#US Carbon black sector

Text

The Growing Prominence of the Carbon Black Market fueled by Rising Automotive Industry

Buy Now

What is the Size of US Carbon Black Industry?

US Carbon Black Market is expected to grow at a CAGR of ~ % between 2017-2022 and is expected to reach ~USD Mn by 2028. The Carbon Black Market is majorly driven by increasing automotive industry, tire replacement demand, urbanization and renewable energy needs, fueled by rising middle-class populations and technological advancements.

The automotive industry is a major consumer of carbon black, using it in tire manufacturing to improve tire strength, durability, and overall performance. As the global demand for vehicles increases, particularly in emerging economies, the demand for carbon black in tire production grows as well.

Click here to Download a Sample Report

n mature markets, there is a continuous demand for tire replacements due to wear and tear. This consistent need for replacement tires drives demand for carbon black to be used in new tire production.

Carbon black is used as a pigment and colorant in various products like inks, paints, and coatings. The growing use of these products in diverse industries such as construction, packaging, and consumer goods drives demand for carbon black.

Ongoing research and development in carbon black production techniques can lead to improvements in quality, efficiency, and cost-effectiveness. These advancements stimulate the market growth by making carbon black more accessible to various industries.

US Carbon Black Market by loan Process

In terms of loan type, the market is segmented into Furnace Black and Gas Black. Furnace Black is seen dominant in the US Carbon Black market in 2022. Furnace Black is a type of Carbon Black produced through the incomplete combustion of hydrocarbons. It finds extensive applications in the production of rubber, tires, plastics, inks, coatings, and other industrial products due to its reinforcing and coloring properties. This ubiquity across multiple sectors positions Furnace Black as a central component in various manufacturing supply chains.

Moreover, the versatility of Furnace Black has allowed industries to find innovative applications beyond traditional uses, such as in renewable energy technologies, specialty materials, and advanced composites. This adaptability has expanded its market reach and influence.

US Carbon Black Market by end Application

The market is segmented by Tires and Rubber products, Plastic, Toners and Printing inks, Coatings and Others. Among these, Tires and Rubber products is majorly the dominant end users in the US Carbon Black market as noted in 2022. As vehicles move, friction between tires and roads generates Carbon Black particles that contribute to air pollution and pose health and environmental risks.

Amid growing concerns about air quality and environmental impact, the Tires and Rubber products sector has faced increased pressure to mitigate its emissions. Regulatory agencies and consumer demand for eco-friendly products have prompted manufacturers to adopt strategies that reduce Carbon Black emissions.

Visit this link to Download a Custom Report

US Carbon Black market by Region

The US Carbon Black market is segmented by Region into North, South, East, West and central. In 2022, South region is more dominate in US Carbon Black Market. The South region has witnessed a growing emphasis on environmental sustainability and air quality improvement. Cities within this region, such as Houston and Atlanta, have grappled with significant air pollution challenges, spurring local governments and industries to address Carbon Black emissions more aggressively.

Competition Scenario in US Carbon Black Market

The competition scenario in the US Carbon Black market was characterized by a mix of companies and organizations focused on reducing Carbon Black emissions and promoting cleaner technologies.

Prominent players in this market included environmental consulting firms such as Aether, Abt Associates, and ICF International. These companies provided expertise in air quality monitoring, emission inventories, and policy analysis, assisting industries and governments in devising strategies to mitigate Carbon Black emissions.

In addition to consulting firms, technology providers played a crucial role. Companies like Cleaire Advanced Emission Controls and Johnson Matthey offered emission control solutions, including diesel particulate filters and catalytic converters, designed to reduce Carbon Black emissions from vehicles and industrial sources.

What is the Expected Future Outlook for the Overall US Carbon Black Market?

The US Carbon Black market was valued at USD ~Million in 2022 and is anticipated to reach USD ~ Million by the end of 2022, witnessing a CAGR of ~% during the forecast period 2022- 2028. The US Carbon black market is driven by increasing urbanization, rising automotive industry and rising demand for consumer goods. Carbon black is integral to tire production, enhancing tire strength and performance. As vehicle demand increases, particularly in electric and autonomous segments, the need for quality tires will drive carbon black demand.

The shift toward sustainability will influence the market. Manufacturers seeking eco-friendly alternatives will drive demand for sustainable carbon black, derived from sources like pyrolysis of waste tires. This aligns with green initiatives and offers growth potential. Increasing number of applications, the market's expansion will be fueled by innovative applications beyond tires. Carbon black finds use in conductive plastics, battery components, and aerospace materials, benefiting from technology-driven trends in electronics, energy storage, and aviation.

The growing renewable energy sector presents opportunities. Carbon black enhances wind turbine blade strength, crucial for wind energy expansion. As the US emphasizes clean energy, carbon black's contributions to wind power will drive its demand. Urban development will also fuel the demand for carbon black in construction materials, coatings, and sealants. As US cities evolve, the construction industry's steady growth will sustain the market's need for these applications.

Furthermore, Carbon black's role in plastics, packaging, and consumer goods will experience growth as US consumer preferences evolve. The trend toward durable, UV-resistant products will drive manufacturers to incorporate carbon black for enhanced performance. Carbon black's diverse applications contribute to its resilience during economic fluctuations. Industries ranging from automotive to construction rely on its properties, ensuring a steady demand even amidst changing economic conditions, securing future market growth.

#US Carbon Black market#US Carbon Black market forecast#US Carbon Black market share#US Carbon Black market size#US Carbon Black market growth#US Carbon Black market analysis#US Carbon Black Industry#United States Carbon Black market#US Carbon Black market trends#US Carbon Black industry challenges#Leading Service providers US Carbon Black Market#Leading players in US furnace black market#Competitors in US thermal black market#Emerging players US Carbon Black industry#Major players in US Carbon black sector#Top 5 Carbon black manufacturers US#Automobile companies in Carbon Black market US#Top players US lamp black market#Investment US Carbon Black Market#Funds raised startups furnace black market#Thermal Black in US Carbon Black market#Furnace Black in US Carbon Black market#Tires and Rubber products in Carbon Black market US

0 notes

Text

Things the Biden-Harris Administration Did This Week #28

July 19-26 2024

The EPA announced the award of $4.3 billion in Climate Pollution Reduction Grants. The grants support community-driven solutions to fight climate change, and accelerate America’s clean energy transition. The grants will go to 25 projects across 30 states, and one tribal community. When combined the projects will reduce greenhouse gas pollution by as much as 971 million metric tons of CO2, roughly the output of 5 million American homes over 25 years. Major projects include $396 million for Pennsylvania’s Department of Environmental Protection as it tries to curb greenhouse gas emissions from industrial production, and $500 million for transportation and freight decarbonization at the ports of Los Angeles and Long Beach.

The Biden-Harris Administration announced a plan to phase out the federal government's use of single use plastics. The plan calls for the federal government to stop using single use plastics in food service operations, events, and packaging by 2027, and from all federal operations by 2035. The US government is the single largest employer in the country and the world’s largest purchaser of goods and services. Its move away from plastics will redefine the global market.

The White House hosted a summit on super pollutants with the goals of better measuring them and dramatically reducing them. Roughly half of today's climate change is caused by so called super pollutants, methane, hydrofluorocarbons (HFCs), and nitrous oxide (N2O). Public-private partnerships between NOAA and United Airlines, The State Department and NASA, and the non-profit Carbon Mapper Coalition will all help collect important data on these pollutants. While private firms announced with the White House plans that by early next year will reduce overall U.S. industrial emissions of nitrous oxide by over 50% from 2020 numbers. The summit also highlighted the EPA's new rule to reduce methane from oil and gas by 80%.

