#Torque sensors

Explore tagged Tumblr posts

Text

Torque is a quantity that cannot be ignored when describing a car's engine. Not only in the field of automobile engines, Torque appears in almost all fields and industries. For process monitoring, drive technology testing, and quality assurance, the use of Torque sensors solves efficiency problems. Join us to learn more about this type of sensor!

0 notes

Text

Achieving High-Precision Material Testing with Star EMBSYS Servo Tensile Testing Machines

In modern material science and quality assurance, precision testing is critical for ensuring product reliability, safety, and compliance. Tensile strength—the ability of a material to withstand pulling forces—is a fundamental property that influences product design across industries such as automotive, aerospace, construction, electronics, and packaging. A servo tensile testing machine is an essential tool for conducting such tests with high accuracy and repeatability. Among the leading providers in this domain, Star EMBSYS has earned a reputation for delivering advanced, durable, and efficient tensile testing systems that meet international standards and industrial demands.

Precision Engineering with Intelligent Servo Control

Star EMBSYS's servo tensile testing machines are built with high-end servo motors and closed-loop control systems that provide exceptional accuracy in force application and displacement measurement. These systems are ideal for testing a wide range of materials including metals, polymers, composites, textiles, and rubber. Whether for R&D or routine quality checks, Star EMBSYS machines offer controlled testing environments with programmable test parameters, user-defined speed settings, and automatic data logging.

Equipped with load cells of varying capacities, high-resolution extensometers, and digital controllers, Star EMBSYS machines provide accurate stress-strain curves and real-time feedback on material behavior under tensile loads. Their advanced software suite allows operators to analyze mechanical properties such as yield strength, ultimate tensile strength, elongation, and modulus of elasticity with ease. Results are displayed in graphical and tabular formats, enabling quick interpretation and reliable decision-making.

What truly differentiates Star EMBSYS is the seamless integration of mechanical precision with software intelligence—enabling automated test cycles, data export, and report generation to reduce human intervention and enhance efficiency.

Tailored Solutions with Industry-Focused Features

Understanding that different industries have varying testing requirements, Star EMBSYS offers custom-built servo tensile testing machines tailored to specific applications. From compact benchtop models for academic institutions to high-capacity floor-standing units for industrial testing labs, the company provides scalable solutions without compromising on performance.

Star EMBSYS machines support a wide range of grips and fixtures to accommodate samples of different shapes, sizes, and materials. This flexibility allows manufacturers and quality control labs to conduct a full range of tests, including tensile, compression, flexural, and peel tests. Moreover, the machines are designed with operator safety in mind, featuring protective enclosures, overload protection, and emergency stop systems.

In addition to manufacturing top-tier equipment, Star EMBSYS offers robust after-sales support, calibration services, operator training, and remote diagnostics. Their commitment to customer satisfaction and technical excellence makes them a preferred partner across sectors including automotive OEMs, aerospace manufacturers, research labs, and educational institutions.

Conclusion

In today’s competitive industrial landscape, investing in a servo tensile testing machine is crucial for maintaining material integrity and meeting quality standards. Star EMBSYS delivers state-of-the-art solutions that combine accuracy, flexibility, and reliability—backed by superior service and customization options. For businesses that prioritize precision testing and product performance, Star EMBSYS stands out as a trusted and forward-thinking provider in the tensile testing segment.

Visit:- https://www.starembsys.com/servo-tensile-testing-machine.html

0 notes

Text

Smart Traction: Intelligent All-Wheel Drive Market Accelerates to $49.3 Billion by 2030

The intelligent all-wheel drive market is experiencing remarkable momentum as automotive manufacturers integrate advanced electronics and artificial intelligence into drivetrain systems to deliver superior performance, safety, and efficiency. With an estimated revenue of $29.9 billion in 2024, the market is projected to grow at an impressive compound annual growth rate (CAGR) of 8.7% from 2024 to 2030, reaching $49.3 billion by the end of the forecast period. This robust growth reflects the automotive industry's evolution toward smarter, more responsive drivetrain technologies that adapt dynamically to changing road conditions and driving scenarios.

