#Variable Frequency Drives (VFDs)

Explore tagged Tumblr posts

Text

Increase Production Efficiency with Variable Frequency Drives

Increase production efficiency with Variable Frequency Drives (VFDs) by controlling motor speed based on demand. VFDs help reduce energy use, lower maintenance costs, and improve machine performance. They allow smooth motor startups, reduce wear and tear, and extend equipment life. By adjusting speed as needed, VFDs prevent energy waste and support consistent production flow. This leads to higher productivity, better product quality, and fewer breakdowns. VFDs are ideal for industries like manufacturing, HVAC, and water treatment. Upgrade to VFDs today to make your operations more energy-efficient, cost-effective, and reliable. Optimize your production with smart motor control technology.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#Variable Frequency Drives#Vfds

0 notes

Text

Model Part Number

IP20 rated enclosure

🚨ODV-3-843700-3F12-MN (300HP 370A 380-480V 3Ph Standard EMC Filter)

🚨ODV-3-843700-3R12-MN (300HP 370A 380-480V 3Ph High Performance EMC Filter)

🚨ODV-3-844800-3F12-MN (400HP 480A 380-480V 3Ph Standard EMC Filter)

🚨ODV-3-844800-3R12-MN (400HP 480A 380-480V 3Ph High Performance EMC Filter)

IP55 / NEMA12 rated enclosure

🚨ODV-3-843700-3F1N-MN (300HP 370A 380-480V 3Ph Standard EMC Filter)

🚨ODV-3-843700-3R1N-MN (300HP 370A 380-480V 3Ph High Performance EMC Filter)

🚨ODV-3-844800-3F1N-MN (400HP 480A 380-480V 3Ph Standard EMC Filter)

🚨ODV-3-844800-3R1N-MN (400HP 480A 380-480V 3Ph High Performance EMC Filter)

The VFD Exchange

#vfds#drives#variable#frequency#drive#invertekdrives#industrialcontrols#electricmotor#automation#fans#pumps#compressors#farming#irrigation#ventilation#hvac#speed#torque#optidrive#invertek#electrical#motors

0 notes

Text

How to Maximize ROI with Variable Frequency Drives?

Variable frequency drives (VFDs) are an attractive energy management investment for your motors. They are also an effective way to decrease the cost of running motors with variable torque loads like as HVAC systems.

By slowing down the motor to meet the demand, a VFD decreases the power required to keep the load moving. So, this blog will discuss how they help save energy bills along with boosting ROI.

Let’s see how.

How Do VFDs Work?

A variable frequency drive (VFD), which is also called an AC drive or inverter, is a type of motor controller that drives an AC motor by changing the voltage and frequency that is supplied to the motor. This saves a lot of electrical energy and allows operators to accurately set the speed of the motor to the precise level of the required load.

Methods to Maximize ROI with VFDs

1. Choose the Right VFD for Your Application

Every VFD is different. Therefore, you need to consider a few things like:

Motor Compatibility – Match the VFD specifications with your motor's voltage and power rating.

Environmental Conditions – Ensure the VFD is suitable for the operating environment (dust, heat, moisture, etc.).

Application Needs – Different industries require different VFD types—select accordingly for pumps, fans, conveyors, or HVAC systems.

2. Optimize Energy Efficiency

Energy savings are the biggest driver of VFD adoption. To maximize efficiency:

Avoid Running Motors at Full Speed – Adjust speeds based on demand to prevent excess energy use.

Monitor and Analyze Power Consumption – Use built-in monitoring features to track energy savings.

Leverage Regenerative Braking – In applications like elevators, regenerative braking helps save energy by converting excess power into usable electricity.

3. Reduce Maintenance Costs

A well-implemented VFD system lowers maintenance costs significantly.

Soft Start Function Reduces Wear – Unlike traditional soft start motor starters, VFDs gradually ramp up speed, minimizing mechanical stress.

Eliminate Mechanical Drive Components – Using VFDs eliminates the need for belts and gears, which often require regular maintenance.

Monitor Motor Health – Many VFDs have built-in diagnostics to detect potential issues before they lead to failures.

4. Compare Variable Frequency Drive Price vs. Long-Term Benefits

When investing in VFDs, look beyond the initial cost.