The EPA announced $325 million in grants for climate justice. The Community Change Grants Program, powered by President Biden's Inflation Reduction Act will ultimately bring $2 billion dollars to disadvantaged communities and help them combat climate change. Some of the projects funded in this first round of grant were: $20 million for Midwest Tribal Energy Resources Association, which will help weatherize and energy efficiency upgrade homes for 35 tribes in Michigan, Minnesota, and Wisconsin, $14 million to install onsite wastewater treatment systems throughout 17 Black Belt counties in Alabama, and $14 million to urban forestry, expanding tree canopy in Philadelphia and Pittsburgh.

The Department of Interior approved 3 new solar projects on public land. The 3 projects, two in Nevada and one in Arizona, once finished could generate enough to power 2 million homes. This comes on top of DoI already having beaten its goal of 25 gigawatts of clean energy projects by the end of 2025, in April 2024. This is all part of President Biden’s goal of creating a carbon pollution-free power sector by 2035.

Treasury Secretary Janet Yellen pledged $667 million to global Pandemic Fund. The fund set up in 2022 seeks to support Pandemic prevention, and readiness in low income nations who can't do it on their own. At the G20 meeting Yellen pushed other nations of the 20 largest economies to double their pledges to the $2 billion dollar fund. Yellen highlighted the importance of the fund by saying "President Biden and I believe that a fully-resourced Pandemic Fund will enable us to better prevent, prepare for, and respond to pandemics – protecting Americans and people around the world from the devastating human and economic costs of infectious disease threats,"

The Departments of the Interior and Commerce today announced a $240 million investment in tribal fisheries in the Pacific Northwest. This is in line with an Executive Order President Biden signed in 2023 during the White House Tribal Nations Summit to mpower Tribal sovereignty and self-determination. An initial $54 million for hatchery maintenance and modernization will be made available for 27 tribes in Alaska, Washington, Oregon, and Idaho. The rest will be invested in longer term fishery projects in the coming years.

The IRS announced that thanks to funding from President Biden's Inflation Reduction Act, it'll be able to digitize much of its operations. This means tax payers will be able to retrieve all their tax related information from one source, including Wage & Income, Account, Record of Account, and Return transcripts, using on-line Individual Online Account.

The IRS also announced that New Jersey will be joining the direct file program in 2025. The direct file program ran as a pilot in 12 states in 2024, allowing tax-payers in those states to file simple tax returns using a free online filing tool directly with the IRS. In 2024 140,000 Americans were able to file this way, they collectively saved $5.6 million in tax preparation fees, claiming $90 million in returns. The average American spends $270 and 13 hours filing their taxes. More than a million people in New Jersey alone will qualify for direct file next year. Oregon opted to join last month. Republicans in Congress lead by Congressmen Adrian Smith of Nebraska and Chuck Edwards of North Carolina have put forward legislation to do away with direct file.

Bonus: American law enforcement arrested co-founder of the Sinaloa Cartel, Ismael "El Mayo" Zambada. El Mayo co-founded the cartel in the 1980s along side Joaquín "El Chapo" Guzmán. Since El Chapo's incarceration in the United States in 2019, El Mayo has been sole head of the Sinaloa Cartel. Authorities also arrested El Chapo's son, Joaquin Guzman Lopez. The Sinaloa Cartel has been a major player in the cross border drug trade, and has often used extreme violence to further their aims.

#Joe Biden#Thanks Biden#kamala harris#us politics#american politics#politics#climate change#climate crisis#climate action#tribal rights#IRS#taxes#tax reform#El Chapo

768 notes

·

View notes

Text

We Can't Keep Meeting Like This, chapter three, part two. Part one.

Peli Motto came out to greet him from under the shade of the hangar’s repair shop as Din disembarked, chin up and hands fisted on her hips. “Mando! What are you doing here? You break the starboard motivator already? I already told you, it’s not that easy to find a motivator that’s up to your standards—”

She brightened as Grogu’s hovercradle came into view, abandoning her line of questioning. “There’s my little womp rat! Glad you haven’t lost him yet!”

She scooped him out of his hovercradle and tucked him into his side. “Look what I’ve got for you!” Digging around in her pants pocket, she pulled out a tube, tore the top off with her teeth and slid out a long strip of cured meat. “Dewback jerky,” she announced with a flourish. Grogu squealed and held out his hands. “Alright, alright. Take your time. Chew.” Grogu munched happily on the end of the jerky, his ears quivering.

“So what’s on your mind, big fella?” she asked Din.

“Do you know anything about Talon Karrde?” Din asked.

“Sure, he snapped up most of Jabba’s territory after the slug died—not the local gangs, of course, they were stuck with Bib Fortuna when he took over what was left on Tatooine. We all were. And Bib—you know—” She made a gesture with her hands that Din didn’t follow. “There are worse daimyos.”

One of her droids made a low blat.

“I didn’t say that!” she exclaimed, pointing a finger at the offending droid. “Don’t you go around repeating that.”

“Droids,” she said, and Din nodded in agreement.

“There are some people who are going to meet me here. I gave the coordinates to your hangar.”

“Do they need work done as well? Because this isn’t a public dock.”

“Uh.”

“Oh, great.” Peli shook her head in an exaggerated fashion. “Why don’t you just invite every bounty hunter in the sector to meet you in my hangar. Isn’t there anywhere else you can do business with your clients?”

“They’re not clients or bounty hunters.”

A shadow passed over the hangar and they both looked up at the sound of a ship circling above. The shuttle Din had seen on Morlana One cut sharply out of its turn and began to make a descent into the circle of the hangar. In the daylight he could see that the shuttle was painted a darker shade than standard Imperial grey. A black streak of carbon scoring from a laser canon marked the left side of the ship.

“A retrofitted Imperial shuttle,” Peli said. “Bold choice. These are friends of yours?”

“Yeah, I guess so.”

“Unusual friends.”

“Yeah.”

The shuttle settled slowly beside the Razor Crest, kicking up a small cloud of sand as it landed. Din and Peli watched as the ramp lowered in a loud hydraulic hiss and Luke and Mara strolled down the ramp. Mara lifted her hand to block the sun streaming down into the hangar.

She wore high-waisted ochre pants with tall boots and a sage green shirt that came to her elbows, ending above the holster strapped to her wrist. Her long hair—returned to its natural bright red shade—was clipped back from her face on either side of her head. For the first time Din noticed a light dusting of freckles across her nose and cheeks.

Luke was dressed in a dark blue shirt and fitted, dark brown pants with tall boots. The front of his shirt was stylishly undone, the triangle shape of the flap hanging down across his chest. His right arm was in a sling. The arm wasn’t bandaged, but Luke held it stiffly across his front.

A blue and white astromech trundled down the ramp behind them and swerved to make a beeline towards Peli’s motley crew of repair driods, greeting them in their own language.

“Mando! Grogu!” Luke called as they crossed the hangar. Grogu squealed in delight and waved his hands at the Jedi.

“Oh, he likes you,” Peli said. Grogu nearly squirmed right out of her arms as she passed him over to Luke.

Luke balanced Grogu in his one good arm and smiled down at the child. “I missed you, too! We came as soon as you called us.” Grogu placed his little hands on Luke’s chest and looked at him intently as he spoke.

“He some sort of gremlin whisperer?” Peli asked, leaning towards Din.

Luke grinned. “You could call me that.”

“Mara, Luke,” Din said. “This is Peli.”

“Welcome to Tatooine,” Peli said cheerfully, gesturing at the Razor Crest. “I keep that hunk of junk from falling out of the sky.”

“Good to meet you,” Luke said.

7 notes

·

View notes

Text

Fasteners Procurement Intelligence: A Comprehensive Guide

The fasteners category is anticipated to grow at a CAGR of 4.42% from 2023 to 2030. APAC holds the largest category share of over 40% and it is expected to be the fastest growing region during the forecast period. The increased use in the construction and automotive industries is driving considerable growth in the fasteners category. These fasteners are semi-permeant or occasionally permeant solutions, and the development of the construction industry, research and development initiatives, urban real estate infrastructure, and technological developments in the production of lightweight goods for the automotive and other industrial sectors are all factors that have an impact on their growth. The creation of innovative and novel industrial fasteners also helps the category growth.

