#Textile Testing Instruments

Explore tagged Tumblr posts

Text

The recently concluded ITMA ASIA + CITME 2022 has been a great success. GESTER appreciates the presence of all the visitors and extends a heartfelt thank you. This may be the end of the exhibition, but it is not the end of our connection. We look forward to meeting you again in the future!

#Textile Testing Instruments#textile tester#fabric testing equipment suppliers#fabric testing machine manufacturer#Fabric Testing Equipment#Fabric Testing Machine#Textile Testing Machine#Textile Testing Equipment#Fabric Testing Instruments and Equipment's#Physial Testing Instruments And Equipments#itma asia#textiles#fabric#GESTER

0 notes

Text

Candlestick of God

by Adam Kenichi Wekarski

As one who has been completely fascinated by the actual reality of Nuclear Warfare (since my childhood), I have always found the creation of the Atomic Bomb to be the most important moment in all of human history (with exception of the actual beginning & origin of humanity & all of existence itself).

Christopher Nolan’s perfect film, “Oppenheimer”, is a significantly honorable & highly-sophisticated masterpiece that provides a cinematic insight into the individuals who were instrumental in the real life happenings of the theoretical design, creation, and eventual utilization of atomic power (as a means to an end) in one of the most defining moments in all of history.

Julius Robert Oppenheimer (portrayed Perfectly by Cillian Murphy in his finest performance) is the main focus of Nolan’s awe-inspiring cinematic achievement. Often considered to be “The Father of The Atomic Bomb”, J. Robert Oppenheimer (known commonly among his peers, family, and friends simply as, “Robert” and/or “Oppie”) was born in a Jewish household in New York City, New York, U.S.A. on April 22nd, 1904.

Born of a painter (Ella Oppenheimer/Mother) & textile importer (Julius Seligmann Oppenheimer/Father, respectively), J. Robert Oppenheimer is portrayed in the beginning of Nolan’s work as one who has an inherent appreciation for the beauty of artwork (in a somewhat subtle manner), showcased in a rather pensive moment in the beginning of the film (a moment slightly reminiscent of the end of the museum sequence in the American classic, “Ferris Bueller’s Day Off”; perhaps a deliberate cinematic nod). While the initial years of Oppenheimer’s life are not the main focus of this picture (Written & Directed Perfectly by Christopher Nolan), the film itself is based off a biographical book entitled, “American Prometheus: The Triumph and Tragedy of J. Robert Oppenheimer” (a monumental literary undertaking in it’s own right; championed by Martin J. Sherwin & Kai Bird, respectively).

Although the book is based on Oppenheimer’s life’s work (among other things), the film is a three-hour-epic which tells a tale of various meanings:

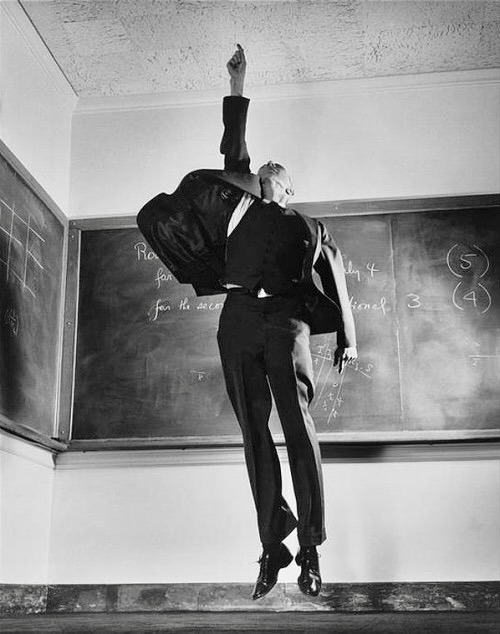

Firstly, the life of J. Robert Oppenheimer, which picks up in this film at the time of his initial years of his scientific legacy, as a student at The University of Cambridge (in Cambridge, England). In his academic years, Oppenheimer was not regarded with favor on the behalf of his scientific community. He had humbling beginnings in the scientific field, regardless of his inherent genius (which he would continue to enthrall himself in his own time). A particularly disturbing, yet accurate, moment in the film occurs when Oppenheimer actually attempts to poison his own instructor due to his considerable dissatisfaction of his experiences at Cambridge (without spoiling the story, this obviously does not come to fruition).

What does come to fruition, however, is the continual movement of subatomic & atomic particles working within the inner-structure of the mind (and overall being) of one J. Robert Oppenheimer (while he continues his pursuit of higher learning & his genuine love for all things astrophysical & theoretical science). Christopher Nolan’s film has a perfect ability of providing a visual interpretation of various scientific theories (whether it be conceptual or experimental) all-the-while providing a visual display of the deeply conflicted characterization of Oppenheimer himself throughout the entirety of his journey (via Murphy’s award-worthy performance). The cinematography of the film Oppenheimer is absolutely perfect (showcasing the undeniable superiority of film versus digital photography). The beauty of the picture is matched by moments of visceral intimacy (going in and out of focus at times with confidence) as well as larger-than-life & monumentally jaw-dropping imagery (especially during “The Trinity Test”). The musical score composed by Ludwig Göransson is a true work of genius as it creates an experimental (and highly profound & meaningful) atmosphere that helps shape the cinematic world within the film “Oppenheimer.” Göransson’s score is a refreshingly beautiful balance of symphonic & orchestral instrumentation while incorporating a tasteful implementation of electronic & synthetic instrumentation to balance the overall structure of the film. As Oppenheimer’s innermost thoughts & flashes of brilliance are scattered across the picture throughout the entirety of the story (with visual flair & editing mystique in a nonlinear method, indicative of Nolan’s directorial style), the musical score accommodates the plot & picture perfectly with a sincerely divine grace & power.

While speaking on power, the notion of atomic & nuclear power is the driving undercurrent of the film’s main protagonist as the story unfolds. As the theoretical possibilities are literally astronomical within the understanding of Oppenheimer’s significantly educated mind (as he displays a fascination for existence at cosmological proportions) - the threat of nuclear weapons being constructed and crafted by the dark forces of Fascism (by Hitler & The Nazis) halfway across the world is the other driving undercurrent of the film’s plot and main characters (all of whom, in real life, did actually place their lives on the line for the sake of our world). The known reality that the Nazis of Germany & Austria (of old) had already devised their own plan to have the ultimate weapon to command their own will over the will of others (as their invasion of Poland was merely a first step in their agenda) was not far from Oppenheimer’s mind as well as the many key individuals of whom had not only shared time with him in his life, but had become spiritual warriors of the cause to stop (once and for all) the unGodly atrocities birthed from the minds of actual evil in Nazi-era Germany.

Key individuals had indeed entered Oppenheimer’s life; individuals like Isidor Rabi (portrayed gracefully by David Krumholtz in his finest performance on screen to date), Ernest Lawrence (portrayed very impressively by Josh Hartnett in his finest performance yet), Lewis Strauss (portrayed masterfully by one Robert Downey, Jr. in his greatest performance since “Chaplin”), Jean Tatlock (portrayed strongly by Florence Pugh in a highly provocative & deeply off-putting performance), Leslie Groves (portrayed incredibly by Matt Damon in my favorite on-screen performance by him since “Good Will Hunting”), Katherine “Kitty” Harris (who would later become Katherine “Kitty” Oppenheimer in real life and in the film; portrayed Perfectly by Emily Blunt in one of my favorite performances in the entire film), as well as many, many other key individuals who played significant roles in the organization of the atomic bomb in order to end what had become known worldwide as “The Axis of Evil” in [accurate] historical documentation.

The countless individuals who shall remain in the history books as having been directly associated with the formation of the U.S. Military effort (not to mention Canada and The United Kingdom, respectively) to create the Atomic Bomb are represented with dignified refinement in Christopher Nolan’s masterwork, “Oppenheimer.” The ensemble cast is enormous, and no one single performance can be understated by any other performance. Every performer on camera honorably captures an accurate portrayal of the manner of which these real life individuals had lived (granted with a dramatic tone mostly reminiscent in any major motion picture’s cinematic retelling of any major historical world event to connect an overall thought to anyone of whom views the picture).

