#Soldering Robot Analysis

Explore tagged Tumblr posts

Text

Writing Scientist Characters

this post is mainly an excuse to post a certain list of lab supplies I've made for a friend and infodump about lab work. but feel free to use this as a little resource when writing characters who are scientists and/or lab nerds. who knows, maybe it'll be of use.

General thoughts

Many people think it's a stereotype that scientist or nerd characters talk using complex technical jargon. While that is true to an extent, there actually is some kind of lab jargon. It varies across different labs and fields, but one thing they have in common is that it seeks to simplify, not the other way around.

gelelectrophoresis becomes elpho

microbiology becomes mibi

deioninized water becomes aqua dist

biochemistry becomes BC

sodium hydroxide becomes NaOH

They will probably not call a glass of water "silicon dioxide and h2o".

...and more. feel free to get creative. If you're writing in any other language than English, you can throw in one or two anglicisms as well. Also, most scientists will never gatekeep their work, and in an opposite fashion, will not shut up about it unless you make them. And no, most chemists do not know the entire periodic table by heart, only the most relevant elements. (main groups and a few commonly used metals of the subgroups) When it comes to characters doing the lab work, keep in mind that there are a lot more people involved than the scientist themself. Most scientists are more occupied with paperwork and data analysis, it is the laboratory technicians and assistants that do most of the practical work. They often have more lab experience than the scientists themselves.

Things you can have your lab nerd character do instead of making random chemicals explode

writing a lab report (and losing their mind over excel)

degreasing the glass bevel stoppers

removing the permanent marker from beakers (labeling is important)

complaining about the lack of funding of [their field] research

cleaning glassware

preparing specimen for examination

googling the most basic equations for their report

checking if the glassware and utensil collections are complete

steal single use plastic pipettes from their lab

pirating expensive textbooks

A list of laboratory supplies and utensils you can have them work with

Laboratory general (chem + bio)

Erlenmayer flasks, beakers, precision scales (3 digits), glass rods, metal spoons/spatulas, screw on glass flasks (autoclave compatible) test tubes, stopcock grease, dispensers with sanitizer and hand cream, gas burners, heating plates, eppendorf pipettes, pipette tips, Peleus pipetting aids, squirting bottles, liquid and powder funnels, incubator/drying chamber, round watch glasses, magnet stirring plates.

Microbiology Autoclave, petri dishes, agar plates, innoculation loops (reusable and metal), clean bench, microscope slides, microscope, drigalski-spatula, test tubes with clamping lids

Histology

Paraffin bath, water bath, scalpels, scissors, razor blades, microtomes (rotating microtome, slide microtome and freezing microtome), histocinette, tweezers (various kinds), ocular

Biochemistry

Sequencing robots, eppendorf tubes, gelelectrophoresis chambers, centrifuge

Analytical Chemistry

Photometer, kuvettes, burettes, mass spectro meters, UV bank (for chromatogrophies), pyknometers, melting point meter, porcelain mortars, pH paper, analytical scales (4 or more digits)

Prep Chemistry

Tripod/standing material, miniature lifting platforms, spiral condenser, colon condenser, round bottom flask (three necked and y- necked), filtration material, Separating funnel

Electrical engineering

Electric generators, Soldering iron, Clamp connectors, plugin connectors, ohm’s resistors, plug in lamps, condensers, transistors, PCBs, amperemeters, voltmeters, multimeters

Mechanics

Tripod/standing material, metal hooks, metal rods, mechanical stop watches, marbles, metal springs, Newton meters, laser motion detectors

Optics

Prisma (various kinds), various glass lenses (concave, convex, biconcave, biconvex), laser pointers, optical bench, mechanical iris diaphragm, looking glasses, monochrome lamps, lamp filters

Most used chemicals

Deionized water, ethanol, NaOH, HCl, H3PO4, NaCl (+ physiological NaCl solution 0.9)

Useful websites for writing science stuff

DNA sequence generator (simple): http://www.faculty.ucr.edu/~mmaduro/random.htm

DNA, RNA and protein sequence generator: https://molbiotools.com/randomsequencegenerator.php Annealing temperature calculator: https://tmcalculator.neb.com/#!/main

Medicine name generator: https://www.fantasynamegenerators.com/medicine-names.php Anything chemistry related: https://www.wolframalpha.com/input?i=chemistry

Commonly used software:

MS Excel

Yenka

CASSY Lab

LabView

SpectraLab

LIMS

LaTex

Slack

Scientist friends, feel free to add onto this.

Have fun writing!

#creative writing#writing#resource#writing resources#science#biology#chemistry#physics#writing guide#writers on tumblr#writeblr#rp#rp resources

118 notes

·

View notes

Text

anyway i came across this article and it's really bad and i'm going to make it your problem

to be clear, i'm not saying "wow yes automation is based fuck people working menial jobs", i just thing this article is... really, really bad.

thoughts in no particular order:

the article references a survey saying that 85% of Americans want (workforce) automation to be restricted to jobs that are dangerous or harmful to humans. i would like to ask whether they're willing to give up

compilers

a good fraction of the infrastructure used to make any kind of CPU in general; you're not hand-soldering at the 10nm node!

printers

the printing press in general

washing machines

a good whack of professional dry cleaning hardware

a good portion of, like, everything that has automation significantly involved in its production

postal mailing address OCR

traffic lights (in lieu of having someone with a stop sign or whatever)

thermostats

and the list goes on

this is the general pattern with the way people talk about automation: everyone says it's bad, nobody wants to give up things that have already been automated, because that's just natural and the way it is. automation is the Bad Thing.

hell, the article even approvingly quotes a tweet saying "We could automate menial jobs so people have time to make art and music but apparently we’d rather automate art and music so people have time for menial jobs." while ignoring the fact that the historical automation the author is complaining about exclusively affected menial jobs! also insert obligatory "robotics are fucking hard" rant here

the comic also talks about punch cards in universities being a "symbol of bureaucracy and alienation" and compares them to punch cards used for drafts, and how it led to people viewing them as helping "the system"

this is, to put it bluntly, terrible analysis! "forcing people to go and fight in a war" and "assigning people to classes" are not even remotely the same thing; you might as well talk about how the written word enables The System! and for that matter, the idea of "The System" as a grand totalizing thing is also bad, in part because it leads you to making mistakes like this.

basically, it's a bad article, bad analysis. totally based on vibes rather than anything coherent. 0/10.

10 notes

·

View notes

Text

PCBA: The Silent Backbone of Electronic Devices

Printed Circuit Board Assembly (PCBA) serves as the critical foundation for nearly every electronic device in our modern world. From smartphones and laptops to industrial automation systems and aerospace equipment, PCBA ensures that the various electronic components within a device function smoothly and cohesively. Its precision and reliability are not just technical necessities but vital to sustaining innovation in the global tech economy.Get more news about PCBA manufacturer,you can vist our website!

Understanding PCBA

At its core, PCBA refers to the process of soldering electronic components onto a printed circuit board (PCB). While a PCB is simply the board with copper traces that connect components electrically, the assembly process transforms it into a fully functional circuit. This involves mounting integrated circuits (ICs), resistors, capacitors, diodes, and other components using either Surface Mount Technology (SMT), Through-Hole Technology (THT), or a hybrid of both, depending on the design and purpose of the device.

