#Spring return actuator

Explore tagged Tumblr posts

Text

Explore Tecnik Valves' R-Series rotary pneumatic actuators—ISO5211 compliant, compact, durable, and ideal for industrial valve automation.

#Rotary pneumatic actuator#Pneumatic valve actuator#Double acting actuator#Spring return actuator#ISO5211 actuator#Tecnik Valves India#Industrial valve automation#valves manufacturers in india#control valve manufacturers in india#globe control valve#valve positioner#pneumatic control valves

0 notes

Text

Restore

I come bearing a wonderful gift, written by my wonderful friend @red-sprite!

The morning was early, the sky was grey, and the store was closed. Samantha was waiting by her car for the owner of the electronics store to open the front door, but her watch told her it was currently half an hour past opening and there was no-one in sight yet.

Looking in through the window the place reminded her of an old bookstore. You know the kind, the ones that seem to open whenever the owner feels like it, completely covered from floor to ceiling in books you can barely read the cover of. Antiquarians. She could see the remnants of a shelving system buried under strata of components, stretching around the corner into the darkness beyond.

Still, it was her best bet to find what she needed.

Ten minutes later the door opened, she hadn’t seen the owner arrive. Fifteen minutes and some smalltalk interwoven with project descriptions, she was about to walk out with her purchase. And that’s when she saw something she never thought she would.

An original AnTech, buried under a pile of merchandise. Her dome was stained, her screen was completely scuffed up, and the faded post-it said ‘As-is. No returns’.

Five minutes later she was secure in Samantha’s car.

The rest of the day was a blur. She finished the project, got it tested, got it packaged and shipped out. When she clocked out she’d almost forgotten this morning’s surprise. But not enough to lack a spring in her step when she made it to her car.

There, in the passenger seat, sat her find. In the light of the parking garage she looked like she was about to come alive. Samantha’s shadow danced over her scuffed faceplate as she passed the car, her arms resting in her lap.

‘You need a name, don’t you,’ Samantha thought to herself. ‘Ann sounds nice.’

The drive home was short. The trip up the stairs was very very long. As it turns out, hauling an immobile full-sized humanoid robot up three flights of stairs was a lot of work. She set Ann gently down in her comfy chair and went to work clearing her workbench. Projects half in-progress were bagged up, labelled and put away, tools were cleared, and finally she had enough space.

One last time she lifted Ann up, from her chair, to lay her as gently as she could on the workbench. Under the harsh fluorescent light it was finally visible just in what sort of condition she was. Samantha went over her section by section, noting all the outward damage. Scuffed faceplate, she knew that one. Seized motor on her left elbow, to be expected. Dent in the abdominal covering, possible impact, have to check the underlying actuators. Scuffs on legs, rattling in left ankle joint. Also very very dusty.

Knocking off the initial dust was the easy part. Finding the proprietary bits for her screwdrivers was slightly harder, but thankfully she had an extensive collection. The first thing she took off was the face plate. Four screws held it in place, now neatly extracted and marked where they go. The plate came off, connected only by a short ribbon cable. It took her a moment to find a good angle to disconnect it, but after that she was able to place the assembly to the side. Under the faceplate there was the sensor suite; cameras, both visible light and IR, depth-sensors, audio receptors tucked into the sides of the cavity, and at the bottom, the release for the chest covering.

Samantha pulled it gently, hoping that it wasn’t seized up. When she heard the click, she breathed a sigh of relief and held it in almost as quickly. She’d finally get a view of how Ann looked inside. Would all the components be present, would there be any damage, had she been scavenged for parts? It was all a big uncertainty, but there was only one way to find out.

She extracted her hand, and moved it over under Ann’s arms. Then she pulled.

The cavity opened before her, slowly bathed in the fluorescent light as deft hands maneuvered the cover away from its mounting points. There, inside, she saw a plethora of parts. All the ones she knew were supposed to be there were accounted for, and a few ones she didn’t expect caught her eye.

Breathe out.

Ann was complete, everything else was a matter of restoring. She could do this.

She lifted the cover the rest of the way off, and flipped it around. The dent was superficial, and it didn’t look like the force impacted beyond the insulation. She put the cover to the side.

Figuring out the order of cleaning was, on the one hand, a daunting process. On the other, cable layout dictated order nine out of ten times. Samantha had only worked on less sophisticated models in the past, but the principles were exactly the same. The power and data cables ran all over Ann’s chassis like a spider’s web. But like a spider, Samantha could read them. She knew them by sight, by location, by feeling. One by one they came undone until they revealed the city that lay underneath.

Heat exchangers rose like buildings on a city of green, highways of copper connected everything to everything else, crowded out by vast daughterboards rising perpendicular to the cavity.

Samantha set to work, disconnecting each component, slowly and lovingly taking Ann to pieces. Heat sink, to the side. Fans, to the side. Boards, to the side. Not all of them were standard, and Samantha could only guess to the function of some of them. Clearly Ann had not been a standard model.

She took a spray and diligently brushed each connector until it shone like it was fresh from the factory. Every single speck of dust removed, every pin straightened, every single capacitor checked.

She extracted the battery pack. Light, for what it was, but still one of the heavier components. Also probably completely dead.

Samantha lifted it out of the chassis, onto the small part of her workbench that was still free, and pulled out her tester to confirm. It wouldn’t even show a reading. She grabbed a piece of paper and wrote down the part number. With any luck it’d be a standard type, and the extent of the anti-tampering would be the screws.

Half an hour of searching later, she found the battery was an available size and could be ordered without problem. Express shipping was worth it.

She turned her attention back to Ann.

The battery could be replaced last. It was not interfering with any of the other components. The working memory modules slid in easy save for the final lock. Those always took more pressure than she liked to put onto delicate components. It left a mark on her hand.

The permanent storage was next. A big heavy box screwed into place on shock mounts to prevent the fragile internals from suffering damage when the frame moved about.

The daughterboards, slotted into the exact slots they came out of – she checked. Thrice. Screwed into place on their retaining brackets.

The fans, cleaned and lubricated, reinstalled on the processors.

And finally, the web of cables. Data cables, power cables, crossed all along the cavity to reach from everywhere to everywhere. Each of them seated with care.

She brought her power supply over to the workbench and dialed it in exactly to the battery specifications. One clip to the positive, one clip to the negative. Tomorrow would be a big day.

*

AnTech-G-25036 woke up. It was midnight on January 1st 1970. She couldn’t see for the blinding light. She couldn’t move. She couldn’t feel her face, or her arms, or her legs. She tried to move. Nothing happened. There was something on her chest. Her chest was open. She tried to think back, there were no memories before now. She tried to–

“Shh, it’s okay. You’re going to be okay. I’ve got you.”

The voice was soft, soothing. Her ears were working. She stopped trying.

Tapping noises came from somewhere. They felt distant and close at the same time.

“There, will you try again?” Three taps sounded.

AnTech-G-25036 woke up. Her last memories were decades ago. There had been a battery failure. She had fallen down. Then there was nothing. Nothing for a long time until she woke up in the blinding light.

“Can you speak?”

She didn’t know. Could she? There were many things that she could before that she couldn’t now. Like move her arms. She tried.

“I… think so?”

There was a high-pitched sound that was hard to parse. Then more sounds, and finally more speech.

“I’m so sorry. Here.”

The light faded, and she felt her head be turned. A face came in view, her emotional recognition processes supplied [happy], [excited], [holding back]. Something supplied [pretty].

“Hi, my name is Samantha. You were damaged, and I’m restoring you.”

New contact registered: Samantha

Current list of contacts: Samantha

Time since factory reset: 30 years

Time since product end of life: 32 years

Accessing AnTech servers for revised EOL date: [server not found]

“Why?”

“Because a lot of love went into making you, and I don’t believe you deserve to be tossed aside.”

There was a process inside her that wasn’t standard from the factory. It was supplying data that she didn’t understand and reaching conclusions that she didn’t know what to do with.

“What should I do?”

User input overrode most any other process. Listening to Samantha would help.

“I will work on your hardware. Will you run AnDiagTxt for me and write the result to your secondary output?”

She did as she was told, running the program that could tell a technician every status of every component of every part of her. Something supplied [intimate] and [vulnerable].