Higher Efficiency Equals Faster ROI – A higher-priced, high-efficiency VFD can offer greater savings over time.

Consider Incentives and Rebates – Many governments and utility companies offer incentives for energy-efficient motor control solutions.

Factor in Downtime Reduction – VFDs decrease machine downtime by preventing motor damage, contributing to cost savings.

5. Implement Smart Automation

Modern VFDs integrate with smart automation systems to optimize operations. They can communicate with sensors to adjust motor speed dynamically. Even the cloud-based systems enable real-time monitoring and troubleshooting. Operators, hence can adjust the speed based on real-time demand and avoid unnecessary energy use.

Final Thoughts

In the end, using a clean VFD with a motor saves significant energy. However, initially, you have to pay a significant variable frequency drive price, but one can enjoy numerous benefits that they offer. These help lower material, labor, and other expenses along with improving efficiency and reducing maintenance costs. With VFDs, you can optimize your motor control and lower energy bills.

0 notes

Text

Variable Frequency Drive (VFD)

Amtech Electronics India Limited is a leading Variable Frequency Drive (VFD) manufacturer in India, established in 1987 and headquartered in Gandhinagar. Specializing in motor control and automation solutions, the company offers a wide range of VFDs, including the Axpert-Eazy+ Series (0.75–2100 kW) and Regenerative VFDs (4Q Series), designed for energy efficiency, precision control, and compliance with global standards like IEEE-519:2014 for harmonics. Their products cater to industries such as cement, automotive, and renewable energy, with clients including Ambuja Cement and Bajaj Auto.

Amtech’s VFDs feature advanced technologies like IGBT-based PWM control, sensorless vector control, and low harmonic distortion (<5%), ensuring robust performance in harsh environments. The company is ISO 9001:2015 certified and adheres to international safety norms (CE, UL, CSA), with a focus on green technology and energy-saving solutions. Their portfolio also includes medium-voltage drives, soft starters, and power quality products like Active Harmonic Filters, supporting India’s Make in India initiative.

With over three decades of expertise, Amtech combines innovation with reliability, making it a trusted partner for industrial automation and sustainable motor control solutions. For more details contact us!

#Variable Frequency Drive (VFD)#Variable Frequency Drive#Variable Frequency Drive Manufacturer#vfd#VFD Manufacturer#VFD Manufacturer in India

1 note

·

View note

Text

The Evolution and Advantages of a VFD Pump in Industrial Applications

The introduction of Variable Frequency Drive (VFD) pumps is considered a tremendous advancement in pump technology. Unlike standard pumps that function at a fixed speed, VFD pumps can control the speed of their motors to match variable requirements this feature proves to be a remarkable development in energy savings and improves efficiency during operation. In today's time, the importance of this capability is more than ever since sustainability and cost-effectiveness spell the very life of industry. VFD pumps optimize the speed control of the pump motor, thereby minimizing energy consumption and reducing the number of components that wear down improve process control, thus proving its worth in all industries.

#Automation#PLC#VFD#Automotive#Tech#information technology#technolgy#plc automation#vfdsystem#vfd#Variable Frequency Drive (VFD)#acdrives#ac drives#allen bradley#Rockwell Automation

1 note

·

View note

Text

Low Harmonic Drives: Driving Towards a Greener Future How Clean Power is Empowering the Automotive Industry