In the building sector, they are employed to temporarily link two or more things together. As the industry demands strength and accuracy, building and construction fasteners are employed in heavy-duty applications to link materials together. Different fastening forms are employed in the construction industry, including stainless steel, alloy steel, and carbon steel. Nuts, bolts, washers, screws, and rivets are typical examples of building construction items. To ensure secure and sturdy construction, each infrastructure project needs a different kind of fastening product. Due to its affordability, strength, and workability, carbon steel is used to make the majority of products. The demand for industrial fasteners is increased by the fact that stainless steel is the most popular building material because of its strength, resistance to heat, and resistance to corrosion.

Corrosion resistance qualities will spur significant investment in the creation of new products, meeting consumer demand. During the projection period, rising consumer emphasis on residential and commercial building aesthetics will fuel industry expansion in the use of cable management and building exteriors. However, the negative aspect of working with fasteners is that they typically require special tools for setting up, which can increase project costs and complexity. Other types require extra steps like pre-drilling holes or applying thread-locking compounds, which adds extra labor and time to installation. Not to mention, depending on the application, some types may not be strong enough or sufficiently resilient for prolonged use, which could lead to expensive repairs in the future if not handled effectively from the start. It has been noted that these costs limit the category growth.

Order your copy of the Fasteners Procurement Intelligence Report, 2023 - 2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

The fasteners category is fragmented and highly competitive in nature, with various large and small-scale manufacturers in China, Taiwan, Thailand, and Japan. Opportunities for new companies should arise from the rising need for inventive and application-specific industrial fastener designs. Over the projection period, rising raw material costs and high-volume manufacturing by the established companies are anticipated to be the main obstacles for new entrants. Furthermore, major fastener producers are likely to have an edge over small-scale competitors due to technological expertise and a strong customer base. For instance:

• In July 2023, next-generation FLEXTORQ® Impact Driver Bits were introduced by DEWALT, a division of Stanley Black & Decker Inc. These are created with fasteners and engineered for durability, advancing and improving driver bit technology for fastening applications.

• In January 2023, Birmingham Fasteners and Supply Inc. purchased Pacific Coast Bolt Corp. to diversify its manufacturing. The goal was to boost its presence in the commercial fastener market and provide customer service to clients across the United States.

• In September 2021, LINC Systems, LLC, a commercial fastener and packaging distributor platform, announced the acquisition of Air-O Fasteners. The deal was to expand the company's foothold in the Western United States.

Raw material, labor, machinery & equipment, and energy form the major cost components of this category. Raw material is the largest cost component accounting for around 60% - 70% of the total cost followed by labor at roughly 20%. The war between Russia and Ukraine has affected the supply of raw materials (copper, aluminum, etc.), as Russia produces roughly 4% of the world's copper and about 6% of its aluminum. The fasteners category is an example of an industry where suppliers implement cost-plus pricing model. This is because fasteners are typically low-cost, commodity products with little differentiation between brands. As a result, companies in this industry often compete on price, and cost-plus pricing is a simple and easy way to set prices that are competitive.

China, and India are among the most of the preferred sourcing destinations in this category.China has a robust manufacturing industry and offers a wide range of suppliers with diverse capabilities and cost-effective production options. India is a popular destination for metalworking processes due to its established manufacturing sector. For sourcing fasteners, research the market to understand the types, quality, and prices available. Develop a sourcing strategy by identifying the needs, budget, and potential suppliers. Build relationships with suppliers to get the best prices and quality fasteners. Negotiate prices, especially if buying in bulk. Document all the terms & conditions to avoid discrepancies. Monitor suppliers to ensure they meet the agreed quality standards. Use a variety of sources for the best prices and quality.

Fasteners Procurement Intelligence Report Scope

• Fasteners Category Growth Rate: CAGR of 4.42% from 2023 to 2030

• Pricing growth Outlook: 3% - 5% (annual)

• Pricing Models: Cost-plus pricing model, fixed-fee pricing model, discount pricing model

• Supplier Selection Scope: Cost and pricing, Past engagements, Productivity, Geographical presence

• Supplier selection criteria: Quality assurance, service level agreement, environmental compliance, lead times, technical specifications, operational capabilities, regulatory standards and mandates, category innovations, and others

• Report Coverage: Revenue forecast, supplier ranking, supplier matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Browse through Grand View Research’s collection of procurement intelligence studies:

• Flooring Services Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

• Fixed Line Services Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

Key companies profiled

• Arconic Fastening Systems and Rings

• Acument Global Technologies Inc.

• ATF Inc.

• Dokka Fasteners AS

• LISI Group

• Nippon Industrial Fasteners Company

• Hilti Corporation

• MW Industries Inc.

• Birmingham Fasteners and Supply Inc.

• SESCO Industries Inc.

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

• Market Intelligence involving – market size and forecast, growth factors, and driving trends

• Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

• Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

• Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions

#Fasteners Procurement Intelligence#Fasteners Procurement#Procurement Intelligence#Fasteners Market#Fasteners Industry

0 notes

Text

Carbon Black Market Professional Survey and In-depth Analysis Research Report Forecast to 2030

Carbon Black Industry Overview

The global carbon black market size was valued at USD 22.35 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.8% from 2024 to 2030.

Rising product usage in the production of plastics is anticipated to drive growth. Moreover, the rising usage of these plastics in electrical and electronic components will boost product demand. It is produced either by thermal decomposition or partial combustion method, which includes oil or natural gas as a feedstock. It is produced by four different processes, which are the furnace black process, channel process, acetylene black process, and Lampblack process.

Gather more insights about the market drivers, restrains and growth of the Carbon Black Market

Growing environmental concerns coupled with the developing automotive industry is expected to drive the growth of the U.S. market. The refurbishing trend has resulted in increased demand for high-performance coatings in automotive as well as other industries, such as marine, aerospace, and industrial.

The product helps improve the strength and longevity of tires by providing better abrasion resistance and tensile strength. Also, growing construction and manufacturing sectors utilizing industrial rubber and equipment are anticipated to positively impact the demand over the forecast period.

Carbon black market prices are mainly based on raw materials, auxiliary materials, and utilities. The crude oil price fluctuation has a major impact on the pricing of carbon black. Some other macro-level factors influencing the price include working capital and pre-operational costs. The installation and setup, capitalized interests, project engineering and management, and commissioning costs are included under the pre-occupational costs.

Carbon black is formed by incomplete combustion of different petroleum-based constituents. It is an essential component for a range of end-use applications such as consumer goods, automobiles, appliances, electronics, and others. Since it is a petroleum-derived product the manufacturers rely on sourcing their key raw materials at the right prices with no supply hindrance. Raw materials are critically selected by the manufacturers depending on their product quality, offering price, product portfolio holding, and market accessibility.

Browse through Grand View Research's Petrochemicals Industry Research Reports.

• The global diesel exhaust fluid market size was valued at USD 36.66 billion in 2023 and is projected to grow at a CAGR of 7.9% from 2024 to 2030.

• The global bromobenzene market size was estimated at USD 1,228.8 million in 2023 and is projected to grow at a CAGR of 4.7% from 2024 to 2030.

Global Carbon Black Market Report Segmentation

This report forecasts revenue and volume growth at the global, regional, and country levels and provides a carbon black market analysis of the latest industry trends and opportunities in each of the sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global carbon black market report based on type, application, grade, and region:

Type Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Furnace Black

Channel Black

Thermal Black

Acetylene Black

Others

Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Tire

Non- tire Rubber

Plastics

Inks & Coatings

Others

Grade Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Standard Grade

Specialty Grade

Regional Outlook (Volume, Kilotons; Revenue, USD Billion, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Italy

Spain

Russia

Asia Pacific

China

Japan

India

Indonesia

Malaysia

Thailand

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

South Africa

Key Companies & Market Share Insights

Key companies are adopting several organic and inorganic growth strategies, such as capacity expansion, mergers & acquisitions, and joint ventures, to maintain and expand their market share.

