#Smart factories IoT

Explore tagged Tumblr posts

Text

Explore how manufacturing, electronics, and robotics have transformed mankind—from early automata and industrial machinery in the 1950s to today's smart factories, AI-powered robots, and space exploration. Learn how innovations like CNC machines, pick-and-place electronics robots, surgical bots, and Mars rovers increased productivity, safety, and scientific discovery, playing a pivotal role in human progress and future advancements.

#Manufacturing programs#Manufacturing Electronics History#The role of robots in human evolution#Industrial automation impact#CNC and robotics evolution#pick-and-place electronics robots#Smart factories IoT#Surgical robots' benefits#Mars rover robotics#Electronics and human progress

0 notes

Text

Using the Internet of Things (IoT) in manufacturing has totally changed how stuff gets done, making it way better. It’s like giving factories a major upgrade! This technology has made factories run quicker, smarter, and safer. In this article, we’ll chat about why IoT is so cool and how it’s making manufacturing awesome.

2 notes

·

View notes

Text

Manufacturing IoT in the Automotive Industry - Key Companies and Trends to Know

Explore how top companies are using IoT in automotive manufacturing to boost efficiency and reduce costs. Learn how Theta Technolabs, a leading IoT app development company in Dallas, builds smart IoT solutions to power innovation in the automotive industry.

#IoT Solutions#IoT in automotive manufacturing#IoT app development company#smart factory solutions#industrial IoT solutions#Technology

0 notes

Text

The Industrial IoT Revolution: Market Forecast and Leading Players to Watch in 2023–2031

Industrial IoT Market Report: Growth, Trends, and Future Outlook

The Industrial Internet of Things (IIoT) represents a transformative wave in industrial operations, leveraging the power of connected devices, sensors, and advanced analytics to optimize processes, improve efficiency, and unlock new business opportunities. IIoT connects machines, devices, sensors, and systems to collect and analyze data in real time, enabling industries to achieve smarter decision-making, reduce operational costs, and enhance productivity.

The global Industrial IoT (IIoT) market was valued at USD 334.53 billion in 2022 and is projected to reach USD 2,916.21 billion by 2031, growing at an impressive CAGR of 27.2% during the forecast period (2023–2031). This rapid growth highlights the increasing demand for IoT-enabled technologies across various industrial sectors, making IIoT a vital part of the digital transformation process in manufacturing, supply chains, and infrastructure.

Request a Free Sample (Free Executive Summary at Full Report Starting from USD 1850): https://straitsresearch.com/report/industrial-iot-market/request-sample

Key Trends in the Industrial IoT Market

Increased Adoption of Smart Manufacturing: Manufacturers are embracing IIoT for process automation, predictive maintenance, real-time monitoring, and supply chain optimization. This trend is expected to continue as more companies focus on reducing downtime and improving product quality through connected devices.

Advancements in Edge Computing and AI Integration: The rise of edge computing is reducing latency, enabling faster data processing at the source. Integrating AI and machine learning with IIoT systems allows industries to gain insights from real-time data, improving decision-making capabilities.

Focus on Cybersecurity: As the number of connected devices increases, so does the potential vulnerability to cyberattacks. Ensuring robust cybersecurity measures within IIoT systems is becoming a top priority for businesses.

5G Connectivity: The rollout of 5G technology is enhancing the capabilities of IIoT by offering faster and more reliable communication between connected devices. This enables applications that require low latency, such as autonomous vehicles and real-time remote monitoring.

Sustainability and Energy Efficiency: Industries are increasingly adopting IIoT technologies to improve energy efficiency, reduce emissions, and support sustainability goals. Sensors and data analytics enable more efficient resource management, leading to reduced waste and energy consumption.

Industrial IoT Market Size and Share

The IIoT market is witnessing substantial growth across various regions, driven by technological advancements, an increasing number of connected devices, and the need for automation. The major industrial sectors benefiting from IIoT include manufacturing, energy, automotive, pharmaceuticals, and more. Businesses are investing heavily in IIoT to streamline their operations, reduce operational costs, and ensure more efficient use of resources.

The market is also being driven by increasing government initiatives aimed at fostering smart city projects, digital infrastructure, and sustainable industrial practices. As industries continue to digitize their operations, the demand for IIoT solutions is poised to grow exponentially.

