#Tape Slitting Rewinding Machine

Explore tagged Tumblr posts

Video

youtube

Tape Slitting and Rewinding Machine: Efficient Precision for Perfect Rol...

0 notes

Text

High-Performance Printing & Converting Machines | Advanced Solutions

In the modern world, the printing and packaging industry has started to completely rely on precision, effectiveness, and novelty. Advanced technology such as slitting rewinding machines, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems is among the most significant tools rendering final mba product quality.

Machine manufacturers and converters rely heavily on high-level technological tools to speed up the process of production, increase accuracy, and aid versatility of their machines. The description of the machines' importance in various industrial applications has been outlined in a set of present practice method, showing machines' necessity in printing and packaging industries today.

Slitting Rewinding Machine

A slitting rewinding machine is a vital component in industries dealing with flexible packaging, paper, films, and foil materials. It enables the precise slitting and rewinding of large master rolls into smaller rolls with accurate tension control.

Key Features of a Slitting Rewinding Machine:

High-Speed Performance: Ensures rapid slitting and rewinding without compromising quality.

Precision Cutting: Adjustable slitting blades provide clean and accurate cuts.

Tension Control Mechanism: Maintains optimal tension for smooth rewinding.

User-Friendly Interface: Automated controls for easy operation and reduced downtime.

Versatile Applications: Suitable for plastic films, aluminum foils, paper rolls, and adhesive tapes.

Applications of Slitting Rewinding Machines:

Flexible Packaging Industry: For slitting plastic films and foils.

Label Production: Converts large rolls into label-sized formats.

Printing Industry: For handling coated and laminated materials.

Label Die Cutting Machine

A label die cutting machine is essential for the precise cutting of labels, stickers, and adhesive sheets. It ensures clean edges, intricate shapes, and high-speed production for industries requiring mass labeling.

Key Features of a Label Die Cutting Machine:

Rotary & Flatbed Cutting: Supports various die-cutting methods for different label types.

Automatic Waste Removal: Ensures a cleaner output with no excess material.

High Cutting Accuracy: Ideal for custom shapes and intricate label designs.

Multi-Layer Processing: Allows multiple layers for enhanced durability.

User-Friendly Control Panel: Simplifies operation and reduces labor requirements.

Applications of Label Die Cutting Machines:

Food & Beverage Labeling: Used for bottle and container labeling.

Pharmaceutical Industry: For precision-cut medical labels.

Cosmetic & Personal Care Products: Ensures premium quality label cutting.

Paper Core Cutting Machine

A paper core cutting machine is used to cut paper tubes and cores to the desired length, ensuring smooth edges and accurate dimensions for various industrial applications.

Key Features of a Paper Core Cutting Machine:

High Cutting Precision: Produces accurate and smooth cuts for uniform core sizes.

Adjustable Cutting Lengths: Allows customization for different applications.

Heavy-Duty Construction: Ensures durability and longevity.

Automatic & Manual Operation: Supports both automatic and manual cutting modes.

Dust-Free Operation: Minimizes waste and enhances cleanliness.

Applications of Paper Core Cutting Machines:

Packaging Industry: For manufacturing paper cores for packaging rolls.

Printing Sector: Used for paper roll cores and film winding.

Textile Industry: For fabric and yarn core cutting.

Hot Foil Stamping Machine

A hot foil stamping machine enhances the visual appeal of printed products by adding metallic and holographic foil designs. It is widely used in luxury packaging, book covers, greeting cards, and promotional materials.

Key Features of a Hot Foil Stamping Machine:

Advanced Foil Transfer Technology: Ensures sharp and clean imprints.

Temperature & Pressure Control: Allows precise adjustments for different materials.

Multi-Purpose Applications: Works on paper, plastic, leather, and fabric.

Automatic Foil Feeding System: Ensures smooth and continuous foil application.

Energy-Efficient Design: Reduces operational costs and improves efficiency.

