#Stainless Steel 304 Seamless Pipes

Text

#STAINLESS STEEL 304 PIPES SUPPLIER#STAINLESS STEEL 1.4301 PIPE#STAINLESS STEEL 304 PIPE#STAINLESS STEEL 304 SEAMLESS PIPES#SS 304 PIPES#ASME SA312 STAINLESS STEEL TP304 PIPES SUPPLIER

0 notes

Text

Premium Stainless Steel 304 Seamless Pipe Manufacturer in India

One of the biggest Stainless Steel 304 Seamless Pipe Manufacturer in India is Shree Impex Alloys. We have been offering our clients a large assortment of 304 stainless steel seamless pipes. A range of standards, sizes, thicknesses, and custom lengths are available for SS 304 Seamless Pipes. We never cut corners when it comes to quality and provide premium SS 304 Seamless Pipes to customers worldwide as one of the top Stainless Steel 304 Seamless Pipe Suppliers in India.

As one of the leading ss 304 seamless pipe suppliers in Mumbai, Shree Impex Alloys has a sizable stock of these pipes in sizes that are common for the industry. Austenitic grades 304, 304L, 316, 316L, and 316L in diameters ranging from 6NB to 1200NB make up the majority of our stock.

Our exceptional quality stainless steel 304 seamless pipe has earned Shree Impex Alloys respect across the world as a Stainless Steel 304 Seamless Pipe Supplier in India. We are achieving new heights in the production of some of the best 304 stainless steel seamless pipe thanks to our internal capabilities.We provide stainless steel pipes in a variety of cities, including Stainless Steel Pipe Manufacturer in Kolkata, ss pipe supplier in pune and ss pipe suppliers in bangalore

#Stainless Steel 304 Seamless Pipe Manufacturer in India#Stainless Steel 304 Seamless Pipe Supplier in India#ss 304 seamless pipe suppliers in mumbai#ss pipe supplier in pune

0 notes

Text

The Versatile Marvels: Stainless Steel Tubing Coil and Stainless Steel Welded Pipe

Stainless steel, an exceptional material known for its strength, durability, and corrosion resistance, has found widespread use across various industries. Among its many applications, Stainless Steel Tubing Coil and stainless steel welded pipes stand out as true marvels. Let's explore these versatile components that have revolutionized the world of engineering and construction.

#Stainless Steel Tubing Coil#stainless steel welded pipe#schedule 10 stainless steel pipe#stainless steel pipe schedule 40#stainless steel pipe fittings#seamless stainless steel tubing#stainless steel pipe supplier#304 stainless steel tubing#stainless steel pipe#stainless steel tubing

1 note

·

View note

Link

Triple Nine Piping Solutions Inc. is one of the trusted market leaders in India. We have been engaged in manufacturing & exporting Buttweld fittings in a wide range of materials, grades, shapes, sizes & other specifications. Our buttweld fittings are manufactred in materials like stainless steel, duplex steel, super duplex steel, aluminium alloys and high nickel alloys. We have served our prestigious clients by giving them quality products, timely delivery on a regular basis at the most reasonable prices.

#Stainless Steel 304 Seamless Pipes Nickel 200 Welded Pipes Inocnel ERW Pipes Monel Buttweld fittings Hastelloy Flanges Incoloy Threaded forg#Buttweld fittings#Low price buttwedl fittings#Hihg quality buttweld fittings

0 notes

Photo

New Post has been published on https://www.vividracing.com/blog/top-8-best-mods-for-a-800-hp-c7-z06-corvette/

Top 8 Best Mods for a 800+ HP C7 Z06 Corvette

If you’re looking to take your Corvette’s power and presence to the next level, you’ve come to the right place. In this guide, we’ll explore the top 8 best mods that can transform your Z06 into an 800+ horsepower beast, unleashing its full potential on the track or the street.

From enhancing exhaust notes to optimizing engine performance and improving traction, each of these mods plays a crucial role in elevating your driving experience. Whether you’re a seasoned enthusiast or just diving into the world of automotive upgrades, these carefully selected parts and accessories are sure to make a significant impact on your Corvette’s performance and aesthetics.

So buckle up, rev your engines, and let’s dive into the details of the Kooks Headers, Kooks X-Pipe, Borla ATAK Axleback exhaust, Cordes Performance upgrades including the 2.30″ LT4 Upper Pulley Kit and Engine Bay Ice Tank, the Low Side Fuel System for optimal fuel delivery, the traction-boosting Mickey Thompson Et Street SS Tires, and the stylish yet functional Forgestar D5 Drag Wheels. Get ready to experience the thrill of pushing your C7 Z06 Corvette to new heights!

youtube

https://www.vividracing.com/blog/wp-content/uploads/img-c7z06_forgestard5_mickeythompsonetstreet-3-scaled.jpg

1.) Kooks 1-7/8″ x 2″ x 3″ Stainless Steel Headers Chevrolet Corvette C7 2014-2019

When it comes to elevating your Corvette’s performance, few names carry as much weight as Kooks Headers and Exhaust. With a legacy spanning over 50 years, Kooks has solidified its position as a leader in the High Performance Exhaust Industry since 1962. What sets Kooks apart is not just their reputation but their unwavering commitment to delivering top-notch headers and exhaust systems for street, race, and off-road applications.

The accolades speak for themselves – Kooks has secured hundreds of championships and set numerous records across renowned racing organizations like NHRA, IHRA, NMCA, NMRA, NASCAR, NASA, SCCA, and many others. This level of success is a testament to the quality and performance of Kooks products.

What makes Kooks truly special is their dedication to craftsmanship and American manufacturing. With three generations of family leadership at the helm, every Kooks product is handcrafted right here in the USA. This commitment to quality control and precision ensures that every header and exhaust system that bears the Kooks name meets the highest standards of excellence.

The Kooks Headers and Exhaust kit for the C7 Corvette includes a 1-7/8″ x 2″ x 3″ Stainless Steel Long Tube Header, Cometic Multi-Layer Gaskets, Stage 8 Header Bolts, O2 Extensions, and Torca Clamps. Crafted from premium 304 Stainless Steel, these components not only offer exceptional durability but also add a touch of aesthetic appeal with their stainless steel finish.