In addition to the enormous ensemble cast is the enormous production design of the film. It’s particularly astounding to observe how Oppenheimer had become involved in the most important government protocol known to modern society, and then had the most important responsibility of practically producing a space within the nation to run highly-classified government operatives & lead numerous scientists (of both men and women) to create something that had never been physically manifested before by anyone. Cillian Murphy’s charming on-screen dynamics with his peers & colleagues (even among some of the most fascinating & completely serious situations; i.e. The personal politics becoming an element of interference & conflict even among the very people who worked as a team to construct the nuclear solution to the atomic problem; the complete classification of his work due to the priority of the U.S. Military; the priority of national security; his overall personal relationships while putting a new team of scientists together to perform the most massive scientific undertaking in a race against evil) - is just as organic as it is compelling to observe on film.

The reality of Oppenheimer’s associations with the Communist Party (as well as his own family members and friends) are presented very clearly throughout the entire film. Regardless of the numerous verbal warnings from fellow scientists such as Ernest Lawrence to keep politics outside of the laboratory (due to Oppenheimer’s rather open and highly vocal political opinions in favor for the Communist ideals with an intensely pro-worker stance), Oppenheimer continued to struggle to find the balance between his own personal convictions & morals as an individual as well as working within the functioning realm of national loyalty & honorable servitude. As the film continues into the development of Oppenheimer’s leadership as an instructor for his own students (which continues to increase in numbers), he eventually calls upon the brightest and most capable minds within his field to join the cause of stopping the world from being totally annihilated by the forces of darkness (as the Nazi army had continued to murder & genocide countless innocent lives in Europe on a daily basis and intended on dominating the world by total violence & mass genocide).

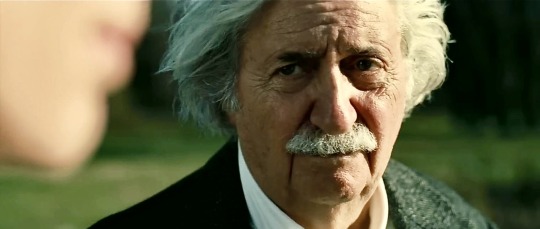

With a newly formed team and his continued work alongside Leslie Groves (a true man of the cause; a decorated Engineer of the U.S. Military who did his service to his country with much Pride & Honor) to build a physical location to perform what would later be referred to as “The Manhattan Project” (which was a perfect recreation in terms of production design of the classified military operation in Los Alamos, New Mexico, U.S.A.), Oppenheimer’s vision had come to fruition in the most tangible form (with the relentlessness of Groves throughout the entirety of the nuclear arms race). After the painstaking search for the perfect team to create the most destructive force known to humankind was completed (even with a briefly elusive encounter between Oppenheimer & Albert Einstein [portrayed by Tom Conti with awe-inspiring perfection & grace] in the beginning of the film when Strauss extends an invitation to Oppenheimer), the increase of scientific gravitas becomes ever more present with each scene in the film and each additional scientist of whom helps construct “the weapon to end all wars.” With each additional individual who presents more & more ideas to the table (so-to-speak) on how to successfully achieve the most effective scientific results (during an intimate look inside the American think-tank that constructed the weaponization of atomic power), the collaborative efforts put forth by the men and women who built the atomic bomb was frequently rife with conflict & tremendous disagreement due to the meeting of massive minds (often harboring massive ideas & massive egos to boot).

The potential security threat that Oppenheimer’s Communist ties initially raised had been dissolved by Leslie Groves due to his concrete belief in Oppenheimer’s intellectual abilities as a Scientist. This clear confidence, regardless of personal reservations, is what prompts Robert Oppenheimer’s brother, Frank Oppenheimer (portrayed respectably by Dylan Arnold) to join the highly classified government operation to defeat the Nazis in the race for atomic power (regardless of his clear ties with the Communist Party). The cause had become greater than us all as our personal politics and personal reservations regarding who did [or did not] pose a potential security threat to our nation had been placed as a postponed priority during a race against time (and an actual race against evil). Just as it has always been (in regards to the most important moments in human history), desperate times called for desperate measures. This is the compelling beauty of the unified cooperation & sincere teamwork that had actually happened in real life with real human beings who truly did save the world from the further influence of the destructive forces of darkness (and our absolute end as an overall existence). Regardless of differing political ideologies, many individuals came together for the common cause to stop the world from succumbing to the most sinister darkness ever known to be (by collectively constructing a proverbial candlestick of God to bring forth from the heavens the ultimate force of light).

Secondly, “Oppenheimer” is a picture about the tragic betrayal & political persecution of J. Robert Oppenheimer despite his awe-inspiring commitment & loyalty to The United States of America as a government and as a nation (as well as the entirety of humanity and existence on Earth). The second act of this three-act work of art is primarily focused around the McCarthy-era “Red Scare” that occurred in America that followed the aftermath of the end of World War II in the following decade. The Red Scare had essentially been a witch-hunt in contemporary America for anyone who was a Communist, held affiliations with the Communist Party, or was suspected of having potential connections and/or ties with any individual(s) or organization(s) associated or in some way, shape, or form, and/or of having any relations with Communism as a whole (very reminiscent of another important socio-political picture focused on the era of McCarthyism in America entitled, “Good Night and Good Luck”).

Regardless of Oppenheimer’s complete commitment & sincere dedication to the cause of our great nation, he was still held under a severe amount of scrutiny and political punishment for his past associations with the Communist Party. In addition to a public hearing which had placed his entire scientific credibility & honor as a man under an unnecessary humiliation that attempted to destroy his life, family, and career - He also faced a significant amount of antagonistic questioning on a daily basis regarding a tapestry of arbitrary & meaningless questions that were implemented more severely & viciously with each passing day in order to further diminish, attack, and otherwise destroy his character (regardless of him & his family’s sacrifice for the greater good).

The second act is duplicitous in the sense that it’s nonlinear in it’s presentation (similar to the earlier work by Nolan, “Memento”). Act two is primarily in black & white, a clear indication of the nature of the duality of Oppenheimer’s scientific & humanitarian achievement in that he was once an exciting figure full of potential in the first act (with a sense of hope & color & adventure), and now the second act has him facing questions (in a stark contrast to act one) regarding his own character and his associations (in addition to the very achievement he was called upon in order to save the world from total annihilation, by the very people who asked for his help). The second act happens simultaneously with the first act which is a stroke of genius in the direction, writing, and overall production quality of the film. Without revealing too much in order to preserve the quality of the picture, the second act is a complete torment on Oppenheimer’s character and his actions and overall judgment calls (as the man responsible for having a scientific team working for the U.S. Military & U.S. Government that actually had Russian spies and double-agents infiltrating classified U.S. intelligence during The Manhattan Project and The Trinity Test). The truly unfortunate reality is that Oppenheimer, while being a genius who worked alongside many, many brilliant & wise individuals, still managed to succumb to the double-cross of individuals of whom were trusted with the highest security clearances in our own U.S. Government (while covertly operating within the means of international political subversion & government espionage).

While I will not indulge further into the premise regarding the socio-political plot-related themes of the film, I will indeed acknowledge the Kubrickian fashion in which Nolan has immersed his direction in this particular film (in all of it’s 70mm glory). Without spoiling the story for anyone; there is one scene during Oppenheimer’s questioning where the film provides a visual representation of how deeply each question had cut Oppenheimer as a person (and character). What would seem to be a completely gratuitous sex scene during Oppenheimer’s questioning (courtesy of Florence Pugh & Cillian Murphy, both in a highly artistic light), is actually an astonishing symbolic gesture that showcases the real suffering that was not only endured by Julius Oppenheimer (having been known for his illicit affairs), but also his wife, Katherine, during one of the worst times in Oppenheimer and his family’s life (which fed into Kitty’s alcoholism despite her own intellect & genius in real life). The questions of Oppenheimer’s commitment to our country, and to the greatest cause in the world, and the questioning of his personal affairs in order to smear his good name was discovered to be a deliberate method of private interest (facilitated by an individual later revealed in the film).

Oppenheimer’s credibility & worthiness had been completely tested, challenged, and disgraced regardless of the fact that he utilized his intellect (and the intellect of countless individuals in his immediate life that had all worked together) in order to bring an end to the forces of darkness by using the most powerful form of light: Atomic Power.

