive options for cost-sensitive applications. The average selling price for standard shafted Hall effect sensors has declined steadily, squeezing profit margins for manufacturers. This pricing pressure is particularly acute in high-volume consumer applications where even marginal cost differences significantly influence purchasing decisions.

Additionally, the growing adoption of integrated sensor solutions that combine multiple sensing modalities presents a competitive challenge for standalone Hall effect sensor providers.

MARKET CHALLENGES

Complex Supply Chain Disruptions to Impact Production Capacities

The shafted Hall effect sensor market continues to grapple with multifaceted supply chain challenges that emerged following recent global disruptions. Semiconductor material shortages have particularly affected sensor production, given their reliance on specialized magnetic materials and integrated circuits. Lead times for certain critical components have extended dramatically, forcing manufacturers to either maintain larger inventories or risk production delays. These challenges are compounded by rising transportation costs and geopolitical factors affecting rare earth material supplies essential for sensor manufacturing.

Other Significant Challenges Include:

Technical Limitations in Extreme Environments While shafted Hall effect sensors perform well in most industrial conditions, their reliability can be compromised in extremely high-temperature or highly corrosive environments. This limitation restricts their applicability in certain heavy industrial and aerospace applications where alternative technologies may be preferred.

Miniaturization Demands The persistent industry trend toward smaller form factors presents engineering challenges for maintaining sensor accuracy and durability in ever-shrinking packages, requiring continuous R&D investments.

MARKET OPPORTUNITIES

Emerging IoT Applications to Create New Growth Verticals

The rapid proliferation of Industrial Internet of Things (IIoT) deployments is opening substantial new opportunities for shafted Hall effect sensor manufacturers. These sensors are increasingly being integrated into predictive maintenance systems and smart equipment monitoring solutions. The ability of Hall effect sensors to provide reliable, contactless position data makes them ideal for IIoT applications where continuous monitoring is essential. Market analysts project strong growth in this segment as industries increasingly adopt condition-based maintenance strategies that rely on real-time sensor data.

Medical Device Innovations to Drive Premium Sensor Demand

The medical equipment sector is emerging as a high-growth market for precision shafted Hall effect sensors. These components are finding increasing use in advanced imaging systems, robotic surgical equipment, and portable medical devices. The medical sensor market commands premium pricing due to stringent reliability requirements and regulatory certifications. Several leading sensor manufacturers have recently introduced medical-grade shafted Hall effect sensors with enhanced EMI resistance and sterilization capability, specifically targeting this lucrative segment.

SHAFTED HALL EFFECT SENSORS MARKET TRENDS

Automotive Electrification Drives Demand for Hall Effect Sensors

The global shafted Hall Effect sensors market is witnessing significant growth, driven primarily by the increasing electrification of automotive systems. These compact, durable sensors play a critical role in modern vehicle systems, enabling precise angular position sensing in throttle valves, pedal positions, and transmission systems. With electric vehicle production expected to grow at a CAGR of over 26% through 2030, OEMs are incorporating more Hall Effect sensors to monitor motor position and speed in electrified powertrains. The automotive sector now accounts for nearly 42% of all shafted Hall Effect sensor applications globally.

Other Key Trends

Miniaturization and IoT Integration

The demand for compact, rugged position sensors has increased across industrial automation and consumer electronics sectors. Shafted Hall Effect sensors – combining high accuracy with small form factors – are increasingly being integrated into IoT-enabled devices. Their ability to operate in harsh environments without physical contact makes them ideal for smart factory equipment, where they monitor parameters like fluid levels, valve positions, and actuator movements. The industrial segment is projected to account for over 28% of market revenue by 2030 as Industry 4.0 adoption accelerates.

Technological Advancements in Sensing Capabilities

Recent innovations are expanding the capabilities of shafted Hall Effect sensors to meet evolving industry needs. Rotary Hall Effect sensors now achieve angular resolutions below 0.1°, while linear variants offer sub-millimeter precision. Manufacturers are also developing multi-axial sensing solutions that combine position and speed measurement in single packages, reducing system complexity. These advancements are particularly valuable in medical devices and robotics, where precision motion control is critical. The integration of self-diagnostics and digital interfaces (like I²C and SPI) is further enhancing their utility in connected industrial systems.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Global Expansion Drive Market Competition

The global Shafted Hall Effect Sensors market is moderately fragmented, with established multinational corporations competing alongside specialized regional players. Sensata Technologies leads the market with its comprehensive portfolio of rugged, high-performance sensors designed for automotive and industrial applications. The company’s strong engineering capabilities and vertically integrated manufacturing give it a competitive edge in pricing and quality control.

TE Connectivity and Amphenol Corporation maintain significant market positions due to their extensive distribution networks and ability to provide customized sensor solutions. These companies have strategically expanded their production facilities in Asia to capitalize on growing demand from China’s automotive sector.

Several European manufacturers like Gefran and Elen srl have carved out strong niches in precision industrial applications. Their expertise in developing sensors that operate reliably in harsh environments has made them preferred suppliers for heavy machinery and automation systems.

Meanwhile, DiscoverIE Plc and Novotechnik are investing heavily in next-generation Hall Effect technologies that integrate digital interfaces and IoT capabilities. These enhancements allow for predictive maintenance features – a key value proposition for industrial customers looking to minimize downtime.

List of Key Shafted Hall Effect Sensor Manufacturers

Sensata Technologies (U.S.)

TE Connectivity (Switzerland)

Amphenol Corporation (U.S.)

Gefran (Italy)

Elen srl (Italy)

Servotech Instrumentation (India)

P3 America (U.S.)

Novotechnik (Germany)

Vishay (U.S.)

DiscoverIE Plc (U.K.)

Segment Analysis:

By Type

Rotary Hall Effect Sensor Segment Leads Due to Wide Industrial and Automotive Applications

The market is segmented based on type into:

Rotary Hall Effect Sensor

Linear Hall Effect Sensor

By Application

Industrial Equipment Segment Dominates Market Owing to Automation and Process Control Requirements

The market is segmented based on application into:

Industrial Equipment

Automotive

Telecommunications Equipment

Others

By End-User

Manufacturing Sector Holds Major Share Due to Precision Measurement Needs

The market is segmented based on end-user into:

Manufacturing Industries

Automotive OEMs

Telecom Providers

Consumer Electronics

Others

Regional Analysis: Shafted Hall Effect Sensors Market

North America The North American market for shafted Hall effect sensors is driven by strong demand from the industrial automation and automotive sectors, particularly in the U.S. and Canada. The U.S. accounts for the majority of the regional market due to heavy investments in Industry 4.0 adoption, with leading manufacturers such as Sensata Technologies and TE Connectivity headquartered here. Stringent safety regulations in automotive applications, particularly in electric vehicles (EVs), further boost demand. However, the market faces challenges from increasing competition from alternative sensing technologies and supply chain disruptions.

