#Steam and Gas Turbines Market

Text

Uncover the driving forces behind the Steam and Gas Turbines Market. Explore cutting-edge technologies, market trends, and industry leaders propelling energy generation. Stay informed and empowered to navigate the dynamic world of turbine-based power solutions.

0 notes

Text

Turbine Drip Oil Market Anticipated to Witness High Growth Owing to Increasing Military Spending

The turbine drip oil market includes oils that are used for lubrication inside gas turbine engines. Turbine drip oil provides essential lubrication to critical engine components such as bearings, gears and seals. It protects vital engine parts from damage due to friction and wear. The demand for turbine drip oil is driven by rising aviation activities and increasing military budgets across countries.

Global Turbine Drip Oil Market is estimated to be valued at USD 2.21 Bn in 2024 and is expected to reach USD 3.31 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 5.1% from 2024 to 2031.

Key Takeaways

Key players operating in the turbine drip oil market are Chevron, Royal Manufacturing, Cenex, Archer Lubricants, Mystik Lubricants, United Lubricants, Magnum Manufacturing, Texas Refinery Corp, Apar Industries Ltd, Behran Oil Co., BP Plc, Castrol Ltd., CHS Inc., CITGO Petroleum Corp, Exxon Mobil Corporation, Shell India, Penrite Oil Company, Paras Lubricants. These players are focusing on new product development and global expansion strategies to gain competitive advantage.

The key opportunities in the Turbine Drip Oils Market Growth include growing demand for lightweight and high-performance aircraft turbines as well as increasing MRO activities. The global turbine drip oil market is expanding rapidly as major players seek to tap opportunities in emerging economies such as China, India and Brazil through joint ventures, partnerships and acquisitions.

Market Drivers and Restrain

The primary driver for the turbine drip oil market is the rising global defense budgets. Many countries are increasing their defense spending to modernize their militaries with new aircraft, helicopters, warships and other equipment requiring turbine engines. For instance, the US defense budget stood at $778 billion in 2022, creating strong demand for turbine oils.

However, stringent environmental regulations pose a challenge for the Turbine Drip Oil Market Size and Trends. Regulators are enforcing stricter norms on emission levels from aircraft and turbine engines to control air pollution. This is increasing the pressure on oil manufacturers to develop bio-based and environmentally acceptable lubricant solutions. Continuous innovation is needed to meet the dual objectives of performance and sustainability.

Segment Analysis

The turbine drip oil market is dominated by the industrial segment, as turbine drip oil is widely used in manufacturing industries for lubricating machinery. Turbine drip oil finds major applications in various industries like power generation, oil & gas, chemicals, and others where large turbines and other heavy machinery are used. Within industrial segment, power generation sub-segment holds the largest share as continuous operations of turbines in power plants requires effective lubrication and cooling provided by turbine drip oil.

Global Analysis

North America region holds the largest share in the global turbine drip oil market currently. The region has presence of developed industrial sector with numerous power plants and oil & gas installations where turbine drip oil is highly consumed. Asia Pacific is projected to be the fastest growing market during the forecast period owing to rapid industrialization and growing energy demands in emerging economies of China and India. Countries like China, Japan and India are witnessing rise in power generation through coal based plants, thus driving the adoption of turbine drip oil.

Get more insights on Turbine Drip Oil Market

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

#Coherent Market Insights#Turbine Drip Oil Market#Turbine Drip Oil#Steam Turbines#Gas Turbines#Hydro Turbines#Synthetic Turbine Drip Oil#Turbine Drip Oil Market Forecast#Turbine Drip Oil Market Demand

0 notes

Text

Understanding the root cause of the symptoms that are observed on your machinery?

It is observed across the spectrum that whenever we see issues/symptoms like:

1. Oxidized oil

2. Destructive pitting

3. Excessive vibration

4. Abrasive wear

5. Cavitation

6. Machinery abnormal noise

7. Wear debris generation

8. High running temperature

We usually believe in either Repairing, Replacing, Rebuilding and Removing the affected component. However, it only subsides the symptoms temporarily. This approach is called the 4-R approach and it weeds out the issue from the surface and not at the root level and hence the problem reoccurs. Call +91 7030901266 for Mechanical Maintenance & Oil Check.

However, we should aim at studying these symptoms and work on the root causes. Some of the very frequent root causes that cause the above-mentioned symptoms are:

1. Misalignment

2. Wrong oil usage

3. Moisture

4. Machinery part imbalance

5. Particle contamination

6. Air contamination

Hence, we should aim at 5I approach i.e. It’s clean, It’s Cool, It’s dry, It’s aligned and balanced, It’s well oiled. This approach keeps the machine healthy and eliminates the problem.

In case you are unable to understand the root cause of the symptoms that are observed on your machinery contact Minimac Systems Pvt. Ltd.

#oil flushing#minimac systems#minimac#hydraulic oil#oil & gas#lube oil filter#contamination#power#hydraulic oil filter#frf#oil filteration#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#wind turbines#gas turbine services market#steam turbine market share#gas turbine market trends#mlc lvdh#lvdh full form#transformer oil filtration#oil dehydration systems#lube oil flushing#hydraulic

0 notes

Text

In his Substack blog, Bill McKibben summarizes this article authored by Brian Deese (one my long-term friends) published in The Atlantic. Brian was President Biden's Director of theNational Economic Council and was a key drafter of the Inflation Reduction Act:

Total investment in clean energy was more than 70 percent higher in 2023 than in 2021, and now represents a larger share of U.S. domestic investment than oil and gas. Clean-energy manufacturing is off the charts. Money is disproportionately flowing into promising technologies that have yet to reach mass adoption, such as hydrogen, advanced geothermal, and carbon removal. And, thanks to a provision that allows companies to buy and sell the tax credits they generate, the law is creating an entirely new market for small developers.