Fitment is seamless for various Corvette models, including the Chevrolet Corvette C7 LT1 6.2L (2014-2019), Chevrolet Corvette C7 Z06/Z07 LT4 6.2L (2015-2019), and Chevrolet Corvette C7 ZR1 LT5 6.2L (2019).

So, if you’re ready to “Get Kookin with KOOKS!” and experience a performance boost like never before, the Kooks Headers and Exhaust system is a must-have addition to your C7 Corvette.

2.) Kooks OEM X 3 X 2 3/4 (OEM) C7 X Pipe Chevrolet Corvette C7 6.2L -All models 2014-2019

Upgrade your Chevrolet Corvette C7’s exhaust system with the high-performance Kooks X-Pipe. Crafted from T-304 Aircraft Quality Steel, this 3″ x 3″ X-Pipe optimizes exhaust gas flow for maximum power and a thrilling exhaust note.

Features:

OEM x 3″ Front connections to factory catalytic converter

3″ x 3″ X-Pipe

3″ x 2 3/4″ Mid-Pipes. Connects to 2 3/4″ OEM Style Exhaust.

Benefits:

Enhanced engine efficiency with reduced back pressure

Dyno and race-tested for optimal performance

Direct fitment for Chevrolet Corvette C7 6.2L models 2014-2019

Limited lifetime warranty to the original purchaser

Note: Designed for off-road use only and not CARB compliant for California.

Experience over fifty years of exhaust system craftsmanship with the Kooks X-Pipe, delivering power and performance for your Corvette C7.

3.) Borla ATAK Axleback Exhaust System Chevrolet 6.2L V8

The Borla ATAK Axleback exhaust system is the ideal companion to your Kooks X-Pipe and Headers upgrade for the Chevrolet Corvette C7, offering a seamless integration that results in a host of performance benefits. Together, these high-performance exhaust components optimize exhaust flow, reduce back pressure, and improve engine efficiency, translating into a noticeable increase in horsepower and torque for exhilarating acceleration. What truly sets this combination apart is the distinctive Borla Sound of Power, delivering an aggressive yet refined exhaust note that not only enhances driving excitement but also sets your Corvette apart from the crowd. Crafted from polished T-304 stainless steel, the Borla exhaust system not only ensures premium quality and durability but also adds a touch of visual appeal to your Corvette’s rear end. With precision CNC manufacturing and Borla’s Million-Mile Warranty backing, you can trust that your exhaust system will fit perfectly and be covered for the long haul. Together, the Kooks X-Pipe and Headers with the Borla ATAK Axleback exhaust unleash the full potential of your Corvette C7, offering an unmatched driving experience that’s as thrilling as it is refined.

4.) Cordes Performance 2.30″ LT4 Upper Pulley Kit Chevrolet Corvette 2014-2021

Upgrade your Chevrolet Corvette’s performance with the Cordes Performance 2.30″ LT4 Upper Pulley Kit, designed specifically for models from 2014 to 2021. This kit offers a significant improvement by reducing the pulley size from the OEM 2.5 inches to a 2.3-inch diameter, resulting in a boost of 2-3 psi over stock levels. Included in the kit are essential components such as a press-on hub, 10 titanium torx bolts for secure installation, and the pulley itself featuring the newest griptec finish for enhanced traction and durability. Notably, the OEM belt can be reused if you have a stock-size lower, ensuring compatibility and ease of installation. This kit is compatible with all LT4 superchargers, making it a versatile and effective upgrade for unlocking additional power and performance from your Corvette’s engine. Experience improved boost levels and overall driving excitement with the Cordes Performance 2.30″ LT4 Upper Pulley Kit, tailored to elevate your Corvette’s performance to new heights.

5.) Cordes Performance Engine Bay Ice Tank Chevrolet Corvette 2014-2021

Elevate your Chevrolet Corvette’s cooling capabilities with the Cordes Performance Engine Bay Ice Tank designed for models from 2014 to 2021. Cordes Performance Racing, renowned as the premier GM LTX/LTX motorsports company in Arizona, brings a wealth of expertise and passion to every product they offer. As a family-run business deeply committed to performance excellence, Cordes Performance Racing not only focuses on building high-level performing vehicles but also prioritizes the overall presentation, ensuring that you’re proud to showcase your Corvette. The Engine Bay Ice Tank is no exception, crafted using the highest-quality components to deliver optimal cooling efficiency and performance reliability. By maintaining lower engine temperatures, especially during high-performance driving or track sessions, this ice tank ensures that your Corvette operates at the peak of its performance, providing consistent power delivery and reliability. Trust Cordes Performance Racing to go above and beyond in enhancing your Corvette’s cooling system, enabling you to push the limits with confidence and enjoy an exhilarating driving experience every time you hit the road or track.

6.) Cordes Performance Low Side Fuel System Chevrolet Corvette 2014-2021

(Image may differ from actual product)

Enhance the fuel delivery and performance of your Chevrolet Corvette from 2014 to 2021 with the Cordes Performance Low Side Fuel System. Cordes Performance Racing stands as the premier GM LTX/LTX motorsports company in Arizona, driven by a deep passion for excellence in automotive performance. As a family-run business, Cordes Performance Racing not only focuses on building high-level performing vehicles but also emphasizes an overall presentation that you’ll be proud to showcase. The Low Side Fuel System exemplifies this commitment, utilizing only the highest-quality components to ensure optimal fuel delivery and engine performance. Compatible with Chevrolet Corvette C7 models from 2014 to 2021, including the C7ZO6 and C7ZR1 variants, this fuel system upgrade is designed to keep your vehicle at the peak of its performance, providing consistent fuel delivery and power output. Trust Cordes Performance Racing to go the extra mile in upgrading your Corvette’s fuel system, delivering reliability and performance that you can count on for every drive.

