#Subsea engineering

Explore tagged Tumblr posts

Note

🌻

Fun fact: The emergency return time from the moon is shorter than the emergency return time from 1000ft/304m saturation diving!

An emergency return from lunar orbit is approx 4 days. But to safely surface from a saturation dive of that depth you need to undergo safe decompression for 11 days or very very bad things happen to practically all your tissues. (I can talk about the bends too if you want!)

The rule of thumb (actual dive plans don't use rules of thumb, but it's a good rough estimate for our purposes) for deep saturation diving is 24 hours deco per 100ft plus 24 hours safety margin, so a 1000ft dive would mean you need 11 days of decompression! and deepest dive recorded was 1752ft, so that's not even as bad as it gets!

The problem with this is that it's not safe for you to leave the hyperbaric chamber or for anyone to enter (rapid compression is ALSO bad) so if you have a medical emergency or something that necessitates an emergency surfacing no one can help you.

Deep sea operations are absolutely fascinating! the logistics of decompression are so difficult that deep sea operations are done at ambient pressure so that there's no decompression at the start and end of shift, only one really long one at the end of a work rotation. It's a bit like working on a space station but with the pressure going in the opposite direction.

10 notes

·

View notes

Text

My husband, who was in the UN peacekeeping force and has worked with explosives most of his life, agrees I’m being really brave about having the flu 🤒

#his resume sounds made up#military#lumberjack#coal mine#demolition specialist#subsea explosions engineer#it’s ridiculous

6 notes

·

View notes

Text

Navigating the Future of Subsea Engineering: A Deep Dive into Innovation and Expertise

In the dynamic world of underwater exploration and technology, Sea Engineering stands at the forefront, driving innovation and ensuring the safe and efficient operation of subsea systems. Our work, rooted in meticulous design and engineering excellence, plays a crucial role in the advancement of subsea equipment and diving systems. read full post....

1 note

·

View note

Text

Offshore Decommissioning: Ensuring Safety and Environmental Protection as Assets Reach the End

Regulatory Framework for Offshore Asset Removal One of the first tasks when an offshore oil or gas asset reaches the end of its productive life is deciding on the appropriate decommissioning plan. International regulations provide guidelines on asset removal and seabed clearance to minimize environmental impacts and ensure worker safety. The U.K. Offshore Petroleum Activities (Decommissioning of Offshore Installations and Pipelines) Regulations 2005 requires asset owners to submit a detailed decommissioning program outlining proposed removal timelines and methods. Similarly, regulations in other offshore jurisdictions like Norway and the U.S. Gulf of Mexico mandate assessing removal versus in-place decommissioning options and developing plans to address well plugging and seabed remediation. Regulators thoroughly review proposed decommissioning scopes to ensure full compliance with global safety and environmental standards before approving projects. Engineering Challenges of Removal Operations Physically dismantling and removing large, complex offshore structures presents formidable engineering challenges. Assets may weigh thousands of tons and require meticulous preparation before pieces can be sectioned and lifted. Mobile offshore drilling units (MODUs) like jack-up rigs usually follow a sequence of legs removal, topsides separation and piece-small dismantling over multiple offshore campaigns. For fixed platforms, engineers first separate and extract valuable equipment while simultaneously making cuts at strategic weak points designed for demolition. Specialty vessels then carefully hoist massive steel sections or large pre-assembled pieces for transfer to onshore disposal or recycling sites. Harsh weather conditions and remote offshore locations increase project complexity, requiring multi-phase operations over several months or years to fully carry out decommissioning scopes. Environmental Protection Measures During Decommissioning Due to the potential for disturbing subsurface environments and releasing pollutants, Offshore Decommissioning activates stringent safety protocols and environmental safeguards. Project teams install protective booms, conduct seabed surveys and continuously monitor for hydrocarbon leaks and accidental spills. Cutting and blasting operations undergo extensive risk assessments and utilize techniques like hydraulic sheer cuts that minimize underwater noise and dispersion of debris. Waste streams get properly categorized as hazardous or non-hazardous for disposal through approved routes. Long-term monitoring also examines any ongoing impacts on benthic habitats or marine life from structure removal activities. Proactive planning ensures decommissioning projects meet global standards to restore offshore sites and protect surrounding ecosystems. Get more insights on Offshore Decommissioning

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

#Offshore Decommissioning#Oil And Gas#Dismantling#Marine Engineering#Environmental Impact#Energy Transition#Subsea#Platform Removal

0 notes

Text

The ballistic missile hit the Rubymar on the evening of February 18. For months, the cargo ship had been shuttling around the Arabian Sea, uneventfully calling at local ports. But now, taking on water in the bottleneck of the Bab-el-Mandeb Strait, its two dozen crew issued an urgent call for help and prepared to abandon ship.

Over the next two weeks—while the crew were ashore—the “ghost ship” took on a life of its own. Carried by currents and pushed along by the wind, the 171-meter-long, 27-meter-wide Rubymar drifted approximately 30 nautical miles north, where it finally sank—becoming the most high-profile wreckage during a months-long barrage of missiles and drones launched by Iranian-backed Houthi rebels in Yemen. The attacks have upended global shipping.

But the Rubymar wasn’t the only casualty. During its final journey, three internet cables laid on the seafloor in the Bab-el-Mandeb Strait were damaged. The drop in connectivity impacted millions of people, from nearby East Africa to thousands of miles away in Vietnam. It’s believed the ship’s trailing anchor may have broken the cables while it drifted. The Rubymar also took 21,000 metric tons of fertilizer to its watery grave—a potential environmental disaster in waiting.

An analysis from WIRED—based on satellite imagery, interviews with maritime experts, and new internet connectivity data showing the cables went offline within minutes of each other—tracks the last movements of the doomed ship. While our analysis cannot definitively show that the anchor caused the damage to the crucial internet cables—that can only be determined by an upcoming repair mission—multiple experts conclude it is the most likely scenario.