Evolution Beyond Traditional All-Wheel Drive

Intelligent all-wheel drive systems represent a significant advancement over conventional mechanical AWD configurations, incorporating sophisticated electronic controls, multiple sensors, and predictive algorithms to optimize traction and handling in real-time. These systems continuously monitor wheel slip, steering input, throttle position, and road conditions to make instantaneous adjustments to torque distribution between front and rear axles, and increasingly between individual wheels.

Unlike traditional AWD systems that react to wheel slip after it occurs, intelligent systems use predictive algorithms and sensor data to anticipate traction needs before wheel slip begins. This proactive approach enhances vehicle stability, improves fuel efficiency, and provides superior performance across diverse driving conditions from highway cruising to off-road adventures.

Consumer Demand for Enhanced Safety and Performance

Growing consumer awareness of vehicle safety and performance capabilities is driving increased demand for intelligent AWD systems. Modern drivers expect vehicles that can confidently handle adverse weather conditions, challenging terrain, and emergency maneuvering situations. Intelligent AWD systems provide these capabilities while maintaining the fuel efficiency advantages of front-wheel drive during normal driving conditions.

The rise of active lifestyle trends and outdoor recreation activities has increased consumer interest in vehicles capable of handling diverse terrain and weather conditions. Intelligent AWD systems enable crossovers and SUVs to deliver genuine all-terrain capability without compromising on-road refinement and efficiency.

SUV and Crossover Market Expansion

The global shift toward SUVs and crossover vehicles is a primary driver of intelligent AWD market growth. These vehicle segments increasingly offer AWD as standard equipment or popular options, with intelligent systems becoming key differentiators in competitive markets. Manufacturers are positioning advanced AWD capabilities as premium features that justify higher trim levels and increased profitability.

Luxury vehicle segments are particularly driving innovation in intelligent AWD technology, with features such as individual wheel torque vectoring, terrain-specific driving modes, and integration with adaptive suspension systems. These advanced capabilities create compelling value propositions for consumers seeking both performance and versatility.

Electric Vehicle Integration Opportunities

The electrification of automotive powertrains presents unique opportunities for intelligent AWD systems. Electric vehicles can implement AWD through individual wheel motors or dual-motor configurations that provide precise torque control impossible with mechanical systems. Electric AWD systems offer instant torque delivery, regenerative braking coordination, and energy management optimization.

Hybrid vehicles benefit from intelligent AWD systems that coordinate internal combustion engines with electric motors to optimize performance and efficiency. These systems can operate in electric-only AWD mode for quiet, emissions-free driving or combine power sources for maximum performance when needed.

Advanced Sensor Technology and Data Processing

Modern intelligent AWD systems incorporate multiple sensor technologies including accelerometers, gyroscopes, wheel speed sensors, and increasingly, cameras and radar systems that monitor road conditions ahead of the vehicle. Machine learning algorithms process this sensor data to predict optimal torque distribution strategies for varying conditions.

GPS integration enables intelligent AWD systems to prepare for upcoming terrain changes, weather conditions, and road characteristics based on location data and real-time traffic information. This predictive capability allows systems to optimize performance before challenging conditions are encountered.

Manufacturer Competition and Innovation

Intense competition among automotive manufacturers is driving rapid innovation in intelligent AWD technology. Brands are developing proprietary systems with unique characteristics and branding to differentiate their vehicles in crowded markets. This competition accelerates technological advancement while providing consumers with increasingly sophisticated options.

Partnerships between automotive manufacturers and technology companies are creating new capabilities in intelligent AWD control systems. Artificial intelligence, cloud computing, and advanced materials are being integrated to create more responsive and efficient systems.

Regional Market Dynamics

Different global markets exhibit varying demand patterns for intelligent AWD systems based on climate conditions, terrain characteristics, and consumer preferences. Northern markets with harsh winter conditions show strong demand for advanced traction systems, while emerging markets focus on systems that provide value-oriented performance improvements.