7.) Forgestar D5 Drag Wheel

18×12 5×120.65 50mm Gloss Black w/ Machined Lip

The Forgestar D5 Drag Wheel in 18×12 size with a 5×120.65 bolt pattern and 50mm offset is a game-changer for high-performance builds like the 800hp C7 Z06 Corvette. Forgestar performance wheels are renowned for bridging the gap between forged and cast wheels, delivering exceptional strength and lightweight characteristics crucial for demanding applications. Using an innovative rotary formed production process, Forgestar creates a lightweight cast wheel with strength and impact values comparable to forged wheels, making them ideal for street, racing, and drag racing applications. The Drag Wheel variant is drag strip approved with SFI 15.1 and 15.2 ratings, ensuring top-notch safety and performance standards. The wheel features a rotary forged flow-formed barrel, monoblock construction, and a Gloss Black finish with a machined lip, combining aesthetics with functionality. Its lightweight design not only enhances acceleration and handling but also clears big brake kits for improved stopping power. The raised center cap adds axle clearance convenience, while bead knurling ensures secure tire fitment. With a load rating of 1600 lbs and meticulous attention to detail in construction, the Forgestar D5 Drag Wheel is a must-have for high-performance enthusiasts looking to maximize their C7 Z06 Corvette’s potential on the drag strip and beyond.

Mickey Thompson ET Street S/S Tire – P345/35R18

The Mickey Thompson ET Street S/S Tire in P345/35R18 size is a high-performance street-to-strip tire designed for enthusiasts seeking exceptional traction on both the street and the drag strip. Featuring radial construction and the renowned R2 compound, this tire delivers superior performance in 15- to 20-inch fitments. It is D.O.T. approved for street use, making it a versatile choice for daily driving and track days alike. The ET Street S/S tire boasts an equivalent tread void as the ET Street Radial II but with improved hydroplane resistance, ensuring excellent dry traction while maintaining safety in wet conditions. The proven R2 compound, also used in top “drag radials,” provides superior traction at the strip, often requiring minimal or no burnout for optimal performance. Tubeless construction adds convenience with a leak-free seal, eliminating the need for tubes. With specifications like a centerline tread depth of 6.0/32″, an inflated overall diameter of 27.8 inches, and a maximum rim width of 13.5 inches, this tire offers a perfect balance of performance and durability. Whether you’re hitting the drag strip or cruising the streets, the Mickey Thompson ET Street S/S Tire is the ideal choice for enthusiasts seeking exceptional traction and performance in a street-legal package.

By combining top-notch performance upgrades from industry leaders, the Chevrolet Corvette C7 Z06 transforms into an 800hp powerhouse ready to dominate the streets and the track. The Kooks Headers and Exhaust system, along with the Borla ATAK Axleback exhaust, not only optimize exhaust flow but also enhance the aggressive exhaust note, while the Cordes Performance 2.30″ LT4 Upper Pulley Kit and Engine Bay Ice Tank ensure optimal engine cooling and power delivery. The Cordes Performance Low Side Fuel System keeps fuel delivery consistent, while the Forgestar D5 Drag Wheels and Mickey Thompson ET Street S/S Tires provide traction and stability necessary for harnessing the massive power output. Together, these meticulously selected upgrades create a harmonious synergy, elevating the Corvette C7 Z06 to 800hp and delivering an exhilarating driving experience that’s as thrilling as it is refined.

As always, if you need any assistance with selecting the right parts for your car, feel free to shoot us an email at [email protected] or give us a call at (480) 966-3040. Whether it’s helping you pick the best parts, or being a shoulder to cry on, we’ll be here!

#800hp C7 Z06 Corvette#Borla ATAK#c7 z06#Chevrolet#Cordes Performance#Corvette#Engine Bay Ice Tank#exhaust#Forgestar Drag Wheels#Headers#kooks#Low Side Fuel System#Mickey Thompson

2 notes

·

View notes

Text

Stainless steel 304L seamless tubes are a staple in various industries due to their outstanding properties and versatile applications. Kamal Piping, a leading supplier in the field, provides high-quality 304L seamless tubes that meet the rigorous demands of modern engineering and industrial processes. In this blog, we delve into what makes stainless steel 304L seamless tubes exceptional and explore their numerous benefits and applications.

What is Stainless Steel 304L?

Stainless steel 304L is a low-carbon version of the 304 alloy, one of the most widely used stainless steel types. The "L" in 304L stands for "low carbon," which means it has a maximum carbon content of 0.03%. This lower carbon content significantly reduces the risk of carbide precipitation during welding, making it an excellent choice for applications that require welding and higher corrosion resistance.

Key Properties of Stainless Steel 304L

Corrosion Resistance: Stainless steel 304L offers excellent resistance to a wide range of atmospheric environments and many corrosive media. This makes it ideal for use in environments where exposure to corrosive elements is a concern.

2. Strength and Durability: Despite its low carbon content, 304L maintains high strength and durability, making it suitable for a variety of structural applications.

3. Formability and Weldability: The alloy's composition allows it to be easily formed and welded without the risk of sensitization, which can lead to intergranular corrosion.

4. Temperature Resistance: 304L stainless steel can withstand temperatures up to 870°C (1600°F) without significant scaling or loss of strength, making it suitable for high-temperature applications.

5. Hygienic Properties: Its non-reactive surface and ease of cleaning make it a preferred material in the food and beverage, pharmaceutical, and healthcare industries.

Advantages of Seamless Tubes

Seamless tubes are produced through a process that does not involve welding, resulting in a product with no seams or joints. This manufacturing method offers several advantages:

Higher Pressure Tolerance: Seamless tubes can withstand higher pressures due to their uniform structure and absence of welded seams.

Improved Strength: The seamless construction ensures greater tensile strength and durability.

Reduced Risk of Leaks: With no welded joints, the potential for leaks is significantly minimized, making seamless tubes ideal for critical applications.

Smoother Surface Finish: Seamless tubes generally have a smoother internal and external surface finish, which is crucial for applications requiring precise fluid flow and cleanliness. Applications of Stainless Steel 304L Seamless Tubes

Thanks to their exceptional properties, stainless steel 304L seamless tubes are used in a wide range of applications across various industries:

1.Oil and Gas Industry: Used in pipelines, heat exchangers, and refinery equipment due to their corrosion resistance and high-pressure tolerance.

2.Chemical Processing: Ideal for handling corrosive chemicals and high-temperature processes.

3.Food and Beverage: Utilized in dairy, brewing, and food processing equipment where hygiene and corrosion resistance are paramount.

4.Pharmaceuticals: Employed in the production of equipment and piping systems that require strict sanitary conditions.