Europe Europe remains a key market for shafted Hall effect sensors, driven by advancements in industrial automation and strong automotive manufacturing activities in Germany, France, and Italy. The EU’s focus on precision engineering and energy-efficient solutions supports sensor adoption in high-performance applications. Market leaders like Gefran and Novotechnik have capitalized on the region’s emphasis on quality-controlled manufacturing. However, strict regulatory compliance and elevated production costs compared to Asian manufacturers present constraints for market expansion.

Asia-Pacific The Asia-Pacific region dominates global consumption of shafted Hall effect sensors, primarily due to rapid industrialization in China, Japan, and India. China, being a manufacturing powerhouse, leads in both production and utilization of these sensors across automotive and telecommunications sectors. Cost-effectiveness and scalability of local suppliers such as Vishay and Servotech Instrumentation fuel market growth. Meanwhile, Japan’s precision manufacturing industry and India’s expanding automation sector contribute significantly. Though price sensitivity remains a challenge, increasing investments in smart manufacturing are expected to sustain demand.

South America Market growth in South America is gradual, influenced by Brazil’s and Argentina’s emerging industrial sectors. While adoption of shafted Hall effect sensors is primarily seen in automotive manufacturing, economic instability limits widespread industrial automation. Local players face competition from imported products, yet the growing focus on upgrading manufacturing facilities hints at untapped potential. Regulatory gaps and limited R&D investments hinder faster technological adoption despite the expanding market.

Middle East & Africa This region shows moderate demand, primarily driven by industrial and automotive applications in GCC countries such as Saudi Arabia and the UAE. Investments in smart infrastructure and gradual industrial diversification are creating opportunities for sensor integration. However, the market’s growth remains constrained by reliance on imports and limited local manufacturing capabilities. Though still nascent, strategic collaborations with international players like Amphenol Corporation could enhance market penetration in the long term.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Shafted Hall Effect Sensors markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Shafted Hall Effect Sensors market was valued at USD 260 million in 2024 and is projected to reach USD 380 million by 2032, growing at a CAGR of 4.8%.

Segmentation Analysis: Detailed breakdown by product type (Rotary Hall Effect Sensor, Linear Hall Effect Sensor), application (Industrial Equipment, Automotive, Telecommunications Equipment), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (USD 85 million in 2024), Europe, Asia-Pacific (fastest growing at 6.2% CAGR), Latin America, and Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including Sensata Technologies (12% market share), TE Connectivity, Amphenol Corporation, and Vishay, covering product portfolios, R&D investments, and strategic developments.

Technology Trends & Innovation: Assessment of miniaturization trends, integration with IoT systems, and advancements in magnetic sensing technologies.

Market Drivers & Restraints: Evaluation of factors including industrial automation growth, automotive electrification trends, and challenges related to raw material pricing volatility.

Stakeholder Analysis: Strategic insights for sensor manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

Understanding the Role of Hollow Shaft Rotary Encoders in Modern Robotics

Introduction to Rotary Encoders in Robotics

Rotary encoders are fundamental components in robotic systems, serving as critical feedback devices that measure the rotation, position, and direction of motor shafts. These sensors translate mechanical motion into electrical signals, which control systems then interpret to ensure precise movement. Among the various types of rotary encoders, hollow shaft rotary encoders have emerged as a key player due to their compact design, ease of integration, and high reliability. As robotics continues to permeate sectors like manufacturing, healthcare, logistics, and consumer electronics, understanding the specific contributions of hollow shaft rotary encoders becomes vital. Their importance lies not only in their functional capabilities but also in how they influence design flexibility and performance optimization in robotic applications. By integrating seamlessly into existing architectures, these encoders reduce mechanical complexity while improving feedback accuracy. This comprehensive examination will explore how these components are revolutionizing modern robotics, from their design advantages to their roles in various robotic subsystems.

Evolution of Rotary Encoders and Robotic Needs

The development of rotary encoders parallels the evolution of robotics itself. Early robotic systems relied on open-loop controls, often leading to inaccuracies and inefficiencies. As the demand for precision and repeatability grew, rotary encoders became indispensable. Initially, these sensors were bulky and susceptible to environmental interference. Over time, however, innovations in materials, signal processing, and miniaturization led to more robust and compact designs. Hollow shaft rotary encoders, in particular, emerged as a response to the need for space-saving yet highly accurate feedback devices. Robotics has evolved from simple pick-and-place machines to complex, autonomous entities requiring precise coordination across multiple axes. This shift necessitated encoders capable of delivering consistent, high-resolution feedback without contributing to design bulk. In mobile robots, surgical devices, and industrial arms, space is a premium commodity. Hollow shaft encoders allow engineers to route cables or mechanical shafts through the encoder's center, optimizing spatial configuration and reducing wear on moving parts. This evolution marks a significant turning point in the interplay between sensor technology and robotic capability.

Anatomy of a Hollow Shaft Rotary Encoder

At its core, a hollow shaft rotary encoder consists of a rotor, stator, and signal processing circuitry housed in a compact unit. What distinguishes it from other encoder types is the central hollow section through which a shaft or cabling can pass. This seemingly simple design offers substantial advantages. The rotor attaches directly to the rotating shaft, while the stator remains fixed to the structure. As the shaft turns, the encoder senses the angular displacement and transmits corresponding electrical signals. These signals may be digital or analog, depending on the encoder type and application. Typically, hollow shaft encoders utilize optical, magnetic, or capacitive technologies to detect movement. Optical encoders, for instance, use a light source and a photo-detector array to interpret interruptions in a coded disc. This method provides high-resolution data, essential for robotic operations requiring micrometer-level precision. Additionally, many hollow shaft encoders incorporate features like integrated bearings, multi-turn tracking, and error correction protocols, ensuring they maintain accuracy even under high-speed or high-vibration conditions.

Integration in Robotic Joint Systems

One of the primary applications of hollow shaft rotary encoders in robotics is within joint systems. Whether in humanoid robots or articulated industrial arms, joint movement must be monitored and controlled with utmost precision. Hollow shaft encoders facilitate this by being mounted directly onto the joint actuators, enabling real-time position feedback. Their hollow design allows power and data cables to pass through the joint axis, reducing external cabling and potential points of failure. This configuration not only enhances the mechanical efficiency of the joint but also simplifies maintenance and design. In collaborative robots, or cobots, where safety and fluid motion are paramount, these encoders help ensure smooth articulation and responsive behavior. They support closed-loop control systems that adjust motor output dynamically based on encoder feedback. This loop is crucial for tasks like pick-and-place operations, precision welding, or surgical manipulations, where even millimeter-level deviations can compromise functionality or safety. By offering a balance of compactness, accuracy, and reliability, hollow shaft rotary encoders are central to robotic articulation systems.

