#Stainless steel plates

Text

The Ultimate Guide to Stainless Steel Plate: Types, Uses, and Advantages

Stainless steel plate is a remarkable material that plays an essential role in countless industries. Its durability, versatility, and aesthetic appeal make it a top choice for many applications. Whether you're designing kitchenware or constructing high-rise buildings, understanding the types, uses, and advantages of stainless steel plates can elevate your projects to new heights. Dive into this ultimate guide to discover everything you need to know about stainless steel plates and why they are indispensable in today's world.

The Ultimate Guide to Stainless Steel Plate: Types, Uses, and Advantages

Stainless steel plates come in various types, each tailored for specific applications. Their unique alloy compositions and finishes cater to diverse industries, from aerospace to food service. Knowing the right type ensures optimal performance and longevity.

These plates are incredibly versatile, offering resistance to corrosion, high temperatures, and wear. They’re ideal for structural components as well as decorative finishes. Understanding their advantages allows businesses and individuals alike to make informed choices that enhance both functionality and design.

Stainless Steel Plate

Stainless steel plate is a versatile material known for its durability and resistance to corrosion. It comes in various grades and finishes, making it suitable for numerous applications across industries.

From construction to culinary uses, stainless steel plates offer strength without compromising aesthetics. Their smooth surface makes them easy to clean and maintain, which adds to their appeal in both industrial settings and everyday kitchenware.

1. Alloy & Finish

Stainless steel plates come in various alloys and finishes, each tailored for specific applications. Common alloys include 304 and 316, known for their corrosion resistance and durability. The choice of alloy often depends on the environment where it will be used.

Finishes range from polished to brushed or matte, affecting both aesthetics and functionality. A polished finish is ideal for food-grade applications, while a brushed finish offers a sleek look with reduced visibility of fingerprints. Each option serves different needs effectively.

2. Dimensions

Dimensions of stainless steel plates can vary significantly based on the intended application. Common thicknesses range from 0.025 inches to several inches, depending on structural requirements.

Width and length also differ widely, with standard sizes often reaching up to 60 inches in width and lengths exceeding 120 inches. Custom dimensions are available for specialized projects, ensuring that every need is met without compromise. Each dimension plays a crucial role in performance and durability across various applications.

3. Size / Quantity

When selecting stainless steel plates, size and quantity play a crucial role. Plates come in various dimensions to suit different applications, from small components to large structural pieces. Understanding your project's specific requirements helps determine the appropriate size.

Additionally, ordering the right quantity ensures efficiency and cost-effectiveness. Whether you're buying for industrial use or personal projects, having enough material on hand can streamline production processes and reduce delays. Always plan ahead to meet your needs effectively.

Product Details

Understanding product details is crucial when selecting stainless steel plates. Each plate varies in thickness, size, and finish to meet specific needs across industries.

When evaluating these products, consider their alloy composition and surface treatment. These factors influence durability and resistance to corrosion, essential for many applications. High-quality specifications lead to better performance in demanding environments, ensuring that the chosen stainless steel plate serves its purpose effectively.

Alloys & Finishes

Stainless steel plates come in various alloys and finishes, each tailored for specific applications. Common alloys include 304 and 316, known for their corrosion resistance and durability. The choice of alloy affects the plate's strength, formability, and resistance to harsh environments.

Finishes can range from brushed to polished surfaces, impacting both aesthetics and functionality. A smooth finish is ideal for easy cleaning in food processing settings, while a textured surface enhances grip in industrial applications.

Spec Charts

Spec charts are essential tools for understanding the various characteristics of stainless steel plates. They clearly outline important specifications like thickness, width, length, and alloy composition. This information helps buyers make informed decisions based on their specific needs.

Moreover, spec charts provide details about mechanical properties such as tensile strength and yield strength. By consulting these charts, you ensure that the selected stainless steel plate meets the demands of your project without compromising quality or performance.