The PCBA Process

The process typically begins with solder paste application, where a stencil is used to apply the paste on predefined areas of the PCB. Automated pick-and-place machines then accurately position the tiny components onto the board. This is followed by reflow soldering, where the board is passed through a controlled oven to melt the solder and secure the components.

For boards requiring through-hole components, manual or wave soldering is used. Once soldered, the board undergoes inspection and testing—ranging from Automated Optical Inspection (AOI) to X-ray analysis and functional testing—to ensure quality and performance. Advanced PCBA plants employ high levels of automation, drastically reducing human error and improving output consistency.

Applications Across Industries

PCBA's influence stretches far beyond consumer electronics. In the automotive sector, it powers systems ranging from infotainment units to electric vehicle battery management. In healthcare, PCBA-based medical devices like ECG machines and portable monitors are critical to patient diagnostics and care. Aerospace and military applications demand high-reliability PCBA to function under extreme environments—an area where rigid quality controls and testing standards become indispensable.

Trends and Innovations

The PCBA landscape continues to evolve rapidly with advances in miniaturization, multi-layer boards, and flexible circuits. With the rise of the Internet of Things (IoT), demand for compact, power-efficient, and wireless-capable assemblies has exploded. Manufacturers are investing in smart factories, using AI-driven inspection and robotics to further optimize production.

Meanwhile, environmental considerations are pushing green manufacturing methods, such as lead-free solder and recyclable board materials. Companies are also embracing design-for-manufacturing (DFM) principles to streamline assembly and minimize waste.

Conclusion

Though rarely visible to end-users, PCBA is the invisible force driving the electronics revolution. Its blend of engineering precision, automation, and innovation enables the digital tools and systems we rely on daily. As global technology continues to push boundaries, PCBA will remain the structural and functional heart of that progress—quietly pulsing behind every screen, circuit, and sensor.

0 notes

Text

Pick and Place Machine: Automating Precision in PCB Assembly

Introduction

In the fast-paced electronics industry, manufacturers require efficient, scalable, and precise solutions for PCB assembly. A pick and place machine plays a central role in Surface Mount Technology (SMT) manufacturing by automating component placement, reducing errors, and enhancing production speed. Whether producing consumer electronics, automotive systems, or industrial devices, these machines ensure high-quality assembly at scale.

What is a Pick and Place Machine?

A pick and place machine is an automated system that selects, aligns, and mounts electronic components onto Printed Circuit Boards (PCBs). By replacing manual component placement, it improves speed, accuracy, and overall efficiency in electronics manufacturing.

Key Benefits of Pick and Place Machines

High-Speed Production – Automates component handling and positioning, significantly reducing assembly time.

Superior Accuracy & Reliability – Ensures precise component placement, minimizing defects.

Reduced Labor Costs – Minimizes manual work, increasing overall efficiency.

Compact & High-Density PCB Designs – Supports miniaturization for advanced electronics.

Scalability for Large-Volume Production – Ideal for mass PCB assembly with consistent quality assurance.

How a Pick and Place Machine Works

1. Component Feeding

Electronic components are supplied through reels, trays, or tubes, ready for placement.

2. Optical Vision & Alignment System

Advanced camera technology scans and aligns components, ensuring precise positioning.

3. High-Speed Placement

Robotic arms pick components and accurately position them onto PCBs.

4. Soldering Preparation

Once components are placed, the PCB moves to the reflow oven, where solder paste melts to form secure connections.

5. Final Inspection & Testing

Automated Optical Inspection (AOI), X-ray analysis, and electrical testing verify placement accuracy and performance.

Why Invest in a Pick and Place Machine?

1. Increased Efficiency & Output

Automation accelerates production cycles while maintaining high placement accuracy.

2. Lower Manufacturing Costs

Optimized workflows reduce labor expenses and improve resource utilization.

3. Superior Product Reliability

Ensures strong solder joints and extended durability.

4. Adaptability for Industry Growth

Supports IoT devices, automotive electronics, and advanced consumer technology.

Conclusion

A pick and place machine is a vital asset in modern SMT assembly, delivering speed, accuracy, and cost-effective scalability. Investing in high-performance automation technology enables manufacturers to streamline production, improve product quality, and stay ahead in a competitive industry.

0 notes

Text

Miniaturized Components Boost Global SMT Equipment Market Demand

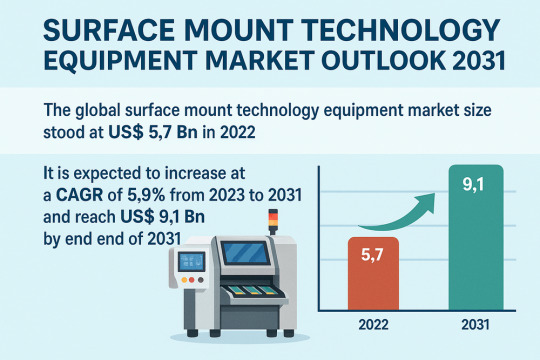

The global surface mount technology (SMT) equipment market is poised for substantial growth over the coming decade. Valued at USD 5.7 Bn in 2022, the market is projected to advance at a compound annual growth rate (CAGR) of 5.9% between 2023 and 2031, ultimately reaching USD 9.1 Bn by 2031. SMT equipment plays a critical role in the electronics manufacturing industry by enabling efficient, high-speed, and reliable assembly of surface-mounted components on printed circuit boards (PCBs). The widespread integration of miniaturized and high-performance electronics in consumer devices, automotive systems, telecommunications infrastructure, and industrial automation is significantly driving the adoption of SMT equipment.

Market Drivers & Trends

One of the major drivers of the SMT equipment market is the increasing demand for compact and lightweight electronic devices. With consumer electronics becoming smaller and more multifunctional, the need for advanced SMT machines capable of precise, high-speed placement of components has grown exponentially.

The ongoing shift toward Industry 4.0 and smart manufacturing is also influencing SMT equipment trends. Manufacturers are now integrating artificial intelligence (AI), robotics, and IoT-enabled systems into their production lines to boost efficiency and reduce defects. This trend is reshaping the traditional SMT landscape and encouraging investments in intelligent SMT lines with real-time monitoring and self-correction capabilities.

Additionally, the proliferation of electric vehicles (EVs) and advanced driver-assistance systems (ADAS) is generating new opportunities for SMT equipment manufacturers, particularly in the automotive electronics segment.

Latest Market Trends

Several trends are shaping the SMT equipment market today:

Integration of AI and machine learning in SMT systems to enhance placement accuracy and reduce human intervention.

Adoption of 3D inspection systems for quality control, ensuring higher yield rates and better defect detection.

Expansion of flexible and hybrid SMT lines to accommodate varying production volumes and product types.

Sustainability-focused designs, such as energy-efficient reflow ovens and lead-free soldering systems, are gaining traction amid rising environmental concerns.

These trends are not only boosting productivity but are also redefining customer expectations and pushing market players toward more adaptive and future-ready solutions.