5.Automotive and Aerospace: Used in exhaust systems, fuel lines, and hydraulic systems where durability and performance are essential.

6.Construction: Applied in structural components that require a combination of strength and aesthetic appeal.

Why Choose Kamal Piping for 304L Seamless Tubes?

Kamal Piping is a trusted name in the stainless steel industry, known for its commitment to quality and customer satisfaction. Here’s why you should consider Kamal Piping for your 304L seamless tube needs:

Quality Assurance: Each tube undergoes rigorous testing to ensure it meets the highest standards of quality and performance.

Wide Range of Sizes: Kamal Piping offers an extensive selection of tube sizes and specifications to meet diverse application requirements.

Expertise: With years of experience, the company provides expert guidance and support to help customers select the right products for their needs.

Competitive Pricing: Despite offering premium products, Kamal Piping ensures competitive pricing, making it an excellent choice for cost-effective solutions. Conclusion

Stainless steel 304L seamless tubes are an integral component in many industrial and commercial applications, offering unmatched corrosion resistance, strength, and versatility. Kamal Piping stands out as a reliable supplier of these high-quality tubes, providing products that meet the stringent demands of various industries. Whether you’re in the oil and gas sector, food and beverage industry, or any other field requiring robust and durable tubing solutions, stainless steel 304L seamless tubes from Kamal Piping are an excellent choice.

0 notes

Text

Stainless Steel 304 Pipes, SS 304 Tubes Supplier, Exporter - Shree Viratra Enterprises

Stainless Steel 304 Pipes & Tubes is a metallic pipe constructed of austenitic stainless steel that contains 18% chromium and 8% nickel. Shree Viratra Enterprises is a major supplier and manufacturer of all types and sizes of Stainless Steel 304 Pipes and tubes. In the ASTM requirements, the pipe specifications range from A312 to A358. The dimensions vary in accordance with ASTM, ASME, and API requirements. Welded and SS 304 pipes, as well as electric fusion welded pipes, are available.

Top supplier of SS 304 Welded Pipe, Stainless Steel 304 Square Pipe, 304 Stainless Steel Pipe, SS 304 Pipe Price, SS 304 Pipe, 304 Stainless Steel Tube, 304 Stainless Pipe, Stainless Steel 304 Seamless Pipe, SS 304 Square Tube, ASTM A213 Tp304 Seamless Pipe,stainless steel 304 pipes, ss 304 pipes, 304 SS Pipe

The 304 austenitic stainless steel alloy is used to make pipes and tubing. This alloy offers exceptional strength, endurance, and resistance to corrosion because it contains minor amounts of carbon, manganese, and silicon, along with chromium and nickel. Shree Viratra Enterprises manufactures, produces, and exports superior raw material-made stainless steel 304 pipes and tubes. It is necessary to cold-work stainless steel to boost its tensile strength. Type 304 is much less intense than type 302 because of its lower carbon concentration.

Stainless steel 304 pipes and tubes are available in the following dimensions, grades, and specifications. This alloy’s pipes and tubes are utilised in various industries, such as petrochemicals, food processing, construction, and pharmaceuticals. They are renowned for their adaptability, resilience to high temperatures, and toughness in adverse environments — 304 stainless steel. To satisfy the needs of many applications, pipes and tubes come in various diameters, forms, and thicknesses. Usually, two primary methods are employed in their manufacturing: seamless and welded. While welded pipes and tubes are created by joining two pieces of the alloy, seamless pipes and tubes are formed by extruding a solid billet.

What are some frequently asked questions about SS 304 seamless pipes and welded pipes?

What is a 304 stainless steel pipe and used for?

SS 304 Seamless Pipes – Pipe Fittings is a corrosion-resistant, versatile material primarily composed of chromium and nickel. It offers excellent resistance to corrosion, oxidation, and high temperatures, making it ideal for a wide range of applications. Commonly used in industries such as food processing, pharmaceuticals, chemical processing, and construction, it’s favored for its durability and sanitation properties. Its non-reactive nature also makes it suitable for transporting various fluids and gases. Whether in structural frameworks, piping systems, or architectural designs, 304 stainless steel pipes are valued for their strength, longevity, and resistance to both internal and external environmental factors.

What is the difference between TP304 and 304 stainless steel?

The terms TP304 and 304 stainless steel represent identical materials but find application in distinct contexts. “TP304” serves as a specialized designation within the domain of piping and tubing, specifically denoting a stainless steel variant suitable for the fabrication of seamless pipes and tubes. Conversely, “304 stainless steel” assumes a broader usage across diverse industries, acting as a descriptor for a particular grade of stainless steel alloy encompassing various manifestations such as sheets, bars, and pipes, irrespective of whether they are seamless or welded. Fundamentally, while TP304 and 304 stainless steel denote the same alloy, their utility and reference contexts diverge accordingly.

0 notes

Text

Stainless Steel 304 Pipe

Top 12 stainless steel 304 pipe supplier in India. Buy ex-stock of SS 304 seamless and welded tube in custom sizes at affordable price in Mumbai. Check weight and schedule chart.

Stainless Steel 304 Pipe

0 notes

Text

Supplier of SS Pipes and Fittings in Chhattisgarh

Company Overview:

Rahul Steel India is an approved Manufacturer and Supplier of SS Pipes and Fittings in Chhattisgarh, India.

We specialize in manufacturing, supplying, and exporting a wide range of stainless steel (SS) pipes and fittings.

Our products are crafted from high-quality stainless steel, ensuring durability, reliability, and compliance with international standards.

SS Pipes:

Types: Seamless and welded.

Grades: Available in various grades to meet different industrial requirements.

Sizes: Wide range of sizes from small to large diameters.

Lengths: Single random, double random, and custom cut lengths.

SS Fittings:

Types: Elbows, tees, reducers, caps, stub ends, and more.

Standards: Comply with ASTM, ASME, and other relevant international standards.

Sizes: Available in multiple sizes to fit various piping needs.

Shapes: Offered in different shapes to suit specific application requirements.

Material and Specifications:

Material Grades: Includes 304, 304L, 316, 316L, and other grades of stainless steel.

Dimensions: Standard dimensions or customized as per client specifications.