The damage to the internet cables comes when the security of subsea infrastructure—including internet cables and energy pipelines—has catapulted up countries’ priorities. Politicians have become increasingly concerned about the critical infrastructure since the start of the Russia-Ukraine war in February 2022 and a subsequent string of potential sabotage, including the Nord Stream pipeline explosions. As Houthi weapons keep hitting ships in the Red Sea region, there are worries the Rubymar may not be the last shipwreck.

The Rubymar’s official trail goes cold on February 18. At 8 pm local time, reports emerged that a ship in the Bab-el-Mandeb Strait, which is also known as the Gate of Tears or the Gate of Grief, had been attacked. Two anti-ship ballistic missiles were fired from “Iranian-backed Houthi terrorist-controlled areas of Yemen,” US Central Command said. Ninety minutes after the warnings arrived, at around 9:30 pm, the Rubymar broadcast its final location using the automatic identification system (AIS), a GPS-like positioning system used to track ships.

As water started pouring into the hull, engine room, and machinery room, the crew’s distress call was answered by the Lobivia—a nearby container ship—and a US-led coalition warship. By 1:57 am on February 19, the crew was reported safe. That afternoon, the 11 Syrians, six Egyptians, three Indians, and four Filipinos who were on board arrived at the Port of Djibouti. “We do not know the coordinates of Rubymar,” Djibouti’s port authority posted on X.

Satellite images picked up the Rubymar, its path illuminated by an oil slick, two days later, on February 20. Although the crew dropped the ship’s anchor during the rescue, the ship drifted north, further up the strait in the direction of the Red Sea.

For three days, satellite photos show, the vessel largely stayed in place thanks to low winds and weak currents. Then, on February 22, satellite images show peculiar circular wave patterns hitting the ship, as seen in the image below. One former naval intelligence analyst familiar with the images, who asked not to be named for safety reasons, says this could be a sign the anchor may have come loose. One image, they say, appears to show an unidentified object, which could be a small boat, nearby.

Both the wind and currents picked up on February 23, when the ship began drifting for a second time, says Robert Parkington, an intelligence analyst with geospatial analysis firm Geollect. “As wind increases, as current increases, that chance for movement gets so much higher,” says Parkington, who monitored the Rubymar’s movements with data from satellite technology firm Spire Global. “Even a small breeze can have an impact on where the vessel’s moving.”

More than 550 internet cables run along the ocean floors and connect the world. They link continents and economies, beaming everything from Zoom calls to financial transactions every millisecond. Twelve of the cables run through the Bab-el-Mandeb Strait, says Alan Mauldin, research director at telecom research firm TeleGeography. “These cables vary massively in their age, also in their capacities,” Mauldin explains. The region is a crucial, but vulnerable, choke point.

While the Rubymar was drifting, three cables were damaged: the Seacom/Tata cable, a 15,000-kilometer-long wire running the length of East Africa and also connecting it to India; the Asia Africa Europe-1 (AAE-1), which snakes 25,000 kilometers and links Europe to East Asia; and the Europe India Gateway (EIG), made of 15,000 kilometers of cable and joining India with the United Kingdom.

The Seacom cable went down at 9:46 am on February 24, according to new analysis shared exclusively with WIRED by Doug Madory, director of internet analysis at the web monitoring firm Kentik. Five minutes later, at around 9:51 am, the AAE-1 cable dropped offline. Madory says the third damaged cable, EIG, was already mostly offline following a separate fault elsewhere. A telecom industry notice seen by WIRED confirms the three faults and says this was the EIG’s second. The notice says the damage is located around 30 kilometers away from where the cables land in Djibouti and are at depths of around 150 meters.

To determine when the cables lost connectivity, Madory examined internet traffic and routing data from multiple networks. For instance, a network linked to Equity Bank Tanzania, the analysis shows, lost connectivity from the Seacom cable; moments later, it was impacted by the AAE-1 damage. The two clusters of outages impacted countries in East Africa, including Tanzania, Kenya, Uganda, and Mozambique, Madory says. But they also had an impact thousands of miles away in Vietnam, Thailand, and Singapore. “The loss of these submarine cables disrupted internet service for millions of people,” he says. “While service providers in the affected countries have shifted to using the remaining cables, there exists a loss of overall capacity.” The analysis matches when the Seacom cable went offline, says Prenesh Padayachee, the company’s chief digital officer. Both AAE and EIG cables are owned by consortiums of companies, which did not respond to requests for comment.

The telecom industry builds backups into its systems to account for disruptions—and the approach mostly works. When one cable goes offline, traffic is sent via other routes. “Connectivity just went away,” says Thomas King, the chief technology officer of German-based internet exchange DE-CIX, which used the AAE-1 cables. “The issue was detected automatically. Rerouting happens also automatically,” King says. Other firms sent data on different paths around the world.

In the days after damage to the cables first emerged, one unconfirmed press report claimed Houthi rebels could have sabotaged the cables. There has been no public evidence to support this. Farzin Nadimi, a senior fellow at the Washington Institute think tank who has been monitoring the region, says it is most likely that the Rubymar damaged the cables, but Houthi sabotage should not be entirely ruled out, as “highly trained” divers could reach the cables’ depths. Telecom firms have reported fears about Houthi damage to cables, while Houthi spokespeople have repeatedly denied responsibility for the disruptions.

“We don’t even know if the cable is fully broken yet,” Padayachee says. “All we know is that the cable is damaged to a level where we’ve lost comms.” It could have been cut, or even dragged along the seabed and bent so light signals cannot pass through the cable, he says.

Many in the marine and cable industry have turned toward the Rubymar’s drift as the likely cause for the outage. Padayachee says it is the most “plausible” scenario given the ship’s predicted drifting speed. “If you work out the distance between the two cables that roughly relates to the same sort of timeframe as to when one cable will be affected to when the other cable will be affected,” the timing makes sense, he says, adding that the cables are 700 to 1,000 meters apart.

