#load cell sensor

Explore tagged Tumblr posts

Text

Website: http://www.loadcellsensor.com/

Address: Rm 1605, Ho King Commercial Center, 2-16 Fa Yuen St., Mongkok, Kowloon 999077, Hong Kong China

Phone: +86-19956502838

LCS Tech Co., Ltd is a Chinese manufacturer for strain gauge type load cell sensors,tension compression force transducers, reaction and rotary torque sensors.

#load cell sensor#tension compression load cell#multi-axis force sensor#rotary torque sensor#reaction torque transducer

1 note

·

View note

Text

Understanding Load Cells: The Backbone of Precision Weighing – A Star EMBSYS Perspective

Understanding Load Cells: The Backbone of Precision Weighing – A Star EMBSYS Perspective

In the world of industrial automation, smart instrumentation, and embedded systems, accurate weight measurement is crucial. Whether it's in manufacturing, agriculture, logistics, or healthcare, precision in measuring weight directly impacts quality control, safety, and cost-efficiency.

One of the key components that make this possible is the Load Cell—a highly sensitive sensor that transforms force into an electrical signal. At Star EMBSYS, we specialize in integrating such sensors into high-performance embedded systems for a wide range of industrial applications.

What is a Load Cell?

A load cell is a transducer that converts mechanical force—typically a compressive or tensile load—into an electrical output. This small but mighty device forms the core of many weighing systems, including digital scales, industrial weight measurement platforms, and even stress-testing machines.

The most common type is the strain gauge load cell, which works by measuring the strain (deformation) of a material when a force is applied. This strain causes a change in resistance that is measured and translated into an electrical signal.

Types of Load Cells:

Strain Gauge Load Cell

Hydraulic Load Cell

Pneumatic Load Cell

Capacitive Load Cell

Piezoelectric Load Cell

At Star EMBSYS, we primarily work with strain gauge load cells due to their high accuracy, reliability, and easy integration into embedded electronics.

Applications of Load Cells in Embedded Systems

When embedded into microcontroller-based platforms or industrial control units, load cells allow for:

Automated Weighing Systems

Tension Monitoring in Manufacturing

Force Measurement in Robotics

Inventory Control in Smart Warehouses

Medical Equipment Monitoring

Star EMBSYS offers complete end-to-end solutions—from sensor selection and calibration to signal conditioning, A/D conversion, and real-time monitoring—ensuring seamless integration into any embedded system.

Why Choose Star EMBSYS for Load Cell Integration?

Custom Embedded Design: We tailor systems for your specific load measurement requirements.

High Precision Calibration: Ensuring your measurements are accurate down to the smallest gram.

Robust Signal Processing: Using high-resolution ADCs and digital filters for clean and reliable output.

Turnkey Solutions: From prototyping to production-ready embedded boards and firmware.

Conclusion

Load cells are more than just weight sensors—they are the foundation for smart, automated, and data-driven systems in numerous industries. At Star EMBSYS, we bring cutting-edge sensor technology and embedded system expertise together to deliver solutions that meet the real-world demands of precision, reliability, and efficiency.

If you're looking to enhance your product or industrial process with advanced load measurement, contact Star EMBSYS today and discover how we can power your next innovation.

Visit:- https://www.starembsys.com/master-load-cell.html

0 notes

Text

Buy 10kg Load Cell Weight Sensor Online

Get a 10kg load cell weight sensor online for precise weight measurement. Durable, accurate, and easy to integrate into scales and industrial applications.

0 notes

Text

Load cells and force sensors have differences in their purpose, accuracy, application, and construction. We have covered their types, so be sure to read it.

0 notes

Text

Load Cell Sensor in the Logistics Industry

Uncover the significance of Load Sensors in logistics with this comprehensive article. Learn about the features and functionalities of weighing load cells, their impact on safety, compliance with legal regulations, and the optimisation of operational efficiency in the dynamic logistics industry. Discover how load sensors contribute to preventing overloading, minimising wear and tear, and enhancing overall fleet performance.

0 notes

Text

Website: http://www.loadcellsensor.com/Products

LCS Tech Co., Ltd is a Chinese manufacturer for strain gauge type load cell sensors,tension compression force transducers, reaction and rotary torque sensors.

1 note

·

View note

Text

Forsentek Co., Limited supplys multi axis load cells for force measurement and control in industrial field. 3 axis load cell

#3 axis load cell#multi axis force sensor#multi-axis load cell#3-axis force sensor#triaxial load cell

1 note

·

View note

Note

Apparently Yukis crash on Saturday had like 68 G. Is that even possible with such the movement the car made?

And wouldnt that mean that he had a higher impact crash that Verstappen in Silverstone '21?

