#Solar Cell Modules

Explore tagged Tumblr posts

Text

#solar module manufacturers in india#solar cell manufacturers in india#solar pv module manufacturers in india#solar panel factory in india#solar panel makers in india#solar panel producers in india#solar plate manufacturer in india

1 note

·

View note

Text

PERC Solar Cells: Enhancing Efficiency & Reducing BOS Costs

Explore value of mono-PERC solar cells, driving down costs while boosting efficiency. Learn how PERC technology reduces both module and Balance of System costs

#PERC solar cells#Mono-PERC technology#Solar module efficiency#Reduce BOS costs#High efficiency solar panels#Solar cost reduction

0 notes

Text

The United States solar power market size is projected to exhibit a growth rate (CAGR) of 17.6% during 2024-2032. The favorable government initiatives, rapid technological advancements, growing awareness of environmental sustainability, climate change and the need to reduce greenhouse gas emissions, rising energy demand and increasing investment in research and development (R&D) efforts represent some of the key factors driving the market.

#United States Solar Power Market Report by Technology (Photovoltaic Systems#Concentrated Solar Power Systems)#Solar Module (Monocrystalline#Polycrystalline#Cadmium Telluride#Amorphous Silicon Cells#and Others)#End Use (Electricity Generation#Lighting#Heating#Charging)#Application (Residential#Commercial#Industrial)#and Region 2024-2032

0 notes

Text

https://www.maximizemarketresearch.com/market-report/global-solar-cell-modules-market/72469/

Global Solar Cell Modules Market is expected to grow at a CAGR of 8.9% during the forecast period and is expected to reach USD 177.59 Bn by 2030.

0 notes

Text

Here's How Grew's 3-stage Backward Integration Proves To Be A Gamechanger! Learn how GREW's 3-stage backward integration in ingot, cell, and wafer manufacturing is revolutionizing India's solar industry, paving the way for energy independence.

#manufacturing of ingots#manufacturing of wafers#manufacturing of cells#solar manufacturing in j&k#solar power companies#3.2 solar module plant in kathua

0 notes

Text

Amorphous solar panels are thin-film pv modules with glass as substrate. These solar panels can generate electricity under weak light source conditions, making them ideal for solar applications with low power consumption or low-light environments. Although the conversion efficiency of amorphous solar panels is not high, they are widely used in various devices such as electronic calculators, wireless sensors, watches, mask for soldering, speedometer and car security devices.

Amorphous solar panels have proven to be a versatile and reliable source of energy for a variety of applications. With their ability to generate electricity even under weak light source conditions, they offer a unique solution for solar power needs in low power consumption or low-light environments.

#amorphous solar panels#amorphous solar cells#indoor solar cells#custom solar modules#iot solar#Findy Solar

1 note

·

View note

Text

Illuminating the Future: Solar Panel Manufacturers in Noida

In Noida, the future is bright, thanks to companies like Sanguard Solar. As a leading solar panel manufacturer in Noida, solar street light manufacturer, and solar LED lighting manufacturer, Sanguard Solar is paving the way for a more sustainable and energy-efficient city. With their commitment to quality, innovation, and sustainability, they are indeed a beacon of hope in the journey towards a greener future.

So, whether you're a homeowner, business owner, or a local government representative, consider Sanguard Solar for all your solar energy needs. Embrace the power of the sun and be part of the solution for a cleaner, brighter, and more sustainable Noida.

Contact Now -: http://www.sanenergy.in/

#solar panel manufacturers company in noida#solar panel manufacturer in noida#solar street light manufacturer in noida#solar led street light manufacturer in noida#Solar modern reneweable energy#Rular Solar Renewable energy#EPC solar plant projects#PPC solar plant projects#solar led lighting manufacturers in noida#solar Projects#solar Cells#PV modules#120kw solar panel#330 Solar module#540kw Solar module#LI_ION batteries#54 Amp li-on batteries manufacturers#LI_ION batteries manufactures#Solar Plant#Floating solar plant

1 note

·

View note

Text

PLI scheme for Pharma, drones and textiles to be modified by govt

New Delhi: The government is planning to make adjustments to the production-linked incentive PLI scheme for pharmaceuticals, drones, and textile sectors. According to an official statement, these modifications are intended to stimulate investment and bolster manufacturing. An official source has stated that these sectors were chosen on the basis of their performance under the existing scheme for various products.