Enhancing Mobility in Autonomous Robots

Autonomous mobile robots (AMRs) require robust sensory systems to navigate complex environments accurately. Hollow shaft rotary encoders play an essential role in this context by providing reliable feedback on wheel or track rotation. Unlike incremental encoders that only track changes in position, absolute feedback systems offer the advantage of positional memory. This becomes crucial in navigation, where knowing the robot's exact orientation at any given time determines path planning and obstacle avoidance efficacy. In differential drive systems, for instance, encoders mounted on each wheel shaft measure relative speeds and directions, allowing for accurate steering and speed control. The compact nature of hollow shaft encoders is especially beneficial in mobile platforms, where every millimeter of space impacts battery size, payload capacity, or sensor load. Their integration also enhances durability since fewer external mechanical parts mean less exposure to dust, moisture, or mechanical wear. This synergy of design efficiency and functional robustness makes hollow shaft encoders indispensable in robotic mobility subsystems.

Role in Precision Tasks and Fine Manipulation

Modern robotics increasingly involves tasks requiring fine motor control, such as electronic assembly, 3D printing, and medical interventions. In these scenarios, the encoder’s resolution and responsiveness directly impact task accuracy. Hollow shaft rotary encoders contribute significantly by enabling micro-adjustments based on real-time positional data. In robotic arms used for electronic manufacturing, for instance, components must be placed with sub-millimeter accuracy. The encoder's feedback ensures that the tool tip follows the programmed path without deviation. Similarly, in 3D printing, layer consistency and nozzle positioning depend heavily on precise rotary feedback. Medical robotics, particularly in minimally invasive surgery, represents another frontier where precision is non-negotiable. Here, hollow shaft encoders are used in tool actuation systems, allowing surgeons to perform complex procedures remotely with high confidence in the robot's positional accuracy. The encoders’ inherent design also aids in sterilization and integration within tight surgical tool assemblies. Thus, their role extends from mechanical feedback to enabling new capabilities in high-precision robotic tasks.

Environmental Robustness and Industrial Viability

Robotic systems often operate in harsh environments—factories, outdoor settings, or hazardous locations. Devices integrated into such systems must exhibit resilience to temperature fluctuations, vibrations, dust, and moisture. Hollow shaft rotary encoders are increasingly engineered with these challenges in mind. Manufacturers offer variants with IP-rated enclosures, corrosion-resistant materials, and sealed optical systems. This robustness allows them to function reliably in automotive assembly lines, mining robots, or agricultural drones. In temperature-controlled warehouse automation, for example, encoders must perform consistently despite frequent exposure to cold or variable humidity levels. The absence of exposed cables and the encoder’s enclosed design minimize contamination risks and mechanical wear. These features contribute to lower maintenance demands and longer operational lifespans, which are critical in high-throughput industrial settings. Moreover, their compatibility with various communication protocols—such as EtherCAT, CANopen, and SSI—ensures that they can be integrated into diverse control architectures without extensive modification. This adaptability further cements their place in modern industrial robotics.

Supporting Safety and Redundancy Mechanisms

Safety is a fundamental concern in robotics, particularly in collaborative or human-facing environments. Encoders play a vital role in ensuring operational safety by providing accurate position feedback for motion verification and error detection. Hollow shaft rotary encoders are especially suited for redundant systems, where multiple sensors verify each other's outputs. This redundancy ensures that if one sensor fails, the system can continue operating safely or shut down in a controlled manner. In safety-rated robotic arms, encoders are often employed in tandem with other sensors to monitor limits and ensure compliance with predefined safety envelopes. Their high resolution and low latency make them ideal for such critical feedback loops. Additionally, their compact form factor allows for integration into secondary safety circuits without adding bulk. The feedback from these encoders also enables soft-limit programming, which prevents actuators from moving beyond safe zones. In service robots or exoskeletons, where human safety is paramount, this encoder-driven feedback becomes essential for real-time decision-making and reactive control.

Future Outlook: Smart Integration and Predictive Maintenance

As robotics evolves towards greater autonomy and intelligence, the role of feedback devices like hollow shaft rotary encoders is also transforming. Modern encoders are increasingly being equipped with smart features such as self-diagnostics, condition monitoring, and real-time data streaming. These capabilities feed into predictive maintenance systems, helping operators detect wear or misalignment before it causes failure. For example, by monitoring signal consistency or rotational anomalies, the encoder can alert the system to potential mechanical issues. This proactive approach reduces downtime and extends the life of robotic assets. Furthermore, as artificial intelligence becomes integral to robotics, encoder data can be used to train machine learning models for movement optimization and adaptive control. Smart encoders also support advanced communication standards that facilitate seamless integration into IoT-enabled infrastructures. This trend indicates a shift from passive sensing to active data contribution, where encoders not only report motion but also enhance system intelligence. Such evolution positions hollow shaft rotary encoders as foundational components in next-generation robotic ecosystems.

Precision Engineering Meets Practical Application

The intersection of precision engineering and practical robotic application is where hollow shaft rotary encoders demonstrate their full potential. As manufacturing tolerances tighten and robotic roles diversify, the demand for encoders that can deliver high-resolution feedback in compact, rugged packages continues to grow. These devices are not only vital for motion tracking but also contribute to reducing system complexity, enhancing safety, and enabling adaptive control. Their utility spans industries and use-cases, from autonomous warehouse robots to robotic-assisted surgery. As designers push the boundaries of what robots can achieve, they increasingly turn to encoders that offer a balance of size, accuracy, and integration flexibility. Among these, the hollow shaft rotary encoder stands out for its ability to combine mechanical elegance with technical performance. Its role in facilitating the compact, precise, and reliable movement is central to the continued advancement of robotics.

Enhancing Control Through Advanced Feedback Systems

In many robotic systems, especially those with complex kinematics, advanced feedback is necessary to synchronize multiple actuators. Here, the absolute rotary encoder proves instrumental. By providing unique position values that do not require recalibration after power loss, these encoders enhance system reliability and responsiveness. This becomes particularly valuable in automated systems that must resume operation immediately after interruptions. Their use simplifies control algorithms and reduces computational overhead, which in turn allows for more fluid and responsive robotic behavior. From industrial automation lines to mobile robotic platforms, absolute encoders bring consistency and predictability, even under dynamic load changes or complex trajectories. When integrated with real-time control loops, they enable smoother transitions, better torque management, and reduced mechanical stress. These benefits contribute to more agile and longer-lasting robotic systems.