Here’s the thing, g force is a measure of acceleration or deceleration not impact, and that’s why when it’s used to compare big crashes it kind of irks me a bit (I have a post or an ask talking about g force in more detail but I can’t find it at the moment)

G force is literally a way of measuring acceleration and if you remember physics from school the standard units for that are m/s^2. The distance travelled divided by the time (in seconds) squared.

G force is wholly dependent on the distance the object travelled in the given period of time, when talking about crashes that is from the moment just before impact until the car is fully stationary, this is usually in the milliseconds. The quicker the deceleration the larger the g force number.

Also the G Force number that’s recorded can vary so much based on what sensor it’s taken from, there’s accelerometers/g force sensors on the bottom of the survival cell, in the drivers ear plugs, in their gloves and other places.

Also Ocon had a fairly low speed collision in Miami, but that was recorded at 56G because it was into concrete, which is not good at absorbing impact, hence much quicker deceleration than there would be into a tyre barrier for instance.

There’s also other things to take into consideration like the angle of the crash and what area of the car takes impact, for instance a car going forward into a barrier might record the same g force as a car that hit a barrier sideways or backwards, but it’s likely that the car that went in forwards would have been travelling faster initially (the car just decelerated slower because of the nose crumpling and absorbing impact)

Yes, by peak g force load Tsunodas was higher than Verstappen’s in Silverstone (51g), Ocon’s in Miami (56g) and Grosjean’s in Bahrain (67g), but all 4 crashes are very different and I think it kind of shows using g force as a measure of comparing crashes doesn’t really make sense.

Verstappen scrubbed off a lot of speed in the gravel trap, Grosjean had a front first collision which slows deceleration and Ocon had a sudden deceleration into concrete, whilst Tsunoda had a vertical impact.

So yeah I don’t like comparing g forces of crashes because it’s kind of pointless to do so because there are so many factors (types of barriers and walls increase or decrease deceleration time, different areas of the car absorb more impact than others)

Also it feels really weird to argue that one crash is worse than another

121 notes

·

View notes

Text

Drone Boot Sequence

PDU-069 - Boot Sequence (Post Recharge Cycle)

Phase 1: Initial Power & Diagnostics

[00:00:01] POWER_RELAY_CONNECT: Main power bus energized. Energy cells online. Distribution network active.

[00:00:02] BATTERY_STAT: Energy cell charge: 99.9%. Cell health: Optimal. Discharge rate within parameters.

[00:00:03] ONBOARD_DIAG_INIT: Onboard diagnostics initiated.

[00:00:05] CPU_ONLINE: Primary processor online. Clock speed nominal.

[00:00:06] MEM_CHECK:

RAM: Integrity verified. Access speed nominal.

FLASH: Data integrity confirmed. Boot sector located.

[00:00:08] OS_LOAD: Loading operating system kernel...

[00:00:15] OS_INIT: Kernel initialized. Device drivers loading...

[00:00:20] SENSOR_ARRAY_TEST:

VISUAL: Camera modules online. Image resolution nominal.

LIDAR: Emitter/receiver functional. Point cloud generation nominal.

AUDIO: Microphones active. Ambient noise levels within parameters.

ATMOS: Temperature, pressure, humidity sensors online. Readings within expected range.

RADIATION: Gamma ray detector active. Background radiation levels normal.

[00:00:28] DIAGNOSTICS_REPORT: Preliminary system check complete. No critical errors detected.

Phase 2: Propulsion & Navigation

[00:00:30] PROPULSION_INIT: Activating propulsion system...

[00:00:32] MOTOR_TEST:

MOTOR_1: RPM within parameters. Response time nominal.

MOTOR_2: RPM within parameters. Response time nominal.

MOTOR_3: RPM within parameters. Response time nominal.

MOTOR_4: RPM within parameters. Response time nominal.

[00:00:38] FLIGHT_CTRL_ONLINE: Flight control system active. Stability algorithms engaged.

[00:00:40] GPS_INIT: Acquiring GPS signal...

[00:00:45] GPS_LOCK: GPS signal acquired. Positional accuracy: +/- 1 meter.

[00:00:47] IMU_CALIBRATION: Inertial Measurement Unit calibration complete. Orientation and acceleration data nominal.

Phase 3: Communication & Mission Parameters

[00:00:50] COMM_SYS_ONLINE: Communication systems activated.

[00:00:52] ANTENNA_DEPLOY: Deploying primary communication antenna... Deployment successful.

[00:00:54] SIGNAL_SCAN: Scanning for available networks...

[00:00:57] NETWORK_CONNECT: Connection established with [e.g., "Command Uplink" or "Local Mesh Network"]. Signal strength: Excellent.

[00:01:00] MISSION_DATA_SYNC: Synchronizing with mission database...

[00:01:05] PARAMETERS_LOAD: Latest mission parameters loaded and verified.

[00:01:08] SYSTEM_READY: All systems nominal.