Analysis of Key Players

The surface mount technology equipment industry is consolidated with the presence of a few players holding major market share. Leading manufacturers are following the latest surface mount technology equipment market trends and engaging in new product launches and mergers & acquisitions to consolidate their presence in the global market.

Dou Yee Enterprises (S) Pte. Ltd., JUTZE Intelligence Technology Co., Ltd., Koh Young Technology, Mirtech, Nordson Corporation, Omron Corporation, PARMI Corporation, Saki Corporation, Test Research, Inc., Vi Technology (Mycronic AB), Viscom AG, Vitrox Corporation, and Yamaha Motor Co., Ltd. are a few notable players that offer inspection equipment. While ASML Holding, N.V., Fuji Machine Mfg. Co., Ltd., Hitachi, Ltd., Juki Corporation, KLA-Tencor Corporation, Koh Young Technology, Mycronic AB, Nordson Corporation, Orbotech Ltd., Panasonic Corporation, PARMI Corp., Test Research, Inc., and Yamaha Motor Co., Ltd. are key notable players offering surface mount technology equipment.

Recent Developments

The past few years have seen a wave of strategic developments in the SMT equipment market:

ASMPT introduced a new line of modular SMT systems featuring AI-assisted analytics to optimize throughput.

Panasonic unveiled a next-gen placement machine with enhanced component recognition and autonomous calibration features.

Witte Technology GmbH expanded its European manufacturing facility to increase capacity and meet rising global demand.

Several players have formed partnerships with automotive and telecom firms to tailor SMT solutions for specific industry requirements, such as 5G infrastructure and EV component manufacturing.

Download to explore critical insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=5516

Market Opportunities

Numerous opportunities lie ahead for stakeholders in the SMT equipment space:

Growing electronics manufacturing services (EMS) sector in Asia-Pacific, particularly in countries like China, Vietnam, and India, is creating demand for scalable SMT systems.

The rise of smart wearables and IoT devices presents a growing segment for compact SMT solutions.

High-reliability applications in aerospace, defense, and medical electronics require advanced SMT capabilities, opening niche but profitable markets.

Government incentives in semiconductor and electronics manufacturing across various regions are encouraging infrastructure development and equipment procurement.

Future Outlook

Looking forward, the SMT equipment market is set to evolve in alignment with global digitization and electrification trends. As AI and predictive maintenance become standard in manufacturing environments, the integration of such capabilities in SMT systems will become a key differentiator. Additionally, geopolitical shifts and supply chain restructuring are expected to drive investments in localized manufacturing, fueling SMT equipment demand in emerging markets.

The future of the SMT equipment market will be shaped by technological agility, customization, and sustainability all critical to addressing the dynamic needs of modern electronics manufacturing.

Market Segmentation

The SMT equipment market can be segmented based on:

Equipment Type:

Placement Equipment

Inspection Equipment

Soldering Equipment

Screen Printing Equipment

Cleaning Equipment

Application:

Consumer Electronics

Automotive

Industrial Electronics

Telecommunications

Medical Devices

Aerospace & Defense

End-user:

OEMs (Original Equipment Manufacturers)

EMS Providers

This segmentation highlights the market’s diverse application base and underscores the necessity for flexible and tailored SMT solutions.

Regional Insights

Asia-Pacific dominates the global SMT equipment market, driven by a robust manufacturing ecosystem, especially in China, Japan, and South Korea. The region is expected to remain a powerhouse throughout the forecast period.

North America is witnessing increasing demand due to reshoring efforts and innovations in automotive and medical electronics.

Europe, led by Germany and the UK, is focusing on high-precision SMT systems for automotive and industrial applications.

Latin America and the Middle East & Africa are emerging markets with growing infrastructure and electronics demand, albeit at a relatively slower pace.

Why Buy This Report?

This comprehensive market research report offers:

In-depth analysis of current and future market trends

Thorough competitive landscape assessment including company profiles and market share

Detailed segmentation and regional breakdowns

Insights into technological innovations and investment opportunities

Strategic recommendations for stakeholders, investors, and policymakers

Whether you are a market entrant, investor, OEM, or EMS provider, this report serves as a crucial tool for making informed business decisions.

Explore Latest Research Reports by Transparency Market Research: GPS Tracking Device Market: https://www.transparencymarketresearch.com/gps-tracking-device-market.html

E-Beam Wafer Inspection System Market: https://www.transparencymarketresearch.com/e-beam-wafer-inspection-system-market.html

Filtered Connectors Market: https://www.transparencymarketresearch.com/filtered-connectors-market.html

Commercial Security Systems Market: https://www.transparencymarketresearch.com/commercial-security-systems-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

The Manufacturing Process Behind a High-Quality Water Cooler: From Design to Delivery

Water coolers have become an essential fixture in offices, schools, hospitals, and homes, offering convenient access to clean and temperature-controlled drinking water. But what many people don’t realize is the complex, multi-stage process involved in creating a reliable, efficient, and durable water cooler. From concept to consumer, every step demands precision engineering, quality assurance, and innovation.

In this article, we explore the detailed journey a water cooler manufacturer undertakes to produce high-quality machines—from initial design to final delivery.

1. Research and Product Design

The process begins with market research and user analysis. Leading water cooler manufacturers study customer preferences, workplace needs, and health and safety standards to inform product development.

Design engineers then create blueprints using CAD (Computer-Aided Design) software. They consider various factors such as:

Ergonomics and user accessibility

Energy efficiency

Cooling/heating mechanisms

Aesthetic appeal

Material durability

Water purification systems (e.g., UV, reverse osmosis, activated carbon)

Prototypes are developed and tested in-house to assess functionality, safety, and ease of maintenance. Only after a rigorous evaluation is the design finalized for mass production.

2. Material Sourcing and Component Fabrication

Once the design is approved, the manufacturing phase begins with sourcing raw materials. This typically includes:

Stainless steel or ABS plastic for external casing

Food-grade tubing for water flow systems

Copper or aluminum coils for thermal exchange

Filtration media and UV lamps for purification

Compressor units and thermostats for temperature control

As a reliable water cooler manufacturer, quality assurance starts at this stage. All materials must meet safety, environmental, and regulatory standards (such as RoHS or NSF certifications).

Component fabrication involves:

Injection molding for plastic parts

Sheet metal processing for structural frames

Coil winding and assembly for refrigeration systems

Each component is inspected to ensure it meets exact specifications before entering the assembly line.

3. Assembly and Integration

During the assembly stage, all the components are carefully integrated into a cohesive unit. This process typically includes:

Installing the internal water tank and cooling/heating systems

Routing of internal plumbing and wiring

Mounting the compressor, filters, and control panels

Sealing, insulation, and exterior casing attachment

Advanced manufacturers use semi-automated production lines with precise robotic systems for tasks that require high accuracy, such as soldering or welding.

Each unit is subjected to leak tests, electrical safety checks, and performance diagnostics. Manufacturers simulate real-world usage to ensure durability under various conditions.