Type 304 Stainless Steel Plate

Type 304 stainless steel plate is a versatile and widely used material. Known for its excellent corrosion resistance, it’s ideal for various applications, from kitchen equipment to industrial machinery. This alloy contains chromium and nickel, enhancing its durability.

The smooth finish of Type 304 makes it easy to clean and maintain. It offers good weldability and formability, making it a favorite among fabricators. Whether you need strong structural support or aesthetic appeal, this plate type delivers exceptional performance.

Properties and Uses

Stainless steel plates are known for their exceptional strength and durability. They resist corrosion, making them ideal for harsh environments. Their non-reactive surface is perfect for food applications, ensuring safety and hygiene.

These plates are versatile across various industries. From construction to automotive manufacturing, their reliability makes them a preferred choice. Their aesthetic appeal also lends well to design elements in architecture and home décor, adding style without compromising function.

304 Stainless Plate

304 stainless plate is one of the most commonly used stainless steel grades. It boasts excellent corrosion resistance and high-temperature strength. This makes it ideal for a variety of applications across different industries.

The versatility of 304 stainless plate lends itself well to both industrial and residential uses. From kitchen appliances to chemical processing equipment, this material stands out for its durability and ease of fabrication, ensuring long-lasting performance in demanding environments.

Features and Benefits

Stainless steel plates are renowned for their durability and corrosion resistance, making them a reliable choice in various applications. They withstand extreme temperatures, ensuring longevity even in harsh environments.

Another significant benefit is their aesthetic appeal. The sleek finish of stainless steel enhances visual charm while maintaining functionality. This makes it suitable not just for industrial use but also for decorative purposes in architecture and design projects.

Stainless Steel Sheet Plate

Stainless steel sheet plates are versatile materials used in various industries. Their thin profile combined with strength makes them ideal for applications where weight and durability matter.

These plates come in various thicknesses, finishes, and sizes to meet specific project requirements. Whether it’s for architectural designs or industrial machinery, stainless steel sheet plates offer both functionality and aesthetic appeal. They resist corrosion while providing a sleek look that can enhance any design element.

379 Products

When exploring stainless steel plate options, the variety is impressive. With H3:379 products available, you’ll find a diverse range tailored to meet specific needs.

These products showcase different alloy compositions and finishes, ensuring that you can choose the right one for your project. Whether it’s for industrial applications or specialized uses, there’s something suitable in this extensive collection. Each option promises durability and strength while maintaining aesthetic appeal.

Explore Different Options

When it comes to stainless steel plates, variety is key. You can choose from different grades that offer unique benefits tailored for specific applications. Whether you need something for construction or food service, there’s an option available.

Different finishes also enhance the aesthetic and functional qualities of the plate. From brushed to polished surfaces, selecting the right finish can elevate your project while ensuring durability and resistance to corrosion. Explore these choices to find what fits your needs best.

Stainless Steel Plate and Stainless Steel Sheet

Stainless steel plate and stainless steel sheet differ mainly in thickness. Plates are thicker, typically over 0.25 inches, making them ideal for structural applications. Sheets, on the other hand, are thinner and more versatile for various uses.

Both materials offer excellent corrosion resistance and durability. They can be easily fabricated or welded to meet specific project demands. Whether you need a robust plate for construction or a flexible sheet for manufacturing, both options provide outstanding quality and reliability.

Industrial and Construction Applications

Stainless steel plates play a vital role in industrial and construction applications. Their strength and durability make them ideal for structural components, such as beams and supports. These materials withstand harsh conditions while maintaining integrity.

In the manufacturing sector, stainless steel plates are utilized in machinery frames, equipment housings, and tanks. Their corrosion resistance ensures longevity even in challenging environments. This versatility makes them essential across various industries, from aerospace to construction projects.

Dishes, Cups, and Bowls

Stainless steel plates are not just for industrial use. They’re also perfect for kitchenware, such as dishes, cups, and bowls. Their sleek design adds a modern touch to any dining experience while being incredibly durable.