Thirdly, Christopher Nolan’s monumental cinematic achievement is, symbolically-speaking, about the Greek tragedy of the Titan known as Prometheus (originally based off of Hesiod’s ancient mythological poetry, “Theogony”; as well as the 5th Century [B.C.] epic trilogy written by Aeschylus, “Prometheia”; a trilogy of tragedy consisting of “Prōmetheús Desmótēs” (a.k.a. “Prometheus Bound”), “Promētheus Lyomenos” (a.k.a. “Prometheus Unbound”), and “Promētheús Pyrphóros” (a.k.a. “Prometheus The Bringer of Fire”). In the calculated words of Oppenheimer, himself, as he identifies with the paradigm of which confined Prometheus before him, “…I am become Death, the destroyer of worlds…” (taken from Eastern Philosophical Sanskrit spiritual text; quoting Vishnu of the Hindu faith; Bhagavad Gita, approximately 4th Century BCE). As Oppenheimer’s ability to “bring fire” to humanity (a cinematic similarity of the mythological tragedy of Prometheus), having stolen fire from Zeus and having given it to Humanity (in addition to civilization & science & knowledge from the heavens), the mythological being’s tale had become an obvious parallel to Oppenheimer in his actual waking life (when he was indeed alive on this earth and did aim to wield the power of the universal light). Regardless of Oppenheimer’s world-changing achievement (and the further harm it would prevent on a mass level), he was still able to intellectually determine his own profound understanding of the bloodshed & death that would be the result of his scientific creation (despite the necessity to stop the seemingly unstoppable armies of Germany & Japan at the time). Oppenheimer, like Prometheus before him, had successfully managed to reach for the stars and pull the light down from the heavens, and bring it to humanity on earth in order to prevent Zeus from completely obliterating and destroying humanity as a whole.

In Nolan’s masterpiece, as Prometheus had learned the ability to seize the power of fire could indeed be harnessed from the heavens, Oppenheimer had learned the ability to seize the atomic power that could actually be harnessed from existence itself (as the molecular structure of all existence as we know it is indeed a physical result of atomic activity combined with spiritual energy [individually & collectively]) within an interaction between the tangible & intangible forces of cosmic energy & matter & waves of sound.

As in the tale of Prometheus, after having brought fire to earth from the heavens, the following punishment was the eternal torture & torment of Prometheus (condemned by Zeus). Prometheus was shackled to a boulder, as his immortal liver was eaten on a daily basis (having the ability to regenerate each day) by an Eagle (typically identified as the emblem of Zeus). In a contemporary context, an eagle also identifies as a symbol of State Power; Authority of The State; Government Power. Zeus, in Nolan’s cinematic interpretation, has a much more fascinating and complex representation via two different major political figures (both Adolf Hitler as well as President Truman; the inherent duality of state power). Without giving anything away - The brief cameo of President Truman (as he and Oppenheimer meet) is an encounter similar to that of when Peter Finch’s ‘Howard Beale’ meets Ned Beatty’s ‘Arthur Jensen’ in the film “Network” (albeit more brief). While Oppenheimer’s brilliance and complete concern over the social responsibility of striving for a world where we no longer need to use any such weapons in order to remain a functioning society - President Truman (portrayed masterfully by an actor who shall remain nameless to maintain the integrity of the picture) shows the true nature of the political world by declaring the contrary and asserting a further implementation of research & development to deter any further international threats (regardless of Oppenheimer’s clear concern of any government having such access to such extensive means of weaponized methods of power on the nuclear level).

It’s a truly fascinating & monumental statement to have applied the cinematic telling of one of the most important moments in human history while simultaneously bringing forth poetic symbolism of a Greek tragedy (utilizing the most powerful form of cinematic triplicity; particularly with the utilization of Einstein who plays more like a force of nature rather than a man). The third act of the film releases Oppenheimer from his proverbial rock of eternal torment in his own modern Tartarus, as he is released by the help of the every-day scientist, David Hill (portrayed perfectly in a minor, but completely effective role by Rami Malek). As Heracles before him, Hill’s presence sheds new light on an intriguing internal development within the scientific community which not only shows the duplicitous nature of the second act, but also the duplicitous nature of the individuals of whom had called upon Oppenheimer to help create the atomic bombs that would be dropped on the civilian cities of Hiroshima & Nagasaki, Japan (respectively). Rami Malek’s brief, but significantly important role in the film is the pivotal turning point that grants Oppenheimer, his family, and his associations (both past and current) freedom from previous prejudice & extreme ridicule (in a gratifying on-screen showdown that brings forth the most important message of the entire film).

Lastly, and most importantly, the overall message of Nolan’s masterpiece is about honoring the people who deliberately rise to the occasion in order to save the good grace of humanity & the sanctity of life as we know it (regardless of prior or potential political affiliation or one’s professional ego or private interest). The importance of speaking up on the behalf of the ones who do good in the world, and celebrating each achievement in order to propel the individual (and the collective) further into the future is essential in all industries (not just the scientific field). The ones who literally step forward to save & preserve the fate of humankind & our world (by intellect, spirit, or body) should be awarded for their good faith (not punished or tortured or removed by exclusion due to the absurdity of bureaucracy or envious competitors or kicked back into the world merely as paupers, or as the film refers, a “Lowly shoe salesmen”).

In conclusion: The elusive moment between Einstein & Oppenheimer (which comes back around full circle from Act one through Act three) is a highly powerful moment on film that provides an insight into the purity of true genius & brilliance (more importantly & above all else: a wisdom that burns inside within the spirit of Oppenheimer as it had in Einstein; a candlestick of God’s light from within: All-Knowing, regardless of the tumultuous path ahead of the man that became known as “The Father of The Atomic Bomb”). The beauty of the film is not one individual’s achievement, but the collaborative achievement of the goodness of humanity as a species in order to stop the darkest evil known to humankind. It was one individual who lead a team of individuals (with unmeasurable personal & professional sacrifice on everyone’s behalf), a true human being alongside other noble human beings who did what was necessary to preserve the sanctity of life as we cherish it to be. Considering the known reality that the relevance of an actual threat of nuclear warfare still exists in our modern time (approximately one century after the real atomic bomb had been created by the most important team of individuals who placed, not only country above party, but humanity above it all), perhaps Christopher Nolan’s cinematic echo of the past will allow us all to consider the priority of humanity’s future as we look towards a better time, not just for a certain few, but for ALL of us as an entire world (now & forever).

#Oppenheimer#CillianMurphy#EmilyBlunt#MattDamon#RobertDowneyJr.#FlorencePugh#DavidKrumholtz#JoshHartnett#MatthewModine#TomConti#LudwigGöransson#HoyteVanHotema#ChristopherNolan#EmmaThomas#JuliusRobertOppenheimer#HeinrichFriedrichFüger#Movies#Film#Art#CandlestickOfGod#AdamWekarski#AWESOME#TheMostImportantMovieOfALLTIME

14 notes

·

View notes

Text

What Is Hemp?

It’s A Trillion Dollar Cash Crop.

youtube

Hemp is a name given to a strain of the cannabis plant.

Hemp is a name given to cultivars of the cannabis plant (Cannabis sativa) that have been selected over many generations for fiber and seed production. Most hemp cultivars contain less than 1.5% THC, a narcotic compound that has the potential for abuse in high concentrations. Cannabis sativa cultivars selected and developed for their drug properties, referred to as marijuana, or dagga, can have a THC content of 3%-25%. Hemp is a bast fiber, producing its fibers in the stalk similar to flax, kenaf, and sun hemp.

Multiple Uses

Hemp fiber and seed are used to produce a wide range of commodities including food and beverage products, fiberboard, insulation, paper, composites, textiles, carpets, animal bedding and feed, cosmetics, body-care products, soaps, paints, fuels, and medicines.

Hemp Seed Food and Beverage Products

Hemp seed contains about 25% protein, 30% carbohydrates, & 15% insoluble fiber. Hemp seed is reported to contain more easily digestible protein than soybeans. Hemp seed contains all 8 amino acids essential to human nutrition. Hemp seed is high in calcium, magnesium, phosphorus, potassium, carotene, sulfur, iron and zinc, as well as Vitamins A, E, C, B1, B2, B3, and B6.

