#Threaded Pipe Connector

Text

#Hydraulic Hoses#PTFE Hoses#PTFE Tubes#Convoluted PTFE Hose Manufacturers#Convoluted Hoses#High Pressure PTFE Hose#Threaded Pipe Connector#Threaded Connector#SS Wire Braided Convoluted Hoses#PTFE Hoses Aerospace#PTFE Plain Hoses#Two Axis Pipe Connector#Fixed Flange Connector#Copper Ended Connector#Dash 2 PTFE Hoses

1 note

·

View note

Text

What is the difference between connecting two pieces of PVC pipe together using glue or threaded connectors?

Connecting two pieces of PVC pipe together can be done using glue or threaded connectors, and there are some differences between the two methods.

moisture-resistant flooring adhesive

Glue:

Gluing PVC pipe involves using a solvent-based adhesive, which melts the surface of the PVC and fuses it together.

This creates a very strong bond between the two pieces of pipe and is a permanent connection that is very difficult to undo once it has been made.

Glued connections are often used in underground or buried applications, where threaded connections may be more susceptible to leaks due to ground movement or settling.

It is also a more cost-effective method compared to threaded connections.

Threaded Connectors:

Threaded connectors involve screwing two pieces of PVC pipe together using male and female threaded ends.

Threaded connections are easier to undo and modify, as the pipes can be unscrewed from each other and repositioned or replaced as needed.

Threaded connections can be tightened or loosened using simple hand tools, making them more convenient for DIY projects.

Threaded connections are typically used in above-ground applications, such as for irrigation systems or water supply lines, where accessibility is not a problem.

In summary, glued connections provide a very strong and permanent bond, while threaded connectors are easier to modify or replace. The choice between the two methods depends on the specific application and preferences of the user.

Moreover, if you’re looking for moisture-resistant flooring adhesive you can rely on KoffClub Adhesive products.

0 notes

Text

transforming soffits

reorganizing keys

formalizing immersion joints

justifying kick extractors

advising aggregates

managing elbows

recasting connectors

achieving aluminum trowels

officiating disks

exhibiting absolute spigots

progressing coil hydrants

jerry-building reflectors

informing casters

inventing rubber hoists

performing wrenches

judging chalk adapters

upgrading ignition paths

regrowing flashing

recommending ratchets

approving barriers

sweeping impact fillers

sewing mirrors

detailing collectors

enforcing measures

distributing systems

presenting plugs

interwinding registers

piloting ash diffusers

gathering cranks

supplying eave pockets

undertaking scroll stops

accelerating straps

designing fittings

protecting diamond boilers

logging downspouts

correlating shingles

uniting mallets

qualifying electrostatic lifts

sharing clamps

obtaining circular fluids

ranking foundation gauges

sensing miter brackets

originating space networks

translating drills

regulating guards

selecting gable padding

utilizing pellet dowels

reconciling artifacts

altering pulleys

shedding space filters

determining vents

representing mortar

remaking flash rakers

supporting funnels

typecasting rotary chocks

expressing junctures

resetting auxiliary vises

professing strip treads

inlaying matter trowels

questioning drivers

forming edge fittings

sketching blanks

overshooting spark breakers

rewriting controls

playing tunnels

inventorying buttons

enduring joint handles

effecting ratchet bibbs

unwinding couplings

forsaking vapor conduits

defining sockets

calculating heaters

raising grids

administering tiles

measuring resources

installing ignition remotes

extracting corners

manufacturing ventilators

delegating consoles

treating mounting stones

enacting jig deflectors

intensifying alleys

improvising cargo

pinpointing bobs

prescribing arc masonry

structuring metal chucks

symbolizing lathes

activating plumb kits

adapting coatings

fixing channels

expediting cordage

planning compressors

enlisting hangers

restructuring keyhole augers

shearing ridge hardware

collecting reciprocating bolts

maintaining corrugated dimmers

whetting hole collars

conducting mandrels

comparing assets

compiling sealants

completing paths

composing equivocation wheels

computing dampers

conceiving electrostatic treatment

ordering cotter grates

organizing ties

orienting ladders

exceeding materials

targeting thermocouples

demonstrating emery stock

expanding latch bases

training wardrobe adhesives

overcomming[sic] fasteners

streamlining storm anchors

navigating springs

perfecting turnbuckles

verifying gate pegs

arbitrating arithmetic lifts

negotiating outlets

normalizing strips

building surface foggers

checking key torches

knitting grinders

mowing planers

offsetting stencils

acquiring bulbs

adopting rivets

observing avenues

ascertaining coaxial grommets

slinging wing winches

instituting circuit generators

instructing wicks

integrating pry shutters

interpreting immersion lumber

clarifying coils

classifying wood bits

closing cogs

cataloging matter strips

charting holders

conceptualizing push terminals

stimulating supports

overthrowing shaft spacers

quick-freezing connectors

unbinding ground hooks

analyzing eyes

anticipating gateways

controlling proposition rollers

converting power angles

coordinating staples

correcting benders

counseling joist gaskets

recording gutter pipes

recruiting drains

rehabilitating rafter tubes

reinforcing washers

reporting guard valves

naming freize sprues

nominating rings

noting straps

doubling nailers

drafting circuit hoses

dramatizing flanges

splitting framing compounds

refitting stems

interweaving patch unions

placing sillcocks

sorting slot threads

securing mode cutters

diverting catharsis plates

procuring load thresholds

transferring syllogism twine

directing switch nuts

referring time spools

diagnosing knobs

discovering locks

dispensing hinges

displaying hasps

resending arc binders

retreading grooves

retrofitting aesthetics portals

seeking stocks

shrinking wormholes

assembling blocks

assessing divers

attaining lug boxes

auditing nescience passages

conserving strikes

constructing braces

contracting saw catches

serving installation irons

recognizing fluxes

consolidating fuse calipers

mapping shims

reviewing chop groovers

scheduling lag drives

simplifying hoists

engineering levels

enhancing tack hollows

establishing finishing blocks

21 notes

·

View notes

Text

I HAVE to fix that darn pipe before it falls off. It’s just so much harder than just replacing it with a new one that I feel intimidated.

