#UPS System Manufacturers in Ahmedabad

Text

#Top 10 Power Supply Manufacturers in India#Power Supply Manufacturers in Ahmedabad#DC Power Supply Manufacturers in Ahmedabad#AC Power Supply Manufacturers in Ahmedabad#Electronic Power Supply Manufacturers in Ahmedabad#Electrical Power Supply Manufacturers in Ahmedabad#Industrial Power Supply Manufacturers in Ahmedabad#Commercial Power Supply Manufacturers in Ahmedabad#Domestic Power Supply Manufacturers in Ahmedabad#Renewable Energy Power Supply Manufacturers in Ahmedabad#Solar Power Supply Manufacturers in Ahmedabad#UPS System Manufacturers in Ahmedabad#Inverter Manufacturers in Ahmedabad#Battery Manufacturers in Ahmedabad#Charger Manufacturers in Ahmedabad#Power Solution Providers in Ahmedabad

0 notes

Text

SEMICONDUCTORS

(How India is progressing in this sector)

1.What is a Semiconductor?

Semiconductors are materials which has electrical conductivity ranging between conductors and insulators. Conductors are good conductors of electricity while Insulators are bad conductors of electricity.

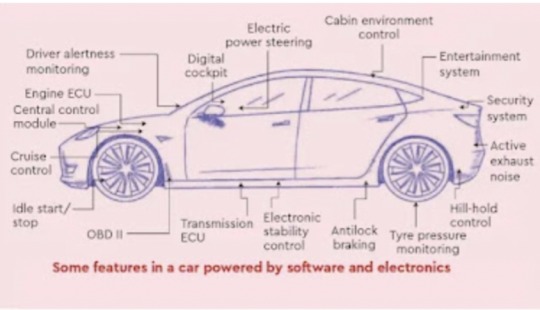

2.Where is a semiconductor used?

Semiconductors are used in manufacture of various electronic devices like diodes, transistors and integrated circuits. The most popular use of a semiconductor is in cars. In vehicles these semiconductor chips are used to control emission systems, driver assist systems etc. Not only in electric cars these chips are also used in petrol cars.

3.A Semiconductor is made up of which material?

Generally a Semiconductor chip is made up of silicon, germanium and gallium arsenide. Out of these three germanium is the oldest.

4.How will a semiconductor help?

First of all semiconductors regulate the flow of electricity and assist in making electronics function. Secondly the electrical conductivity of a semiconductor can be controlled over a wide range making them versatile for various applications. As I told you earlier that a semiconductor is not only used in electric cars but also in petrol cars, this is because semiconductors increase fuel efficiency in cars. By using semiconductors in engine control systems car manufacturers can achieve more precise control of the engine resulting in improved fuel economy and lower emissions.

So these were some common questions people ask when they hear about a semiconductor.

Now you must know that how it will help India and what steps India is taking to manufacture semiconductors in India.

At present Taiwan, USA, Japan, South Korea, China, Israel, Netherlands, UK and Germany can manufacture semiconductors. Out of these countries China and Taiwan produce a large amount of semiconductor.

More exciting thing was that USA and China were in contention with each other in this matter. During era of Donald Trump there aroused a semiconductor war between USA and China. USA wanted to disrupt China's semiconductor manufacturing and hence put a lot of sanctions on China. USA also funded Taiwan and wanted Taiwan to produce more semiconductors than China.

In all this India was benefited a lot. India also wanted to develop semiconductor plants in country and facilitate ATMANIRBHAR BHARAT initiative.

https://ism.gov.in/ this is the link of Government's India Semiconductor Mission. This mission aims at forming a semiconductor ecosystem in India.

Government of India is also working on many other semiconductor initiatives like SPECS initiative. Moreover a joint venture of Vedanta electronics manufacturing giant Foxconn has finalised Dholera Special Investment Region near Ahmedabad for setting up their semiconductor display manufacturing facility.

So much progress is happening in India and surely it will facilitate India's economy and will also provide more job opportunities. India will surely emerge as a Developed nation in upcoming years and these semiconductor initiatives are like a cherry on the cake.

Watch this video for more info.

I hope you liked my article

Pls put forward your views in comment section

Till then PEACE OUT........

My insta : sm_it_22

~Written By Smit.

3 notes

·

View notes

Text

The Features and Benefits of Services ERP

ERP systems are used across industries, from manufacturing to retail. They have different features and benefits depending on the size of their users' organizations (and whether they make cars or suits).

Investing in enterprise software is a big decision. While the monetary cost and your team's time investment can seem overwhelming, implementing the right ERP system will go a long way toward helping you compete with other companies in your industry. We’ve listed 10 key benefits of upgrading to an ERP system, so you can make a business case for how it can help your organization thrive in our hyper-paced, ever-changing world.

A successful ERP implementation hinges on a number of factors, including careful planning and goal setting. Once deployed, however, an ERP system will provide tremendous benefits to any business that implements it well.

Shanti Technology ranks among the top ERP software companies in Mumbai, Pune, Bhopal, Surat, Rajkot. STERP Software Pvt. Ltd. (Previously Known as Shanti Technology), is a Leader in Engineering and manufacturing ERP software in India, with headquarter in Vadodara, Gujarat. STERP Software Pvt. Ltd. has branch offices located in various cities across India such as Ahmedabad, Rajkot, and Surat in Gujarat, Mumbai and Pune in Maharashtra, as well as Bhopal in Madhya Pradesh.

What is Enterprise Resource Planning (ERP)?

Enterprise Resource Planning (ERP) is a type of software that organizations use to manage and automate various business functions, such as finance, procurement, human resources, and supply chain management. The purpose of ERP is to provide a centralized, integrated view of an organization's operations and data, enabling real-time decision-making and improved efficiency. ERP systems typically include modules for various business functions and provide a common database, user interface, and set of business processes. By integrating data and processes across departments, ERP helps organizations streamline operations, reduce costs, and improve overall performance.

Shanti Technology ranks among the best ERP software companies in India. STERP Software Pvt. Ltd. (Previously Known as Shanti Technology), is a Leader in Engineering and manufacturing ERP software in India, with headquarter in Vadodara, Gujarat. STERP Software Pvt. Ltd. has branch offices located in various cities across India such as Ahmedabad, Rajkot, and Surat in Gujarat, Mumbai and Pune in Maharashtra, as well as Bhopal in Madhya Pradesh.

What benefits can I expect for my business when adopting an ERP?

Improved data accuracy and consistency: ERP helps ensure that data is entered correctly and consistently across all departments, reducing errors and improving decision-making.

Increased efficiency: ERP automates many manual processes, freeing up employees to focus on higher-level tasks and increasing overall efficiency.

Better visibility into business operations: ERP provides real-time access to business data, enabling organizations to make informed decisions based on accurate, up-to-date information.

Enhanced customer satisfaction: ERP helps organizations provide more accurate and timely information to customers, improving customer satisfaction.

Improved supply chain management: ERP provides real-time visibility into inventory levels, delivery schedules, and supplier performance, enabling organizations to manage their supply chain more efficiently.

Better financial management: ERP provides real-time financial information, enabling organizations to better plan and control their finances.

Compliance: ERP helps organizations comply with regulatory requirements by providing a centralized repository of data and automated processes.