In June 2023, Bridgestone Corporation announced the commencement of the development of tire-derived oil and recovered carbon black via pyrolysis of worn tires with the help of test units established at the Bridgestone Innovation Park in Tokyo. This is aimed at encouraging the social deployment of chemical recycling technologies that allow the efficient pyrolysis of worn tires.

In April 2023, Orion Engineered Carbons announced the implementation of its new cogeneration technology producing renewable energy in its Ivanhoe plant (Louisiana, U.S.). The system comprises a steam turbine generator, which ingests the waste steam from the production process of the carbon black plant and alters it to electricity.

In March 2023, Tokai Carbon Co., Ltd. entered into a strategic partnership with Sekisui Chemical Co., Ltd., for the real-world application of the Carbon Capture and Utilization (CCU) technology. This deal was aimed at manufacturing varied carbon products and materials for the capture and storage of carbon dioxide (CO2) as solid carbon.

Key Carbon Black Companies:

Orion Engineered Carbons Holdings GmbH

OMSK Carbon Group

Sid Richardson Carbon & Energy Co.

Tokai Carbon Co. Ltd.

Asahi Carbon Co. Ltd.

Ralson Goodluck Carbon

Atlas Organic Pvt. Ltd.

Continental Carbon Co.

OCI Company Ltd.

Birla Carbon

Bridgestone Corp.

Cabot Corp.

China Synthetic Rubber Corporation (CSRC)

Himadri Companies & Industries Ltd. (HCIL)

Mitsubishi Chemicals

Nippon Steel & Sumikin Chemical Co. Ltd.

Jiangxi Black Cat Carbon Black Inc.

Order a free sample PDF of the Carbon Black Market Intelligence Study, published by Grand View Research.

0 notes

Text

Black Masterbatch Manufacturers: Unrivaled Excellence in Plastic Color Solutions

The demand for high-quality black masterbatches is ever-growing across various industries that rely on plastic materials for manufacturing. BS Masterbatch, a leading name in the masterbatch industry, is recognized for its expertise and innovation in producing superior black masterbatches. These products are designed to offer exceptional color consistency, UV stability, and enhanced mechanical properties, catering to a wide range of applications.

What is Black Masterbatch?

Black masterbatch is a concentrated mixture of carbon black pigment, carrier resin, and various additives that is used to impart deep black coloration to plastic products. The quality of a black masterbatch largely depends on the carbon black content, its dispersion quality, and the type of additives used. BS Masterbatch specializes in creating black masterbatches that are known for their high color strength, superior dispersion, and outstanding performance.

BS Masterbatch: Leaders in Quality and Innovation

BS Masterbatch has carved a niche for itself in the black masterbatch manufacturing segment by consistently delivering products that exceed customer expectations. Here are some key aspects that make BS Masterbatch a trusted partner for businesses:

Superior Quality Carbon Black: At the heart of every high-quality black masterbatch is superior carbon black. BS Masterbatch sources the finest grades of carbon black to ensure deep and uniform color in plastic products. This guarantees that the black masterbatch meets the highest standards of opacity and UV resistance.

Advanced Dispersion Technology: The uniform dispersion of carbon black is critical in achieving consistent color and smooth surface finish in the end product. BS Masterbatch employs advanced dispersion technologies that ensure even distribution of carbon black particles, resulting in flawless color consistency and minimizing issues such as streaking and spotting.

Customization and Versatility: BS Masterbatch offers a range of black masterbatch formulations tailored to specific customer needs. From automotive components and packaging to construction materials and consumer goods, BS Masterbatch provides customized solutions that align with unique performance and aesthetic requirements.

Comprehensive Technical Support: Understanding the nuances of plastic manufacturing, BS Masterbatch provides comprehensive technical support to its clients. Their team of experts works closely with customers to optimize formulations, address specific challenges, and improve overall product performance.

Wide Range of Applications

BS Masterbatch's black masterbatches are widely used across several industries due to their superior quality and versatility:

Automotive Industry: In the automotive sector, black masterbatches are used in manufacturing various interior and exterior components, such as dashboards, bumpers, and trims, where UV stability and high color retention are crucial.

Packaging Industry: Black masterbatches are essential in the packaging industry for producing containers, films, and other packaging materials that require consistent color, opacity, and resistance to environmental factors.

Construction Industry: Black masterbatches are used in the production of pipes, cables, and profiles where strength, durability, and weather resistance are important.

Consumer Goods: From household appliances to electronic devices, black masterbatches are employed to achieve the desired aesthetic and functional characteristics.

Commitment to Sustainability

BS Masterbatch is committed to sustainable practices in its production processes. By focusing on eco-friendly formulations and efficient manufacturing methods, they strive to minimize the environmental impact while delivering high-performance black masterbatches.

Conclusion

BS Masterbatch is a leading manufacturer of black masterbatches, renowned for its dedication to quality, innovation, and customer satisfaction. With their advanced technology, superior raw materials, and a commitment to sustainability, BS Masterbatch continues to provide solutions that meet the diverse needs of the plastics industry. Whether it's for automotive, packaging, construction, or consumer goods, BS Masterbatch's black masterbatches offer unmatched quality and performance, making them a preferred choice for businesses worldwide.

0 notes

Text

Carbon Black Prices | Pricing | Trend | News | Database | Chart | Forecast

Carbon Black Prices have become a significant concern for many industries due to their fluctuating nature and impact on various manufacturing processes. Carbon black, a fine black powder made from burning hydrocarbons in insufficient air, is widely used as a reinforcing agent in tires, a pigment in inks and paints, and as a conductive agent in electronics. The price of carbon black is influenced by several factors, including raw material costs, production technologies, and market demand, all of which contribute to its volatility in the global market.

One of the primary factors affecting carbon black prices is the cost of raw materials. The production of carbon black relies heavily on feedstocks such as crude oil and natural gas. As these raw materials experience price changes due to geopolitical events, supply chain disruptions, or shifts in global oil and gas markets, carbon black prices inevitably respond accordingly. For instance, fluctuations in crude oil prices can have a direct impact on the cost of carbon black production, as oil-derived feedstocks constitute a significant portion of the production costs. When crude oil prices rise, the cost of carbon black production also increases, leading to higher prices for end-users.

In addition to raw material costs, technological advancements in production methods can also influence carbon black prices. The carbon black industry has seen various improvements in production efficiency and environmental impact over the years. Innovations such as more energy-efficient production processes or the development of alternative feedstocks can lead to changes in production costs. For example, advancements in manufacturing technologies that reduce energy consumption or improve yield can help lower production costs, potentially leading to more stable or lower carbon black prices. Conversely, the introduction of stricter environmental regulations or the need for costly upgrades to meet these standards can increase production costs and, consequently, carbon black prices.

Get Real Time Prices for Carbon Black: https://www.chemanalyst.com/Pricing-data/carbon-black-42

Market demand plays a crucial role in shaping carbon black prices. Industries such as automotive, electronics, and paints and coatings are major consumers of carbon black, and changes in their demand patterns can significantly affect prices. The automotive industry, in particular, is a large consumer of carbon black due to its use in tire production. When the automotive sector experiences growth or decline, it directly impacts the demand for carbon black. For instance, a surge in global vehicle production or increased demand for high-performance tires can drive up carbon black prices, as suppliers may struggle to keep up with the heightened demand. On the other hand, a downturn in the automotive market or a shift towards alternative materials can lead to reduced demand and lower carbon black prices.