4. Quality Control and Compliance Testing

Quality control is one of the most critical stages for any reputable water cooler manufacturer. Units are tested for:

Cooling/heating efficiency

Electrical safety

Flow rate and pressure consistency

Water purity and taste

Noise levels

In addition, models must comply with industry-specific standards like:

CE (Conformité Européenne)

UL (Underwriters Laboratories)

ISO 9001 and ISO 14001 for manufacturing and environmental management

Products that fail these stringent tests are either reworked or discarded to maintain brand reputation and customer safety.

5. Packaging and Delivery

After passing final inspections, the water coolers are carefully packaged using protective materials to prevent damage during transit. Packaging is typically eco-friendly and labeled with product instructions, certification marks, and warranty details.

Units are then distributed via logistics partners to showrooms, retailers, or directly to customers. Many manufacturers now offer direct-to-consumer shipping, especially for customized or branded units.

Conclusion

The journey from a conceptual sketch to a fully functional water cooler involves advanced engineering, rigorous testing, and meticulous craftsmanship. A high-quality water cooler manufacturer invests in design innovation, precision manufacturing, and robust quality control systems to deliver products that are not only efficient and stylish but also safe and long-lasting.

By understanding this intricate process, consumers and businesses alike can make more informed decisions when choosing a water cooler that meets both performance and reliability expectations.

0 notes

Text

0 notes

Text

In-Depth Analysis of Toggle Switch Terminal Connection Methods: Technical Selection and Scenario Adaptation for Soldered, Plug-In, and PCB-Mounted Designs

Introduction

In B2B applications such as industrial control, automotive electronics, and medical equipment, the terminal connection method of a toggle switch is a critical factor determining product reliability, installation efficiency, and long-term maintenance costs. Soldered, plug-in, and PCB-mounted designs each have unique advantages and limitations, requiring a comprehensive evaluation of electrical performance, environmental resistance, and production automation. This article analyzes structural design, application scenarios, and compatibility challenges, supported by industry cases (e.g., automotive ECU controls, industrial PLC modules) and emerging trends (e.g., high-density PCB integration), to provide engineers and procurement decision-makers with a systematic selection guide.

1. Soldered Terminal Connections: The "Permanent Bond" for High Reliability

Structure & Process

Physical Connection: Permanently fixes switch terminals to PCBs or wires via soldering (solder or reflow).

Terminal Type: Through-hole pins (0.6–1.2mm diameter), typically made of tin-plated or gold-plated phosphor bronze.

Key Standard: Compliant with IPC-A-610 to avoid cold joints or voids.

Applications & Cases

High-Vibration Environments: Siemens’ train control panels use soldered toggle switches validated for 10-year maintenance-free operation under EN 61373.

High-Current Loads: ABB frequency converters employ soldered emergency stop switches to withstand 50A short-circuit currents.

Pros & Cons

Advantages: Stable contact resistance (<5mΩ), superior vibration resistance (passes MIL-STD-202G), low cost (no connectors required).

Limitations: Difficult repairs (thermal desoldering needed), limited flexibility in automated production.

Innovations

Hybrid solder-crimp terminals (e.g., TE Connectivity’s DUOBILIT) balance reliability and removability.

High-temperature solder (Sn96.5Ag3Cu0.5) extends lifespan in automotive engine compartments.

2. Plug-In Terminals: Modular Flexibility for Easy Maintenance

Structure & Standards

Connection Types: Tab terminals, receptacles, or spring cages with 5–20N insertion force (UL 310).

Common Sizes: 2.8mm (automotive) or 4.8mm (industrial) tab widths.

Applications & Cases

Medical Equipment: GE MRI control switches use gold-plated tabs for <3mΩ contact resistance and 10,000-cycle durability.

Smart Home Gateways: C&K’s T-series plug-in terminals enable cross-device compatibility.

Pros & Cons

Advantages: Tool-free installation, hot-swappable (e.g., data center PDUs), space-efficient (2.54mm pitch).

Limitations: Higher contact resistance (+10–30% vs. soldered), vibration-induced loosening (requires locking mechanisms).

Innovations

Foolproof designs (e.g., AMP’s Mate-N-Lok asymmetric tabs).

Self-cleaning multi-point contacts (e.g., JST PA series).

3. PCB-Mounted Terminals: Miniaturization for High-Density Integration

Structure & Process

Mounting Types: Through-hole (THT) or surface-mount (SMT) with L/J-shaped leads.

Typical Dimensions: THT pins (3–5mm length), SMT packages (60% smaller than THT).

Applications & Cases

Consumer Electronics: ALPS SSSS series SMT toggle switches (2.3mm thickness) in TWS earphone cases.

Robotics: SMT switches integrated with FPGAs on 0.5mm-pitch PCBs.

Pros & Cons

Advantages: Ultra-compact, automated production-friendly (>20,000 CPH), low EMI.

Limitations: Vulnerable to PCB flexing, limited heat dissipation.

Innovations

Hybrid SMT-THT designs (e.g., E-Switch TL series).

Flexible PCB-compatible curved pins (Würth Elektronik WM series).

4. Compatibility Challenges & Solutions

Cross-Platform Adaptation: Phoenix Contact’s COMBICON modular terminals switch between THT and plug-in modes.

Moisture Resistance: 3M Parylene coating + O-rings prevent dendrite growth.

High-Frequency Noise: C&K KSC series with shielded pins and Rogers RO4003 substrates.

5. Industry Trends & Selection Guide

Smart Integration: LEM GoSwitch series with current sensors and I²C interfaces.

Green Manufacturing: DSM EcoPaXX halogen-free materials for RoHS 3.0 compliance.

en.dghongju.com

0 notes

Text

Exploring the Role of High-Speed Cameras in Industrial Automation

The rapid advancements in technology have significantly transformed the industrial landscape, with automation leading the charge in improving efficiency and productivity. High Speed Cameras have become a crucial component in Industrial automation. Among the many tools driving this transformation, high-speed cameras have emerged as indispensable devices in industrial automation. These cameras enable manufacturers and engineers to capture and analyze high-speed processes with unmatched precision and detail. Let’s delve into the pivotal role high-speed cameras play in industrial automation and how companies like Imaging Source machine vision cameras contribute to their effectiveness.

High-Speed Cameras: A Game-Changer in Industrial Automation

High-speed cameras are designed to capture events at exceptionally high frame rates, allowing the analysis of processes that occur too quickly for the human eye or standard cameras to perceive. In industrial settings, these cameras are essential for troubleshooting, quality control, and process optimization.

Key applications of high-speed cameras in industrial automation include:

1. Quality Control and Inspection: High-speed cameras are used to identify defects in manufacturing processes, such as misaligned components, irregularities in product dimensions, or surface flaws. By capturing high-resolution footage at thousands of frames per second, manufacturers can pinpoint errors and address them promptly, ensuring superior product quality.

2. Machine Diagnostics: High-speed imaging allows engineers to analyze the performance of machinery, detecting issues such as vibrations, misfires, or wear and tear. This predictive maintenance approach minimizes downtime and extends the lifespan of critical equipment.

3. Process Optimization: By providing detailed insights into high-speed processes, these cameras help optimize operations such as material handling, assembly line performance, and packaging. Engineers can fine-tune workflows to maximize efficiency and reduce waste.