Better project management: ERP provides project management tools that help organizations plan, track, and execute projects more efficiently.

Scalability: ERP systems can be easily scaled to accommodate business growth.

Improved collaboration: ERP systems provide a centralized platform for collaboration, enabling employees from different departments to work together more effectively.

Solutions offered by ERP software companies in India are one-of-a-kind and specially designed ERP software for engineering companies that follow the fashion in which people work today. It focuses on strategic IT Initiatives. These solutions maximize the availability of the systems or processes and reduce the risks as well.

Benefits of ERP systems

Integration: ERP systems integrate all business functions into a single system, reducing data redundancy and increasing efficiency.

Improved decision-making: ERP provides real-time access to data and analytics, enabling better decision-making.

Increased productivity: ERP automates many manual processes, freeing up employees to focus on higher-level tasks.

Enhanced customer satisfaction: ERP helps companies provide more accurate and timely information to customers.

Better supply chain management: ERP helps companies manage their supply chain more efficiently by providing real-time visibility into inventory levels, delivery schedules, and supplier performance.

Improved financial management: ERP provides real-time financial information, enabling better financial planning and control.

Compliance: ERP helps companies comply with regulatory requirements by providing a centralized repository of data and automated processes.

Better project management: ERP provides project management tools that help companies plan, track, and execute projects more efficiently.

Scalability: ERP systems can be easily scaled to accommodate business growth.

Mobile accessibility: Many ERP systems provide mobile apps that allow employees to access business data and complete tasks from anywhere.

Shanti Technology is one of the most popular ERP software for engineering companies. Solutions offered by Shanti technology are one-of-a-kind and specially designed ERP software for engineering companies that follow the fashion in which people work today. It focuses on strategic IT Initiatives. These solutions maximize the availability of the systems or processes and reduce the risks as well.

The cumulative benefit of an ERP system is the competitive advantage it delivers.

Yes, that's correct. By streamlining operations, improving data accuracy, and providing real-time visibility into business operations, ERP can give organizations a competitive advantage by enabling them to make more informed decisions, respond more quickly to market changes, and increase efficiency. Additionally, ERP can help organizations improve customer satisfaction, manage their supply chain more effectively, and comply with regulatory requirements, all of which can contribute to a competitive advantage.

#ERP software for engineering company#ERP Software Companies in Mumbai | Pune | Bhopal | Surat | Rajkot - STERP#ERP software Companies in India#ERP software

7 notes

·

View notes

Text

Dholera International Airport is a gateway for connecting Gujarat to the World

Dholera International Airport (DIH) will be one of India's largest planned airports, transforming the region of Gujarat into one of the world's most important nodes for air travel and economic activity. The airport is to be located proximate to Dholera Smart City, around 100 kilometers southwest of Ahmedabad, hence an integral part of Dholera Special Investment Region that would further speed up industrial growth and connectivity within India and beyond.

This greenfield project to be developed at this site would meet not only the growing needs for air travels within the state of Gujarat, but at the same time, sustain the economic ambitions of the region by promoting trade, tourism, and industrialization. Being an aspiring significant aviation hub, Dholera International Airport is scheduled to repute the role of Gujarat in Indian aviation.

Strategic Location and Significance

The fundamental reason for getting benefited by Dholera International Airport is its strategic location. This place would be readily accessible to India's first smart city-Dholera Smart City-and thus would most likely be the gateway of choice for both domestic as well as international incoming traffic. This airport, being close to the significant industrial zones like DSIR, would surely facilitate the passage of goods and services, thus boosting the logistics and trade sectors of this region.

At the same time, DIH would also offer relief to Sardar Vallabhbhai Patel International Airport in Ahmedabad as that is the only international airport serving the state of Gujarat. On completion of DIH, Gujarat would be able to boast better airport capacities and could efficiently cater to a rising tide of passengers and cargo flights.

Better Quality Infrastructure and Facilities

The infrastructures at Dholera International Airport would be of the latest state-of-the-art with the capacity to handle a large number of air traffic. The plan has phases but, on completion of the project, the airport would initially handle up to 30 million passengers every year and have a vision for more expansion according to growing demands. Features would include several runways, an integrated passenger terminal, cargo terminals, and most modern systems for air traffic control.

Efficiency would be the theme behind airport design. Airport design would target a seamless travel experience at every level of check-in to boarding the aircraft. It will use smart technology: automatic baggage handling, biometric identification at check-in and security, and more advanced systems in these elements, streamlining and accelerating the functioning of the airport. Not far from this will be a cargo terminal that will help boost industrial activities in providing fast, safe transportation of products to manufacturing, pharmaceutical, and even the technology sector.

Economic Impact

The Dholera International Airport shall turn into a growth driver for the entire region. Designing and construction of the airport will give boost to construction job, aviation support, logistics and hospitality jobs. This number will grow manifolds through direct employment in the surrounding regions. Growing passenger and cargo traffic will attract new businesses, hotels, and retail shops in the regions.

Airport connectivity would further strengthen connectivity for Dholera Smart City, will attract foreign investment in the manufacturing, technology, renewable energy, and logistics sectors by encouraging businesses to be set up in this region as their business processes are highly reliant on fast and efficient international trade. Also, the state of Gujarat would be benefited by DIH's easy transportation of air cargo with respect to its industrial base with chemicals, textiles, and automotive industries.

Promote Tourism

Other than the economic point, Dholera International Airport has immense scope to initiate a new tourism trend for Gujarat. The places are multicultural and historical, including various Rann of Kutch, Gir National Park (last place for Asiatic lions), iconic Somnath Temple, and many more. Travel and visiting such tourist spots would become accessible effortlessly through this new airport for international as well as domestic tourists.

The coastal regions of Gujarat would imply Dholera International Airport would be an area relatively close to the beaches and thus a potential hot bed for beach tourism and marine activities. Once the airport is saturated with some forms of tourist infrastructure, the area will be considered one of the prime destinations for eco-tourism, cultural tourism, and even adventure tourism.

Future Potential

While construction work has already been initiated for Dholera International Airport, it shall be one of the country's leading aviation projects in the future. Significant approaches have been taken by the Gujarat government to develop the project, and therefore, the government has progressed forward for winning over the success of the airport through contributions given by private and public partners for funding and developing the project. Given that Dholera International Airport will have a class of world infrastructure combined with a strategic location for economic transformation, it will bridge gaps between domestic and international air travel for the state of Gujarat.

Future expansions of the airport entailed further runway extensions, better cargo facilities, as well as the development of a dedicated aerotropolis, a city built around the airport itself, with commercial, residential, and industrial facilities. This strong integration of aviation and urban development will only make Dholera's status as a global business and transportation hub more powerful.

Conclusion

Dholera International Airport is not just an airbase, but it is an icon of the development landmark of Gujarat also for India. The relation with the rest of the world improves the developmental process, will support the economy at growth, and attract investments in this region to make it a trade and tourism hub on the international map. And, in due course of time, this Dholera international airport would prove to be that game changer for Gujarat and eventually India, propelling the nation toward a more connected and prosperous future.