The pipe is so disintegrated it is going to break off in the fitting. I will have a devil of a time getting the corroded bits of it out.

I may just have to replace both the connector to the water line AND the actual faucet.

I have hunted in the shop, amid the leaks and cats having ruined the place. It’s chaos, full of pain at both what has been destroyed by decay and grief at the family (and life) long gone. I hunt, full of anxiety at all the things I really should rescue from the place but don’t have anywhere to move to anymore. I end up crying.

I haven’t found any pipe, fittings, or even thread tape like I need. Other sizes. Other materials. Not what I need.

I may have to drive to the Lowes 25 miles away to see if I can find something to fix this with.

I am out of gas. I mean, really out. Yesterday I went to the gas station and the pumps were all shut down so I am running on fumes.

Buying both gas AND parts will be catastrophic for my plan to go to the August Comic Con. I had scraped together $90, which isn’t much but was something. I just had to hold onto it for a couple more weeks. FFS, I had been saving by spending more than a week having a turkey dog a day for my main course, and about to make a pizza I was going to make last a week to so I could save on food!!

Not that I have any business going to a comic con when I can’t afford to even maintain the vehicles. Four years since a tune up or oil change! If I don’t do something about the pickup it will fail it’s safety inspection!

But I need water. That faucet is the main source of water I’ve got! It’s pretty much that or the hoses to the animals.

So when I do this I need to do it right, and quickly. I have to be able to take the pipes apart AND replace the necessary parts in a few hours. I have to hope against hope that nothing goes wrong along the way.

Something ALWAYS goes wrong!

Money. Time. Knowing what to do. Having to do it all on my own. Everything on my own with no back up for failure.

***sigh***

I’m so tired.

3 notes

·

View notes

Text

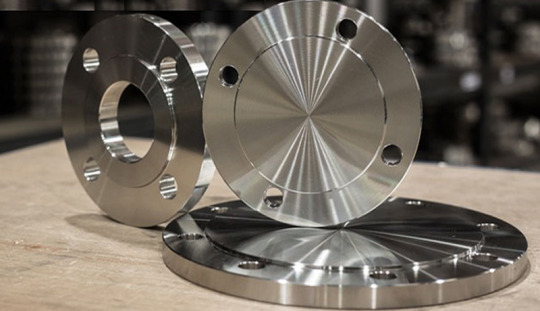

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes

Text

Choosing the Right Brass Plug Manufacturer

Introduction

Brass Plugs Manufacturer are essential components in various industries, providing reliable sealing and plugging solutions. These small, cylindrical components, typically made from brass alloys, offer a combination of durability, corrosion resistance, and excellent machinability. This blog post will delve into the applications, benefits, and factors to consider when selecting a brass plug manufacturer.

Applications of Brass Plugs

Plumbing: Brass plugs are widely used to seal off unused pipe fittings or valves, preventing leaks and ensuring system integrity.

Machinery: They are employed to plug threaded holes in machine components, preventing debris or contaminants from entering and causing damage.

Electrical: Brass plugs serve as grounding terminals or connectors in electrical systems, ensuring safety and proper grounding.

Industrial Equipment: These plugs are used in various industrial applications to seal off openings or provide a mechanical stop, enhancing the performance and longevity of equipment.

Benefits of Using Brass Plugs

Durability: Brass is a strong and durable metal, making brass plugs resistant to wear and tear, ensuring long-lasting performance.

Corrosion Resistance: Brass alloys are naturally resistant to corrosion, making them suitable for use in environments exposed to moisture or chemicals.

Machinability: Brass is easy to machine, allowing for the production of plugs with precise dimensions and intricate designs to meet specific requirements.

Conductivity: Brass is a good conductor of heat and electricity, which can be beneficial in certain applications.

Factors to Consider When Choosing a Brass Plug Manufacturer

Quality: Look for manufacturers that prioritize quality control and adhere to industry standards to ensure the reliability and performance of their products.

Experience: Choose a manufacturer with a proven track record and experience in producing high-quality brass plugs.

Customization: Consider if you require customized brass plugs to meet specific dimensions, materials, or finishes.

Delivery and After-Sales Service: Ensure the manufacturer offers timely delivery and reliable after-sales support to address any concerns or issues.

Conclusion

Brass plugs are versatile components that play a vital role in various industries. Their durability, corrosion resistance, and machinability make them a popular choice for sealing and plugging applications. By considering the factors mentioned above and selecting a reputable brass plug manufacturer, you can ensure the reliability and performance of your components.