Regulatory requirements for vehicle stability and safety systems in various regions influence the adoption of intelligent AWD technology. Standards for electronic stability control and traction management create baseline requirements that intelligent AWD systems can exceed.

Manufacturing and Cost Considerations

The increasing sophistication of intelligent AWD systems requires significant investment in research and development, manufacturing capabilities, and supplier relationships. However, economies of scale and advancing semiconductor technology are helping to reduce system costs while improving performance and reliability.

Modular system designs enable manufacturers to offer different levels of AWD sophistication across vehicle lineups, from basic intelligent systems in entry-level models to advanced torque-vectoring systems in performance vehicles.

#intelligent all-wheel drive#smart AWD systems#advanced traction control#automotive drivetrain technology#AWD market growth#intelligent torque distribution#electronic stability control#vehicle dynamics systems#all-terrain vehicle technology#automotive safety systems#performance AWD#electric vehicle AWD#hybrid drivetrain systems#torque vectoring technology#predictive AWD control#adaptive traction systems#automotive electronics#drivetrain electrification#active differential systems#terrain management systems#AWD coupling technology#automotive sensors#machine learning automotive#AI-powered drivetrain#connected vehicle systems#autonomous driving technology#SUV market growth#crossover vehicle technology#premium automotive features#automotive innovation trends

0 notes

Text

Bee Pacer: Redefining Urban Commuting with Power, Comfort, and Style In the fast-evolving world of electric bikes, BeeCool Bikes has consistently stood out as a brand that marries innovation with practicality. Our latest offering, Bee Pacer, is no exception. Designed for urban explorers, commuters, and adventure seekers alike, this mid-drive electric bike combines cutting-edge technology with sleek aesthetics to deliver an unparalleled riding experience. Whether you’re navigating city streets, tackling hills, or cruising along scenic paths, the Bee Pacer is engineered to elevate every journey. Let’s dive into what makes this e-bike a game-changer.

#bee pacer ebike#beecool#beecoolbikes#mid drive motor#mid drive#torque sensor#ebikefun#ebike adventures#ebikelife#ridemorebehappy#color display#factory direct sale

1 note

·

View note

Text

Torque Sensor Market: Current Analysis and Forecast (2024-2032)

According to the UnivDatos Market Insights analysis, the increasing adoption in the automotive industry for fuel-efficient vehicles, the rising demand for precise measurement in industrial automation, and advancements in medical devices requiring high-precision torque control will drive the global scenario of the Torque Sensor market. As per their “Torque Sensor Market” report, the global market was valued at USD 7.8 Billion in 2023, growing at a CAGR of 5.8% during the forecast period from 2024 - 2032 to reach USD XX Billion by 2032.

The torque sensor market is witnessing robust growth, driven by the increasing demand for precise torque measurement across various industries such as automotive, aerospace, and industrial automation. In the automotive sector, the need for accurate torque measurement is paramount for optimizing engine performance, improving fuel efficiency, and ensuring the reliability of vehicle components. The rise in electric and hybrid vehicle adoption further amplifies this demand, as these vehicles require advanced torque measurement solutions to manage electric motor performance and battery efficiency. Technological advancements in sensor design, including wireless and non-contact torque sensors, are enhancing the efficiency and performance of these applications.

In the industrial sector, torque sensors are integral to the automation and robotics industries, where precision and efficiency are critical. The adoption of Industry 4.0 practices has led to increased utilization of torque sensors in manufacturing processes to ensure operational accuracy and product quality. Additionally, the aerospace and defense sectors rely on torque sensors for testing and monitoring aircraft components, ensuring safety and performance standards are met. These sectors' focus on innovation and high-performance standards continues to drive the adoption of advanced torque sensor technologies.

Looking forward, the torque sensor market is poised for sustained growth. Companies are investing heavily in research and development to create innovative, cost-effective torque sensors that cater to the evolving needs of various industries. Expansion into emerging markets, particularly in the Asia-Pacific region, offers significant growth potential due to rapid industrialization and increasing automotive production. Moreover, strategic partnerships and collaborations are facilitating the development of integrated solutions, enhancing value for end-users. Overall, the market's future looks promising with continued technological advancements and strategic investments from key industry players.