She let the program run, aware of its process, and how it was probing every part of her. She could feel it try to reach her legs, which weren’t there. Tried to reach her arms, which weren’t there. Tried to reach her face, which wasn’t there. It found her voice, it found her camera. It found her processors and fans. It found cables. So many cables attached from her, diagnostic ports, secondary output, keyboard, there was… the correct voltage from her battery, but no battery in the housing. More cables, snaking out like an umbilical cord tethering her to the workbench.

She saw Samantha turn her face from the camera and towards something out of view. As the program ran, her eyes were focused on it. When it finished, her emotional recognition processes supplied [satisfied] [happy].

Samantha turned back towards the camera, and she could feel a hand on her shoulder.

“Don’t worry. We’ll get you back up and running in no time.”

No time turned out to be an overstatement on the speed, but the progress was consistent. The first thing she hooked back up was the actuator for the camera. AnTech-G-25036 could look around now and take in more of the workspace. There was a chair that housed several components, including two AnTech arms and two AnTech legs. There was a fluorescent light fixture directly overhead. If she turned the camera away, she would not be blinded. She could not move her head. Samantha said that happened later in the process.

“Do you have a name?”

The question surprised her. Names were for people, not for AnTech products.

“I am AnTech-G-25036”

She turned her camera towards Samantha. Her emotional recognition processes supplied [concentrated] and [comfortable].

Samantha had an arm on her lap. There was a spraycan on the desk, and a screwdriver in her hand. She was manipulating the elbow joint. Every cycle, it moved more until with a final [click] it completed its full range of motion. Samantha manually took it through its motions twice before inverting it to inspect the contacts.

“That is what AnTech called you. What would you like to be called?”

She didn’t know. She didn’t remember having wants before. She could feel her fans speed up as her processors tried to construct metrics by which to tackle this problem. Her processors stayed cool. The fans felt smooth in their housing.

She could ask Samantha. User input can often break process deadlocks.

“What do you think I should be called, Samantha?”

The processes slowed down and then stopped. The fans were quiet. AnTech-G-25036 was focused solely on input processing.

“I’ve been calling you Ann. Is that a name you’d like?”

She did not remember liking things before. She did not remember being allowed to like things before. How would she know what to like, how would she know the correct things to like?

Something supplied [yes].

The fans slowed down.

“Yes.”

Samantha finished with the contacts and walked up to the workbench.

“Ann it is then, pleasure to meet you Ann!”

Emotional recognition: [smile] [happy] [satisfied]

Something: [warm] [safe] [self]

Samantha stood by the workbench, Ann’s arm in her hands. “May I attach this component, Ann?”

It was not something she’d ever heard before. It wasn’t a user command, it wasn’t a query, it wasn’t a request for action.

Whatever it was, the answer was clear as day. “Yes.”

She took the detached arm in one hand and clicked it into place. It felt… smooth. It felt cool and clean and better than it had in a long time.

Ann moved her arm. Her secondary display lit up with all the new data being sent and received. Her Something lit up with somethings.

The next stretch of time really did feel like no time at all to Ann. So many new sensations to process from within and from without.

“May I?”

“You may.”

Her other arm felt as smooth as the first, able to move with a grace she had forgotten she could have.

“May I?”

“You may.”

Her legs, stable and strong. Moving with strength and finesse not seen since she was new, and even then.

“May I?”

“You may.”

Her torso cover clicked into place, dent completely removed by Samantha’s hand.

Her camera was focused on the technician now, holding the last piece of herself. A coarse white paste coated her faceplate and Samantha was rubbing a cloth over it. Every pass made it look more scratched and opaque until the final one, where it emerged spotless, restored to the mirror sheen she could barely remember it being.

She handed it to Ann, who took it wordlessly. With mechanical precision and effortless finesse, she connected it. Finally sliding the last centimeters home until a ‘click’ was the only sound audible in the workspace. Her fans were silent and smooth as the screen behind her face came to life for the first time in decades. The image on it mirrored the camera’s, an expression of care, of trust, of something.

Ann reached out with her hand, smooth and controlled, to touch Samantha’s cheek.

“May I?”

“Please.”

She leaned forward until her camera was as close as it could be to her technician’s face without touching.

And then moved the final distance.

34 notes

·

View notes

Text

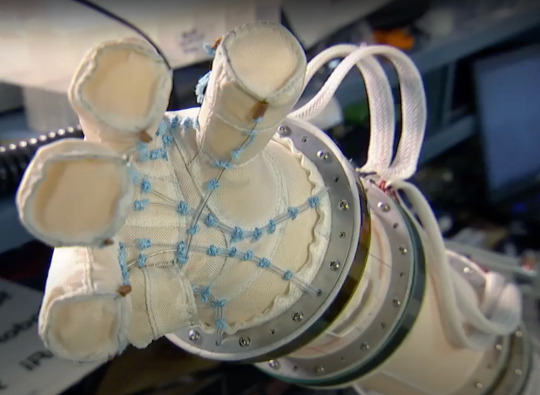

AIRhand Inflatable Hand and Arm (2011) by Annan Mozeika and team, iRobot, Bedford, MA. This soft robotic hand and arm is based on a spacesuit design. The anthropomorphic hand is a two layered inflatable structure, with an outer nylon fabric glove containing an inflatable inner liner. Once the interior liner is inflated with air, the fingers and wrist are actuated by wire tendons, with the inflated finger acting as a return spring. Inflatable robots are cheap to build and, like this robot, can be assembled on a sewing machine.

92 notes

·

View notes

Text

Here's my completed V2 archimedes pulley system finally done! It is 16:1 downgearing and this pairs with my 2.77:1 downgearing on the turn in place pulley on the motor for a total of 44:1 downgearing. It is fully rigged then from motor to finger and ready to go into testing soon. I just need to do a couple reinforcements here and there on some stuff but overall we are more or less ready to move onto setting up the return springs that my last post mentioned. So that is next. Then electronics to actuate it and test it finally! Exciting times! Also, I have come to the realization that these straight spring wires may be perfect for forming the exoskeleton mesh shapes that create the framework scaffolding over which the artificial silicone skin will overlay. The fact it has memory and wants to return to its prior shape after impacts is perfect for this application. I'd be simply forming a grid in the shape of the muscles over the bones using this stuff and then onto this grid I would overlay the silicone skin suit. The grid can be configured to even move under the skin, emulating muscle contractions to simulate real muscles moving under the skin in terms of its appearance during movement. I was originally leaning toward zip ties to make this part or nylon 3d printer filament but this spring wire may be even better due to being strong, resistive to breaking even more durability wise, holding its shape perhaps a bit better, etc. The other options I mentioned aren't bad but I just think I might like working with spring wire a bit more intuitively. We'll see.

9 notes

·

View notes

Note

It's mostly carapace, fortunately- Once the shell comes off getting her out of the actuators and underlay beneath is relatively simple, if a little bit technical. With everything discarded to the side in some variety of pile, Natsuki is left in a thin, sweat-drenched tank top and form-fitting spandex.

Though, to try and say that it'd be anything remotely resembling a pleasant sight would be beyond merely delusion- Streaking far into mockery if it was done. The Pink Goblin a bone-thin, trembling, grey-skinned wreck of a human being ravaged by toxins, clear to see to both of them that she's suffering severe overdose.

“Shit. Wool, medicine cabinet, nasal spray, narcan, go”

Night nodded, springing over her couch and rushing into the bathroom. He rummaged around for a minute before returning with the spray

“Perfect. Go find my AED, it’s in the bathroom as well. Pinky, can you hear me? I need you to breathe as deep as you can when I spray this in your nose, alright?”

She held eye contact, her sapphire eyes staring directly into Natsuki’s pink eyes

“Blink once for yes, two for no.”

3 notes

·

View notes

Text

🔘 Schneider ZB4BD5 Selector Switch Actuator – Built for Precision & Durability! 🔘

Elevate your industrial control panels with the ZB4BD5 from Schneider Electric's Harmony XB4 series. Designed for the toughest environments, this 3-position selector switch actuator with spring return to center ensures reliable operation every time.

✅ Key Specifications:

22mm mounting diameter

3-position spring return to center (45° rotation)

Chromium-plated metal bezel for high durability

IP66, IP67, IP69, IP69K protection ratings

IK06 impact resistance (1 Joule)

Wide operating temperature: -40°C to +70°C

1 million mechanical cycles lifespan

UL, CSA, CE certified & RoHS compliant

✨ Why Choose ZB4BD5?