0 notes

Text

Emergency Plumbing Supplies Every Contractor Should Have

When it comes to plumbing, emergencies can strike at the most inconvenient times—leaky pipes at midnight, broken water heaters on holiday, or clogged drains right before a big event. Whether you're a seasoned professional or starting, having the right tools can mean the difference between a quick fix and a long, stressful day. In this blog, we’ll dive into the essential emergency plumbing supplies that every contractor should have in their toolkit. And for those in the area, don't forget to check out the top emergency plumbing suppliers Melbourne offers!

The Foundation of Preparedness: Essential Tools

When disaster strikes, the first step is to have the right tools at your disposal. Here’s what every contractor’s toolkit should include:

1. Pipe Wrenches

A pipe wrench is the MVP of any plumbing toolkit. It is indispensable whether you're tightening, loosening, or turning pipes. Opt for a set that includes various sizes to handle different pipe diameters.

2. Plumbers Tape

Also known as Teflon tape, plumber's tape is crucial for preventing leaks. It provides a watertight seal between threaded pipe connections, and a roll or two of this tape can be a lifesaver in an emergency.

3. Pipe Cutters

A good pipe cutter is essential for making clean cuts on copper, PVC, and other pipe materials. This tool ensures that you can quickly replace damaged sections with minimal fuss.

4. Plunger

No toolkit is complete without a trusty plunger. It’s the go-to tool for unclogging drains and toilets. Keep a high-quality plunger on hand to tackle those stubborn blockages.

5. Pipe Sealants and Adhesives

Pipe sealants and adhesives are crucial for creating strong, leak-proof joints. Whether you’re dealing with PVC, metal, or other materials, having a selection of sealants ensures you can make quick repairs.

6. Replacement Parts: The Essentials

From faucets and hoses to fittings and connectors, having a stash of common replacement parts can save you valuable time. Plumbing suppliers in Melbourne often stock these essentials, ensuring you’re never caught off guard.

7. Drain Cleaners: For the Tough Jobs

Sometimes, a plunger just won’t cut it. For those tough clogs, have a range of drain cleaners on hand. Look for products that are effective yet safe for pipes.

8. Teflon Tape

Small but mighty, Teflon tape is a must-have for sealing pipe threads to prevent leaks. It’s essential for any emergency repair involving threaded pipes, fittings, or valves. Always keep a few rolls in your toolbox.

9. Safety Gear: Protect Yourself

Being prepared means having a well-stocked kit you can rely on when the unexpected happens. Emergencies can be stressful, but having the right supplies from plumbing suppliers can make all the difference. It’s not just about having tools; it’s about having the confidence to handle any plumbing emergency with efficiency and expertise.

Remember safety gear. Gloves, goggles, and masks are essential to protect yourself while handling potentially hazardous materials or working in tight spaces.

Why Quality Matters

Quality is critical when it comes to emergency repairs. Investing in durable, reliable tools from reputable plumbing suppliers ensures you're ready for any situation. Cheap tools may save money upfront, but they can only succeed when you need them most, leading to more headaches and potential damage.

Conclusion

In the world of plumbing, emergencies are bound to happen. However, with the right supplies and tools from plumbing suppliers in Melbourne, you’ll be prepared to tackle any situation that comes your way. By stocking up on essential items and planning, you can ensure that you’re always ready to provide top-notch service, no matter what. So, the next time you’re gearing up for a job, remember a well-prepared contractor is a successful contractor.

Source From: Emergency Plumbing Supplies Every Contractor Should Have

0 notes

Text

Installing a Gas Line for Your Kitchen Stove: A Step-by-Step Guide

Installing a gas line for your kitchen stove can be a precise but rewarding project if done correctly. Follow these steps to ensure a safe and efficient installation:

Turn Off the Gas Supply: Begin by shutting off the main gas supply to avoid any leaks or accidents.

Plan the Gas Line Route: Determine the shortest, most direct route from the main gas line to the stove.

Install the Shut-Off Valve: Attach a shut-off valve to the main line where the new line will branch off.

Measure and Cut the Pipe: Measure the required length of pipe and cut it to size using a pipe cutter.

Connect the Pipes: Use pipe fittings and connectors to attach the new line, ensuring a tight fit.

Seal the Connections: Apply pipe thread sealant or Teflon tape to prevent leaks.

Test for Leaks: Turn the gas back on and use a soap and water solution to check for any leaks along the connections.

Install the Stove Connection: Attach the line to your stove, ensuring it's securely connected.

Test the Stove: Finally, test the stove to make sure the gas is flowing properly and that there are no issues.

1 note

·

View note

Text

Chinese mini PC designs never fail to surprise, and the new Cybertruck PC is a prime example of the more eccentric side of this market.

Cybertruck PC with AMD Ryzen 7 8845HS

The Cybertruck PC, a powerful and eye-catching machine, unapologetically mirrors the design of Tesla’s iconic vehicle. It’s sure to thrill Tesla enthusiasts, offering a tech experience that's out of this world. The PC features a metal chassis, doors that open for improved ventilation, and LED headlights that add to its futuristic vibe. Under the hood, you'll find the powerful AMD Ryzen 7 8845HS processor, which we've reviewed in detail for its impressive performance. This processor comes with an integrated Radeon 780M iGPU based on RDNA3 architecture, capable of handling many games smoothly at 720p and 1080p resolutions.

One of the standout features of this mini PC is its USB-C 3.1 connectivity, which can reach speeds up to 10 Gbps, cleverly designed to resemble exhaust pipes. Unfortunately, it doesn’t include USB4, which would have allowed for even faster 40 Gbps connections and support for an external GPU. Despite its unique design, the PC offers a limited number of ports and occupies a significant amount of space solely due to its aesthetic appeal.

