#Vibration Sensor Market

Text

Vibration Sensor Market Size, Share, Trends, Outlook, Forecast 2024-2032

According to IMARC Group latest report titled “Vibration Sensor Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032”, offers a comprehensive analysis of the industry, which comprises insights on vibration sensor market forecast. The report also includes competitor and regional analysis, and contemporary advancements in the global market.

The global vibration sensor market size reached US$ 4.5 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 7.4 Billion by 2032, exhibiting a growth rate (CAGR) of 5.4% during 2024-2032.

Request a Free Sample Report: https://www.imarcgroup.com/vibration-sensor-market/requestsample

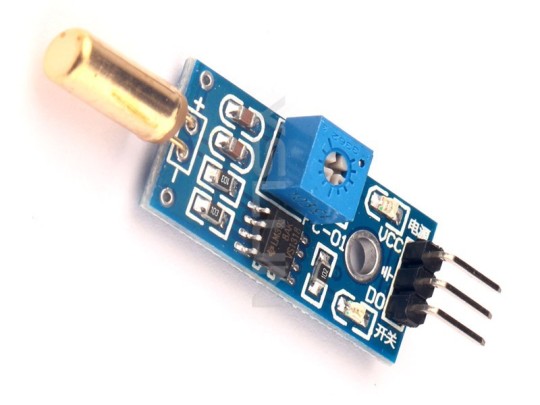

A vibration sensor, also known as an accelerometer or vibration transducer, is a device designed to detect and measure vibrations in machinery or structures. It converts mechanical vibrations into electrical signals, providing valuable data for monitoring equipment health and identifying potential issues. Vibration sensors are widely used in various industries, including manufacturing, aerospace, automotive, and infrastructure. They help prevent equipment failure, reduce maintenance costs, and enhance overall operational efficiency by detecting abnormal vibrations that may indicate misalignments, imbalance, or wear. The collected data aids in predictive maintenance strategies, ensuring timely intervention and preventing unexpected breakdowns in machinery or structural components.

Market Trends:

The global market is majorly driven by the increasing emphasis on predictive maintenance. In line with this, industries worldwide are increasingly adopting predictive maintenance strategies, leveraging vibration sensors to monitor equipment health. These sensors play a pivotal role in detecting abnormalities in machinery early on, reducing downtime, and optimizing maintenance schedules. Furthermore, the rise of Industry 4.0 and the broader trend of industrial automation contribute significantly to the market's growth. Vibration sensors are integral components of smart manufacturing systems, enabling real-time monitoring and control of machinery. This facilitates data-driven decision-making, improves overall equipment effectiveness, and supports the transition toward more efficient and connected industrial processes. Besides, the expanding use of vibration sensors in diverse applications, including automotive, aerospace, healthcare, and infrastructure, drives market diversification. In the automotive sector, for example, vibration sensors contribute to vehicle safety and performance monitoring. In healthcare, they play a role in medical diagnostics and monitoring equipment. Additionally, rapid technological advancements, particularly in sensor design and data analytics, enhance the capabilities of vibration sensors. Integrated wireless communication and Internet of Things (IoT) connectivity enable seamless data transmission and remote monitoring, fostering the adoption of these sensors across various industries.

View Full Report with TOC & List of Figure: https://www.imarcgroup.com/vibration-sensor-market

Competitive Landscape

The competitive landscape of the industry has also been examined along with the profiles of the key players operating in the market.

Analog Devices Inc.

Bosch Sensortec GmbH (Robert Bosch GmbH)

Dytran Instruments Inc.

Emerson Electric Corp.

FUTEK Advanced Sensor Technology Inc.

Hansford Sensors Ltd.

Honeywell International Inc.

National Instruments Corporation

NXP Semiconductors N.V.

Rockwell Automation

Safran Colibrys SA

SKF

TE Connectivity Ltd.

Texas Instruments Incorporated.