Wall Thickness: Range from Schedule 5S to Schedule XXS (heavier on request).

End Types: Plain end, beveled end, threaded, etc.

Features and Benefits:

Corrosion Resistance: Excellent resistance to corrosion, making them suitable for harsh environments.

High Strength: Superior mechanical properties providing high strength and durability.

Versatility: Suitable for a wide range of applications in different industries.

Ease of Fabrication: Can be easily fabricated to fit specific needs.

Applications:

Industrial Piping

Construction

Food and Beverage

Pharmaceutical

Water Treatment

Rahul Steel India is Supplier of SS Pipes and Fittings in Chhattisgarh Including Raipur, Bilaspur, Kanker, Raigarh, Rajnandgaon, Bemetara, Baikunthpur, Ambikapur, Jagdalpur, Chirimiri, Kondagaon, Manendragarh, Bhatapara, Baloda Bazar, Sakti, Takhatpur, Ambagarh Chowki, Sarangarh, Khairagarh, Dharamjaigarh, Bilha, Arang, Simga, Katghora, Saraipali, Bijapur, Kharsia, Pandariya, Pithora, Kurud, Pathalgaon, Akaltara, Ramanujganj, Bagbahara, Gharghoda, Jashpur Nagar, Bishrampur, Mahasamund, Mungeli, Korba, Dhamtari.

For further inquiries or to discuss customization options, please feel free to contact us.

Read the full article

#Akaltara#AmbagarhChowki#Ambikapur#Arang#Bagbahara#Baikunthpur#BalodaBazar#Bemetara#Bhatapara#Bijapur#Bilaspur#Bilha#Bishrampur#Chhattisgarh#Chirimiri#Dhamtari#Dharamjaigarh#Exporter#Gharghoda#India#Jagdalpur#JashpurNagar#Kanker#Katghora#Khairagarh#Kharsia#Kondagaon#Korba#Kurud#Mahasamund

0 notes

Text

Supplier of Stainless Steel Pipes and Tubes in Tamil Nadu

Meghmani Metal Industries is a Manufacturer and Supplier of Stainless Steel Pipes and Tubes in Tamil Nadu, India.

Established in 2011, Meghmani Metal Industries is dedicated to providing exceptional products to the metal industry.

We offer a wide array of stainless steel products, including plates, coils, bars, pipes, tubes, flanges, valves, fittings, fasteners, channels, and flats, meticulously catering to various industrial requirements.

Stainless Steel Pipes and Tubes refer to stainless steel pipes and tubes. Stainless steel is a type of steel alloy containing chromium, which provides excellent resistance to corrosion and oxidation, making it ideal for various industries.

Stainless steel pipes and tubes come in grades like 304 for general use, 316 for marine environments, and 321 for high temperatures.

Stainless steel pipes and tubes facilitate the seamless transfer of materials, enabling efficient production across diverse industries. Their smooth surfaces and uniform dimensions ensure minimal friction and consistent flow, optimizing productivity and reducing downtime.

Their sleek and modern appearance adds a touch of sophistication to architectural designs, interior decor, and industrial machinery, enhancing the visual appeal of any environment.

Stainless steel pipes and tubes find applications in construction, oil and gas, chemical, food and beverage, automotive, medical, water treatment, aerospace, heat exchangers, renewable energy, marine, pharmaceutical, and power industries.

Meghmani Metal Industries is a Manufacturer and Supplier of Stainless Steel Pipes and Tubes in Tamil Nadu and locations like Arcot, Chengalpattu, Chennai, Chidambaram, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kanchipuram, Kanniyakumari, Kodaikanal, Kumbakonam, Madurai, Mamallapuram, Nagappattinam, Nagercoil, Palayamkottai, Salem, Thanjavur, Tiruchchirappalli, Tirunelveli, Tiruppur, Thoothukudi, Udhagamandalam, Vellore.

If you have any questions or need further information, feel free to reach out to us.

Read the full article

#aerospace#architecturaldesigns#Arcot#Automotive#bars#channels#chemicalindustry#Chengalpattu#Chennai#Chidambaram#chromium#coils#Coimbatore#consistentflow#construction#Corrosionresistance#Cuddalore#Dharmapuri#Dindigul#efficientproduction#Erode#fasteners#fittings#Flanges#Flats#foodandbeverage#heatexchangers#hightemperatures#IndustrialApplications#Industrialmachinery

0 notes

Text

#STAINLESS STEEL 304 PIPES SUPPLIER#STAINLESS STEEL 1.4301 PIPE#STAINLESS STEEL 304 PIPE#STAINLESS STEEL 304 SEAMLESS PIPES#SS 304 PIPES#ASME SA312 STAINLESS STEEL TP304 PIPES SUPPLIER

1 note

·

View note

Text

Best Stainless Steel 304 Seamless Pipe Manufacturer in India

Shree Impex Alloys is a major Stainless Steel 304 Seamless Pipe Manufacturer in India. We have been providing our customers with a wide selection of Stainless Steel 304 Seamless Pipes. SS 304 Seamless Pipes are available in a variety of specifications, standards, diameters, thicknesses, and custom lengths. As a leading Stainless Steel 304 Seamless Pipe Supplier in India, we never compromise on quality and offer high-quality SS 304 Seamless Pipes all over the world.

As one of the leading ss 304 seamless pipe suppliers in Mumbai, Shree Impex Alloys has a sizable stock of these pipes in sizes that are common for the industry. Austenitic grades 304, 304L, 316, 316L, and 316L in diameters ranging from 6NB to 1200NB make up the majority of our stock.

Global recognition for Shree Impex Alloys as a Stainless Steel 304 Seamless Pipe Supplier in India is a result of our superior quality stainless steel 304 seamless pipe. With the assistance of our in-house capabilities, we are reaching new heights in producing some of the highest quality 304 stainless steel seamless pipe.We provide stainless steel pipes in a variety of cities, including Stainless Steel Pipe Manufacturer in Kolkata, ss pipe supplier in pune and ss pipe suppliers in bangalore

#Stainless Steel 304 Seamless Pipe Manufacturer in India#Stainless Steel 304 Seamless Pipe Supplier in India#ss 304 seamless pipe suppliers in mumbai#ss pipe supplier in pune

0 notes

Text

304 Stainless Steel Tubing: The Epitome of Durability and Versatility

Stainless steel is a remarkable material that has revolutionized various industries due to its exceptional properties. Among its various grades, 304 Stainless Steel Tubing stands out as a popular choice for tubing applications due to its impressive combination of corrosion resistance, strength, and versatility. As an expert in the field, I am delighted to delve into the attributes and applications of 304 stainless steel tubing.