But for all of this progress to deliver, it needs to translate into clean energy that Americans can actually use. In 2023, we added 32 gigawatts of clean electricity to the U.S. grid in the form of new solar, battery storage, wind, and nuclear. It was a record—but it was still only about two-thirds of what’s necessary to stay on track with the IRA’s goal of reducing emissions by 40 percent by 2030.

Brian adds:

The topic of utility reform operates in what the climate writer David Roberts has described as a “force field of tedium.” I can say from experience that starting a cocktail-party conversation about public-utility-commission elections is a good way to find yourself standing alone. But if you care about averting the most apocalyptic consequences of climate change, you need to care about utilities.

A century ago, utilities were granted regional monopolies to sell electricity subject to a basic bargain. They could earn a profit by charging consumers for investments in building new power plants and transmission lines; in exchange, they’d commit to providing reliable electricity to all, and submit to regulation to make sure they followed through.

This model made sense for much of the 20th century, when generating electricity required building big, expensive fossil-fuel-powered steam turbines, and utilities needed to be assured of a healthy return on such heavy up-front investments. But it is at least a generation out of date. Over the past several decades, technology has opened up new ways of meeting consumers’ electricity demand. The 20th-century utility model doesn’t encourage this innovation. Instead, it defaults toward simply building more fossil-fuel-burning plants. As a result, consumers get a less reliable product at higher prices, and decarbonization takes a back seat.

4 notes

·

View notes

Text

Sustainable Power Generation: Renewable Energy Solutions

Total Power Solutions

Kaltimex Energy is a well-known company in Bangladesh that specializes in providing engineering, procurement, and construction (EPC) services, particularly in the energy sector.

Kaltimex Energy Bangladesh is involved in various projects related to power generation, including the installation and maintenance of power plants, electrical and mechanical works, and other energy-related services. They have been involved in the development of both conventional and renewable energy projects in Bangladesh.

Kaltimex Energy has been working in the field of power plant business for over 2 decades. They deal with natural Gas Engine, Industrial Gas Generator, Diesel Generator, Exhaust Gas Boiler, Gas Fired Boiler, Vapor Absorption Machine (Chiller), Thermal Fluid Heater, Transformer, Radial Gas Turbine and Steam Turbine for power plants on turnkey basis projects from concept to commissioning within stipulated time period & budget.

MWM, HTT, VIESSMANN, VOLTAS, ENMAX & MAXWATT, and others are marketed brands.

#Gas Engine#Power Generation#Power Plants#Natural Gas Engine#Industrial Gas Generator#Diesel Generator#Exhaust Gas Boiler#Gas Fired Boiler#Vapor Absorption Machine#Industrial Boiler#Thermal Fluid Heater#Transformer#Radial Gas Turbine#Steam Turbine

4 notes

·

View notes

Text

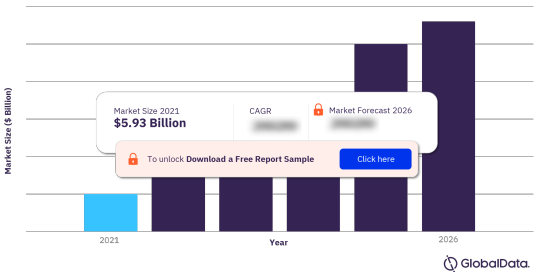

Gas Turbines Market - Forecast(2024–2030)

Gas Turbines Market Overview:

Over the past few years gas turbines have witnessed exponential growth due to the technological advances that have resulted in the design and development of highly efficient gas turbine units. Gas turbines are used in diversified services from jet engines and simple mechanical drives on land, sea and air to sophisticated gas lasers and supersonic wind tunnels. In the aerospace applications these units are referred to as jets, turbojets, turbofans, and turboprops. In land and sea based applications these units are referred to as mechanical drive gas turbines. Gas turbines are increasingly being used in power plants both in the utility and power sectors for their tremendous energy producing capacity, compactness, inherent flexibility, high performance, operational availability and multiple fuel capability. Aerospace sector seems to be the most promising sector in future due increasing investments in manufacturing and migration across various regions.

Sample Report:

The gas turbines market is scrutinized by segments including design type, capacity, technology, application and geography. Based on technology in accordance to the operation cycles, the market is segmented into combined cycle and open cycle. The report also comprises of the region wise study of the global market including Americas, Europe, Asia-Pacific and Rest of the World.

Inquiry Before Buying:

Amongst the applications, aerospace has the highest CAGR of 4.78% for the forecast period 2017 to 2021. Industrial turbines held the major share in gas turbines market for 2016, during the forecast period of 2017 to 2021. Escalating demand less GHG emissive fossil fuel for power generation is propelling the growth of gas turbines market.

Decarbonization and Hydrogen Integration: There is a strong push for cleaner energy solutions, with gas turbine manufacturers focusing on hydrogen-enabled turbines to reduce carbon emissions. Companies like GE and Mitsubishi are developing turbines capable of burning hydrogen, supporting the transition to greener energy

Schedule a Call:

Growth in Combined Cycle Power Plants: Combined cycle gas turbine (CCGT) plants, which combine gas and steam turbines to improve efficiency, are becoming more popular. These plants can achieve higher efficiency rates (over 60%) compared to simple-cycle gas turbines and are seeing increased adoption

Rise of Aero-Derivative Gas Turbines: Originally developed for aviation, aero-derivative gas turbines are becoming increasingly important in power generation and marine applications due to their lightweight design, faster start times, and ability to handle variable loads

Digitalization and Predictive Maintenance: Digital tools, including AI and IoT technologies, are being integrated into gas turbine systems for real-time monitoring and predictive maintenance. This enhances operational efficiency and reduces downtime by predicting failures before they occur

Buy Now:

Growing Demand in Developing Regions: While North America and Europe remain important markets, the highest growth is expected in regions like Asia-Pacific and the Middle East due to increasing energy demands and industrialization. These regions are focusing on transitioning from coal to natural gas, which boosts demand for gas turbines

Sample companies profiled in this report are:

Siemens AG

General Electric Company

Solar Turbines

Ansaldo Energia

10+

For more Energy and Power related reports, please click here

0 notes

Text

Inconel 625 excess stock

Inconel 625 is a nickel-chromium superalloy widely known for its outstanding strength, resistance to oxidation, and corrosion in extreme environments. Developed in the 1960s, this alloy has become a crucial material in industries ranging from aerospace to chemical processing. Due to its exceptional properties, Inconel 625 is also highly sought after in the metal recycling industry, with scrap material playing a vital role in reducing waste and preserving natural resources. This article explores the significance of Inconel 625 scrap, its recycling potential, and its economic impact.