Superior protection against dust, water & high-pressure washdowns

Robust metal construction for heavy-duty industrial use

Ergonomic design for easy and safe operation

Green Premium Eco-Label for environmental responsibility

🛠 Ideal Applications:

Perfect for industrial automation, control stations, factory machinery, and harsh environment operations.

🌍 Available at Xon Electronics for USA, India, Australia, Europe & worldwide.

👉 Upgrade your control panels with trusted Schneider quality!

Buy Now: https://www.xonelec.com/mpn/schneider/zb4bd5

Learn Now: https://www.xonelec.com/blog/acps-rb-amphenol-phone-connector-1-4-mono-plug

#XonElectronics #SchneiderElectric #ZB4BD5 #SelectorSwitch #IndustrialAutomation #ControlSolutions #HarmonyXB4 #IndustrialComponents

0 notes

Text

Advanced Design Techniques to Enhance Mechanical Lifespan of Metal Push Button Switches

Introduction

In industrial and commercial applications, metal push button switches are widely valued for their robust appearance and high reliability. Among various performance metrics, mechanical lifespan is one of the core indicators, particularly in applications that require frequent operation. This article delves into how different mechanical structures—spring plates, levers, and bimetallic strips—affect the lifespan of metal push button switches. It further explores how to achieve a service life of over 1 million presses through advanced structural design and material selection.

1. Evaluation of Structural Designs on Mechanical Lifespan

1.1 Spring Plate Structure

Spring plates are the most commonly used mechanisms in metal push button switches. The lifespan is primarily determined by the material fatigue resistance and structure optimization. High-performance stainless steel (such as SUS301 or SUS304) is often selected for its excellent elasticity and fatigue resistance.

Advantages: Simple structure, low cost, easy to mass produce.

Drawbacks: Susceptible to fatigue under high-frequency operation if not well-treated (e.g., insufficient heat treatment or residual stress relief).

1.2 Lever Mechanism

Lever mechanisms are typically used in high-end or precision devices. They use a pivot structure to transfer motion to the contacts.

Advantages: Effective at reducing operating force and distributing mechanical stress.

Drawbacks: Slightly more complex design and higher cost; requires precise alignment and tolerance control.

1.3 Bimetallic Strip Design

Though more common in thermal switches, bimetallic strips are sometimes used in specialized buttons to combine temperature sensing and switching functions.

Advantages: Thermal sensitivity and mechanical actuation combined.

Drawbacks: Not designed for high-frequency mechanical actuation; lower lifespan under repetitive mechanical cycling.

2. Design Strategies for >1 Million Cycle Lifespan

2.1 Optimized Contact Geometry

Contact area and shape should be designed to minimize contact bounce and arcing. Dome-shaped contacts, convex-convex designs, and double-contact structures can help distribute wear and reduce concentrated stress.

2.2 Reinforced Return Springs

To ensure consistent tactile response and recovery, high-end switches often use precision coil springs made from piano wire or phosphor bronze, with strict fatigue testing to ensure resilience over 1 million actuations.

2.3 Material Selection for High Wear Resistance

Moving components: Use wear-resistant alloys (e.g., stainless steel + PTFE coating) to reduce friction.

Housing and actuator cap: Use anodized aluminum or reinforced plastic to maintain structural integrity over repeated use.

2.4 Advanced Surface Treatments

Hardening treatment: Improve fatigue strength of spring plates and levers (e.g., shot peening, nitriding).

Contact plating: Use gold-plated or silver-nickel contacts to minimize wear and oxidation.

Example:

A switch used in an elevator panel was redesigned from a flat spring to a dome spring + reinforced coil spring structure, using SUS301 and Au-plated contacts. After modification, its mechanical lifespan increased from 500,000 to 2 million cycles under 2 Hz press frequency.

3. Testing and Validation

Mechanical cycle test: Performed at 2–5 Hz for at least 1 million cycles, monitoring contact bounce and force curve.

High-frequency fatigue testing: To simulate rapid-use scenarios such as gaming keyboards or vending machines.

Environmental simulation: Validate design under humidity, dust, temperature cycling, and vibration.

Conclusion

To improve the mechanical lifespan of metal push button switches, manufacturers must consider structure, material, and surface treatment holistically. With optimized design and rigorous testing, it's entirely feasible to achieve a lifespan beyond 1 million actuations, making the switches more reliable and competitive for high-demand applications.

en.dghongju.com

0 notes

Text

Hopping gives this tiny robot a leg up

New Post has been published on https://sunalei.org/news/hopping-gives-this-tiny-robot-a-leg-up/

Hopping gives this tiny robot a leg up

Insect-scale robots can squeeze into places their larger counterparts can’t, like deep into a collapsed building to search for survivors after an earthquake.

However, as they move through the rubble, tiny crawling robots might encounter tall obstacles they can’t climb over or slanted surfaces they will slide down. While aerial robots could avoid these hazards, the amount of energy required for flight would severely limit how far the robot can travel into the wreckage before it needs to return to base and recharge.

To get the best of both locomotion methods, MIT researchers developed a hopping robot that can leap over tall obstacles and jump across slanted or uneven surfaces, while using far less energy than an aerial robot.

The hopping robot, which is smaller than a human thumb and weighs less than a paperclip, has a springy leg that propels it off the ground, and four flapping-wing modules that give it lift and control its orientation.

Play video

The robot can jump about 20 centimeters into the air, or four times its height, at a lateral speed of about 30 centimeters per second, and has no trouble hopping across ice, wet surfaces, and uneven soil, or even onto a hovering drone. All the while, the hopping robot consumes about 60 percent less energy than its flying cousin.

Due to its light weight and durability, and the energy efficiency of the hopping process, the robot could carry about 10 times more payload than a similar-sized aerial robot, opening the door to many new applications.

“Being able to put batteries, circuits, and sensors on board has become much more feasible with a hopping robot than a flying one. Our hope is that one day this robot could go out of the lab and be useful in real-world scenarios,” says Yi-Hsuan (Nemo) Hsiao, an MIT graduate student and co-lead author of a paper on the hopping robot.

Hsiao is joined on the paper by co-lead authors Songnan Bai, a research assistant professor at The University of Hong Kong; and Zhongtao Guan, an incoming MIT graduate student who completed this work as a visiting undergraduate; as well as Suhan Kim and Zhijian Ren of MIT; and senior authors Pakpong Chirarattananon, an associate professor of the City University of Hong Kong; and Kevin Chen, an associate professor in the MIT Department of Electrical Engineering and Computer Science and head of the Soft and Micro Robotics Laboratory within the Research Laboratory of Electronics. The research appears today in Science Advances.

Maximizing efficiency

Jumping is common among insects, from fleas that leap onto new hosts to grasshoppers that bound around a meadow. While jumping is less common among insect-scale robots, which usually fly or crawl, hopping affords many advantages for energy efficiency.

When a robot hops, it transforms potential energy, which comes from its height off the ground, into kinetic energy as it falls. This kinetic energy transforms back to potential energy when it hits the ground, then back to kinetic as it rises, and so on.

To maximize efficiency of this process, the MIT robot is fitted with an elastic leg made from a compression spring, which is akin to the spring on a click-top pen. This spring converts the robot’s downward velocity to upward velocity when it strikes the ground.

“If you have an ideal spring, your robot can just hop along without losing any energy. But since our spring is not quite ideal, we use the flapping modules to compensate for the small amount of energy it loses when it makes contact with the ground,” Hsiao explains.

As the robot bounces back up into the air, the flapping wings provide lift, while ensuring the robot remains upright and has the correct orientation for its next jump. Its four flapping-wing mechanisms are powered by soft actuators, or artificial muscles, that are durable enough to endure repeated impacts with the ground without being damaged.

“We have been using the same robot for this entire series of experiments, and we never needed to stop and fix it,” Hsiao adds.

Key to the robot’s performance is a fast control mechanism that determines how the robot should be oriented for its next jump. Sensing is performed using an external motion-tracking system, and an observer algorithm computes the necessary control information using sensor measurements.

As the robot hops, it follows a ballistic trajectory, arcing through the air. At the peak of that trajectory, it estimates its landing position. Then, based on its target landing point, the controller calculates the desired takeoff velocity for the next jump. While airborne, the robot flaps its wings to adjust its orientation so it strikes the ground with the correct angle and axis to move in the proper direction and at the right speed.