#stainless steel pipe#304 stainless steel tubing#seamless stainless steel tubing#schedule 10 stainless steel pipe#stainless steel tubing coil#stainless steel welded pipe#stainless steel pipe supplier#stainless steel pipe schedule 40#stainless steel tubing#stainless steel pipe fittings

0 notes

Link

Triple Nine Piping Solutions Inc. is one of the trusted market leaders in India. We have been engaged in manufacturing & exporting ferrous and nonferrous products in a wide range of materials, grades, shapes, sizes & other specifications. Our products include pipes & tubes, pipe fittings, flanges, bars & rods, sheets & plates, fasteners in materials stainless steel, duplex steel, super duplex steel, aluminium alloys and high nickel alloys. We have served our prestigious clients by giving them quality products, timely delivery on a regular basis at the most reasonable prices.

1 note

·

View note

Text

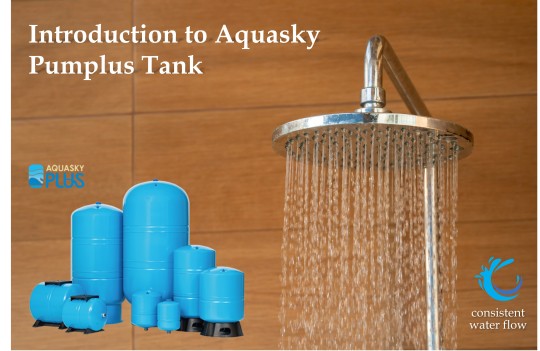

Introduction to the Pumplus Well Tank |Aquasky

A pressure tank is a general term for a vessel designed to hold liquids or gases under pressure. Depending on their specific applications, these tanks are referred to by various names across industries. In this article, we will focus on residential pressure water booster systems, where they are commonly known as Well Tanks or Sanitary Water Tanks.

1. Introduction to the Pumplus Well Tank

The Aquasky PumPlus Pressure Tank is an indispensable part of residential pressurized water systems, providing water pressure at a consistent level. The tank stores supplemental water between the diaphragm and liner, and the pressurized air chamber creates a supply circle. This innovative design significantly reduces the frequency of motor startups, maintaining steady system pressure and enhancing the efficiency of household appliances such as dishwashers and washing machines. It also ensures a strong water flow for showering and bathing.

Designed as an energy-saving solution, the PumPlus pressure tank requires no maintenance and, when paired with a properly sized pump, provides reliable and long-lasting service. This system not only minimizes energy consumption and protects against water hammers but also stabilizes water pressure to effectively meet daily needs.

Aquasky's commitment to quality and efficiency is embodied in the PumPlus series, which exemplifies the best in diaphragm-type pressure tank technology, offering a practical solution for managing residential water systems.

2. Design and Features of the Pumplus Well Tank

Constructed from cold-rolled carbon steel, the Pumplus Well Tank is built to withstand high pressures and harsh environmental conditions, making it ideal for for coastal areas prone to corrosion. With capacities ranging from 1 to 500 liters, it meets a variety of residential system sizes and requirements.

* Material and Construction:

The study cold-rolled carbon steel exterior of the tank offers excellent resistance to a wide range of atmospheric environments and corrosive media, ensuring durability and reliability in potable water systems.

* Connector Design:

To enhance tank adaptability and strength, the Pumplus Well Tank incorporates three types of stainless steel connectors:

* Male Straight Connector: Used on smaller and horizontal tanks for straightforward attachment to plumbing systems.

* Reinforced Male Connector: Features a reinforcing plate that increases the welding circumference by 50%, enhancing the strength and durability of the connection.

* Elbow Female Connector: Designed for medium and large tanks, this design features a side opening that facilitates easier pipe installation, improving the installation process.

* Internal Structure:

Inside, the tank is divided by a flexible rubber butyl diaphragm into two main chambers: the Water Chamber and the Air Chamber.

* The Water Chamber: Equipped with a corrosion-resistant propylene (PP) liner that molds to the tank shell's shape, preventing water contact with the steel shell and ensuing corrosion. It features a type 304 stainless steel threaded outlet for seamless connection to the water supply.

* The Air Chamber: Sealed and pre-charged with nitrogen to enhance stability and reduce maintenance needs, featuring an air valve for crucial pressure adjustments.

* The diaphragm is the only moving part, dynamically adjusting to changes in water volume to maintain consistent pressure and prevent water logging.

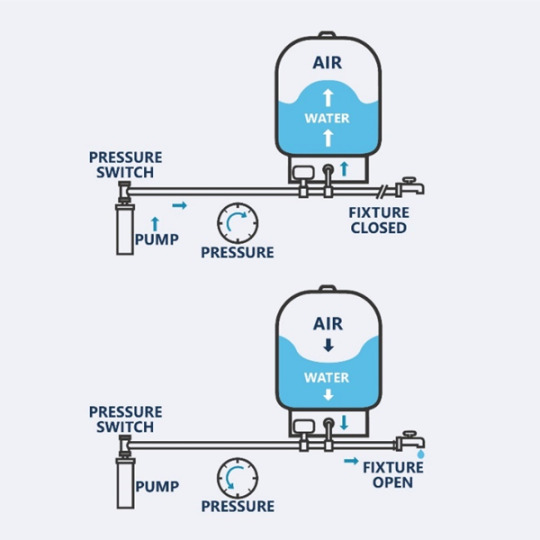

3. How Pumplus Works Inside a Pump System

In a pump system not equipped with a pressure tank, water is not very compressible, and pipes can only store a small amount of water. As a result, when you open a tap, the pressure drops quickly, leading to minimal water output. At this point, the pressure falls to the "on" setting of the pressure switch, prompting the pump to activate and start pumping again.