Hemp seed imported into the United States or Canada must be steam sterilized at between 180 degrees F and 212 degrees F for 15 minutes to prevent sprouting. Many US facilities receive imported viable seed under customs bond, steam it, and release it to the consignee or customer with a Certificate of Sterilization.

Hemp food and beverage products include hemp oil and seed, flour, pasta, cheese, tofu, salad dressings, snacks, sweets, hemp protein powders, soft drinks, beer, and wine. Hemp beer can be made from the seed, flowers, sprouts, and seed cake that is a by-product of oil pressing. Hemp beer is produced and sold in Europe and the United States of America.

Hemp Oil

Hemp seed is 25% to 35% oil, and is one of the oils lowest in saturated fats (8%). Hemp seed oil is the richest source of polyunsaturated essential fatty acids (80%). Hemp seed oil is the only common edible seed oil containing Omega-6 Gamma-Linolenic Acid. Hemp seed oil is very fragile and not suitable for cooking.

Pressed hemp seed oil must be bottled immediately under oxygen-free conditions, and must be refrigerated in dark, airtight containers.

Fiberboard

Hemp fiberboard tested by Washington State University Wood Materials and Engineering Laboratory proved to be two and one half times stronger than wood MDF composites, and the hemp composite boards were three times more elastic.

Hemp herds can be used in existing mills without major changes in equipment. Russia, Poland and other Eastern European countries already manufacture composite boards from hemp and other plant materials.

Pulp and Paper

The major use of hemp fiber in Europe is in the production of specialty papers such as cigarette paper, archival paper, tea bags, and currency paper. The average bast fiber pulp and paper mill produces 5,000 tons of paper per year. Most mills process long bast fiber strands, which arrive as bales of cleaned ribbon from per-processing plants located near the cultivation areas.

Composites

Until the 1930’s, hemp-based cellophane, celluloid and other products were common, and Henry Ford used hemp to make car doors and fenders. Today hemp herds can be used to make new plastic and injection-molded products or blended into recycled plastic products. Hemp fibers are introduced into plastics to make them stiffer, stronger and more impact resistant. Hemp plastics can be designed that are hard, dense, and heat resistant, and which can be drilled, ground, milled, and planed.

Hemp plastic products currently made include chairs, boxes, percussion instruments, lampshades, bowls, cups, spectacles, jewelry, skateboards, and snowboards.

Hemp Animal Care

Hemp horse bedding and cat litter are produced and sold in Europe. After oil is extracted from the hemp seed, the remaining seed cake is about 25% protein and makes an excellent feed for chicken, cattle, and fish. Chickens fed hemp seed on a regular basis have been found to produce more eggs, without the added hormones used in most poultry plants.

Fuels

Hemp seed oil can be combined with 15% methanol to create a substitute for diesel fuel which burns 70% cleaner than petroleum diesel. Hemp stalks are rich in fiber and cellulose, making them conducive for conversion into ethanol and methanol fuels that have a higher octane than gasoline and produce less carbon monoxide. These biomass fuels are also free from sulfur, and do not require the addition of lead and benzene used to boost octane and improve engine performance in fossil fuels. Ethanol holds condensation, eliminating oxidation and corrosion, and is reported to reduce carbon dioxide emissions by more than 30%.

Hemp has been studied in Ireland as a biomass fuel to generate electricity. Hemp has been reported to yield 1000 gallons of methanol per acre year. Hemp stalk can be converted to a charcoal-like fuel through a thermochemical process called pyrolysis. Henry Ford operated a biomass pyrolitic plant at Iron Mountain, Michigan in the mid-20th.

Paints and Varnishes and Binders

Until the 1930's, most paints were made from hemp seed oil and flax seed oil. Hemp oil makes a durable, long lasting paint that renders wood water-resistant. Hemp herds have the potential to make glues for composite construction products that are non-toxic and superior to binders currently used. With this technology, industry can produce composite products where all components are derived from hemp.

Markets for Hemp Pulp

Some paper manufacturers already have the equipment to process decorticated hemp fiber into paper. The leading European supplier of non-wood pulp, Celesa, currently produces about 10,000 tons per year of pulp from hemp. The use of hemp pulp in blends with recycled fiber of other non-wood fibers is growing. Tests by several European pulp and paper producers suggest that hemp pulp may replace cotton cost effectively in several specialty paper applications.

Potential Markets for Medical Application of Low-THC Hemp Cultivars

Many cannabis medicines have been produced using cannabis cultivars high in THC, and there has been medical research into cannabis that is low in THC and high in CBD. CBD is a cannabinoid that does not have many of the psychoactive effects associated with THC. CBD has been used to treat the following medical conditions: epilepsy, dystonic movement disorders, inflammatory disorders, pain, chronic insomnia, chorea, cerebral palsy, and Tourette's syndrome. According to a July 1998 report by the National Institute of Health, CBD may hold promise for preventing brain damage in strokes, Alzheimer’s disease, Parkinson’s disease and even heart attacks and has been found to prevent brain cell death in an experimental stroke model.

Please share this with your friends.

youtube

#hemp farming#hemp foods#hemp fuel#industrial hemp#hemp plastic#hemp paper#hemp fibers#hemp seeds#hemp prohibition

4 notes

·

View notes

Text

The Use of Digital Tensile Testing to Reduce Product Waste

Source of Info: https://www.perfectgroupindia.co.in/blog/the-use-of-digital-tensile-testing-to-reduce-product-waste

Introduction

Digital Tensile Testing helps to reduce product waste by guaranteeing that materials fulfills strength and durability standards. In order to avoid flaws and reduce rejection rates, industries depend on accurate testing to identify weak materials early. Manufacturers improve quality and reduce wasteful material use by improving manufacturing processes through the analysis of tensile strength. This method helps the environment by increasing productivity and reducing waste production. Perfect Group India helps companies maintain the quality of their products by offering advanced testing solutions. By providing durable, better items with no waste, investing in trustworthy tensile testing not only maintains resources but also increases customer satisfaction.

What is Digital Tensile Testing? Digital Tensile Testing is a method to find the strength of materials by applying controlled force before it breaks. Manufacturers can use this test to find out how much pressure material can withstand before failing. The testing offers important new information about the flexibility, load bearing capacity and stretching of the material.

How Digital Tensile Testing Reduces Product Waste

Preventing Material Defects Material flaws often result in product failures, which can result in manufacturing waste. Before raw materials are used in manufacturing this equipment makes sure they meet strength requirements. This helps in the early detection of weak materials, which avoids the production of defective products.

Enhancing Product Durability Products that break under pressure result in unhappy customers and more returns. By choosing materials with the proper tensile strength this device helps in the design of durable items. This guarantees durability and saves materials.

Reducing Production Errors A main source of material waste is manufacturing errors. Businesses can reduce defective sections and reduce weak materials by using equipment to check the quality of parts in advance of the production process.

Optimizing Material Usage Manufacturers can choose the best materials by looking at the strengths of various materials. Businesses can use less material without sacrificing strength to testing, which reduse waste and costs.

Improving Quality Control Standards High standards of quality are required for industries to meet performance and safety requirements. By maintaining that materials meet industry standards this equipment lowers the possibility of recalls and the delivery of defective products to customers.

Industries Benefiting from Digital Tensile Testing

Packaging Industry Materials used for packaging that allowed it to withstand force and pressure while being transported. Digital Tensile Testing helps guarantee that packaging materials are durable to withstand handling and transportation damage.

Automotive Industry Vehicles require strong and durable materials to guarantee their safety. By checking that plastic and metal components have the proper strength to lower failure rates and improve performance.

Construction Industry This device is used to analyze the strength and durability of structures like steel and composite materials. This improves the use of materials and avoids structural failures.

Textile Industry Instrument is used by materials and textile manufacturers to measure the strength and flexibility of materials. Better durability is guaranteed and waste from cut or weak fabrics is decreased.

Plastic and Polymer Industry Various industries make a large amount of plastics. By guaranteeing that plastic materials fulfill the required strength and flexibility requirements, equipment helps to avoid product failures and wasted materials.

