#Sheet Metal Design

Text

Mastering Precision Sheet Metal Fabrication: Where Art Meets Science

Precision sheet metal fabrication is the artful synergy of craftsmanship and scientific knowledge. Whether it's in the automotive industry, electronics manufacturing, or medical equipment production, precision sheet metal plays a pivotal role. In this blog post, we delve deep into the world of precision sheet metal and explore how this art and science intertwine.

Defining Precision Sheet Metal

Precision sheet metal fabrication is a highly specialized manufacturing process that encompasses various methods of cutting, bending, stamping, and welding metal sheets. The goal of these processes is to produce parts and components to exact specifications and dimensions without compromising the quality of the metal material. These parts are typically used in applications that demand high levels of precision, requiring meticulous control and inspection at every step.

Applications of Precision Sheet Metal

Precision sheet metal finds wide-ranging applications across various industries, including but not limited to:

Electronics Manufacturing: Precise enclosures, panels, and connectors are essential to ensuring the safety and stability of internal components in electronic products.

Medical Equipment: Medical devices often require highly precise components to ensure accurate measurements and operations.

Aerospace Industry: Aerospace demands lightweight, high-strength components, and precision sheet metal is key to achieving this goal.

Automotive Manufacturing: Various components in automobiles, including bodywork, chassis, and engine parts, rely on precision sheet metal fabrication.

The Craftsmanship of Precision Sheet Metal

The manufacturing process of precision sheet metal is an art that marries precision with expertise. It involves critical steps such as:

Design and Planning: Careful design and planning are necessary before commencing fabrication, ensuring accuracy and consistency.

Material Selection: Choosing the right metal material is crucial for the performance of the final product.

Cutting and Stamping: Employing cutting and stamping machinery to shape the metal sheets into the desired form.

Bending and Shaping: Utilizing bending and shaping operations to curve metal sheets into the required shapes.

Welding and Assembly: Welding individual components together to assemble the final product.

Quality Control

The essence of precision sheet metal lies in quality control. Rigorous quality control procedures and inspection methods ensure that every component meets specifications. This includes the use of high-precision measuring tools, visual inspections, and material testing.

Conclusion

Precision sheet metal fabrication is a domain where craftsmanship and scientific knowledge beautifully converge. Its wide-ranging applications, from electronics to aerospace, make it indispensable in our modern world. Through continual refinement of processes and quality control methods, precision sheet metal fabrication will continue to play a pivotal role in supporting our modern way of life and technological advancements. It's a testament to how art and science work hand in hand to create excellence in manufacturing.

#aviation#sheet metal fabrication#sheet metal manufacturing#sheet metal stamping#sheet metal design#sheet metal market#robots#robotics

7 notes

·

View notes

Text

american typewriter

2 notes

·

View notes

Text

The Versatility of Sheet Steel Work in Modern Construction

Sheet steel work has become a cornerstone in modern construction, owing to its versatility, strength, and durability. The adaptability of sheet steel makes it an ideal choice for various applications, from building frameworks to intricate architectural details. Let’s delve into the multifaceted world of sheet steel work and understand its pivotal role in contemporary construction.

What is Sheet Steel Work?

Sheet steel work involves the manipulation of steel sheets into different shapes and sizes for use in construction and manufacturing. These steel sheets are typically fabricated through processes like cutting, bending, and welding, allowing for precise and customised applications. The inherent strength of steel, combined with its flexibility, makes it a preferred material for both structural and aesthetic purposes.

Applications in Construction

Structural Components: One of the primary uses of sheet steel is in the construction of structural components. Steel sheets are used to create beams, columns, and girders that form the skeleton of buildings and bridges. The high tensile strength of steel ensures that these structures are robust and can withstand substantial loads.

Cladding and Roofing: Sheet steel is extensively used for cladding and roofing due to its weather-resistant properties. Steel sheets can be coated with various finishes to enhance their resistance to corrosion and provide an attractive appearance. This makes them suitable for both industrial and residential buildings.