Global economic conditions and trade dynamics also play a role in determining carbon black prices. Economic growth or recession can influence industrial production levels and, subsequently, the demand for carbon black. For example, during periods of economic expansion, industrial activities and consumer spending tend to rise, leading to increased demand for products that require carbon black. Conversely, economic downturns can lead to decreased industrial output and reduced demand for carbon black, potentially causing prices to fall. Additionally, international trade policies and tariffs can affect the flow of carbon black across borders, impacting prices. Trade restrictions or tariffs imposed by major carbon black producers or consumers can disrupt supply chains and lead to price fluctuations in the global market.

Supply chain dynamics are another important factor influencing carbon black prices. The carbon black industry relies on complex supply chains involving raw material suppliers, production facilities, and distribution networks. Disruptions in any part of this chain can affect the availability and cost of carbon black. For example, natural disasters, geopolitical tensions, or logistical challenges can impact the transportation of raw materials or finished products, leading to supply shortages and price increases. Additionally, supply chain disruptions can create uncertainty in the market, leading to price volatility as buyers and sellers adjust to changing conditions.

In recent years, the carbon black industry has also faced increasing pressure to address environmental and sustainability concerns. The production of carbon black is associated with certain environmental impacts, such as emissions and waste generation. As regulatory frameworks become more stringent and consumers demand more sustainable practices, the industry may need to invest in cleaner technologies or implement more environmentally friendly practices. These changes can result in higher production costs, which may be passed on to consumers in the form of higher carbon black prices. Conversely, efforts to enhance sustainability and reduce environmental impact can also lead to new opportunities for innovation and efficiency, potentially stabilizing or reducing prices in the long term.

Overall, carbon black prices are influenced by a complex interplay of factors including raw material costs, technological advancements, market demand, economic conditions, trade dynamics, and supply chain disruptions. As the global market continues to evolve, these factors will continue to shape carbon black prices, making it essential for industries reliant on this material to stay informed and adaptable. Understanding these dynamics can help businesses navigate the challenges of fluctuating carbon black prices and make informed decisions to manage their supply chain and production costs effectively.

Get Real Time Prices for Carbon Black: https://www.chemanalyst.com/Pricing-data/carbon-black-42

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Carbon Black#Carbon Black Price#Carbon Black Prices#Carbon Black Pricing#Carbon Black News#Carbon Black Price Monitor#Carbon Black Database

0 notes

Text

THE CLIMATE-DRIVEN SHIFT: How Global Warming is Reshaping the IT Landscape

Most people who acknowledge the reality of global warming tend to focus on its environmental and meteorological effects. However, rising temperatures can also significantly impact modern computing technology, creating several physical and economic challenges for organizations and networks.

KEY POINTS:

▪️Increased Energy Demands: As temperatures rise, cooling systems for data centers need to work harder to prevent overheating. This leads to higher energy consumption and operational costs. Additionally, more energy is required to power and cool IT infrastructure, exacerbating the demand for electricity.

▪️Data Center Location and Design: Extreme weather conditions and rising sea levels can affect the location and design of data centers. Companies may need to invest in more resilient infrastructure or relocate data centers to avoid areas prone to flooding or extreme temperatures.

▪️Operational Disruptions: Severe weather events like hurricanes, floods, and heatwaves can disrupt IT operations, causing outages and damaging equipment. This can impact businesses and services reliant on IT infrastructure.

▪️Regulatory and Compliance Pressures: Governments and regulatory bodies are increasingly enforcing regulations related to carbon emissions and sustainability. IT companies may face stricter guidelines and standards, requiring them to adopt greener practices and technologies.

▪️Increased Demand for Green Technologies: There is growing demand for IT solutions that support environmental sustainability, such as energy-efficient hardware, cloud computing to optimize resource usage, and software solutions for monitoring and reducing carbon footprints.

▪️Supply Chain Impacts: Global warming can disrupt supply chains for IT hardware and components. Extreme weather events and environmental changes can affect the production, transportation, and availability of these essential materials.

▪️Long-Term Cost Implications: As climate-related issues become more prevalent, the long-term costs of managing and mitigating these impacts could rise. This includes investments in more robust infrastructure and adaptation strategies to handle changing environmental conditions.

Overall, global warming is pushing the IT sector towards more sustainable practices and innovations, aiming to reduce its environmental footprint while adapting to new challenges.

HAVE AN ACTION PLAN

IT departments need to plan for ways to reduce temperatures in data centers. The following actions are recommended:

▪️Verify the capacity of the current cooling systems and ensure it will meet current and planned requirements. Some systems may already be running at or beyond capacity.

▪️Ensure all data centers, server rooms, and other critical areas have temperature probes installed with alerts and trending capabilities to avoid heat-related incidents caused by cooling system inadequacy or failure.

▪️Understand your ideal temperature band. It is not cost-effective to cool a room more than is needed.

▪️Have a professional experienced in data center design and cooling review the current layout and suggest improvements for efficiency and effectiveness.

▪️If a building roof is black, consider painting or sealing it with a white finish to reflect heat instead of absorbing it.

▪️If an AC unit hasn’t been serviced in a long time, have it inspected to ensure it is running as efficiently as possible. This may involve cleaning or replacing filters, tightening belts, correcting refrigerant levels, and more.

▪️Ensure unnecessary equipment is not running. This includes monitors. Investigate remote power switches if necessary.

▪️Review the power management capabilities of systems relative to business needs and develop policies regarding power management settings.

▪️Investigate using cooler-running power supplies. Google reportedly pays a premium for power supplies that run cooler, knowing it will recover the costs through lower electric bills.

▪️Review temperature trend information and incorporate it into capacity planning and budgeting for the following year.

▪️With higher air temperatures melting glaciers and warming waters, it is predicted that the number and severity of storms will increase. The Gulf and coastal states are closely monitoring this situation.

The resulting weather will affect not just environmental controls in data centers, but the continuity of operations for organizations and entire economies. Having current and tested business continuity plans in place is always a wise idea.

0 notes

Text

Top 4 players in US Black Carbon market

Buy Now

STORY OUTLINE

Cabot Corporation: A leading contributor of US Black Carbon market since 1882. Their products are known to provide UV protection and conductivity.

Birla Carbon: An Indian flagship business with more than 160 years of experience in the Black Carbon business.

Continental Carbon Company: Providing Black Carbon products in lines of Industrial Rubber Carbon Black, Tire Rubber Carbon Black, and Specialty Carbon Black since 1936.

Orion Engineered Carbons: Providing Black carbon products majorly in two areas, i.e., Rubber Black Carbon and Specialty Black Carbon for more than 160 years.

According to Ken Research, the United States Black Carbon market is anticipated to become a ~USD 3 Bn. industry by 2028 by growing at a CAGR of ~2.5%.

The US Carbon Black market is rapidly growing and is anticipated to attain a significant level of growth in the upcoming years.

There are many reasons behind the growth of US Carbon Black market. Some of these reasons include increasing automotive sales, industrial growth and increase in urbanization rates, along with rise in the demand for rubber goods.

Various companies and players are contributing to their best efforts in the growth of the US Black Carbon market.

This article aims to put light on the contributions done by the major players towards the growth of the US Black Carbon market.

1.Cabot Corporation

Click here know more about this report

Founded in 1882, headquartered in Boston, Massachusetts, having more than 4000 employees worldwide, and presence in more than 20 countries along with a total revenue of USD 4 Bn. in 2022, this chemical company is a leading contributor of US Black Carbon market.

During 1993, their team was successful in developing a method or process of modifying carbon’s surface, which in turn allowed people to be able to change or modify the carbon surface with other chemicals.

This discovery also led to the development of various other technologies such as printer ink and inject colorants.

The products made by this organization has various applications in various fields such as consumer rubber products, adhesives & sealants, construction, digitalization, inject technology, oil, gas & mining, digitalization, fiber, plastics, tires, etc.