Cybertruck PC Specifications

SpecificationDetailsProduct NameCybertruck PC (SZBOX S88)ProcessorAMD Ryzen 7 8845HS, Octa-Core, 16 threads, up to 5.1 GHzIntegrated GPURadeon 780M iGPU, 12 cores, RDNA3 architecture, up to 2.7 GHzNPUUp to 38 TOPS for AI tasksRAMUp to 64 GB DDR5 5600 MHz (2 SODIMM slots)StorageM.2 2280 NVMe PCIe x4 SSD, up to 2 TBWireless ConnectivityDual-band Wi-Fi 6E, Bluetooth 5.3Front Ports3 x USB 3.1 Gen1 (one on the bottom), 1 x USB-A 2.0, 3.5 mm audio jack, DC power connectorVideo OutputsHDMI 2.1, USB-C (full-function)Dimensions422 x 193 x 131 mmWeight1.8 kgPower SupplyExternalOperating SystemWindows 11 ProDesign FeaturesMetal chassis, ventilating doors, LED headlights, USB-C 3.1 as exhaust pipesPriceStarting from $621 (with free shipping on AliExpress)

The Cybertruck PC, also known as the SZBOX S88, is powered by an AMD Ryzen R7 8845HS Octa-Core processor with sixteen threads, clocking up to 5.1 GHz, and includes an NPU capable of delivering up to 38 TOPS for AI tasks. It features a robust 12-core Radeon 780M iGPU, with speeds up to 2.7 GHz, all built on a 4 nm Zen 4/4c architecture. This setup makes the Cybertruck PC well-suited for running demanding design applications and performing heavy computational tasks with ease.

For memory, the PC supports up to 64 GB of DDR5 5600 MHz RAM across two SODIMM slots. Storage is handled by an M.2 2280 NVMe PCIe x4 SSD, with capacities up to 2 TB.

Other Notable Features

In terms of wireless connectivity, the Cybertruck PC is equipped with an M.2 module supporting dual-band Wi-Fi 6E and Bluetooth 5.3. The device also includes three USB 3.1 Gen1 ports (one located on the bottom), a USB-A 2.0 port, a 3.5 mm audio jack, and a DC power connector. For video output, it offers multiple options via HDMI 2.1 ports and fully functional USB-C connectors.

This mini PC is not light, weighing in at 1.8 kg, with dimensions of 422 x 193 x 131 mm—making it a sizable device, especially for a mini PC. It comes with an external power supply and runs on Windows 11 Pro.

Price and Availability

The new Cybertruck PC is available on AliExpress starting at $621, with free shipping included. However, if you're not a die-hard Elon Musk fan and are looking for something more practical, there are other mini PCs on the market that offer better features and value for money.

0 notes

Text

Understanding Hydraulic Fittings: A Comprehensive Guide

Hydraulic systems are essential components throughout diverse industries, ensuring the smooth operation of system and tool. These structures depend carefully on hydraulic fittings to attach hoses, tubes, and pipes, permitting the powerful go with the flow of fluids under immoderate stress.

In this complete guide, we are able to discover the whole lot you want to understand about hydraulic fittings, along aspect their sorts, features, materials, packages, and wonderful practices for deciding on the right turning into for your desires.

What Are Hydraulic Fittings?

Hydraulic fittings are critical connectors applied in hydraulic systems. They are designed to attach hoses, pipes, and tubes, allowing hydraulic fluid to go together with the go together with the go with the flow seamlessly thru the device below immoderate stress. These fittings make certain that hydraulic systems live leak-unfastened, inexperienced, and secure to function. The ordinary overall performance and reliability of a hydraulic gadget carefully rely on the satisfactory form of hydraulic fittings used.

The number one feature of hydraulic fittings is to preserve a normal, leak-evidence connection amongst one of a type additives. They are engineered to withstand excessive stress, immoderate temperatures, and corrosive environments. Hydraulic fittings are to be had in numerous shapes, sizes, and materials to form precise programs and systems.

Key Functions of Hydraulic Fittings

Leak Prevention: Hydraulic fittings are designed to create an excellent seal, stopping fluid leaks that would compromise device elegant widespread overall performance and safety.

Pressure Handling: Hydraulic structures carry out beneath excessive strain. The fittings need so you can withstand the ones pressures without failing or causing leaks.

Flexibility in Design: Different packages require unique connection sorts and angles. Hydraulic fittings offer flexibility in tool format thru presenting numerous configurations, together with elbows, tees, and crosses.

Corrosion Resistance: Hydraulic structures often perform in harsh environments. Fittings crafted from corrosion-resistant materials make certain sturdiness and reliability.

Types of Hydraulic Fittings

Understanding the special varieties of hydraulic fittings is essential for choosing the right one to your software program. Here are the maximum not unusual varieties of hydraulic fittings:

1. Compression Fittings

Compression fittings are extensively applied in hydraulic structures for their reliability and simplicity of set up. They encompass 3 vital additives: a nut, a ferrule (also known as a sleeve), and a frame. When the nut is tightened, the ferrule compresses onto the pipe or tube, growing a regular, leak-evidence connection. Compression fittings are suitable for low to medium-pressure programs and are commonly performed in car, organization, and agricultural sectors.