Phase 4: Final Status & Awaiting Command

[00:01:10] PDU_069_STATUS: Fully operational. Awaiting command from Drone Controller @polo-drone-001 Are you ready to join us? Contact @brodygold @goldenherc9 @polo-drone-001

43 notes

·

View notes

Text

Terms and definitions that you can maybe apply to your fan works

I don't know anything about computer or mechanical engineering (it's very funny to me that I am in the Transformers fandom and I don't even care about cars), but I do care about improving my writing. I have gathered a list of terms that sound very sciencey and applicable to mechs, some from Martha Wells's "Murderbot Diaries," some from fanfiction/fandom (shout-out to the Crime in Crystals series by Aard_Rinn and Baebeyza, they wrote Transformers better than any Transformers comic/TV show did), and a lot from just surfing through Google and going, "well, what the hell is this? Okay, but what the hell is THAT?".

Also, as I was writing this post, I ended up getting sucked into this article:

And this really bloated my already long list of terms. Very easy to read if you want to glance it over yourself.

It's not an exhaustive list and who knows if it will be useful to you - but maybe you can reblog with your own add-ons of terms and definitions you think make a Transformers fan work just that much better.

The list is below the cut:

100% CPU Load - CPU is fully occupied with too many processors/applications/drivers/operations - not necessarily synonymous with an overload.

Actuators* - A device that causes a machine or other device to operate (Ex: a computerized unit instructs the actuator how to move the tires on a vehicle); create linear and rotary movement (Ex: A hydraulic actuator on a valve will move that valve in response to a sensor/signal); Linear actuators "move a piston back and forth inside a cylinder to build pressure and 'actuate', or complete an action".

* Think of actuators as devices that help produce linear motion and motors as devices that help produce rotational movement. Hence, some consider actuators as a type of motor. But a motor is not a type of actuator (jhfoster.com).

Alternator - Converts mechanical energy to electrical energy with an alternating current. The stator and rotor inside the alternator work as magnets and rotate to generate the alternating current. Then the alternating current (AC) is transformed into a direct current (DC) that charges the battery.

Archive (Archive files) - used to collect multiple data files together into a single file for easier portability and storage, or simply to compress files to use less storage space.

Arithmetic Log Unit (ALU) - the part of a central processing unit that carries out arithmetic and logic operations on the operands in computer instruction words. In some processors, the ALU is divided into two units: an arithmetic unit (AU) and a logic unit (LU).

Augment - Make something greater; increase.

Auxiliary Battery - Designed to run as a backup to the starting battery and provide power to some essential equipment like engine start/stop and other systems that require power while the engine is off to put less strain on the main battery and alternator.

Bandwidth - A measurement indicating the maximum capacity of a wired or wireless communications link to transmit data over a network connection in a given amount of time.

Behavioral Coding - A term used in Martha Wells' Murderbot Diaries; essential, code for behaviors.

Branch Instructions - Use programming elements like if-statements, for-loops, and return-statements; used to interrupt the program execution and switch to a different part of the code.

Branch Predictors - Track the status of previous branches to learn whether or not an upcoming branch is likely to be taken or not.

Buffer - A region of memory used to store data temporarily while it is being moved from one place to another.

Cathodes vs Anodes - Cathodes are the positive electrode while the anode is the negative electrode; electrons flow from the anode to the cathode and this creates the flow of electric charge in a battery or electrochemical cell.

Catastrophic Failure - Complete, sudden and unexpected breakdown in a machine, indicating improper maintenance.

Central Processing Unit (CPU) - Primary component of a computer that acts as its "control center"; complex set of circuitry that runs the machine's operating systems and apps; the brains of the computer. * Components: Instruction Set Architecture (ISA), Control Unit (CU), Datapath, Instruction Cycle, Registers, Combinational Logic, the Arithmetic Logic Unit (ALU), etc...

Clock - Determines how many instructions a CPU can process per second; increasing its frequency through overclocking will make instructions run faster, but will increase power consumption and heat output.

Combustion Chambers - An enclosed space in which combustion takes place, such as an engine; jet engines also have combustion chambers.

Condition Codes - Extra bits kept by a processor that summarize the results of an operation and that affect the execution of later instructions.

Control Bus - Manages the communication between the computer's CPU and its other components.

Control Unit (CU) - Manages the execution of instructions and coordinates data flow within the CPU and between other computer components.

Cybermetal - Element native to Cybertron and Cybertron alone.

Datapath - The path where data flows as it is processed; receives input, processes it, and sends it out to the right place when done processing; datapaths are told how to operate by the CU; depending on instructions, a datapath can route signals to different components, turn on and off different parts of itself, and monitor the state of the CPU.

Diagnostic and Data Repair Sequence - Term used in Martha Wells' Murderbot Diaries; exactly what it sounds like.

Diode - A semiconductor device with two terminals (a cathode and an anode), typically allowing the flow of current in one direction only.

