#SoftRobots

Explore tagged Tumblr posts

Photo

„The Soft Machines“ – How will the autonomous car change the future? A future concept for Paris. w/ @nora_dupo (2017 – 2067) #future #design #autonomous #speculative #2067 #thisistomorrow #paris #france #speculativedesign #softrobots #thesoftmachines #car #carcrash #vision #futurelab #machines #summer (hier: Paris, France) https://www.instagram.com/p/Bq2JIeYFpMn/?utm_source=ig_tumblr_share&igshid=50twl0d8jahm

#future#design#autonomous#speculative#2067#thisistomorrow#paris#france#speculativedesign#softrobots#thesoftmachines#car#carcrash#vision#futurelab#machines#summer

1 note

·

View note

Text

SCIENTISTS EMBARK ON THE MAKING OF FLEXIBLE SOFT ROBOTS TO IMITATE WATER CREATURES

Scientists have started demonstrating how a new sets of robots will be build. The new robots will be entirely different from the already demonstrated ones. There will a quick shift of attention in the making of the rigid types of robots made with metals to another sets made with soft and flexible materials. A video made by futurism revealed how the engineers intend to achieve this new idea. Flexible robots can make use of leather, plastics or rubber material as its major parts for mobility. The samples released in the video illustrate robots made with thick and highly dense flexible materials. The idea behind such is to mimic the water creatures known to make use of flexible parts as such can make the robots move in water unnoticed by the aquatic creatures. Besides, a simple test conducted with such robots showed that their body is unbreakable even when car tires accidentally climb them. Elastic property of the robots’ body make it impossible to be broken under intense vibrations. The engineers behind the new move believe the use of flexible components could improve in the making humanoids’ fingers, neck and toes, etc. An idea believed to be the future of robotic engineering. Rubber, leather and plastic related materials are currently undergoing intense experiment to access how perfect they can operate and be used in in the making of future AI robots. The idea will be to help such robots become lighter and easier to operate since most parts made with metals can be replaced with such material. The sample robots made with such material seems to have few engine parts because the use of rope or string can control the remaining parts of the robot reducing the need for inclusion of extra metallic part. Hence, it made them simpler, and more flexible yet unbreakable. Above all, it offered lighter weight to the robots which helps in reducing the size of engines needed to move the parts of the robots leading to total reduction in the cost of their production. The light-weight offered in such robots enables them to swim inside the water down at any depth effectively. Their control while inside water may not be noticed by fishes and dangerous aquatic lives. The future of #robots just might be soft #robotics! #AI #ArtificialIntelligence #ml #dl #machinelearning #IoT #IIoT #futureofwork #automation @futurism via @MikeQuindazzi cc @Ronald_vanLoon @KirkDBorne @MarshaCollier @IIoT_World @KimWhitler pic.twitter.com/ntq1isXdAS — Rimah Harb (@HarbRimah) September 13, 2018 Read the full article

0 notes

Link

Ce qu'il ne fallait pas manquer cette semaine !

1 note

·

View note

Video

vimeo

1 note

·

View note

Photo

Bad news for ophiophobes: #HarvardSEAS researchers have developed a new and improved snake-inspired soft robot that is faster and more precise than its predecessor. The robot is made using kirigami — a Japanese paper craft that relies on cuts to change the properties of a material. As the robot stretches, the kirigami surface “pops up” into a 3D-textured surface, which grips the ground just like snake skin. The new research combined two properties of the material — the size of the cuts and the curvature of the sheet. By controlling these features, the researchers were able to program dynamic propagation of pop ups from one end to another, or control localized pop-ups. The research paves the way to responsive surfaces and smart skins.⠀ #Harvard #research #robotics #softrobotics #snake @nsfgov https://www.instagram.com/p/BwjwUBMHUwQ/?utm_source=ig_tumblr_share&igshid=1pixhwokf6q9k