Key Market Segmentation:

Our report has categorized the market based on region, product, technology, material, and end-use industry.

Breakup by Product:

Accelerometers

Velocity Sensors

Non-Contact Displacement Transducers

Others

Breakup by Technology:

Piezoresistive

Strain Gauge

Variable Capacitance

Optical

Others

Breakup by Material:

Doped Silicon

Piezoelectric Ceramics

Quartz

Breakup by End-Use Industry:

Automotive

Healthcare

Aerospace and Defence

Consumer Electronics

Industrial Machinery

Others

Breakup by Region:

North America (United States, Canada)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Asia Pacific (China, Japan, India, Australia, Indonesia, South Korea, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

Key Highlights of the Report:

Market Performance (2018-2023)

Market Outlook (2024-2032)

Porter’s Five Forces Analysis

Market Drivers and Success Factors

SWOT Analysis

Value Chain

Comprehensive Mapping of the Competitive Landscape

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

0 notes

Text

Predictive Maintenance Technologies: Key Drivers and Opportunities for 2031

The Predictive Maintenance Market is on a significant growth trajectory, with projections estimating it will reach $79.1 billion by 2031, growing at an impressive compound annual growth rate (CAGR) of 30.9% from 2024 to 2031, according to the latest publication by Meticulous Research®. This surge reflects the increasing demand for advanced maintenance solutions that aim to lower operational costs, enhance asset performance, and manage complex infrastructure systems more effectively.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5936

Market Drivers and Opportunities

The robust growth in the predictive maintenance sector is largely driven by the need to reduce maintenance expenses and improve the efficiency of asset management. Predictive maintenance offers a proactive approach, utilizing advanced analytics and real-time data to forecast equipment failures before they occur, thereby minimizing downtime and optimizing maintenance schedules.

One of the key growth drivers is the rising adoption of predictive maintenance technologies across various sectors, particularly in complex infrastructure systems. As industries strive to leverage data-driven insights to boost performance and reliability, predictive maintenance has become integral to their operational strategies. Additionally, the expansion of predictive maintenance solutions into healthcare devices and navigation systems presents new growth opportunities for market participants.

Challenges and Market Constraints

Despite the optimistic outlook, the predictive maintenance market faces several challenges. Data privacy and security concerns pose significant constraints, as organizations must safeguard sensitive information while implementing predictive maintenance technologies. Moreover, the industry grapples with a shortage of skilled workforce capable of managing and interpreting the sophisticated technologies involved in predictive maintenance.

Technological Advancements and Trends

The integration of cutting-edge technologies such as digital twins and augmented reality (AR) is transforming the predictive maintenance landscape. Digital twins—virtual replicas of physical assets—allow for real-time monitoring and simulation, enhancing predictive maintenance capabilities. Meanwhile, AR technologies are facilitating more interactive and immersive maintenance experiences, enabling technicians to visualize and address potential issues more effectively.

Market Segmentation and Insights

The predictive maintenance market is segmented into various categories, each contributing to its overall growth. Here's a detailed breakdown of these segments:

Offering

Software: In 2024, software is anticipated to dominate the predictive maintenance market, capturing over 81.0% of the share. The significant share is attributed to the growing need for software solutions to streamline maintenance activities, ensure compliance, and provide valuable insights into equipment performance and maintenance trends.

Services: Although starting from a smaller base, the services segment is expected to exhibit the highest CAGR during the forecast period. This growth is driven by the increasing demand for predictive maintenance services to analyze equipment data and identify potential issues, coupled with the integration of IoT, AI, and machine learning for real-time monitoring.

Hardware: This segment includes sensors (such as vibration, temperature, pressure, acoustic, and ultrasonic sensors), data acquisition systems, connectivity devices, and other hardware components. Hardware plays a crucial role in collecting and transmitting data for predictive maintenance solutions.