Buy Full Report (Exclusive Insights with In-Depth Data Supplement): https://straitsresearch.com/buy-now/industrial-iot-market

Industrial IoT Market Statistics

The global market value was USD 334.53 billion in 2022.

The market is expected to grow to USD 2,916.21 billion by 2031, with a CAGR of 27.2% during the forecast period (2023–2031).

North America holds a significant share of the market, driven by the adoption of advanced industrial technologies and the presence of key players like Cisco, IBM, and Honeywell.

Asia Pacific (APAC) is expected to witness the highest growth due to rapid industrialization, increasing investments in smart factories, and government support for smart manufacturing initiatives.

Regional Trends and Impact

North America: The North American region, particularly the United States and Canada, dominates the global IIoT market due to a robust manufacturing base, the presence of key technology companies, and early adoption of IoT-enabled technologies. The region’s focus on automation, smart factories, and energy efficiency has led to a high demand for IIoT solutions.

Asia Pacific (APAC): APAC is expected to witness the fastest growth in the IIoT market, primarily driven by the increasing industrialization in countries like China, Japan, and India. The region's push towards smart manufacturing, government initiatives supporting industrial automation, and rapid adoption of advanced technologies like AI, robotics, and 5G are propelling the growth of the IIoT market.

Europe: Europe is another key region for IIoT, driven by strong industrial sectors such as automotive, chemicals, and energy. The European Union’s focus on Industry 4.0 and digital transformation is increasing the demand for IIoT technologies across manufacturing, energy, and logistics.

LAMEA (Latin America, Middle East, and Africa): While still a developing market, the LAMEA region is showing significant potential for IIoT growth, especially in industries such as oil and gas, utilities, and agriculture. Increased investment in infrastructure and digitalization is expected to drive the demand for IIoT solutions in these regions.

Industrial IoT Market Segmentation

By Offering

Hardware:

Industrial Robots: These robots are essential for automating repetitive tasks in industries such as manufacturing and automotive, improving efficiency and reducing errors.

Industrial PC: Industrial PCs are used for data processing, monitoring, and control in industrial environments.

Industrial Sensors: Sensors play a critical role in collecting data from machines and devices to monitor conditions like temperature, pressure, and vibration.

Distributed Control System (DCS): DCS solutions enable centralized control of industrial processes, helping manage large-scale production systems.

Smart Meters: Smart meters are essential for monitoring and managing energy consumption in industries, contributing to energy efficiency.

Human Machine Interface (HMI): HMIs provide a visual interface for operators to interact with industrial control systems.

Control Devices: Devices that help regulate and control industrial processes, ensuring smooth operations.

Software: Software solutions in IIoT are used for data collection, processing, analytics, and visualization. These software tools enable industries to derive actionable insights from the vast amount of data generated by IIoT devices.

Services:

Training & Consulting Services: These services help organizations integrate IIoT technologies into their existing systems and operations.

Support and Maintenance Services: These services ensure that IIoT solutions continue to operate efficiently and without disruption.

By Connectivity

Wired Connectivity:

Ethernet: Provides high-speed, reliable data transmission for industrial applications.

Fieldbus: Used in process control systems for connecting field devices and control systems.

Wireless Connectivity:

Wi-Fi, Bluetooth, Cellular Connectivity, Satellite Connectivity: Wireless connectivity solutions offer flexibility and scalability for IIoT applications, especially in large industrial environments.

By End-use Industry

Aerospace and Defense

Automotive

Chemicals

Energy & Power

Food & Beverage

Metal and Mining

Oil & Gas

Pharmaceutical

Semiconductor & Electronics

Others (Healthcare, Water & Wastewater, etc.)

Each of these industries is increasingly adopting IIoT technologies to improve operational efficiency, ensure product quality, reduce costs, and enhance safety.

Market Segmentation with Insights-Driven Strategy Guide: https://straitsresearch.com/report/industrial-iot-market/segmentation

Top Players in the Industrial IoT Market

Several companies are leading the way in the IIoT market, providing innovative solutions and services:

Huawei Technology Co., Ltd.