Integrating a pressure tank into a pump system significantly enhances its operation and extends the pump's lifespan by managing water pressure more efficiently. The tank stores water under pressure, operating as follows:

* As water is drawn from the well and pumped into the tank, it compresses the air in the upper part of the tank, increasing the internal pressure. When this pressure reaches its maximum limit t(ypically 50 to 60 PSI), the pump stops pumping water, maintaining pressure in the system.

* When water is demanded - such as opening a faucet - the compressed air in the air pressure zone is released. This air pressure deflates, pushing against the rubber diaphragm in the tank and expelling water through the plumbing system. Once the water level drops to a certain level and the air pressure in the tank drops to a pre-set minimum (typically 30 to 40 PSI), the pump reactivates to refill the tank.

* When the tap shuts, then the water stops flowing and the pressure in the system builds. When the pressure reaches the “off” setting of the switch or controller, then this turns the pump off and the pipes remain pressurized.

The tank's air pressure and water volume are controlled by a pressure switch, which has preset high and low pressure thresholds.

This system reduces the frequency of pump cycling, which is crucial for preventing wear and tear on the pump and saving electricity. By buffering the pressure and storing water in advance, the tank ensures a steady supply and reduces the stress on the pump, which is especially important for systems where pumps are not designed to start frequently, such as submersible bore pumps.

Picture 1: The work of the pressure tank within a system

4. Benefits of Using Pumplus Well Tanks

Pumplus Well Tanks are expertly designed to boost the efficiency and longevity of water systems, providing several key benefits. These tanks store pressurized water, significantly reducing the frequency of pump cycling, which not only extends the pump’s lifespan but also conserves energy and lowers utility costs. This feature also improves battery life in systems where applicable. The tanks ensure a consistent water flow and pressure, crucial for both residential comfort and industrial applications. Additionally, they offer protection against water hammers, which can cause sudden and harmful pressure changes, thus safeguarding your plumbing infrastructure. With a Pumplus Well Tank, you gain instant access to well water without needing to manually activate the pump, enhancing operational convenience and reducing the mechanical strain on your pump.

By integrating a Pumplus Well Tank into your system, you not only safeguard the mechanical integrity of your pump but also enhance the overall functionality and efficiency of your water supply system, ensuring it operates smoothly and quietly.

5. Pumplus Pressure Tank Models by Aquasky

* In-line Models

Available sizes: 3, 8, 12, 18, 24 liters

These models are typically installed directly in the main water supply line and feature a 1” connection, making them ideal for seamless integration into residential systems.

* Vertical Stand Models

Available sizes: 40, 60, 80, 100, 120, 130, 160, 200, 240, 300, 325, 450, 500 liters

* Tanks ranging from 40 to 120 liters come with a 1” connection and a plastic base, suitable for moderate residential use.

* Larger sizes from 130 to 325 liters include a 1-1/4” connector and plastic base, designed for extensive residential or light commercial applications.

* The largest tanks, 450 and 500 liters, are equipped with a 1-1/4” connector and an iron support base, ideal for commercial settings requiring substantial water capacity.

* Horizontal Models

Available sizes: 18, 24, 40, 60, 80, 100 liters

These are equipped with a 1” connection and a plastic pump stand, providing flexibility and durability for various installation environments.

6. Methods for Choosing the Correct Size of Pumplus Pressure Tank

Choosing the proper size for your Pumplus pressure tank is crucial to prevent premature pump failure and ensure efficient system operation. Here are the detailed steps and considerations:

* Residential Capacity Based on Drawdown Capacity:

* Determine Flow Rate: Measure how many liters per minute your pump produces.

* Calculate Minimum Runtime: Typically, one minute is sufficient. Multiply the flow rate by the minimum runtime to determine the drawdown capacity, ensuring the pump operates efficiently without frequent cycling.

The formula: Flow Rate (LPM) x Minimum Runtime (1 minute) = Drawdown Capacity

For example: 60 LPM flow rate x 1 = 60 liters drawdown capacity.

* Set Pressure Switch: The pressure switch setting is the pressure at which the pump turns on to fill the tank up, and the pressure at which the pump shuts off, knowing the tank is full. Standard settings range from 2.07/3.45 bar to 2.76/4.14 bar, where the first number is the cut-in pressure and the second is the cut-out pressure. This setting significantly impacts the drawdown capacity and system efficiency.

* Residential Capacity Based on Fixture Count:

The capacity of the pump system in gallons per minute (GPM) should equal the number of fixtures in the home. This must take into account all use for the kitchen, bath, appliances, outside irrigation, a pool, and special fixtures, such as a hot tub. In this model, modern home with two bathrooms (three outlets each), kitchen sink, dishwasher, washing machine, laundry tub, and two outside hose outlets would require a capacity of 12 gallons per minute, based on the 12 fixtures or outlets.

Aquasky’s experts suppose each water faucet flows out 10 litres of water each time, so customer just needs to know the number of water faucet inside the water system, and they can select a correct size pressure tank.

* Using Aquasky Selection Tool

Please link to the following AQUASKY website: https://aquaskyplus.com/sel_tools.php

Enter demand figures, AQUASKY will help you calculate the proper size pressure tank.

7. Installation Process

Installing an Aquasky Pumplus Well Tank is a critical step in ensuring efficient operation and extended longevity of your water system.

Start by removing any existing equipment such as old steel galvanized tanks, air volume controls, and plugging or removing bleeder and snifter valves. After unpacking your new tank, begin the initial setup by removing the air valve cap and using a standard tire pressure gauge to check and adjust the tank’s pre-charge pressure. This should be set to 2 PSI below the pump’s cut-in pressure setting, ensuring adjustments are made when the tank is empty and the system pressure is at 0 PSI to avoid inaccuracies. Typically, Pumplus tanks come with a preset cut-in pressure of 30 PSI, so adjust the pre-charge to 28 PSI. Consult your pump’s documentation for specific settings, often found under the pressure switch cover.