Higher disbursement scheme for PLI scheme

The official said, “Disbursement of production-linked incentives (PLI) for white goods (AC and LED lights) would start this month and that would push the amount of disbursement, which was only Rs 2,900 crore till March 2023.”

After the identification of sectors, a combined note for approval from the Union Cabinet will be sent. The change in disbursement includes an extension of time for Pharma sectors, and addition of products in some sectors. Within the textile industry, there is a proposal to expand the scope of particular products within the technical textiles category, while in the drone sector, there is a plan to raise the incentive amount.

Read More here : https://apacnewsnetwork.com/2023/09/pli-scheme-for-pharma-drones-and-textiles-to-be-modified-by-govt/

#advanced chemistry cell#advanced chemistry cell battery#auto#mobiles#Dronesdrones and textiles to be modified by govt#food products#high-efficiency solar PV modules#Higher disbursement scheme for PLI scheme#Medical Devices#Ministry of Commerce and Industry#Objective of the PLI scheme#pharmaceuticals and drones#PLI scheme#PLI scheme for Pharma#scheme aims#specialty steel#Telecommunications#textiles#white goods

0 notes

Text

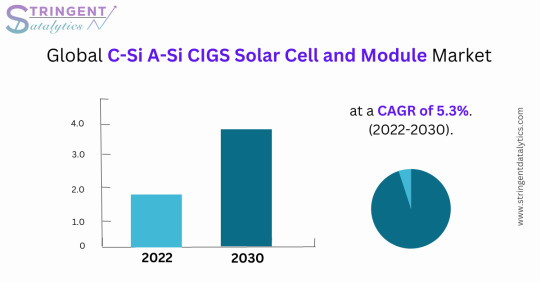

C-Si A-Si CIGS Solar Cell and Module Market

0 notes

Photo

Winds of change blew through the East, stirring up a strange and mysterious effect. Global polysilicon prices had suddenly dropped, while China polysilicon prices had risen just as quickly. There was no waiting for the dust to settle, for news seemed to spread with a speed that defied all explanation. Was some otherworldly force behind it, or was it merely the workings of a more mundane nature? Whatever the cause, the result was undeniable and had the people of the region asking questions they had no way of answering. Such was the power of the unknown.

#Markets#Markets & Policy#Modules & Upstream Manufacturing#Opinion & Analysis#ingots#photovoltaic#photovoltaics#polysilicon#PV#PV modules#PV plant#silicon#Solar#solar cell#Solar Cells#solar energy#solar modules#solar panels#Solar Power#Solar PV#Solar wafers#Technology#wafers#fault#global#Chinese#demand#manipulation

0 notes

Text

#Top 10 solar panel manufacturers in india#top 10 solar module manufacturers in india#top 10 solar panel company in india#top solar panel manufacturers in india#solar panel manufacturing company in india#solar cell manufacturing company in india#top 10 solar panel manufacturers in gujarat#top ten solar panel in india.#make in india

1 note

·

View note

Text

"This year the world will make something like 70bn of these solar cells, the vast majority of them in China, and sandwich them between sheets of glass to make what the industry calls modules but most other people call panels: 60 to 72 cells at a time, typically, for most of the modules which end up on residential roofs, more for those destined for commercial plant. Those panels will provide power to family homes, to local electricity collectives, to specific industrial installations and to large electric grids; they will sit unnoticed on roofs, charmingly outside rural schools, controversially across pristine deserts, prosaically on the balconies of blocks of flats and in almost every other setting imaginable.

Once in place they will sit there for decades, making no noise, emitting no fumes, using no resources, costing almost nothing and generating power. It is the least obtrusive revolution imaginable. But it is a revolution nonetheless.