Increasing Adoption in the Automotive Industry:

The automotive industry is a significant driver for the torque sensor market. As the demand for high-performance and fuel-efficient vehicles increases, manufacturers are integrating advanced torque sensors to monitor and optimize engine and drivetrain performance. These sensors play a crucial role in electric vehicles (EVs) and hybrid vehicles, which require precise torque measurements to enhance energy efficiency and performance.

Example: The European Union's "Green Deal" and the accompanying "Fit for 55" package aim to reduce greenhouse gas emissions by 55% by 2030. These policies include stringent regulations on vehicle emissions and fuel efficiency, pushing automakers to adopt advanced technologies, including torque sensors, to meet these targets.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=63672

Growing Demand in Industrial Automation:

Industrial automation is another key driver for the torque sensor market. With the rise of Industry 4.0, there is a growing need for accurate and real-time torque measurement in various automated processes. Torque sensors are essential in ensuring the proper functioning and safety of automated machinery, leading to improved productivity and reduced downtime in manufacturing and production facilities.

Example: The German government's "Industrie 4.0" initiative supports the widespread adoption of advanced manufacturing technologies, including torque sensors. This policy includes financial incentives and subsidies for companies investing in automation and smart factory technologies, encouraging the integration of torque sensors in industrial applications.

Advancements in Medical Devices:

The medical sector is increasingly utilizing torque sensors in various applications, such as robotic surgery, prosthetics, and rehabilitation devices. The precise measurement of torque is critical in these applications to ensure the safety and effectiveness of medical devices. As the healthcare industry continues to advance, the demand for high-precision torque sensors is expected to grow significantly.

Example: The U.S. Food and Drug Administration (FDA) has implemented policies that support the development and approval of advanced medical devices, including those that use torque sensors. The FDA's Breakthrough Devices Program, for instance, provides expedited review and approval processes for innovative medical technologies, encouraging the adoption of advanced sensors in medical devices.

Conclusion

The torque sensor market is experiencing significant growth driven by three major factors: the increasing adoption in the automotive industry, the growing demand in industrial automation, and advancements in medical devices. Government policies play a pivotal role in accelerating this growth by providing regulatory support and financial incentives. The European Union's "Green Deal" and "Fit for 55" package are pushing the automotive sector towards greater efficiency and lower emissions, thereby fostering the adoption of torque sensors. Similarly, Germany's "Industrie 4.0" initiative is promoting the integration of advanced manufacturing technologies, including torque sensors, in industrial automation. In the medical sector, the U.S. FDA's supportive policies for innovative medical devices are encouraging the use of precise torque measurement technologies in cutting-edge medical applications. These combined efforts are shaping a robust and dynamic torque sensor market, poised for continued expansion and innovation.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Automotive Steering Torque Sensors Market is Estimated to Witness High Growth Owing to Increasing Demand

Automotive steering torque sensors play an important role in steering systems by directly measuring the rotational forces applied to the steering shaft. They are primarily utilized in advanced driver assistance systems such as electronic power steering, automobile stability control, and anti-lock braking systems. The growing emphasis on vehicle safety and introduction of autonomous driving technologies are expected to drive the demand for automotive steering torque sensors over the forecast period.

The Global Automotive Steering Torque Sensors Market is estimated to be valued at US$ 8589.78 Mn in 2024 and is expected to exhibit a CAGR of 7.9% over the forecast period 2024 to 2031.

Key Takeaways Key players operating in the Automotive Steering Torque Sensors are Robert Bosch Gmbh, Denso Corporation, Crane Electronics, Honeywell International, Sensor Technology, Valeo, TE Connectivity, Kistler Instruments Pvt. Ltd., Norbar Torque Tools Ltd., Bourns, Inc., Advanced Micro Electronics Co. Ltd., Methode Electronics, Inc., and others. The key players are focused on developing innovative torque sensors with enhanced accuracy and durability.

The Automotive Steering Torque Sensors Market Size is expected to create significant opportunities for automotive steering torque sensor manufacturers. Furthermore, the increasing adoption of autonomous vehicles will further propel the demand.