Anchor damage, alongside earthquakes and landslides, is one of the most common ways subsea internet cables are disrupted. For instance, multiple cables in the Red Sea region were damaged by a ship dragging its anchor in 2012. There are also several types of anchor, explain William Coombs and Michael Brown, professors at Durham University and the University of Dundee, respectively, who are researching the dynamics of anchors and how they can damage underwater cables. Some anchors sit on the seabed while others dig into the ground, they say. “If the soil type is not right, and the cable has quite shallow burial or it is on the seabed, you are going to catch it if your anchor starts to drag,” Brown says.

“Considering the timings of when outages were reported, considering the rough location of where those cables are known to be, and considering where we believe to be the location of the Rubymar, I would say that there is a likely possibility that the anchor did cause the damage,” says Parkington of Geollect.

The Rubymar finally sank on March 2. Videos reportedly taken inside the ship, gathered by Saudi state-owned news organization Al Arabiya English, show water gushing into the ship after the missile strike. As the Rubymar took on more water and partially submerged, experts say, its drifting likely slowed and eventually brought it to a complete stop.

While the ship has finished its journey, the three internet cables will remain offline for some time. Padayachee, from Seacom, says that the Yemeni government is likely to approve permits for the company’s repair plans in the next couple of weeks, with repairs to all three damaged cables possibly starting later in April.

Padayachee says that additional security measures are being put in place for the operation, but the repair work itself should be relatively straightforward. The repairs are taking place in water only a couple of hundred meters deep—shallow compared to other cases where cables are more than a mile deep. When the cables are pulled out of the water by the repair crew, it should be possible to say whether the cuts were caused by the anchor or deliberately.

The Rubymar presents one potential final challenge: Padayachee says the location of the cable damage is believed to be around one or two miles away from where the ship sank. “It doesn’t look like it will affect anything in the repair operation,” he says. “It could change by the time they get there: The vessel may have moved or, in fact, the vessel may have broken up and parts of it moved around.” The US Central Command has said the Rubymar also presents a “subsurface impact risk to other ships.”

The Houthi’s missile launches, meanwhile, don’t look like they will stop any time soon. Other ships have been damaged; lives have been lost, and those factors will impact repairs. “It's not something you usually see: trying to have a cable ship into those waters, recover the cable, make a repair, and then be able to return to port. It's a long process. It’s risky,” says Mauldin, from TeleGeography. The risk, for other internet cables, is a repeat of the Rubymar. “It is not out of the question,” Madory concludes in his analysis, “that we could have another vessel, struck by a missile, inadvertently cut another submarine cable.”

16 notes

·

View notes

Text

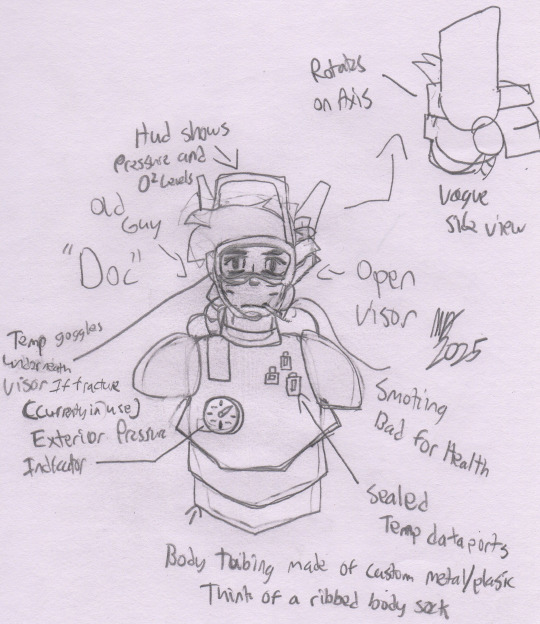

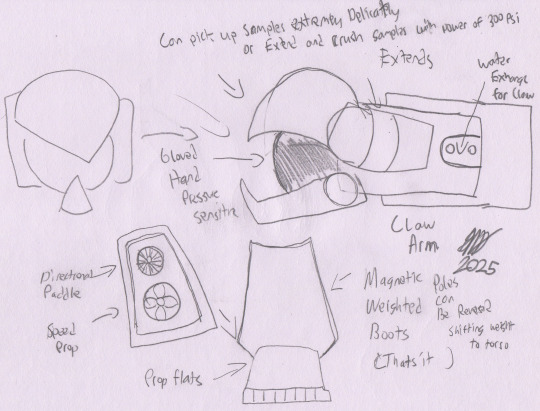

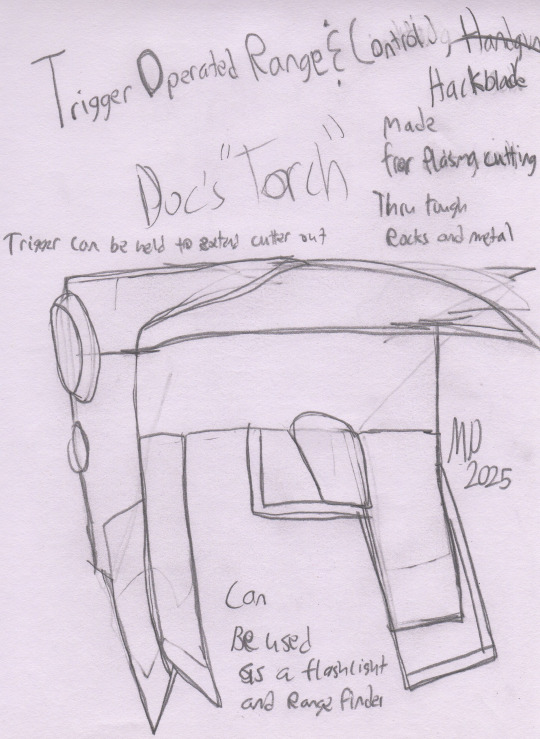

Project update #2!