Cisco

General Electric

Schneider Electric

Rockwell Automation

ABB

Texas Instruments

Honeywell

IBM

KUKA AG

NEC Corporation

Bosch

Siemens AG

SAP

Endress+Hauser

Accenture PLC

STMicroelectronics

These companies are at the forefront of developing and implementing IIoT solutions, helping industries to leverage IoT technologies for better efficiency, safety, and profitability.

Table of Contents for the Industrial IoT Market Report: https://straitsresearch.com/report/industrial-iot-market/toc

Conclusion

The Industrial IoT market is experiencing rapid growth as industries worldwide adopt connected devices, advanced analytics, and automation to enhance productivity, reduce costs, and improve decision-making. With significant investments in IIoT infrastructure, the market is poised to expand substantially in the coming years, especially in sectors such as manufacturing, energy, automotive, and pharmaceuticals. As technologies like AI, 5G, and edge computing continue to evolve, the potential for IIoT to drive industrial transformation will only increase, presenting enormous opportunities for businesses and industries to embrace the future of connected manufacturing and operations.

About Straits Research

Straits Research is a leading provider of market research and intelligence services. With a focus on high-quality research, analytics, and advisory, our team offers actionable insights tailored to clients’ strategic needs.

Contact Us Email: [email protected] Address: 825 3rd Avenue, New York, NY, USA, 10022 Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Industrial IoT#IIoT#Industrial Internet of Things#Smart Manufacturing#IoT Market Growth#Industry 4.0#Automation#Connected Devices#Predictive Maintenance#Smart Sensors#Edge Computing#Industrial Robotics#Market Research#IoT Solutions#5G Connectivity#IIoT Market Trends#Global Market Forecast#Honeywell#Cisco#Siemens#IIoT Adoption#Digital Transformation#Smart Factories#Industrial Automation#Market Segmentation#Straits Research

0 notes

Text

Sterison’s IoT Smart Factory: The Future of Manufacturing

Discover the power of the IoT Smart Factory with Sterison Technology. Our solutions provide real-time visibility into your entire manufacturing ecosystem by combining cutting-edge IoT connectivity with advanced analytics. Enhance operational efficiency, minimize wastage, and make data-driven decisions that keep you ahead of the competition. Sterison’s IoT Smart Factory solutions are your gateway to smarter, more efficient production systems.

0 notes

Text

Interwork Software Solutions provides comprehensive Industry 4.0 solutions, integrating advanced technologies like IoT, AI, blockchain, and data analytics to enhance operational efficiency, drive automation, and support digital transformation across industries, fostering sustainable, smart, and connected business ecosystems.

0 notes

Text

#industrial iot#technology#iot app development#iot development company#smart manufacturing#industrial IoT#smart factories#manufacturing technology#digital transformation#Industry 4.0#IoT in manufacturing

0 notes

Text

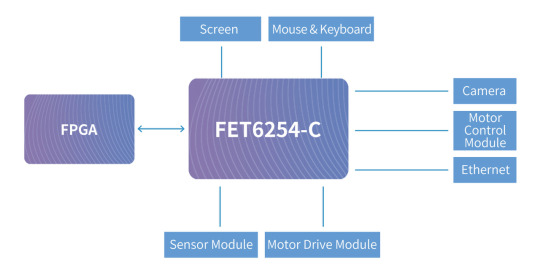

Industrial Data Acquisition and Control System Solution Based on FET6254-C SoM

Against the backdrop of rapid development in communication and networking technologies, smart factories are gradually achieving data-driven, networked, and intelligent management. In this trend, the utilization of the Industrial IoT has become an indispensable key step in achieving industrial data collection and control.

Traditional industrial data collection and control systems typically require connection to multiple data collection devices, perform high-speed communication, handle complex data processing, and achieve high-definition multimedia display functions. The embedded system based on ARM+FPGA architecture has rich peripheral interfaces, high-definition display high-speed transmission, and other functions, which are more capable of high-speed industrial data acquisition tasks. The flexibility and performance of this embedded system make it an ideal choice to meet the needs of smart factories, which can effectively improve the efficiency and accuracy of industrial data processing.