4. Robotics and Automation Systems: High-speed cameras are integral to the development and operation of robotic systems. They enable precise monitoring and control of robotic movements, ensuring accurate and consistent performance in tasks like welding, sorting, and assembly.

The Role of Imaging Source Machine Vision Cameras in Enhancing High-Speed Imaging

Imaging Source machine vision cameras play a vital role in supporting high-speed imaging applications by providing top-tier optical and imaging solutions. The performance of a high-speed camera is heavily reliant on the quality of its components, and this is where Imaging Source machine vision cameras excel. From precision imaging to robust hardware, their products ensure that high-speed cameras deliver optimal performance in industrial environments.

Here’s how Imaging Source machine vision cameras enhance high-speed imaging:

● Precision Imaging: High-speed cameras demand components that can handle extreme frame rates without compromising image clarity. Imaging Source machine vision cameras offer solutions specifically designed to maintain sharpness and resolution, even at high speeds.

● Durable Components: Industrial settings can be harsh, with exposure to dust, heat, and vibrations. The robust hardware from Imaging Source machine vision cameras ensures reliability and longevity in such demanding environments.

● Customization: Every industrial application has unique requirements. Imaging Source machine vision cameras provide tailored solutions that meet specific high-speed imaging needs, ensuring seamless integration with camera systems.

Case Studies: High-Speed Cameras in Action

The impact of high-speed cameras in industrial automation is evident across various industries:

1. Electronics Manufacturing: In PCB assembly lines, high-speed cameras monitor soldering processes, detecting defects such as solder bridges or insufficient solder deposits. With the help of solutions from Imaging Source

machine vision cameras, these cameras achieve unparalleled precision, ensuring flawless circuitry.

2. Automotive Industry: High-speed cameras analyze crash tests and airbag deployments to improve vehicle safety. In manufacturing, they monitor robotic arms on assembly lines, ensuring consistent performance and rapid error detection.

3. Pharmaceuticals: The production of pills and syringes requires meticulous inspection to meet stringent quality standards. High-speed cameras equipped with components from Imaging Source machine vision cameras ensure that every product is flawless before reaching consumers.

The Future of High-Speed Imaging in Industrial Automation

The integration of high-speed cameras with artificial intelligence and machine learning is set to revolutionize industrial automation. By enabling real-time analysis and decision-making, these technologies will further enhance efficiency and productivity. Imaging Source machine vision cameras will continue to play a crucial role in this evolution by providing advanced imaging solutions that meet the demands of next-generation systems.

Conclusion

High-speed cameras have become a cornerstone of industrial automation, enabling manufacturers to achieve higher levels of precision, efficiency, and quality. Their role in quality control, machine diagnostics, and robotics underscores their importance in modern industries. Companies like Imaging Source machine vision cameras are instrumental in this journey, providing the imaging solutions necessary for high-speed cameras to excel in demanding industrial environments. As technology continues to advance, the collaboration between high-speed imaging and precision imaging solutions will unlock new possibilities in industrial automation.

MV Asia Infomatrix Pte Ltd -

http://mvasiaonline.com/

#Imaging Source machine vision cameras#machine vision automation singapore#manufacturing quality#MVAsiaInfomatrix

0 notes

Text

SMT Lines: Revolutionizing Electronics Manufacturing with Speed and Precision

Introduction

Electronics manufacturers face growing demands for high-speed, cost-efficient, and reliable production. Surface Mount Technology (SMT) lines provide the solution, enabling automated component placement, soldering, and inspection to optimize PCB assembly. Whether producing smart devices, automotive electronics, or industrial systems, SMT lines enhance efficiency, accuracy, and scalability in manufacturing.

What Are SMT Lines?

SMT lines are integrated production systems designed to automate PCB assembly, replacing manual soldering with high-speed, robotic accuracy. These lines ensure rapid, precise, and scalable electronics manufacturing.

Benefits of SMT Lines

Faster Production – Automation speeds up component placement and soldering.

Greater Accuracy & Reliability – Reduces errors and enhances product consistency.

Cost Optimization – Minimizes labor expenses and material waste.

Compact & High-Density Designs – Enables miniaturization for advanced electronics.

Scalability for Mass Production – Supports large-scale assembly with uniform quality.

Core Components of SMT Lines

1. Solder Paste Printer

Applies precise solder paste layers onto PCBs, preparing them for component placement.

2. Pick-and-Place Machine

High-speed robotics position SMT components onto the PCB with optical precision.

3. Reflow Oven

Controlled heating cycles melt solder paste, securing component connections.

4. Inspection & Quality Control

Automated Optical Inspection (AOI), X-ray analysis, and functional testing verify assembly accuracy.

5. PCB Unloading & Packaging

Finished boards undergo final testing, packaging, and distribution.

Why Invest in SMT Lines?

1. Increased Efficiency & Output

Automation improves production speed while maintaining high assembly precision.

2. Lower Manufacturing Costs

Optimized processes minimize labor dependency and operational waste.

3. Superior Product Reliability

Ensures strong solder joints and long-term durability.

4. Adaptability for Industry Growth

Supports IoT applications, automotive electronics, and advanced consumer technology.

Conclusion

SMT lines have transformed electronics production with automation, speed, and cost-effectiveness. Investing in state-of-the-art SMT technology enables manufacturers to streamline operations, enhance product quality, and stay ahead in a competitive industry.

0 notes

Text

Exploring the Role of High-Speed Cameras in Industrial Automation

The rapid advancements in technology have significantly transformed the industrial landscape, with automation leading the charge in improving efficiency and productivity. High Speed Cameras have become a crucial component in Industrial automation. Among the many tools driving this transformation, high-speed cameras have emerged as indispensable devices in industrial automation. These cameras enable manufacturers and engineers to capture and analyze high-speed processes with unmatched precision and detail. Let’s delve into the pivotal role high-speed cameras play in industrial automation and how companies like Imaging Source machine vision cameras contribute to their effectiveness.

High-Speed Cameras: A Game-Changer in Industrial Automation

High-speed cameras are designed to capture events at exceptionally high frame rates, allowing the analysis of processes that occur too quickly for the human eye or standard cameras to perceive. In industrial settings, these cameras are essential for troubleshooting, quality control, and process optimization.

Key applications of high-speed cameras in industrial automation include:

1.Quality Control and Inspection: High-speed cameras are used to identify defects in manufacturing processes, such as misaligned components, irregularities in product dimensions, or surface flaws. By capturing high-resolution footage at thousands of frames per second, manufacturers can pinpoint errors and address them promptly, ensuring superior product quality.

Machine Diagnostics: High-speed imaging allows engineers to analyze the performance of machinery, detecting issues such as vibrations, misfires, or wear and tear. This predictive maintenance approach minimizes downtime and extends the lifespan of critical equipment.

Process Optimization: By providing detailed insights into high-speed processes, these cameras help optimize operations such as material handling, assembly line performance, and packaging. Engineers can fine-tune workflows to maximize efficiency and reduce waste.

4.Robotics and Automation Systems: High-speed cameras are integral to the development and operation of robotic systems. They enable precise monitoring and control of robotic movements, ensuring accurate and consistent performance in tasks like welding, sorting, and assembly.