These items resist rust and corrosion, making them ideal for everyday use. Whether you’re serving up a casual meal or hosting a dinner party, stainless steel dishware is both stylish and practical, enhancing your table setting effortlessly.

Stainless Steel Options for Foodware

Stainless steel options for foodware offer an excellent blend of durability and style. Whether you're selecting dishes, cups, or bowls, stainless steel provides a hygienic surface that resists bacteria and is easy to clean. Its non-reactive nature ensures no metallic taste transfers to your food or drink.

Choosing stainless steel for your culinary needs means investing in longevity. These products withstand daily wear while maintaining their sleek appearance. Plus, they are often lightweight yet sturdy—perfect for both home use and outdoor adventures.

Consider incorporating stainless steel items into your kitchen arsenal today. Not only do they elevate meal presentation but also provide peace of mind regarding safety and sustainability. Enjoy the benefits of using high-quality materials designed to last!

0 notes

Text

What are the Different Material Grades of stainless steel plates

Stainless steel plates come in various grades, each with unique properties and applications. Here’s a concise breakdown to help you navigate through the different types:

Austenitic Stainless Steel (Grade 300 Series): This type is the most common and versatile. It offers excellent corrosion resistance, high ductility, and good weldability. Grade 304 and Grade 316 are popular choices, with Grade 316 offering superior corrosion resistance, particularly in marine environments.

Ferritic Stainless Steel (Grade 400 Series): Known for its magnetic properties, ferritic stainless steel is less corrosion-resistant compared to austenitic grades but offers good strength and machinability. Grade 430 is commonly used in appliances and automotive trim.

Martensitic Stainless Steel (Grade 400 Series): Martensitic grades are heat-treatable and offer high strength and hardness. They are commonly used in cutlery, surgical instruments, and industrial equipment. Grade 410 and Grade 420 are examples of martensitic stainless steels.

Duplex Stainless Steel: This grade combines the properties of austenitic and ferritic stainless steels, offering excellent corrosion resistance and high strength. It finds applications in chemical processing, oil and gas, and marine environments.

Precipitation-Hardening Stainless Steel: These grades can be strengthened by precipitation hardening, offering high strength, toughness, and corrosion resistance. They are used in aerospace components, nuclear reactors, and high-performance applications.

Conclusion:

Choosing the right grade of stainless steel plates is crucial for ensuring optimal performance and longevity in various applications. Whether you require corrosion resistance, strength, or machinability, there’s a stainless steel grade suitable for your needs. For quality stainless steel plates, consider contacting Omsteel, a trusted supplier known for its wide range of high-quality stainless steel products.

0 notes

Text

Meeting Industry Demands: Premium Steel Supplies in Melbourne

Quality stainless steel, and high-quality steel play a crucial role in manufacturing stainless-steel products. Steel supplies in Melbourne are done by leading companies in the business and one must choose a trustworthy leading company, which provides the best quality material steel products to the industry as per the requirements. It not only provides steel but also understands the needs of industries and supplies many steel products like stainless steel angles, stainless steel solid bars, and more. In addition, the leading company’s stainless steel is certified and provides the best service delivery.

Let’s Have a Look at Some Stainless-Steel Products Supplied by The Best Suppliers

Steel Plates and Coils: These stainless steel plates have various functions and are used in many industries like manufacturing, pharmaceuticals, daily life, and the food industry. Plates and coils are available in different sizes to fulfil the requirements of the users.

Stainless Steel Solid Bar: Suppliers offer different shapes of stainless-steel solid bars like, round, flat, and square to reach the specific requirements. The available range of grades is 304 and 316, because of the high quality of stainless steel used in brackets, ornamental work, and more.

Steel Sheets: Stainless steel sheets are available in the range of 430, 316, and 304 as per the demand of projects. These sheets provide great strength, and versatility and rust free for use in different industrial projects.

Stainless Steel Fittings: Grade 316 and 304 bends, and quality steel angles are available in many sizes. These fittings offer high strength, corrosion resistance, and durability, and are adaptable for the outside as well as inside use.