In the industrial data acquisition and control system, high-speed data acquisition system and embedded human-computer interaction system cooperate closely to build an intelligent industrial management system. The main task of the high-speed data acquisition system is to collect the key data in the industrial production process in real time and ensure the accuracy and timeliness of the data. This involves high-speed communication with multiple data acquisition devices, as well as sophisticated data processing and multimedia display capabilities.

As the main control center, the embedded human-computer interaction system coordinates and manages each module and resource, and is responsible for receiving the data from the FPGA terminal. It not only visualizes the data to the user, but also achieves more flexible control through human-computer interaction. The system also realizes the connection with the industrial MES + ERP system through the communication module, and transmits the collected data to the cloud for storage. This design not only improves the efficiency of data processing, but also greatly reduces the risk of manual data entry, and realizes the intelligent management of industrial data.

The whole system architecture provides a more comprehensive and efficient data management solution for enterprises. This not only helps to reduce human errors in the production process, but also makes better use of human resources and improves production efficiency. With the continuous development of communication and network technology, such industrial data acquisition and control system will become an important support for industrial intelligence in the future.

The main control device of the industrial data acquisition control system can adopt Forlinx Embedded FET6254-C SoM, which is based on TI's AM62x series industrial processor design, with the main frequency up to 1.4GHz, is a multi-core heterogeneous processor, adopting the Cortex-A53+Cortex-M4F combination of processing core + control core architecture; the functional safety features can be realised by the M4F core and its dedicated peripherals, and the startup and operation of the M4F core no longer depend on the A53 core. The M4F core and its dedicated peripherals enable functional safety features, and the M4F core is no longer dependent on the A53 core for startup and operation.

It can provide excellent data processing capability and human-computer interaction experience, and can control the motor drive module in real time to meet the requirements of data processing, task scheduling and human-computer interaction of the real-time control system.

It support parallel bus support for ARM high-speed communication with the FPGA to provide access. FET6254-C supports TI processor-specific general-purpose memory controller interface GPMC, high data read and write rate of up to 100MB / s, support for multiple chip selection, the configuration is more flexible, and at the same time can provide a variety of methods to connect with the peripheral devices and a wide range of external devices can be communicated.

The FET6254-C SoM integrates a rich set of functional interfaces. It supports two Gigabit Ethernet with TSN support, which provides fast data transmission and connection capability to meet the demand of industrial data acquisition and control systems for high bandwidth and low latency; it also supports three communication interfaces, such as CAN FD, I2C, I2S, which provide a reliable, high-speed and real-time data transmission method for the normal operation and efficient performance of industrial data acquisition and control system; with rich interface resources such as USB, UART, PWM, SPI, etc., it can be used to connect various sensors, actuators, motor drive modules, and mouse and keyboard devices.

The control system provides support for normal operation and efficient performance; with rich interface resources such as: USB, UART, PWM, SPI, etc., can be used to connect a variety of sensors, actuators, motor drive modules, as well as the mouse, keyboard devices, etc., can be achieved in industrial data acquisition and control of a variety of signals and data, to achieve the monitoring and control of the production process; the SoM adopts an industrial-grade temperature and wide range of design, to ensure that the stability and reliability of the product to meet the requirements of industrial application environment.

Originally published at www.forlinx.net.

0 notes

Text

Make your Factories Smarter through Cutting-edge Technologies Achieve higher productivity and quality by connecting machinery and equipment to your network, and collecting and visualizing measured data.

0 notes

Text

Edge Data Center Market- Optimizing IT Infrastructure for Business

The edge data centers facilitate quick delivery of data services with minimal latency. Edge caching is adopted by various industries dominated by IT and Telecommunication. Edge data centers provide their customers with high security and greater data control. Time-sensitive data is processed faster with edge data centers. Integration of advanced technologies such as AI and 5G is expected to create a lucrative growth opportunity for companies.

Apart from quick data delivery, low latency is another attractive feature of edge catching. In telecommunication companies edge catching is used to get better connectivity and proximity. IoT devices are bound to create huge data that need processing. Having a centralized server won’t be a feasible option here. Edge data centers could increase processing speed. Medical pieces of equipment may rely on edge data centers for robotic surgeries and extremely low latency.