Over the course of 2023 the world’s solar cells, their panels currently covering less than 10,000 square kilometres, produced about 1,600 terawatt-hours of energy (a terawatt, or 1tw, is a trillion watts). That represented about 6% of the electricity generated world wide, and just over 1% of the world’s primary-energy use. That last figure sounds fairly marginal, though rather less so when you consider that the fossil fuels which provide most of the world’s primary energy are much less efficient. More than half the primary energy in coal and oil ends up as waste heat, rather than electricity or forward motion.

What makes solar energy revolutionary is the rate of growth which brought it to this just-beyond-the-marginal state. Michael Liebreich, a veteran analyst of clean-energy technology and economics, puts it this way:

In 2004, it took the world a whole year to install a gigawatt of solar-power capacity... In 2010, it took a month In 2016, a week. In 2023 there were single days which saw a gigawatt of installation worldwide. Over the course of 2024 analysts at BloombergNEF, a data outfit, expect to see 520-655gw of capacity installed: that’s up to two 2004s a day...

And it shows no signs of stopping, or even slowing down. Buying and installing solar panels is currently the largest single category of investment in electricity generation, according to the International Energy Agency (IEA), an intergovernmental think-tank: it expects $500bn this year, not far short of the sum being put into upstream oil and gas. Installed capacity is doubling every three years. According to the International Solar Energy Society:

Solar power is on track to generate more electricity than all the world’s nuclear power plants in 2026 Than its wind turbines in 2027 Tthan its dams in 2028 Its gas-fired power plants in 2030 And its coal-fired ones in 2032.

In an IEA scenario which provides net-zero carbon-dioxide emissions by the middle of the century, solar energy becomes humankind’s largest source of primary energy—not just electricity—by the 2040s...

Expecting exponentials to carry on is rarely a basis for sober forecasting. At some point either demand or supply faces an unavoidable constraint; a graph which was going up exponentially starts to take on the form of an elongated S. And there is a wide variety of plausible stories about possible constraints...

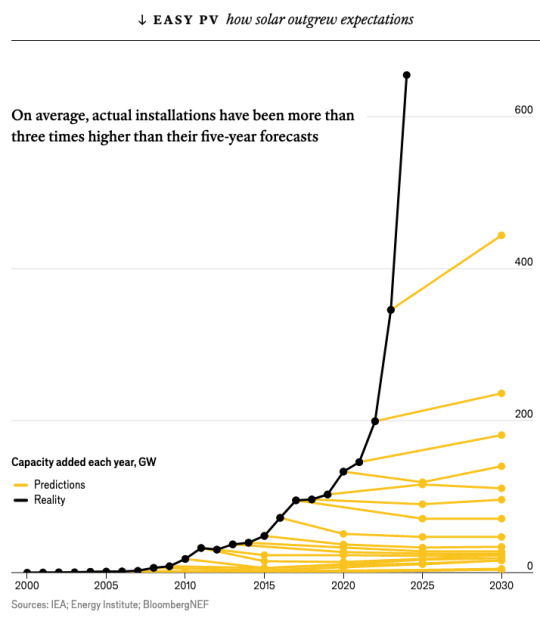

All real issues. But the past 20 years of solar growth have seen naive extrapolations trounce forecasting soberly informed by such concerns again and again. In 2009, when installed solar capacity worldwide was 23gw, the energy experts at the IEA predicted that in the 20 years to 2030 it would increase to 244gw. It hit that milestone in 2016, when only six of the 20 years had passed. According to Nat Bullard, an energy analyst, over most of the 2010s actual solar installations typically beat the IEA’s five-year forecasts by 235% (see chart). The people who have come closest to predicting what has actually happened have been environmentalists poo-pooed for zealotry and economic illiteracy, such as those at Greenpeace who, also in 2009, predicted 921gw of solar capacity by 2030. Yet even that was an underestimate. The world’s solar capacity hit 1,419gw last year.

-via The Economist, June 20, 2024

--

Note: That graph. Is fucking ridiculous(ly hopeful).

For perspective: the graph shows that in 2023, there were about 350 GW of solar installed. The 5-year prediction from 2023 said that we'd end up around 450 GW by 2030.

We hit over 600 GW in the first half of 2024 alone.