Leading steel supplier companies give various options for stainless-steel products to reach the demand of users in the market. To get high-quality stainless steel products keep in touch with suppliers who always value the needs of users and understand how to satisfy the user's choices for supplying stainless steel.

Source

0 notes

Text

Stainless Steel 310 Sheets & Plates Suppliers, Stockists and Exporters in India

Shree Venktesh Wires and Steels Pvt. Ltd. as suppliers and exporters of Stainless steel 310 & 310s Plates & Sheets in India, Saudi Arab, Qatar and UAE available high quality Stainless Steel Sheet and Plates in provide in310 & 310s. Shree Venktesh Wires and Steels Pvt. Ltd. is the well-known Supplier, Stockiest, Dealer & Exporter of Hot Rolled Coils, Cold Rolled Coils, Stainless Steel Sheets, and Plates.

0 notes

Text

https://onetouchexim.com/stainless-steel-plate-vs-stainless-steel-sheet/

0 notes

Text

Supplier of SS Plates in India

Supplier of SS Plates in India:

Meghmani Metal Industries:

We are an engineering company based in Ahmedabad that has been working with numerous industry leaders in a variety of fields since 2011. We frequently provide these leaders with our metal products. As a manufacturer, supplier, and stockist of all types of industrial raw materials with SS, MS, aluminium, brass, coppers, and other…

View On WordPress

0 notes

Text

SV Stainless Steel: What are the grades of Stainless Steel Coils?

There are numerous applications for hot rolled stainless steel coils, including heating and cooling, appliances, automotive, and industrial equipment. The quality and strength of the final product will be determined by the grade of stainless steel used in coils.

Stainless steel is a great choice for many things, but it can also be used in a variety of ways when it comes to Coil Making. Grades of stainless steel are better suited for specific purposes, and with the proper techniques and tools, anyone can make quality coils using this metal. Furthermore, certain techniques can be used to improve the quality of the finished product.

Grades of Stainless Steel Coils:

Hot-rolled stainless steel coils are available in a range of grades based on the steel’s level of alloy content and quality.

Here are some grades for Stainless Steel Coils

SS 304

SS 304L

SS 316L

Duplex 2205

Duplex 31803

Duplex 1.4462

Duplex 317L

And plenty of others.

Duplex stainless steel coils are made from high-quality stainless steel alloys that have been heat-treated to make them resistant to wear and tear. Duplex stainless steel is created by mixing two distinct types of stainless steel, Ferritic and Austenitic. Ferritic stainless steel is more robust and resistant to extreme heat. Austenitic stainless steel contains a variety of alloys that makes the steel much more defiant to corrosion. They are also free from impurities, making them ideal for many heavy-grade applications.

Duplex 2205 stainless steel coils are made from alloys that have been heat-treated to a lower level of quality but still offer good resistance to wear and tear. Duplex 2205 is one of the most superior stainless steel grades in the market. It contains 22% chromium, 3% molybdenum, 5-6% nickel, and some amount of nitrogen. Duplex 2205 is more stress resistant, has zero to no corrosive response, maximum strength, and great impact toughness. They are also free from impurities, making them suitable for industrial applications.

The 300 series of grades, like 304, 304L, 316, and others are considerably less in quality but not less competent. These grades of steel are often used where corrosion resistance must not be the top priority and strength and flexibility are required. Each of these grades is corrosion-resistant and widely used in plenty of industries.

Types of Stainless Steel Coils:

Hot-rolled stainless steel coils are available in a variety of grades, depending on the level of steel content and the way the coil is cold-rolled. The grades can be divided into two categories: Hot Rolled and Cold Rolled.