0 notes

Text

Railway Track Accessories manufacturer- Expert Engineers

Railway Track Accessories Manufacturer : Expert Engineering

At Expert Engineering Solutions, we are proud to be a leading Railway Track Accessories Manufacturer, dedicated to providing the railway industry with superior products that ensure the smooth operation and maintenance of railway tracks. Our extensive range of railway track accessories is designed to meet the diverse needs of railway projects, offering reliability and performance you can depend on.

As a distinguished Railway Track Accessories Manufacturer, we understand the critical role these components play in maintaining the safety and efficiency of railway systems. Our product lineup includes essential accessories such as rail joints, sleepers, fasteners, and track fittings, each engineered with precision to withstand the demanding conditions of railway environments.

Our commitment to quality is evident in every product we manufacture. We utilize advanced technology and adhere to stringent quality control processes to ensure that our railway track accessories meet the highest standards. Whether you're involved in new railway construction or track maintenance, our solutions are designed to deliver exceptional performance and longevity.

At Expert Engineering Solutions, we recognize that each railway project has unique requirements. That’s why we offer customized solutions tailored to specific project needs, ensuring that our accessories integrate seamlessly with your existing infrastructure. Our team of experts works closely with clients to understand their needs and provide products that enhance the overall efficiency and safety of railway operations.

As a trusted Railway Track Accessories Manufacturer, our goal is to support the railway industry with high-quality components that contribute to the successful execution of railway projects. Choose Expert Engineering Solutions for reliable and innovative railway track accessories that stand up to the rigors of the railways and ensure smooth, uninterrupted services.

For more Information:

2/A Manilalmukhi Estate, B/h Gayatri Temple, N.H.No-8,Ahmedabad, Gujarat

9725054977

0 notes

Text

Automatic Hydraulic Brick Making Machine in Tamil Nadu

Company Overview:

Robexo Industries is a Manufacturer, and Supplier of Automatic Hydraulic Brick Making Machine in Tamil Nadu, India.

Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India.

The Automatic Hydraulic Brick Making Machine fully automates the process by using hydraulic pressure to mold and press various raw materials, such as cement, sand, fly ash, and clay, into bricks.The machine is designed for high productivity, producing uniform bricks in large quantities with little manual intervention.

The hydraulic system ensures that each brick is compressed to its optimal density, resulting in a durable and high-quality final product.

Types of Automatic Hydraulic Brick Making Machine:

Solid Bricks: Standard rectangular bricks for load-bearing walls and structural applications.

Hollow Bricks: Lightweight bricks with cavities for better insulation in non-load-bearing structures.

Interlocking Bricks: Uniquely shaped bricks that interlock, reducing the need for mortar and speeding up construction.

Paver Blocks: Durable blocks used for pavements, roads, and landscaping.

Features:

Automatic operation with PLC control

Hydraulic system for consistent brick formation

High-pressure molding for dense bricks

Vibration system for enhanced brick density

Easy maintenance with quick cleaning and replacement of parts

Adjustable brick size and shape

Automatic pallet feeding and unloading syste

Robexo Industries is a Manufacturer, and Supplier of Automatic Hydraulic Brick Making Machine in Tamil Nadu, India Including Chidambaram, Arcot, Ariyalur, Chengalpattu, Chennai, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kallakurichi, Kanchipuram, Kanniyakumari, Karur, Krishnagiri, Madurai, Mayiladuthurai, Nagapattinam, Namakkal, Nilgiris, Perambalur, Pudukkottai, Rajapalayam, Ramanathapuram, Ranipet, Salem, Sivagangai, Tenkasi, Thanjavur, Theni, Thoothukudi, Tiruchirappalli, Tirunelveli, Tirupathur, Tiruppur, Tiruvallur, Tiruvannamalai, Tiruvarur, Vellore, Viluppuram, Virudhunagar, Salem, Udhagamandalam.

For more information and inquiries, feel free to contact us.

View Product: Click Here

Read the full article

#Ahmedabad#Arcot#Ariyalur#AutomaticHydraulicBrickMakingMachine#AutomaticHydraulicBrickMakingMachineinAhmedabad#AutomaticHydraulicBrickMakingMachineinIndia#Chengalpattu#Chennai#Chidambaram#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Erode#Exporter#ExporterofAutomaticHydraulicBrickMakingMachine#India#Kallakurichi#Kanchipuram#Kanniyakumari#Karur#Krishnagiri#Madurai#Manufacturer#ManufacturerofAutomaticHydraulicBrickMakingMachineinAhmedabad#Mayiladuthurai#Nagapattinam#Namakkal#Nilgiris#Perambalur

0 notes

Text

Three Rollers Positioning Labeling Machine for Round Bottle

Company Overview:

Shiv Shakti Machtech is a Manufacturer, Supplier, and Exporter of Three Rollers Positioning Labeling Machine for Round Bottle in Ahmedabad, Gujarat, India.

A Three Rollers Positioning Labeling Machine for Round Bottle is an advanced solution for ensuring that labels are applied with precision and efficiency.

This machine is designed specifically for round bottles, providing seamless and high-quality labeling for a variety of industries, such as pharmaceuticals, food and beverage, cosmetics, and more.

Other Name of Machine:

Automatic Full Wrap Sticker Labeling Machine, 360 Degree Wrap-Around Labeler for Round Bottles, Round Bottle Full Wrap Labeling System, 3-Roller Full Wraparound Bottle Labeler, Positioning Round Bottle Label Applicator, High-Speed Wrap-Around Labeling Machine, Automatic Round Container Labeling Machine, Full Body Wrap Labeler for Jars and Cans

How Does It Work?

The operation of a three rollers positioning labeling machine involves several steps:

Bottle Feeding: Bottles are fed into the machine, typically through a conveyor system.

Positioning: As the bottles enter the labeling area, the three rollers grip and stabilize the bottle, ensuring it remains upright and secure.

Label Application: The machine applies the label precisely to the designated area of the bottle, using either pressure-sensitive or adhesive labels.

Finishing Touches: After labeling, the bottles can go through additional processes like inspection or packing.

Features and Benefits:

Three-Roller System: Precise label positioning and alignment.

Automatic Labeling: High-speed labeling (up to 60 bottles/minute).

Adjustable Bottle Size: Accommodates various bottle diameters with help of change parts.

Label Length Detection: Automatic label length adjustment.

No-Label No-Apply Function: Prevents label waste..

Shiv Shakti Machtech is an Exporter of Three Rollers Positioning Labeling Machine for Round Bottle and

an exporter worldwide, including to Algeria, Angola, Antigua, Barbuda, Argentina, Armenia, Australia,

Austria, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana,

Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile,

Colombia, Congo, Democratic Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica,

Ecuador, Egypt, Guinea, Ethiopia, Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece,

Guyana, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan,

Kenya, South Korea, North Korea, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia,

Maldives, Mali, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique,

Myanmar (Burma), Namibia, Nepal, Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama,

Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal,

Serbia, Singapore, Slovakia, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden,

Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United

Arab Emirates (UAE), United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City,

Venezuela, Vietnam, Yemen, Zambia, Zimbabwe.

For further details or inquiries, feel free to reach out to us.