Autonomous vehicles need to share data among vehicles in the same or other networks. A network of edge data centers could collect data and assist in emergency response. With the onset of Industry 4.0, companies will focus on building smart factories. Having an edge data center will help companies in planning their machine’s maintenance and quality management. Owing to a smaller footprint, lower latency, and faster processing edge data centers are anticipated to remain a key part of the IT infrastructure of companies.

0 notes

Text

hiotron : Top IoT Solution Providers in Pune

Build end-to-end IoT eco-system with multiple wireless sensor nodes connected to the IoT Gateway as a Hardware client, Front end custom mobile App/Dashboard as a Front end client & Custom platform as an IoT platform including implementation of top 5 Industrial IoT case studies. hiotron is Top IoT Solution Providers in Pune

View More at: https://www.hiotron.com/

#industry 4.0 solution for smart manufacturing#iot solution for smart factory pune#iot training in pune

0 notes

Text

Fogwing is an innovative and comprehensive Internet of Things (IoT) platform that offers a wide range of services and solutions for businesses and organizations looking to leverage the power of IoT technology. The website, https://www.fogwing.io/, serves as the online presence for Fogwing, providing detailed information and access to their IoT platform. The platform offers end-to-end solutions for IoT device management, data acquisition, real-time monitoring, analytics, and automation

#industrial iot#iiot#cmms software#smart factory market#industrial revolution#cheapest software#technology#united states of america#india

0 notes

Text

IoT Security Challenges in India: Protecting Smart Homes & Connected Devices

IoT is transforming the way people live by making their homes smart with devices such as security cameras, smart locks, and voice assistants. In India, IoT technology is adopted at a pace that cyber threats are rising rapidly. With weak security protocols, outdated software, and unawareness, Indian households are vulnerable to cyberattacks. In this blog, we will explore the major IoT security challenges in India and how individuals can safeguard their smart homes and connected devices. If you are looking to strengthen your understanding of cybersecurity, enrolling in a cyber security course can be a game-changer.

The IoT Boom in India

India is witnessing the highest adoption of IoT across homes and businesses. From smart TVs to intelligent thermostats, IoT is revolutionizing life. This booming technology, however, offers a large target size for hackers too who exploit the vulnerability of devices to gain unauthorized access to data.

Fundamental Drivers of IoT Adoption in India:

Increased internet penetration with low-priced data plans

Government initiatives such as Smart Cities Mission and Digital India

Increasing adoption of smart home devices as they become increasingly affordable

Growing application of industrial IoT in health, agriculture, and manufacturing

Chief IoT Security Challenges in India

Poor Authentication & Default Passwords

Most IoT devices have a factory-set password that the user ignores or fails to change. Hackers exploit these default credentials to take over the devices, entry private networks, and crack sensitive information.

Lack of Security Updates & Patches

Most smart devices have limited or no firmware updates, which makes them vulnerable to cyber threats. Many Indian consumers do not check for security updates, leaving their devices susceptible to known exploits.

Data Privacy Concerns

Smart devices collect vast amounts of personal data, from voice recordings to daily routines. Without stringent data protection policies, this information can be misused or leaked by malicious actors.

Botnet Attacks & DDoS Threats

Cybercriminals hijack unprotected IoT devices to form botnets, which are used to launch massive Distributed Denial of Service (DDoS) attacks. These attacks can cripple networks and cause disruptions to online services.

Unsecured Wi-Fi Networks

Many Indian households rely on poorly secured Wi-Fi connections, providing an easy entry point for hackers. Without encryption or strong passwords, attackers can intercept sensitive information and compromise connected devices.

Absence of Specific Cybersecurity Legislation for IoT

India has advanced in data protection with the Digital Personal Data Protection Act, but there is no dedicated IoT security framework. The absence of it leaves the manufacturer to choose cost over security and sell devices which are not so well protected in the market.

How to Secure Smart Homes & Connected Devices

Change Default Credentials

Always change the default usernames and passwords of the IoT after installation. Use strong, unique passwords and implement multi-factor authentication wherever possible.

Update Firmware Periodically

Scan for software and security updates on all smart devices, and install them as soon as they are available. In case your device can no longer get any updates, consider replacing it with a newer version that is at least as secure.

Secure Your Wi-Fi Network

Use a robust Wi-Fi password, and make sure WPA3 encryption is turned on. Limit remote access to your router, and make an IoT-specific network so that those devices can't contaminate your primary network.