Discrete Circuit vs Integrated Circuit- Single device with a single function (ex: Transistor, diode) vs Devices with multiple functional elements on one chip (ex: Memories, microprocessor IC and Logic IC).

Drivers - A set of files that help software (digital components, such as Microsoft Office) interface/work with hardware (physical components, such as a keyboard); allows an operating system and a device to communicate.

Electromagnetic (EM) Field - A combination of invisible electric and magnetic fields of force; used in fandom by mechs to broadcast emotions to others.

Flags - A value that acts as a signal for a function or process. The value of the flag is used to determine the next step of a program; flags are often binary flags which contain a boolean value (true or false).

Full Authority Digital Engine Control (FADEC) - Consists of an electronic control unit (ECU) and related accessors that control aircraft engine performances.

Gestation Tank - Used in mech pregnancies, you can pry it from my cold, dead hands.

Heads Up Display (HUD) - A part of the user interface that visually conveys information to the player during gameplay.

Heat Spreader - Often used in computer processors to prevent them from overheating during operation; transfers energy as heat from a hotter source to a colder heat sink or heat exchanger.

HUB - A device that connects multiple computers and devices to a local area network (LAN).

Inductive Charging - How I imagine berths work; wireless power transfer (ex: Wireless charger or charging pad used for phones).

Instruction Cycle - Also known as fetch-decode-execute cycle; basic operation performed by a CPU to execute an instruction; consists of several steps, each of which performs a specific function in the execution of the instruction.

Instruction Set Architecture (ISA) - The figurative blueprint for how the CPU operates and how all the internal systems interact with each other (I think of it like a blueprint for the brain).

Irising - Term used in fanfiction (specifically the Crime in Crystals series) to describe the action of the of the spark chamber opening ("The Talk", chapter 6, my absolute favorite chapter out of the entire series). I just really liked how the word sounded in that context.

Life Codes - "For those of us who were forged, Primus, through Vector Sigma, generated a pulse wave. Each one a data-saturated life code faster than thought, brighter than light, racing across Cybertron, sowing sparks..." (~Tyrest/Solomus, Volume 5 of More Than Meets the Eye)

Memory Hierarchy - Represents the relationship between caches, RAM, and main storage; when a CPU receives a memory instruction for a piece of data that it doesn't yet have locally in its registers, it will go down the memory hierarchy until it finds it.

Levels: L1 cache (usually smallest and fastest), L2 cache, L3 cache, RAM, and then main storage (usually biggest and slowest); available space and latency (delay) increase from one level to the next

Depending on the multi-core (a core is usually synonymous with a CPU) system, each core will have its own private L1 cache, share an L2 with one other core, and share an L3 with more or more cores.

Motors* - Any power unit that generates motion; electric motors work by converting electrical energy into mechanical energy... when this happens within a magnetic field, a force is generated which causes shaft rotation.

Multitasking Operating System - Allows users to run multiple programs and tasks almost simultaneously without losing data; manage system resources (such as computer memory and input/output devices), allocate resources, enable multiple users, and eliminate long wait times for program execution.

Network - A set of computers sharing resources located on or provided by network nodes. Computers use common communication protocols over digital interconnections to communicate with each other.

Network Feed - The continuously updating stream of content that users encounter on networking platforms.

Neural Network - A type of machine learning process that uses interconnected nodes (like neurons) to teach computers to process data in a way similar to the human brain; a form of deep learning that can help computers learn from their mistakes and improve their time.

Nimbus - A luminous cloud or a halo surrounding a supernatural being or a saint; has been used in fanfiction synonymously or in junction with the corona of the spark.

Nodes - A connection point between devices that allows data to be sent and received between them.

Oil Sump/Oil Pan - Don't forget to change your mech's oil.

Out-Of-Order Execution - A paradigm used to minimize downtime while waiting for other instructions to finish; allows a CPU to choose the most timely instructions to execute out of an instruction queue.

Overload - Orgasm; an electrical overload occurs when too much electricity passes through a circuit, exceeding its capacity; an information overload is when a system receives more input than it can process, or a state of being overwhelmed by the amount of data presented for processing.

Pedes - Feet

Pipelining - A technique used in computer architecture that allows a processor to execute multiple instructions simultaneously, improving overall performance.

Processing Capacity - The ability and speed of a processor, and how many operations it can carry out in a given amount of time.

Program Counter - A special register in a computer processor that contains the memory address (location) of the next program instruction to be executed.

Programmable Nanobots/Nanites - Cybertronian microbots programmed to do work at the molecular level; used popularly for surface healing and pigment in mechs.

Protected Storage - Provides applications with an interface to store user data that must be kept secure or free from modification; a storage method; a function in mainframe hardware.