View Product: Click Here

Read the full article

#Ahmedabad#Algeria#Angola#Antigua#Argentina#Armenia#Australia#Austria#Bahrain#Bangladesh#Barbuda#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#Botswana#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#CentralAfricanRepublic#Chad#Chile#Colombia#Congo

0 notes

Text

Understanding Geocell: Revolutionizing Ground Stabilization and Soil Erosion Control

In the realm of civil engineering and construction, geocells have emerged as an innovative solution for ground stabilization and soil erosion control. As environmental challenges increase, the demand for effective and sustainable construction methods has led to the widespread adoption of geocell materials. This article will delve into the characteristics, applications, and advantages of geocells, highlighting the roles of geocell suppliers in India and the availability of geocell material in Ahmedabad.

What is Geocell?

Geocells, often referred to as cellular confinement systems, are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) or similar materials. These cells are expanded and filled with soil, gravel, or other materials to create a stable base for various applications. The design allows for significant improvements in load distribution and reduces soil erosion, making geocells an essential tool in modern civil engineering.

Key Features of Geocells

Durability: Geocells are made from robust materials that resist UV degradation, chemicals, and environmental stresses. This durability ensures a long lifespan even in harsh conditions.

Flexibility: The cellular design allows geocells to adapt to various soil types and conditions, making them suitable for diverse applications.

Cost-Effectiveness: By reducing the amount of fill material needed and enhancing soil stability, geocells can significantly lower overall project costs.

Ease of Installation: Geocells are relatively easy to install, requiring minimal equipment and labor, which can help expedite construction timelines.

Environmental Benefits: By minimizing erosion and promoting vegetation growth, geocells contribute to sustainable land management practices.

Applications of Geocells

Geocells find numerous applications across various sectors, showcasing their versatility:

1. Soil Stabilization

In areas with weak or loose soil, geocells provide essential support by confining the soil and distributing loads evenly. This application is particularly beneficial in road construction and parking lots.

2. Erosion Control

Geocells are effective in controlling soil erosion on slopes, riverbanks, and coastal areas. By filling the cells with vegetation or stones, they create a robust barrier against erosion forces.

3. Retaining Walls

Geocells can be utilized in the construction of retaining walls, where they provide support while allowing for natural drainage. This helps prevent soil buildup behind the wall.

4. Green Infrastructure

In urban areas, geocells can be integrated into green infrastructure projects, such as permeable pavements and rain gardens. They help manage stormwater runoff while promoting plant growth.

5. Reinforced Roads

Geocells can be employed in road construction to reinforce the base layer, enhancing load-bearing capacity and extending the lifespan of roadways.

The Role of Geocell Suppliers in India

As the demand for geocell technology grows, Geocell suppliers in India are stepping up to provide high-quality products that meet various construction needs. These suppliers offer a range of geocell products tailored to different applications and environments.

Geocell Material in Ahmedabad

Ahmedabad is emerging as a hub for construction materials, including geocells. The availability of Geocell material in Ahmedabad allows local construction companies to access these innovative products quickly, promoting the adoption of sustainable practices in the region.

Advantages of Choosing Indian Manufacturers

Diverse Product Range: Geocell manufacturers in India offer a variety of geocell options, allowing clients to choose products suited for specific applications.

Competitive Pricing: Local manufacturing often results in lower costs compared to importing geocells, making them an economical choice for construction projects.

Quality Assurance: Many Indian manufacturers adhere to international quality standards, ensuring that geocells perform effectively in various applications.

Timely Delivery: Local suppliers can provide faster delivery times, allowing construction projects to proceed without delays.

Frequently Asked Questions (FAQs)

1. What materials are geocells made from?

Geocells are primarily made from high-density polyethylene (HDPE), which offers strength, flexibility, and resistance to environmental degradation.

2. How do geocells help in erosion control?

Geocells confine soil or other materials within their cellular structure, creating a stable barrier that reduces erosion from water runoff and wind, while also supporting vegetation growth.

3. Can geocells be used for both commercial and residential projects?

Yes, geocells are versatile and can be used in a wide range of projects, including residential landscaping, commercial parking lots, and large-scale infrastructure developments.

Summary

In conclusion, geocells represent a significant advancement in the fields of civil engineering and environmental management. Their durability, versatility, and cost-effectiveness make them invaluable for applications such as soil stabilization, erosion control, and green infrastructure. With the growing demand for sustainable construction practices, geocell suppliers in India are well-positioned to meet the needs of various sectors, particularly with the availability of geocell material in Ahmedabad. As the industry continues to evolve, the adoption of geocell technology will play a crucial role in promoting responsible and efficient construction practices, contributing to a more sustainable future.

0 notes

Text

The Importance of Quality Control in Textile Manufacturing: A B2B Perspective

In the world of textile manufacturing, where precision and quality are paramount, ensuring consistent and high-quality output is crucial for success, particularly in the B2B market. The reputation of a textile manufacturer hinges on the quality of its products, and any deviation can lead to significant financial losses and damaged business relationships. This article delves into the significance of quality control in textile manufacturing, offering insights for B2B buyers and outlining the steps necessary to maintain high standards.

Surat garment manufacturers

Understanding Quality Control in Textile Manufacturing

Quality control (QC) in textile manufacturing refers to the process of inspecting, testing, and maintaining the quality of raw materials, production processes, and finished products. It encompasses a wide range of activities, including the selection of raw materials, monitoring production processes, and conducting final product inspections to ensure that the textiles meet specified standards.

For B2B buyers, quality control is a critical factor in choosing a textile supplier. Inconsistent quality can lead to production delays, increased costs, and dissatisfaction among end consumers. Therefore, B2B buyers must ensure that their suppliers adhere to stringent quality control practices to maintain the integrity of their supply chain.

The Role of Raw Materials in Quality Control

The foundation of any quality textile product lies in the raw materials used. High-quality raw materials are essential for producing textiles that meet industry standards. The selection of raw materials should involve a thorough assessment of factors such as fiber strength, color fastness, and resistance to wear and tear.

For example, in cotton textiles, the quality of the cotton fiber directly impacts the durability and feel of the finished product. Suppliers must source cotton from reputable growers and conduct tests to ensure that the fibers meet the required specifications. Similarly, in synthetic textiles, the quality of the polymers used in production plays a vital role in determining the final product's characteristics.

The Importance of Process Control

Process control is another critical aspect of quality control in textile manufacturing. This involves monitoring and regulating the various stages of production to ensure that the processes are consistent and produce textiles that meet the desired quality standards.

In weaving, for instance, process control involves ensuring that the looms are correctly set up and that the tension of the threads is maintained throughout the production run. Any deviation in these parameters can lead to defects such as uneven weaving or weak spots in the fabric. Similarly, in dyeing, precise control of temperature, time, and chemical concentrations is essential to achieve consistent color and avoid issues like color bleeding or fading.

For B2B buyers, understanding the importance of process control can help in assessing potential suppliers. Buyers should inquire about the manufacturing processes in place and the measures taken by the supplier to ensure consistency and quality throughout production.

textile manufacturers in Ahmedabad

The Role of Technology in Quality Control

Advancements in technology have significantly enhanced the ability of textile manufacturers to maintain high-quality standards. Automation, digital monitoring, and advanced testing equipment have revolutionized the quality control process, enabling manufacturers to detect and address issues more efficiently.