Firewall & Security Solutions The use of firewalls and network security solutions monitors traffic and can block malicious activity on IoT networks. 5. Limit Data Sharing & Permissions

Assess permission for smart appliances and reduce or limit the devices from accessing unsecured personal information. De-activate unused add-ons, remote access in devices.

Cyber Security Courses

IoT-based cyber-attacks are minimized if awareness against the threat builds. To boost that awareness further, take time out to become a certified graduate of cyber security by signing for courses in areas like best security practices, principles of ethical hacking, and defending digital systems.

Road Ahead to Improving Indian IoT Security:

The Indian government, device manufacturers, and consumers must take proactive steps to mitigate IoT security risks. Stronger security standards, public awareness, and robust cybersecurity laws are the need of the hour to secure the future of IoT in India.

Conclusion

IoT devices offer incredible convenience but also introduce significant security risks. Protecting smart homes and connected devices requires a combination of best practices, awareness, and robust cybersecurity measures. By staying informed and adopting the right security strategies, individuals can ensure a safer IoT experience.

If you’re passionate about cybersecurity and want to build expertise in protecting digital systems, consider taking a cyber security course to gain hands-on knowledge and skills in ethical hacking, network security, and data protection.

3 notes

·

View notes

Text

CNC Press Brake Machine in India: Shaping the Future of Metal Bending

In the dynamic world of metal fabrication, CNC Press Brake Machines have become indispensable. These machines are critical in industries that demand precision bending and forming of sheet metal components. In India, the rising focus on infrastructure development, automotive manufacturing, and localized production has driven the adoption of CNC press brake technology across various sectors.

From small workshops to large-scale factories, CNC press brakes are revolutionizing how Indian manufacturers handle metal forming—efficiently, accurately, and consistently.

What is a CNC Press Brake Machine?

A CNC (Computer Numerical Control) Press Brake Machine is used to bend and shape metal sheets with precision. It uses a punch and die to perform various bends, guided by a CNC system that ensures exact specifications for angle, length, and repetition.

Modern CNC press brakes are far more advanced than traditional mechanical or hydraulic versions. They come with programmable controls, automated back gauges, and advanced sensors to deliver high-speed and high-precision bending.

Why CNC Press Brakes are Gaining Popularity in India

1. Precision and Consistency

In sectors like automotive, aerospace, and electronics, even minor deviations in part dimensions can lead to quality issues. CNC press brakes eliminate human error and ensure consistent output across batches.

2. Growing Industrialization

India’s expanding industrial base, especially in Tier 2 and Tier 3 cities, is fueling demand for reliable fabrication equipment. CNC press brakes allow businesses to scale up production without compromising on accuracy.

3. Labour Efficiency

With a skilled labor shortage and rising wages, automation is becoming more attractive. CNC press brakes require minimal human intervention, reducing labor costs and dependency on manual operators.

4. Government Incentives

Government initiatives like Make in India and Production Linked Incentive (PLI) Schemes are encouraging manufacturers to invest in advanced machinery, including CNC press brakes, for higher productivity.

Key Features of CNC Press Brake Machines in the Indian Market

High-Tonnage Capability: Machines ranging from 30 to 1000+ tons to suit various applications.

CNC Control Systems: Brands like Delem, ESA, and Cybelec offer intuitive interfaces for programming and automation.

Servo-Electric or Hydraulic Drive Systems: Depending on precision, energy efficiency, and speed requirements.

Multi-Axis Back Gauge: Enables complex bends and reduces setup time.

Automatic Tool Changers (ATC): For higher production environments.

Leading Indian and International Brands

India has a strong presence of both domestic and international CNC press brake manufacturers. Some notable names include:

Hindustan Hydraulics

Electropneumatics

Energy Mission

LVD India

Amada (Japan)

Durma (Turkey)

Yawei (China)

These companies offer machines tailored to the needs and budget of Indian manufacturers.

Applications in India

Automobile Body & Chassis Manufacturing

Kitchen Equipment Fabrication

Electrical Enclosures & Cabinets

Elevator and Escalator Components

Construction and Infrastructure Products

Railways and Defence Equipment

Challenges for Indian Buyers

High Initial Investment: CNC press brakes can be capital intensive, though the ROI is excellent over time.