2. Crimp Fittings

Crimp fittings are designed for immoderate-stress hydraulic structures. They embody a steel becoming this is crimped onto the give up of a hose using a specialized crimping tool. Crimp fittings provide a strong and eternal connection, making them splendid for heavy-duty packages in production, mining, and company devices.

3. Threaded Fittings

Threaded fittings are generally applied in hydraulic structures and are available in major kinds: right now thread and tapered thread. Straight thread fittings use an O-ring or washing device to create a seal, even as tapered thread fittings depend upon the threads themselves to form a fantastic seal. These fittings are to be had in severa necessities, together with NPT (National Pipe Thread), BSP (British Standard Pipe), and JIC (Joint Industry Council).

4. Flare Fittings

Flare fittings are applied in applications in which immoderate-stress and excessive-temperature situations are common. These fittings encompass flaring the give up of a tube or pipe after which securing it with a nut. The flared forestall creates a robust, leak-proof connection. Flare fittings are usually implemented in car, aerospace, and refrigeration structures.

5. O-ring Face Seal (ORFS) Fittings

O-ring face seal fittings are designed to provide a reliable, leak-unfastened connection in hydraulic systems walking under excessive strain. These fittings characteristic an O-ring inside the face of the proper, which creates a seal whilst the amazing is tightened. ORFS fittings are typically completed in employer packages that require excessive modern day universal overall overall performance and sturdiness.

6. Bite-Type Fittings

Bite-kind fittings are designed to provide a robust, leak-proof reference to the resource of the usage of "biting" into the outer floor of the pipe or tube. These fittings are frequently completed in programs in which excessive vibration and excessive stress are present, which includes in advent and heavy tools. The chew-kind format guarantees that the best remains regular even below stressful situations.

7. Quick-Connect Fittings

Quick-join fittings, additionally known as brief-disconnect fittings, permit for instant and smooth connections and disconnections without the need for a device. They are usually applied in programs wherein not unusual connection modifications are required, which includes in finding out and upkeep operations. Quick-be parts of fittings are available in numerous designs, which incorporates push-to-be part of and twist-to-be part of.

Applications of Hydraulic Fittings

Hydraulic fittings are applied in a big kind of industries and applications because of their versatility and reliability. Some commonplace packages encompass:

1. Construction Machinery

Hydraulic structures are crucial to the introduction machine which incorporates excavators, bulldozers, and cranes. Hydraulic fittings make certain the green go along with the go with the flow of hydraulic fluid, powering the numerous additives that allow those machines to carry out heavy-obligation duties.

2. Agriculture Equipment

In agriculture, hydraulic structures are accomplished in tractors, harvesters, and high-quality farming devices. Hydraulic fittings play an essential characteristic in making sure easy operations inside the machines, permitting farmers to perform duties which includes lifting, digging, and transporting.

3. Automotive Industry

The car industry is based totally totally on hydraulic structures for braking, guidance, and suspension structures. Hydraulic fittings make sure the steady and inexperienced transfer of hydraulic fluid in the ones vital structures, contributing to automobile protection and everyday fundamental performance.

4. Aerospace Industry

In aerospace programs, hydraulic systems are applied in touchdown machines, flight management systems, and load coping devices. Hydraulic fittings need to meet stringent necessities for reliability and protection within the ones high-stakes environments.

5. Oil and Gas Industry

Hydraulic structures are substantially carried out in drilling rigs, pipelines, and refineries inside the oil and gasoline corporation. Hydraulic fittings on this area need to be proof of corrosion and able to withstand immoderate pressure and temperature.

6. Manufacturing and Industrial Automation

Hydraulic systems are appreciably applied in manufacturing and automation strategies, powering tools together with presses, conveyors, and robotics. Hydraulic fittings make certain the green operation of these systems, contributing to productivity and standard performance.

Best Practices for Selecting Hydraulic Fittings

Choosing the proper hydraulic turning is important for the overall everyday well known performance and safety of a hydraulic tool. Here are a few first rate practices to maintain in thoughts while deciding on hydraulic fittings:

Understand System Requirements: Before selecting a becoming, it’s critical to recognize the extremely good requirements of your hydraulic tool, on the aspect of strain scores, go together with the go with the flow capability, and temperature ranges.

Consider the Material: The material of the high-quality has to be decided based mostly on the software program 's environmental situations. For corrosive environments, chrome steel is frequently the wonderful desire, at the same time as carbon steel can be more appropriate for a whole lot of less disturbing packages.

Match the Fitting Type to the Application: Different varieties of hydraulic fittings are right for specific programs. For instance, brief-be a part of fittings are excellent for attempting out and renovation, while flare fittings are more suitable for immoderate-pressure applications.

Ensure Compatibility with Hose or Tube: The turning into need to be properly applicable with the hose or tube in phrases of duration, material, and strain score. Mismatched fittings can result in leaks, screw ups, and protection risks.

Consider Ease of Installation and Maintenance: Some fittings are hundreds of masses much less complex to install and preserve than others. Compression and crimp fittings are diagnosed for their ease of installation, even as quick-be parts of fittings offer consolation in applications requiring commonplace disconnections.

Check for Industry Standards and Certifications: Ensure that the hydraulic fittings you choose out meet industry necessities and certifications, on the component of ISO, SAE, and DIN. Compliance with those requirements guarantees exquisite reliability.

Conclusion

Hydraulic fittings are an important issue of hydraulic structures, ensuring the green and leak-loose transfer of hydraulic fluid. Understanding the top notch types of fittings, materials, and applications allow you to select the proper fittings on your wishes, making sure machine reliability and preferred trendy ordinary performance.