Meeting Modern Demands with Cutting-Edge Solutions

The robotic landscape is shifting rapidly, driven by needs for flexibility, scalability, and intelligence. In this context, the absolute position encoder emerges as a critical component, especially in scenarios where exact positioning is non-negotiable. Whether it’s aligning robotic cameras, controlling prosthetic limbs, or managing the angular position of robotic grippers, these encoders deliver the granularity required for high-precision tasks. They also facilitate seamless feedback for AI-driven decisions, particularly in adaptive robotics that interact with unpredictable environments. The encoder's ability to provide exact position data without drift ensures consistent performance across repetitive tasks. In emerging sectors like robotics-as-a-service or modular robotics, where plug-and-play compatibility is essential, these encoders ensure that new modules or replacements can integrate smoothly and function reliably. As expectations for precision, speed, and autonomy grow, so too does the importance of dependable, high-performance feedback systems like the absolute position encoder.

0 notes

Text

Precision and Reliability with Absolute Rotary Encoders

Enhance your industrial operations with our range of Absolute Rotary Encoders. These advanced sensors ensure precision and reliability, offering absolute position feedback for rotating shafts without the need for recalibration after power cycles. Our encoders are designed for diverse applications, from robotics to industrial automation, with variations like Single-turn and Multi-turn models available. Trust in our Absolute Rotary Encoders to deliver high accuracy and durability in harsh environments. Explore our selection now to streamline your motion control needs with cutting-edge technology.

0 notes

Text

Technical features and operating precautions of integrated servo motors

1.Basic components of integrated servo motors Integrated servo motors are mainly composed of servo motor body, encoder and driver. The servo motor body is the component that performs mechanical movement. The encoder is used to feedback the position and speed information of the motor, and the driver is responsible for receiving control signals and driving the motor to operate. The control circuit is responsible for generating control signals and monitoring the operating status of the motor to ensure accurate control and stable operation of the system.

2.Working steps of integrated servo motors 1. Receiving control signals: The servo motor receives control signals from the external controller through the driver. These signals tell the servo system where to move, at what speed or direction to move. 2. Driving the motor: The driver sends power to the servo motor to drive it to rotate according to the received control signal. 3. Feedback monitoring: The encoder or other feedback device inside the servo motor measures the current position and speed of the output shaft and feeds this information back to the control circuit. 4. Adjustment control: The control circuit compares the feedback signal with the target value, adjusts the motor's current, voltage and other parameters to ensure that the motor can accurately reach and maintain the set position or speed.

3.Technical features of integrated servo motors

1.High-precision control: The integrated servo motor adopts advanced closed-loop control technology, and the encoder provides real-time feedback of the motor's position and speed information to achieve precise control. Its positioning accuracy can reach 0.001mm or even higher.

2.Fast response: The integrated servo motor has fast response capability and can reach the target position and speed in a very short time. This gives it a significant advantage in situations where high-speed and high-precision motion is required.

3.Good stability: The integrated servo motor adopts advanced control algorithms and drive technologies, which can maintain stable operating performance in various complex environments. At the same time, it has strong anti-interference ability and can effectively resist external interference and noise.

4.High flexibility: The integrated servo motor can be customized according to actual needs to meet the needs of different applications. In addition, it also supports multiple control modes, such as position control, speed control and torque control.

5.Intelligent design: The integrated servo motor usually adopts high-performance DSP to achieve precise and smooth motor control, which greatly improves the system integration and reduces the workload of wiring. Its opto-isolated differential signal input and multiple communication methods (such as CAN communication and Modbus communication) further improve the system's integration and maintainability. 6. High efficiency and energy saving: The integrated servo motor can maintain low temperature and energy consumption during operation, ensuring high efficiency and energy saving. For example, Schneider Electric's Lexium MDrive motor achieves high stability and low operating temperature through closed-loop control, thus ensuring high efficiency and energy saving.

4.Precautions for the operation of the integrated servo motor 1. Use environment: Try to use the servo motor in a clean and dust-free environment, and avoid using it in heavy oil, dusty or humid places to prevent damage to the motor. 2. Regular maintenance: Regularly check the housing, screws, bearings and other parts of the integrated servo motor to ensure that they are not damaged or loose. At the same time, keep the motor clean and dry to avoid the influence of moisture and dust. 3. Avoid overload work: During use, avoid overloading the integrated servo motor, and always observe the working condition of the motor to ensure that it operates within a safe range. 4. Avoid overheating: Regularly check whether the cooling fan of the integrated servo motor is working properly to prevent the motor from overheating. If the motor is found to be overheating, check the cause immediately and take measures. 5. Standard operation: When operating the integrated servo motor, follow the operating procedures to avoid misoperation and barbaric operation. Adjust the motor's speed, position, load and other parameters according to actual needs to ensure the stability and safety of the motor. 6. Cable protection: Ensure that the cable of the integrated servo motor is not subjected to torque or vertical load due to external bending force or its own weight, especially at the cable outlet or connection. The elbow radius of the cable should be as large as possible to avoid immersion in oil or water. 7. Parameter configuration: The parameter configuration of the integrated servo motor is directly related to its motion performance and load capacity. When configuring the parameters, select and adjust according to factors such as the motor model, specification, and application scenario to ensure that the motor operates in the best condition.

Source:https://olgana.pixnet.net/blog/post/180444976

0 notes

Text

Pepperl Fuchs | Incremental Rotary Encoder 14143613600Y47043

The Pepperl+Fuchs Incremental Rotary Encoder 14143613600Y47043 is a high-performance, reliable device designed to provide precise and accurate rotational measurements in industrial automation systems. As part of Pepperl+Fuchs' renowned series of sensors, this incremental rotary encoder plays a critical role in monitoring and controlling rotational movements in machinery, robotics, and other applications where position feedback is essential.

This particular model is designed with a robust construction, ensuring durability and long-lasting performance even in demanding environments. It uses incremental encoding technology to detect the angular position of a rotating shaft and convert it into an electrical signal that can be easily interpreted by control systems and machinery. The encoder produces a series of pulses, which represent the rotational movement, allowing precise speed and position control.

Key Features:

Incremental Output: The encoder provides incremental signals, typically in quadrature format, which are used to measure both rotational speed and position. This makes it ideal for applications requiring continuous feedback and motion control.

High Precision and Accuracy: Designed to meet high standards of precision, the encoder ensures accurate measurements of rotational movements. It is suitable for applications that demand high resolution and repeatability, such as industrial automation, robotics, and CNC machinery.

Durable and Robust Design: The Pepperl+Fuchs Incremental Rotary Encoder is built to withstand harsh conditions, including vibration, dust, moisture, and temperature fluctuations. Its sturdy housing ensures reliable performance in tough environments.

Versatile Mounting Options: With flexible mounting and connection options, this encoder can be easily integrated into a variety of machines and equipment, making it a versatile choice for OEMs and system integrators.

Wide Range of Applications: This model is ideal for use in applications where rotational position feedback is essential, including in conveyor systems, motors, actuators, pumps, and more. It can also be used in packaging, automotive, and material handling industries.