Skill Development: Operators need training to use CNC systems effectively.

After-Sales Service: Choosing a vendor with reliable local support is crucial for maintenance and uptime.

The Road Ahead: Smart Factories & Industry 4.0

India is steadily moving towards smart manufacturing. CNC press brakes are now integrating with IoT, ERP systems, and robotic automation, enabling real-time monitoring, predictive maintenance, and remote troubleshooting. This evolution is making Indian factories more agile and globally competitive.

Conclusion

The CNC Press Brake Machine is no longer a luxury—it's a necessity in modern Indian manufacturing. With its unmatched accuracy, efficiency, and automation capabilities, it empowers businesses to meet rising customer expectations while optimizing operational costs.

As India continues to climb the global manufacturing ladder, CNC press brake machines will play a pivotal role in shaping the future—quite literally.

2 notes

·

View notes

Text

Top 10 Pneumatic Actuator Brands In 2025

The pneumatic actuator market continues to thrive in 2025, driven by advancements in automation and industrial efficiency. Based on comprehensive evaluations by CN10/CNPP research departments, which integrate big data analytics, AI-driven insights, and market performance metrics, here are the leading brands shaping the industry.

1. SMC (SMC Corporation)

Performance & Reliability: As a global leader since 1959, SMC delivers over 10,000 pneumatic components, including high-precision cylinders, valves, and F.R.L. units. Its products are renowned for durability, energy efficiency, and adaptability to extreme industrial conditions. Industry Applications: Widely used in automotive manufacturing, semiconductor production, and robotics, SMC’s actuators ensure seamless automation across 80+ countries. Its China-based facilities, established in 1994, serve as a primary global production hub.

2. FESTO (Festo AG & Co. KG)

Performance & Reliability: With nearly a century of expertise, Festo combines innovative engineering with IoT-enabled solutions. Its actuators emphasize precision control, low maintenance, and compatibility with smart factory ecosystems. Industry Applications: Festo dominates sectors like pharmaceuticals, food processing, and renewable energy, offering customized automation systems that enhance productivity and sustainability.

Other Notable Brands In The 2025 Rankings

While SMC and Festo lead the list, the following brands also excel in specific niches:

Brand A: Specializes in compact actuators for medical devices.

Brand B: Focuses on heavy-duty applications in construction machinery.

Brand C: Pioneers eco-friendly designs with reduced carbon footprints.

Key Trends Driving Market Growth

Smart Automation: Integration of AI and real-time monitoring in actuator systems.

Sustainability: Energy-efficient designs aligned with global decarbonization goals.

Customization: Tailored solutions for niche industries like aerospace and biotechnology.

This ranking underscores the critical role of innovation and adaptability in maintaining competitive advantage. Brands that prioritize R&D and cross-industry collaboration are poised to lead the next decade of pneumatic automation.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com

2 notes

·

View notes

Text

𝐇𝐨𝐰 𝐀𝐈 𝐚𝐧𝐝 5𝐆 𝐀𝐫𝐞 𝐓𝐫𝐚𝐧𝐬𝐟𝐨𝐫𝐦𝐢𝐧𝐠 𝐁𝐮𝐬𝐢𝐧𝐞𝐬𝐬 𝐆𝐫𝐨𝐰𝐭𝐡 | 𝐓𝐡𝐞 ����𝐮𝐭𝐮𝐫𝐞 𝐨𝐟 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧

The fusion of AI and 5G is revolutionizing businesses worldwide. With ultra-fast connectivity and real-time data analytics, companies are unlocking new opportunities for efficiency, automation, and customer engagement.

Learn how AI and 5G work together to:

Enhance real-time decision-making

Improve IoT connectivity for smart industries

Power AI-driven automation and predictive analytics

Personalize customer experiences like never before

From smart factories to AI-powered healthcare, discover how these technologies are shaping the future of business. Don't miss out—watch now - https://youtu.be/w1nDoqzVj0g

Follow for more tech insights.

#ai#5g#businessgrowth#innovation#futuretech#iot#automation#digitaltransformation#smarttechnology#bigdata

2 notes

·

View notes