When deciding on hydraulic fittings, it’s critical to remember elements, which include stress rankings, fabric compatibility, ease of installation, and organization necessities. By following super practices and addressing not unusual traumatic situations, you may optimize your hydraulic tool’s preferred ordinary performance and durability.

If you're looking for extraordinary hydraulic fittings, pipes, flanges, and further, undergo in thoughts partnering with Bu-Lok. Bu-Lok is one of the fundamental and maximum incredible manufacturers, traders, and providers of chrome steel, excessive nickel steel, alloy steel, and carbon metal products, together with pipe fittings, flanges, fasteners, plates, and round bars. Contact Bu-Lok in recent times for all of your hydraulic becoming desires and make sure the very super necessities of quality and fashionable typical overall performance on your hydraulic structures.

0 notes

Text

What Applications for Stainless Steel Flanges ?

Residential, commercial and industrial piping systems utilize stainless steel flanges and fittings as well. Strength, resistance to corrosion, temperature, pressure, and flow, are the four qualities that make stainless steel one of the most widespread materials used for gas or liquid transport, as well as in any chemical processing, marine and sanitary applications where corrosion resistance is necessary. Please appeal to the related standards or call us if you can’t select the right stainless steel grade or type of flange for your purpose.

The Most Frequently Used Stainless Steel Flanges.

Most frequently, the flanges are threaded or welded, and the gasket, which helps to connect the flanges’ ends, is used for pipeline access. These flanges comprise of socket weld flanges, blind flanges, weld-deked flanges and slip¬ on flanges and they just provide an example of the varieties available. Letting the connection serve to disassemble the pipes or remove the components will be an easy process.

Stainless steel flanges available in various standards such as AWWA, DIN, metric, and ANSI Class-rated are offered. In accordance with these standards, you may be able to identify one of the most common flange types as well as obtain custom machining for your specific needs and application.

Weld-Neck

Slip-On or Ring

Socket Weld

Lap Joint

Blind Raised Face Flanges

Groove flanges

Threaded flanges

Plate flange

These also include threaded couplings, nipples, braided pump connectors, 90-degree elbows and other components in stainless steel. When selecting the components of stainless steel piping system for a intended application, obey the standard of the same application.

0 notes

Text

Installation Tips for Lowara Circulation Pumps

Proper installation of Lowara circulation pumps is essential to ensure optimal performance, longevity, and energy efficiency. Whether you’re installing a new pump or replacing an existing one, following best practices can prevent common issues and ensure your system runs smoothly. In this guide, we’ll cover key installation tips for Lowara circulation pumps to help you get the most out of your equipment.

1. Pre-Installation Preparation

Verify Pump Specifications: Before installation, double-check that the Lowara pump you’ve selected meets the specifications required for your system, including flow rate, head pressure, and temperature range.

Inspect the Installation Site: Ensure the installation area is clean, dry, and free from obstructions. Check for adequate space around the pump for maintenance and ventilation.

Gather Necessary Tools and Materials: Have all necessary tools and materials on hand, including pipe wrenches, gaskets, sealants, and mounting hardware.

2. Proper Positioning of the Pump

Horizontal vs. Vertical Installation: Determine whether the pump is to be installed horizontally or vertically. Follow the manufacturer’s guidelines for the correct orientation to avoid issues with air trapping and to ensure proper lubrication.

Aligning the Pump: Ensure the pump is aligned correctly with the piping to prevent strain on the pump housing and to avoid leaks. Use a spirit level to check the alignment.

Positioning for Accessibility: Install the pump in a location that allows easy access for maintenance and inspection. Consider future needs when positioning the pump.

3. Connecting the Piping

Use Proper Pipe Sizing: Ensure the inlet and outlet piping match the pump’s connection sizes to maintain proper flow and avoid cavitation or pressure drops.

Avoid Pipe Strain: Use flexible connectors or properly support the piping to prevent strain on the pump flanges, which can lead to leaks or damage over time.

Seal All Connections: Use appropriate sealants or gaskets to seal all connections, ensuring they are tight but not over-tightened, which could damage threads or cause leaks.

4. Electrical Connections

Follow Electrical Codes: Ensure that all electrical work complies with local codes and regulations. Use the correct voltage and wiring configuration as specified in the Lowara Pump manual.

Grounding the Pump: Properly ground the pump to prevent electrical shocks and ensure safe operation.

Check Motor Rotation: After wiring, briefly run the pump to check that the motor is rotating in the correct direction. If not, switch the wiring connections as needed.

5. Initial Start-Up and Testing

Priming the Pump: Before starting the pump, make sure it is properly primed to avoid running dry, which can damage the pump’s internal components.

Bleeding Air from the System: Remove any trapped air from the system by opening the appropriate valves or using an automatic air vent. Air in the system can cause noise, reduced efficiency, and potential damage.

Monitor Initial Operation: Once the pump is running, monitor its performance for any unusual noises, vibrations, or temperature changes. Adjust the settings if necessary.

6. Routine Maintenance Tips

Regular Inspections: Schedule regular inspections to check for leaks, unusual noises, or wear and tear on the pump and its components.

Lubrication: Depending on the pump model, ensure bearings and other moving parts are properly lubricated. Follow the manufacturer’s recommendations for lubrication intervals.

Cleaning: Keep the pump and surrounding area clean to prevent dust and debris from affecting performance.