Project update 2! Meet Doc, a 30-40s single uncle with a niece as his only family, brilliant and naïve, he has his doctorate in Marine Biology, Archeology, and is also a subsea engineer on the side. Here's some pages detailing his gear. What does the sea have in store for his diving, fame or death? We'll find out soon, first he needs to know what HE wants, knowledge or a payout?

#original character#myart#oc#trans artist#ocs#original project#subsea#tech wear#deep sea#secret project#art#blueprint#ongoing project

3 notes

·

View notes

Text

The funniest thing I learned while answering that Yuno ask is Umbilical cords being used for paternity tests but only after the child is born.

It's funny to think she's just been flaunting that with her first trial song being titled Umbilical and her second song having this line,

"Hooked up till the morning to this sweet “Umbilical Cable”."

Which is completely different from the umbilical cord and actually a cable that supplies oxygen to divers but has other uses as well.

So the first time, she's just describing the process that led to a, "You are not the father!" The second time, she is literally describing a feature needed for something to function.

Springer Nature

In general, umbilical cable is a kind of integrated functional structure, whose structure is similar to a baby’s helically wound umbilical cord which is widely used in aerospace field (such as between the launch pad and the vehicle or between the space suit and the vehicle), diving (such as the umbilical cable that supplies oxygen for diving suits), and ocean engineering (such as applications to ROV underwater robot and subsea production systems).

Yeah I started this to go hey isn't funny that this thing she brings up a lot kind of fucked her over in the end. So I've been imagine her just bringing it up with bitter hatred like I fucking hate these things. Then I realized she's just bringing up a completely different apparatus in Tear Drop which if destroyed could lead to a person suffocating.

Huh Haruka and Yuno parallels be like,

"Suffocating someone all by yourself tonight?" - "Crimes of passion and asphyxiation just go so well together."

Though in Undercover, it says her lord's being pulled, meaning her story just involves both an umbilical cord and an umbilical cable since they put that shot in quotation marks. The Milgram team and Deco specifically are so funny for this lyric choice.

4 notes

·

View notes

Text

ERW Pipes in Oil and Gas Industry: Key Roles and Market Trends

A stable and efficient infrastructure is crucial for the transportation of hydrocarbons in the oil and gas industry. Electric Resistance Welded (ERW) pipes are a critical component that assumes a central role in this system. The pipes in question are renowned for their multifunctionality, resilience, and economical nature, rendering them a widely favoured option for diverse applications within the oil and gas industry. The strength of seamless connectivity - Choose ERW Pipes offered by Tube Trading Co. – an excellent ERW Pipe Supplier in Gujarat for your critical applications.

This blog examines the significant functions of ERW pipes within the industry and investigates the most recent market trends pertaining to these important components.

What are ERW Pipes?

ERW pipes are a variant of steel pipes that are manufactured through the application of a high-frequency electrical current along the edges of the steel strip or coil. The flow of electrical current produces thermal energy, resulting in the fusion of the adjacent edges and the creation of a connection without any visible seams. ERW pipes are extensively utilised in the oil and gas sector owing to their exceptional mechanical characteristics, rendering them appropriate for many applications in both onshore and offshore environments.

Key Roles of ERW Pipes in the Oil and Gas Industry:

Exploration and Production:

ERW pipes are widely employed in drilling activities within the upstream portion of the oil and gas industry. The primary function of these pipes is to act as protective casings for the wellbore, thereby preserving its structural integrity and mitigating the risk of collapse during the drilling process. ERW pipes are utilised in well-completion operations to enhance the effective extraction of hydrocarbons.

Transportation:

Transportation plays a crucial role in the hydrocarbon industry as it facilitates the movement of extracted hydrocarbons from wells to processing units or refineries. ERW pipes, known for their exceptional strength and weldability, serve as the fundamental component of pipelines utilised for the extensive transit of oil and gas. They facilitate the uninterrupted transportation of hydrocarbons from the point of extraction to the ultimate consumers.

Distribution and Storage:

Electric resistance welded (ERW) pipes are of significant importance in the midstream sector, since they are utilised for the purpose of distributing and storing refined fuels, including petrol, diesel and natural gas. The utilisation of these pipes is crucial to the establishment of distribution networks and terminals, facilitating the effective transportation of energy products to end-users.

Offshore Applications:

ERW pipes are commonly utilised in offshore drilling and production due to their notable resilience in challenging marine environments. These components find application in the construction of platforms, risers, and subsea pipelines, offering enhanced stability and dependability in demanding offshore environments.

Experience efficiency in every weld. Order precision-engineered ERW Pipes offered by Tube Trading Co. – a renowned ERW Pipe Provider in Gujarat!

Market Trends of ERW Pipes in the Oil and Gas Industry:

Increasing Demand:

The increasing global demand for electric resistance welded (ERW) pipes within the oil and gas sector is driven by the ongoing growth of exploration and production operations, with a particular emphasis on emerging economies. The consistent expansion in energy consumption and the imperative for novel infrastructure are significant factors that contribute to the heightened adoption of Electric Resistance Welded (ERW) pipes.

Technological Advancements:

Technological advancements in the field of ERW pipes are being pursued by manufacturers through ongoing investments in research and development, with the aim of improving their inherent qualities. The utilisation of advanced welding methodologies and enhanced steel compositions has resulted in the development of pipes exhibiting elevated levels of strength, corrosion resistance, and durability. Consequently, these pipes have emerged as highly suitable for deployment in demanding oil and gas applications.

Environmental Considerations:

The increasing focus of the industry on sustainability and environmental preservation has led to a transition towards more environmentally friendly practices. ERW pipes, due to their environmentally friendly nature and recyclability, are very compatible with these objectives, hence establishing themselves as a favoured option for enterprises that prioritise environmental consciousness.

Focus on Pipeline Safety:

The issue of pipeline safety has garnered significant attention due to worries surrounding leaks and ruptures, resulting in the implementation of more stringent regulations and standards. The superior weld quality and consistency of ERW pipes result in a decreased likelihood of failures, hence enhancing the safety of pipelines.