For instance, automated inspection systems can scan textiles for defects such as holes, stains, or uneven weaving at a much faster rate than manual inspections. These systems use cameras and sensors to detect anomalies, allowing for real-time adjustments to the production process. This not only improves the accuracy of quality control but also reduces the time and labor costs associated with manual inspections.

Additionally, digital monitoring systems can track production data, such as temperature, humidity, and machine settings, in real-time. This data can be analyzed to identify trends and potential issues, allowing manufacturers to take proactive measures to maintain quality.

B2B buyers should consider the technological capabilities of their suppliers when evaluating their quality control processes. Suppliers who invest in advanced technology are more likely to produce textiles that meet high-quality standards consistently.

The Impact of Quality Control on Supply Chain Management

Quality control is not just about ensuring that the finished product meets specifications; it also plays a crucial role in supply chain management. In the B2B market, any disruption in the supply chain can have a ripple effect, leading to delays, increased costs, and loss of business.

Effective quality control helps to minimize these risks by ensuring that each stage of the production process meets the required standards. For example, by conducting thorough inspections of raw materials, manufacturers can prevent defective materials from entering the production process, reducing the likelihood of quality issues later on.

Moreover, quality control extends to the logistics and packaging of finished products. Proper packaging ensures that textiles are protected during transportation, reducing the risk of damage. B2B buyers should look for suppliers who prioritize quality control at every stage of the supply chain, from raw material sourcing to final delivery.

textile industry in Ahmedabad

The Economic Benefits of Quality Control

Investing in quality control may seem like an added expense, but it offers significant economic benefits in the long run. For textile manufacturers, maintaining high-quality standards reduces the risk of product recalls, returns, and rework, all of which can be costly. It also enhances the manufacturer’s reputation, leading to increased customer loyalty and repeat business.

For B2B buyers, partnering with a supplier who prioritizes quality control can lead to cost savings through reduced wastage, fewer product defects, and a more efficient supply chain. It also allows buyers to confidently market their products as high-quality, which can justify higher price points and increase profit margins.

Regulatory Compliance and Quality Control

In the textile industry, compliance with regulatory standards is a key aspect of quality control. Manufacturers must adhere to various regulations related to product safety, environmental impact, and labor practices. For example, textiles must meet safety standards regarding the use of chemicals, such as azo dyes, which are restricted in many countries due to their potential health risks.

Environmental regulations also play a significant role in quality control. Manufacturers must ensure that their processes comply with regulations on waste management, water usage, and emissions. Failure to comply with these regulations can result in fines, legal action, and damage to the manufacturer’s reputation.

B2B buyers must ensure that their suppliers are compliant with all relevant regulations. This not only reduces the risk of legal issues but also demonstrates a commitment to ethical and sustainable business practices.

The Role of Certification in Quality Control

Certifications are an essential tool for verifying the quality of textiles and the processes used in their production. Certifications such as ISO 9001 (Quality Management Systems), Oeko-Tex Standard 100 (Textile Safety), and GOTS (Global Organic Textile Standard) provide assurance that a manufacturer adheres to high-quality standards and ethical practices.

For B2B buyers, certifications offer an easy way to assess the quality and reliability of a supplier. When selecting a supplier, buyers should look for certifications that are relevant to their industry and product requirements. Certified suppliers are more likely to consistently deliver high-quality products and maintain compliance with regulatory standards.

Ahmedabad textile exporters

The Human Element in Quality Control

While technology and certifications play a crucial role in quality control, the human element cannot be overlooked. Skilled and experienced personnel are essential for implementing and maintaining quality control processes. This includes everyone from the workers on the production floor to the quality control inspectors and management.

Training is a vital component of quality control. Workers must be trained to operate machinery correctly, follow standard operating procedures, and identify potential quality issues. Regular training programs ensure that workers stay updated on the latest quality control techniques and industry standards.

Moreover, a culture of quality should be fostered within the organization. This means that everyone, from top management to floor workers, should prioritize quality in their work. A strong commitment to quality at all levels of the organization is key to maintaining high standards and producing textiles that meet the expectations of B2B buyers.

Quality Control Challenges in Textile Manufacturing

Despite the best efforts of manufacturers, quality control in textile manufacturing is not without its challenges. Some of the common challenges include:

Variability in Raw Materials: Natural fibers, such as cotton, can vary in quality depending on factors like weather conditions and soil quality. This variability can make it challenging to maintain consistent quality in the final product.

Complexity of Production Processes: Textile manufacturing involves multiple processes, each of which must be carefully controlled. Any deviation in one process can affect the overall quality of the product.

Technological Limitations: While technology has advanced significantly, there are still limitations in detecting certain types of defects, particularly those related to the feel or drape of the fabric.

Human Error: Despite automation, human error remains a factor in quality control. Mistakes in setting up machinery, mixing dyes, or inspecting products can lead to defects.

Addressing these challenges requires a combination of advanced technology, skilled personnel, and a strong commitment to quality at all levels of the organization.

textile mills in Ahmedabad

Conclusion: The Value of Quality Control for B2B Buyers

For B2B buyers, quality control in textile manufacturing is more than just a box to tick; it is a critical factor in choosing a reliable supplier. High-quality textiles are essential for maintaining the integrity of the buyer’s brand and ensuring customer satisfaction. By partnering with suppliers who prioritize quality control, B2B buyers can reduce the risk of defects, delays, and supply chain disruptions, leading to a more efficient and profitable business.

Labisa: Your Trusted Partner in Quality Textiles

At Labisa, we understand the importance of quality control in textile manufacturing. Our commitment to excellence is reflected in every stage of our production process, from sourcing the finest raw materials to delivering finished products that meet the highest standards. With state-of-the-art technology, skilled personnel, and a culture of quality, we ensure that our textiles exceed the expectations of our B2B clients.

Whether you’re looking for premium fabrics, sustainable textiles, or custom solutions, Labisa is your trusted partner in quality. Contact us today to learn more about our products and how we can support your business.

Contact Information:

Afzal: +91 98929 39564

Labisa Sales: +91 81699 85975

Email: [email protected], [email protected]

Address: Sion West, Dharavi, Mumbai, Maharashtra 400017

Partner with Labisa for textiles that meet your quality standards and elevate your brand in the market.

0 notes

Text

Dholera Smart City in Gujarat: A New Era for Urbanization in India By City Expert

India has taken a step into this ambitious endeavor by the very much talked about Smart Cities initiative in an attempt to put this very ambitious dream onto the development map of the country, courtesy of the flagship initiative of Dholera Smart City, whose name alone speaks of providing a new turn to the face of urban development in the country. The project will come up near Ahmedabad in Gujarat, about 100 kilometers from the city.Dholera would not be just a smart city, but a global industrial city that would promote speeding up economic development not only in Gujarat but for the whole of the Indian sub-continent.

A Concept of Vision

Dholera Smart City would also form one of the biggest infrastructure projects ever undertaken-the Delhi-Mumbai Industrial Corridor, where a 1,500-km stretch between Delhi and Mumbai is going to be used for the construction of new industrial cities. Planned over a surface of more than 920 square kilometers, the smart city is designed with over two million citizens in the future. Strategically located, this city is close to sea ports, highways, and the proposed Dholera International Airport. Therefore, this place is sure to attract many industries and businesses.