Globally, the Asia Pacific region dominated the market and is expected to exhibit the highest CAGR during the forecast period. China, Japan, and India have emerged as major markets for automotive steering torque sensors owing to increasing automotive production and sales.

Market drivers The increasing demand for advanced driver assistance systems in passenger and commercial vehicles is a major factor driving the growth of automotive steering torque sensors market. Features like stability control, traction control, anti-lock braking help in improving road safety. Furthermore, the growing adoption of electric power steering systems that utilize torque sensor technology is also fueling the market growth. Stringent safety norms especially in European and North American regions have further promoted the integration of torque sensors in vehicle steering systems.

PEST Analysis Political: The Automotive Steering Torque Sensors Market Size And Trends is governed by strict regulations regarding automotive safety and emissions. Manufacturers must comply with regulations for vehicle automation, driver assistance systems and functional safety standards.

Economic: The global economy recovery is driving automotive production and sales which is positively impacting the demand for automotive steering torque sensors. rising disposable incomes in developing countries is increasing vehicle ownership.

Social: Technology features such as driver assistance, autonomous driving, and connected vehicles are increasingly being adopted. Sensors play a key role providing input data to driver assistance systems. Safety and reliability are important considerations for consumers.

Technological: Advancements in sensor design, materials, and manufacturing processes are improving sensor accuracy, response time and durability. Technologies integrating multiple sensors and software are enabling advanced driver assistance and autonomous driving capabilities. Connectivity integration in sensors allows remote diagnostics.

In terms of value, Asia Pacific holds the largest share of the automotive steering torque sensors market due to high production volumes in China, India, Japan and South Korea. Europe is also a major region supported by strong automotive manufacturing presence in Germany, France, Italy and UK.

North America is anticipated to exhibit the fastest growth during the forecast period owing to rising demands for electric and autonomous vehicles in the US and Canada. Government mandates and investments to develop autonomous vehicle infrastructure will drive additional sensor needs in the region. Get More Insights On, Automotive Steering Torque Sensors Market About Author: Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163

#Automotive Steering Torque Sensors Market Trends#Automotive Steering Torque Sensors Market Share#Automotive Steering Torque Sensors#Automotive Steering Torque Sensors Market

0 notes

Text

Precision and Compliance with Star EMBSYS Torque Wrench Calibration Machines

In high-precision industries where torque application is critical—such as automotive, aerospace, energy, and heavy engineering—torque wrenches must deliver consistent, accurate force to maintain performance and safety. Calibration of these tools is not just a regulatory requirement but also a foundational element of quality control. A torque wrench calibration machine ensures that torque tools remain within defined limits of performance. Leading the way in this niche segment is Star EMBSYS, a company known for delivering advanced, reliable, and cost-effective torque calibration solutions tailored to industry needs.

Engineered Accuracy and Intelligent Design

Star EMBSYS torque wrench calibration machines are built with precision engineering and embedded systems technology to offer unmatched accuracy, reliability, and repeatability. The machines are designed to test and calibrate both manual and digital torque wrenches across a wide torque range, ensuring compliance with international standards such as ISO 6789.

Each unit is equipped with a high-resolution digital display, torque sensors with low uncertainty, and data acquisition systems for real-time monitoring and analysis. The machines also feature automatic peak torque capture, programmable test parameters, and seamless integration with calibration software. These capabilities not only reduce the margin of error but also streamline the calibration process, saving time and labor.

Star EMBSYS’s calibration machines come with user-friendly controls and a robust mechanical build, ensuring consistent results even under repeated industrial use. This attention to both performance and durability ensures that clients receive a long-term, low-maintenance solution that fits seamlessly into their quality assurance workflows.

Trusted by Industry, Backed by Service

What sets Star EMBSYS apart in the calibration equipment space is not just the technical excellence of its machines, but also its commitment to customer-centric service and adaptability. The company provides custom-built torque calibration systems based on client specifications, whether it’s for high-capacity torque tools used in heavy machinery or low-range tools used in precision electronics.