Hot Rolled Coil:

Hot rolling means the steel rolling of coils with extreme heat. The steel coil is made to cool to room temperature. Cooling at high temperatures allows it to easily elongate the steel into sheets and coils but is not uniform. The internal stress is limited when compared to cold rolled steel. Hot-rolled steel is easily moldable and weldable, with increased elasticity and toughness. Hot rolled coils are applied:

Automotive Frames

Agricultural Equipment

Metal Buildings

Railroad Equipment

Construction

Beams

Cold Rolled Coil:

Cold Rolled Coil is similar to hot rolling, only the cooling down process is done by blasting lower temperatures at the rolled coil. Due to extreme cool down, the hardness of cold rolled steel is more and stronger than hot rolled clients. The finishing is better and is resistant to tension breaking. Cold rolled coils are used in:

Metal Furniture

Structural Parts

Home Appliances

Water Heater

Metal Containers

Fan Blades

Computer Cabinets

The hardness and corrosion resistance of stainless steel coils are also affected by their grade. As the grade increases, the steel becomes softer and is more corrosion-resistant.

Uses for stainless steel coils:

In addition to food storage, sporting goods, automotive and industrial components, and construction, hot-rolled stainless steel coils can also be used for a variety of other applications. The grades of stainless steel coils available on the market vary in terms of the quality of the steel, the processing and finishing techniques used, and the temperature range at which they can be used.

The higher the quality of the steel, the finer the grain, and the more uniform the thickness of the coil. Coils of higher quality grades can be used for applications that require greater accuracy, such as medical devices and sporting goods. Coils of lower-quality are less expensive but can be less accurate and require consistent thickness. Automobiles and industrial components are typical applications where they are not required to provide the highest degree of accuracy.

Hot-rolled stainless steel coils can be used in a variety of applications, including:

Food Preparation and Storage

Sporting Goods

Automotive and Industrial Components

Conclusion

SV Stainless is the leading stainless steel coil exporter in India and overseas. They have partnered with Jindal Stainless Ltd for manufacturing, and SV Stainless performs as the stainless steel coil supplier and stainless steel stockist. They specialize in Stainless Steel Flats, like

SS Sheets

SS Plates

SS Coils

0 notes

Text

SV Stainless Steel: Uses and Importance of Stainless Steel Sheets, Plates, and Coils

Stainless Steel sheets, plates, and coils are all used in various industries, from home appliances to automobiles. Stainless steel sheets, plates, and coils are essential components used in industrial settings to protect against corrosion and wear. Metals such as steel, nickel, carbon, and others are commonly used in the manufacturing of sheets. The use of sheets depends on the specific application.

Steel sheeting is used for various applications, such as building roofs and metal boxes. It is solid and durable. Stainless steel sheeting is used in a variety of applications, such as shipbuilding — strong, durable, and light at the same time. Sheeting is used to create pipes in walls and ceilings. Water doesn’t cause damage and it never corrodes or tarnishes. Carbon sheeting is used in the automobile industry to reduce resistance to heat flow and improve structural quality.

Applications of Stainless Steel Sheets and Plates

Stainless steel sheets, plates and coils are essential to the kitchen and are used for cooking food. The sheets and plates are usually made of stainless steel, but they are used for cooking and other purposes. They are widely used for Kitchenware, Furniture, and Construction, Machineries and other Industries.

The main uses of sheets and plates include:

• Cooking utensils — Sheets and plates are used in Kitchen products because they provide a better quality to cook and serve the food.

• Furniture — Sheets and plates are used for making furniture. They are also used as a base for making beds and other items like tables and chairs.

• Industrial purposes — They are used in manufacturing machines and appliances.

. Construction — Sheets are converted into bars, pipes, vent ducts used in residential and commercial constructions.

• Tools — Tools are also made with them. These are used for driving nails, screws, bolts, knives, forks, etc.

• Medical uses — They are used to manufacture dental instruments, equipment, and other items.

• Safety purpose — They are used for safety purposes. It is used for manufacturing fireproof material. It is also used for manufacturing fire fighting material.

• Electrical purpose — They are also used for electrical purposes. It is used for manufacturing electrical wires and insulation materials.

Why Are Stainless Steel Flats Important?