Applications of Hot Foil Stamping Machines:

Luxury Packaging: Enhances premium product packaging.

Branding & Promotions: Used for high-end business cards and brochures.

Security Printing: Adds holographic elements for anti-counterfeiting.

UV Curing Systems

A UV curing system is an advanced technology used for instant drying and curing of inks, coatings, and adhesives using ultraviolet light. This method ensures high-quality finishes, durability, and eco-friendly operations.

Key Features of a UV Curing System:

Instant Drying & Curing: Reduces production time significantly.

Energy Efficiency: Consumes less power compared to traditional drying methods.

Eco-Friendly Operation: Eliminates the need for solvents and harmful chemicals.

High Durability: Ensures scratch-resistant and long-lasting prints.

Wide Compatibility: Suitable for offset, flexographic, and screen printing.

Applications of UV Curing Systems:

Printing Industry: For UV-cured inks and coatings.

Electronics & PCB Manufacturing: Ensures durable protective coatings.

Medical Devices: Used for adhesive bonding in healthcare applications.

Why Invest in High-Performance Printing & Converting Machines?

Enhanced Production Efficiency – Reduces downtime and increases output.

Precision & Quality – Ensures accurate cutting, stamping, and curing.

Cost-Effective Solutions – Optimizes material usage and reduces waste.

Versatile Applications – Suitable for various industries, from packaging to textiles.

Advanced Automation – Minimizes manual labor and improves operational accuracy.

By integrating the latest slitting rewinding machine, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems, manufacturers can achieve superior productivity and quality.

Project Name: UV Graphic Technologies Pvt. Ltd

Address: Plot 15, Sector 140A, Noida UP 201305

Contact No: 919810114365

Email ID: [email protected]

Our Website: https://gtigti.com/

Linkedin ID: https://www.linkedin.com/company/uv-graphic-technologies-pvt-ltd/

You tube: https://www.youtube.com/watch?v=EleXfuBanIk&ab_channel=AbhayDatta

0 notes

Text

Bopp / Paper Tape Coating Machine

Mohindra is recognized as one of the top manufacturers of Doctoring Slitting Machines in India. Although we are located in Delhi, we supply our wide range of products across the country. We use premium quality raw materials in the production of all our machines. As you may know, the demand for Doctoring Slitting Machines is increasing daily, driven by the rising consumption of paper bags in India. Mohindra Machine stands out as a leading manufacturer of Doctoring Slitting Machines. We are dedicated to producing and supplying these machines to potential customers in the market. The Doctoring Slitting Machine is designed to cut and convert large sheets of paper, foil, and film materials into narrower rolls. These machines consist of three main components: the slitter, unwind, and rewind.

#Bopp paper tape coating machine price#Bopp paper tape coating machine price in india#Bopp paper tape coating machine in india#Bopp paper tape coating machine for sale

1 note

·

View note

Text

lamination machine manufacturer in india

We are manufacturer and supplier of Bopp self adhesive tape slitting Machine. Our product range also comprises of Rotogravure printing, Lamination machine, Slitting machine, Doctring rewinding machine, Trimwinder machine.

#lamination machine#lamination machine manufacturer#lamination machine supplier#lamination machine in ahmedabad#lamination machine in india#lamination machine supplier in india

0 notes

Text

The benefits of using anti slip tape

There are many benefits to using anti slip tape. This type of tape can help to prevent accidents by providing a much needed grip on slippery surfaces. It can also help to protect against wear and tear, as well as making it easier to clean up any spills.

The application of anti slip tape

What are the selection criteria for anti slip tape?

What is the working principle of anti slip tape?

The application of anti slip tape

There are many different types of anti slip tape, each with their own unique properties and benefits. However, all anti slip tapes share one common trait: they all help to keep you safe from slipping and falling.