The Dholera development plan is a concept of developing a smart city which will achieve efficient use of technology and data to further enhance delivery mechanisms of urban services and optimize resource utilization towards setting up of sustainable living environments. Therefore, it would be a city, either built on advance infrastructure which has smart grids and transport systems, water management and waste management systems, which makes the city energy efficient, green, and technologically advanced.

World-Class Infrastructure

Infrastructures of Dholera Smart City will serve the future. The city boasts of a strong transport network; however, it is its planned mass rapid transit system (MRTS) and Dholera International Airport that are yet to roll into action. These transport links will seamlessly connect with other major cities in Gujarat and India, thus increasing Dholera's role as an industrial and business hub.

One of the other future features that Dholera's infrastructure will have is the smart grids for power through a grid that would give constant and efficient power supply. The city will utilize renewable energy through solar power, with Dholera Solar Park right next door, touted to be one of the largest in India. Water resources management, too would follow this approach in regards to sustainability: Water harvesting systems more sophisticated structures are provided for rainwater harvesting, seawater desalination, and wastewater reclamation so that water supply is sufficient not only to the residents but to the industries as well.

Underground utility ducts in Dholera ensure proper protection for essential infrastructure, including power, water supply, and gas lines. The engineering design ensures easy access for maintenance. This aligns with the city's smart design philosophy, where sustainability and efficiency are adopted together.

Economic Opportunities

Dholera Smart City is building the infrastructure of the future while growing the economy. It is an investment destination for any part of the world under the plan of becoming the hub for large-scale industries. The government's business-friendly environment, along with incentives by the ports, highways, and airports, is making Dholera suitable for manufacturing, electronics, automobiles, pharmaceuticals, and renewable energy.

Thousands of employment opportunities will be created during the period of construction as well as when the industries start functioning in the smart city. The entire region will be transformed into an economic hub that shall provide employment opportunities to the residents of this region, thus augmenting the economy of Gujarat and even India.

Sustainability and Green Living

What is quite different about Dholera as compared to the other cities is that its slogan is going to be based on sustainability and green living.Dholera smart city in gujrat It has been considered important since inception that this city be designed in such a manner as to reduce the ecological footprint. With the handholds of renewable sources of energy, eco-friendly edifices, and smart resource management systems carrying the promise of eventually becoming carbon-neutral, Dholera will be developed.

The healthy and lively green areas of the Dholera region, parks, and open areas will be created. In respect to this need, the city planning allows for easy access to green areas for the residents of Dholera, with a balance between life at work, play, or rest. Dholera will, with sustainable urban development, be a model not only for other smart cities within India but also for other smart cities throughout the world.

Smart Technologies for a Better Life

Technologies would form the core of Dholera Smart City. The city would offer an integrated command and control center that would monitor and track such services in real time; it could be traffic, public safety, utilities, or waste. Such services would then be delivered more efficiently with the help of data analytics, sensors, and automation, thus settling prompt issues that may arise.

Besides that, smart services in the form of high-speed internet, app-based transport services, and smart governance would provide a smart platform that makes government services available to the citizens with ease. These will make life easier, more efficient, and connected at Dholera.

Conclusion

The future of India's urban development is Dholera Smart City. Dholera, therefore, would be a landmark example for the development of smart cities through visionary design, advancement of infrastructure, economic opportunities, and sustainability. This will, therefore, provide a reason for change in the region itself but will collectively be a reason for the overall economic development of Gujarat and India as a whole. In fact, it is a statement by the project regarding India's capability to take the lead for the design of smart, sustainable, and future-proof cities for the world.

0 notes

Text

Vial Automatic Sticker Labelling Machine in Egypt

Laxmi Pharma Equipment is Manufacturer, Supplier and Exporter of Vial Automatic Sticker Labelling Machine in Egypt.

Our Manufacturing Unit is in Ahmedabad, Gujarat, India.

Vial Automatic Sticker Labelling Machine Manufacturer specializes in designing, producing, and supplying machines that automatically apply adhesive labels to vials.

These machines are essential for industries such as pharmaceuticals, cosmetics, food and beverage, and healthcare, where precise and efficient labelling is crucial.

Our machine applies labels to vials with pinpoint accuracy, ensuring each label is perfectly aligned and securely affixed.

Boost your production efficiency with rapid labelling capabilities that keep your packaging line moving smoothly and quickly.

Features:

No change parts are required for change over of Vials size.

Synchronized speed of Label Dispensing, Conveyor and Pressing Device.

Easy to change label application height.

Self protected against any voltage fluctuations.

Suitable for On-Line Ink Jet and Contact Coding System.

Suitable for Partial, Full Wrap Around and Overlap Labeling.

High Production Speed up to 250 Vials/min.

PLC based system with touch screen HMI.

Conveyor & servo speed synchronized and controlled from HMI.

In built Speed Indicator & Counter.

There is no requirement of Oil or Grease for maintenance.

Online rejection system (if required).

Applications:

Pharmaceuticals

Laboratory Equipment

Food and Beverage

Cosmetics

Healthcare

Laxmi Pharma Equipment is an Exporter of Vial Automatic Sticker Labelling Machine in Egypt Including Cario, Alexandria, Giza, Shubra el-Khema, Port Said, Suez, EL mahalla el Kubra, El Mansoura, Tanta, Asyut, Fayoum, Zagazig, Ismailia, Khusus, Aswan, Damanhur, El- Minya, Damietta, Luxor, Qena, Beni Suef, Sohag, Shibin el-Kom, Hurghada, Banha, Mallawi.

For more information and inquiries, feel free to contact us.

View Product: Click Here

Read the full article

#Alexandria#Aswan#Asyut#Banha#BeniSuef#Cario#Damanhur#Damietta#ELmahallaelKubra#ElMansoura#El-Minya#Exporter#ExporterofVialAutomaticStickerLabellingMachineinEgypt#Fayoum#Giza#Gujarat#Hurghada#India#Ismailia#Khusus#LaxmiPharmaEquipment#Luxor#Mallawi#Manufacturer#ManufacturingUnitisinAhmedabad#PortSaid#Qena#Shibinel-Kom#Shubrael-Khema#Sohag

0 notes

Text

The Ultimate Guide to Leading Hydraulic Flow Control Valve Manufacturers India

We are a top maker of hydraulic flow control valves manufacturer in Mumbai, Ahmedabad, Chennai, Delhi, Vadodara, Gujarat, Bangalore, Rajasthan, and Ghaziabad India. Our company creates precise solutions for controlling fluids in various industries. With modern production facilities and skilled engineers, we aim to provide top-notch products. These products are designed to meet the specific needs of our customers. Our valves are perfect for the automotive, construction, and manufacturing sectors. They help increase efficiency, cut costs, and boost performance.

Key Takeaways

Comprehensive range of hydraulic flow control valves manufactured in India

State-of-the-art production facilities and experienced engineering team

Tailored solutions for diverse industries, including automotive, construction, and manufacturing

Improved efficiency, cost savings, and performance for customers

Commitment to delivering high-quality, precision-engineered products

Introduction to Hydraulic Flow Control Valves

Hydraulic flow control valves are key parts in hydraulic systems. They make sure the fluid flows in a controlled way. These valves keep the flow rate steady, even when pressure or load changes. This makes them crucial for efficient work in many industries.