Have you ever gone through the different things that you use in your daily life? You may have different types of clothes, plates, and other stuff. So, when it comes to using sheets, plates,and coils, it is essential to know why it is important for you.

Stainless steel sheets, plates and coils are resistant to corrosion and are better in quality. It has a wide range of applications in various industries. Stainless steel can be utilized during extreme conditions. The durability, tensile strength and corrosion resistance makes it more practical. The anti-abrasive nature assures low maintenance. The stainless steel comes is numerous grade each one step better and used for specific applications,

Here are some of the Stainless Steel Grades.

● 304

● 304L

● 309

● 310

● 410

● 420

● 430

● 441

● And plenty more.

Stainless Steels sheets, plates and coils can be easily molded into various requirements. Majorly they are used to produce more stainless steel objects like, pipes, tubes, fasteners, flanges and other industry steel equipped products.

Conclusion:

SV Stainless Steel is the best Stainless Steel Sheets exporter and Stainless Steel Plate Supplier. They are the leading Stainless Steel Coils stockists and distributors for Jindal Stainless Ltd. Jindal Stainless Ltd are the manufacturing partners for SV Stainless Steel for the

0 notes

Text

#We are one of the leading importers#stockists and suppliers and manufacturer of Stainless Steel. We offer a wide range of raw materials both LONG & FLAT Products to meet a var#Stainless Steel Tubes#Stainless Steel Sheets#Stainless Steel Plates#Stainless Steel Strips#Stainless Steel Rods#Stainless Steel Bars#Stainless Steel Wires angels#Stainless Steel Pipe#nickel bars and rods#nickel pipe and tubes#nickel sheet#nickel plates#nickel coils#nickel flanges#alloy bars and rod#alloy pipes and tubes#alloy plates#alloy sheets#alloy coils#alloy flanges#duplex rods#duplex bars#duplex coils#duplex sheet#duplex plate#duplex pipes#duplex tubes#carbon steel rods

0 notes

Text

Stainless Steel (Stainless Steel) according to the definition of GB/T20878-2007 is stainless, corrosion resistance as the main characteristics, and chromium content of at least 10.5%, the maximum carbon content is not more than 1.2% of steel.

stainless steel plate

Stainless Steel (Stainless Steel) is the abbreviation of stainless acid steel, air, steam, water and other weak corrosion medium or stainless steel called stainless steel; And the chemical corrosion resistant medium (acid, alkali, salt and other chemical corrosion) corrosion of steel called acid steel.

stainless steel sheet

Due to the difference in chemical composition and make their corrosion resistance is different, ordinary stainless steel is generally not resistant to chemical medium corrosion, and acid resistant steel is generally stainless. The word "stainless steel" does not simply refer to a kind of stainless steel, but represents more than one hundred kinds of industrial stainless steel, the development of each stainless steel in its specific application field has good performance. The key to success is first to find out the purpose, and then to determine the right type of steel. There are usually only six types of steel related to construction applications. They all contain 17 to 22% chromium, and the better steels also contain nickel. The addition of molybdenum can further improve the atmospheric corrosion, especially the corrosion resistance of chloride-containing atmosphere.

#stainless steel sheet#stainless steel#stainless steel plate#generally stainless#stainless steel price#stainless steel plates