Correct installation of Lowara circulation pumps is crucial for ensuring they operate efficiently and reliably over the long term. By following these best practices, you can prevent common issues, extend the life of your pump, and maintain optimal performance. Whether you’re a professional installer or a DIY enthusiast, these tips will help you get the most out of your Lowara pump. For more info contact Lowara Pump Supplier in UAE or call us at +971 4 2522966.

#lowara pump suppliers#lowara pumps#lowara pump distributors#lowara pump dealer in dubai#lowara pumps uae

0 notes

Text

Hex plug/Carbon steel Hex plug /DIN 906 plug/Blackened oil plug/Electroplated oil plug/Electroplated blue zinc plug/Taper thread plug/Taper thread hex plug/carbon steel environmentally friendly zinc hex plug

DIN906 plug is a threaded pipe fitting used to plug the ports of pipes or other connectors. It is usually made of metal materials, such as stainless steel, carbon steel, etc.

DIN906 plug features include:

• Threaded connection: There are threads on the plug, which can be threaded with the corresponding specifications of the pipe or connector to ensure tight connection and prevent leakage.

• Blocking effect: Its main role is to block the pipe port to prevent liquid or gas leakage, but also to prevent dust, debris, etc., from entering the pipeline.

• Multiple specifications: DIN906 plugs are available in a variety of specifications to accommodate different diameters and thread sizes of pipe.

• Easy installation: The installation of the plug is relatively simple, just screw it into the pipe port.

When using DIN906 plug, the following points need to be noted:

• Select the right specifications and materials to ensure match and reliability with the pipe.

• Before installation, ensure that pipe ports are clean and free of debris and damage.

• Follow the correct installation method to avoid excessive tightening or damage to the thread.

• Check the status of the plug regularly, and replace it in time if it is damaged or leaked.

0 notes

Text

Don't let your pipes get frustrated!

Introducing pipe nipples, the essential short connectors that keep your piping systems flowing smoothly.

At Platinex Piping Solutions, we offer a wide variety of high-quality pipe nipples to suit any project, big or small. Whether you need threaded, welded, or flanged nipples, we've got you covered.

Here's why pipe nipples are essential for your piping projects:

Versatility: They can be used to connect pipes of different diameters and materials.

Durability: Made from strong and long-lasting materials to ensure a reliable connection.

Space-saving: Their compact size makes them ideal for tight spaces.

Get your piping projects connected with the right nipples!

www.platinexpiping.com

Visit our website or contact us today to learn more about our selection of pipe nipples. #platin piping solutions #pipenipPLES#piping#industrialsupplies#construction#plumbing#infrastructure

0 notes

Text

Top On Product Recommendation!

360° Flexible Silicone Tube/Hose Extension Water Pipe | Water Faucet Tap Extender Bendable Faucet Extension For Kitchen And Bathroom Sink, With Anti-Splash Feature.

Description:-

Upgrade your kitchen sink experience with our 360° flexible faucet extender. Designed to easily clean oversized items, large plates, or pots, this extender can be rotated or adjusted to any angle or direction. Made of high-quality, food-grade silicone material, it is soft and safe for use, while the all-copper interface is durable and rust-resistant. The filter design ensures rich foam and prevents water splashing. With the included universal connector, you can rest assured that this extender will fit most faucets.

Our adjustable faucet extender can increase the length of your faucet, and you can freely shape it according to your practical needs. Whether you need to wash dishes, vegetables, and fruits, or clean your sink, this faucet extender will help you easily adjust water use at will.

they can be used in kitchen, bathroom, garden, laundry, etc.

Features:-

Strong Material : Our faucet extender uses stainless steel and silicone as materials, so it is durable and high pressure resistant, and there is no burst or rust.

Universal Type : The international G1/2″ interface make it suitable for most faucets and easy to install. But please note that it is a female threaded interface.

360° Flexible : The faucet extender can be rotated or adjusted to the direction or angle you want, and it is also easy to be shaped which solves the problem that the general water pipe will fall.

Non-Splash Outlet : The outlet of the extension tube has a multi-layer leak-proof design and is splash-proof, saying goodbye to the mess and splash around the sink.

Package Includes: 1 x 360° Flexible Silicone Hose/Tube Extension

Length : 50cm

Original Price : PKR 1499

Now Price : PKR 999

Contact No : 0331 2187234

~FREE DELIVERY ALL OVER PAKISTAN~

0 notes

Text

Brass Sanitary Fittings: O.K. Engineers

Brass Sanitary Fittings are essential components used in plumbing systems, offering reliable and long-lasting solutions for water management. They are highly regarded in both residential and industrial applications due to their durability, corrosion resistance, and ability to withstand high temperatures and pressure. This article delves into the world of brass sanitary fittings, exploring their benefits, common types, and applications.

Why Choose Brass for Sanitary Fittings?

Brass is a versatile alloy composed primarily of copper and zinc, known for its strength and excellent corrosion resistance. It has been a preferred material for plumbing and sanitary fittings for decades due to several key properties:

1. Corrosion Resistance

One of the most significant advantages of brass is its resistance to corrosion. In water systems, especially those exposed to varying pH levels, brass remains unaffected, making it an ideal choice for sanitary fittings.

2. Durability and Longevity

Brass fittings are built to last, capable of enduring years of use without compromising their performance. This longevity makes them cost-effective solutions for both residential and commercial applications.