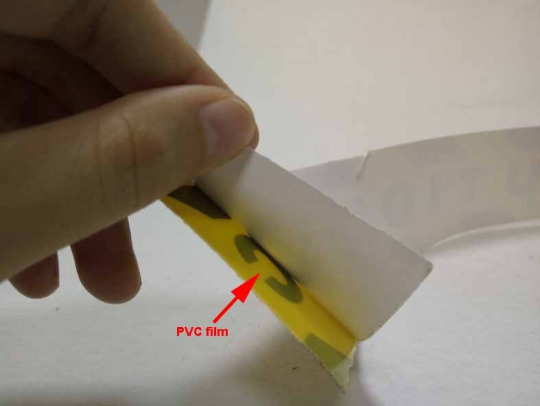

anti slip tape is typically made from a variety of different materials, including rubber, PVC, and even metal. The type of material used will usually depend on the specific application for which the tape is being used. For example, metal anti slip tape is often used in industrial settings where there is a lot of foot traffic, as it is extremely durable and can withstand heavy wear and tear.

The rubber and PVC anti slip tapes are often used in residential and commercial settings as they are more forgiving if someone does happen to slip and fall. These types of tapes are also typically much less expensive than their metal counterparts.

No matter what type of anti slip tape you choose, make sure that it is applied correctly in order to ensure the best possible results. If you are unsure about how to apply the tape, or if you have any other questions about its use, be sure to consult with a professional before proceeding.

What are the selection criteria for anti slip tape?

1. When purchasing, check whether there are burrs on the surface of the anti slip tape.

2. The adhesive should be strong and durable, waterproof.

3. Check the anti-fouling ability of anti slip tape. This material has strong wear resistance and excellent water absorption function, so its application range is extremely wide.

What is the working principle of anti slip tape?

anti slip tape is used in the coating process of double-sided adhesive tape. When the double-sided tape is pulled out from the coating machine, it needs to be guided out by rollers. If the surface of the guide roller is not specially treated, the adhesive will stick to the roller and affect the Production and tape quality. The surface of the roll is usually covered with a low surface energy material to prevent sticking. This single-sided non-slip tape is specially designed for this application. It is coated with a durable adhesive on one side to firmly stick to the surface of the output roller, and the other side is made of special low surface energy rubber, which can effectively prevent the adhesive from being damaged Adhesive effect.

Jiangmen E Win Adhesive Products Co., Ltd is equipped with all kinds of professional production equipment. The factory has glue coating machine, rewinding machine, slitting machine, hot shrink machine and die-cutting machine.

0 notes

Link

Heavy duty and hi-speed Self Adhesive Tape Slitting Rewinding Machine with features of coreless rewinding, fully automatic and accurate process for BOPP. Slitting of all types of material like Plastic, Paper, Flexible Packaging, Tube, etc. makes us most experienced manufacturer, exporter & supplier of Slitter Rewinder Machine. Self Adhesive Tape Slitting Rewinding Machine, Slitting Rewinding Machine, Self Adhesive Tape Slitting Rewinding Machine, Tape Slitting Rewinding Machine, BOPP Tape Slitter Rewinder Machine

#Self Adhesive Tape Slitting Rewinding Machine#Slitting Rewinding Machine#Tape Slitting Rewinding Machine#BOPP Tape Slitter Rewinder Machine

0 notes

Link

Krishna Engineering Works is biggest manufacture of all types of BOPP Rewinder Die Cutter Machine for all types of Rotogravure Printing Machine, Lamination, Coating Machine, Slitting Machine, Rewinding. For any inquiry or information visit our website “krishnaengineeringworks.com” or contact us at [email protected]

#BOPP Rewinder Machine#BOPP Machine Manufacturer#BOPP Machine at best price#BOPP Tape Rewinding Machine#BOPP Tape Slitting Machine#Tape Rewinding Machine Manufacturer