0 notes

Text

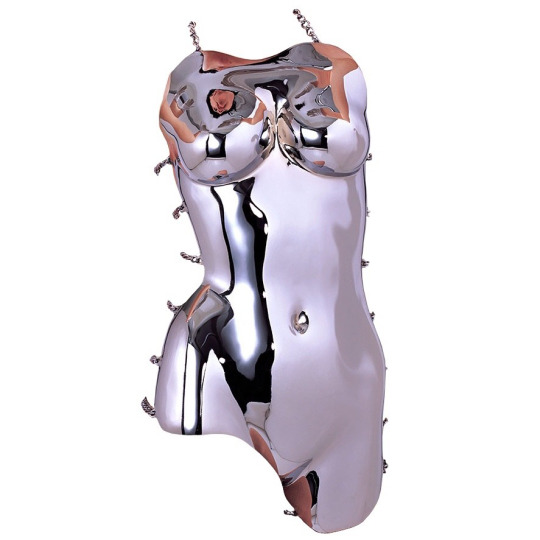

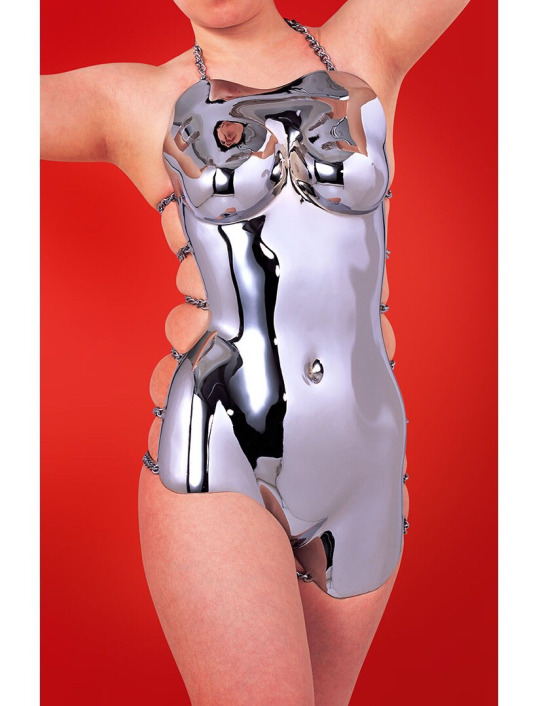

Hyun Joo: Stainless Steel Body Plate (2008)

743 notes

·

View notes

Text

Well ain't this bizarre

I ordered some more belt buckles and instead of 1.5"s they sent me 1.25s. and I just opened em cuz I have a project I want em for except wait no they ARE 1.5" of the same design, just... Dinkier? This is very confusing

#looking at it it looks like its chrome on brass#maybe my older ones were nickel plated steel or stainless steel?#im pretty sure i wouldnt have ordered this in CB if NP was available

16 notes

·

View notes

Text

Lightweight Stainless Steel: Advancements in Strength-to-Weight Ratios

Stainless steel has long been recognized for its exceptional durability and resistance to corrosion. However, the traditional image of stainless steel often conjures thoughts of heavy, industrial-grade materials. In recent years, there have been significant advancements in the development of lightweight stainless steel, which have revolutionized various industries. In this blog, we will delve into the world of lightweight stainless steel, exploring its properties, manufacturing processes, and the remarkable impact it has had on the strength-to-weight ratios in modern engineering.

The Versatility of Stainless Steel Plates and stainless steel Sheets

Before we delve into the lightweight variants of stainless steel, it's essential to understand the role of stainless steel plates and sheets in various applications.

Stainless Steel Plates and Sheets

Stainless steel plates and stainless steel sheets are fundamental building blocks in many industries. They are crafted from high-quality stainless steel, an alloy known for its resistance to corrosion and staining, making it ideal for a wide range of applications. These applications include kitchen appliances, architecture, automotive components, and industrial machinery, among others.

Manufacturing Stainless Steel Products

The process of manufacturing stainless steel products involves several crucial steps:

1. Melting and Refining: High-quality raw materials are melted and refined in furnaces to create a homogeneous stainless steel alloy.

2. Casting: The molten stainless steel is cast into specific shapes, such as billets or slabs.

3. Hot Rolling: The cast material is hot-rolled into sheets or plates of varying thickness.

4. Cold Rolling: If needed, the hot-rolled stainless steel sheets are cold-rolled to achieve the desired thickness and finish.

5. Finishing: The sheets or plates are then subjected to various finishing processes, which can include cutting, pickling, and surface treatments to enhance their properties.

Advancements in Lightweight Stainless Steel

Traditionally, stainless steel is known for its strength and durability. However, the introduction of lightweight stainless steel has expanded its utility into areas where weight is a critical factor. These advancements have been made possible through innovations in alloy composition and manufacturing techniques.