The Role of Imaging Source Machine Vision Cameras in Enhancing High-Speed Imaging

Imaging Source machine vision cameras play a vital role in supporting high-speed imaging applications by providing top-tier optical and imaging solutions. The performance of a high-speed camera is heavily reliant on the quality of its components, and this is where Imaging Source machine vision cameras excel. From precision imaging to robust hardware, their products ensure that high-speed cameras deliver optimal performance in industrial environments.

Here’s how Imaging Source machine vision cameras enhance high-speed imaging:

Precision Imaging: High-speed cameras demand components that can handle extreme frame rates without compromising image clarity. Imaging Source machine vision cameras offer solutions specifically designed to maintain sharpness and resolution, even at high speeds. ● Durable Components: Industrial settings can be harsh, with exposure to dust, heat, and vibrations. The robust hardware from Imaging Source machine vision cameras ensures reliability and longevity in such demanding environments. ● Customization: Every industrial application has unique requirements. Imaging Source machine vision cameras provide tailored solutions that meet specific high-speed imaging needs, ensuring seamless integration with camera systems.

Case Studies: High-Speed Cameras in Action

The impact of high-speed cameras in industrial automation is evident across various industries:

1.Electronics Manufacturing: In PCB assembly lines, high-speed cameras monitor soldering processes, detecting defects such as solder bridges or insufficient solder deposits. With the help of solutions from Imaging Source machine vision cameras, these cameras achieve unparalleled precision, ensuring flawless circuitry.

Automotive Industry: High-speed cameras analyze crash tests and airbag deployments to improve vehicle safety. In manufacturing, they monitor robotic arms on assembly lines, ensuring consistent performance and rapid error detection.

3.Pharmaceuticals: The production of pills and syringes requires meticulous inspection to meet stringent quality standards. High-speed cameras equipped with components from Imaging Source machine vision cameras ensure that every product is flawless before reaching consumers.

The Future of High-Speed Imaging in Industrial Automation

The integration of high-speed cameras with artificial intelligence and machine learning is set to revolutionize industrial automation. By enabling real-time analysis and decision-making, these technologies will further enhance efficiency and productivity. Imaging Source machine vision cameras will continue to play a crucial role in this evolution by providing advanced imaging solutions that meet the demands of next-generation systems.

Conclusion

High-speed cameras have become a cornerstone of industrial automation, enabling manufacturers to achieve higher levels of precision, efficiency, and quality. Their role in quality control, machine diagnostics, and robotics underscores their importance in modern industries. Companies like Imaging Source machine vision cameras are instrumental in this journey, providing the imaging solutions necessary for high-speed cameras to excel in demanding industrial environments. As technology continues to advance, the collaboration between high-speed imaging and precision imaging solutions will unlock new possibilities in industrial automation.

#machine vision system#high resolution camera distributor#cognex#vision inspection#xenics infrared camera in mumbai

0 notes

Text

Key Factors to Consider When Choosing an X-Ray Inspection System

X-ray inspection systems have become indispensable in industries like manufacturing, electronics, food processing, and aerospace, offering unparalleled accuracy in detecting defects and ensuring quality control. However, selecting the right X-ray inspection system can be a challenging task, given the variety of options available in the market. Choosing the wrong system can lead to inefficiencies, higher costs, and potential risks to your production process. To help you make an informed decision, this article outlines the key factors to consider when selecting an X-ray inspection system for your needs.

1. Industry-Specific Requirements

Different industries have unique demands when it comes to X-ray inspection. The system you choose should be tailored to the specific requirements of your sector.

Food Industry: Systems must detect foreign objects like metal, glass, and bone while meeting strict regulatory standards.

Electronics: High-resolution systems are essential for inspecting solder joints, PCBs, and micro-components.

Aerospace and Automotive: Systems need to detect internal cracks or voids in critical components to ensure safety.

Understanding your industry’s specific requirements will help you narrow down options and select the most suitable system.

2. Inspection Resolution and Sensitivity

The resolution and sensitivity of an X-ray inspection system determine its ability to detect small or subtle defects. High-resolution systems are crucial for industries like electronics and aerospace, where even minute defects can have significant consequences.

Key Considerations:

Check the resolution of the detector and the size of defects the system can identify.

Ensure the system provides consistent sensitivity across varying materials and densities.

Higher resolution often comes with a higher price tag, so balance your needs with your budget.

3. System Throughput and Speed

For industries with high production volumes, the speed and throughput of the X-ray system are critical. A slower system can create bottlenecks, impacting overall efficiency.

Key Considerations:

Evaluate the inspection speed and whether it aligns with your production line’s output.

Check if the system can handle batch or continuous inspections without compromising accuracy.

Some systems are designed for high-speed applications, making them ideal for industries like food processing and packaging.

4. Ease of Integration and Scalability

The X-ray inspection system should integrate seamlessly into your existing production line or workflow. Additionally, it should offer scalability to accommodate future growth or changes in production demands.

Key Considerations:

Ensure the system supports easy integration with current conveyor belts, robotic arms, or other automated systems.

Look for modular designs that allow upgrades or expansion without replacing the entire system.

Seamless integration reduces downtime and ensures smooth operations.

5. Software Capabilities

Modern X-ray systems are equipped with advanced software for analysis, reporting, and automation. The right software can enhance functionality and usability.

Key Features to Look For:

User-friendly interface and intuitive controls.

Automated defect detection using AI or machine learning.

Real-time monitoring and data analysis capabilities.

Compatibility with your existing quality management systems.

Advanced software can significantly reduce human error and improve inspection accuracy.

6. Regulatory Compliance

In industries like food and pharmaceuticals, compliance with regulatory standards is non-negotiable. The X-ray system you choose must meet these standards.

Key Considerations:

Verify that the system adheres to industry-specific regulations such as FDA, HACCP, or ISO certifications.

Ensure it has features like contaminant detection or radiation shielding to meet safety requirements.

Compliance ensures smooth audits and avoids potential legal issues.

7. Maintenance and Support

An X-ray inspection system is a long-term investment that requires regular maintenance and support to perform optimally.

Key Considerations:

Evaluate the manufacturer’s service offerings, including maintenance contracts and warranty terms.

Check for the availability of spare parts and the ease of replacing them.

Ensure the system comes with robust technical support and training resources.

Reliable maintenance and support minimize downtime and extend the system’s lifespan.

8. Cost and Return on Investment (ROI)

While cost is a significant factor, it’s essential to assess the value the system brings to your operations rather than focusing solely on the initial price.

Key Considerations:

Compare the system’s cost with the benefits it offers, such as improved accuracy, reduced waste, and enhanced quality control.

Calculate the potential ROI by factoring in productivity gains, reduced defect rates, and customer satisfaction.

Investing in a high-quality system may involve higher upfront costs but can lead to substantial savings over time.

9. Radiation Safety

X-ray systems emit radiation, which can pose risks if not properly contained. Ensuring the system meets safety standards is vital for protecting operators and complying with regulations.

Key Considerations:

Check for shielding features that minimize radiation exposure.

Ensure the system complies with radiation safety standards such as ANSI or CE certifications.

Proper safety measures create a secure working environment and build trust with employees.