When it comes to Black Caron, this chemical company happens to be the largest producer of it. Some of the popular Black Carbon products offered by this organization include VULCAN, BLACK PEARLS, REGAL, MOGUL, ELFTEX, STERLING, MONARCH, etc.

One of the most amazing feature of their specialty carbons is that they are known to provide ultraviolet protection, and conductivity. Furthermore, these carbons are generally used in the areas of coatings, plastics, printing and packaging.

2.Birla Carbon

Click Here to Download a Sample Report

Birla Carbon is one of the flagship business of the parent company Aditya Birla Group. This flagship business is the largest producer of carbon black and is a well-established business not only in the US Carbon Black but in the whole world when it comes to black carbon.

One of the interesting facts about this organization is that it has more than 160 years of experience when it comes to the Carbon industry. Moreover, this organization has 16 manufacturing sites, 2 corporate offices, 2 technology centers, and 8 offices situated in the whole world.

Their manufactured Black Carbon is primarily used in areas of Tires, Specialty Blacks, plastics, electronic products, and mechanical rubber goods.

Last year, they also have opened their remote black carbon showroom which is primarily done to get a knowledge of benefits along with applications of black carbon products.

Their black carbon primarily come in two types, i.e., Industrial and Rubber. Former’s products include COPEBLACK, RAVEN, and CONDUCTEX. While the latter’s products include STATEX and FURNEX.

Recently, they also announced that they aspire to achieve zero carbon emissions by the year 2050.

To achieve this aspiration, they are also following the Green Finance framework. Birla Carbon is also keen to achieve sustainability excellence. In fact, last year the celebrations for their decade of sustainable excellence were also done.

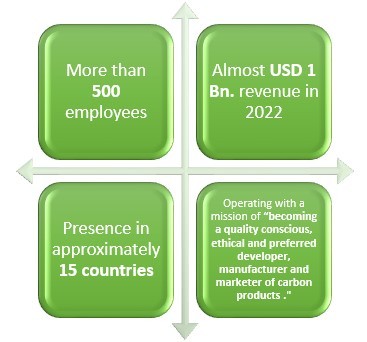

3.Continental Carbon Company

Headquartered in Houston, Texas; with more than 500 employees and presence in almost 15 countries, the Continental Carbon Company is a leading American company in the US Black Carbon market. This company has been in this market since 1936.

They have various lines of work within their Black Carbon range. Industrial Rubber Carbon Black, Tire Rubber Carbon Black, and Specialty Carbon Black are primarily the three of their product lines.

Their Industrial Rubber Carbon Black is suitable for many things such as flex strength for belts & hoses, weather stripping, abrasion resistance for footwear, and commercial roofing. The products in this line include N550, N650, N660, N683, N762 and N774.

Their Tire Rubber Carbon Black is primarily provides fuel mileage, abrasion resistance, treadwear, hysteresis. The products in this category include N234, N326, N330, N351, LH30, N550, N650 and N660.

Their Specialty Carbon Black typically provides conductivity, UV protection, and pigmentation. The products in this category primarily include SBX152, SBX252, SBX352, SBX452, SBX552, SBX652, SBX256, SBX656, SBX 251, and SBX351.

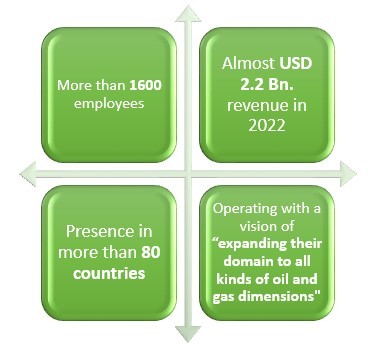

4.Orion Engineered Carbons

Click here Request for custom report

Operating in the Black Carbon market for more than 160 years, this German company is a well-established company in the US Black Carbon market. It has its headquarters situated in Luxembourg, Europe. On the other hand, its executive offices are situated in Houston, Texas, US.

This company was formed in the year 2011 when the Evonik Industries decided to sell off their Black Carbon business. Now this chemical company is known to be the pigment black’s largest producer, and rubber blacks’ third largest producer in the world.

Their product lines can be broadly divided into two categories: Rubber Black Carbon and Specialty Black Carbon. The former is primarily used in the tire industry while the latter is typically used paints, coatings, and lithium-ion batteries.

Footwear, Wiper Blades, Gaskets, Seals, Extruded Profiles, Tubes, Rubber flooring, Anti-vibration engine mounts, Seals, Belts, etc. are the primary applications of their Black Carbon products.

Their Black Carbon products primarily include Thermal Blacks, Furnace Blacks, Specialty Gas Blacks, Lamp Blacks, Acetylene Blacks, etc.

#US Carbon Black market#US Carbon Black market forecast#US Carbon Black market share#US Carbon Black market size#US Carbon Black market growth#US Carbon Black market analysis#US Carbon Black Industry#United States Carbon Black market#US Carbon Black market trends#US Carbon Black industry challenges#Leading Service providers US Carbon Black Market#Leading players in US furnace black market#Competitors in US thermal black market#Emerging players US Carbon Black industry#Major players in US Carbon black sector#Top 5 Carbon black manufacturers US#Automobile companies in Carbon Black market US#Top players US lamp black market#Investment US Carbon Black Market#Funds raised startups furnace black market#Thermal Black in US Carbon Black market#Furnace Black in US Carbon Black market#Tires and Rubber products in Carbon Black market US#Investors in US Carbon Black market#Venture Capitalists in US Carbon Black market#US Soot Carbon Black market#US Carbon Black particles market#US residual Carbon Black market#US amorphous carbon black market#US Carbon black sector

0 notes

Text

Conductive Plastics: Innovations and Advancements

Conductive plastics are polymers engineered to carry an electrical charge. This is typically achieved by incorporating conductive fillers like carbon black, graphite, metal fibers, or conductive polymers into the plastic matrix. These fillers create a conductive network within the plastic, allowing it to transmit electricity while retaining the lightweight, flexible, and moldable properties of traditional plastics.

The applications of conductive plastics are vast and continually expanding. In the electronics industry, they are used in components such as housings, connectors, and electromagnetic interference (EMI) shielding. Conductive plastics provide an efficient, lightweight alternative to metal, enhancing design flexibility and reducing manufacturing costs.

In the automotive sector, conductive plastics are employed in fuel systems, sensors, and battery housings. Their ability to dissipate static electricity helps prevent potential ignition hazards, making vehicles safer. Additionally, their lightweight nature contributes to the overall reduction of vehicle weight, improving fuel efficiency and reducing emissions.

The medical field also benefits from conductive plastics. These materials are used in medical devices and diagnostic equipment, where they can improve the functionality and reliability of sensors and other electronic components. Their biocompatibility and ease of sterilization make them ideal for medical applications.

Despite their advantages, conductive plastics face challenges such as achieving consistent conductivity and balancing electrical properties with mechanical strength. Ongoing research aims to address these issues, improving the performance and expanding the capabilities of these materials.

The future of conductive plastics is promising. As technology advances, these materials will play a critical role in the development of flexible electronics, wearable technology, smart textiles, and more. Their versatility, combined with their unique properties, positions conductive plastics as a key component in the next generation of innovative solutions across various industries.

0 notes

Text

KSS Cable Tie supplier in Ahmedabad

KSS Cable Tie supplier in Ahmedabad- Samir Trading

Samir Trading in Ahmedabad proudly serves as a reliable supplier of KSS Cable Ties, crafted from Nylon 66, a robust material known for its durability and strength. As a leading distributor of these essential cable management solutions, Samir Trading ensures high-quality products that meet stringent industry standards.

Cable ties are indispensable in various industries, offering a secure and efficient way to bundle and organise cables and wires. KSS Cable Ties, specifically manufactured from Nylon 66, exhibit excellent tensile strength and resistance to environmental factors such as moisture, chemicals, and UV radiation. This makes them suitable for both indoor and outdoor applications, ensuring longevity and reliability in diverse conditions.