1. Alloy Composition

The development of lightweight stainless steel begins with careful consideration of alloy composition. By altering the ratio of elements such as nickel, chromium, and molybdenum, engineers can create stainless steel sheet metal with reduced density while retaining its strength and corrosion resistance. This lightweight stainless steel is often referred to as "high-strength, low-density stainless steel."

2. Advanced Manufacturing Techniques

In addition to alloy composition, advanced manufacturing techniques have played a pivotal role in producing lightweight stainless steel. Precision control over the rolling and annealing processes ensures that the final product possesses the desired mechanical properties while maintaining a lower weight.

3. Automotive Industry

One of the primary beneficiaries of lightweight stainless steel is the automotive industry. The demand for vehicles that are more fuel-efficient and environmentally friendly has driven the need for lighter materials. Lightweight stainless steel is now being used in the production of components such as exhaust systems, chassis, and body panels, reducing vehicle weight and improving fuel economy.

4. Aerospace Applications

In the aerospace sector, where every ounce counts, lightweight stainless steel has become a game-changer. It is used in the construction of aircraft components, including structural elements and fuel tanks. This not only reduces fuel consumption but also enhances the overall performance and longevity of aircraft.

5. Architecture and Construction

Architects and builders are also embracing lightweight stainless steel for its aesthetic appeal and durability. It is used in the construction of modern, sleek buildings and bridges. The reduced weight makes installation and transportation more efficient, while the material's corrosion resistance ensures longevity in challenging environmental conditions.

6. Consumer Electronics

The consumer electronics industry benefits from lightweight stainless steel in the production of laptops, smartphones, and wearables. This not only reduces the overall weight of these devices but also ensures their robustness and resistance to wear and tear.

The Economic Aspect: Stainless Steel Price

Despite the numerous advantages of lightweight stainless steel, it's important to address the economic aspect, particularly stainless steel prices. While these advanced alloys offer a host of benefits, they can be more expensive to produce than traditional stainless steel. However, the long-term cost savings resulting from improved fuel efficiency, reduced maintenance, and extended product lifespans often justify the initial investment.

The Future of Lightweight Stainless Steel

The development and adoption of lightweight stainless steel are expected to continue growing in the coming years. As industries across the board seek to reduce their environmental impact and enhance efficiency, lightweight stainless steel offers a compelling solution. Its versatility, strength, and resistance to corrosion make it an attractive choice for a wide range of applications.

In conclusion, the evolution of lightweight stainless steel has ushered in a new era in engineering and design. This remarkable material has significantly improved strength-to-weight ratios in industries ranging from automotive to aerospace, contributing to more sustainable and efficient solutions. For those looking to source high-quality stainless steel plates and stain steel sheets, consider Shree Venktesh Wires and Steels Pvt Limited. They have established themselves as leading stockists and distributors of Jindal Stainless Ltd., a reputable provider of stainless steel products. Contact them today to explore the possibilities of lightweight stainless steel in your industry.

#Stainless steel plates#stain steel sheets#manufacturing stainless steel products#stainless steel sheet metal

0 notes

Text

Is this actionable? I feel like they should have to pay for your microwave if you try it.

8 notes

·

View notes

Text

arm ring hours

#im still so sad my old arm ring fucking turned my arm green I hate plated shit so much#AND IT WASNT CHEEEEAAAAAAPPPPP i bought it at a fucking craft fairrrrrrrrrrr boooooo#speaking of plated shit.#I need to replace my mjolnir eventually I just haven’t found one i like yet#im not mad abt that one tho bc I was paying for the chainmail obvs not the charm#i do wanna get a stainless steel replacement but at the same time i am really fond of this mjolnir even if the plating is completely gone#good memories attached to it— it’ll go on the altar for sure whenever i do find a good replacement#my face#lol wasn’t i just talking abt selfies without my face……….

4 notes

·

View notes