Deployment Mode

Cloud-Based Deployments: Projected to account for over 58.0% of the market share in 2024, cloud-based deployments are favored for their scalability and advanced analytics capabilities. These platforms enable businesses to handle large volumes of data and leverage cloud computing resources for predictive modeling and real-time analysis.

On-Premise Deployments: While on-premise solutions offer greater control over data and infrastructure, the cloud-based segment is expected to grow at a faster rate due to the increasing preference for cloud solutions in managing and analyzing predictive maintenance data.

Organization Size

Large Enterprises: Expected to hold over 74.0% of the market share in 2024, large enterprises benefit from predictive maintenance to avoid costly unplanned downtime and repairs. The ability to monitor equipment health in real time and take proactive measures is crucial for maintaining operational efficiency.

Small & Medium-Sized Enterprises (SMEs): The SME segment is projected to grow at the highest CAGR during the forecast period. SMEs are increasingly adopting predictive maintenance to automate equipment monitoring, comply with regulatory requirements, and enhance operational efficiency.

Technology

Internet of Things (IoT): The IoT segment is anticipated to capture the largest market share in 2024. IoT-based predictive maintenance provides real-time data on equipment performance, aiding in early failure detection and improved technician efficiency.

AI and Machine Learning (ML): The AI and ML segment is expected to grow at the highest CAGR, driven by the adoption of AI for real-time analytics and predictive modeling. AI and ML algorithms enhance energy efficiency and reduce the environmental footprint of industrial operations.

Application

Temperature Monitoring: Expected to account for over 26.0% of the market share in 2024, temperature monitoring is crucial for early intervention and preventive action. This application helps in detecting equipment malfunctions and scheduling maintenance activities.

Vibration Analysis: While starting from a smaller base, vibration analysis is projected to grow at the highest CAGR. This application aids in detecting, measuring, and analyzing vibrations in machinery, thereby enhancing product quality and reducing downtime.

End-Use Industry

Manufacturing: The manufacturing sector is anticipated to hold over 30.0% of the market share in 2024. Predictive maintenance is widely adopted to avoid unscheduled downtime and improve production efficiency as part of Industry 4.0 initiatives.

Healthcare: The healthcare segment is expected to grow at the highest CAGR, driven by the increasing use of IoT and telematics in healthcare facilities. Predictive maintenance helps in monitoring medical equipment and ensuring timely maintenance.

Geography

North America: Expected to hold over 33.0% of the market share in 2024, North America leads the predictive maintenance market due to the high demand in the healthcare sector, technological advancements, and a robust industrial base.

Asia-Pacific: The Asia-Pacific region is projected to register the highest CAGR, driven by rapid industrialization, government initiatives, and the expansion of small and medium-sized enterprises in countries like China, India, and Japan.

Key Players

The predictive maintenance market features several prominent players, including:

International Business Machines Corporation (U.S.)

ABB Ltd (Switzerland)

Hitachi, Ltd. (Japan)

Siemens AG (Germany)

Amazon Web Services, Inc. (A Subsidiary of Amazon.com, Inc.) (U.S.)

Google LLC (A Subsidiary of Alphabet Inc.) (U.S.)

Microsoft Corporation (U.S.)

Emerson Electric Co. (U.S.)

Oracle Corporation (U.S.)

Splunk Inc. (A Subsidiary of Cisco Systems, Inc.) (U.S.)

Axiomtek Co., Ltd. (Taiwan)

Presage Insights Pvt Ltd (India)

XMPro Inc. (U.S.)

Faclon Labs Private Limited (India)

SenseGrow Inc. (U.S.)

Read Full Report @ https://www.meticulousresearch.com/product/predictive-maintenance-market-5936

Conclusion

The predictive maintenance market is set for substantial growth, driven by advancements in technology, increasing adoption across various sectors, and the rising need to optimize maintenance processes and reduce costs. While challenges such as data privacy and a skilled workforce persist, the opportunities for growth and innovation in predictive maintenance solutions remain robust. As industries continue to embrace digital transformation, predictive maintenance will play a crucial role in enhancing operational efficiency and driving long-term sustainability.