Easy Installation and Integration: The encoder is designed for quick and easy integration into existing systems, with minimal setup required. Its compatibility with a wide range of control systems makes it a convenient option for a variety of industrial sectors.

Specifications:

Model Number: 14143613600Y47043

Type: Incremental Rotary Encoder

Resolution: Offers high-resolution pulse output for detailed position feedback.

Electrical Interface: Typically available in standard formats like TTL or HTL, ensuring compatibility with various control systems.

Shaft Diameter: Available in different shaft sizes to meet specific mechanical requirements.

Power Supply: The encoder operates on a wide range of supply voltages, ensuring flexibility for various setups.

The Pepperl+Fuchs 14143613600Y47043 Incremental Rotary Encoder is a reliable and cost-effective solution for applications that require precise motion control. Whether in a factory automation system, a robotics project, or an industrial machine, this encoder delivers dependable performance, ensuring smooth operation and optimal productivity. Its high accuracy, robust construction, and easy integration make it a top choice for professionals in industrial and automation fields.

1 note

·

View note

Text

Classification and technical characteristics of servo motors

1.Definition of servo motors A servo motor is an engine that controls the operation of mechanical components in a servo system. It is an auxiliary motor indirect speed change device. The servo motor can control the speed and position accuracy very accurately, and can convert the voltage signal into torque and speed to drive the control object. The rotor speed of the servo motor is controlled by the input signal and can respond quickly. In the automatic control system, it is used as an actuator, and has the characteristics of small electromechanical time constant, high linearity, and starting voltage. It can convert the received electrical signal into angular displacement or angular velocity output on the motor shaft.

2.Classification of servo motors 1.DC servo motor The DC servo motor is the earliest servo motor. It is powered by a DC power supply and can achieve precise control of the motor by controlling the current size and direction. It has high speed and torque, fast response speed, and high control accuracy. It is suitable for industrial automation fields with high-precision control, such as CNC machine tools, printing machines, packaging machines, etc. However, due to the presence of brushes and brush rings in DC servo motors, long-term operation may cause brush wear, affecting the performance and life of the motor. 2.AC servo motor The AC servo motor is powered by an AC power supply and has a high speed and torque. It uses the principle of electromagnetic induction to convert electrical energy into mechanical energy and achieves precise control through pulse signals. The AC servo motor has a simple structure, brushless commutation, and long life. It is suitable for fields with high-precision control and high-power output, such as wind turbines, ship power systems, rail transportation, etc. In addition, the AC servo motor also has good dynamic performance and anti-interference ability, which can meet the working requirements in various complex environments. 3.Brushless servo motor The brushless servo motor is a motor without brushes and brush rings, and the current and torque are controlled by an electronic controller. It has the characteristics of high efficiency, high reliability and long life, and is suitable for application scenarios that require high precision and long-term operation. Brushless servo motors are widely used in robots, automation equipment, medical equipment and other fields.

3.Technical characteristics of servo motors 1.High precision The servo motor adopts advanced closed-loop control technology, and the encoder provides real-time feedback of the motor's position and speed information to achieve precise control. Its positioning accuracy can reach 0.001mm, or even higher, and is suitable for occasions with extremely high position accuracy requirements. 2.High response speed Servo motors have fast response capabilities and can reach the target position and speed in a very short time. This makes it have significant advantages in situations where high-speed and high-precision motion is required. 3.Good stability Servo motors use advanced control algorithms and drive technologies to maintain stable operating performance in various complex environments. At the same time, they have strong anti-interference capabilities and can effectively resist external interference and noise. 4.High flexibility Servo motors can be customized according to actual needs to meet the needs of different applications. In addition, it supports multiple control modes, such as position control, speed control, and torque control. 5.Other technical features Servo motors also have the characteristics of high efficiency, low noise, and low heat generation. Its high efficiency is reflected in the ability to convert more electrical energy into mechanical energy and reduce energy waste; low noise and low heat generation make it quieter and more comfortable during operation.

4.Methods for increasing the speed of servo motors 1.Adjust the feedback signal The speed control of servo motors can be achieved through feedback signals, such as position feedback, encoders, etc. When the servo motor speed is low, the parameters of the feedback mechanism can be adjusted appropriately, such as increasing the resolution of the encoder or increasing the number of encoder lines, so as to improve the feedback accuracy of the servo motor and thus increase the speed. 2.Increase the voltage Increasing the voltage is one of the important ways to increase the speed of the servo motor. The higher the voltage, the corresponding current will also increase, which will cause the motor to output greater torque, thereby increasing the speed. However, while increasing the voltage, it is necessary to pay attention to controlling the temperature of the motor to avoid damage caused by overheating. 3.Optimize the control parameters Optimizing the control parameters of the servo motor can also increase the speed. When optimizing the control parameters, it is necessary to consider factors such as the parameters of the feedback link, the parameters of the feedforward link, and the response speed of the controller, and conduct system analysis and simulation verification to finally obtain reasonable control parameters. 4.Replace the high-speed motor If a higher speed is required, it can be achieved by directly replacing the high-speed servo motor. The high-speed servo motor is more sophisticated in design and can withstand higher speeds and loads, thereby achieving higher control accuracy and speed requirements. 5.Increase the mechanical reduction ratio When the speed of the high-speed servo motor has reached the upper limit, a higher speed can be achieved by increasing the mechanical reduction ratio. The mechanical reduction ratio can be achieved by using mechanical elements such as gears, belts and couplings of different specifications. However, it should be noted that increasing the mechanical reduction ratio will reduce the output torque of the motor.

Source:https://community.networkofcare.org/blogs/amber_stepper_motor/archive/2024/10/26/classification-and-technical-characteristics-of-servo-motors.aspx

1 note

·

View note

Text

SINAMICS V90: Future-Proofing Your Automation System

Automation systems are central to achieving heightened efficiency, precision, and scalability across various sectors. However, as important as these systems are, they face significant challenges—complex installation processes, integration issues with existing technologies, and a constant need for upgrades to handle evolving industrial demands.

A good example of this technological breakthrough is the Siemens SINAMICS V90 servo drive system, which provides a reliable solution suited to modern industrial requirements. This article explores how the SINAMICS V90 not only enhances current operational capabilities but also ensures businesses are equipped for future challenges, setting a new standard in automation excellence.

What is SINAMICS V90?

The SINAMICS V90 is a highly optimized servo drive system designed to meet the versatile demands of motion control applications. This system, comprising the Siemens V90 servo drive and the SIMOTICS S-1FL6 servo motor, is engineered for a wide range of applications, making it a cost-effective solution that enhances the competitive edge of businesses by reducing time-to-market.

Performance: With features like a 1 MHz pulse train setpoint and 20-bit encoder resolution, the system achieves high positioning accuracy, essential for precision-driven processes. The drive and motor offer a 300% overload capacity, which, along with fast acceleration and braking capabilities, significantly boosts productivity.