Properties and Composition of Inconel 625

Inconel 625 is an alloy primarily composed of nickel (58% minimum), chromium (20-23%), molybdenum (8-10%), and niobium (3-4%). These elements, along with trace amounts of iron, carbon, and silicon, give the material its superior mechanical strength and thermal stability. The alloy’s ability to maintain integrity under extreme temperatures, up to 980°C (1800°F), makes it a popular choice for harsh environments such as offshore drilling, gas turbines, and heat exchangers.

Uses and Applications of Inconel 625

Inconel 625 is widely used in a variety of industries due to its resistance to chemical degradation and heat. Its main applications include:

Aerospace: Components for jet engines, exhaust systems, and turbine seals.

Marine Engineering: Parts in saltwater environments where corrosion resistance is essential.

Chemical Processing: Equipment for handling highly corrosive materials like acids.

Nuclear and Power Generation: Used in reactor cores, steam generators, and heat recovery systems.

Given these demanding applications, Inconel 625 is often replaced or discarded as parts wear out, creating a steady stream of scrap material.

Recycling of Inconel 625 Scrap

Recycling Inconel 625 scrap is a highly efficient way of reusing valuable metals, especially nickel and chromium. The recycling process typically involves:

Collection and Sorting: Scrap Inconel 625 is collected from industrial sources, often in the form of used machinery parts, offcuts from manufacturing, or defective components. It is then sorted to remove contaminants such as oil, dirt, and other metals.

Melting and Refining: The scrap is melted in a vacuum or an inert atmosphere to prevent contamination during the recycling process. Advanced refining techniques are used to maintain the purity of the alloy.

Recasting and Forming: Once the alloy is purified, it is recast into new forms such as bars, plates, or rods, which can then be used in manufacturing.

The recycling process not only conserves resources but also significantly reduces the environmental impact of mining and metal production. Nickel mining, in particular, is energy-intensive and generates large amounts of waste. By recycling Inconel 625, industries can reduce the demand for newly mined nickel, chromium, and molybdenum, cutting down greenhouse gas emissions and the environmental footprint of metal production.

Economic Impact of Inconel 625 Scrap

The value of Inconel 625 scrap is primarily driven by the high price of nickel, one of its main components. Market fluctuations in nickel prices, often influenced by global supply and demand, can directly impact the price of scrap. In general, clean, uncontaminated Inconel 625 scrap fetches a high price in the recycling market. As industries increasingly seek sustainable materials, demand for high-quality scrap metals has grown, providing economic incentives for recycling programs.

In addition to environmental benefits, Inconel 625 scrap contributes to cost savings in manufacturing. Since recycled metal is often cheaper than newly produced material, manufacturers that utilize recycled Inconel 625 can reduce production costs while still benefiting from the alloy's unique properties.

Challenges in Inconel 625 Scrap Recycling

Despite the numerous advantages, there are challenges in recycling Inconel 625 scrap. These include:

Contamination: Scrap material must be thoroughly cleaned and sorted, as contamination with other metals or substances can reduce the quality of the recycled alloy.

Technological Requirements: The recycling process requires sophisticated technology to maintain the alloy's composition and performance characteristics.

Market Volatility: Prices for nickel and other metals in Inconel 625 can fluctuate, affecting the profitability of recycling operations.

Future Outlook for Inconel 625 Scrap Recycling

The future of Inconel 625 scrap recycling is promising, especially as industries continue to move toward more sustainable practices. With advancements in recycling technologies, the process is becoming more efficient and cost-effective. Additionally, global efforts to reduce carbon emissions and conserve natural resources are likely to drive further demand for recycled superalloys like Inconel 625.

As the global demand for high-performance materials continues to grow, Inconel 625 scrap will remain a valuable resource. Its role in reducing the need for newly mined metals, combined with the economic benefits of recycling, underscores the importance of continued investment in recycling infrastructure and technologies.

Conclusion

Inconel 625 scrap represents both a challenge and an opportunity for the recycling industry. Its high nickel and chromium content make it valuable in the secondary metals market, but recycling requires advanced technology and expertise to ensure the alloy retains its essential properties. As industries continue to prioritize sustainability, the importance of recycling Inconel 625 scrap will only increase, helping to conserve resources, reduce environmental impact, and support the global shift toward more sustainable manufacturing practices.

0 notes

Text

Among The Best Engineering Colleges In Kolkata Make The Right Choice

There are so many colleges to choose from that often students and guardians are vacillated by the options available. Engineering is the most demanded degree across different industries therefore choosing an institute that helps in building a strong base is a must to get a better job. Engineering is one of the most interesting and high-paying professions because of its scientific and mathematical amalgamation that tricks one's mind to solve complicated issues. This article will help you find one of the top engineering colleges in Kolkata and choose a college that fits your needs.

Amity University Kolkata campus provides its students with the finest in class facilities, faculties and opportunities to ace in the career. The university helps the students build a solid foundation to learn various important skills like critical thinking, problem-solving, technical abilities and much more that are a must-have in the job market.

Below are a few reasons to pursue courses from one of the best engineering colleges in West Bengal:

1. Presence of ample employment opportunities across diverse industries such as aerospace, automobile, biomedical, chemical, civil, EV, mechanical and environmental space.

2. The course is versatile in nature as the requirements of engineers are growing with the advancement in the ever-growing world of technology and science.

3. Studying engineering from the top engineering university in Kolkata provides the chance for growth paying students huge salary packages. It is one of the most esteemed professions and engineers are consistently in high demand across the world.