1 note

·

View note

Link

Slitting Rewinding Machine for Batch Printing Coding, Slitting Machines, Slitter Rewinder Machine for Industry specific Batch Printing, Batch Printing, Slitter Rewinder Machine, Doctoring Rewinding Machine, Batch Coding Machine, Packaging Machine, Printing Machine, Fabric Folding Machine, Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner).Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying. The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation. It is great substitute to online coding / batching operation

http://www.windingrewindingmachine.com/slitting-rewinding-machine-for-batch-printing-coding.php

#batch coding machine#batch printing machine#slitter machine manufacturer#winder Rewinder machine#Winding Rewinding Machine Manufacturer#slitter Rewinder#slitting rewinding machine#motor winding machine price#date printing machine#manual batch coding machine#Bopp tape slitting machine#batch printing machine price#rewinding machine price#paper winding machine#digital batch coding machine

1 note

·

View note

Link

We have been successfully Manufacturing, Exporting & Supplying all types of Doctoring Slitting Rewinding Machine and Winding Rewinding Machine for Inkjet Printer & Batch Printing. Our Doctoring Slitting Rewinding Machine is featuring on spending less power. Also, majorly used for Doctoring Slitting all types of Laminates like Foil, Paper, LDPE, HDPE, PVC. Doctoring Rewinding Machine, Doctoring Machine, Slitting Rewinding Machine, Doctoring Slitting Rewinding Machine, Slitter Rewinder Machine Manufacturer, Slitting and Rewinding Machine, Paper Rewinder Machine, Paper Slitting Machine for Sale, Surface Slitter Rewinder, Paper Slitting and Rewinding Machine, Paper Rewinder Machine Manufacturers, Slitting and Rewinding, Slitting Rewinding, BOPP Tape Slitting Rewinding Machine, Aluminium Foil Slitting Machine, Thermal Paper Slitter Rewinder, Roll Slitter Rewinder, Paper Slitting Rewinding Machine, Aluminium Slitting Machine, Paper Roll Slitter Rewinder, Paper Rewinder for Sale

#Doctoring Rewinding Machine#Doctoring Machine#Slitting Rewinding Machine#Doctoring Slitting Rewinding Machine#Slitter Rewinder Machine Manufacturer#Slitting and Rewinding Machine#Paper Rewinder Machine#Paper Slitting Machine for Sale#Surface Slitter Rewinder#Paper Slitting and Rewinding Machine#Paper Rewinder Machine Manufacturers#Slitting and Rewinding#Slitting Rewinding#BOPP Tape Slitting Rewinding Machine#Aluminium Foil Slitting Machine#Thermal Paper Slitter Rewinder#Roll Slitter Rewinder#Paper Slitting Rewinding Machine#Aluminium Slitting Machine#Paper Roll Slitter Rewinder#Paper Rewinder for Sale

1 note

·

View note

Link

Aluminium Foil Slitter Rewinder Machine Manufacturer India, Slitter Rewinder Machine also for paper, film, non-woven, BOPP tape materials, Aluminium Foil Slitter Rewinder Machine for packaging industry. High speed production level to meet client's requirement. We manufacture Aluminium Foil Slitter Rewinder Machine can be used for Slitting thin Aluminium Foil for any microns. Wide Range of our Slitter Rewinder machine are used for slitting Aluminium Blister Foil. We offer Aluminium Foil Slitting Machines from 9 micron to 40 microns.

#Aluminium Foil Slitter Rewinder Machine#Aluminium Foil Slitter Rewinder Machine manufacturer#Aluminium Foil Slitter Machine#Slitter Rewinder Machine#Slitter Rewinder Machine manufacturer#Slitter Rewinder Machines#Slitting Rewinding Machine#Slitting Rewinding Machines#Slitting Rewinding Machine Manufacturer#BOPP Slitter Rewinder Machine#BOPP Tape Slitting Machine

1 note

·

View note

Link

KEW ENGG. And MFG. PVT. LTD Manufacturer, exporter, and supplier of Duplex Slitter Rewinder Machine. Duplex slitter machine It is the cantilever type that incorporates a range of best design features. Slitter design includes three motor control systems used to achieve high-speed correction. For more information:

Visit Our Website: kew.net.in

Email: [email protected]

Contact us: +91-7940085305

#Duplex Slitter Rewinder Machine#Duplex Slitter Rewinder#Slitter Rewinder Machine#Slitter Rewinder#Slitter Rewinder Machine Manufacturer#Automatic Slitting & Rewinding Machine#Tape Slitter Rewinder

1 note

·

View note

Link

#Máquina Cortadora#Cortadora Rebobinadora#Fabricante De Maquinas Industriales#Slitter Machine Manufacturer#Paper Slitting Machine#Bopp Tape Slitting Machine#Slitting Rewinding Machine

1 note

·

View note

Link

Krishna Engineering Works manufactures a cantilever slitting machine, which covers a range of best design features of a slitter rewinder machine. The design of this machine includes three motor control systems and unloads pneumatic brakes with load cell feed brake digital edge/line guiding to achieve high-speed correction. All the activities of the product are focused on providing pleasure and satisfaction to the customer with full time and consistent quality. We are a manufacturer of Cantilever Slitting Machine, High-Speed Slitting Rewinding Machine, all types of Slitter Machine, etc.

#Cantilever Slitting Machine#Cantilever Machine#Slitting Machine#Slitter Rewinder Machine#Tape Slitting Machine#Fabric Slitting Machine for Sale#Slitter Rewinder#High Speed Slitting Machine Manufacturers

1 note

·

View note

Link

KEW ENGG & MFG PVT LTD is manufacturing standard quality of biggest High Barrier Metalized BOPP Film Slitter Rewinder Machine. Metallised Film for use as sealant layer to enhance moisture barrier of laminates in VFFS and HFFS applications. For more information visit our website: kew.net.in

#slitter machine#slitting and rewinding machine#bopp tape#manufacturing#paper slitter machine#film slitting machine

1 note

·

View note

Text

Slitter Rewinder Machine Manufacturer

Slitter Rewinder Machine Manufacturer

High Performance and High-Speed Slitting Rewinding Machine for different types of Industries. KEW is a company engaged in manufacturing, exporting, and supplying Flexible Packaging, Paper, Tire-Cord, Textile Machinery & Equipment. In the Flexible Packaging category, we manufacture Slitting Machine, Roll Slitter, Foil Slitter Rewinder, Slitter Rewinder Machine, Slitter Rewinder, Paper Slitting Machine, Film Slitter Rewinder, Tape Slitter Rewinder, Fabric Slitter Rewinder, Drum Type Slitter Rewinder, Flexible Packaging Slitter Rewinder. All types of Slitter Rewinder with Web Guiding System for various types of materials and different industries. For Slitting Rewinding, we have processed all types of material like LD, PVC, Paper, Film, Cloth, Nylon, etc. We have more than 1400 installations of Slitter Rewinder in India and overseas. Rewinding Machine, Pepar Slitter, Slitting Cutter for converting machine.

#Slitting Machine#Roll Slitter#Foil Slitter Rewinder#Slitter Rewinder Machine#Slitter Rewinder#Paper Slitting Machine#Film Slitter Rewinder#Tape Slitter Rewinder#Fabric Slitter Rewinder#Drum Type Slitter Rewinder

2 notes

·

View notes

Link

KEW ENGG MFG PVT LTD is biggest manufacturer, exporter & supplier of all types of Slitter rewinder machine at best price and standard quality. Our Audio tape grade slitting rewinding machine is with 11.5 thicknesses in microns also, It has excellent tensile strength, elongation properties & surface roughness properties. For more information or have any types of query about machine please coordinate with us at [email protected]

#Audio Tape grade Slitter Rewinder Machine#Slitter rewinder machine#slitting rewinding machine#slitter rewinder at best price

0 notes