Architectural Details: The malleability of sheet steel allows architects to design intricate details that add aesthetic value to buildings. From decorative facades to customised fittings, sheet steel can be shaped into virtually any form, offering endless design possibilities.

HVAC Systems: Sheet steel work is also crucial in the fabrication of HVAC (Heating, Ventilation, and Air Conditioning) systems. Ductwork made from steel sheets ensures efficient airflow and longevity, making it a reliable choice for both commercial and residential applications.

Advantages of Using Sheet Steel

Durability: Steel is one of the most durable materials available, offering a long lifespan with minimal maintenance. This durability translates into cost savings over the long term, as structures require fewer repairs and replacements.

Sustainability: Steel is 100% recyclable, making it an environmentally friendly choice. Using recycled steel in construction reduces the demand for virgin materials and lowers the overall environmental impact of building projects.

Strength-to-Weight Ratio: Steel has a high strength-to-weight ratio, meaning it can support large loads without being excessively heavy. This is particularly beneficial in high-rise buildings and bridges, where weight is a critical consideration.

Conclusion

Sheet steel work is an indispensable component of modern construction, providing the necessary strength, flexibility, and aesthetic appeal required in today's architectural projects. Whether for structural support, decorative elements, or functional components, sheet steel continues to prove its worth in various applications. As construction techniques and technologies evolve, the role of sheet steel is set to become even more significant, paving the way for innovative and sustainable building solutions.

0 notes

Text

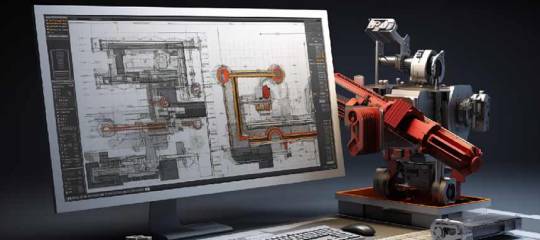

Master the art of sheet metal design! This guide explores 10 expert tips for optimizing and improving your sheet metal drafting and modeling techniques, ensuring precision and efficiency in your designs. Learn effective strategies for documentation, grain direction, material selection, and more.

#Sheet Metal Design#Sheet Metal Modeling#Sheet Metal Drafting#3D CAD Modeling#Material Selection#Grain Direction

0 notes

Text

Sheet Metal Drawing Services and Sheet Metal Shop Drawings Service

Shalin Design, a premier metal design services company, specializes in sheet metal design and drawing services for contractors, fabricators, and engineers.

#Sheet Metal Design and drawing Services#sheet metal design#sheet metal design services#sheet drawing services#Shalin Designs

0 notes

Video

youtube

Sheet Metal Production Machine In India Factory

sheet metal, sheet metal manufacturer, sheet metal supplier, sheet metal machine, Sheet metal enclosure roll forming machine manufacturer.

#youtube#sheet metal#metal sheet#sheet metal drawing#sheet metal design#sheet metal box supplier#sheet metal manufacturer China

0 notes

Text

#3d art#3d printing#rapidprototyping#sheet metal design#sheet metal parts#manufacturing#prototype#silicon#3dmodel#scans#3d scanning services

0 notes

Text

Sheet Metal Fabrication

Santech Sheet Metal exceeds standards with quality sheet metal fabrication solutions. We produce custom-made metal components with immaculate quality and quick turnaround times using cutting-edge equipment and a competent crew. Trust us with your sheet metal needs and you will see the highest level of craftsmanship and dependability in every project.

#display racks#display racks manufacturers#retail display racks#supermarket display racks#santech sheet metal#sheet metal fabrication#sheet metal manufacturing#sheet metal design

0 notes

Text

#sheet metal fabrication#sheet metal design#sheet metal manufacturing#metal punching#metal welding#metal stamping#metal shearing#metal forming

1 note

·

View note

Text

#dark art#gothic art#fantasy art#dark illustration#horror#dark fantasy art#gothic#horror art#black metal art#tattoo design#tattoo flash#flash sheet

2K notes

·

View notes

Text

0 notes

Text

5 Common Misconceptions About Sheet Metal Contractors Debunked

In the world of construction and manufacturing, sheet metal contractors play a vital role. However, there are several misconceptions surrounding their work that often lead to misunderstandings. Let’s debunk some of these myths to gain a clearer understanding of what sheet metal contractors really do.