Conclusion

Choosing the right X-ray inspection system is critical for ensuring the efficiency and safety of your production processes. By considering factors such as industry requirements, resolution, throughput, integration, software capabilities, compliance, and cost, you can make an informed decision that aligns with your business needs. Investing in the right system not only improves product quality but also enhances your brand reputation and operational efficiency. Take the time to evaluate your options, and you’ll find an X-ray inspection system that delivers long-term value.

0 notes

Text

0 notes

Text

0 notes

Text

Robotic Arm Market 2024 : Industry Analysis, Trends, Segmentation, Regional Overview And Forecast 2033

The Robotic Arm Global Market Report 2024 by The Business Research Company provides market overview across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, the Middle East, and Africa, encompassing 27 major global industries. The report presents a comprehensive analysis over a ten-year historic period (2010-2021) and extends its insights into a ten-year forecast period (2023-2033).

Learn More On The Robotic Arm Market: https://www.thebusinessresearchcompany.com/report/robotic-arm-global-market-report

According to The Business Research Company’s Robotic Arm Global Market Report 2024, The robotic arm market size is expected to see rapid growth in the next few years. It will grow to $69.16 billion in 2028 at a compound annual growth rate (CAGR) of 17.0%. The growth in the forecast period can be attributed to robotic arms used in manufacturing, enhanced efficiency, precision, and speed in production processes, increasing productivity and cost-effectiveness, automation in various sectors, including automotive, and growth in e-commerce. Major trends in the forecast period include the growing complexity of manufacturing processes, technological advancements in robotics, advanced technological infrastructure, advancement of robotic arms in healthcare, and increasing technological integration.

The expansion of the e-commerce industry is expected to propel the growth of the robotic arm market going forward. The e-commerce industry refers to the buying and selling goods and services over the internet. It has transformed how businesses and consumers interact, offering convenience, accessibility, and a global reach. The growth of e-commerce is driven by the widespread use of smartphones, internet access, and a broad selection of online products. Robotic arms are crucial in optimizing supply chain and logistics operations within the e-commerce industry, enabling businesses to manage inventory more efficiently, reduce operational costs, and enhance overall productivity. For instance, in February 2024, according to the United States Census Bureau, a US-based government agency, in 2023, e-commerce sales were projected to reach $1,118.7 billion, marking a 7.6% (±1.2%) increase from 2022, while total retail sales saw a 2.1% (±0.4%) rise over the same period. In 2023, e-commerce sales constituted 15.4% of total sales, compared to 14.7% in 2022. Therefore, the expansion of the e-commerce industry is driving growth in the robotic arm market.

Get A Free Sample Of The Report (Includes Graphs And Tables): https://www.thebusinessresearchcompany.com/sample.aspx?id=17249&type=smp

The robotic arm market covered in this report is segmented –

1) By Type: Articulated, Cartesian, Selective Compliance Articulated Robot Arm (SCARA), Spherical Or Polar, Cylindrical, Other Types 2) By Payload Capacity: Less Than 500 Kilogram (KG), 500-3000 Kilogram (KG), 3001 Kilogram (KG) And Above 3) By Axis: 1-Axis, 2-Axis, 3-Axis, 4-Axis, 5-Axis, 6-Axis, 7-Axis 4) By Application: Materials Handling, Cutting And Processing, Soldering And Welding, Assembling And Disassembling, Other Applications 5) By End-User Industry: Automotive, Electrical And Electronics, Metals And Machinery, Plastics And Chemicals, Food And Beverages, Other End-User Industries

Major companies operating in the robotic arm market are focusing on developing innovative products such as collaborative robots (cobots) to gain a competitive advantage. Cobots are designed to work alongside human operators, enhancing productivity and efficiency in various industrial settings. For instance, in 2021, Universal Robots, a Denmark-based industrial automation company, launched the UR20 cobot, featuring a 20kg payload capacity and a reach of 1.75m. The UR20 boasts advanced safety features, including force-sensing technology and intuitive programming, making it suitable for various applications, from material handling to machine tending. The UR20 is designed to provide up to 30% more speed and torque, advanced motion control capabilities, and a first-class user experience. Its 20kg payload and 1.75m reach make it an ideal match for applications ranging from palletizing to part handling and assembly.

The robotic arm market report table of contents includes:

1. Executive Summary

2. Robotic Arm Market Characteristics

3. Robotic Arm Market Trends And Strategies

4. Robotic Arm Market - Macro Economic Scenario

5. Global Robotic Arm Market Size and Growth ..............

32. Global Robotic Arm Market Competitive Benchmarking

33. Global Robotic Arm Market Competitive Dashboard

34. Key Mergers And Acquisitions In The Robotic Arm Market

35. Robotic Arm Market Future Outlook and Potential Analysis

36. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market - Forecast(2024 - 2030)

AI in Cobots Market Overview

The global AI in cobots market in 2021 reached $118.2 million and is estimated to grow at a CAGR of 34.22% during the forecast period to reach $616.3 million by 2027. The entire robotics industry is witnessing the effects of Covid-19 pandemic, with strain felt on the supply chain restricting parts of imports and equipment exports in H1 2021 especially. The overall economic uncertainty also pushed majority of customers to defer purchases in order to conserve capital. Recent advancements in Machine Learning and human robot interaction have enabled collaborative robots to precisely execute tasks in dynamically changing workspaces, enabling operations and material handling to run more smoothly, efficiently and productively. AI is now intelligently powering cobots by leveraging billions of hours of iterative machine learned practices in manufacturing, production and engineering. Collaborative robots (cobots) represent a variant of industrial robots and is currently considered to be one of the fastest growing segments in industrial automation driven by improved technology such as virtual assistants, cloud computing, internet of things. A cobot is a type of robot that is designed to operate alongside humans in shared workspaces. These machines are easy to program and deploy, can increase productivity manifold, and offer high returns on investment.

Report Coverage

The report: “AI in Cobots Market – Forecast (2022-2027)”, by IndustryARC covers an in-depth analysis of the following segments of the AI in Cobots market

By Payload: Up to 5 Kg, 5 to 10 Kg, Above 10 Kg. By Application: Handling, Assembling/Disassembling, Welding and Soldering, Dispensing, Packaging and Others. By End User: Automotive, Electronics, Semiconductor, Plastics and Polymer, Food and Beverage, Healthcare, Metals and Machining and others. By Geography: North America (U.S, Canada, Mexico), South America (Brazil, Argentina and others), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC (China, Japan India, SK, Aus and Others), and RoW (Middle east and Africa).

Request Sample

Key Takeaways

Group PSA’s Sochaux plant in France has chosen Universal Robots UR10 for its "Plant of the Future" Project. Two UR10 cobots have been implemented at the Sochaux plant in screw driving applications on body-in-white assembly lines to increase performance and reduce production costs at the factory.

In 2019, Walmart has planned to invest $2.7 billion to add new robots totaling almost 4,000 robots in its stores and facilities in order to shift human workforce to customer service roles. The robots are majorly used for scanning, sorting goods from delivery trucks. This is set to create opportunities for AI in cobots in retail sector.