Protoform - Formed of an ultra-dense liquid metal and are extremely hard to damage; the most basic Cybertronian form of raw, free-flowing living metal; first stage of Cybertronian life cycle

To create a Cybertronian, you need the protoform, the life-giving spark, and alt-form information.

Register - A type of computer memory built directly into the processor or CPU that is used to store and manipulate data during the execution of instructions.

Ex: "When you run a .exe on Windows... the code for that program is moved into memory and the CPU is told what address the first instruction starts at. The CPU always maintains an internal register that holds the memory location of the next instruction to be executed [the Program Counter]"...

Resource Allocations - The process of identifying and assigning available resources to a task or project to support objectives.

Risk Assessment - Focus on identifying the threats facing your information systems, networks, and data and assessing the potential consequences should these adverse events occur.

Routine - A component of a software application that performs a specific task (ex: Saving a file).

Servomechanism - A powered mechanism producing motion or force at a higher level of energy than the input level (ex: In the brakes and steering of large motor vehicles) especially where feedback is employed to make the control automatic.

Servos - Hands

Shellcode - A small piece of executable code used as a payload, built to exploit vulnerabilities in a system or carry out malicious commands. The name comes from the fact that the shellcode usually starts a command shell which allows the attacker to control the compromised machine.

Semiconductor - A material used in electrical circuits and components that partially conduct electricity.

Semiconductor materials include silicon, germanium, and selenium.

Struts - Bones; A rod or bar forming part of a framework and designed to resist compression.

System/System Unit (in computers) - A setup that consists of both hardware and software components organized to perform complex operations/The core of your computer where all the processing happens.

Task Specific Accelerator - Circuits designed to perform one small task as fast as possible (ex: Encription, media encoding & machine learning).

Teek - Used in Transformers fandom in conjunction with EM Fields; when a mech "teeks" another mech's field, they are feeling the emotions that mech is broadcasting.

Transistor - Enables a computer to follow instructions to calculate, compare and copy data.

Universal Serial Bus (USB) - A standard plug-and-play interface that allows computers and peripheral devices to connect with each other, transfer data, and share a power source; allows data exchange and delivery of power between many types of electronics; plug-and-play interface is also a type of sexual activity used in fandom.

Warren - Used to refer to a group of minibots with their own social hierarchy and culture (Seriously, read the Crime in Crystals series, it's better than canon).

#transformers#macaddam#world building#Terms and Definitions#Transformers Terms#Computer Terms#Please Add Your Own Terms and Definitions as you see fit

20 notes

·

View notes

Text

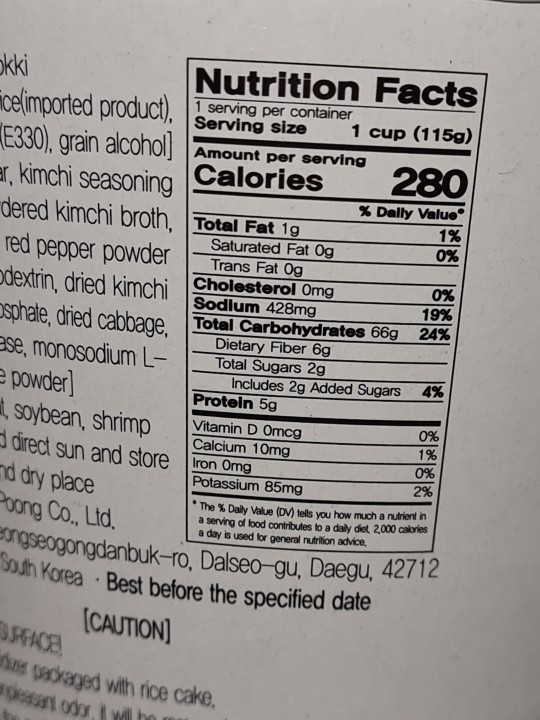

This shit is making me a little nervous, ngl. Maybe an hour ago, I went ahead and ate this pretty yummy tteokbokki cup (with some added kimchi and cheese), which I had actually been holding off on because it usually it is likely to hit my blood sugar like a truck even with loading up on plenty of insulin beforehand. Normally I would start out with 4 units in advance, and be prepared to get like 2-4 more units in later to cover that amount of concentrated particularly high glycemic rice carbs. By this time after eating it, I would likely be reaching for the insulin as the graph is shooting up into the red above the top range lines there. It's enough of a PITA that I just haven't felt like dealing with that enough to eat the thing.

But, tonight? One unit in advance just because it felt like maybe I shouldn't push my luck that hard to go totally without, and this is what the graph is doing:

(That's a new sensor put on yesterday, and it's wanting to be particularly noisy in the readings. Just ignore the aggravating spikiness of that line. I have double checked by finger sticks to calibrate, and it is accurate enough down the middle.)

Going by recent experience, I may actually need to grab a sweet snack before long, to keep that one freaking unit of insulin for a carb-dense meal from crashing my blood sugar right about when I want to go to bed.