Hydraulic Flow Control Valves Manufacturer in India

India is now a key place for making top notch hydraulic flow control valves manufacturer. Many leading companies serve a wide range of industries. These hydraulic flow control valves manufacturers in India have modern production setups all over the country. They ensure their products are of high quality and delivered on time.

Production Facilities and Capabilities

These top companies have set up their production places in important industrial areas. They are in Ahmedabad, Vadodara, Mumbai, and Ghaziabad. This lets them reach a wide range of customers in fields like building, mining, farming, and making things. Their modern facilities have the newest machines and skilled engineers and technicians. They aim to make products that are of the highest quality.

Factors to Consider When Choosing a Manufacturer

Choosing the right manufacturer for your hydraulic flow control valves is key. You want a product that meets your needs and boosts your hydraulic system's efficiency. Here are important factors to think about.

Quality Standards

Quality is a top priority. Look for a company with industry certifications like ISO or ASME. They should have a strong focus on testing and quality control. This means the valves you buy will be reliable and perform well.

Customization Options

Being able to customize your hydraulic flow control valves can make a big difference. Find a manufacturer that offers many customization options. This lets you adjust the valves to fit your specific needs, improving your hydraulic system's performance.

Hydraulic Flow Control Valves Manufacturer in Ahmedabad

We are a top maker of hydraulic flow control valves in India, located in Ahmedabad. This spot lets us easily reach customers in the western region, including Gujarat. Our advanced production and skilled engineers make us ready to give custom solutions for our clients in Ahmedabad and Gujarat.

Conclusion

If you work in manufacturing, building, or farming, our hydraulic flow control valves manufacturer in Mumbai, Ahmedabad, Chennai, Delhi, Vadodara, Gujarat, Bangalore, Rajasthan, and Ghaziabad can boost your equipment's performance and efficiency. Our Ahmedabad place has the newest tech and strict quality checks. This ensures our products are top-notch. Being a hydraulic flow control valves maker in Ahmedabad, we're all about great customer service and support. Our expert team is here to help you pick the best valve for your needs. They also offer help with setting up, keeping up, and fixing any issues.

#Hydraulic Flow Control Valve Manufacturers#ahmedabad#Mumbai#Chennai#rajshthan#ghaziabad#gujarat#bangalore#delhi#vadodara

0 notes

Text

Eris Therapeutic Limited, a subsidiary of Eris Lifesciences Ltd, is actively hiring for various roles in the Quality Control (QC) department, including QC Microbiology and GLP/Finish Product, as well as Environmental Health and Safety (EHS) professionals. This exciting opportunity is based near Bavla, Ahmedabad..

QC Microbiology Senior Executive Role

Designation: Senior Executive – QC Microbiology

Qualification: M.Sc. in Microbiology

Experience: 8-10 years

Location: Near Bavla, Ahmedabad

CTC Offered: Up to ₹7.50 LPA

Preferred Experience: OSD/Injectable plant exposure

Key Responsibilities:

Oversee microbiological testing and ensure compliance with Good Laboratory Practices (GLP).

Handle the preparation and review of microbiology protocols, SOPs, and analysis reports.

Conduct routine and non-routine microbiological analysis of raw materials, in-process samples, and finished products.

Monitor environmental conditions in production areas and ensure all quality standards are adhered to.

Provide technical expertise and support to resolve microbiological issues during production.

This role requires candidates with strong knowledge of microbiological testing, experience in OSD (Oral Solid Dosage) or injectable manufacturing environments, and a commitment to quality control processes.

QC GLP / Finish Product Executive/Senior Officer Role

Designation: Executive/Sr. Officer – Quality Control

Qualification: B.Pharm / M.Sc. (Chemistry)

Experience: 3-6 years

Location: Near Bavla, Ahmedabad

Preferred Experience: Pharmaceutical experience in OSD/Injectable/Ointment plants

Key Responsibilities:

Handling all lab instruments of HPLC, GC, Dissolution, D. T., Apparatus, Weighting balance, Friability, Hardness, Tester, FTIR, UV – Spectrophotometer.

Analysis of semi product product, In-process, Finish products, Stability testing, Process validation.

Participate in Lab incident /OOS/OOT/Analysis of deviation.

Must be worked in semi finish product/Finish product/ GLP section.

This role is ideal for professionals with experience in GLP and quality control, specifically in pharmaceutical settings, and who are looking for opportunities to contribute to a growing and dynamic team.

EHS Officer Role

Designation: EHS Officer

Qualification: Diploma in Industrial Safety

Experience: 5-7 years

Location: Near Bavla, Ahmedabad

Preferred Experience: Pharmaceutical industry exposure

Key Responsibilities:

ETP & RO operation and daily monitor of PH,TDS , BOD and COD.

Fire Hydrant system & Fire extinguishers.

Fire alarm system.

Monitoring the work permits and other activities in campus to ensure safe working.

Ensuring the safe construction activities in co-ordination with PMC to ensure accident-free site.

Regular inspection of Fire pump room, service block, HSD yard, LPG banks and STP.

Conducting risk analysis and ensuring the proper solution to avoid the risk & hazard.

Record keeping and documentation of EHS related work.

Inspection of machines, lifting tools and other equipments to ensure the compliance and safe working.

Checking of firefighting and detection system to ensure the proper working.

Training to the construction workers and service staff.

Ensuring the safety induction of workers in co-ordination with PMC.

Ensuring contractor’s safety programme.

Inspects the facility to identify safety, health, and environmental risks.

Develops and implements inspection policies and procedures, and a schedule of routine inspections.

Develops health and safety procedures for all areas of the company.

Prepares and schedules training to cover emergency procedures, workplace safety, and other relevant topics.

Monitors compliance with safety procedures.

Ensures that material safety data sheets are maintained and readily accessible when needed.

Maintains records of discharge of or employee exposure to hazardous waste and/or pollutants, as required.

Prepare data for GPCB form 3, 4, 5.

Maintain record of safety form no. 9,10,11,37.

Prepare HIRA, and Environmental Aspect Impact.

This role demands candidates with robust EHS management skills, a proactive approach to safety, and experience in the pharmaceutical industry.

How to Apply

Interested candidates who meet the qualifications and experience criteria can submit their updated resumes with the following details:

Total Experience

Qualification

Current Salary

Notice Period

Designation

Submit your CV to:

📧 [email protected]

0 notes

Text

Mustard Oil Pet Bottle Capping Machine

Company Overview:

Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Mustard Oil Pet Bottle Capping Machine.

A mustard oil PET bottle capping machine is a specialized piece of equipment designed to securely cap plastic bottles (typically made from PET, or polyethylene terephthalate) filled with mustard oil.

The food and beverage industry commonly uses these machines to seal bottles airtight, preserving oil quality and freshness while preventing leaks and contamination during transport and storage.The capping process can be fully automatic, semi-automatic, or manual, depending on production needs. These machines are typically integrated into a complete bottling line, but can also be used as standalone units.