Design: The robust design of the Siemens V90 includes PCB coating and high-quality bearings, enhancing the system's reliability even in harsh environmental conditions. Integrated safety functions like STO (Safe Torque Off) provide additional security, preventing unexpected motor movement and ensuring the safety of both machinery and operators.

Ease of Use: Commissioning the SINAMICS V90 is straightforward, thanks to the SINAMICS V-Assistant, a standalone graphic configuration software that simplifies setting parameters, jogging, troubleshooting, and monitoring. This user-friendly approach ensures quick setup and minimal downtime.

SINAMICS V90 Servo Drive Capabilities

The V90 servo drive system, designed for optimal performance and easy operation, includes a range of features tailored for efficient automation. Below is a table highlighting key attributes and capabilities of the system:

Feature

Description

Power Range

0.05 to 7.0 kW, accommodating both single and three-phase networks.

Motor Compatibility

Specifically paired with SIMOTICS S-1FL6 servo motors for enhanced performance.

Communication Interfaces

Multiple options including PTI, PROFINET, USS, or Modbus RTU for versatile integration.

Drive Sizes

Available in eight converter frame sizes and seven motor shaft heights to suit various applications.

Cooling

Designed to operate without external cooling; heat dissipation through the motor surface.

Installation

Features quick-release connectors for fast and straightforward installation.

Overload Capability

Capable of handling a threefold overload, ensuring robust operation under demanding conditions.

Commissioning

Plug-and-play setup with minimal configuration needed for quick commissioning.

Control Compatibility

Integrates seamlessly with Siemens SIMATIC PLC control systems for streamlined automation.

Application Across Industries

The Siemens V90 is suitable for diverse applications such as pick & place, labeling, horizontal packaging, and printing. Its ability to manage both simple and complex motion control tasks makes it a preferred choice for industries looking for a reliable and efficient automation solution.

Coupled with the SIMOTICS S-1FL6 servo motor, the V90 servo drive system showcases its flexibility and efficiency across a broad spectrum of industries.

Manufacturing and Production Control In the manufacturing sector, the Siemens V90 drive system is frequently utilized for precise position and speed control, essential for assembly lines and automated production processes. The integration with SIMATIC S7-1200 and S7-1500 PLCs via PROFINET enhances its functionality, allowing for seamless communication and synchronization of complex manufacturing operations.

Packaging and Assembly: For industries focused on packaging and assembly, the SINAMICS V90 motor provides reliable solutions for conveyor systems and automated assembly lines. The drive's ability to perform with high dynamic responses ensures that operations are not only fast but also accurate, which is crucial for maintaining throughput and reducing downtime.

Robotics and CNC Machines: The adaptability of the V90 extends to robotics and computer numerical control (CNC) machining. Here, the drive system excels in applications requiring complex motion sequences and high precision, such as in robotic arm positioning and CNC machining centers.

Material Handling: The v90 also finds its application in material handling systems, where smooth and controlled motion is necessary. Its robust design supports the demands of applications like cranes and lifting equipment, providing the necessary control to handle materials safely and efficiently.

Textile and Woodworking: These industries require precise control for processes like weaving, cutting, and engraving. The V90's ability to handle complex motion sequences makes it a valuable asset, improving productivity and product quality.

Benefits of the SINAMICS V90

The SINAMICS V90 servo drive system, integral to Siemens' SINAMICS product line, delivers notable advantages across a range of industrial applications. Here are some key benefits detailed through real-world use cases and statistical data:

Energy Efficiency and Cost Savings: The Siemens v90 motor is designed to optimize energy use, particularly in applications like pumps, fans, and compressors. By transitioning from mechanical control systems to variable-speed drives, the V90 significantly reduces power consumption, especially under partial load conditions. This shift can result in up to 70% savings on energy costs, making a substantial economic impact for businesses focused on sustainability and efficiency.

Scalability and Flexibility: With a broad spectrum of power ratings (0.05 to 7.0 kW) and the ability to operate across single and three-phase networks, the Siemens V90 offers remarkable scalability. This flexibility is further enhanced by its compatibility with various communication interfaces such as PTI, PROFINET, USS, and Modbus RTU, allowing seamless integration into existing automation systems.

Operational Efficiency: The SINAMICS V90 system is known for its quick commissioning features and high reliability, which significantly reduce downtime and maintenance costs. The drive system is not only easy to install but also ensures continuous, trouble-free operation across diverse environmental conditions.

Diverse Industrial Applications: From manufacturing and robotics to packaging and material handling, the Siemens V90 motor proves its versatility. For example, in manufacturing, it facilitates precise control over machinery, enhancing product quality and production rates. In material handling, it provides the necessary control to manage operations smoothly and safely.

Integration in Automation Systems: As part of Siemens' Totally Integrated Automation (TIA) philosophy, the v90 drive system works cohesively within a larger automation framework. This integration capability allows for centralized control and management of various drive tasks, streamlining operations and reducing complexity.

Conclusion: Your Next Steps with Naksh Technology

Naksh Technology Solutions LLP is committed to driving innovation and efficiency in automation through the SINAMICS V90 and its comprehensive suite of automation solutions. As industries evolve, partnering with a leader like Naksh ensures that your automation systems are not only up to date but also future-proof. For more information or to schedule a consultation, explore our website and discover how we can make a significant impact on your operational success.

0 notes

Text

Optical Encoder Market – In Depth Insight Analysis to 2033 | Global Insight Services

An optical encoder is a type of sensor that uses light to measure position or speed. Optical encoders are used in a variety of applications, including industrial machinery, automotive systems, and medical devices.

Optical encoders work by shining a light on a photosensitive surface, such as a photodiode, phototransistor, or photoelectric cell. As the light hits the surface, it is reflected back in a pattern that can be read by the encoder. The encoder then converts the light pattern into electrical signals that can be interpreted by a computer or other type of controller.

Optical encoders are often used in applications where precise measurements are required, such as in CNC machines and 3D printers. They are also used in applications where high speeds are involved, such as in automotive systems.

Key Trends

Some of the key trends in optical encoder technology include miniaturization, higher resolutions, and improved durability.

Miniaturization is important for applications where space is limited, such as in handheld devices.

Higher resolutions allow for more precise positioning and control, while improved durability ensures that the encoder can withstand harsh environments.

Key Drivers

Some of the key drivers of the optical encoder market are:

Increasing demand for precision and high-speed applications: Optical encoders are increasingly being used in a variety of applications where precision and high speeds are required.

Miniaturization trend: The trend of miniaturization is also driving the demand for optical encoders as they can be very easily integrated into smaller devices and systems.

Improved performance and reliability: Optical encoders have also gained popularity due to the fact that they offer improved performance and reliability as compared to other types of encoders.