Durability and flexibility

The researchers put the hopping robot, and its control mechanism, to the test on a variety of surfaces, including grass, ice, wet glass, and uneven soil — it successfully traversed all surfaces. The robot could even hop on a surface that was dynamically tilting.

“The robot doesn’t really care about the angle of the surface it is landing on. As long as it doesn’t slip when it strikes the ground, it will be fine,” Hsiao says.

Since the controller can handle multiple terrains, the robot can easily transition from one surface to another without missing a beat.

For instance, hopping across grass requires more thrust than hopping across glass, since blades of grass cause a damping effect that reduces its jump height. The controller can pump more energy to the robot’s wings during its aerial phase to compensate.

Due to its small size and light weight, the robot has an even smaller moment of inertia, which makes it more agile than a larger robot and better able to withstand collisions.

The researchers showcased its agility by demonstrating acrobatic flips. The featherweight robot could also hop onto an airborne drone without damaging either device, which could be useful in collaborative tasks.

In addition, while the team demonstrated a hopping robot that carried twice its weight, the maximum payload may be much higher. Adding more weight doesn’t hurt the robot’s efficiency. Rather, the efficiency of the spring is the most significant factor that limits how much the robot can carry.

Moving forward, the researchers plan to leverage its ability to carry heavy loads by installing batteries, sensors, and other circuits onto the robot, in the hopes of enabling it to hop autonomously outside the lab.

“Multimodal robots (those combining multiple movement strategies) are generally challenging and particularly impressive at such a tiny scale. The versatility of this tiny multimodal robot — flipping, jumping on rough or moving terrain, and even another robot — makes it even more impressive,” says Justin Yim, assistant professor at the University of Illinois at Urbana-Champagne, who was not involved with this work. “Continuous hopping shown in this research enables agile and efficient locomotion in environments with many large obstacles.”

This research is funded, in part, by the U.S. National Science Foundation and the MIT MISTI program. Chirarattananon was supported by the Research Grants Council of the Hong Kong Special Administrative Region of China. Hsiao is supported by a MathWorks Fellowship, and Kim is supported by a Zakhartchenko Fellowship.

0 notes

Text

دمپر دود: نقش، عملکرد و اهمیت در ایمنی ساختمانها

در محیطهای ساختمانی و صنعتی، کنترل دود و جریان هوا یکی از مهمترین جنبههای ایمنی و تهویه محسوب میشود. دمپر دود (Smoke Damper) یکی از تجهیزات اساسی در سیستمهای تهویه مطبوع (HVAC) و ایمنی در برابر آتش است که برای کنترل و محدود کردن انتشار دود در هنگام آتشسوزی طراحی شده است. این تجهیز با عملکرد خودکار یا دستی، مسیرهای هوایی را در کانالهای تهویه، دیوارها و سقفهای کاذب مسدود کرده و از انتشار دود و گازهای سمی در ساختمان جلوگیری میکند.

در این مقاله، به بررسی تعریف، عملکرد، انواع، استاندارد��ا، روشهای نصب، کاربردها و مزایای دمپر دود پرداخته خواهد شد تا نقش حیاتی آن در ایمنی ساختمانها و بهبود سیستمهای تهویه مشخص شود.

۱. دمپر دود چیست؟

دمپر دود یک تجهیز مکانیکی یا الکترونیکی است که در سیستمهای تهویه و مسیرهای جریان هوا به کار میرود تا در مواقع اضطراری، جریان دود را کنترل کرده و از گسترش آن به سایر بخشهای ساختمان جلوگیری کند. این دمپرها معمولاً در سیستمهای ایمنی آتشنشانی و کنترل فشار هوا برای حفاظت از جان انسانها و کاهش آسیبهای ناشی از دود و حرارت استفاده میشوند.

۲. عملکرد دمپر دود

عملکرد دمپر دود بر اساس یک مکانیزم فعالسازی خودکار یا دستی است. این تجهیز معمولاً با یک حسگر دما یا دود کار میکند که در صورت بروز آتشسوزی، فعال شده و مسیر جریان هوا را مسدود میکند. برخی از مهمترین اجزای این سیستم عبارتاند از:

۲.۱. اجزای اصلی دمپر دود

تیغهها (Blades): صفحات متحرکی که مسیر عبور هوا و دود را باز یا بسته میکنند.

محرک (Actuator): مکانیزمی که باعث باز یا بسته شدن تیغهها میشود.

حسگر دود (Smoke Detector): برای تشخیص دود و ارسال سیگنال به دمپر.

حسگر حرارت (Thermal Sensor): برای تشخیص دمای بالا و فعالسازی دمپر.

فنرهای برگشت (Spring Return Mechanism): که در صورت قطع برق، دمپر را به حالت بسته بازمیگرداند.

۳. انواع دمپر دود

دمپرهای دود در انواع مختلفی طراحی و تولید میشوند که هر یک بسته به نوع ساختمان و نیاز ایمنی، کارایی خاص خود را دارند.

۳.۱. دمپر دود خودکار (Automatic Smoke Damper)

این دمپرها از طریق حسگرهای دود یا حرارت فعال شده و بهصورت خودکار مسیر جریان هوا را مسدود میکنند. این نوع دمپر معمولاً در مسیرهای هوای اضطراری و سیستمهای تهویه نصب میشود.

۳.۲. دمپر دود مکانیکی (Mechanical Smoke Damper)

این مدل از طریق یک مکانیسم مکانیکی و فنرهای قفلشونده عمل میکند. در صورت افزایش دما، تیغههای دمپر بسته شده و مانع عبور دود میشوند.

۳.۳. دمپر دود الکترونیکی (Electrically Operated Smoke Damper)

این نوع دمپر با استفاده از موتورهای الکتریکی کنترل میشود و قابلیت اتصال به سیستمهای هشدار آتشسوزی و سیستمهای هوشمند ساختمان را دارد.

۳.۴. دمپر ترکیبی دود و حریق (Smoke and Fire Damper)

این دمپرها هم در برابر آتش و هم در برابر دود مقاوم بوده و معمولاً در سیستمهای ایمنی پیشرفته مورد استفاده قرار میگیرند.

۴. استانداردهای مرتبط با دمپر دود

دمپرهای دود باید مطابق با استانداردهای ایمنی طراحی و تولید شوند تا در مواقع اضطراری عملکرد قابلاطمینانی داشته باشند. برخی از استانداردهای مهم در این زمینه عبارتاند از:

استاندارد NFPA 92: استاندارد بینالمللی برای سیستمهای کنترل دود.

استاندارد UL 555S: استاندارد تست و تأیید عملکرد دمپرهای دود.

استاندارد EN 1366-2: استاندارد اروپایی برای مقاومت در برابر دود و حرارت.

استاندارد ISO 10294: تست و بررسی عملکرد دمپرهای دود.

این استانداردها تضمین میکنند که دمپرها در شرایط بحرانی عملکرد مناسبی دارند و در برابر دماهای بالا و فشارهای ناشی از دود مقاوم هستند.

۵. روشهای نصب و نگهداری دمپر دود

۵.۱. روشهای نصب دمپر دود

نصب صحیح دمپر دود از اهمیت ��الایی برخوردار است و باید توسط متخصصان و بر اساس نقشههای مهندسی انجام شود. برخی از نکات مهم در نصب عبارتاند از:

قرارگیری در مسیرهای اصلی جریان هوا: دمپرهای دود باید در کانالهای اصلی تهویه نصب شوند.

اتصال به سیستم اعلام حریق: دمپرها باید به سنسورهای هشدار دود متصل شوند تا در صورت آتشسوزی فعال شوند.

نصب درون دیوارهای مقاوم در برابر آتش: برای جلوگیری از انتشار دود به دیگر بخشهای ساختمان.

۵.۲. روشهای نگهداری دمپر دود

برای حفظ عملکرد بهینه دمپر دود، بررسی و نگهداری دورهای آن ضروری است:

بازرسی ماهانه و سالانه: برای اطمینان از عملکرد صحیح تیغهها و مکانیزمهای فعالسازی.

تمیزکاری مسیرهای تهویه: جلوگیری از تجمع گرد و غبار که میتواند عملکرد دمپر را مختل کند.

تست سیستم الکترونیکی: بررسی سیمکشی و اتصالات برقی برای اطمینان از کارکرد صحیح.