Market Consolidation:

The ERW pipe market is currently through a process of consolidation, wherein prominent industry participants are actively engaging in mergers and acquisitions to enhance their range of products and increase their market reach. The objective of this trend is to address the increasing demand and sustain a competitive advantage within the sector.

Final Thoughts:

ERW pipes are of significant importance within the oil and gas sector, as they fulfil crucial functions throughout a range of activities spanning from exploration to distribution. The indispensability of these components in the industry's infrastructure can be attributed to their versatility, durability, and cost-effectiveness.

The anticipated increase in the utilisation of ERW pipes is attributed to the escalating demand for energy and the heightened significance of environmental considerations. The continuous endeavours of manufacturers to innovate and enhance these pipes will inevitably result in the development of more effective and environmentally friendly solutions, thereby strengthening their significance as a crucial element within the ever-evolving realm of oil and gas transportation and distribution. Seamless solutions for your piping needs – Partner with Tube Trading Co. – the most reliable ERW Pipe Supplier in Gujarat today!

#ERW Pipe Supplier in Gujarat#ERW Pipe Provider in Gujarat#Business#Manufacturer#Steel industry#Steel company#Oil and gas industry#Oil companies#Agriculture industry

6 notes

·

View notes

Text

🔩 Threading in Process | Performance in Every Piece 📍 Ananka Fasteners Pvt. Ltd. In focus: Double-ended studs (Size: 1/2" x 61mm) 📏 Material Grade: B8 Class 2 🛠️ Ready for Roll Threading — a process that enhances strength, accuracy, and surface finish. This is not just a stud — it’s a symbol of our precision-engineered excellence. At Ananka Fasteners, we combine advanced manufacturing with global quality benchmarks. ✅ ISO Certified | Progressing towards Aerospace and API Certifications 🌐 We're not just in India anymore — now proudly operating in the USA and UK. (Details on our profile.) 🎯 Headquartered in India. https://anankafasteners.com/contact-us/

💼 Industries We Serve: * Marine * Oil & Gas * Offshore * Chemical Processing * Subsea * Nuclear * Medical Devices 🔧 Our Capabilities: * Design & Prototyping * Rapid Manufacturing * Custom Coating & Plating 🔩 Our Product Range Includes: * High-performance fasteners * Custom fastener solutions * Precision-engineered components * Specialty alloy products * Corrosion-resistant and non-standard parts * Metric and Imperial sizes We engineer with intent. We manufacture with excellence.

#AnankaFasteners#StudBolts#ThreadRolling#B8Class2#PrecisionMachining hashtag#ISOcertified hashtag#AerospaceFasteners hashtag#OilAndGas hashtag#RollThreading hashtag#CustomFasteners hashtag#ManufacturingIndia hashtag#USA hashtag#UK hashtag#GlobalEngineering#MetricImperial#EngineeringExcellence

0 notes

Text

How Offshore Drilling Services Drive Energy Infrastructure Growth

As the global demand for reliable energy sources intensifies, offshore drilling services play a foundational role in expanding and strengthening the world’s energy infrastructure. From discovering new reserves to supporting long-term production, offshore drilling operations are essential in enabling economic growth, industrial development, and energy security.

At SCOFI, we are proud to provide cutting-edge offshore drilling solutions that not only fuel the world—but also build the infrastructure that keeps it running.

Offshore Drilling: The Engine Behind Energy Development

Offshore reserves account for a significant portion of the world’s oil and gas supply. These operations do more than extract hydrocarbons—they catalyze infrastructure investment in pipelines, ports, storage terminals, refineries, and shipping lanes.

SCOFI’s comprehensive offshore drilling services are a critical first step in this development chain, supporting:

Exploration and appraisal of offshore reserves

Establishment of long-term production platforms

Integration of marine logistics and transport systems

Expansion of onshore support infrastructure

By enabling access to energy beneath the ocean floor, we help lay the foundation for regional and national infrastructure expansion.

Building a Connected Energy Ecosystem

Offshore drilling doesn’t operate in isolation. It directly contributes to the growth of interconnected infrastructure, such as:

Subsea pipelines and flowlines to transport oil and gas from offshore rigs to processing facilities

Floating production units (FPSOs) and platform infrastructure that serve as offshore energy hubs

Onshore facilities including terminals, processing plants, and export depots

Workforce housing, ports, and roads built to support offshore operations

With each drilling project SCOFI undertakes, we not only unlock energy—but also help create the physical infrastructure needed to sustain long-term energy production and delivery.

SCOFI’s Role in Infrastructure-Driven Growth

As a trusted offshore services provider, SCOFI is uniquely positioned to support the complete offshore development lifecycle—from exploration to infrastructure integration. Our services include:

✅ Deepwater and shallow water drilling

✅ Well intervention, coiled tubing, and completion

✅ Engineering and project management consulting

✅ Offshore logistics and marine support

✅ HSE compliance and environmental risk mitigation

By combining drilling expertise with strategic logistics and operational foresight, we help clients scale infrastructure faster and more efficiently.

Advancing Sustainability Through Smart Development

Modern offshore projects must also align with environmental and social sustainability goals. SCOFI supports this through:

Low-impact drilling and emissions-reduction technologies

Real-time environmental monitoring systems

Safe decommissioning and site restoration practices

Supporting local workforce development and infrastructure investment

In this way, SCOFI’s offshore drilling services not only grow infrastructure—they help build responsible, future-ready energy systems.

Conclusion

Offshore drilling is more than a method of extraction—it’s a catalyst for infrastructure growth, energy access, and global economic development. Through innovative, reliable offshore drilling services, SCOFI helps shape the energy networks that power nations and industries.