Over the past few decades, variable frequency drives (VFDs) have become widespread in industrial and commercial applications for their ability to control motor speed and torque. Traditionally, VFDs utilize pulse width modulation (PWM) techniques to vary motor voltage and frequency. However, PWM generates high harmonic currents that can damage motors, heat up transformers and power cables, and potentially cause voltage distortions on the utility grid. To address these challenges, a new generation of low harmonic drives has emerged based on advanced switching algorithms. What are Harmonics? In electrical systems, harmonics refer to sinusoidal voltages or currents having frequencies that are integer multiples of the fundamental power supply frequency, usually 50 or 60 Hz. Harmonics are produced by non-linear loads like adjustable speed drives that draw non-sinusoidal currents from the power source. The extra frequencies generated interact with the system impedance and generate losses, heating, vibrations, torque pulsations and can even cause misoperation of protective devices if sufficiently high in magnitude. Harmonics cause additional power losses in distribution transformers and overvoltages that reduce insulation lifetime. They can also interfere with communication lines. Traditional PWM Drives and their Harmonic Impact Traditional PWM VFDs employ insulated-gate bipolar transistors (IGBTs) or thyristors to rapidly switch the motor voltages on and off, generating quasi-square wave voltages to control motor speed. However, when these non-sinusoidal voltages are applied to the motor windings, they produce harmonic currents in the supply lines that are integer multiples of the fundamental supply frequency. Specifically, PWM drive techniques generate dominant 5th and 7th order harmonics that can propagate back into the utility system if not properly filtered. The harmonic currents not only stress motor windings but also increase I2R losses in the supply feeders and distribution transformers. Low Harmonic Drives can cause overheating in older transformers not designed for harmonics. Harmonic distortions also increase circulating currents within delta-wye grounded transformers. To mitigate these issues, dedicated harmonic filters need to be installed, increasing overall system costs. Excessive harmonics if left unchecked can even cause protective relays to malfunction. Advancements in Low Harmonic Drive Technology To address harmonic pollution from VFDs, innovative drive manufacturers have developed new low harmonic drive technologies based on advanced switching algorithms that naturally minimize the generation of lower order harmonics. Pulse-Density Modulation

One such technique is pulse density modulation (PDM) where the IGBTs are switched at high frequencies using narrower pulses compared to traditional square waves. By spacing the pulses closer together over time, PDM produces quasi-sinusoidal drive output voltages that inherently contain lower harmonics. PDM drives generate less than 5% total harmonic distortion (THD) without additional filters. Active Front End Drives

Another option is active front end (AFE) drives with a front-end rectifier consisting of IGBTs or MOSFETs instead of diode bridges. The AFE rectifier actively shapes the supply current waveform to follow the voltage waveform and provide near unity power factor without harmonics. AFE drives come with integrated DC chokes to absorb any remaining higher order harmonics internally, keeping them well below 5% THD.

Get more insights on Low Harmonic Drives

Also read related article on Ransomware Protection Market

Unlock More Insights—Explore the Report in the Language You Prefer

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Low Harmonic Drives#Harmonic Mitigation#Low Harmonic VFD#Variable Frequency Drives#Harmonic Distortion Reduction#Energy-Efficient Drives#Harmonic Filters

0 notes

Text

The Power of VFDs: How Variable Frequency Drives Enhance Industrial Performance

In the Scope of industrial automation, efficiency and control are crucial for optimizing performance and reducing operational costs. Variable Frequency Drives (VFDs) have emerged as a powerful tool in achieving these goals. By allowing precise control over motor speed and torque, VFDs enhance industrial performance across a wide range of applications. This blog explores how VFDs work, their benefits, and their impact on industrial processes.

What Are Variable Frequency Drives (VFDs)?

Variable Frequency Drives (VFDs) are electronic devices used to control the speed and moment of electric motors by varying the frequency and voltage supplied to the motor. Unlike traditional motor control systems that operate at a fixed speed, VFDs adjust motor speed dynamically, based on the specific needs of the application.

A VFD system typically consists of three main components:

Rectifier: Converts incoming AC power to DC power.

DC Bus: Filters and smooths the DC power.

Inverter: Converts DC power back to AC power at the desired frequency and voltage.

How VFDs Enhance Industrial Performance

Energy Efficiency: VFDs are famous for their energy-saving capabilities. By adjusting the motor speed to match the load requirements, VFDs reduce energy consumption. For example, in applications such as fans and pumps, where speed adjustments can lead to significant energy savings, VFDs help lower electricity costs and improve overall energy efficiency.

Improved Process Control: With VFDs, operators can fine-tune motor speeds to optimize process performance. This precise control ensures that machinery operates at the optimal speed for various production stages, leading to enhanced product quality and reduced wear and tear on equipment.

Extended Equipment Life: VFDs reduce mechanical stress on motors and associated components by allowing gradual acceleration and deceleration. This minimizes the impact of sudden starts and stops, extending the lifespan of equipment and reducing maintenance needs.

Reduced Operational Costs: By improving energy efficiency and reducing maintenance requirements, VFDs help lower overall operational costs. The initial investment in VFD technology is often offset by long-term savings in energy bills and maintenance expenses.