Unlock Growth Potential in Your Industry – Get Your Sample Report Now@ https://www.globalinsightservices.com/request-sample/GIS23886

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS23886

Market Segments

The optical encoder market is segmented by configuration, application, and region. By configuration, the market is classified into shafted, absolute, and others. Based on application, it is bifurcated into healthcare equipment, consumer electronics, and others. Region-wise, the market is segmented into North America, Europe, Asia Pacific, and the Rest of the World.

Key Players

The global optical encoder market includes players such as Honeywell International, Rockwell International, Renishaw PLC, Allied Motion Technologies, Sensata Technologies, US Digital, Bourns Inc., Dynapar, GrayHill, CodeChamp, and others.

Drive Your Growth Strategy: Purchase the Report for Key Insights@ https://www.globalinsightservices.com/checkout/single_user/GIS23886

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis.

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1-833-761-1700 Website: https://www.globalinsightservices.com/

About Global Insight Services:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes

Text

Future Trends: The Advancement of Encoders in Industrial Automation

Industrial automation has come a long way since its commencement, with technology playing a critical role in enhancing efficiency, productivity, and precision in manufacturing and other industrial processes. One key component dynamic these improvements is the encoder. Encoders, which convert motion into an electrical signal that can be read by a control device, are fundamental in ensuring precise movement and positioning of machinery. As we look to the future, the advancement of encoders in industrial automation is set to bring about significant changes and improvements. This blog explores the future trends in encoder technology and their impact on industrial automation.

What Are Encoders?

Before diving into future trends, it’s essential to understand what encoders are and how they function. Encoders are sensors that provide feedback on position, speed, and direction of a rotating shaft or linear movement. They are crucial in applications where precise control of motion is required. There are two main types of encoders:

Rotary Encoders: These encoders measure the rotational position and speed of a shaft. They can be either incremental or absolute.

Linear Encoders: These measure the linear position and speed of an object, providing feedback for precise control in linear motion applications.

Future Trends in Encoder Technology

As technology continues to progress, several trends are influential the future of encoders in industrial automation. These trends promise to enhance the capabilities of encoders, making them more accurate, reliable, and versatile.

1. Higher Resolution and Accuracy

One of the most significant trends is the push for higher resolution and accuracy in encoders. As industries demand greater precision, manufacturers are developing encoders with finer resolution capabilities. Higher resolution encoders provide more detailed feedback, allowing for better control and accuracy in applications such as semiconductor manufacturing and precision machining.

2. Integration of Advanced Communication Protocols

Modern industrial automation systems rely heavily on communication networks to exchange data between various components. The integration of advanced communication protocols such as Ethernet/IP, PROFINET, and EtherCAT into encoders is becoming increasingly common. These protocols enable faster and more reliable data transmission, improving the overall efficiency and performance of automation systems.

3. Miniaturization and Compact Designs

With the trend towards smaller and more compact machinery, there is a growing demand for miniaturized encoders. Advances in micro-electromechanical systems (MEMS) technology have made it possible to develop compact encoders without compromising performance. These smaller encoders are ideal for applications with limited space, such as medical devices and compact robotic systems.

4. Enhanced Durability and Environmental Resistance

Industrial environments can be harsh, with factors such as dust, moisture, and extreme temperatures posing challenges to encoder performance. Future encoders are being designed with enhanced durability and environmental resistance. Encoders with IP67 or higher ratings, for example, can withstand exposure to water and dust, ensuring reliable performance in demanding conditions.

5. Development of Wireless Encoders

Wireless technology is making its way into industrial automation, and encoders are no exception. Wireless encoders eliminate the need for cables, reducing installation complexity and maintenance requirements. They are particularly useful in applications where wired connections are impractical or hazardous. Advances in wireless communication protocols are ensuring that wireless encoders provide reliable and secure data transmission.

6. Increased Customization and Flexibility

Industries are increasingly seeking customized solutions to meet specific application requirements. Encoder manufacturers are responding by offering more customizable and flexible products. This trend includes the ability to configure encoders with different output signals, mounting options, and communication interfaces. Customizable encoders allow for tailored solutions that optimize performance in specific applications.

7. Integration with Advanced Sensors

Encoders are being integrated with other advanced sensors to provide more comprehensive feedback and control. For example, combining encoders with gyroscopes and accelerometers can enhance the precision and stability of motion control systems. This integration is particularly valuable in applications such as autonomous vehicles and advanced robotics.

8. Energy Efficiency and Power Management

As industries strive to reduce their carbon footprint and energy consumption, the energy efficiency of automation components is becoming increasingly important. Future encoders are being designed with energy-efficient components and power management features. Low-power encoders are particularly beneficial in battery-powered applications, such as portable devices and remote monitoring systems.

9. Enhanced Safety Features

Safety is a top priority in industrial automation, and encoders are playing a crucial role in enhancing safety measures. Encoders with built-in safety features, such as redundant sensing elements and self-diagnostics, provide additional layers of protection. These safety features help prevent accidents and ensure the reliable operation of machinery in critical applications.

Impact of Future Encoder Trends on Industrial Automation

The advancements in encoder technology are set to have a profound impact on industrial automation. Here are some key ways these trends will shape the future of industrial processes:

Improved Precision and Quality

Higher resolution and accuracy in encoders will lead to improved precision and quality in manufacturing processes. This is particularly important in industries such as aerospace, automotive, and electronics, where even minor deviations can have significant consequences. Enhanced precision will result in higher-quality products and reduced waste.

Increased Efficiency and Productivity

The integration of advanced communication protocols, IoT capabilities, and wireless technology will streamline data exchange and improve the efficiency of automation systems. Real-time data collection and analysis will enable predictive maintenance, reducing downtime and increasing productivity. Automation systems will be able to operate more smoothly and efficiently, leading to cost savings and higher output.

Greater Flexibility and Customization

The trend towards customization and flexibility in encoder design will allow industries to implement customized solutions that meet specific requirements. This flexibility will enable manufacturers to optimize their processes and achieve better performance. Customizable encoders will also make it easier to adapt to changing production needs and technological advancements.

Enhanced Safety and Reliability

The incorporation of advanced safety features and durable designs will enhance the reliability and safety of industrial automation systems. This is crucial in applications where safety is paramount, such as in the chemical, pharmaceutical, and food industries. Reliable encoders with robust safety features will help prevent accidents and ensure consistent performance.

Adoption of Smart Manufacturing Practices

The integration of IoT and Industry 4.0 capabilities into encoders will drive the adoption of smart manufacturing practices. Smart factories, equipped with connected and intelligent components, will be able to optimize operations, reduce energy consumption, and improve overall efficiency. The data generated by smart encoders will provide valuable insights for continuous improvement and innovation.