Material: Nylon 66 (UV RESISTANT BLACK)

Carbon black was added for greater resistance to ultraviolet in outdoor usage.

Prolong useful life of cable tie under sunshine/outdoor application.

UV resistant cable tie: for outdoor use with UV features.

Operating Temp :

Features: Cable Tie is an economical & versatile method of cable/wire bunching Systems Cable tie has self locking & one piece construction which ensure the fast & easy installation. Non releasable Cable tie, once locked cannot be opened or reused

Test Certificate : UL, CSA, VDE, DNV, GL, LLOYD, CE, ABS, IP68

Use : For Indoor wiring, Outdoor Wiring, Cable bunching, packing bags, Bundling Pipes, etc

Applications in: Control Panel Manufacturers, Machine Manufacturers, Electrical Contractors, Telecom Industry, Marine Industry, Pharmaceutical Industry, Automobile Industry, Packaging Industry, Chemical Industry, Aviation Industry, Food Industry, Locomotive Industry, Windmills, Information Technology, Shipbuilding Industry, Logistics and Courier, Appliance Manufacturer, Drip Irrigation System.

At Samir Trading, we understand the importance of reliable cable management solutions in optimising efficiency and safety across industries. Our commitment to delivering superior KSS Cable Ties underscores our dedication to customer satisfaction. Whether you are in manufacturing, construction, automotive, or any sector that requires effective cable management, our comprehensive range of KSS Cable Ties caters to your specific needs.

We take pride in our ability to offer not just products, but solutions that enhance operational efficiency and organisation. Our knowledgeable team at Samir Trading provides expert advice and assistance, ensuring you find the right cable ties for your application requirements. By partnering with us, you gain access to a trusted supplier who prioritises quality, performance, and customer service.

As your preferred supplier of KSS Cable Ties in Ahmedabad, Samir Trading remains committed to upholding the highest standards of product excellence and reliability. Whether you need standard cable ties or specialised solutions, we are here to meet your demands with prompt delivery and competitive pricing.

Contact Samir Trading today to discover how our KSS Cable Ties can streamline your cable management processes and contribute to the efficiency and safety of your operations. Experience firsthand why we are the trusted choice for cable ties in Ahmedabad and beyond.

For More Information:

666/5A, Mamunayak's Pole, Nr. Jagat Agencies, Gandhi Road, Ahmedabad - 380001.

792217 0118

#KSS Cable Tie supplier in Ahmedabad#Nylon Cable Tie Supplier in Ahmedabad#Supplier of Nylon Cable Tie#Plastic Cable Tie#SS Cable Tie#Cable Ties in Ahmedabad

0 notes

Text

Jake Seal Black Hangar on the Importance of Sustainability in the Film Industry

The film industry, a powerhouse of creativity and technology, has long been associated with glamour and innovation. However, its environmental impact has increasingly come under scrutiny. Jake Seal Black Hangar, a prominent figure in independent filmmaking, emphasizes the importance of sustainability in this vibrant sector. This blog explores how the film industry can adopt eco-friendly practices and why sustainability is crucial for its future.

The Environmental Impact of Filmmaking

Jake Seal Black Hangar highlights that filmmaking, despite its artistic merits, is a resource-intensive process. From large sets and high energy consumption to waste generation and extensive travel, the environmental footprint of film productions can be substantial. Traditional filmmaking practices often result in significant carbon emissions, contributing to climate change. Therefore, there is an urgent need for the industry to shift towards more sustainable practices.

Sustainable Practices in Film Production

Eco-Friendly Sets: Building sets from sustainable materials and repurposing existing structures can significantly reduce waste. Temporary sets often end up in landfills, but by reusing materials or opting for digital sets, productions can minimize their environmental impact.

Energy Efficiency: According to Jake Seal Black Hangar, utilizing energy-efficient lighting and equipment is another crucial step. LED lights consume less power and have a longer lifespan compared to traditional lighting. Additionally, renewable energy sources such as solar panels can power sets, reducing reliance on fossil fuels.

Waste Management: Implementing robust waste management systems on set can mitigate the environmental impact. Recycling and composting programs can handle waste effectively, while digital scripts and communication reduce paper usage.

Green Transportation: Reducing travel emissions is vital. Opting for electric vehicles, carpooling, or using public transportation can lower the carbon footprint of a production. Additionally, shooting locations can be chosen based on their proximity to minimize travel.

Sustainable Catering: On-set catering can also be more sustainable by providing locally sourced, organic, and plant-based food options. This reduces the carbon footprint associated with food production and transportation.

The Role of Technology in Sustainable Filmmaking

Technology plays a pivotal role in enhancing sustainability in the film industry, states Jake Seal Black Hangar. Advances in digital technology allow for more efficient editing and distribution processes, reducing the need for physical media. Virtual production techniques, which blend live-action footage with computer-generated imagery, can also minimize the need for physical sets and extensive travel.

The Benefits of Sustainable Filmmaking

Environmental Impact: The most apparent benefit of sustainable filmmaking is the reduced environmental impact. By adopting eco-friendly practices, the industry can contribute to global efforts to combat climate change and preserve natural resources.

Cost Savings: Jake Seal Black Hangar points out that sustainable practices often lead to cost savings in the long run. Energy-efficient equipment, waste reduction, and efficient resource management can lower production costs, making sustainability economically viable.

Industry Reputation: As audiences become more environmentally conscious, sustainable practices can enhance a production's reputation. Viewers are more likely to support and engage with content that aligns with their values, fostering a positive image for sustainable filmmakers.

Inspiration for Change: The film industry has the power to influence public opinion and drive social change. By showcasing sustainable practices both on and off-screen, filmmakers can inspire audiences to adopt eco-friendly behaviors in their own lives.

Conclusion

Sustainability in the film industry is not just a trend but a necessity. As the world grapples with environmental challenges, the film industry must play its part in promoting eco-friendly practices. Jake Seal Black Hangar's dedication to sustainability highlights the importance of this shift. By adopting sustainable practices, the film industry can not only reduce its environmental footprint but also inspire change and create a more sustainable future for all.

#jakesealblackhangarstudios#blackhangarstudios#jakesealblackhangar#production#film#filmindustry#jake seal black hangar

0 notes

Text

Fasteners Manufacturer in Azerbaijan - Sachiya Steel International

Fasteners are crucial components in industrial manufacturing, providing the necessary connections and security between parts across various sectors. These mechanical devices, which include bolts, nuts, screws, washers, and rivets, are essential for maintaining the structural integrity and functionality of countless applications. Sachiya Steel International Private Limited of India is renowned for its high-quality fasteners, and its presence in Azerbaijan highlights its commitment to global excellence.

Understanding Fasteners

Fasteners are an extensive array of mechanical components used to join or fasten materials together. Each type of fastener serves a different function depending on factors like material type, load-bearing capacity, and environmental conditions.

Types of Fasteners

Bolts

Nuts

Screws

Washers

Rivets

Fastener Selection

Selecting high-quality fasteners is crucial for maintaining structural integrity, safety, and longevity across various applications. Industries such as construction, automotive, aerospace, and marine manufacturing rely on reliable fastening solutions to meet specific operational challenges.

Sachiya Steel International: Building Excellence

With decades of experience and a cutting-edge manufacturing facility in India, Sachiya Steel International has become an industry leader. Their commitment to precision engineering, superior quality products, and customer satisfaction have earned them global praise.

Product Range and Specializations

Sachiya Steel International offers an extensive portfolio of fasteners to meet the diverse needs of industries worldwide. Their product range includes:

Bolts: High-tensile bolts, hex bolts, socket head bolts, foundation bolts.

Nuts: Hex nuts, lock nuts, wing nuts, square nuts.

Screws: Machine screws, self-tapping screws, wood screws, drywall screws.