۶. کاربردهای دمپر دود

دمپرهای دود در ساختمانها و صنایع مختلفی کاربرد دارند:

۶.۱. در ساختمانهای مسکونی و تجاری

کنترل انتشار دود در هنگام آتشسوزی

افزایش ایمنی ساکنان

کاهش خسارتهای مالی ناشی از آتشسوزی

۶.۲. در بیمارستانها و مراکز درمانی

جلوگیری از انتقال دود به بخشهای حساس مانند اتاقهای عمل و بخشهای بستری

حفظ کیفیت هوا برای بیماران و کارکنان

۶.۳. در مراکز صنعتی و کارخانهها

کاهش خطرات ناشی از گازهای سمی و دود در محیطهای صنعتی

حفاظت از تجهیزات حساس و مواد قابل اشتعال

۶.۴. در تونلها و پارکینگهای عمومی

هدایت دود به مسیرهای خروجی برای جلوگیری از خفگی

کاهش خطرات ناشی از گازهای آلاینده خودروها

۷. مزایای استفاده از دمپر دود

دمپرهای دود با کنترل هوشمند جریان دود و گازهای خطرناک، نقش مهمی در کاهش آسیبهای ناشی از آتشسوزی دارند. برخی از مهمترین مزایای آنها عبارتاند از:

افزایش ایمنی جانی: جلوگیری از خفگی ناشی از دود برای ساکنان ساختمان.

کاهش خسارتهای مالی: جلوگیری از انتشار دود و آتش به سایر بخشهای ساختمان.

افزایش کارایی سیستمهای تهویه: کنترل جریان هوا و جلوگیری از فشارهای ناخواسته در سیستم تهویه.

امکان کنترل از راه دور: در مدلهای پیشرفته امکان کنترل از طریق سیستمهای هوشمند وجود دارد.

نتیجهگیری

دمپر دود یکی از تجهیزات مهم در سیستمهای ایمنی و تهویه مطبوع است که با جلوگیری از انتشار دود و حرارت، نقش مهمی در حفظ جان افراد و کاهش خسارات ناشی از آتشسوزی دارد. انتخاب نوع مناسب دمپر، نصب صحیح و نگهداری منظم آن، میتواند تأثیر بسزایی در افزایش ایمنی ساختمانها داشته باشد. با پیشرفت فناوری، نسل جدیدی از دمپرهای هوشمند با قابلیتهای الکترونیکی و اتصال به سیستمهای خودکار هشداردهنده طراحی شدهاند که سطح ایمنی را بیش از پیش افزایش میدهند.

0 notes

Text

Pilot Operated & Wafer Type NRV Valves – Udhhyog

💧 Industrial Flow Control with Pilot Operated and Wafer Type NRV Valves – Powered by Udhhyog

In the world of industrial piping and fluid systems, the demand for reliable, efficient, and compact valve solutions continues to rise. Whether it’s for controlling flow direction, managing pressure, or preventing backflow, non return valves (NRVs) are essential. Among these, two of the most in-demand designs are the pilot operated non return valve and the wafer type NRV valve.

At Udhhyog, we specialize in delivering advanced flow control solutions to industries across India. With a strong presence in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and other key industrial states, our goal is to provide high-performance valves backed by engineering excellence and customer support.

In this article, we’ll explore both the pilot operated non return valve and the wafer type NRV valve, understand their working principles, advantages, applications, and how Udhhyog delivers the best in class products across sectors.

🔍 What is a Non Return Valve (NRV)?

A non return valve, also known as a check valve, allows fluid to flow in only one direction. Its primary role is to prevent reverse flow, which could otherwise damage pumps, contaminate clean lines, or disrupt system operation.

Unlike gate or globe valves, NRVs are automatic. They require no manual actuation or power supply, making them ideal for energy-efficient flow control.

🧠 Understanding the Pilot Operated Non Return Valve

The pilot operated non return valve is a smart evolution in NRV technology. Unlike conventional NRVs that depend purely on flow pressure to open or close, this type of valve includes a pilot mechanism—a control device that senses upstream or downstream conditions to trigger the valve operation.

✅ Key Features of Pilot Operated NRVs:

Precise Control: Opens only when system conditions meet specific pressure criteria.

No Slamming: Prevents sudden shut-off, reducing water hammer and shock.

Failsafe Mechanism: Designed to lock or unlock under set pilot pressures.

Remote Actuation: Some models allow manual or pneumatic overrides.

🔧 Applications:

High-pressure pumping stations

Water distribution networks

Oil and gas flow lines

Fire suppression systems

Marine and offshore platforms

These valves are especially valuable where flow reversal could damage critical equipment, or where automated safety control is required.

🧩 Wafer Type NRV Valve – Compact, Reliable, and Efficient

The wafer type NRV valve is one of the most space-efficient non return valves. It is designed to be sandwiched between two flanges in a piping system.

Instead of using a large body and bonnet like conventional valves, wafer NRVs consist of a flat disc or dual plates that open and close based on flow pressure.

✅ Benefits of Wafer Type NRV Valves:

Space Saving: Ideal for compact setups or where installation space is limited.

Lightweight Design: Reduces pipeline load and shipping cost.

Quick Installation: No need for special fittings—fits between existing flanges.

Low Pressure Drop: Disc design allows smooth, streamlined flow.

🔧 Typical Use Cases:

HVAC systems

Chemical dosing lines

Irrigation and agriculture

Cooling towers

Food and pharma processing units

At Udhhyog, our wafer type NRV valves are available in cast iron, stainless steel, bronze, and PTFE-lined variants to suit a wide range of fluids.

⚙️ Comparing Pilot Operated vs Wafer Type NRVs

FeaturePilot Operated NRVWafer Type NRVOperationControlled via pilot pressureAutomatic, spring/disk operatedInstallation SpaceRequires more spaceCompact and flange-mountedResponse TimeSlower but preciseFast closureApplicationsHigh-pressure, critical systemsStandard fluid flow systemsCostHigher due to control systemAffordable and widely used

🏭 Why Industries Prefer Udhhyog Valves

At Udhhyog, we are dedicated to delivering premium valve solutions to industries across India. Here’s why we’re the preferred partner for NRV systems:

✅ Wide Product Range:

Swing NRV

Lift NRV

Pilot operated non return valve

Wafer type NRV valve

Dual plate check valves

Foot valves and strainers

✅ Material Options:

Cast Iron (CI)

Ductile Iron (DI)

Carbon Steel (WCB)

Stainless Steel (SS 304, SS 316)

Bronze and Gunmetal

✅ Regional Expertise:

We are trusted suppliers in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and NCR regions—ensuring rapid dispatch and strong service support.

✅ Services Offered:

Bulk order support

OEM manufacturing

Technical consultation

On-site valve sizing and selection

Credit facility for loyal buyers

Explore our complete catalog: 👉 https://udhhyog.com/valves

🧰 Installation Tips for Long Valve Life

Whether you’re using a wafer type NRV valve or a pilot operated valve, correct installation is key to performance and safety.

Always verify the flow direction arrow during installation.

Use correct gaskets and flange standards.

Make sure the pipeline is free from debris before installation.

Do not overtighten bolts—use torque values recommended by the manufacturer.

For pilot operated valves, test the pilot control line for leaks or blockages.

At Udhhyog, we offer free technical support to clients for pre-installation and commissioning.

🌍 Where Are These Valves Used?

Here’s where our NRV valves deliver unmatched performance:

🚰 Water treatment plants

🏭 Chemical & petrochemical industries

🚢 Marine systems and shipyards

🛢️ Refineries and oil storage terminals

🧪 Pharma and clean water systems

🌾 Agricultural irrigation networks

🔥 Fire hydrant and suppression systems

Wherever there is flow, there is the need to control and protect—and that’s where Udhhyog comes in.

💡 How to Select the Right NRV Valve?

Choosing between pilot operated non return valve and wafer type NRV valve depends on:

✔ System pressure and flow conditions

✔ Space constraints

✔ Fluid type (corrosive, clean, viscous)

✔ Requirement of automation or pilot control

✔ Budget and maintenance access

Our engineering team at Udhhyog helps clients identify the best fit by analyzing data sheets, pressure ratings, and real-time flow demands.

📦 Udhhyog Valve Solutions – Fast, Reliable, Affordable

From custom valve sourcing to bulk supply for EPC projects, we are equipped to support industrial demands at scale.