Features:

Automatic or semi-automatic operation

Adjustable cap tightening torque

Compatibility with various cap sizes and types (e.g., screw, snap-on, or sports caps)

High-speed capping (up to 100 bottles per minute)

Bottle handling and sorting systems

Integration with filling and labeling machines

Shiv Shakti Machtech is a Mustard Oil Pet Bottle Capping Machine in Ahmedabad, Gujarat, India Including

Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi,

Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa,

Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur,

Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una,

Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur,

Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha,

Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool,

Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore,

Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore,

Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram,

Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner,

Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia,

Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar,

Chhachhrauli.

For further details or inquiries, feel free to reach out to us.

View Product: Click Here

Read the full article

#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner#Brahmapur#Changodar#Chennai#Chhachhrauli

0 notes

Text

Supplier of FRP Blower

Sunfiber is a Manufacturer and Supplier of FRP Blower in Odisha, India.

Our manufacturing unit is located in Ahmedabad, Gujarat, India.

An FRP blower is a type of blower made from fiberglass reinforced plastic. This material combines the strength of fiberglass with the flexibility and chemical resistance of plastic.

The result is a blower that offers exceptional durability, especially in environments where corrosion and chemical exposure are concerns.

Technical Specifications:

Blower Housing: Constructed from FRP (Fiber Reinforced Plastic) for enhanced structural integrity and protection.

Material of Construction (MOC): Available in PP (Polypropylene), HDPE (High-Density Polyethylene), PVC (Polyvinyl Chloride), FRP (Fiber Reinforced Plastic), and FRV (Fiber Reinforced Vinylester).

Capacity: Handles up to 100,000 liters.

Thickness: Ranges from 3 mm to 50 mm.

Electric Motor: Driven by electric motors tailored to specific power and speed requirements.

Applications: Suitable for the chemical industry, pharmaceutical industry, bromide and bromine processing, metal manufacturing, and dust control systems.

Features:

Fiberglass-reinforced plastic (FRP) construction

Corrosion-resistant and chemical-resistant

High-efficiency air handling capabilities

Low-maintenance and durable design

Customizable inlet and outlet connections

Sunfiber is a Manufacturer and Supplier of FRP Blower in Odisha, India Including Angul, Boudh, Balangir, Bargarh, Balasore, Bhadrak, Cuttack, Deogarh, Dhenkanal, Ganjam, Gajapati, Jharsuguda, Jajpur, Jagatsinghapur, Khordha, Keonjhar, Kalahandi, Kandhamal, Koraput, Kendrapara, Malkangiri, Mayurbhanj, Nabarangpur, Nuapada, Nayagarh, Puri, Rayagada, Sambalpur, Subarnapur, Sundargarh, Bhubaneswar, Cuttack, Balasore, Paradeep, Balangir, sambalpur,berhampur, Baripada, Mayurbhanja, Keonjhar, Rourkela, Jaypore.

If you have any questions or need more information, feel free to reach out to us.

View Product: Click Here

Read the full article

#ExporterofFRPBlower#FRPBlower#India#ManufacturerofFRPBlower#Odisha#SupplierofFRPBlower#SupplierofFRPBlowerinOdisha

0 notes

Text

Tata Semiconductor Plant in Dholera: A Milestone in India's Tech Revolution

The decision of the Tata Group to establish a semiconductor plant in Dholera, Gujarat, is no less than a transformative development in the quest for technological self-reliance by India. Indeed, the latest semiconductor manufacturing unit is arguably the most ambitious industrial project taken up by the country so far and surely bound to reshape India's standing in the global tech landscape by responding to a very critical need for homegrown chip production. This would decrease India's reliance on the importation of semiconductors, acting as a catalyst for economic growth by fostering innovation, job creation, and investments being driven into the economy.

Semiconductor manufacturing plays an important part.

Semiconductors are the lifeline of modern technology, right from simple smartphones and computers to complex automotive systems and industrial equipment; in other words, they power everything. The industry has turned highly indispensable for the emerging sectors of artificial intelligence, 5G telecommunications, and electric vehicles. Its manufacturing capability has conventionally been lacking in India, which is under heavy imports of the product from countries like Taiwan, South Korea, and China.

This dependence came into sharp focus with the COVID-19 pandemic, which has contributed to the global shortage of semiconductors beyond the disruption of supply chains. Further delays and disruption of production lines of key industries greatly raise the need for India to domestically initiate its production of semiconductors. As a matter of fact, the moves of Tata in this sector mark bold and strategic answers to these questions, in tune with the broader push of the Indian government towards self-reliance through its "Atmanirbhar Bharat" initiative.

Why Dholera?

Dholera is an emerging high-tech industries and innovation ecosystem situated in the Dholera Special Investment Region. Dholera presents infrastructure at par with modern times and complete smart city capability, modern logistics with a robust power supply, and complementary renewable energy resources. It is ideally located for setting up semiconductor manufacturing. The proximity of the region to Ahmedabad city and industrial corridors links it to other major domestic and international markets.

Development of Dholera as a Smart City-a completely ecologically balanced urban unit, fully integrated with technology-will add to the incentive that companies like Tata can have for investing in the region. Besides, smart infrastructure, energy-efficient buildings, and eco-friendly industrial practices will make Dholera's ecosystem supportive of high-tech industry development, while ensuring environmental sustainability.

Economic Impact and Job Creation

The effect of the Tata Semiconductor Plant at Dholera will be great, concerning the economic impact it will have on not only the region but also the whole country. Manufacturing semiconductors is a really complex and highly skilled process involving the latest technologies. Thus, the plant will generate a number of high-skilled employment opportunities, especially in engineering, semiconductor design, and research and development areas.

Associated jobs and business activities will also be created by the plant itself: logistics, maintenance, and component supplies. Growth in industry will cause a ripple effect to increase local businesses, real estate development, and infrastructure in the surrounding areas.

Beyond that, the plant will bring much other investment with it from other global technology companies desirous of taking advantage of the burgeoning semiconductor industry in India. Since India has grown into one of the largest markets for electronic and technology products, this semiconductor plant will be very pivotal in ensuring a reliable domestic supply for chips, reduction of imports, and enabling local manufacturers to have products that can compete in the global market.

Building India's Technological Independence

The plant acts as a foraying point in establishing the general semiconductor ecosystem of India to accelerate innovation and research within the themes of chip design, fabrication, and testing. With some experience in these fields, India will be able to position itself as a global powerhouse in semiconductor R&D and hence turn out stronger in the global tech platform, developing new paths towards export-oriented growth.

Geopolitical and Strategic Importance

In this geopolitics, semiconductors have become a sort of strategic asset for various nations of the world.

The Dholera plant in Tata Semiconductor will enable India to increasingly participate in international supply chains, negotiate a better position vis-à-vis trade agreements, and create collaborations with world technology leaders. It is here that, with this strategic advantage, India will play a leading role in determining the course that technology and innovation will take in the future.

Conclusion

The Tata Semiconductor Plant at Dholera is thus the biggest leap this Indian journey has ever taken toward global leadership in high-tech manufacturing. With this kind of potential for economic growth, highly skilled employment, and a place in the semiconductor supply chain, it is surely a turning point that the technological destiny of this country is going to come across. The investment in semiconductor manufacturing will aid Tata in assuring that India continues to be competitive, resilient, and self-reliant at a time when the world is getting increasingly dependent on digital technologies.

0 notes