Key Features of Digital Tensile Testing Equipment

High Precision Load Sensors – Guarantees accurate tensile strength measurement.

User-Friendly Digital Display – Provides real time test data for quick analysis.

Automated Data Recording – Reduces manual errors and improves consistency.

Multiple Testing Modes – Allows testing of different materials with ease.

Robust Build Quality – Provide durability and quality performance.

Why Choose Perfect Group India for Digital Tensile Testing? Advanced equipment solutions from Perfect Group India help businesses increase quality control and reduce material waste. Our equipment is perfect for a variety of industries because it is made with accuracy, productivity and ease of use.

Benefits of Choosing Our Solutions:

Advanced Technology for accurate and reliable testing

Customizable Equipment to suit different industry needs

Expert Support for smooth integration and instructions for use

Cost-Effective Solutions to help industries improve material use

The Future of Digital Tensile Testing in Waste Reduction Advances devices to provide more accurate and faster results. Further developments in testing techniques will reduce waste or increase material productivity and support environmentally friendly manufacturing. By guaranteeing product quality and reducing wasteful resource use, businesses that invest in this equipment stays productive.

Conclusion Digital Tensile Testing reduces product waste by guaranteeing material strength, durability and security in manufacturing industries. Through checking for material flaws before manufacturing, companies can reduce rework and avoid defects. Quality is increased and costs are reduced as a result.

Perfect Group India provides advanced testing solutions that help companies in reducing waste and maintaining quality. Manufacturers can improve the environment and improve material use with accurate force measurement. By guaranteeing that products meet the requirements, these tests help to reduce failures and returns. Investing in trustworthy testing techniques increases saving resources and environmental responsibility in addition to quality improvement.

#industrial#equipments#perfectgroupindia#perfectinstruments#technology#droptester#business#toploadertester

0 notes

Text

Colorimeter Market Drivers: Key Technological and Industrial Factors Shaping Global Market Growth

The colorimeter market is experiencing notable growth, driven by a combination of technological advancements, increased quality control standards, and the growing need for accurate color measurement across multiple industries. These drivers are shaping a competitive and innovation-driven landscape, with companies investing heavily in more precise, efficient, and user-friendly colorimetry solutions. From manufacturing to pharmaceuticals, and from textiles to petroleum, colorimeters have become essential tools for ensuring product consistency and meeting regulatory compliance.

Rising Industrial Demand for Accurate Color Measurement

One of the primary drivers for the growth of the colorimeter market is the increasing demand for accurate and efficient color measurement across a broad spectrum of industries. Sectors such as food and beverage, pharmaceuticals, paints and coatings, textiles, and chemicals rely heavily on colorimeters to maintain product uniformity and quality. In industries where color plays a critical role in consumer perception and regulatory compliance, these devices are indispensable. For example, in the food industry, consistent color can indicate product freshness or quality, while in pharmaceuticals, it ensures the consistency and stability of formulations.

Technological Advancements Fueling Market Expansion

Technology is a significant catalyst in propelling the colorimeter market forward. Modern colorimeters are now more compact, user-friendly, and capable of high-precision measurements. Integration with digital platforms, wireless connectivity, and cloud-based data storage are transforming how industries collect, analyze, and share color data. These features not only improve accuracy but also increase efficiency, reduce human error, and streamline workflow processes. Portable and handheld colorimeters are becoming particularly popular due to their convenience in field applications, allowing on-site quality checks without the need for lab setups.

Regulatory Compliance and Quality Control Requirements

The growing emphasis on meeting international quality standards is another key driver. Regulatory bodies across industries are setting stricter guidelines for color consistency, particularly in products such as medicines, food items, and industrial coatings. Businesses are investing in high-performance colorimeters to ensure their products meet these standards and avoid costly recalls or regulatory penalties. The increasing adoption of standardized testing and reporting procedures further strengthens the need for advanced color measurement technologies, bolstering market growth.

Environmental Awareness and Sustainability Initiatives

Sustainability has emerged as a core focus in product manufacturing, influencing the materials, methods, and monitoring systems used in production. As industries move toward eco-friendly practices, the role of colorimeters in monitoring natural dyes, eco-friendly coatings, and biodegradable packaging materials becomes more critical. Accurate color measurement helps companies develop sustainable alternatives without compromising on visual appeal or quality, reinforcing the value of colorimeters in environmentally conscious production.

Growth in Research and Development Activities

Investment in research and development is pushing the boundaries of what colorimeters can do. Innovations in sensor technology, software development, and material science are giving rise to more sophisticated instruments capable of multi-angle measurements, complex data analysis, and integration with automated systems. These advancements are not only improving performance but also expanding the application scope of colorimeters, from traditional sectors like textiles to emerging fields like biotechnology and nanomaterials.

Expanding Applications in Emerging Markets

Emerging markets, especially in Asia-Pacific, Latin America, and parts of Africa, are seeing increased demand for color measurement tools due to rapid industrialization and urbanization. Growing manufacturing sectors, improved infrastructure, and rising consumer expectations are encouraging local businesses to adopt advanced quality control instruments like colorimeters. Additionally, government initiatives supporting industrial modernization are further boosting market penetration in these regions.

Increased Adoption in the Petroleum and Chemical Sectors

The petroleum and chemical industries are increasingly using colorimeters for product testing and quality analysis. In the petroleum sector, colorimeters help determine the quality and composition of fuels and lubricants. Variations in color can indicate contamination, aging, or blending issues, which are critical factors for operational safety and regulatory compliance. In chemicals, colorimeters assist in maintaining consistency in dyes, pigments, and intermediate products, playing a vital role in production accuracy and safety.

Conclusion

The colorimeter market is set to continue its upward trajectory, fueled by a blend of industrial demand, regulatory pressure, technological innovation, and expanding global applications. As companies strive for quality, sustainability, and competitiveness, the role of advanced color measurement tools becomes even more essential. With ongoing developments in smart technologies and digital integration, the future of the colorimeter market looks promising, offering new opportunities for manufacturers and end-users alike.

0 notes

Text

Digital Bursting Strength Tester Manufacturers in India

Source of Info: https://www.perfectgroupindia.co.in/blog/digital-bursting-strength-tester-manufacturers-in-india

Introduction

A Digital Bursting Strength Tester is an important device to measure the strength and durability of materials such as paper, fabric and packaging. For the best testing equipment, many Indian industries choose reliable manufacturers. One such brand that is well-known for providing secure and easy to use devices is Perfect Group India. These testers help in making sure that products can withstand pressure while being used or transported. Manufacturers provide user-friendly and productive testers that satisfy various industrial needs by using modern technology. Selecting the correct equipment will benefit Indian businesses in a variety of industries in the future by improving product quality and automating processes.

What is a Digital Bursting Strength Tester?

A lab tool called a Digital Bursting Strength Tester is used to measure the amount of pressure needed to cause materials like paper, leather, cloth or corrugated board to burst. It functions by forcing a sample to burst under hydraulic pressure. It is simple to keep an eye on quality standards thanks to the digital display with accurate results.

This tester is widely used in industries where material strength is important such as printing, textiles and packaging.

Why Bursting Strength Matters

The strength of the material analyzes how well it can protect the contents when it comes to packaging in particular industries like FMCG, pharmaceuticals and e-commerce. Product loss and damage can result from low-quality packaging. To analyze their packaging materials and avoid quality problems, businesses require trustworthy instruments.

Businesses can guarantee that their products stay safe during handling, storage and transportation by selecting the right instrument.

Manufacturers of Bursting Strength Tester in India

Advanced solutions for testing the strength of packaging materials are offered by perfect group india. These devices help in guaranteeing the security of the product while in transportation. For businesses that value quality assurance and durable packaging performance they are required.

Why Choose Perfect Group India?

Perfect Group India is important for its dedication to customer satisfaction, innovation, and quality. The company uses a variety of advanced testing tools to guarantee reliable results and durability. Perfect Group India, which is trusted by businesses all over the country, supports accurate results by combining technology with a simple interface. Select them if you want trustworthy solutions for your testing requirements.

What makes Perfect Group India unique is as follows:

High-Quality Engineering

Our Digital Bursting Strength Tester is made with high-quality parts and durable materials to guarantee accurate measurements.