0 notes

Text

Reliable Downhole Pressure Sensor in UAE for Extreme Oilfield Conditions

Looking for accurate pressure monitoring solutions for oil and gas operations? A downhole pressure sensor in UAE is essential for high-performance drilling, reservoir management, and geothermal exploration. Built to withstand extreme pressure and temperature, these sensors deliver real-time, reliable data from deep wells and harsh environments. Their compact, corrosion-resistant design and high accuracy make them ideal for demanding applications such as managed pressure drilling, artificial lift systems, and subsea operations. Whether you're monitoring well integrity or optimizing production, downhole sensors play a vital role in ensuring safety and efficiency. Explore high-quality, durable options at Telektron, your trusted source for downhole pressure sensor in UAE. Engineered for extreme environments. Built for results.

0 notes

Text

Exploring the Industrial Benefits of Super Duplex and High Nickel Alloys

In today’s complex world of industrial engineering and manufacturing, material performance is key to safety, longevity, and efficiency. Out of all the alloys, we see Super Duplex stainless steels and High-Nickel alloys, which perform very well in terms of mechanical strength, corrosion resistance, and performance in tough environmental settings. These materials are the backbone of what we see in modern-day industrial applications, which traditional materials often can’t perform in.

Understanding Super Duplex Alloys

Super Austenitic and ferritic stainless steel grades are what Super Duplex stainless steels are; they combine the best of the austenitic and ferritic groups. What they do is present very high strength and also great corrosion resistance, which is what they are known for. In terms of composition, UNS S32750 and UNS S32760, which are types of Super Duplex, contain more chromium, molybdenum, and nitrogen as compared to what we see in standard duplex steels.

Super Duplex alloys’ greatest asset is their performance in pitting and crevice corrosion, which they display in chloride-rich environments like that of seawater or chemical processing units. They thus excel in offshore oil and gas fields, desalination plants, heat exchangers, and marine hardware.

In addition to corrosion resistance, what is put forward by Super Duplex steels is their excellent mechanical strength, which in fact is to see that of standard austenitic stainless steels doubled. This, in turn, allows for the use of thinner sections, which in turn reduces material weight and cost without a trade-off in structural integrity. Also, they do very well at withstanding high pressures and temperatures, which in particular does very well in high-stress environments.

Benefits of High Nickel Alloys

High Nickel alloys like Inconel, Hastelloy, Monel, and Incoloy are designed for service in extreme environments. They put on a great show of resistance to oxidation, corrosion, and high temperatures, which in turn makes them a great choice for aerospace, chemical processing, nuclear power, and marine engineering industries.

The large nickel content, which in turn improves the alloy’s performance against chemical attack, in particular from acids, bases, and other corrosive materials. This is a key feature in which other metals may experience great degradation or failure. For example, we see Inconel used in jet engine components for its strength at high temperatures, and Hastelloy, which is put to use in very aggressive chemical plants that require the best in corrosion resistance.

Another key benefit of high-nickel alloys is their thermal stability. They preserve mechanical properties over a wide temperature range, which in turn guarantees long service life and reliable performance in variable thermal conditions.

Industrial Applications

Super Duplex and High Nickel alloys are used in a variety of high-performance sectors:

Oil & Gas: In subsea piping systems, pressure vessels, pumps, and valves which is where strength and corrosion resistance are a must, we see both of these materials.

Chemical Processing: Equipment that deals with acidic or corrosive substances benefits from what these alloys have to offer.

Power Generation: In nuclear and thermal power plants, we see that high-nickel alloys are used for components that bear high temperatures and radiation.

Marine Industry: Super Duplex is a preferred material for boat propellers, seawater cooling systems, and other marine hardware because of its great chloride resistance.

Conclusion

As industries grow in complexity and we see an increase in the demand for more challenging environments, the need for robust, corrosion-resistant, and heat-tolerant materials is on the rise. Super Duplex and High Nickel alloys present the best of what is available in terms of material properties, which in turn guarantee superior performance over the long term in very demanding applications. We see in investment in these materials, which not only improves plant reliability but also reduces maintenance, breaks down inactivity, and as such, is a smart decision for the future of industrial engineering.

#ss 409#410 ss material#s s coil#ss pipe fittings manufacturer in india#stainless steel manufacturers in mumbai#ss 430 stainless steel

0 notes

Text

AI's Transformative Role in Subsea Vehicle Design: An Overview

Subsea vehicle design is transforming remarkably. And AI is playing a decisive role in the evolution. Due to AI, the capabilities of underwater vehicles have increased. read full article.....

1 note

·

View note

Text

How Ship Manufacturing Companies in the UAE Support the Offshore and Energy Sectors

Ship manufacturing companies in UAE are increasingly taking on a vital function in servicing the expansion and viability of energy and offshore operations region-wide. As the global economy demands higher efficiency and production in energy, demand for extremely advanced marine infrastructure is increasing rapidly—and the UAE is centering itself as a world leader in shipping construction and sea logistics.

Thanks to world-class ports, capable engineering resources, and sophisticated facilities, the UAE has built a marine ecosystem that is directly replenishing the offshore oil, gas, and renewable energy industries. Local firms such as VU Marine are spearheading this growth, constructing vessels and providing services optimized for extreme offshore conditions.

Strategic Value of Ship Building Companies in UAE ship building companies in UAE are favored by the country's position at the intersection of global shipping lanes and offshore oil-rich deposits. This makes the UAE ideally positioned to accommodate the full offshore supply chain—energy exploration and platform construction down through vessel supply and crew transportation.

Over the years, investment in maritime infrastructure, dry docks, fabrication facilities, and innovation centres has made it possible for UAE shipbuilders to design, construct, and deliver vessels capable of addressing the sophisticated requirements of offshore and subsea operations. These include workboats and tugboats, jack-up barges, landing craft, and accommodation modules.

For the energy industry operators offshore, access to such assets locally provides speed, reliability, and less operational risk. Rather than importing vessels or depending on far-reaching supply chains, energy operators can work directly with builders in the UAE to tailor vessels compatible with their very specific operating needs.

Specialized Vessels for Offshore Operations Offshore oil activities rely on a vast array of marine support vessels. They form the backbone of the day-to-day operations of oil and gas platforms, wind farms, and subsea cable installations. They consist of:

Crew Boats: Built to take workers back and forth from shore bases to offshore platforms rapidly and securely.