Sheet Metal Work is Limited to Roofing and Gutters Contrary to popular belief, sheet metal contractors aren’t solely responsible for roofing and gutter installations. While they do handle these tasks expertly, their expertise extends far beyond. From HVAC systems to custom fabrications for machinery, sheet metal contractors are adept at various applications, making them indispensable in numerous industries.

Sheet Metal Work is Only for Large-Scale Projects Another misconception is that sheet metal contractors are only needed for massive construction projects. In reality, they cater to projects of all sizes, including residential, commercial, and industrial. Whether it’s crafting bespoke metal fittings for a home renovation or fabricating intricate components for a manufacturing plant, sheet metal contractors are equipped to handle diverse projects with precision and efficiency.

Sheet Metal Work is Basic and Uncreative Some might think that working with sheet metal involves nothing more than cutting and bending metal sheets. However, this couldn’t be further from the truth. Sheet metal contractors are skilled artisans who bring creativity and innovation to their craft. They can transform raw materials into intricate designs and custom fabrications, turning clients' visions into reality. Whether it’s creating unique architectural features or crafting aesthetically pleasing signage, sheet metal contractors excel in blending functionality with artistry.

Sheet Metal Work is Expensive While quality craftsmanship comes at a price, the notion that sheet metal work is exorbitantly expensive is unfounded. In fact, investing in sheet metal solutions often proves to be cost-effective in the long run. The durability and longevity of sheet metal products reduce the need for frequent repairs and replacements, ultimately saving both time and money. Additionally, sheet metal contractors offer bespoke solutions tailored to clients' specific requirements, ensuring optimal value for their investment.

Sheet Metal Work is Hazardous and Unsafe While working with metal does pose certain risks, modern safety protocols and equipment mitigate these hazards significantly. Sheet metal contractors undergo extensive training to adhere to safety standards and guidelines, ensuring a secure working environment for themselves and others. By employing best practices and utilising appropriate protective gear, sheet metal contractors minimise the likelihood of accidents and injuries on the job.

By debunking these misconceptions, it becomes evident that sheet metal contractors are indispensable professionals with a diverse skill set and a commitment to excellence. Whether it’s crafting bespoke fabrications or executing intricate installations, their expertise and dedication contribute to the success of various projects across industries. So, the next time you require sheet metal work, remember to dispel these myths and appreciate the invaluable contributions of these skilled artisans.

0 notes

Link

Any building product constructed of sheet metal design has a significant gap between the initial concept sketch and the finished product. For instance, early models and drawings go through an iterative process while building a metal canopy to accommodate customized requirements. Before it is approved for manufacture, revisions to the basic canopy frame, design principles, look and feel, etc., are made.

#CAD Drafters#Sheet Metal Design#Sheet Metal Detailed Drawing#Sheet Metal Drafting#Sheet Metal Drawing#Sheet Metal Fabrication

0 notes

Text

thinking about my rat son again, and this time i know how to draw his hair! forgot how to draw archer tho

#artists on tumblr#traditional art#digital art#metal gear#mgs#metal gear oc#mgs oc#oc#character design#fujin#tew#tew 3 au#evil gear au#au#archer#full redesign sheet coming soon!

57 notes

·

View notes

Text

a while back I made a post with the kid characters 10 years older to when they're around the age of the original cast. that was fun so

yeah

here are the originals with edits (tails and marine are taller)

#sonic the hedgehog#older versions#shadow the hedgehog#knuckles the echidna#amy rose#silver the hedgehog#blaze the cat#metal sonic#ref#ref sheet#older designs

458 notes

·

View notes

Text

Tool and Die Manufacturing

1 note

·

View note