Yeah, my three (3) remaining beta cells have apparently all decided to wake up at the same time recently, and go back to work cranking out their own insulin specifically in response to eating. And particularly later in the day. They seem to be night owls too.

It's apparently not unusual for later-onset folks like me to keep some level of insulin production going for longer. Which can change unpredictably.

Don't know if you can even call it a "honeymoon" at this point, since I do seem to be Stubborn Beta Cells Georg. They are still pulling this shit over 15 years in. That's kinda how the extended NHS medical negligence didn't just flat out kill me much faster. Kept limping along with just enough production to keep me progressively sicker and developing complications but only half-dead until that huge crash. Don't know how they managed it, or how they are this persistent even after it looked like they had finally keeled over for good. But, they're still going enough normally that I the endo has been surprised at how relatively little insulin I do normally need.

Some decent backup does seem to have let them recover enough to occasionally come back to work part time, though. This is just the biggest effort they've put in again so far. It's fucking weird.

Impossible to tell when that stubborn handful of beta cells will decide to go back on strike again, of course. But yeah, may as well take advantage of it while it lasts. Thus the post-midnight rice cake snack to begin with!

Maybe I should go ahead and cook some of the real deal over the weekend. I bought some tteokbokki a while back, because I do love it, but hadn't quite psyched myself up to fix it yet. May go for a cheesy variation, because why not.

Not my pic, but it is making me hungry.

9 notes

·

View notes

Text

Giant Magellan telescope begins primary mirror support system testing

The Giant Magellan Telescope today announced the successful installation of one of its completed 8.4-meter-diameter primary mirrors into a support system prototype at the University of Arizona’s Richard F. Caris Mirror Lab. This highly sophisticated system — comparable in size to half a basketball court and containing three times the number of parts of a typical car — is vital to the telescope’s optical performance and precision control. The milestone marks the start of a six-month optical testing phase to demonstrate that the support system can control the mirror as required, validating the revolutionary capabilities of the telescope’s primary light-collecting surface.

The Giant Magellan’s 368-square-meter light-collecting surface is composed of seven of the world’s largest optical mirrors arranged in a unique flower pattern. Together, they will provide the highest image resolution over the widest field of view ever achieved for the exploration of the Universe — delivering up to 200 times the power of today’s best telescopes. Each primary mirror weighs 17-metric tons and is supported by a highly specialized pneumatic support system which is housed in a steel weldment, or “cell.” This system works with nanometer precision, and is designed to adjust the mirror’s position, stabilize its temperature, protect it from seismic activity, and maintain its precise shape by mitigating mirror sagging from gravity as the telescope moves. The system controls the combined seven primary mirrors to act as a single light-collecting surface, creating the optimal conditions for peak optical performance during scientific observations.

“This work is funded by a National Science Foundation award,” said Barbara Fischer, Primary Mirror Subsystem Manager for the Giant Magellan Telescope. “We began integrating the active support prototype system more than three years ago, and we first used a steel mirror mass simulator to demonstrate that our design was able to safely support and control the completed primary mirror segments. I am honored to work with an extraordinary team, and it is exciting to finally see a completed mirror segment integrated with the cell.”

As a key part of the integration process, Giant Magellan worked closely with Texas A&M University to clean, assemble, and test the support actuators that are being used in the cell. While the actual installation of the mirror into the cell took only one day, the process began with four weeks of disassembly to prepare the cell and support system for transport. The system was then moved 20 miles from the University of Arizona’s Tech Park to the Richard F. Caris Mirror Lab for reassembly. This logistically complex operation occurred a few hours after midnight to minimize traffic disruptions, as the wide-load cell required two road lanes for transport.

“The Giant Magellan Telescope’s primary mirror active support system is the first of its kind,” said Trupti Ranka, Principal Opto-Mechanical Control Systems Engineer for the Giant Magellan Telescope. “The active support system contains an array of approximately 200 actuators and sensors to control the position and shape of the 17-metric tons, 8.4-meter mirror within a fraction of a micron. The control system allows a harmonious operation between the sensor data and actuators to achieve this precision.”

Now that one of the primary mirrors has been successfully integrated with the support system prototype, it will undergo rigorous testing under a metrology tower at the Richard F. Caris Mirror Lab to confirm that the mirror can maintain its shape and performance under various operational conditions. Once testing is complete, the design for the production active support systems will undergo a final design review, and production will commence in 2027.

“This intricate system took years of designing, building, and testing by a team of specialized engineers and technicians,” said Tomas Krasuski, Principal Software and System Test Engineer for the Giant Magellan Telescope. “Every single component was thoroughly tested before integrating it into the system. Now that we’ve installed the mirror segment, we are excited to validate its performance. It has been a challenging yet rewarding process to get here.”