Platform Supply Vessels (PSVs): Bringing fuel, tools, equipment, and other materials to offshore rigs.

Anchor Handling Tug Supply Vessels (AHTS): For anchor handling on oil rigs and towing of heavy offshore installations.

Barges and Landing Crafts: Carrying materials and vehicles between the ports and distant project locations.

Accommodation Barges: Accommodating offshore crew during project work or servicing.

The UAE shipbuilding sector can design and build all of these vessel types with specialized features to meet operational, environmental requirements.

The Importance of UAE Marine Service Providers In addition to vessel building, marine service providers in UAE provide essential assistance during the life cycle of a vessel. They provide repair, maintenance, retrofitting, system upgrades, inspection, and technical advisory services. This assistance helps offshore operators achieve uptime, meet global safety standards, and prolong the life of their marine fleets.

Dry dock facilities throughout the UAE service everything from hull maintenance and engine overhaul to extensive structural alterations and fuel system upgrades. Such services are particularly crucial for those ships involved in harsh offshore conditions where saltwater, pressure, and continuous use result in quicker wear and tear.

Since they have access to timely maintenance and quality assurance, offshore businesses are able to ensure continuity in their projects without the attendant delays and costs of acquiring parts or technicians from overseas.

VU Marine: A Key Industry Player VU Marine, established in 2009 and with headquarters in the Hamriyah Free Zone, is now one of the UAE's most proficient builders of offshore and utility ships. The shipbuilder focuses its activities on the construction of steel and aluminum vessels deployed in oil, gas, and marine logistic industries. Its range of products includes tugboats, flat-top barges, crew boats, landing crafts, and modular workboats.

What distinguishes VU Marine is the capability to provide high-performance ships with emphasis on quality, safety, and compliance. The company's internal expertise goes beyond building to include:

Retrofitting and conversion of existing vessels

Project-specific blueprint-based customized fabrication

Quality control and certification preparation

Project management, logistics, and delivery coordination

VU Marine's ships facilitate offshore logistics, material transport, crew operation, and marine infrastructure projects across the UAE and internationally. Their efforts have underpinned major oil and gas developments, port expansions, and marine energy transitions in various regions.

Embracing Technology and Sustainability With the evolving marine industry, UAE shipbuilders are embracing the latest cutting-edge technology to enhance vessel performance, safety, and environmental standards. Most ship building establishments are currently incorporating:

Hybrid power plants for improved fuel efficiency and lower emissions

Improved navigation and automation equipment for safe offshore operations

Sensor-enabled diagnostics for predictive maintenance

Modular design for faster build schedules

There is also increasing emphasis on sustainability. UAE builders are constructing ships that comply with international emissions requirements and are increasingly considering the use of alternative fuels, like hydrogen or biofuels. Retrofitting existing vessels to optimize fuel use and minimize carbon footprints is becoming increasingly popular, particularly for offshore service vessels.

VU Marine is a part of this shift. The company is already producing energy-efficient ship designs and low-emission retrofitting solutions that meet regional environmental and industry standards.

Value Delivered by Top Shipbuilding Companies Top shipbuilding companies in the UAE deliver significant competitive value to the region's offshore and energy industries. Their activities directly support the strategic objectives of the country's energy security, industrial self-sufficiency, and diversification of the economy.

Some of the primary advantages they provide are:

Quick mobilization of fleets in offshore project openings or expansions

Specialized solutions for severe marine environments and shallow water entry

Local spare parts availability and technical assistance, reducing downtime

Export chances for ships designed in the UAE but operating across the world

Employment generation and skill upgradation in ship construction, engineering, and project management

By constructing and keeping up a broad fleet of offshore support vessels locally, the UAE enhances its hydrocarbon infrastructure and acquires resilience against shocks in the international marketplace or logistical dislocation.

Looking Ahead As worldwide energy trends move towards renewables, the UAE shipbuilding industry is gearing up to service new forms of offshore operations. They involve ships for installing offshore wind farms, cabling, and supporting floating solar parks. The knowledge accumulated over decades in oil and gas logistics will now form a crucial part of creating the marine infrastructure of the future.

Conclusion The UAE marine sector has evolved into the backbone of the offshore energy business. Ship manufacturing companies in UAE, like VU Marine, are fueling this process with manufacturing advanced vessels, providing full-cycle services, and driving shipbuilding technology innovation.

From crew transfer vessels to platform supply ships, from barges to repair them to upgrades to fuel systems, the local shipbuilders' input touches every corner of the industry. With speed, precision, and sustainability being their driving values, the UAE shipbuilding community is poised to handle the needs of both current energy solutions and future offshore innovations.

0 notes

Text

United Kingdom Offshore Decommissioning Market is Driven by Rising Market Opportunities

The United Kingdom Offshore Decommissioning Market involves the systematic retirement and removal of redundant offshore oil and gas infrastructure, including platforms, subsea wellheads, pipelines, and support vessels. This service portfolio encompasses engineering surveys, structural dismantling, waste treatment, and site remediation, ensuring environmental compliance and safety. Advantages of these decommissioning solutions include reduced liability for operators, optimized resource recovery, and minimized ecological impact through advanced waste segregation and recycling processes.

The need for robust United Kingdom Offshore Decommissioning Market services has surged in response to aging North Sea assets, stringent regulatory frameworks, and growing emphasis on sustainable end-of-life management. Companies leverage market research and market insights to tailor turnkey offerings that address logistical challenges, cost controls, and stringent decommissioning schedules. In addition to delivering technical expertise, providers integrate digital monitoring and remote operations to enhance project predictability and reduce downtime. The market’s scope extends beyond removal to include well plugging, platform disposal, and marine ecosystem restoration. As more fields reach their end-of-life phase, decommissioning demand is expected to accelerate, offering significant market opportunities for established and emerging players.