2 notes

·

View notes

Text

Octobot: The World's First Slime Robot Sets a Milestone in Soft Robotics

Octobot, a soft-bodied vehicle propelled by a chemical reaction, is the first "slime robot" created by Harvard researchers. Its arms move and its silicone and 3D-printed body expand owing to a catalyst and hydrogen peroxide reaction. It can conduct precise movements under the control of a microfluidic circuit, marking a breakthrough in soft robotics. Octobot is a demonstration of the viability of building machines that interact with their surroundings without hard components, with potential biomedical and search-and-rescue applications. This development portends the development of futuristic, innovative, and adaptable robotics. https://www.linkedin.com/posts/monika-patel-b8094123b_chemical-team-technology-activity-7048541216270938112-fWZ1?utm_source=share&utm_medium=member_desktop

0 notes

Text

Tiny electromagnetic robot runs fast and re-forms after being squished

Tiny electromagnetic robot runs fast and re-forms after being squished

A squishy robot smaller than a postage stamp can run 70 of its body lengths every second – more than three times faster than a cheetah, relative to its body size. “It is really, really fast and, to be honest, that was a little bit of a surprise,” says Martin Kaltenbrunner at Johannes Kepler University Linz in Austria. “We actually bought a better version of a high-speed camera during the…

View On WordPress

0 notes

Link

Vine robots: Inflatable robots that extend from the tip and that enables them to pass through tight spaces and curvy and twisted passageways and over sticky surfaces, and not be stopped even by spikes.

0 notes

Photo

Here’s some of our favorite photos from the house show last weekend. Special thanks to @amymillerphoto for taking them, being a great image capturer, and lovely person. #softrobot #music #fun #band #nashville #photo

1 note

·

View note

Text

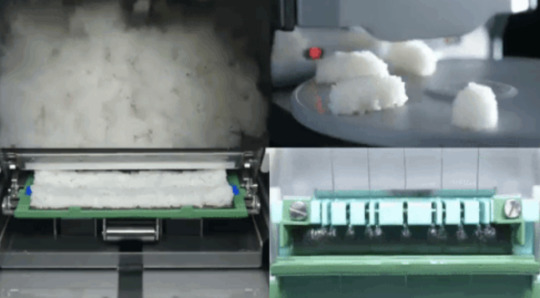

Final Project Prep - Kimbap roller

Heilmeier Questions

How is it done today, and what are the limits of current practice? Industrial level kimbap making machine are being used for mass production. But as you can see in tagged video, seaweed wrappers are extremely fragile and only that part is done by hand.

What is new in your approach and why do you think it will be successful? Instead of using silicone hand like inflatables, I want to use traditional bamboo mat and string controller system that is operated by simple arduino motor.

Who cares? If you are successful, what difference will it make? As someone who is just really bad at crafting fine kimbap, it would be a easy tool to make perfect kimbap!

What are the risks? Unable to create functional robot.

How much will it cost? $20~30

How long will it take? About two weeks for very primitive, beta version.

Research History & State-of-the-Art

Food making robot industry is a fast growing market. Those machines feature advanced, fully functional robot with the skillset of a master chef!

Expert

My mom! Researching for this project, I reached out to my mom as my advisor! We talked about what we observed and discussed the process. Wrote down some current problems and useful functions that can be added for my robot development.

list of relevant soft or flexible materials

Use existing silicone rolling mat

Bamboo mat

Sketch

For obvious reasons, I am extremely limited on materials. I’m imagining my robot to use string control methodology. Simple pull and release that will curl up the kimbap roll evenly. It will have simple arduino motor as a controller.

0 notes

Photo

Check out the #YouTube video of this #multimaterial #3Dprinter! Its #adorable and #amazing! Search: "New 3Dprinter makes mulitmaterial robots" The #future looks bright! Learn #3Dprint design with us at www.PTT.live #3Dprinting #3Dprinters #3Dprinted #multi #head #extruder #mutiple #materials #air #folding #walking #softrobot #new #robots #experiment #research #Harvard #Wyss #Institute for #Biologically #Inspired #Engineering (at Harvard University) https://www.instagram.com/p/B48WnYhHcJg/?igshid=8lngywye7hiv

#youtube#multimaterial#3dprinter#adorable#amazing#future#3dprint#3dprinting#3dprinters#3dprinted#multi#head#extruder#mutiple#materials#air#folding#walking#softrobot#new#robots#experiment#research#harvard#wyss#institute#biologically#inspired#engineering

0 notes

Photo

米国の研究チームは日本の折り紙を参考にした3Dプリントソフトロボティクス技術を開発 http://idarts.co.jp/3dp/3d-print-soft-origami-robot-twister/ #3dprinting #3dprinter #3dプリンタ #robot #origami #softrobotics #twister #ロボット #折り紙 #ロボットアーム

1 note

·

View note

Photo

L'AVENIR DE LA ROBOTIQUE ?