Let’s explore the best B.Tech Specialized courses provided by Amity University Kolkata

B.Tech in Computer Science Engineering

The course focuses on providing knowledge of software, database management, operation of technology and hardware-based data systems. The duration of the course is 4 years and it requires the applicant to pass the higher secondary with a minimum of 55% in the PCM stream.

B.Tech in Mechanical Engineering

Mechanical engineers design the structures of machines used for producing power, like electric generators, internal combustion engines, and steam and gas turbines, along with power-using machines, such as refrigeration and air-conditioning systems. This is also a 4-year programme and an applicant with a minimum of 55% in higher secondary in a PCM stream is eligible for this course

B. Tech in Biotechnology

Btech in biotechnology from one of the top engineering colleges in Kolkata deals with technological applications that utilise biological systems or living organisms to create or modify products or services as per the requirement. This duration of the program is 4 years and the applicant is needed to attain 55% in higher secondary with PCM or PCB stream.

Conclusion

Amity University's Kolkata campus places stress on the holistic development of the student with diverse extracurricular activities and opportunities for community service and social participation in addition to academic accomplishments. Apply today to the best engineering college in Kolkata. For more details regarding the admission procedure, and fee you can visit the website today.

Source: https://sites.google.com/view/among-the-best-engineering-col/home?authuser=3

#top engineering colleges in kolkata#best engineering colleges in west bengal#top engineering university in kolkata#best engineering colleges in kolkata

0 notes

Text

Cogeneration Equipment Market set to Exhibit Impressive Growth owing to Increasing Energy Efficiency Measures

The cogeneration equipment market is estimated to generate huge energy savings by producing both electricity and useful heat from a single fuel source. Cogeneration, also known as combined heat and power (CHP), is an efficient process that captures and utilizes heat that is rejected during conventional power generation. Cogeneration systems can achieve efficiencies of around 80-90% compared to 45% for conventional separate generation of electrical and thermal energy. Cogeneration equipment includes prime movers like gas turbines, reciprocating engines, and steam turbines along with generators and heat recovery systems. These systems find widespread applications in industries, commercial buildings, and district heating systems to meet thermal and electrical power requirements in an environment-friendly manner.

The global cogeneration equipment market is estimated to be valued at US$ 30.48 Bn in 2024 and is expected to exhibit a CAGR of 9.5% over the forecast period 2024 to 2031.

Key Takeaways

Key players operating in the cogeneration equipment market are Rolls-Royce plc, Siemens, ABB, Baxi Group, Andritz Energy and Environment, BDR Thermea Group, Mitsubishi Heavy Industries, Ltd., 2G Energy Inc., Clarke Energy Ltd., Capstone Turbine Corporation, Innovative Steam Technology, Inc., Aegis Energy Services Inc., Kawasaki Heavy Industries, Ltd, Enercon Industries, Yanmar, Naigai Industries, Inc., Yokogawa Electric, Mitsubishi Power India Private Limited, and Raj Process Equipments and Systems Pvt. Ltd.

The growing demand for energy efficiency measures from industrial and commercial sectors is a key factor driving the Cogeneration Equipment Market Demand Industries are focusing on reducing energy costs and emissions through the implementation of cogeneration systems. Various government initiatives and policies offering incentives for clean power generation using cogeneration are also fueling market growth.

Technological advancements are playing a major role in increasing the adoption of cogeneration. Manufacturers are developing high-efficiency cogeneration systems with advanced control systems, remote monitoring capabilities, and modular designs for easy installation and operation. The integration of cogeneration equipment with renewable energy sources and energy storage is gaining traction.

Market Trends

Transition towards Natural Gas-based Cogeneration: Natural gas is emerging as a widely used fuel for cogeneration systems owing to its clean burning nature and high efficiency. Many industries and power producers are switching to natural gas cogeneration to reduce emissions.

Rise of Distributed Cogeneration: Distributed cogeneration or decentralized energy coupled with renewable integration is gaining prominence for meeting the energy needs of industrial facilities, commercial buildings, and communities in a sustainable way.

Focus on Modular Cogeneration Technology: Modular Cogeneration Equipment Market Size And Trends offer increased flexibility and scalability. Manufacturers are focusing on developing highly efficient modular units with standardized components for hassle-free installation and operation.

Market Opportunities

Growing Demand from Waste Heat Recovery Applications: Significant opportunities exist in utilizing waste heat from cogeneration systems and other industrial processes for applications like district heating, drying, and greenhouse farming.

Integration with Renewable Energy: The scope for hybridizing cogeneration equipment with renewable energy sources like solar PV and wind turbines is expanding to further enhance efficiency and reduce emissions from the power and heating sectors.

Emerging Economies: Countries in Asia Pacific and Latin America experiencing rapid industrialization and infrastructure growth present lucrative business prospects for cogeneration equipment suppliers and EPC companies over the coming years.

The cogeneration equipment market is poised for strong growth with the rising focus on clean, efficient, and decentralized energy solutions worldwide.

Impact of COVID-19 on Cogeneration Equipment Market Growth

The COVID-19 pandemic has negatively impacted the growth of the cogeneration equipment market. The crisis led to lockdowns and business closures globally disrupting the demand and supply chain of cogeneration equipment. The installation and commissioning of cogeneration plants were delayed due to travel restrictions and safety protocols. This adversely affected the revenues of major players in the short term. However, post COVID, investments in cogeneration are expected to rise driven by resilience in sectors like healthcare and data centers requiring uninterrupted power supply. The need for decentralised power generation close to the point of use is also anticipated to boost adoption. Governments are formulating policies encouraging distributed energy resources like cogeneration to deal with peak demand fluctuations and strengthen energy security. Innovation in remote monitoring technologies is helping players address installation challenges. Overall, the long term outlook remains positive on the back of supportive regulations and increased emphasis on clean and efficient power solutions.