🔹 Available Sizes: 15mm to 600mm 🔹 Pressure Classes: PN10, PN16, PN25, ANSI 150# 🔹 Certifications: ISI, ISO, IBR-compliant products 🔹 MOQ: As per customer need 🔹 Delivery Time: 2–5 working days (based on location)

🔚 Conclusion

If you're setting up a critical pumping system or optimizing a process line, the pilot operated non return valve offers unmatched control and protection. On the other hand, the wafer type NRV valve gives you compact, cost-effective backflow prevention.

At Udhhyog, we bring you both—crafted to perfection, tested for performance, and delivered with service you can trust.

📞 Get in touch today to order, get specifications, or schedule a consultation. Let’s power your industrial pipelines with the best in flow control engineering.

#PilotOperatedNRV#WaferTypeNRVValve#NonReturnValve#CheckValvesIndia#FlowControlValves#UdhhyogValves#DelhiValveSupplier#IndustrialValvesIndia#BackflowPrevention#EngineeringSolutions

0 notes

Text

Pilot Operated & Wafer Type NRV Valves – Udhhyog

💧 Industrial Flow Control with Pilot Operated and Wafer Type NRV Valves – Powered by Udhhyog

In the world of industrial piping and fluid systems, the demand for reliable, efficient, and compact valve solutions continues to rise. Whether it’s for controlling flow direction, managing pressure, or preventing backflow, non return valves (NRVs) are essential. Among these, two of the most in-demand designs are the pilot operated non return valve and the wafer type NRV valve.

At Udhhyog, we specialize in delivering advanced flow control solutions to industries across India. With a strong presence in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and other key industrial states, our goal is to provide high-performance valves backed by engineering excellence and customer support.

In this article, we’ll explore both the pilot operated non return valve and the wafer type NRV valve, understand their working principles, advantages, applications, and how Udhhyog delivers the best in class products across sectors.

🔍 What is a Non Return Valve (NRV)?

A non return valve, also known as a check valve, allows fluid to flow in only one direction. Its primary role is to prevent reverse flow, which could otherwise damage pumps, contaminate clean lines, or disrupt system operation.

Unlike gate or globe valves, NRVs are automatic. They require no manual actuation or power supply, making them ideal for energy-efficient flow control.

🧠 Understanding the Pilot Operated Non Return Valve

The pilot operated non return valve is a smart evolution in NRV technology. Unlike conventional NRVs that depend purely on flow pressure to open or close, this type of valve includes a pilot mechanism—a control device that senses upstream or downstream conditions to trigger the valve operation.

✅ Key Features of Pilot Operated NRVs:

Precise Control: Opens only when system conditions meet specific pressure criteria.

No Slamming: Prevents sudden shut-off, reducing water hammer and shock.

Failsafe Mechanism: Designed to lock or unlock under set pilot pressures.

Remote Actuation: Some models allow manual or pneumatic overrides.

🔧 Applications:

High-pressure pumping stations

Water distribution networks

Oil and gas flow lines

Fire suppression systems

Marine and offshore platforms

These valves are especially valuable where flow reversal could damage critical equipment, or where automated safety control is required.

🧩 Wafer Type NRV Valve – Compact, Reliable, and Efficient

The wafer type NRV valve is one of the most space-efficient non return valves. It is designed to be sandwiched between two flanges in a piping system.

Instead of using a large body and bonnet like conventional valves, wafer NRVs consist of a flat disc or dual plates that open and close based on flow pressure.

✅ Benefits of Wafer Type NRV Valves:

Space Saving: Ideal for compact setups or where installation space is limited.

Lightweight Design: Reduces pipeline load and shipping cost.

Quick Installation: No need for special fittings—fits between existing flanges.

Low Pressure Drop: Disc design allows smooth, streamlined flow.

🔧 Typical Use Cases:

HVAC systems

Chemical dosing lines

Irrigation and agriculture

Cooling towers

Food and pharma processing units

At Udhhyog, our wafer type NRV valves are available in cast iron, stainless steel, bronze, and PTFE-lined variants to suit a wide range of fluids.

⚙️ Comparing Pilot Operated vs Wafer Type NRVs

FeaturePilot Operated NRVWafer Type NRVOperationControlled via pilot pressureAutomatic, spring/disk operatedInstallation SpaceRequires more spaceCompact and flange-mountedResponse TimeSlower but preciseFast closureApplicationsHigh-pressure, critical systemsStandard fluid flow systemsCostHigher due to control systemAffordable and widely used

🏭 Why Industries Prefer Udhhyog Valves

At Udhhyog, we are dedicated to delivering premium valve solutions to industries across India. Here’s why we’re the preferred partner for NRV systems:

✅ Wide Product Range:

Swing NRV

Lift NRV

Pilot operated non return valve

Wafer type NRV valve

Dual plate check valves

Foot valves and strainers

✅ Material Options:

Cast Iron (CI)

Ductile Iron (DI)

Carbon Steel (WCB)

Stainless Steel (SS 304, SS 316)

Bronze and Gunmetal

✅ Regional Expertise:

We are trusted suppliers in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and NCR regions—ensuring rapid dispatch and strong service support.

✅ Services Offered:

Bulk order support

OEM manufacturing

Technical consultation

On-site valve sizing and selection

Credit facility for loyal buyers

Explore our complete catalog: 👉 https://udhhyog.com/valves

🧰 Installation Tips for Long Valve Life

Whether you’re using a wafer type NRV valve or a pilot operated valve, correct installation is key to performance and safety.

Always verify the flow direction arrow during installation.

Use correct gaskets and flange standards.

Make sure the pipeline is free from debris before installation.

Do not overtighten bolts—use torque values recommended by the manufacturer.

For pilot operated valves, test the pilot control line for leaks or blockages.

At Udhhyog, we offer free technical support to clients for pre-installation and commissioning.

🌍 Where Are These Valves Used?

Here’s where our NRV valves deliver unmatched performance:

🚰 Water treatment plants

🏭 Chemical & petrochemical industries

🚢 Marine systems and shipyards

🛢️ Refineries and oil storage terminals

🧪 Pharma and clean water systems

🌾 Agricultural irrigation networks

🔥 Fire hydrant and suppression systems

Wherever there is flow, there is the need to control and protect—and that’s where Udhhyog comes in.

💡 How to Select the Right NRV Valve?

Choosing between pilot operated non return valve and wafer type NRV valve depends on:

✔ System pressure and flow conditions

✔ Space constraints

✔ Fluid type (corrosive, clean, viscous)

✔ Requirement of automation or pilot control

✔ Budget and maintenance access

Our engineering team at Udhhyog helps clients identify the best fit by analyzing data sheets, pressure ratings, and real-time flow demands.

📦 Udhhyog Valve Solutions – Fast, Reliable, Affordable

From custom valve sourcing to bulk supply for EPC projects, we are equipped to support industrial demands at scale.

🔹 Available Sizes: 15mm to 600mm 🔹 Pressure Classes: PN10, PN16, PN25, ANSI 150# 🔹 Certifications: ISI, ISO, IBR-compliant products 🔹 MOQ: As per customer need 🔹 Delivery Time: 2–5 working days (based on location)

🔚 Conclusion

If you're setting up a critical pumping system or optimizing a process line, the pilot operated non return valve offers unmatched control and protection. On the other hand, the wafer type NRV valve gives you compact, cost-effective backflow prevention.

At Udhhyog, we bring you both—crafted to perfection, tested for performance, and delivered with service you can trust.

📞 Get in touch today to order, get specifications, or schedule a consultation. Let’s power your industrial pipelines with the best in flow control engineering.

#PilotOperatedNRV#WaferTypeNRVValve#NonReturnValve#CheckValvesIndia#FlowControlValves#UdhhyogValves#DelhiValveSupplier#IndustrialValvesIndia#BackflowPrevention#EngineeringSolutions

0 notes

Text

Pilot Operated & Wafer Type NRV Valves – Udhhyog

💧 Industrial Flow Control with Pilot Operated and Wafer Type NRV Valves – Powered by Udhhyog

In the world of industrial piping and fluid systems, the demand for reliable, efficient, and compact valve solutions continues to rise. Whether it’s for controlling flow direction, managing pressure, or preventing backflow, non return valves (NRVs) are essential. Among these, two of the most in-demand designs are the pilot operated non return valve and the wafer type NRV valve.