Enhanced Flexibility: VFDs offer flexibility in industrial applications, allowing for easy adjustments to motor speed and performance. This flexibility is beneficial for processes that require variable speeds or frequent changes in operational conditions.

Noise Reduction: VFDs can help reduce noise levels in industrial environments by controlling motor speed more smoothly. This is particularly useful in applications where noise reduction is a priority, such as in HVAC systems and manufacturing facilities.

Improved Safety: By providing smoother starts and stops, VFDs contribute to safer operation. This gradual control reduces the risk of mechanical failures and accidents associated with abrupt changes in motor speed.

Applications of VFDs

VFDs are employed across various industries, including:

Manufacturing: For controlling transport belts, pumps, and fans.

HVAC: In heating, ventilation, and air conditioning systems to regulate airflow and temperature.

Water Treatment: To manage pumps and motors in water and wastewater treatment facilities.

Mining: For controlling crushers, mills, and other mining equipment.

Future Trends in VFD Technology

As technology continues to advance, VFDs are becoming increasingly sophisticated. Future trends include:

Integration with IoT: Enhanced connectivity for remote monitoring and control.

Advanced Analytics: Data-driven insights for predictive maintenance and process optimization.

Improved Energy Efficiency: More efficient designs and energy-saving features.

0 notes

Text

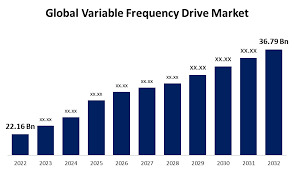

Variable Frequency Drive Market Will Reach USD 35.34 Billion By 2030

The variable frequency drive market is witnessing growth and is projected to reach USD 35.34 billion by 2030. This can be credited to the growing need for energy-effective electrical equipment like fans, motors, and pumps, and rising government guidelines in this field. Fast industrial development is also one of the major reasons propelling the need for these drives. With more and more sectors…

View On WordPress

#energy efficiency#HVAC#industrial applications#Key players#Manufacturing#market trends#Motor Control#Oil & Gas#Variable Frequency Drive#VFD Market

0 notes

Text

#industrial control panel#control panels#electrical control panel#control panel manufacturer#ac to dc panel#vfd#variable frequency drives#control panel#control panel suppliers in india#control panel manufacturers in ahmedbad

0 notes

Text

Siemens A1-116-180-504 Is.03 Base Drive - auto2mation

The Siemens A1-116-180-504 Is.03 Base Drive is a high-quality component designed for reliable motor control in industrial automation systems. Known for its durability and precision, this Siemens base drive supports efficient performance in demanding applications. It is easy to install and integrate, making it a smart choice for engineers and maintenance teams. Ideal for use in manufacturing and process industries, the A1-116-180-504 helps reduce downtime and improve system stability. Trust Siemens for advanced technology and dependable automation solutions. Buy now from Auto2mation – your trusted source for industrial and marine automation parts. Fast shipping and expert support available

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#VFDs#Drives#variable frequency drives

0 notes

Text

Horsepower Model Part Number

IP20 rated enclosure

🚨ODP-2-84300-3HF42-MN (300HP 370A 380-480V 3Ph Standard EMC Filter)

🚨ODP-2-84300-3HR42-MN (300HP 370A 380-480V 3Ph High Performance EMC Filter)

🚨ODP-2-84400-3HF42-MN (400HP 480A 380-480V 3Ph Standard EMC Filter)

🚨ODP-2-84400-3HR42-MN (400HP 480A 380-480V 3Ph High Performance EMC Filter)

IP55 / NEMA12 rated enclosure

🚨ODP-2-84300-3HF4N-MN (300HP 370A 380-480V 3Ph Standard EMC Filter)

🚨ODP-2-84300-3HR4N-MN (300HP 370A 380-480V 3Ph High Performance EMC Filter)

🚨ODP-2-84400-3HF4N-MN (400HP 480A 380-480V 3Ph Standard EMC Filter)

🚨ODP-2-84400-3HR4N-MN (400HP 480A 380-480V 3Ph High Performance EMC Filter)

Kilowatt Model Part Number

IP20 rated enclosure

🚨ODP-2-84200-3KF42-MN (200kW 370A 380-480V 3Ph Standard EMC Filter)