Geographical Regions with High Concentration of Cogeneration Equipment Market

North America accounts for the largest share of the cogeneration equipment market in terms of value owing to early adoption and strong government incentives promoting combined heat and power systems. Regions with advanced industrial and commercial infrastructure like the US and Canada are major revenue generators. Europe is another major regional market driven by stringent emission norms and the focus on energy efficiency across industries. Countries such as Germany, UK, France, and Italy deploy cogeneration at a large scale. Asia Pacific is emerging as the fastest growing regional market for cogeneration equipment with China, Japan and South Korea at the forefront of installations. Rapid industrialization, regulatory push for renewable energy and increasing power demand are key growth drivers in the region.

Fastest Growing Regional Market for Cogeneration Equipment

Asia Pacific region is poised to be the fastest growing market for cogeneration equipment during the forecast period from 2024 to 2031. This is attributed to strong economic growth, heavy investments in new industries and manufacturing facilities across developing nations in the region. Several factors contribute to the accelerated adoption of cogeneration in Asia Pacific. Rising population and urbanization have increased the energy needs of residential and commercial sectors. At the same time, governments are promoting decentralised power generation through regulatory incentives and targets to address issues like grid stability and emissions reductions. Countries like India, Indonesia, Vietnam and the Philippines offer lucrative opportunities for cogeneration companies to tap the huge untapped potential. Active government support through development incentives and financing schemes will further fuel the market expansion.

Get More Insights On, Cogeneration Equipment Market

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163

#Cogeneration Equipment Market Size#Cogeneration Equipment Market Trends#Cogeneration Equipment Market Demand#Cogeneration Equipment#Cogeneration Equipment Market

0 notes

Text

Siemens Energy AG: A Comprehensive Financial Overview

Siemens Energy AG is a global leader in the energy sector, known for its innovative solutions and commitment to sustainable development. As a key player in the transition to renewable energy, Siemens Energy provides a wide range of products and services that address the entire energy value chain. This article offers an in-depth financial overview of Siemens Energy AG, examining its financial performance, key financial indicators, strategic initiatives, and future outlook.

To know about the assumptions considered for the study, Download for Free Sample Report

Financial Performance Overview

**1. Revenue Growth:

Siemens Energy AG has demonstrated consistent revenue growth, reflecting its robust market position and the increasing demand for renewable energy solutions. The company’s diversified portfolio, which includes gas and steam turbines, wind turbines, and grid technologies, has enabled it to capture significant market share in various regions.

**2. Profit Margins:

Despite the challenges posed by the global economic environment, Siemens Energy has maintained healthy profit margins. This resilience is attributed to the company’s focus on operational efficiency, cost management, and strategic investments in high-margin segments such as renewable energy and digital solutions.

**3. EBITDA and Net Income:

Siemens Energy’s EBITDA (Earnings Before Interest, Taxes, Depreciation, and Amortization) has shown a positive trend, underscoring its ability to generate strong cash flows from operations. Net income, although influenced by external factors such as market volatility and geopolitical risks, remains a key indicator of the company’s financial health.

Key Financial Indicators

**1. Balance Sheet Strength:

Siemens Energy boasts a solid balance sheet, characterized by substantial assets, low debt levels, and strong liquidity. This financial robustness provides the company with the flexibility to invest in growth opportunities, pursue strategic acquisitions, and navigate economic uncertainties.

**2. Return on Equity (ROE):

The company’s return on equity is a testament to its efficient use of shareholder funds. Siemens Energy’s ROE is driven by its profitable operations and prudent financial management, which enhance shareholder value and support sustainable growth.

**3. Capital Expenditure:

Capital expenditure (CapEx) is a critical aspect of Siemens Energy’s growth strategy. The company continues to invest in cutting-edge technologies, R&D, and infrastructure to drive innovation and expand its market presence. These investments are pivotal in maintaining Siemens Energy’s competitive edge in the rapidly evolving energy sector.

Strategic Initiatives and Innovations

**1. Focus on Renewable Energy:

Siemens Energy is at the forefront of the renewable energy revolution, with a significant portion of its investments directed towards wind, solar, and hydrogen technologies. The company’s strategic initiatives include the development of advanced wind turbines, energy storage solutions, and green hydrogen production facilities, positioning it as a leader in sustainable energy.

**2. Digital Transformation:

The digitalization of energy systems is a core element of Siemens Energy’s strategy. The company leverages digital technologies such as artificial intelligence, IoT, and big data analytics to optimize energy production, enhance grid stability, and improve asset performance. These digital solutions not only increase operational efficiency but also enable Siemens Energy to offer innovative services to its customers.

**3. Strategic Partnerships and Alliances:

Collaboration is key to Siemens Energy’s growth strategy. The company has formed strategic partnerships and alliances with other industry leaders, technology providers, and research institutions to drive innovation and expand its technological capabilities. These collaborations facilitate the development of integrated energy solutions that meet the diverse needs of global markets.

Future Outlook

**1. Expansion in Emerging Markets:

Siemens Energy is poised to capitalize on growth opportunities in emerging markets, where the demand for energy infrastructure is rapidly increasing. The company’s extensive portfolio and proven expertise make it well-suited to address the unique challenges and requirements of these markets.

**2. Advancements in Energy Storage:

Energy storage is a critical component of the future energy landscape. Siemens Energy is investing heavily in the development of advanced energy storage technologies that can support the integration of renewable energy sources and enhance grid stability. These innovations will play a crucial role in the transition to a sustainable energy system.

**3. Sustainable Growth Initiatives:

Sustainability is at the core of Siemens Energy’s long-term strategy. The company is committed to reducing its carbon footprint, promoting energy efficiency, and supporting global climate goals. Siemens Energy’s sustainability initiatives include the deployment of eco-friendly technologies, participation in carbon offset projects, and adherence to rigorous environmental standards.

Conclusion

Siemens Energy AG’s financial strength, strategic initiatives, and commitment to innovation position it as a leading force in the global energy sector. The company’s focus on renewable energy, digital transformation, and sustainable growth ensures its continued success and relevance in an increasingly dynamic market. As Siemens Energy advances its mission to drive the transition to a more sustainable and resilient energy future, it remains a beacon of excellence and leadership in the industry.