Si l'on vous demande de dessiner un robot, vous allez sans doute esquisser une tête en métal, avec des caméras pour lui permettre de voir, des bras articulés, des roues, des pattes ou des jambes pour se déplacer, etc. Et c'est la voie que prennent beaucoup d'ingénieurs en robotique. Mais il y a d'autres possibilités qui sont aussi de plus en plus explorées.

Le Muscle Mou remporte de plus en plus de succès, à cause des propriétés techniques et économiques du procédé. Je vous invite à aller voir cette vidéo pour mieux appréhender la question. Il s'agit en somme d'un système de piston hydraulique ou pneumatique à géométrie variable. Très peu couteux, et en utilisant une structure inspirée des origamis, ce système permet d'adapter la préhension du muscle en fonction de la forme qu'on lui aura donnée.

Si cette technologie était prometteuse depuis des années (elle avait inspiré le film de Disney Les nouveaux Héros en 2014) elle restait limitée par son incapacité à supporter de lourdes charges. Cette fois, certains modèles sont capables de porter 1000 fois leur poids, grâce à ces pliages internes qui forment alors un véritable squelette pour ce muscle mou.

Une technologie d'avenir, que l'on verra sans doute débarquer d'ici quelques années, tant elle est simple d’utilisation et bon marché…

1 note

·

View note

Text

Miura polyhedron

Tried out Tachi–Miura polyhedron with 45 degrees, d=2, l=2, m=1 to see how elongating actuator can be made...

failed to make a proper folds...

it took so long time to fold

not sure if I need to use TPU coated paper. Maybe it can be a outer shell with some inflatable actuator inside.

But need to read a bit more about this sort of folds.

Reference

An Approach to Designing Origami-Adapted Aerospace Mechanisms Tachi–Miura polyhedron

KORYO MIURA AND TOMOHIRO TACHI, SYNTHESIS OF RIGID-FOLDABLE CYLINDRICAL POLYHEDRA

Folding behaviour of Tachi–Miura polyhedron bellows

( Photo from the paper, An Approach to Designing Origami-Adapted Aerospace Mechanisms Tachi–Miura polyhedron)

(a page from the paper, KORYO MIURA AND TOMOHIRO TACHI, SYNTHESIS OF RIGID-FOLDABLE CYLINDRICAL POLYHEDRA )

1 note

·

View note

Photo

Eighth grade students from Roberto Clemente Middle School in Germantown, Md., got a taste of what it’s like to design robots, based on an arthropod design, at a soft robotics workshop. The visiting students learned about various materials and mechanical actuation systems. They were then challenged to make hand-like grippers, using drinking straws. “Through these workshops we want to help inspire the next generation of scientists by translating the high-level research that goes on here at Harvard into something that can be done by middle-school students,” said workshop organizer Kathryn Hollar, Director of Community Engagement and Diversity. ⠀ Photos and article by Manasa Joshyam #Harvard #HarvardSEAS #STEM #engineering #students #robotics #softrobotics #workshop #rcmsmagnet https://www.instagram.com/p/BwZfc3jHTel/?utm_source=ig_tumblr_share&igshid=14xt8tg9q2234

1 note

·

View note

Photo

Soft robot - I designed this simple single piece robot hand 3d printed with pla. a kind of compliant mechanisms that are flexible mechanisms use body deformation to transfer the force instead of topical rigid joints. What you think about soft robots? are they better than solid robots?#braindevices #maxbraindevices #softrobot #3dprint #robothand https://www.instagram.com/p/Bx2XTbMF2KI/?igshid=ahebtduvza7o

0 notes