At Udhhyog, we specialize in delivering advanced flow control solutions to industries across India. With a strong presence in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and other key industrial states, our goal is to provide high-performance valves backed by engineering excellence and customer support.

In this article, we’ll explore both the pilot operated non return valve and the wafer type NRV valve, understand their working principles, advantages, applications, and how Udhhyog delivers the best in class products across sectors.

🔍 What is a Non Return Valve (NRV)?

A non return valve, also known as a check valve, allows fluid to flow in only one direction. Its primary role is to prevent reverse flow, which could otherwise damage pumps, contaminate clean lines, or disrupt system operation.

Unlike gate or globe valves, NRVs are automatic. They require no manual actuation or power supply, making them ideal for energy-efficient flow control.

🧠 Understanding the Pilot Operated Non Return Valve

The pilot operated non return valve is a smart evolution in NRV technology. Unlike conventional NRVs that depend purely on flow pressure to open or close, this type of valve includes a pilot mechanism—a control device that senses upstream or downstream conditions to trigger the valve operation.

✅ Key Features of Pilot Operated NRVs:

Precise Control: Opens only when system conditions meet specific pressure criteria.

No Slamming: Prevents sudden shut-off, reducing water hammer and shock.

Failsafe Mechanism: Designed to lock or unlock under set pilot pressures.

Remote Actuation: Some models allow manual or pneumatic overrides.

🔧 Applications:

High-pressure pumping stations

Water distribution networks

Oil and gas flow lines

Fire suppression systems

Marine and offshore platforms

These valves are especially valuable where flow reversal could damage critical equipment, or where automated safety control is required.

🧩 Wafer Type NRV Valve – Compact, Reliable, and Efficient

The wafer type NRV valve is one of the most space-efficient non return valves. It is designed to be sandwiched between two flanges in a piping system.

Instead of using a large body and bonnet like conventional valves, wafer NRVs consist of a flat disc or dual plates that open and close based on flow pressure.

✅ Benefits of Wafer Type NRV Valves:

Space Saving: Ideal for compact setups or where installation space is limited.

Lightweight Design: Reduces pipeline load and shipping cost.

Quick Installation: No need for special fittings—fits between existing flanges.

Low Pressure Drop: Disc design allows smooth, streamlined flow.

🔧 Typical Use Cases:

HVAC systems

Chemical dosing lines

Irrigation and agriculture

Cooling towers

Food and pharma processing units

At Udhhyog, our wafer type NRV valves are available in cast iron, stainless steel, bronze, and PTFE-lined variants to suit a wide range of fluids.

⚙️ Comparing Pilot Operated vs Wafer Type NRVs

FeaturePilot Operated NRVWafer Type NRVOperationControlled via pilot pressureAutomatic, spring/disk operatedInstallation SpaceRequires more spaceCompact and flange-mountedResponse TimeSlower but preciseFast closureApplicationsHigh-pressure, critical systemsStandard fluid flow systemsCostHigher due to control systemAffordable and widely used

🏭 Why Industries Prefer Udhhyog Valves

At Udhhyog, we are dedicated to delivering premium valve solutions to industries across India. Here’s why we’re the preferred partner for NRV systems:

✅ Wide Product Range:

Swing NRV

Lift NRV

Pilot operated non return valve

Wafer type NRV valve

Dual plate check valves

Foot valves and strainers

✅ Material Options:

Cast Iron (CI)

Ductile Iron (DI)

Carbon Steel (WCB)

Stainless Steel (SS 304, SS 316)

Bronze and Gunmetal

✅ Regional Expertise:

We are trusted suppliers in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and NCR regions—ensuring rapid dispatch and strong service support.

✅ Services Offered:

Bulk order support

OEM manufacturing

Technical consultation

On-site valve sizing and selection

Credit facility for loyal buyers

Explore our complete catalog: 👉 https://udhhyog.com/valves

🧰 Installation Tips for Long Valve Life

Whether you’re using a wafer type NRV valve or a pilot operated valve, correct installation is key to performance and safety.

Always verify the flow direction arrow during installation.

Use correct gaskets and flange standards.

Make sure the pipeline is free from debris before installation.

Do not overtighten bolts—use torque values recommended by the manufacturer.

For pilot operated valves, test the pilot control line for leaks or blockages.

At Udhhyog, we offer free technical support to clients for pre-installation and commissioning.

🌍 Where Are These Valves Used?

Here’s where our NRV valves deliver unmatched performance:

🚰 Water treatment plants

🏭 Chemical & petrochemical industries

🚢 Marine systems and shipyards

🛢️ Refineries and oil storage terminals

🧪 Pharma and clean water systems

🌾 Agricultural irrigation networks

🔥 Fire hydrant and suppression systems

Wherever there is flow, there is the need to control and protect—and that’s where Udhhyog comes in.

💡 How to Select the Right NRV Valve?

Choosing between pilot operated non return valve and wafer type NRV valve depends on:

✔ System pressure and flow conditions

✔ Space constraints

✔ Fluid type (corrosive, clean, viscous)

✔ Requirement of automation or pilot control

✔ Budget and maintenance access

Our engineering team at Udhhyog helps clients identify the best fit by analyzing data sheets, pressure ratings, and real-time flow demands.

📦 Udhhyog Valve Solutions – Fast, Reliable, Affordable

From custom valve sourcing to bulk supply for EPC projects, we are equipped to support industrial demands at scale.

🔹 Available Sizes: 15mm to 600mm 🔹 Pressure Classes: PN10, PN16, PN25, ANSI 150# 🔹 Certifications: ISI, ISO, IBR-compliant products 🔹 MOQ: As per customer need 🔹 Delivery Time: 2–5 working days (based on location)

🔚 Conclusion

If you're setting up a critical pumping system or optimizing a process line, the pilot operated non return valve offers unmatched control and protection. On the other hand, the wafer type NRV valve gives you compact, cost-effective backflow prevention.

At Udhhyog, we bring you both—crafted to perfection, tested for performance, and delivered with service you can trust.

📞 Get in touch today to order, get specifications, or schedule a consultation. Let’s power your industrial pipelines with the best in flow control engineering.

#PilotOperatedNRV#WaferTypeNRVValve#NonReturnValve#CheckValvesIndia#FlowControlValves#UdhhyogValves#DelhiValveSupplier#IndustrialValvesIndia#BackflowPrevention#EngineeringSolutions

0 notes

Text

Honeywell MN6105VAV Non-Spring Return Direct Coupled Actuator 24 VAC 44 psi | PartsHnC

Manufacturer Name: Honeywell Product Number: MN6105VAV OEM Part Number: MN6105VAV Product Description: Nsr Dca 24Vac Weight:1.12lbs/508.02g

The Honeywell MN6105VAV Nsr Dca 24Vac 44 is an essential component for HVAC systems, particularly variable air volume VAV systems. With a 24-volt alternating current Vac power source, this device operates as a Non-Spring Return NSR.

For an efficient and reliable HVAC system, the Honeywell Non-Spring Return Direct Coupled Actuator is a great choice for optimal system performance.

#MN6105VAV#Honeywell#Honeywellparts#PartsHnC#PartsHnCBuzz#HVACParts#FurnaceParts#AirConditionerParts

0 notes

Text

What is a Pneumatic Actuator: Optimized Guide for Industrial

What is a Pneumatic Actuator ? Optimized Guide for Industrial Use

A pneumatic actuator (also called a *pneumatic cylinder* or *air actuator*) is a critical device in industrial automation. It converts compressed air energy into mechanical motion to open, close, or adjust valves, enabling precise control of fluid flow in pipelines. Known for reliability, speed, and explosion-proof capabilities, pneumatic actuators are widely used in power plants, chemical processing, oil refineries, and more.

How Do Pneumatic Actuators Work

Pneumatic actuators rely on compressed air to drive pistons or diaphragms, generating linear or rotational motion. When air pressure increases, the force pushes a piston or diaphragm, creating movement that operates connected valves. This mechanism allows quick response times and high torque output, making them ideal for demanding industrial environments.

Types of Pneumatic Actuators

Pneumatic actuators are categorized by motion type, structure, and operation mode. Below are the key types, including spring return, double-acting, and Scotch Yoke pneumatic actuators:

1. By Motion Type

- Linear Actuators: Produce straight-line motion (e.g., push-pull rods for gate valves).

- Angular/Rotary Actuators: Generate rotational motion (e.g., quarter-turn ball or butterfly valves).