Furthermore, Star EMBSYS supports its clients with comprehensive technical documentation, on-site training, and after-sales service, ensuring smooth implementation and long-term productivity. With a customer base that includes automotive OEMs, industrial tool manufacturers, and defense contractors, Star EMBSYS has established itself as a trusted calibration partner across India and internationally.

By investing in a torque wrench calibration machine from Star EMBSYS, businesses can safeguard operational accuracy, reduce tool-related defects, and meet stringent compliance standards with confidence. The result is a more reliable production process and greater customer satisfaction across the value chain.

Conclusion

In industries where the accuracy of torque tools can make the difference between safety and failure, a dependable calibration solution is essential. Star EMBSYS torque wrench calibration machines provide the precision, ease of use, and compliance required for modern manufacturing environments. For businesses aiming to elevate their quality assurance processes and maintain industry certifications, Star EMBSYS offers a proven, professional solution that ensures tools remain calibrated, accurate, and compliant.

Visit:- https://www.starembsys.com/torque-wrench-calibration-machine.html

0 notes

Text

Enhancing Spring Quality Control with Star EMBSYS Spring Testing Machines

In today’s precision-driven manufacturing environment, the demand for reliable and accurate testing equipment has never been greater. Springs, being critical components in various mechanical assemblies, must undergo rigorous testing to ensure durability, flexibility, and performance under load. A spring testing machine is essential for evaluating these parameters. Among the notable names in this domain, Star EMBSYS has established itself as a trusted provider of high-quality, technologically advanced spring testing machines that cater to a wide range of industrial needs.

Advanced Technology for Accurate Spring Testing

Star EMBSYS spring testing machines are engineered to deliver precise measurements of compression, tension, and torsion in springs. With increasing demands from automotive, aerospace, electrical, and consumer goods industries, manufacturers need to ensure that every spring meets stringent performance standards. Star EMBSYS addresses this requirement through machines equipped with digital force indicators, load cells, and advanced software integration.

The machines allow for real-time data acquisition, digital calibration, and detailed performance analytics, all of which contribute to enhanced quality assurance processes. Their models offer programmable test cycles, auto peak hold functions, and adjustable testing speeds, making them suitable for both research labs and production floors. The use of microcontroller-based technology ensures consistent readings and minimal human error, reinforcing Star EMBSYS’s reputation for delivering accuracy and reliability.

Custom Solutions and Industry Applications

What sets Star EMBSYS apart is its ability to provide customized solutions tailored to specific industrial requirements. Whether it’s a standard compression spring for shock absorbers or a specialized torsion spring in aerospace assemblies, Star EMBSYS machines can be adapted to test various spring types and sizes. This level of flexibility is crucial for companies that manufacture springs in different configurations and strengths.

The versatility of their machines extends beyond technical features. Star EMBSYS also emphasizes user-friendly interfaces, intuitive controls, and robust after-sales support—components that contribute to operational efficiency and reduced training time. Additionally, their spring testing machines are built with durable materials, ensuring long-term use with minimal maintenance.

Industries that rely heavily on quality spring components—such as automotive OEMs, defense contractors, and electronics manufacturers—benefit immensely from integrating Star EMBSYS testing machines into their production and QA pipelines. By improving the repeatability and accuracy of tests, these businesses not only enhance product quality but also reduce operational costs caused by faulty components.

Conclusion

In a market where precision and performance are critical, Star EMBSYS spring testing machines stand out as an essential investment for manufacturers aiming to uphold product integrity and operational efficiency. Their commitment to innovation, customization, and support makes them a preferred partner for industries demanding the highest standards in spring testing. Businesses looking to streamline quality control and gain a competitive edge will find Star EMBSYS a reliable and forward-thinking ally.

Visit:- https://www.starembsys.com/spring-testing-machine.html

0 notes

Text

Torque Sensors: Precision Force Monitoring Powered by Star EMBSYS Technology

Torque sensors are essential tools in the measurement and control of rotational force in mechanical systems. From automotive testing and industrial automation to aerospace and robotics, torque sensors enable engineers to monitor performance, ensure safety, and improve efficiency. Star EMBSYS, a leader in embedded system innovation, offers advanced torque sensor solutions that combine mechanical precision with intelligent electronics for high-performance applications.