Expansion of Automation into New Areas

Advancements in encoder technology will enable the expansion of automation into new areas and applications. For example, miniaturized and wireless encoders will make it possible to automate processes in confined spaces and remote locations. This expansion will open up new opportunities for automation in industries such as agriculture, healthcare, and logistics.

Conclusion

The future of encoders in industrial automation is bright, with numerous advancements set to enhance their capabilities and impact. Higher resolution, advanced communication protocols, miniaturization, durability, IoT integration, wireless technology, customization, advanced sensors, energy efficiency, and enhanced safety features are some of the key trends shaping the future of encoder technology. These advancements will lead to improved precision, efficiency, flexibility, safety, and the adoption of smart manufacturing practices.

#industrial automation#auto2mation#industrial equipment#industrial spare parts#industrial and marine automation equipment#industrial and marine automation#industrial automation equipment#automation#industrial encoder

0 notes

Text

How to use the automatic parent row processing machine (what are the manufacturers of Zhejiang portable copper row bending machine)?

Before starting the CNC busbar bending machine mold, you must carefully check the various components and function switches. Several important locations such as motors, switches, lines, and grounding. Whether each component is firm and stable, and whether there is a loose situation, if the problem finds the problem, it should be resolved in time. In addition, the parameter indicators of the mold itself should be checked, such as overlapping and solidity, whether the installation meets the specifications, and so on.

Get the spindle position. There are many ways to obtain the spindle position: first, the virtual axis is used, the calculation is simple and accurate; the other is to obtain from the spindle encoder or servo pulse to process the signal of the spindle encoder; the third is to obtain from the measurement encoder. After obtaining the encoder signal, convert it into a spindle position. How to use fully automatic parent arrangement machine

It is often inspected whether the temperature and temperature rise of the motor motor of the bus is too high. It is necessary to often check whether the motor bearing is too hot and lack of oil. If the temperature rising near the bearing nearby is too high, it should be stopped to check. The bone body of the bearings, the exterior of the roller lanes, is cracking, scratching or loss, whether the bearing gap is too large, and the inner ring has rotation on the shaft. The phenomenon mentioned above is revealed, and the bearings must be updated.

How much does the full -automatic parent processing machine use a CNC busbar bending machine? Cymbonia's Machinery Co., Ltd. specializes in producing CNC bending machines; this machine is suitable for large steel structured parts, iron towers, street light rods, high light rods, car beams, car and cargo boxes and other related industries. The We67YK series plate bending machine is mainly used; the SDS -3PB bending machine is full -loop control system, two rack ruler, a photoelectric encoder real -time detection feedback, and a step motor drive screw composition. Two grating ruler; a rear block, a real -time detection feedback correction of the position of the slider; the photoelectric encoder detects the position of the dead block of the oil cylinder to the CNC system. So how many people are asking CNC bending machines? Today, I preliminarily tell you the following, 100,000 to higher; usually around 280,000! Here are the parameters of our CNC bending machine:

In addition, in recent years, local discharge online detectors have been developed, which can perform automatic detection local discharge during the transformer operation. In order to prevent the occurrence of local discharge, the manufacturing unit should deal with the transformer for reasonable structural design; carefully construct, improve the purity of the material, and strictly handle the quality of each link. The operating unit should strengthen the maintenance and monitoring of transformer to effectively prevent the occurrence of local discharge from the transformer.

The total development trend of inverted power supply is to develop towards large capacity, lightweight, high efficiency, modularization, intelligent development and the core of improving reliability, performance and broadening. In the process of welding, cutting, cutting. High -efficiency and high -power density (miniaturization) is one of the main targets pursued by international arc welding inverters. The power consumption of high frequency and reduction of the main devices is the main technical way to achieve this goal. At present, in Japan, Europe and other countries and regions, about 20KHz's arc welding inverter technology has matured, the quality of the product is high and the product has been series. How to use fully automatic parent arrangement machine

Failure three: The parallel deviation of the parallel parallel of the linear rail and the center line of the mold in the rear material. This type of failure needs to release the "X" axis synchronous belt, re -adjust it to the parallel tolerance range, and re -install the synchronous belt.

0 notes

Text

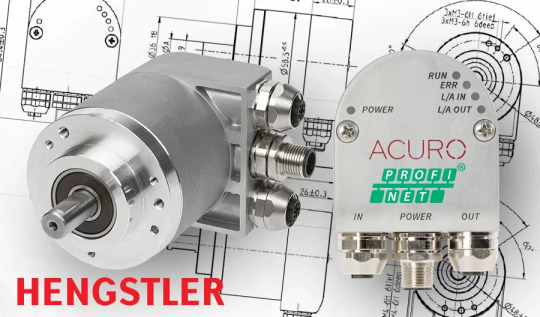

Choosing the Right Profinet Encoder: Characteristics and Best Practices

Profinet Encoder

Multitier encoders with fieldbus, outright encoders collection MEM-Bus, best quality hengstler profinet encoders profile Specifications V4.1 version 3.162 related to Profidrives, demands of the Application Courses 3 and 4, RT Actual Time and IRT Isochronous Real Time Transmission Mode, common telegrams 81, 82, 83, 84, the customer telegram 860, encoders actual time diagnostic function makes sure the gadget state consistent monitoring, MEM-Bus encoders, multitier version with 29-bit resolution, Different mechanical versions are offered. The electric link is provided by 3 M12 adapters, the stout aluminium instance guarantees a high defence level. The building technology allows for high acceleration and rate worth’s and gives the transducer a long life.

Profinet Encoder Characteristics:

Fieldbus user interface: Profinet

Encoder Account V4.1 Variation 3.162

Application courses 3–4

Transmission settings (RT and IRT)

Conventional telegrams 81, 82, 83, and 84

Customer telegram 860

Aluminium situation

Defence level: IP67; shaft side: IP65

Resolution: 29 little bit

PROFINET-ready outright encoders function separately and are non-reactive.

Network frameworks are commonly subject to regular modifications, e.g., in the case of new robotics with constant changes of tools or expansions during procedures. PROFINET-ready outright encoders, Design A58HE (blind hollow birthed) and Version A58SE (shaft), are developed for harsh factory and plant atmospheres.

Conveniently designed right into a wide array of applications, these encoders plug straight right into a connect with marginal requirements and work in different setups, consisting of bus, ring, and star setups that can proceed interaction in the event of a line break.

As absolute encoders, they keep absolute position information even after a power loss, assisting in quick system healing at start-up without the requirement for system re-homing. Prepared for Market 4.0 and the Industrial Internet of Things, data exchange between the Model A58HE, Setting A58SE, and other applications has no influence on the control loophole.

These encoders are non-reactive and can function independently from the PLC or master, moving information through network entrances to various other automation networks and sites, as well as the cloud for analysis.

Encoders with Profane Communications