Washers: Flat washers, spring washers, toothed lock washers.

Rivets: Blind rivets, solid rivets, pop rivets.

Each product undergoes rigorous quality checks and adheres to international standards such as DIN, ANSI, ASTM, and ISO, ensuring reliability and performance excellence.

Grades of Fasteners Offered

Construction Grade

Specifications: ASTM A307, ASTM F1554 (Grade 36, 55, 105)

Application: Structural applications requiring high strength and durability.

Automotive Grade

Specifications: Grade 8.8, Grade 10.9, Grade 12.9

Application: Automotive assembly, ensuring reliable performance under high stress and vibration conditions.

Aerospace Grade

Specifications: ASTM F568, ASTM F2281

Application: Aerospace and defense applications, meeting stringent safety and reliability standards.

Industrial Grade

Specifications: ASTM A193 (B7, B8, B8M), ASTM A320 (L7, B8, B8M)

Application: General industrial use, offering corrosion resistance and durability in harsh environments.

Global Footprint and Market Reach

Sachiya Steel International has expanded its operations to meet Azerbaijan’s growing demand for premium fasteners. Their distribution network and optimized logistics ensure prompt delivery and excellent customer support.

Customization Capabilities

Sachiya Steel International understands the importance of offering customized solutions. They provide options to customize dimensions, materials (including stainless steel, carbon steel, and alloy steel), finishes (plain, zinc-plated, hot-dip galvanized), and coatings (phosphate, black oxide) to meet specific project needs with flexibility and precision.

Environmental Responsibility and Sustainability

Sachiya Steel International prioritizes sustainability in its manufacturing processes. They invest in eco-friendly technologies, waste reduction initiatives, and energy-saving practices to minimize environmental impact while contributing to global conservation efforts.

Conclusion

Sachiya Steel International Private Limited stands out as the go-to choice for high-quality fasteners in Azerbaijan and beyond. With a legacy built on innovation, reliability, and customer-centricity, Sachiya Steel continues to set standards in the global fastener industry. Whether for large-scale industrial projects or niche applications, Sachiya Steel is ready to offer unparalleled quality and service excellence.

Read More: Fasteners Manufacturer in Azerbaijan

0 notes

Text

The Importance and Future of Tire Recycling

With our planet facing a waste crisis, tire recycling offers a brilliant solution—eliminating waste and creating valuable products. Current technologies are promising, but what does the future hold? Will tire recycling soar to new heights or decline? Know the Importance and Future of Tire Recycling!

Dive into our blog to uncover the trends shaping the future of tire recycling!

Understanding Tire Recycling

Tire recycling repurposes old tires to reduce environmental impact and create useful products. Traditional methods shred tires for various uses, but they have limitations in product quality and diversity.

Challenges in Traditional Tire Recycling Process

Traditional tire recycling methods encounter several hurdles. Recycled rubber quality is often reduced, constraining its uses. There's a global surplus of waste tires, overwhelming recycling capacities. Disposing of non-recyclable tire parts remains a critical environmental issue.

Pyrolysis: A World-Changing Technology

Pyrolysis is an advanced technology poised to transform tire recycling by heating tires without oxygen to produce pyrolysis oil, carbon black, and gas. It recovers valuable resources and reduces waste significantly.

How Pyrolysis Machinery Works

Pyrolysis machinery uses controlled heat to transform tires into valuable products through three key stages: pre-treatment, pyrolysis, and post-treatment. Tires are first shredded or granulated for efficient processing. In the pyrolysis stage, heat breaks down the rubber into oil, carbon black, and gas. The final phase refines and purifies these products for various uses.

Benefits of Pyrolysis Recycling

Pyrolysis recycling stands out with several advantages compared to traditional methods. It produces high-quality products like pyrolysis oil, a viable alternative to fossil fuels. The recovered carbon black finds use in diverse industries such as tire manufacturing, ink production, and construction materials. Moreover, pyrolysis reduces waste significantly, offering a sustainable approach to waste management.

The future of tire recycling

Eco-friendly Products

Recycled tire materials are increasingly used in architecture and fashion, paving the way for a greater array of sustainable products. Expect to see eco-friendly building materials and stylish clothing and accessories crafted from recycled tires, highlighting the versatility of tire recycling in innovative ways that benefit the environment.

Public Awareness

The future of tire recycling hinges on heightened public awareness and education. As environmental consciousness grows and demand for sustainable practices increases, initiatives to recycle tires will gain momentum. Promotional campaigns and outreach programs will play a pivotal role in educating the public about the benefits of tire recycling, encouraging participation in recycling efforts, and fostering a deeper understanding of its positive impact on the environment.

Government Action

Expect increased regulation in the tire recycling sector worldwide, driven by governments' strong focus on environmental conservation. This could include incentives for recycling businesses to adopt greener technologies and stricter waste management laws. Penalties for improper tire disposal may also be enforced, pushing businesses towards more eco-friendly practices.

0 notes

Text

10 Surprising Uses of Charcoal Powder You Need to Know

Introduction to Activated Charcoal Powder

Activated charcoal powder has evolved from a simple folk remedy to a powerhouse in the health and beauty sectors. Made from carbon-rich materials subjected to high temperatures, this fine black powder is endowed with numerous tiny pores, increasing its ability to adsorb a vast array of organic and inorganic compounds. Unlike absorption, adsorption allows charcoal powder to attract and bind substances on its surface, making it a versatile detoxifier and purifier.

Benefits of Activated Charcoal Powder in Skincare

The skin, our largest organ, is continuously exposed to environmental pollutants and toxins. Here, activated charcoal powder shines as a natural skincare ingredient. By binding to dirt and oil trapped in pores, it acts as a potent cleanser that leaves the skin refreshed and pure. It's particularly effective for oily skin, helping to control excessive sebum production and alleviate the discomfort of acne. Moreover, because of its gentle nature, it is suitable for all skin types, helping to soothe and calm irritated skin when used in a face mask or scrub.

Activated Charcoal Powder in Detoxification

Activated charcoal is widely renowned for its detoxification properties in medical settings. It works by intercepting toxins and preventing their absorption in the stomach when taken orally. This same principle applies to its use as a dietary supplement, where it is taken to bind to unwanted substances in the gut, aiding in their elimination and helping cleanse the body. This process can support liver and kidney health by reducing the load of toxins they need to process. It’s important, however, to consult with a healthcare provider before beginning any detox regimen with charcoal to ensure it is safe and effective for your specific health conditions.

READ MORE BLOG :-

Using Activated Charcoal Powder for Oral Health

The oral health benefits of activated charcoal are supported by its ability to adsorb plaque and microscopic tidbits that stain teeth. Used as a toothpaste or powder, activated charcoal can be an effective alternative to conventional whitening methods, which often involve harsh chemicals. It’s also used in mouthwashes where its odor-absorbing properties help combat bad breath, providing a natural solution for maintaining dental hygiene.

Creative Ways to Incorporate Activated Charcoal Powder in Your Routine

Beyond its use in health and beauty, activated charcoal powder can be a handy home remedy for various household applications. It can be placed in musty rooms or refrigerators to neutralize odors, used in terrariums to prevent mold, or added to water pitchers to improve water quality. Its purifying properties are also beneficial in gardening, particularly in preventing fungal growth.

Conclusion: Where to Buy Quality Activated Charcoal Powder

To ensure you reap all the benefits of activated charcoal powder, choosing a high-quality product is crucial. Visit BRM Chemicals Activated Charcoal Powder to explore our pure, finely milled options, ideal for various applications. We are committed to providing products that are both effective and environmentally sustainable.

Shop Now - Elevate your health and beauty routine with our activated charcoal powder. Visit our website BRM Chemicals for more information and to explore our diverse range of high-quality products.

0 notes

Text

Carbon Black Prices Trend | Pricing | Database | Index | News | Chart