User-Friendly Interface

With a digital display, simple controls and an easy-to-use sample placement feature our testers are perfect for users of all levels.

Accurate and Fast Results

You can maintain product quality and increase manufacturing productivity with the help of a fast-response digital display which provides reliable and quick results.

Custom Options

We understand that different industries have unique requirements. For this reason we provide models that are customized to meet particular needs in terms of size, features and capacity.

After-Sales Support

To guarantee customers acquire the best return on their investment Perfect Group India provides full support, including installation, training and servicing.

Features of Our Digital Bursting Strength Tester

• Digital Pressure Display: Clear and accurate digital result in real-time

• Adjustable Clamping Mechanism: Easy sample locking for all standard sizes

• Rugged Construction: Built for durable industrial use

• Hydraulic System: Smooth pressure buildup for accurate bursting point

• Easy Maintenance: Low maintenance design with readily available spare parts

Applications of Digital Bursting Strength Tester

The device is used across multiple industries:

• Paper and Packaging: To check the strength of cartons, boxes and paper bags

• Textile Industry: For testing cloth, synthetic fabrics and leather

• Printing: To guarantee the paper can handle printing processes

• Pharmaceutical Packaging: For checking blister packaging, sachets etc.

• Plastic Film and Foils: For analyze strength under pressure

Benefits of Using a Digital Bursting Strength Tester

• Reduces chances of product damage

• Improves quality control

• Saves costs on material rejections

• Improve customer satisfaction

• Meets national and international quality standards

An accurate equipment can help businesses improve quality control while maintaining an advantage in their industry.

Growing Demand in India

With increased awareness of quality control and the rise in global trade more Indian manufacturers are now choosing advanced testing instruments. From startups to large corporations, businesses are focusing on strong, well-tested packaging which is where the Digital Bursting Strength Tester plays an important role.

Conclusion

In order to guarantee the durability and quality of packaging materials across industries, Digital Bursting Strength Tester is important. Perfect Group India provides reliable equipment that satisfies quality standards for companies searching for accurate solutions. Using advanced testing tools has become important because of the increase in demand for strong packaging. These testers give manufacturers accurate information about how reliable a material is allowing them to create higher quality products. Better outcomes, more durable materials and increased customer satisfaction are all results of selecting the correct manufacturer.

0 notes

Text

How IIP / UN Certified Plywood Boxes Help Mumbai’s Exporters Meet Global Standards

Mumbai, being a commercial capital of India, has a booming export industry. From textiles and pharmaceuticals to designer women’s wear and industrial machinery, Mumbai-based businesses rely heavily on high-quality packaging to ensure their products reach international markets safely and in compliance with global standards. This is where IIP / UN Certified Plywood Boxes SUPPLIERS IN MUMBAI play a crucial role.

Why Certification Matters in Export Packaging

In the export business, packaging is more than just protection — it’s about trust, compliance, and brand reputation. International shipments must meet stringent safety, environmental, and logistical regulations. Certification from bodies like the Indian Institute of Packaging (IIP) and the United Nations (UN) ensures that packaging materials, including plywood and fiberboard boxes, comply with these global requirements.

What Are IIP / UN Certified Plywood Boxes?

IIP / UN certified plywood boxes are packaging solutions approved by the Indian Institute of Packaging and recognized under UN guidelines. These boxes are tested for:

Durability

Resistance to environmental factors

Structural integrity during transit

Chemical safety and eco-friendliness

They’re especially ideal for shipping fragile, valuable, or sensitive goods — whether it’s luxury garments or industrial tools.

Key Features of Certified Plywood Boxes

Compliant with ISPM-15 (International Standards for Phytosanitary Measures)

Heat-treated and fumigated to prevent pest infestations

Built to handle rough handling, stacking, and various transport conditions

Importance of Fiberboard Boxes in Lightweight Export Packaging

For lighter items such as designer dresses, accessories, or cosmetics, IIP CERTIFIED FIBERBOARD BOXES SUPPLIERS IN MUMBAI offer an excellent alternative. These boxes are eco-friendly, cost-effective, and certified for international shipping.

Benefits of Fiberboard Packaging:

Lightweight and easy to handle

Customizable shapes and sizes

Approved for air, sea, and land freight

Lower freight charges due to reduced weight

How Certified Boxes Help Exporters in Mumbai

1. Compliance with International Standards

IIP / UN certifications are widely recognized, allowing exporters to ship to countries in Europe, North America, and Asia without facing customs issues.

2. Enhanced Product Safety

Certified boxes are tested under extreme conditions. This ensures your products — whether they are handcrafted lehengas or medical instruments — arrive in perfect condition.

3. Boosts Brand Credibility

When overseas clients receive products in globally certified packaging, it reflects your commitment to quality and professionalism.

4. Prevents Legal Complications

Non-compliant packaging can lead to rejections, fines, or product returns. Certified boxes eliminate this risk.

Choosing the Right IIP / UN Certified Suppliers in Mumbai

Mumbai is home to several packaging manufacturers, but not all are certified. When searching for IIP / UN Certified Plywood Boxes SUPPLIERS IN MUMBAI, ensure they offer:

Certificates issued by IIP or UN

Heat-treated and ISPM-15 stamped packaging

Customization as per your product dimensions

Proven track record of servicing exporters

The same goes for IIP CERTIFIED FIBERBOARD BOXES SUPPLIERS IN MUMBAI — look for those who provide documentation and have experience in export-grade packaging.

Final Thoughts

In the highly competitive export industry, even minor packaging errors can cost businesses time, money, and client trust. IIP / UN Certified Plywood and Fiberboard Boxes provide a robust, compliant, and reliable solution for exporters in Mumbai. Whether you deal in high-end women’s fashion or industrial products, certified packaging can be your passport to smooth and successful international trade.

0 notes

Text

Top Quality Brass Coils Manufacturers in India

Top Quality Brass Coils Manufacturers in India: Powering Precision Across Industries

India’s non-ferrous metal industry is rapidly expanding, and within it, brass coils have gained significant importance due to their excellent mechanical and aesthetic properties. Brass, an alloy of copper and zinc, is widely used for its strength, corrosion resistance, and malleability. These qualities make top quality brass coils Manufacturer a preferred choice across industries like electrical, automotive, construction, electronics, and decorative applications. With India emerging as a global manufacturing hub, several brass coil manufacturers have gained recognition for their quality, consistency, and innovation.

Why Brass Coils?

Brass coils are flat-rolled products typically wound into rolls and used in a range of applications. Their popularity is attributed to key properties such as:

High thermal and electrical conductivity

Resistance to corrosion and fatigue

Easy machinability and formability

Aesthetic golden appearance

They are used in precision engineering components, heat exchangers, musical instruments, electric switchgear, hardware fittings, and more.

Brass Coil Manufacturing in India

India has long been a center for brass production, especially in cities like Jamnagar (Gujarat) and Jagadhri (Haryana). Manufacturers here cater to both the domestic and international markets. Indian companies have adopted modern metallurgical practices and maintain international standards of quality and testing to ensure that their brass coils meet the specific requirements of diverse industries.

Brass coils from India are available in multiple grades such as CuZn10, CuZn30, CuZn37, and CuZn40, with various hardness levels (soft annealed to spring hard) and dimensions. These are suitable for punching, stamping, bending, or further processing into other components.

Leading Brass Coil Manufacturer: Krishna Metal Works (KMW India)

Among the top brass coil manufacturers in India, Krishna Metal Works (KMW India) stands out for its legacy of quality and precision. Established in 1935, the company has grown into a trusted supplier of copper and copper alloy products with a strong global footprint.

Key Highlights of KMW India:

Wide Product Range: KMW offers brass coils in various grades including CuZn05 to CuZn40, catering to different industry needs.

Dimensional Range:

Thickness: 0.05 mm to 3.0 mm

Width: 6 mm to 406 mm

Tempers: Soft, quarter-hard, half-hard, hard, extra-hard, and spring hard

Customization: Products are tailored to meet customer-specific mechanical and chemical properties.

Certifications: The facility is ISO 9001:2015 certified, ensuring consistent product quality.