This is what's called an exponential curve. It's a curve that keeps going up at a rate that gets higher and higher with each year.

This, I firmly believe, is a huge part of what is going to let us save the world.

#solar power#solar energy#climate change#fossil fuels#solarpunk#hopepunk#solar age#optimism#renewable#renewable energy#clean energy#green energy#renewables#solar panels#good news#hope

583 notes

·

View notes

Text

Perovskite solar cells (PSCs) present a revolutionary leap in renewable energy technology with their high efficiency, lightweight, and flexible nature. But their commercial applications are often hindered by their sensitivity to environmental factors like heat and humidity. To address this, a team of researchers led by Professor Takashi Minemoto, a Ritsumeikan Advanced Research Academy Fellow from the College of Science and Engineering, Ritsumeikan University, Japan, along with Dr. Abdurashid Mavlonov from the Research Organization of Science and Technology, Ritsumeikan University, and Dr. Akinobu Hayakawa from Sekisui Chemical Co., Ltd., recently conducted pioneering research to investigate the durability of these PSC modules in harsh environmental conditions. This study was made available online on December 17, 2024, and was published in Volume 286 of Solar Energy on January 15, 2025.

Read more.

7 notes

·

View notes

Text

GREW Energy’s Manufacturing of Ingots, Cells & Wafers: Pioneering India’s Path to Solar Superpower

GREW Energy is revolutionizing India's solar landscape with its robust 3-stage backward integration strategy, encompassing the manufacturing of ingots, wafers, and cells. This strategic approach not only enhances the efficiency and quality of solar PV modules but also positions India as a burgeoning solar superpower on the global stage.

Manufacturing of Ingots: The Foundation of Solar Excellence

At the heart of GREW Energy's backward integration lies the meticulous process of manufacturing ingots. Ingots are the foundational building blocks of solar cells and are critical to ensuring the overall efficiency and durability of solar panels. By producing high-quality ingots in-house, GREW Energy guarantees consistency in the purity and structure of the silicon, which translates into superior solar cells. This self-reliant approach not only reduces dependency on external suppliers but also allows for greater control over the quality of the end product.

Manufacturing of Wafers: Precision and Innovation

The next crucial step in GREW Energy's backward integration is the manufacturing of wafers. These thin slices of semiconductor material are where sunlight is converted into electricity. GREW Energy’s state-of-the-art solar manufacturing in J&K (Jammu & Kashmir) is dedicated to producing high-efficiency wafers, optimized for various environmental conditions. The precision in wafer manufacturing directly impacts the energy conversion efficiency of the solar cells, making this stage vital for the overall performance of solar modules. By integrating this process, GREW Energy ensures that its solar products are equipped to meet the demands of both domestic and international markets.

Manufacturing of Cells: Powering India's Solar Ambitions

The final stage of GREW Energy's backward integration is the manufacturing of cells, where wafers are transformed into active solar cells that generate electricity. This stage is where the true potential of the ingots and wafers is realised. By manufacturing cells in-house, GREW Energy is able to push the boundaries of solar technology, producing cells that are not only efficient but also tailored to withstand India’s diverse climatic conditions. This capability is particularly significant for solar power companies operating in regions like J&K, where the climate poses unique challenges.

Solar Manufacturing in J&K: A Strategic Advantage

GREW Energy's investment in solar manufacturing in J&K (Jammu & Kashmir) is a testament to their commitment to regional development and energy self-sufficiency. By setting up operations in J&K, GREW Energy is not only tapping into the region's potential but also contributing to local employment and economic growth. The strategic location also allows GREW Energy to cater to both northern India and neighboring countries, further establishing India as a key player in the global solar industry.

Setting the Stage for India as a Solar Superpower:

Through its 3-stage backward integration, GREW Energy is setting a new benchmark for solar manufacturing in India. By controlling every stage of the production process—from manufacturing ingots to manufacturing wafers to manufacturing cells—GREW Energy ensures that their solar modules are of the highest quality, efficiency, and reliability. This comprehensive approach not only positions GREW Energy as a leader among solar power companies but also drives India's ambition to become a global solar superpower. With their cutting-edge technology and strategic investments, GREW Energy is not just contributing to India's energy security but is also paving the way for a sustainable future.