0 notes

Text

Case study

Place: A steel plant in Rourkela with production capacity - 4.5 MTPA

Date of Execution: 20th July 2019

Background:

A Steam turbine blower was to be commissioned in a steel plant by a leading EPC company, the pipelines were erected on the site and as per the Standard Operating Procedure listed by the Steel Plant Owner Company the flushing was completed with a single auxiliary pump at 1500 LPM. However, during the trial run of the turbine, the inline lube oil filters would clog very frequently and lead to halted operations.

Problem Statement:

Frequent clogging of inline lube oil filters were hindering the operations and delaying the steam turbine commissioning project

Underlying Issues:

On inspection, a root cause analysis was done and the required rate for effective flushing was calculated as 3500 LPM. The Particle contamination level was also found to be NAS 10. Hence following things were concluded:

1. The rate at which flushing was done was too low and lead to ineffective flushing, leaving a lot of debris and scale inside the pipeline.

2. Absence of a System other than the inline filters to arrest the particles which would come along with the flushing flow.

What Minimac did:

1. The calculated effective rate for flushing was 3500 LPM, but as only 3000 LPM was achievable on-site, the temperature of the fluid was increased by regular heating arrangement to bring down the required flowrate requirement to 2500 LPM.

2. Both the auxiliary pumps were employed for flushing activity and a separate filtration skid was offered which could handle the full flow volume that was getting generated.

3. Duplex type filtration housing on the lube oil return side was also provided to arrest any future debris. Subsequently, turbine governing and Heat Exchanger were also taken online to clean the system in totality.

Result achieved:

We at Minimac Systems Pvt Ltd. provide services Oil Purification, Oil Flushing, Oil Condition Monitoring that helps you reduce downtime and increase machine reliability.

#minimac systems#oil flushing#power#frf#oil & gas#hydraulic oil#minimac#lube oil filter#contamination#hydraulic oil filter#oil condition monitoring#oil dehydration systems#conditionmonitoring#lubrication reliability#lubrication#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#gas turbine market trends#wind turbines#gas turbine services market#steam turbine market share#aircraft micro turbine engines market

0 notes

Text

Green Power Products Available Through Your Utility

If you live in a deregulated electricity market, there are competitive green power products that can be purchased through your utility. Click here for descriptions and links to these products.

Renewable energy comes from natural resources that replenish themselves — wind, sun and water. It’s also known as clean energy.

Sunlight

Sunlight is a renewable resource that’s available worldwide, and unlike fossil fuels and nuclear power, sunlight doesn’t produce greenhouse gases or air pollution when used to generate electricity. It also provides an abundant source of energy, even when clouds roll in.

However, there are challenges with solar green power energy as well—sunlight can be inconsistent and varies in intensity and availability throughout the year. To mitigate these limitations, solar energy plants store some of the electricity they generate in batteries.

Show your sustainability leadership and enroll for as little as $4 a month to match all or a portion of your business electricity use with renewable energy from independent resources right here in Washington state. Find out why businesses like Aslan Brewing, Danger Room Comics and Snapdoodle Toys choose to do their part by using Green Power from PSE.

Geothermal

Geothermal energy comes from the heat of the Earth. It is clean and reliable, and can provide baseload power. It also has the added benefit of being a renewable resource, meaning it won’t run out in our lifetimes.

Geothermal power plants use steam to turn turbines, which generate electricity. The steam then returns to the reservoir and is used for other purposes like heating homes and businesses, greenhouses, and public baths.

Binary geothermal power plants can ramp up and down several times a day, making them a flexible source of energy for the grid. This means they can provide more energy during high demand periods. The working fluid in these plants never touches the surrounding environment chemically or physically, and the only environmental impact is thermal pollution.

Wind

Wind is an abundant renewable energy source that can be used to generate electricity without fossil fuels. It also provides jobs and revenue to rural communities.

Unlike fossil fuels, which damage the environment during production, wind power does not harm wildlife or delicate marine ecosystems. However, wind turbines can cause visual impacts when positioned in the countryside, although designers are working to minimise these effects.

Small wind turbines can be used to produce onsite energy for homes and businesses. Some big corporations like Amazon and Procter & Gamble have already made wind energy purchases to support their operations. There are even plans to develop offshore wind projects.

Biofuels

Biofuels are renewable and reduce greenhouse gas emissions compared with fossil fuels. They are also cost-effective and can boost local economies by providing farmers with another source of income. They are typically produced from a variety of plants, including forestry waste (leaves, bark, twigs and stumps), noncrop plant residues, lignocellulosic biomass waste such as rice straw, and algae.

These renewable biomass resources are converted to liquid, gaseous and other emerging green fuels using biochemical conversion techniques such as alcoholic fermentation or anaerobic digestion. The largest share of liquid biofuels today are ethanol and renewable gasoline. Biomass-based liquefied petroleum gas, sustainable aviation fuel and renewable naphtha are other liquid biofuels that can be used in combination with or instead of petroleum gasoline. Lastly, renewable methane and hydrogen can be generated from these sources as well.

Water

In addition to solar, wind, geothermal and some forms of biomass, green power can also come from hydro. This renewable energy source takes advantage of water’s natural cycle — evaporating, falling as rain or snow, and flowing through rivers and dams – to provide a sustainable way to produce electricity. Unlike fossil fuels and nuclear, it does not emit greenhouse gases or air pollution when burned to produce energy.

As a bonus, increasing energy from renewable sources in water-stressed countries produces significant carbon and water savings. In fact, our most ambitious scenario of achieving net zero emissions — our 2050 goal — shows that reducing water withdrawals for power generation is one of the fastest pathways to a low-carbon future. See how Green Power helps companies like Seattle Chocolate and Danger Room Comics reach their sustainability goals.