Production Facility: A 100,000+ sq. ft. manufacturing plant equipped with modern machinery and rigorous quality testing labs.

KMW India’s brass coils are used in:

Electrical and electronic equipment

Radiator tanks and heat exchangers in automobiles

Ammunition casings and defense equipment

Decorative products and architectural hardware

Textile and construction machinery components

Advantages of Choosing Indian Brass Coil Manufacturers

Indian brass coil manufacturers offer several advantages:

Cost-Effective Solutions: Due to availability of raw materials and skilled labor

High Quality Assurance: Strict quality control and ISO-certified production

Export-Ready Infrastructure: Manufacturers like KMW have extensive logistics capabilities for global shipping

Eco-Friendly Practices: Emphasis on sustainable and environmentally responsible manufacturing

Export Potential

India’s brass coil exports have seen consistent growth due to the global demand for high-quality, affordable metal products. top quality brass coils Manufacturers like KMW India export to regions such as Europe, the Middle East, Southeast Asia, and North America. Their ability to match international standards while offering competitive pricing gives them a strong edge in global markets.

Conclusion

The Indian brass coil manufacturing industry is not only thriving but setting benchmarks in quality and innovation. Krishna Metal Works (KMW India) exemplifies this growth through its dedication to excellence, customization, and international service. Whether for industrial use or aesthetic applications, top-quality brass coils from India offer the perfect combination of performance, reliability, and value.

For businesses seeking dependable brass coil solutions, India—and particularly manufacturers like KMW—should be at the top of the list. With decades of experience, technical expertise, and a customer-first approach, KMW India continues to be a trusted name in the world of non-ferrous metal products.

For more information,

Visit:- https://www.kmwindia.com/brass

0 notes

Text

Abstract Flammability test in textile is a crucial assessment to ensure textile products meet fire safety standards. The LISUN ZY-3 Needle Flame Test provides an effective method for evaluating textile materials’ resistance to ignition by small flames. This article discusses the significance, methodology, and results of using the LISUN ZY-3 Needle Flame Test in textile flammability testing. A comparative table of flammability performance for different textile types is also included to highlight the practical implications of this test. 1. Introduction Textile materials are widely used in everyday life, including clothing, home furnishings, and industrial applications. Ensuring their fire safety is a critical concern in textile manufacturing. The flammability test in textile helps manufacturers assess the risk of textiles catching fire and contributing to flame spread. One of the most effective and widely used tests for this purpose is the LISUN ZY-3 Needle Flame Test, which simulates the impact of small flames on textiles. This article provides a detailed overview of the LISUN ZY-3 Needle Flame Test, its working principles, applications, and the importance of flammability testing in textile industries. ZY-3 Needle Flame Test 2. Importance of Flammability Test in Textile Flammability tests in textile materials are essential for: • Ensuring Consumer Safety: Preventing fire hazards in clothing, upholstery, and curtains. • Regulatory Compliance: Meeting national and international fire safety standards (ISO 11925-2, UL 94, etc.). • Product Quality Control: Enhancing the durability and safety of textiles. • Reducing Fire-Related Risks: Lowering the risk of fire accidents in public and private spaces. 3. LISUN ZY-3 Needle Flame Test: Overview The LISUN ZY-3 Needle Flame Test is an advanced instrument designed to assess the flammability of textiles by exposing them to a controlled flame for a specific duration. It is widely used for safety testing in textiles, electronics, and plastics. 3.1 Features of LISUN ZY-3 Needle Flame Test • Compliance with Standards: Conforms to IEC 60695-11-5, ISO 11925-2, and UL 94 standards. • Adjustable Flame Parameters: Allows precise control over flame height and exposure duration. • Automatic Ignition System: Ensures consistency and accuracy in testing. • Real-Time Data Recording: Facilitates detailed analysis of flammability characteristics. • Safety Mechanisms: Includes automatic shut-off and fire containment features. For more details, visit the official LISUN product page: LISUN ZY-3 Needle Flame Test. 3.2 Test Procedure • Sample Preparation: Textile samples (100mm x 50mm) are conditioned under controlled temperature and humidity. • Flame Application: A 12mm flame is applied to the textile for a defined period (e.g., 5, 10, or 30 seconds). • Observation: The burning behavior, flame spread, and afterflame time are recorded. • Data Analysis: The results are compared with safety thresholds to determine the textile’s flammability rating. 4. Experimental Data and Analysis A series of flammability tests in textile were conducted using the LISUN ZY-3 Needle Flame Test on different fabric types. The table below presents the results: Table 1: Flammability Test Results of Different Textile Materials Textile Type Flame Exposure Time (s) Afterflame Time (s) Char Length (mm) Flammability Rating Cotton Fabric 10 3 60 High Risk Polyester Fabric 10 1 30 Medium Risk Wool Fabric 10 0 20 Low Risk Nylon Fabric 10 2 40 Medium Risk Flame-Retardant Cotton 10 0 15 Very Low Risk 4.1 Interpretation of Results Cotton Fabric exhibited the highest flammability risk due to its prolonged afterflame time and significant charring. Polyester and Nylon Fabrics showed moderate risk, with shorter afterflame times and reduced char length. Wool Fabric demonstrated excellent fire resistance, with no observable afterflame. Flame-Retardant Cotton performed best, with minimal charring and no afterflame, making it ideal for fire-resistant applications. 5. Conclusion The flammability test in textile is essential for ensuring fire safety in textile products. The LISUN ZY-3 Needle Flame Test provides a reliable and standardized method for evaluating the fire resistance of textiles. Experimental results confirm that textile composition significantly affects flammability, with flame-retardant fabrics offering superior protection. Manufacturers should integrate rigorous flammability tests in textile production to enhance product safety and compliance with international fire safety regulations. For more information, visit the LISUN official product page: LISUN ZY-3 Needle Flame Test. Read the full article

0 notes

Text

Bromos Organics: Trusted Bromine Derivatives Manufacturers India

India is a global leader in the production and supply of specialty chemicals, and bromine derivatives play a vital role in many industrial processes. As demand for high-purity chemical compounds grows, manufacturers that emphasize quality, innovation, and sustainability stand out. Bromos Organics is one such name that has earned its place as one of the most trusted bromine derivatives manufacturers in India.

With a strong focus on research, quality control, and customer satisfaction, Bromos Organics provides top-tier brominated compounds for diverse applications across the pharmaceutical, agricultural, and chemical industries.

What Are Bromine Derivatives?

Bromine derivatives are compounds that contain bromine as a central element, often combined with carbon, hydrogen, nitrogen, or oxygen. These derivatives are extensively used in various sectors due to their chemical reactivity and stability. Common applications include:

Flame retardants

Agrochemical intermediates

Pharmaceutical active ingredients (APIs)

Dyes and pigments

Water treatment solutions

Specialty solvents

Because of their specialized nature, bromine derivatives must be manufactured under stringent safety and quality protocols—a standard that Bromos Organics consistently upholds.

Why Choose Bromos Organics?

1. Advanced Manufacturing Infrastructure

Bromos Organics operates with cutting-edge equipment and technologically advanced processes to ensure the production of bromine derivatives meets international standards. Our facility is equipped with high-precision instruments for chemical synthesis, purification, and analysis.

2. Rigorous Quality Assurance

Each batch of our bromine derivatives undergoes rigorous testing and validation. From raw material sourcing to final delivery, quality is integrated into every step of our production process. Our laboratory ensures products meet required purity levels, consistency, and performance benchmarks.

3. Diverse Product Portfolio

Our range of brominated compounds serves various industries. We manufacture intermediates and fine chemicals suitable for:

Pharmaceutical companies looking for high-purity bromine compounds for drug formulations

Agrochemical manufacturers who require brominated building blocks

Industrial clients in need of flame-retardant chemicals and specialty solvents

4. Environmental Commitment

As responsible bromine derivatives manufacturers in India, Bromos Organics places great emphasis on sustainable practices. We follow environmentally conscious processes, minimize chemical waste, and strive to reduce our carbon footprint through innovation and recycling systems.

Applications of Bromine Derivatives

The versatility of bromine derivatives makes them indispensable across sectors:

Pharmaceuticals: Used in the synthesis of anesthetics, sedatives, and anticonvulsants.