The United Kingdom offshore decommissioning market size is expected to reach US$ 2.53 Bn by 2032, from US$ 1.41 Bn in 2025, growing at a CAGR of 8.7% during the forecast period 2025-2032. Key Takeaways

Key players operating in the United Kingdom Offshore Decommissioning Market are:

-Veolia Environnement S.A.

-Derrick Services (UK) Ltd

-Perenco SA

-Ramboll Group A/S

-SAF Gruppen ASA

These market companies command a significant market share through comprehensive decommissioning reports and strategic partnerships. Veolia Environnement S.A. brings extensive waste management capabilities and a strong global footprint, while Derrick Services (UK) Ltd excels in subsea asset recovery and rig dismantling. Perenco SA leverages integrated project execution to minimize costs and downtime. Ramboll Group A/S offers multidisciplinary engineering solutions, blending environmental consulting with offshore dismantling. AF Gruppen ASA focuses on sustainable demolition and recycling, aligned with regional market growth strategies. Collectively, these key players drive innovation in market dynamics, invest in R&D for advanced cutting technologies, and influence industry trends through collaborative pilot projects. Growing demand for offshore decommissioning services in the UK is fueled by an aging asset base and evolving regulatory requirements. Operators seek to optimize business growth by divesting mature fields and reallocating capital towards exploration and renewables. Market analysis highlights that increased scrutiny from regulators, coupled with community expectations for environmental stewardship, mandates comprehensive decommissioning plans. This has led to rising procurement of end-to-end solutions, from plug-and-abandonment to habitat restoration. The shift toward a circular economy underscores recycling and repurposing of structural steel, pipelines, and platforms, unlocking additional market opportunities and revenue streams. Moreover, digital twins, remote inspections, and advanced robotics are reshaping market trends, improving safety metrics and reducing operational costs. As a result, service providers are expanding their portfolios, integrating green technologies, and adopting agile project management to meet the surging demand.

‣ Get More Insights On: United Kingdom Offshore Decommissioning Market

‣ Get this Report in Japanese Language: 英国のオフショア廃止市場

‣ Get this Report in Korean Language: 영국해상해체시장

0 notes

Text

Why the Oil and Gas Industry Still Needs Skilled Professionals in 2025

In spite of rising global emphasis on renewable energy and decarbonization, the oil and gas industry will remain a crucial part of the world's energy supply chain in 2025. Even as the world's transition to clean energy continues to speed up, oil and gas continue to provide more than 50% of the globe's energy demand. With that, the demand for the best professionals in the sector is not only continuing—it's increasing in complexity and significance.

An Ever-Changing Industry With Ever-Changing Needs

The oil and gas industry is experiencing a tremendous transformation fueled by technological innovation, regulatory change, and environmental concerns. Contemporary operations now necessitate professionals with the ability to collaborate with next-generation technologies like AI, machine learning, digital twins, and data analytics. From upstream exploration through downstream refining, the whole value chain necessitates expertise far beyond conventional mechanical and petroleum engineering.

Digital transformation has served to make operations more efficient but has also brought about the need for a new class of professionals—hybrid engineers, data scientists, and managers. This has provided new avenues for young engineers, technicians, and businesspeople to join the industry through specialized training and education.

Workforce Gaps and Aging Experts

A large share of the current oil and gas staff is nearing retirement. Industry reports estimate that almost 50% of existing professionals will retire over the next 5–10 years, leaving behind a critical skills deficiency. Not only must new entrants replace existing gaps, but they must also bring new ideas, technical flexibility, and digital capabilities.

Regrettably, misperceptions regarding the demise of the industry have kept many young professionals from entering oil and gas careers. Nonetheless, the International Energy Agency (IEA) still forecasts excellent demand for natural gas and oil through the 2030s, especially in emerging nations. Thus, it's an even better reason to continue developing a talent pipeline for employees who are prepared to take the helm.

Safety, Compliance, and Sustainability

Compliance with environmental and safety regulations in the energy sector today is tighter than ever before. What businesses require are not only technically capable professionals but also individuals who are highly conversant with health, safety, and environmental (HSE) regulations. Today, operations are sustainable, emissions are minimized, and carbon is managed as core operation strategy.

This generates the need for professionals with knowledge of how to tie safety measures with effective energy practices, and how to assist operations in bringing it in line with international ESG (Environmental, Social, and Governance) targets. Such competence is being increasingly covered in new oil and gas training courses, equipping workers to fulfill the industry's changing mandate.

Global Expansion and Energy Security

Numerous parts of Africa, the Middle East, and Southeast Asia are increasing exploration and production operations to provide domestic energy supplies and lower reliance on imports. They boost energy security but also need a continuous supply of trained staff to operate and maintain new ventures. Skilled people will keep being sought after for jobs from project leadership and drilling activity through logistics and maintenance.

Additionally, offshore petroleum exploration continues to be buoyant, particularly in undeveloped basins. Offshore conditions demand expert expertise in subsea engineering, marine safety, and remote operation—skills that cannot be outsourced or automated readily.

Conclusion: Training is Key to the Industry's Future

The oil and gas sector might be changing, but its demand for skilled, efficient, and innovative professionals is as strong as ever in 2025. With the industry striking a balance between existing operations and innovation and sustainability objectives, education and training are the pillars to ensure an efficient future workforce.

future professional development.

Companies such as Techshore Inspection Services are bridging the skills gap by providing specialized, industry-specific courses designed to address the needs of today's oil and gas industry. Techshore, with its experienced faculty, practical training modules, and international industry approval, prepares students and professionals to excel in a global energy market.

In a world where the energy equation is more complicated than ever, talented professionals trained by such institutes as Techshore will remain the pillars of safe, efficient, and responsible oil and gas operations.Seeking oil and gas management courses is one of the finest methods to learn for this dynamic industry. Such courses provide specialists with required knowledge to manage intricate operations, regulatory complexities, and corporate choices in the energy industry. If you are about to join the industry or aim at enhancing your skills, right training is able to unveil doors for

0 notes