In conclusion, GREW Energy’s 3-stage backward integration is more than just a manufacturing strategy; it is a vision for India's role in the global solar revolution. As the world looks towards cleaner and more sustainable energy sources, GREW Energy is ensuring that India is at the forefront of this transformation, leading the way with innovation, quality, and commitment.

For more: GREW Energy’s Manufacturing of Ingots, Cells & Wafers: Pioneering India’s Path to Solar Superpower

#manufacturing of ingots#manufacturing of wafers#manufacturing of cells#solar manufacturing in j&k#solar power companies#3.2 solar module plant in kathua

0 notes

Text

Excerpt from this story from Canary Media:

Despite the policy uncertainty facing renewables as the Trump administration prepares to take the wheel, the outlook for U.S. solar is generally positive, according to the just-released U.S. Solar Market Insight Q4 2024 report from the Solar Energy Industries Association (SEIA) and energy analysis firm Wood Mackenzie.

This year, the solar industry is set to break installation records and achieve significant manufacturing milestones — including the return of silicon solar cell production to the U.S. for the first time since 2019.

As a testament to the effectiveness of the Inflation Reduction Act (IRA), domestic solar module manufacturing capacity has nearly quintupled since 2022 — courtesy of new or expanded factories in Alabama, Florida, Georgia, Ohio, and Texas that benefited from the law’s tax credits. The U.S. added a record-breaking 9.3 gigawatts of new solar module production capacity in the third quarter alone.

The IRA is also responsible for bringing solar cell manufacturing back to the U.S., with Suniva (which filed for bankruptcy in 2017) restarting production at its Norcross, Georgia factory in November. Solar cells do the actual conversion of sunlight to electricity, but domestic production was halted due to lower-cost imports. The vast majority of the world’s cells are made in China and four Southeast Asian countries whose solar exports are now subject to steep U.S. tariffs.

The U.S. currently has close to 40 gigawatts in module manufacturing capacity, according to Wood Mackenzie — enough to meet almost all of its own demand for panels. But the country will still need to rely on imported solar cells for the foreseeable future; less than 10 gigawatts of cell capacity is under construction in the states.

With the exception of the residential rooftop segment, U.S. solar installations are overperforming in the face of trade headwinds. Corporate and state renewable energy goals are creating high demand for solar, though Wood Mackenzie expects the energy source’s blistering growth to taper off over the next five years as developers face the same woes as the broader power generation sector: a limited workforce, equipment constraints, and interconnection delays.

7 notes

·

View notes

Text

50 Items of Sci-Fi Dungeon Dressing

For filling up a derelict spaceship or magi-tech ruins, this list of science-fiction themed dungeon dressing provides useful items galore. These items can be simple set dressing, plot objectives, or provide environmental storytelling. You decide the condition of the items and if any are still usable.

Short range wrist comms - 60ft

Laser pointer

Air compressor

Emergency beacon x10

Water purification kit

Truth serum

Sedative

Tranquilizer serum

Painkillers

Syringes

Wound sealant

Medscanner (checks vitals)

Hoverboard

Personal datalog

A buggy universal translator

ID cards

Roomba with a knife taped to it

Geiger counter

Heat-vision goggles

Reflective tarp (for camping)

Oxygen tank with mask (1 hr)

Arc welder (1 hr)

Fingerprint lock

Antigrav boots (3/day)

Silencer

Solar cell

Respirator

Lightsticks (waterproof) x10

Gas mask x10

Coldpack

Heatpack

Holopad

Prosthetic exoskeleton

Bionic eye

Star charts

Electric drill (10 charges)

Stopwatch

Ammunition bandolier

Metal manacles

Retina scanner

Smoke alarm

Portable quarantine kit

Laptop computer

Radar scanner (3 charges)

Vocal modulator

Electrical charger

Data drive

Propane tank (10d6 fire damage when set aflame)

Freeze-dry SnackPack TM (20)

Bio-sequencer (for disease ID)

18 notes

·

View notes