Once adjusted, re-secure the air valve cap tightly. Choose an installation site that minimizes risk in the event of leaks and provides adequate drainage, making sure the location’s flooring is level. When making pipe connections, ensure that the pipe size from the tank matches that from the pump to the house, and follow local or state plumbing codes. Refer to the included installation diagram (from Picture 2 to Picture 6) for further guidance. After all connections are secure, prime the pump and restore power. Finally, check all joints to ensure they are airtight, preventing any leaks and guaranteeing system integrity. By carefully following these steps, you will successfully install your Pumplus Well Tank, optimizing its performance and enhancing the durability of your water pressure system.

8. Maintenance and Longevity

Aquasky Pumplus pressure tanks are built to last, but their lifespan greatly depends on proper maintenance and system setup. The longevity of these tanks is influenced by two main factors: the inherent quality of the tank and the suitability of its size and settings for the specific system.

Under typical conditions, Aquasky Pumplus pressure tanks are designed to last about 5 years. With optimal care and ideal water conditions, high-quality models can extend up to 8 years or more. In systems where the water is consistently clean and the tank is correctly sized, the lifespan can reach an average of 10 years.

Here are some tips on how to maximize the lifespan of your pressure tank:

* For optimal performance, it is essential to ensure the tank is properly sized and configured for your system to efficiently handle water demand and minimize wear and tear.

* Regularly monitoring and managing water quality is also crucial, particularly in coastal areas where higher salt content can accelerate corrosion. Installing a filter system can help mitigate damage from sediments like sand or small rocks that might erode the diaphragm over time, potentially leading to leaks.

* To further extend the tank’s life, reduce the frequency of pump cycling to prevent mechanical strain and quick wear of the diaphragm. Regular inspections of the diaphragm and adjustments to the tank’s pre-charge based on water usage or system changes are vital.

9. Conclusion

The Pumplus Well Tank exemplifies the advantages of using a high-quality pressure tank in any pressurized water system. With its sturdy design, efficient operation, and potential for energy savings, it represents a wise investment for ensuring reliable and effective water pressure management.

For more information of Aquaksy Pumplus well tank, you can click website: https://aquaskyplus.com/PUMPLUS.php

Or you can email to us: [email protected]

1 note

·

View note

Text

Unveiling the Excellence of Stainless Steel 304L Pipe

Stainless steel has revolutionized the world of engineering with its exceptional corrosion resistance, durability, and versatility. Among the array of stainless steel grades, 304L stands out as a popular choice for various applications, including piping systems. Stainless Steel 304L pipes offer remarkable strength, reliability, and corrosion resistance, making them indispensable in industries such as petrochemical, pharmaceutical, food processing, and more. In this blog, we'll delve into the features, applications, fabrication methods, and advantages of Stainless Steel 304L pipes, shedding light on their significance in modern engineering.

Understanding Stainless Steel 304L Pipe

Stainless Steel 304L is an austenitic stainless steel alloy with low carbon content, offering enhanced weldability and corrosion resistance compared to standard SS 304. Stainless Steel 304L pipes inherit these advantageous properties, making them ideal for applications requiring superior corrosion resistance, longevity, and structural integrity in diverse operating conditions.

Key Features of Stainless Steel 304L Pipe

Corrosion Resistance: Stainless Steel 304L pipes exhibit excellent resistance to corrosion, oxidation, and chemical attack, ensuring durability and reliability in aggressive environments exposed to acids, alkalis, and corrosive media.

Weldability: The low carbon content in 304L enhances its weldability, allowing for easy fabrication of welded joints with minimal risk of sensitization and intergranular corrosion, making it suitable for welding without post-weld annealing.

Strength and Durability: Stainless Steel 304L pipes offer high tensile strength, impact resistance, and structural stability, enabling reliable performance in high-pressure and high-temperature applications without deformation or failure.

Versatility: Stainless Steel 304L pipes are versatile and adaptable to various fabrication techniques, including seamless and welded manufacturing methods, catering to diverse application requirements.

Applications of Stainless Steel 304L Pipe

Petrochemical Industry: Stainless Steel 304L pipes find extensive use in petrochemical plants for conveying corrosive fluids, gases, and hydrocarbons in pipelines, reactors, and storage tanks, ensuring safe and efficient operation.

Food and Beverage Industry: In the food processing and beverage industry, 304L pipes are utilized for transporting potable water, beverages, dairy products, and food-grade liquids, maintaining hygienic conditions and product purity.

Pharmaceutical Sector: Stainless Steel 304L pipes are employed in pharmaceutical manufacturing facilities for transporting pharmaceutical-grade chemicals, solvents, and sterile fluids in compliance with stringent quality standards and regulatory requirements.

Architectural and Construction: In architectural and construction applications, 304L pipes serve as structural components, handrails, and decorative elements in building facades, bridges, and infrastructure projects, offering aesthetic appeal and durability.

Fabrication Methods for Stainless Steel 304L Pipe

Seamless Pipe Manufacturing: Seamless Stainless Steel 304L pipes are produced through hot extrusion or piercing of solid billets, ensuring uniform composition, dimensional accuracy, and smooth surface finish, ideal for high-pressure and critical applications.

Welded Pipe Fabrication: Welded Stainless Steel 304L pipes are manufactured through processes such as TIG (Gas Tungsten Arc Welding), MIG (Gas Metal Arc Welding), or ERW (Electric Resistance Welding), offering cost-effective solutions for various applications.

Advantages of Stainless Steel 304L Pipe

Corrosion Resistance: Stainless Steel 304L pipes provide superior corrosion resistance, ensuring longevity and reliability in corrosive environments, reducing maintenance requirements and lifecycle costs.

Weldability: The weldability of 304L pipes facilitates ease of fabrication and installation, allowing for efficient assembly of piping systems with minimal risk of weld defects or failure.

Hygiene and Cleanliness: Stainless Steel 304L pipes offer hygienic properties, making them suitable for applications requiring sanitary conditions, such as food processing, pharmaceutical, and beverage industries.

Conclusion

Stainless Steel 304L pipes stand as versatile and reliable conduits in industrial piping systems, embodying durability, corrosion resistance, and performance excellence in diverse applications. By harnessing their advantageous properties and fabrication methods, engineers and plant operators can enhance the efficiency, safety, and sustainability of their processes across various industries. Embrace the craftsmanship and reliability of Stainless Steel 304L pipes to elevate your piping infrastructure and embark on a journey towards unparalleled performance and operational excellence.

0 notes