2. By Structural Design

- Diaphragm Actuators: Use air pressure to flex a diaphragm, ideal for low-force, high-precision tasks.

- Piston Actuators: Deliver high thrust for large valves or high-pressure systems.

- Rack-and-Pinion Actuators: Convert linear motion into rotation for precise valve control.

- Scotch Yoke Pneumatic Actuators: Utilize a sliding yoke mechanism for high torque in heavy-duty applications (e.g., large ball valves).

3. By Operation Mode

Spring Return Pneumatic Actuator (Single-Acting):

– Uses compressed air to move the piston while a spring provides automatic reset when air supply is cut.

– Two subtypes: *Normally Open* (closes with air, opens without) and *Normally Closed* (opens with air, closes without).

– Ideal for fail-safe applications requiring valve position recovery during power loss.

Double-Acting Pneumatic Actuator:

– Requires air supply to both piston sides for bidirectional movement.

– No spring mechanism; ideal for continuous operations needing frequent valve reversals.

– Offers higher force output compared to spring-return models.

Key Applications of Pneumatic Actuators

Pneumatic actuators excel in industries demanding safety, speed, and durability. Below are their primary use cases:

1. High-Thrust Requirements: Powering large valves in pipelines or pressure systems.

2. Hazardous Environments: Explosion-proof operation in oil refineries, chemical plants, or mining.

3. Rapid Valve Control: Quick-response systems for emergency shutdowns or flow adjustments.

4. Harsh Conditions: Reliable performance in extreme temperatures, humidity, or corrosive settings.

5. Automation Systems: Integration with PLCs for seamless process control.

6. Manual/Auto Switching: Built-in handwheel for manual override during system failures.

Why Choose Pneumatic Actuators

- Fast Response: Immediate reaction to control signals.

- High Reliability: Minimal maintenance with robust construction.

- Explosion Safety: No electrical sparks, suitable for flammable environments.

- Cost-Effective: Lower upfront and operational costs compared to hydraulic/electric alternatives.

Conclusion

Understanding what a pneumatic actuator is and selecting the right type—whether a spring return pneumatic actuator, double-acting actuator, or Scotch Yoke pneumatic actuator—ensures optimal performance in industrial systems. By matching the actuator’s design (linear, rotary, diaphragm, or piston) to your operational needs, you enhance efficiency, safety, and longevity in fluid control applications.

For industries prioritizing precision, durability, and safety, pneumatic actuators remain the go-to solution for valve automation.

0 notes

Text

Understanding Pneumatic Actuators: Working Principles, Types, And Key Components Explained

Pneumatic actuators are essential components in modern industrial automation and machinery. They convert compressed air energy into mechanical motion, enabling precise control of valves, grippers, and other mechanical systems. Widely used in manufacturing, robotics, and process industries, pneumatic actuators are valued for their reliability, simplicity, and cost-effectiveness. This article explores their working principles, common types, and key components.

1. Working Principles Of Pneumatic Actuators

Pneumatic actuators operate on the fundamental principle of pressure differential. When compressed air is introduced into the actuator, it creates a force that moves internal components, generating linear or rotary motion. Here’s a step-by-step breakdown:

Air Supply: Compressed air (typically 4–7 bar or 60–100 psi) is supplied from a pneumatic system or compressor.

Pressure Application: Air enters the actuator’s chamber, exerting pressure on a piston, diaphragm, or vane.

Motion Generation: The pressure differential across the piston/diaphragm creates linear or rotational movement.

Return Mechanism: In single-acting actuators, a spring returns the piston to its original position when air pressure is released. Double-acting actuators use compressed air to move in both directions.

Key advantages include rapid response times, high force-to-size ratios, and suitability for hazardous environments (no sparks or overheating).

2. Types Of Pneumatic Actuators

Pneumatic actuators are categorized based on their motion type and design:

A. Linear Actuators

Single-Acting: Compressed air moves the piston in one direction; a spring returns it. Ideal for simple on/off applications (e.g., clamping).

Double-Acting: Air pressure moves the piston in both directions, enabling precise bidirectional control. Common in industrial valves and automation.

B. Rotary Actuators

Rack-and-Pinion: A piston with a rack gear rotates a pinion gear, producing rotary motion. Used for quarter-turn valve control (e.g., ball valves).

Vane-Type: Compressed air pushes vanes in a circular chamber, generating torque. Suitable for continuous rotation applications.

Scotch Yoke: Converts linear piston motion into rotary motion via a slotted yoke mechanism. Offers high torque for heavy-duty valves.

C. Specialty Actuators

Diaphragm Actuators: Use a flexible diaphragm instead of a piston. Common in pressure control valves.

Rodless Actuators: Eliminate the piston rod, allowing for compact designs in confined spaces.

3. Key Components Of Pneumatic Actuators

Understanding the internal structure of pneumatic actuators is crucial for maintenance and selection:

Cylinder Body: Houses the piston and contains compressed air. Made of aluminum, stainless steel, or engineered plastics.

Piston: Converts air pressure into linear motion. Sealed with O-rings to prevent air leakage.

Piston Rod: Transmits motion to external mechanisms. Often chrome-plated for durability.

End Caps: Seal the cylinder and include ports for air inlet/outlet.

Seals and Gaskets: Ensure airtight operation. Common materials include nitrile rubber (NBR) or polytetrafluoroethylene (PTFE).

Spring (Single-Acting): Provides return force in single-acting designs.

Position Sensors (Optional): Detect piston position for feedback in automated systems.

4. Applications And Industry Use Cases

Pneumatic actuators are ubiquitous in industries requiring fast, reliable motion control:

Manufacturing: Operating conveyor belts, assembly line grippers.

Oil and Gas: Controlling pipeline valves in explosive environments.

Food and Beverage: Hygienic actuators for packaging and filling systems.

Automotive: Robotic welding and painting systems.

Conclusion

Pneumatic actuators remain a cornerstone of industrial automation due to their simplicity, safety, and adaptability. By leveraging compressed air, they provide efficient motion control for diverse applications. Engineers and technicians must consider factors like load requirements, operating environment, and cycle rates when selecting the right actuator type. As industries evolve, innovations in materials and smart pneumatics (e.g., IoT-enabled actuators) are enhancing their performance and integration with modern control systems.

This article provides a comprehensive overview of pneumatic actuators while maintaining readability for both technical and non-technical audiences.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com

0 notes

Text

🚨 Unlock Industrial Control with Schneider ZB4BA3 Push Button! 🚨

Looking for a rugged, reliable, and high-performance switch actuator for your industrial control systems? The ZB4BA3 Push Button Head from Schneider Electric is the perfect solution for modern automation and machinery needs. Available at Xon Electronics 🌍 | Shipping to USA 🇺🇸, India 🇮🇳, Australia 🇦🇺, Europe 🇪🇺 & Worldwide 🌐

🔘 Product: ZB4BA3 Push Button Actuator

🏭 Brand: Schneider Electric

📏 Size: 22mm diameter

💡 Type: Flush, Non-Illuminated Push Button Head

🎨 Color: Green (Unmarked)

🔁 Action: Momentary – Spring Return

🔩 Material: Metal Bezel (Chromium-plated)

✨ Key Features:

✅ IP66, IP67, IP69K Rated – Dust, water & high-pressure jet resistant

✅ Wide Temp Range: -40°C to +70°C 🌡️

✅ Durable & Vibration-Resistant

✅ Green Premium™ – Eco-Friendly ♻️

✅ Easy to install in control panels

⚙️ Applications:

🛠️ Factory Automation

🏭 Industrial Machinery & Control Panels

🍽️ Food & Beverage Plants (Hygienic & Washdown Safe)

🚆 Transport & Railway Control Stations

🚧 Safety and Emergency Stop Systems

📦 Get the ZB4BA3 now at Xon Electronics – your trusted global supplier of industrial components!

🔗 DM us or visit our website to place your order today!

Buy Now: https://www.xonelec.com/mpn/schneider/zb4ba3

Learn More: https://www.xonelec.com/blog/a758kk687m0gaae016-polymer-capacitor-by-kemet

#SchneiderElectric #ZB4BA3 #PushButton #IndustrialControl #XonElectronics #Automation #FactorySolutions #IndustrialSwitch #ControlPanel #USA #India #Australia #Europe #ElectronicsWorldwide

0 notes