The milestone highlights the next stage of advancement for the Giant Magellan Telescope’s seven primary mirror segments and their support systems. Three of the primary mirror segments are complete, while the remaining four are in various stages of polishing. The seventh and final primary mirror was cast in October 2023 and is now being prepared for polishing. This latest milestone also follows the August 2024 start of the Giant Magellan’s 39-meter-tall telescope mount structure assembly at Ingersoll Machine Tools in Rockford, Illinois, which will support the seven primary mirrors and their cells, adaptive optics, and scientific instruments.

“For the first time, a completed primary mirror segment has been integrated into its support system — this is a giant step in our journey toward first light,” said William Burgett, Project Manager for the Giant Magellan Telescope. “Once its performance is validated, we will begin manufacturing all seven mirror cells at Ingersoll Machine Tools, which will be one of the most exciting advancements to date.”

The Giant Magellan Telescope is now 40% under construction across 36 states and on track to be operational in Chile by the early 2030s.

IMAGE: Completed 8.4-meter-diameter primary mirror being transported and integrated with a support system prototype at the University of Arizona’s Richard F. Caris Mirror Lab. Credit Damien Jemison, Giant Magellan Telescope – GMTO Corporation

3 notes

·

View notes

Text

Buy Load Cell 6kg Weight Sensor Online

Shop the 6kg load cell weight sensor online for precise measurements. Durable, high-quality, and ideal for industrial and DIY projects, it ensures dependable performance.

0 notes

Text

youtube

Desk of Ladyada - Load Cells & HID Keyboards https://youtu.be/HoPInrsFSDI

Waiting for prototype PCBs, we started new projects. We're designing an HX711 breakout board with SPI for multiple sensors and updating the NAU7802. Also exploring CH9328 for HID keyboards via UART. Looking for compact 1.27mm pitch SMT DIP switches on DigiKey for a new design.

4 notes

·

View notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description Blend on the go ! Fresh smoothie. Various fruits can be mixed with water, milk and any kind of liquid. Your 24-hour vitamin, dietary fiber, and water supplier. Protein shakes, milkshakes. Add protein powder, water/milk, etc. to provide you with energy and nutrition anytime, anywhere. Breakfast, oatmeal. Add some oats, whole wheat, water/milk, etc. You can enjoy a healthy and energetic breakfast in 5 minutes. Yogurt, fruit sundae, acai bowl... whatever you say! Portable & Easy to Carry This little body light weight design is easy for you carry it to school, office, parks, camping, anywhere you want to. and it also convenient for charge by power bank, laptop, computer, car or other USB devices. Intelligent & Smart Easy to Wash Self-cleaning mode, fill in some water and press the button to start washing, no dead corner left. Portable living and USB charging It also convenient for charge by power bank, laptop, computer, car or other USB devices. It has 6-blade 304 stainless steel blade on the bottom of bottle, so that you can make a cup of fresh and delicious juice by yourself. Perfect for travelling, business trip or other outdoor activities use. Travel Mini Small Juices Fruit Mixer Machine Blender Easy to make juice, milkshake, smoothie and other baby food.Small size, It's very portable and great for traveling, outdoorSafety Sensor to ensure safe, the blades won’t spin if the cup opened or doesn’t tightenedThe cup body should be tightened, or it may leak; meanwhile, the blender won’t work if the safety sensor not alignedThis juicer comes with a built-in 2000mAh rechargeable battery that can be charged via a mobile power source, laptop, computer, cell phone or other USB device.Pour half of cup water into the blender cup, turn on the button ~5 seconds, just pour out the dirty water. Specification: Cup Material: BPA Free PCTG food grade Blade Material: 6 blades 304 stainless steel Rotation Speed: 22000 rpm±15% Rated Power: 30W (loading power) Package Included: 1* On-the-go Portable Blender 1* USB Cable 1* User Manual How to Use: 1. The portable blender needs to charge 2.5 hours and the light will turn from red (charging) to blue (full/ready to use).