A torque sensor, also known as a torque transducer, measures the torque—or rotational force—applied to a shaft or axis. It can be used in both static (non-rotating) and dynamic (rotating) applications, making it highly versatile. Depending on the requirement, torque sensors can be based on strain gauge, magnetoelastic, or optical technologies. The electrical signal generated is proportional to the torque applied, which is then processed for display, control, or data logging.

Star EMBSYS leverages its deep expertise in embedded systems to develop smart torque sensor solutions that provide real-time, high-resolution measurements. Their sensors are integrated with embedded microcontrollers for advanced signal conditioning, filtering, and digital communication. This results in more stable, noise-free data and allows for seamless integration into modern control systems.

What sets Star EMBSYS apart is their ability to offer custom torque sensor systems tailored to specific industrial needs. Whether for a precision laboratory setup or a rugged field environment, Star EMBSYS provides sensors that include temperature compensation, overload protection, and customizable output ranges. The embedded software also supports features like zero-torque calibration, peak-hold modes, and fault diagnostics.

For industries working with rotating machinery—such as electric motors, pumps, or wind turbines—Star EMBSYS torque sensors offer both static and rotary variants. These sensors can output analog signals (0–5V, 4–20mA) or digital data via UART, CAN, or SPI, providing flexibility for integration with PLCs, DAQs, or cloud-connected IoT platforms.

Moreover, Star EMBSYS includes support for wireless telemetry in demanding applications, allowing real-time torque data transmission without slip rings or complex wiring—ideal for mobile machinery or test benches.

In summary, torque sensors play a vital role in the monitoring and control of mechanical systems. With its focus on smart design, embedded innovation, and application-specific customization, Star EMBSYS delivers high-performance torque sensor solutions that empower engineers and manufacturers to measure with confidence, accuracy, and efficiency.

Visit:- https://www.starembsys.com/torque-sensor.html

0 notes

Text

EPS Torque Sensor Market

0 notes

Text

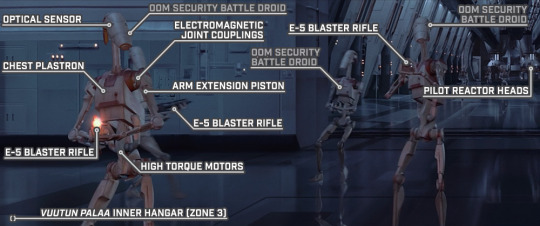

Battle Droids Open Fire

STAR WARS EPISODE I: The Phantom Menace 02:02:27

#Star Wars#Episode I#The Phantom Menace#Battle of Naboo#Vuutun Palaa#Droid Control Ship#Lucrehulk-class LH-3210#starboard main hangar#inner hangar#Zone 3#unidentified battle droid#OOM security battle droid#optical sensor#electromagnetic joint couplings#pilot reactor head#chest plastron#E-5 blaster rifle#arm extension piston#high-torque motors

0 notes

Text

Website: http://www.loadcellsensor.com/

Address: Rm 1605, Ho King Commercial Center, 2-16 Fa Yuen St., Mongkok, Kowloon 999077, Hong Kong China

Phone: +86-19956502838

LCS Tech Co., Ltd is a Chinese manufacturer for strain gauge type load cell sensors,tension compression force transducers, reaction and rotary torque sensors.

#load cell sensor#tension compression load cell#multi-axis force sensor#rotary torque sensor#reaction torque transducer

1 note

·

View note

Text

Website: http://www.loadcellsensor.com/Products

LCS Tech Co., Ltd is a Chinese manufacturer for strain gauge type load cell sensors,tension compression force transducers, reaction and rotary torque sensors.

1 note

·

View note

Text

[155 Pages Report] According to MarketsandMarkets, the torque sensor market size is projected to grow from USD 6.8 billion in 2021 to USD 9.0 billion by 2026

0 notes