🚨ODP-2-84200-3KR42-MN (200kW 370A 380-480V 3Ph High Performance EMC Filter)

🚨ODP-2-84250-3KF42-MN (250kW 480A 380-480V 3Ph Standard EMC Filter)

🚨ODP-2-84250-3KR42-MN (250kW 480A 380-480V 3Ph High Performance EMC Filter)

IP55 / NEMA12 rated enclosure

🚨ODP-2-84200-3KF4N-MN (200kW 370A 380-480V 3Ph Standard EMC Filter)

🚨ODP-2-84200-3KR4N-MN (200kW 370A 380-480V 3Ph High Performance EMC Filter)

🚨ODP-2-84250-3KF4N-MN (250kW 480A 380-480V 3Ph Standard EMC Filter)

🚨ODP-2-84250-3KR4N-MN (250kW 480A 380-480V 3Ph High Performance EMC Filter)

The VFD Exchange

#vfds#drives#variable#frequency#drive#invertekdrives#industrialcontrols#electricmotor#automation#manufacturing#speed#torque#optidrive#invertek#electrical#motors

0 notes

Text

Understanding Scalar and Vector Control in VFDs

Variable Frequency Drives (VFDs) are a game-changer in the world of industrial automation. They help control the speed and torque of electric motors, leading to energy efficiency and improved performance. But did you know there are two main control strategies in VFDs? These are Scalar Control and Vector Control. Each has its strengths and is suited for different applications. Let's dive deep into these two control methods and understand how they work.

What is Scalar Control in a VFD?

Scalar control is the simplest and most widely used method for controlling a VFD variable frequency drive. It focuses on adjusting voltage and frequency in a proportional manner. This method is also known as V/f control (Voltage-to-Frequency control).

How Does Scalar Control Work?

In scalar control, the VFD maintains a constant ratio between voltage and frequency. For example, if a motor runs at 50 Hz with 400V, reducing the frequency to 25 Hz will adjust the voltage to 200V. This keeps the motor's magnetic field stable and ensures smooth operation.

Advantages of Scalar Control

Easy to implement – Simple setup and programming.

Cost-effective – Suitable for applications where precision is not critical.

Reliable for steady loads – Works well in fan and pump applications.

Limitations of Scalar Control

Poor dynamic response – Not suitable for applications requiring rapid speed changes.

Limited torque control – Not ideal for high-torque applications.

Not suitable for precise positioning – Lacks accuracy for robotics or CNC machines.

What is Vector Control in a VFD?

Vector control, also called field-oriented control (FOC), is a more advanced method. It allows independent control of motor torque and flux. This makes it ideal for applications requiring high precision and fast response.

How Does Vector Control Work?

Vector control works by breaking down the motor's magnetic field into two separate components:

Flux-producing component – Controls the magnetizing effect of the motor.

Torque-producing component – Controls the rotational force (torque).

By separately controlling these components, the frequency drive can achieve precise motor control, even at low speeds.

Advantages of Vector Control

High precision – Ensures accurate speed and torque control.

Fast dynamic response – Ideal for applications requiring quick acceleration and deceleration.

More torque at low speeds – This makes it perfect for heavy-duty applications.

Limitations of Vector Control

More complex – Requires advanced tuning and setup.

Higher cost – More expensive compared to scalar control.

Needs feedback sensors – Some vector control methods require encoders for accurate control.

Scalar vs. Vector Control – Which One to Choose?

If you need a VFD variable frequency drive for a simple application like a fan or pump, scalar control is sufficient. But if you need high precision, fast response, and more torque, vector control is the better choice.

Conclusion

Understanding the difference between scalar and vector control helps in selecting the right frequency drive for your needs. While scalar control is easy and cost-effective, vector control offers superior performance and accuracy. If your application requires precise control, vector control is worth the investment. Otherwise, for basic applications, scalar control works just fine.

With the right VFD variable frequency drive, you can improve efficiency, reduce energy consumption, and enhance the lifespan of your motors.

0 notes

Text

A soft starter is an electronic device used to control the acceleration and deceleration of electric motors. It regulates the voltage supplied to the motor during startup, gradually increasing it from zero to the desired speed. Unlike traditional direct-on-line (DOL) starters that apply full voltage to the motor instantaneously, soft starters ensure a controlled and adjustable startup process.