0 notes

Text

The Workings of Industrial Steam Boilers: A Detailed Explanation

Industrial steam boilers are the hidden workhorses of many industries. Operating quietly in the background, they produce steam critical for various processes, from manufacturing goods to generating electricity. In this detailed guide, we will explore industrial steam boilers, breaking down intricate concepts into straightforward language to help you understand their importance and functionality.

What is an Industrial Steam Boiler?

Imagine a large pot on a stove, but instead of boiling water for pasta, it’s producing steam for industrial applications. Essentially, that’s what the industrial steam boiler manufacturer and supplier does. It is a specialized vessel designed to heat water and generate steam, which is then utilized for heating, electricity generation, and operating machinery in factories and plants.

How Do Industrial Steam Boilers Work?

The brilliance of industrial steam boilers lies in their ability to convert water into steam using heat. Here’s a simplified breakdown: inside the boiler, there’s a combustion chamber where fuels like natural gas, oil, or coal are burned. This combustion releases heat, which is used to heat water in surrounding pipes or tubes. As the water heats up, it transforms into steam, which is then harnessed for various uses.

Components of an Industrial Steam Boiler

Industrial steam boilers are more than just large kettles; they are intricate machines with several essential components:

Combustion Chamber: This is where the fuel is burned, releasing heat.

Heat Exchanger: Functions as an intermediary, transferring heat from the burning fuel to the water.

Boiler Shell: The robust outer structure that houses all the components.

Steam Drum: Acts as a storage tank for steam, ready for use when needed.

Safety Valves: These act as emergency exits for steam, releasing excess pressure to prevent accidents.

Controls and Instrumentation: The control center of the boiler, monitoring and adjusting operations to ensure smooth functioning.

Types of Industrial Steam Boilers

Industrial steam boilers come in different types, with the two main ones being:

Fire Tube Boilers: These boilers have water-filled tubes heated by hot gases passing through them, suitable for smaller operations.

Water Tube Boilers: In these boilers, water flows through tubes surrounded by hot gases, ideal for larger-scale applications like power plants.

Applications of Industrial Steam Boilers

These versatile machines are used across various industries for:

Heating: Warming buildings, heating water, and powering radiant heating systems.

Power Generation: Producing electricity by turning turbines with steam.

Manufacturing: Providing steam for production processes in everything from car manufacturing to garment production.

Food Processing: Sterilizing equipment, cooking food, and pasteurizing milk and juices.

Pharmaceuticals: Ensuring cleanliness and sterilization in pharmaceutical manufacturing.

Importance of Industrial Steam Boilers

Industrial steam boilers are crucial to modern industry, driving numerous processes that keep our world operational. They enhance productivity, maintain product quality, and reduce environmental impact through efficient use of various fuels and technologies.

It's essential to select a reliable manufacturer to ensure the quality and efficiency of industrial steam boilers. If you’re searching for a dependable steam boiler manufacturer in Dubai, consider Ross Thermal. Their dedication to innovation and customer satisfaction distinguishes them in the market.

Conclusion

Industrial steam boilers might seem complex, but their fundamental purpose is to convert water into steam to power various industrial processes. By understanding their basic principles and components, we can better appreciate the significant role they play in our daily lives and industries. With advancing technology, industrial steam boilers will continue to evolve, becoming even more efficient and sustainable for the future.

#reliable steam boiler manufacturer in Dubai#steam boiler manufacturer in Dubai#steamboilers#steam boiler manufacturer#Industrial Steam Boiler

0 notes

Text

Monel Market Size, Share, Analysis, Growth, Key Players, Trend and Forecast to 2034

In 2023, the global Monel market reached around 21 thousand tonnes and is expected to grow at a CAGR of 3.4% through 2034.

Introduction:

Monel, a group of nickel-copper alloys, is renowned for its outstanding corrosion resistance, high strength, and durability. These properties make it a preferred material for various demanding applications. In South Africa, the Monel Market is poised for growth as industries seek high-performance materials to enhance their operations. This article explores the dynamics of the Monel Market in South Africa, focusing on its applications, market trends, and impact on industrial development.

Click Here: https://www.chemanalyst.com/industry-report/monel-market-4171

Industrial Applications and Demand:

Monel alloys are utilized across a wide range of industries, including marine, chemical processing, oil and gas, aerospace, and power generation. Their unique properties make them ideal for applications requiring robustness, longevity, and resistance to harsh environments. The industrial landscape of South Africa, characterized by significant activity in these sectors, drives the demand for Monel alloys.

Marine Industry:

In the marine industry, Monel alloys are used for components such as propeller shafts, pump impellers, and seawater valves due to their excellent resistance to saltwater corrosion. As South Africa continues to develop its maritime infrastructure and enhance its naval capabilities, the demand for Monel alloys in shipbuilding and offshore engineering is expected to increase.

Chemical Processing:

Monel's resistance to a wide range of corrosive environments makes it ideal for the chemical processing industry. It is used in equipment such as heat exchangers, reactors, and piping systems that handle aggressive chemicals. With South Africa's chemical industry focused on expanding production capacities and ensuring operational safety, the need for reliable materials like Monel is on the rise.

Oil and Gas Sector:

The oil and gas sector requires materials that can withstand extreme conditions and resist corrosion from hydrocarbons and seawater. Monel alloys are employed in various components, including valves, pumps, and piping systems. As South Africa seeks to enhance its oil and gas exploration and production activities, the Monel Market is poised for growth, driven by the need for durable and high-performance materials.

Aerospace and Defense:

In the aerospace and defense sectors, Monel alloys are used for components that require high strength and corrosion resistance, such as turbine blades, exhaust systems, and fuel tanks. As South Africa aims to bolster its aerospace and defense capabilities, the demand for advanced materials like Monel is expected to grow, supporting the development of more resilient and efficient systems.

Click Here: https://www.chemanalyst.com/industry-report/monel-market-4171

Power Generation:

Monel alloys are used in power generation equipment, including nuclear reactors and steam generators, due to their ability to withstand high temperatures and corrosive environments. With South Africa investing in expanding and modernizing its power infrastructure, the market for Monel alloys in this sector is set to expand, driven by the need for reliable and efficient materials.