Agriculture: Serve as key ingredients in herbicides, pesticides, and fumigants.

Flame Retardants: Widely used in textiles, plastics, and electronics to enhance fire resistance.

Oil & Gas: Employed in drilling fluids and as corrosion inhibitors.

Water Treatment: Brominated compounds are used to control microbial activity in water systems.

With such wide applications, choosing the right manufacturer is critical to ensuring safety, reliability, and compliance.

Commitment to Customer Satisfaction

At Bromos Organics, our client relationships are built on trust, transparency, and long-term value. We collaborate closely with our partners to understand their specific requirements and provide custom solutions as needed. Our agile production capabilities allow us to scale and adapt based on client demand and market trends.

Research and Development at the Core

Continuous innovation is a cornerstone of Bromos Organics’ success. Our dedicated R&D team is constantly working on the development of new molecules, improvement of synthesis routes, and enhancement of product performance. This ensures that our clients stay ahead in a competitive market.

Serving India and Beyond

Though based in Northern India, Bromos Organics serves clients across the country and exports to global markets. As one of the leading bromine derivatives manufacturers in India, we are proud to contribute to India's position as a hub for specialty chemical manufacturing.

Final Thoughts

The demand for high-quality bromine derivatives continues to grow across industries. Whether you need reliable chemical intermediates for pharmaceuticals or robust flame retardants for manufacturing, Bromos Organics offers trusted solutions tailored to your requirements.

With a deep commitment to innovation, sustainability, and client satisfaction, Bromos Organics stands tall among India’s top chemical manufacturers. Partner with us for your bromine compound needs and experience excellence in every interaction.For more information or to explore our product range, visit Bromos Organics.

#BromineDerivativesManufacturersIndia#BromineDerivativesManufacturersNorthernIndia#HYDROBROMICACID48%

0 notes

Text

Leading Dyestuff , Dyesintermediates manufacturer| Hindprakash Chemicals

About Hindprakash Chemicals

Established in 1942, Hindprakash Chemicals Pvt. Ltd. has evolved into a prominent name in the manufacturing, import, and export of dyestuffs and dye intermediates in India. Over the decades, the company has diversified its product range to include textile auxiliaries, specialty chemicals, and other related products, catering to various industries such as textiles, paint, pharmaceuticals, and more

Our Product Range

At Hindprakash Chemicals, we offer a comprehensive array of products designed to meet the diverse needs of our clients:

Dyestuffs: Including acid dyes, cationic basic dyes, direct dyes, disperse dyes, and reactive dyes.

Dye Intermediates: We specialize in both the import and export of high-quality dye intermediates.

Chemicals & Solvents: Supplying basic chemicals and solvents essential for various industrial applications.

Chemicals & Auxiliaries: Offering pretreatment chemicals, dyeing auxiliaries, green acid, printing auxiliaries, finishing auxiliaries, and washing agents .

Pigments: Providing a range of pigments suitable for textiles and other applications.

Resins & Adhesives: Manufacturing resins and adhesives for diverse industrial uses.

Other Products: Including food colors and other specialty products.

Research & Development

Our in-house R&D facility enables the development of new products, improvement of existing processes, and enhancement of product quality. This commitment to innovation leads to cost reduction, better quality for customers, and a reduced environmental footprint. We also offer customized product development under secrecy agreements to meet specific client requirements .

Global Presence

With over 75 years in the industry, Hindprakash Chemicals has expanded its reach globally. We have established subsidiaries and partnerships in various countries, including Vietnam, China, and the UAE, to support our international business and cater to a diverse clientele .

Commitment to Quality

Quality is at the core of our operations. We have dedicated quality control laboratories equipped with modern testing instruments such as spectrophotometers, HPLC, dyeing and printing equipment, and fastness test equipment. These facilities ensure that all our products meet international standards and customer expectations .

Sustainability and Social Responsibility

Hindprakash Chemicals is committed to sustainable practices and social responsibility. We actively engage in activities that promote environmental sustainability and contribute positively to the communities we operate in.

Hindprakash Chemicals, established in 1942, is a leading manufacturer of dyestuffs, dye intermediates & specialty chemicals, committed to quality & innovation

0 notes

Text

Best Water Management Solutions in Vadodara: Advanced Technology for a Sustainable Tomorrow

Vadodara, a thriving industrial and educational hub of Gujarat, has seen rapid urbanization and growth over the last decade. With this development comes the increasing demand for sustainable water management practices. From residential societies to large-scale industries, the need for reliable and efficient water treatment is paramount. This is where Aquamech Engineering Corporation steps in with some of the best water management solutions in Vadodara.

An ISO 9001:2015 certified company, Aquamech Engineering Corporation is redefining how Vadodara manages water and wastewater through innovation, precision, and sustainability.

Advanced and Specialized Service Packages

Aquamech offers forward-thinking, turnkey solutions tailored to suit modern water challenges in Vadodara. Their latest service packages include:

Build-Own-Operate (BOO) and Build-Own-Operate-Transfer (BOOT) models for long-term infrastructure projects.

Containerized Water Treatment Plants on Rental Basis – a flexible option for industries with temporary or fluctuating water treatment needs.

Remote Monitoring of water treatment plants – a tech-savvy solution enabling real-time performance tracking and preventive maintenance.

Energy Saver Automation for ETPs (Effluent Treatment Plants) and STPs (Sewage Treatment Plants), helping industries save both energy and operational costs.

Cooling Tower Auto Blow Down Automation – a smart solution to optimize water usage and prevent scale buildup.

Oxygen Detectors for STPs, ensuring enhanced safety and efficiency.

Car Wash Recycle Systems that promote water reuse in the automotive sector.

These innovations are revolutionizing the way local industries and municipalities approach water sustainability, ranking Aquamech’s offerings among the best water management solutions in Vadodara.

Full-Spectrum Water Services

Aquamech isn’t just a product supplier—it’s a complete solution partner. Their services include:

Operation & Maintenance Contracts (comprehensive or non-comprehensive) to ensure uninterrupted plant performance.

Audits & Consulting to help industries and facilities optimize their water usage and meet compliance requirements.

Laboratory Services offering state-of-the-art water testing for quality assurance and regulatory compliance.

Sanitization Services to maintain hygiene and performance across treatment systems.

Modification & Up-Gradation Services, enabling older water treatment systems to operate like new through cutting-edge enhancements.

Real-Time Analysis Tools including online BOD, COD, pH, and TDS analyzers integrated with pollution control board servers.

All these comprehensive offerings contribute significantly to establishing Aquamech as a provider of the best water management solutions in Vadodara.

Spares, Consumables, and Technical Support

Aquamech ensures continued performance with a full range of spares and consumables, such as:

RO and UF membranes

DM & Softener Resins

Antiscalants, Cleaning Chemicals

Cartridge & Bag Filters

Online instrumentation (pH meters, ORP meters, conductivity meters, etc.)

ETP & STP components

Dosing pumps and more

Whether it’s maintaining a commercial STP or a high-purity water system in a pharmaceutical plant, Aquamech provides end-to-end support.

Industries and Infrastructure Benefiting in Vadodara

Industries in Vadodara—from petrochemical to pharmaceuticals, from food processing to textiles—have seen real benefits through Aquamech’s technology-driven solutions. Even residential townships and commercial establishments have turned to their containerized systems and smart monitoring tools to meet environmental standards and reduce water wastage.

With Vadodara’s growing focus on smart city initiatives and green infrastructure, Aquamech is already playing a vital role in aligning with the city’s long-term vision for sustainability.

Conclusion

Vadodara’s water challenges require more than just conventional fixes—they demand smart, scalable, and sustainable solutions. Aquamech Engineering Corporation brings just that, with a holistic approach that combines technology, service, and innovation.

For industries, municipalities, or private developers looking to adopt the best water management solutions in Vadodara, Aquamech is the go-to partner offering future-ready systems and unmatched customer support.

📩 Get in touch today at [email protected] 📞 Call: (+91) 9833318254 | 22-404-90800 🌐 Visit: A 132, Industrial Area, MIDC Pawane, Navi Mumbai, Maharashtra

0 notes

Text

How to Conduct a Fraud Risk Analysis in Financial Reporting