Working Principles of a Soft Starter

One of the primary functions of a soft starter is to gradually ramp up the voltage applied to the motor. This soft acceleration helps reduce the mechanical stress on the motor's windings and shaft, preventing sudden jerks or shocks during the startup process. By smoothly increasing the voltage, the soft starter allows the motor to reach its full speed without excessive current draw.

Smooth Transition to Full Speed

Once the motor reaches its desired speed, the soft starter ensures a seamless transition to full voltage operation. It monitors the motor's speed and adjusts the voltage supply accordingly to maintain a steady rotation. This feature eliminates sudden jolts or vibrations that could occur during the transition from startup to normal operation.

Types of Soft Starters

Soft starters are available in different configurations, each offering unique features and benefits. The three common types of soft starters are:

Primary Resistance Soft Starter

The primary resistance soft starter employs a series of resistors connected in line with the motor windings. During startup, these resistors limit the initial current flow, gradually reducing their resistance as the motor gains speed. While this type of soft starter provides a simple and cost-effective solution, it dissipates energy in the resistors, resulting in energy losses.

Autotransformer Soft Starter

Autotransformer soft starters use tapped windings on an autotransformer to control the voltage applied to the motor. By adjusting the tap position, the soft starter regulates the voltage level and provides a smooth startup. Autotransformer soft starters are known for their energy efficiency and compact design, making them suitable for a wide range of applications.

Solid-State Soft Starter

Solid-state soft starters utilize power electronics to control the motor's voltage during startup. They employ semiconductor devices like thyristors or silicon-controlled rectifiers (SCRs) to adjust the voltage supply smoothly. Solid-state soft starters offer precise control over the acceleration and deceleration of the motor, making them highly versatile and efficient.

Variable Frequency Drives (VFDs)

While soft starters are effective in controlling the motor's starting current and torque, variable frequency drives (VFDs) offer additional benefits, including speed control and energy savings.

Conclusion

Kimo Instruments, a renowned manufacturer of precision measurement instruments, has made significant contributions to the field of soft starter technology. Soft starters provide an efficient and reliable solution for controlling the starting current and torque of electric motors. By gradually ramping up the voltage and offering precise control over the acceleration process, soft starters minimize mechanical stress, enhance motor performance, and extend the lifespan of motor-driven systems.

#How-Does-a-Soft-Starter-Work#VFDs#Soft-Starter#Electronic-Devices#Variable-Frequency-Drives#Kimo-Instruments#Working-Principles

0 notes

Text

How Switchgears Contribute to Power Quality and Equipment Longevity

In today’s industrial landscape, facility uptime, energy efficiency, and equipment lifespan are directly tied to power quality. Poor power quality doesn’t just inflate energy costs — it silently wears down critical machinery, causes unexpected shutdowns, and leads to costly repairs. One often overlooked hero in this equation is the switchgear. Modern switchgears do far more than just control and protect power circuits; they actively safeguard power quality and extend the life of your equipment.

In this article, we’ll explore the vital role switchgears play in maintaining power quality and ensuring long-term reliability in industrial and commercial facilities.

Understanding Power Quality: Why It Matters

Power quality refers to the stability, reliability, and cleanliness of the electrical power supplied to equipment. Factors that degrade power quality include:

· Voltage sags and swells

· Harmonic distortion

· Transient surges

· Frequency variations

· Imbalance between phases

When power quality is compromised, sensitive equipment like drives, motors, PLCs, and even lighting systems can suffer reduced lifespan, malfunction, or complete failure. High-quality power is not a luxury; it’s a necessity for operational efficiency and safety.

Switchgears: The Gatekeepers of Power Integrity

Switchgears serve as the nerve center of power distribution in any facility. Here’s how modern switchgear solutions help maintain and enhance power quality:

1. Voltage Regulation and Stabilization

Advanced switchgears monitor voltage levels in real time and protect equipment from harmful sags or swells. Features like automatic voltage regulation and voltage balancing ensure your sensitive loads receive stable power, preventing stress on motors and electronic devices.