AI in Cobots Market Segment Analysis – By Application

Material Handling had a major share in the AI in Cobots Market with a value share of approximately 22.3% in 2021. Material handling is one of the major applications of industrial robots. Robots in material handling segment are used in applications such as movement of goods, protection, storage and control of products throughout manufacturing as well as warehousing of the products. Any industries that need to store, receive, dispatch or ship its products always entail industrial robot. Manufacturing and Warehouse operations involving handling of goods becomes complex when it takes place at a larger scale. This is made easy and efficient with the aid of industrial robots. Material handling robots are majorly used in warehousing applications as compared to its counterpart. Material handling applications that benefit from the incorporation of AI cobots encompass picking, packing, palletizing, sorting, and more. The wide-ranging use of these applications makes them a more site-specific solution for safety implementation. Operators and other workers are often moving or transporting other materials around the AI cobot, requiring additional planning to avoid hazardous contact. Safety-rated grippers are rare in the market at the present time. Currently, manufacturers typically use pneumatic grippers, which require safety considerations for impacts and the loss of power or suction. Uses of bar code, RFID, voice-activated receiving and packaging, pick-to-light technology, transportation management system is some of the drifts observed by material handling robots. Cycle counting, annual, physical and perpetual are few approaches of keeping a track of inventory.

Inquiry Before Buying

AI in Cobots Market Segment Analysis – By End User

Among industries, automotive held the largest share in 2021 at 23.2%. The industry development of AI cobots is ongoing in several different areas. Faster reaction time, more exact movement patterns, orientation capabilities, capabilities in imitating humans – all these aspects contribute to advancements in AI driven cobot development. In addition, brain-computer interfaces is an exciting area that has made significant progress recently. In recent developments in technologies such as linked data, parallel processing, edge computing and distributed artificial intelligence allow for efficient decision making by cobots, making execution robust and efficient. A challenge with the market deployment of AI cobots is that insufficient technology maturity hinders the market deployment of cobots. AI Cobot technology includes hardware design, sensors and actuators, efficient information processing, video processing, planning and multiple of fields from artificial intelligence landscapes, along with technologies that ensure safety, predictability and security of the solution. There is currently a need for high amount of signaling, bandwidth, low latency, and fast decision-making capabilities through efficient computing for AI driven cobots in safety-critical environments, wherein the facilities do not need human intervention. While the automation industry was affected during the pandemic, the longterm outlook for automation is positive, as end users evaluate their reliance on overseas supply chains and reevaluate their operations in a world where a pandemic can stop production cold. Automation is hence being looked upon as a valuable bulwark against the risks laid bare during the pandemic, and this can act as a strong growth driver for AI driven cobots and robots in industrial automation end user verticals.

AI in Cobots Market Segment Analysis – By Geography

Geographically, APAC held major share of 37% of AI in cobots market share in 2021, owing to high adoption of automation technologies in industrial and automotive warehouses and increasing investments and funding. North America is the next largest market with 33% revenue share in 2021. South America is witnessing the fastest growth rate with a CAGR of around 46.6% during the forecast period 2022 – 2027 owing to high investments and growing deployment of automation technology mainly in the countries such as Brazil, Argentina and Colombia. Portuguese company MOV.AI has announced in October, 2020 that it has raised $4m in funding. The company has designed its ROS for manufacturers of cobots, as well as academics and automation integrators. It also contributes to the ROS community. Some of the robots with AI enabled are YuMi from ABB, Franka Emika Panda, APAS from Bosch, Aura, Aubo, NEXTAGE and CORO etc.

Schedule a Call

AI in Cobots Market Drivers

Growing demand for automation and technological advancements set to drive the AI In Collaborative Robotics Market

There has been significant growth in AI driven collaborative robotics market owing to the increased demand for automation, high competition in the e-commerce industry, and the advancement in technologies such as Internet of Things (IoT) and Artificial Intelligence (AI). The use of robots reduces the risk of injury to workforce has also witnessed growth. Integration of robots with artificial intelligence (AI) and machine vision technology has been assisting companies in obstacle detection, navigation, movement of the goods. This has been attracting vendors in automating the warehouses and installing the robots in warehouse, thereby driving the collaborative robotics market. In 2019, Geek Plus Robotics, an intelligent logistics robot solution provider had launched the world’s first interweaving sorting robot, which could be an alternative to conveyor systems. Mobile Industrial Robots (MiR), a leading manufacturer of collaborative mobile robots launched a new warehouse robot to automate the transportation of pallets and heavy goods across warehouses. Development of new robots for various applications of warehouses set to boost the demand of collaborative robotics market.

Growth in E-Commerce Sector

E-Commerce industry is rising at global level of retail and logistics. As a result, growing number of e-commerce companies look forward to automate warehouses. Warehouse robots play a key role in e-commerce industry for various applications such as automated storage and retrieval, picking and placing, order fulfillment operations and many others. Adoption of warehouse cobots by e-commerce companies helps in reducing operational and logistical costs and save on delivery time. This has been increasing automation in warehouses in order to deliver goods to shoppers in faster and more efficient ways by increasing productivity of supply chain. In developed countries such as the U.S., and Canada, Grocery retailers are focusing on deploying robots that bring the shelf stacks to human workers, who pick out the right products and package them up to be sent out. These robots travel with high speed, faster than humans, thereby increasing efficiency of the work. In 2019, Amazon had introduced new warehouse cobots in several of its U.S. warehouses that scan and pack items to be sent to customers. It has started using robots in warehouses, which scans goods coming down a conveyor belt raising the scope of adoption. In 2020 Covariant.ai launched its AI robots and solutions through its warehouse bin-picking robots which is being used by companies such as Knapp, a warehouse logistics company and Obeta, a German electronics retailer. As per estimates, around 2,000 AI powered robots have been deployed across warehouses globally.

AI in Cobots Market Challenges

High Initial Investment

The initial cost of AI driven collaborative robots that are used in factories are high as the cost of automation is much higher in comparison with labor costs. This prevents most companies from completely automating their operations with robots. The average selling prices of cobots vary from $25,000 to $50,000 and does not include the installation costs. In addition to this, there is a training cost associated with the robots that further restricts the operators’ likeability for integrating robots into their operating lines. Slow deployment of collaborative robotic systems by smaller and medium enterprises hampers the robotics market. However, high labor costs are set to drive the collaborative robot market during forecast period.

Buy Now

AI in Cobots Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the AI in Cobots market. In 2021, the market of AI in Cobots market has been consolidated by the top players

Fanuc

Techman Robots

Rethink Robots

AUBA Robots

ABB

Kawasaki

KUKA

Yaskawa

Staubli

Universal Robots

Recent Developments

In May 2019, the government of Saudi Arabia announced an investment of $30 billion to upgrade warehousing facilities by adoption of the advanced autonomous robots in the newly built warehouses across Saudi Arabia, thereby contributing towards the growth of the cobots market during forecast period in this region.

In October 2019, the South Korean government announced an investment $150 million to develop the intelligent robots for various industrial application which includes warehousing and logistics, thereby enhancing the growth of the cobots market.

#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market size#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Industry#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market share#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems top 10 companies#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market Report#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Industry outlook

0 notes