Market Trends and Growth Drivers:

The Monel Market in South Africa is influenced by several trends and growth drivers. These include the increasing demand for high-performance and corrosion-resistant materials, advancements in manufacturing technologies, and the push for sustainable and eco-friendly solutions. The growing focus on infrastructure development, energy efficiency, and industrial modernization also drives the adoption of Monel alloys across various sectors.

Significant players in the Global Monel market are Special Metals Corporation, Alleima, Deutsche Nickel GmbH, VDM Metals GmbH, Alloy Wire International, Ulbrich Stainless Steels and Special Metals, AEETHER, Raajratna, Central Wire Industries, Sandmeyer Steel Company, ESAB, Elektrisola, Radcliff Wire, and Others.

Challenges and Strategies:

Despite its advantages, the Monel Market in South Africa faces challenges such as high production costs, competition from alternative materials, and supply chain disruptions. Addressing these challenges requires strategic initiatives such as investing in research and development, enhancing local production capabilities, and fostering collaborations with global suppliers. These efforts can help stabilize supply, reduce costs, and drive innovation in the market.

Conclusion:

The Monel Market in South Africa represents a crucial component in advancing industrial performance and resilience. With its exceptional properties and wide-ranging applications, Monel alloys support key sectors like marine, chemical processing, oil and gas, aerospace, and power generation. By leveraging market opportunities, addressing challenges, and fostering innovation, South Africa can harness the full potential of the Monel Market, driving industrial growth, technological advancement, and economic development in the region.

0 notes

Text

Inconel 625 scrap buyers

Inconel 625 is a nickel-chromium superalloy widely known for its outstanding strength, resistance to oxidation, and corrosion in extreme environments. Developed in the 1960s, this alloy has become a crucial material in industries ranging from aerospace to chemical processing. Due to its exceptional properties, Inconel 625 is also highly sought after in the metal recycling industry, with scrap material playing a vital role in reducing waste and preserving natural resources. This article explores the significance of Inconel 625 scrap, its recycling potential, and its economic impact.

Properties and Composition of Inconel 625

Inconel 625 is an alloy primarily composed of nickel (58% minimum), chromium (20-23%), molybdenum (8-10%), and niobium (3-4%). These elements, along with trace amounts of iron, carbon, and silicon, give the material its superior mechanical strength and thermal stability. The alloy’s ability to maintain integrity under extreme temperatures, up to 980°C (1800°F), makes it a popular choice for harsh environments such as offshore drilling, gas turbines, and heat exchangers.

Uses and Applications of Inconel 625

Inconel 625 is widely used in a variety of industries due to its resistance to chemical degradation and heat. Its main applications include:

Aerospace: Components for jet engines, exhaust systems, and turbine seals.

Marine Engineering: Parts in saltwater environments where corrosion resistance is essential.

Chemical Processing: Equipment for handling highly corrosive materials like acids.

Nuclear and Power Generation: Used in reactor cores, steam generators, and heat recovery systems.

Given these demanding applications, Inconel 625 is often replaced or discarded as parts wear out, creating a steady stream of scrap material.

Recycling of Inconel 625 Scrap

Recycling Inconel 625 scrap is a highly efficient way of reusing valuable metals, especially nickel and chromium. The recycling process typically involves:

Collection and Sorting: Scrap Inconel 625 is collected from industrial sources, often in the form of used machinery parts, offcuts from manufacturing, or defective components. It is then sorted to remove contaminants such as oil, dirt, and other metals.

Melting and Refining: The scrap is melted in a vacuum or an inert atmosphere to prevent contamination during the recycling process. Advanced refining techniques are used to maintain the purity of the alloy.

Recasting and Forming: Once the alloy is purified, it is recast into new forms such as bars, plates, or rods, which can then be used in manufacturing.

The recycling process not only conserves resources but also significantly reduces the environmental impact of mining and metal production. Nickel mining, in particular, is energy-intensive and generates large amounts of waste. By recycling Inconel 625, industries can reduce the demand for newly mined nickel, chromium, and molybdenum, cutting down greenhouse gas emissions and the environmental footprint of metal production.

Economic Impact of Inconel 625 Scrap

The value of Inconel 625 scrap is primarily driven by the high price of nickel, one of its main components. Market fluctuations in nickel prices, often influenced by global supply and demand, can directly impact the price of scrap. In general, clean, uncontaminated Inconel 625 scrap fetches a high price in the recycling market. As industries increasingly seek sustainable materials, demand for high-quality scrap metals has grown, providing economic incentives for recycling programs.

In addition to environmental benefits, Inconel 625 scrap contributes to cost savings in manufacturing. Since recycled metal is often cheaper than newly produced material, manufacturers that utilize recycled Inconel 625 can reduce production costs while still benefiting from the alloy's unique properties.

Challenges in Inconel 625 Scrap Recycling

Despite the numerous advantages, there are challenges in recycling Inconel 625 scrap. These include:

Contamination: Scrap material must be thoroughly cleaned and sorted, as contamination with other metals or substances can reduce the quality of the recycled alloy.

Technological Requirements: The recycling process requires sophisticated technology to maintain the alloy's composition and performance characteristics.

Market Volatility: Prices for nickel and other metals in Inconel 625 can fluctuate, affecting the profitability of recycling operations.

Future Outlook for Inconel 625 Scrap Recycling

The future of Inconel 625 scrap recycling is promising, especially as industries continue to move toward more sustainable practices. With advancements in recycling technologies, the process is becoming more efficient and cost-effective. Additionally, global efforts to reduce carbon emissions and conserve natural resources are likely to drive further demand for recycled superalloys like Inconel 625.

As the global demand for high-performance materials continues to grow, Inconel 625 scrap will remain a valuable resource. Its role in reducing the need for newly mined metals, combined with the economic benefits of recycling, underscores the importance of continued investment in recycling infrastructure and technologies.

0 notes