2. Harmonic Filtering

Some modern switchgear systems come integrated with harmonic filters or support external filtering solutions. Harmonics generated by variable frequency drives (VFDs), UPS systems, and other non-linear loads can cause overheating and inefficiencies. Switchgears mitigate these distortions, protecting downstream equipment and improving overall energy efficiency.

3. Surge and Transient Protection

Switchgears equipped with surge protection devices (SPDs) act as the first line of defense against voltage spikes and transient surges caused by lightning strikes or grid switching events. This protection extends the life of connected equipment by shielding them from these destructive forces.

4. Fault Isolation and Selectivity

When a fault occurs, fast-acting circuit breakers within the switchgear isolate the problem area without disrupting power to the entire facility. This selectivity ensures that critical processes continue running while the fault is contained, preventing system-wide stress and downtime.

5. Power Factor Correction (PFC)

Switchgears can be integrated with power factor correction capacitors that optimize the power factor, reducing losses and improving voltage stability. A better power factor not only saves on utility bills but also reduces the strain on transformers and generators, thus enhancing their longevity.

Equipment Longevity: The Silent Benefit of Quality Power

The connection between switchgears and equipment lifespan is profound:

· Motors last longer when protected from voltage imbalances and harmonics.

· Transformers operate cooler and more efficiently when power factor is optimized.

· Variable Speed Drives (VSDs) avoid overheating when shielded from surges and harmonic distortions.

· Sensitive electronic controls avoid malfunction due to transient spikes and voltage dips.

In essence, well-maintained and properly specified switchgear reduces the electrical “stress” that causes premature equipment aging and failure.

The Shift Toward Digital and Smart Switchgears

The rise of digital switchgear takes power quality management to the next level. Smart switchgears offer:

· Continuous real-time monitoring of voltage, current, harmonics, and power factor

· Predictive analytics to forecast equipment wear and prevent failures

· Remote control and automated fault response for faster issue resolution

Facilities that embrace digital switchgear solutions can transform their maintenance strategies from reactive to proactive, leading to even longer equipment lifespans and lower total ownership costs.

Practical Steps: How to Maximize the Benefits

To harness the full power quality and longevity benefits from switchgears, consider the following best practices:

· Regular Maintenance: Inspect and test switchgear components to ensure optimal performance.

· Correct Specification: Choose switchgears rated for your facility’s load characteristics and future growth.

· Integration with Monitoring Systems: Leverage real-time data to track power quality indicators.

· Invest in Smart Solutions: Upgrade to digital switchgears with built-in diagnostics and analytics.

Conclusion: Switchgears as Strategic Assets

Switchgears are far more than circuit controllers; they are strategic assets that can directly impact your facility’s operational excellence. By stabilizing power quality, filtering disturbances, and protecting against electrical faults, switchgears extend the service life of every connected piece of equipment — from heavy-duty motors to delicate electronic controls.

For engineers, procurement managers, and facility operators, investing in high-quality, modern switchgear solutions isn’t just about compliance — it’s about securing long-term savings, boosting reliability, and optimizing performance.

#low voltage#switchgear#electrical#electrical supplies#911 abc#artists on tumblr#cats of tumblr#cookie run kingdom#batman#arcane#f1#jason todd#electricity#electric vehicles#ides of march

6 notes

·

View notes

Text

Benefits of VFDs in the food and beverage industry

Benefits of VFDs in the food and beverage industry

Variable Frequency Drives (VFDs) are indispensable in the food and beverage industry due to their numerous benefits. Firstly, they contribute significantly to energy efficiency by allowing precise control of motor speed according to process demand, resulting in substantial energy savings. Additionally, VFDs enable enhanced process control and optimization by providing precise speed and torque control, ensuring consistent product quality.

#automation#trending#tumblr trends#viralpost#viral#bestdeals#trendingnow#allen bradley#rockwell automation#plc#vfdsystem#vfd#food and beverages

2 notes

·

View notes

Text

Ok, I have a story like this from my own experience: that guy at the job interview I had some time ago, who tried to "explain" to me, what an inverter was. The problem was, that he confused a power inverter with a VFD (variable frequency drive), said it was the same, while it's obviously not. Like... Dude, at my former job I literally designed inverter systems, you don't know it better than me. The only person, you're making an idiot of is yourself.

More examples of the WORST mansplaining here.

186K notes

·

View notes