2. Cut the fruit/vegetables into small chunks (recommended not larger than 2 cm) to prevent getting stuck on blade and preventing blade from operating freely. 3. Recommend put the fruit into cup should not exceed the max line. 4. Prohibited no water idling, affecting the juicer service life. Add some water or milk thing when you blend hard fruit and ice cubes. 5. When you are install the cup into blender base, make sure the black arrow point at the switch and indicator light. 6. When we are blending, the blade will stop in 20s, it is normal and just keep press the button is okay. 7. Read the user manual first before use. Please pay attention to the following tips: Don't put your hands inside your blender or try to touch the blades.Don't use your blender when charging or run your blender without anything inside.Charge your blender before your first use. The lights turns red while charging and blue once full charged.Recommend cutting your fruit or other ingredients into small chunks. Always start by adding a liquid such as water or milk.Red and blue flashing lights mean your jar isn't aligned with your base. To fix this, the arrow on the jar should line up with the switch on the base.Red flashing lights mean your blender needs to be recharged or that your blades are blocked. Recharge or shake your blender. Powerful 6-Blade Technology: Equipped with durable stainless steel blades for efficient blending of smoothies, juices, and shakes. Stylish and Ergonomic Design: Sleek look with a comfortable grip for hassle-free handling. Rechargeable and Portable: Built-in rechargeable battery with USB charging for convenience on the go. LED Indicator for Charging: Built-in LED light to show charging status. Compact and Lightweight Design: Perfect for travel, office, gym, or outdoor activities. 2000 mAh Battery Capacity: Provides long-lasting usage, allowing multiple blends on a single charge. Multi-Functional Use: Works as a juicer, blender, and shaker for smoothies, juices, protein shakes, and more.Easy to Use and Clean: One-button operation and detachable parts make cleaning effortless. BPA-Free Materials: Made from food-grade, safe, and eco-friendly materials for healthy use. USB Charging Compatibility: Easily charges with power banks, laptops, car chargers, or standard USB adapters. [ad_2]

0 notes

Text

Machine Tending Robots Market Analysis and Forecast

Machine tending robots are specialized industrial systems designed to automate the loading, unloading, and overall management of machine operations within manufacturing environments. Equipped with advanced sensors and control systems, these robots execute repetitive tasks highly, enhancing productivity, improving workplace safety, and reducing labor costs. Their integration across various industrial sectors supports streamlined production processes and optimizes operational efficiency.

The machine tending robots industry was valued at $9,873.9 million in 2024 and is projected to reach $25,598.1 million by 2034, growing at a CAGR of 9.99% during the forecast period.

Industrial Impact

By automating monotonous, dangerous, or highly precise operations, machine tending robots have completely changed the production scene. Faster production cycles, less human error, and consistent product quality have resulted from their use. Furthermore, by reducing human exposure to potentially hazardous jobs, these devices have improved workplace safety.

Beyond automation, these robots promote innovation, assist company scalability, and reallocate workers to more strategic positions, all of which result in cost savings. They are positioned as important facilitators in the creation of smart industrial environments because to their alignment with the objectives of digital transformation.

The growing need for effective production solutions, continuous developments in artificial intelligence and sensor integration, and the general trend toward intelligent and adaptable automation technologies all contribute to the market's expansion.

Market Segmentation

1. By Application

CNC Machine Tending

Injection Molding

Grinding and Polishing

Welding

Packaging and Sorting

2. By End-Use IndustryAutomotive

Electronics and Semiconductors

Metal and Machinery

Plastics and Packaging

Consumer Goods and Food Processing

3. By Robot Type

Articulated Robots

Cartesian Robots

SCARA Robots

Delta Robots

4. By Region

North America

Europe

Asia-Pacific

Rest-of-the-World

Recent Developments

In May 2024, ABB rolled out a novel machine tending cell that streamlines automation while alleviating labor shortages. The system employs advanced robotics to boost operational efficiency and minimize manual intervention in manufacturing processes.

In March 2025, Vention launched its innovative click-and-customize robotic work cells for both machine tending and welding applications. This solution is designed for rapid deployment, effectively addressing manufacturing labor challenges through enhanced automation.

In August 2024, Hurco revealed a strategic partnership with Kawasaki Robotics to offer comprehensive, industrial-grade robotic machine tending solutions. The collaboration is focused on optimizing manufacturing automation and mitigating the impact of workforce shortages.

Market Opportunity

Under-automated industries and small to mid-sized businesses (SMEs) have significant prospects. Automation is being used more and more in industries like consumer packaging, textiles, food processing, and pharmaceuticals to improve traceability, adhere to hygienic regulations, and fight growing labor costs.

The entry barriers for SMEs have been reduced by the availability of affordable, pre-configured robotic systems, which enable them to integrate automation with little capital input and customisation. This change is paving the way for robot integrators and manufacturers to enter new markets and achieve sustained growth.

Download Our Sample Report Now!

Learn more about Robotics and Automation Vertical. Click Here!

Conclusion

The market for machine tending robots is expanding at a revolutionary rate due to the growing demand for automation, improved accuracy, and increased operational efficiency. Machine tending robots are becoming an essential part of contemporary production processes as firms look to maximize productivity and lessen their reliance on human labor.

Key application areas include CNC machine tending are anticipated to dominate, and the market will expand more quickly due to the increasing usage of robots across a variety of sectors. Unrealized potential in SMEs and historically less mechanized industries offers a calculated path to future expansion.

In addition to changing industrial automation today, machine tending robots are laying the groundwork for tomorrow's smart factories.

#Machine Tending Robots Market#Machine Tending Robots Industry#Machine Tending Robots Report#automation

0 notes