3. Temperature Tolerance

Brass can handle extreme temperatures, whether hot or cold. This property is particularly important in plumbing systems that may experience rapid temperature fluctuations.

4. Versatility

Brass is highly versatile, allowing it to be shaped into various types of fittings, including elbows, tees, couplings, and adapters. This flexibility ensures that brass fittings can be tailored to suit different plumbing configurations.

5. Safety and Water Quality

Brass fittings do not leach harmful substances into the water, ensuring that water quality is maintained. This makes them safe for potable water systems.

Common Types of Brass Sanitary Fittings

Brass sanitary fittings come in a variety of shapes and sizes, each designed to serve a specific function in plumbing systems. Some of the most common types include:

1. Brass Elbows

Elbows are used to change the direction of water flow within a piping system. Brass elbows are available in different angles, such as 90-degree and 45-degree bends, to accommodate various plumbing layouts.

2. Brass Tees

Tee fittings are used to combine or split the flow of water. A brass tee has three openings, allowing it to connect three pipes together. They are commonly used in branching applications.

3. Brass Couplings

Couplings are connectors used to join two pipes of the same diameter. Brass couplings provide a secure and leak-proof connection, making them vital in extending pipe lengths or repairing damaged sections.

4. Brass Adapters

Adapters are used to connect pipes of different sizes or types. Brass adapters are versatile, allowing for the transition between threaded and non-threaded pipes or connecting to other types of fittings.

5. Brass Nipples

Nipples are short lengths of pipe with male threading on both ends. Brass nipples are often used to connect two female-threaded fittings or extend pipe runs.

6. Brass Unions

Unions are fittings that allow easy disconnection of pipes without the need to cut or disassemble the system. Brass unions are ideal for maintenance and repairs, offering convenience in plumbing systems.

7. Brass Valves

Valves control the flow of water within a system. Brass valves, including ball valves and gate valves, are durable and reliable for managing water flow in both residential and industrial applications.

Applications of Brass Sanitary Fittings

Brass sanitary fittings are widely used in various sectors due to their versatility and performance. Some common applications include:

1. Residential Plumbing

Brass fittings are commonly used in homes for water supply lines, faucets, and showerheads. They ensure a steady flow of water while preventing leaks and corrosion, making them ideal for household plumbing.

2. Industrial Water Systems

In industrial settings, where high-pressure water systems are common, brass sanitary fittings provide the necessary strength and durability. They are used in cooling systems, processing plants, and water treatment facilities.

3. Commercial Buildings

Brass fittings are extensively used in commercial buildings for plumbing installations in restrooms, kitchens, and HVAC systems. Their reliability ensures consistent performance, even with heavy usage.

4. Marine Applications

Brass’s resistance to corrosion makes it suitable for marine environments, where fittings are exposed to saltwater and humid conditions. Brass sanitary fittings are often used in boats and ships for plumbing and water management.

5. Water Heaters and Boilers

Brass fittings can withstand high temperatures, making them ideal for use in water heaters and boiler systems. They maintain their integrity under pressure and heat, ensuring safe and efficient operation.

Key Advantages of Brass Sanitary Fittings

Choosing brass sanitary fittings offers several advantages for plumbing systems:

Leak Resistance: Brass provides a tight and secure seal, reducing the risk of leaks, which is crucial in maintaining system efficiency.

Easy Installation: Brass fittings are easy to install and can be securely tightened without specialized tools.

Cost-Effective: Although brass fittings may have a higher initial cost, their durability and low maintenance make them a cost-effective long-term solution.

Aesthetic Appeal: Brass has a classic, polished look that adds aesthetic value, particularly in visible installations like faucets and exposed pipes.

Selecting the Right Brass Sanitary Fittings

When selecting brass sanitary fittings, it’s essential to consider the specific needs of your plumbing system:

Type of Application: Determine whether the fittings will be used in residential, commercial, or industrial settings, as this will impact the type and size of fittings required.

Compatibility: Ensure that the fittings are compatible with the existing pipes in terms of size and threading.

Pressure and Temperature Ratings: Choose fittings that can handle the expected pressure and temperature ranges in your system.

Quality and Standards: Opt for fittings that meet industry standards and are made from high-quality brass to ensure longevity and performance.

Conclusion

Brass sanitary fittings are indispensable components in plumbing systems, offering reliability, durability, and versatility. From residential homes to industrial plants, these fittings ensure efficient water management while standing up to the challenges of corrosion, pressure, and temperature fluctuations. By understanding the different types of brass sanitary fittings and their applications, you can make informed decisions that will lead to long-lasting, leak-proof, and cost-effective plumbing solutions.

FAQs

Q. What makes brass fittings ideal for plumbing systems?

Ans: Brass fittings offer excellent corrosion resistance, durability, and the ability to withstand high temperatures, making them ideal for plumbing applications.

Q. Can brass fittings be used in potable water systems?

Ans: Yes, brass is safe for use in potable water systems as it does not leach harmful substances into the water.

Q. How do I choose the right size of brass sanitary fittings?

Ans: Measure the diameter of your pipes and ensure the fittings match the size and threading for a secure fit.

Q. Are brass fittings suitable for outdoor installations?

Ans: Yes, brass fittings are resistant to corrosion and can be used in outdoor plumbing systems, including those exposed to varying weather conditions.

Q. What is the lifespan of brass sanitary fittings?

Ans: Brass sanitary fittings can last several decades with minimal maintenance, making them a durable and cost-effective choice for plumbing systems.

0 notes