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Predictive Maintenance Market#Vibration Analysis#Oil Analysis#Acoustics Monitoring#Motor Circuit Analysis#Temperature Monitoring#Manufacturing#Oil & Gas#AI and Machine Learning#IoT#Data Acquisition Systems#Sensors

0 notes

Text

Accelerometer and Vibration Sensor Market

0 notes

Text

0 notes

Text

#Vibration Sensors Market Size#Industry Analysis By Segmentations#Top Key Players#Trends#Future Development & Forecast

0 notes

Note

what do you like about cars?

I think you knew, upon asking this, that I could only ever have answered with either an ironic one-liner or a dozen-part novel. And unfortunately, this is already the second line, so novel it is. So then, without any further ado than the literal half year that’s gone by since this was asked, let's go.

1. Engineering matters

At the end of last year (aka when I started writing this, yikes) my dear old iPhone 6S moved on to a new home because it simply wasn't keeping up with me anymore. (And again, I was using an iPhone 6S in 2023. If I say a phone is too slow, it's too slow.) I had plenty of criteria for the replacement: a smallish screen not overboard on resolution, ideally a physical media control button and/or vibration toggle, repairability, a FUCKING AUX JACK...

Something like the Sony Xperia 10, whose only real issue is marketing so trash you've only just now learned Sony never stopped making phones.

And yet...

This fancy wallpapers-sporting foldable is a Motorola RAZR 5G, a phone whose too-big screen already broke (though at the edge due to adhesive issues) and those who dared try warn repairing it will be as hard as phone repairs get.

Why the fuck did I buy this?

Well, because it has something more important than the aux jack, proper sizing, and good cameras: it made me go “That’s so cool!”, and when’s the last time a phone made you say that? It's the cusp of a new technology, and whether it becomes the future of phones, a future of phones, or just a weird footnote, it is an island of interesting in a sea of boring.

And sadly, even this island is rapidly sinking. The drive for new form factors has already boiled down to the same two phones and their evolution is sinking into the usual millimetric proportion tweaking, camera rearranging, touchscreen expanding, case material switching, fingerprint sensor moving, and spec improvements not even manufacturers can come up with use cases for.

I mean, seriously, how does the iPhone 15 differ from a software-updated iPhone X (which is apparently not pronounced "x", so I guess the iPhone Twitter)? Nothing is new. Nothing is tackled differently. The user experience does not differ. And why should it, when iPhone users will get a new one out of habit anyway and many are so tech illiterate moving a button could hospitalize them?

Five generation newer and 150% faster are numbers you basically have to trust, because they don't make a difference that matters.

But in cars? 150% faster will matter alright. Even just looking at it.

Cars are a visceral experience to even witness, let alone ride in or drive, and the frantic engineering pursuits for performance and overall capability actually have impactful real world implications beyond "some pockets will bulge 1mm less". And their engineering involves so many fields that there’s always a breakthrough going on somewhere - which leads to another reason their engineering is so interesting: there’s simply so much of it that anyone interested in engineering will find something for them, no matter their level or sector of expertise!

Interested in mechanics? Well, obviously you’ll have a field day!

Aerodynamics? Don't even get me started!

Electronics? You're getting more goods by the year! It spread from engine management to safety assists to infotainment to ergonomic adjustments to even suspension and aerodynamics!

Sound design? Even just working on the way engines sound is a profession of its own, let alone making these barrels of metal and glass propelling themselves at triple digit speeds through hundreds of explosions a second things you can comfortably have a conversation in - and that's not even mentioning horns and chimes!

Hi-Fi? We’ve spent most of a century trying to get concert hall sound from a tiny tin can where everyone sits off-center and everything bumps and shakes around and you have maybe room for two components* a third the normal size and speakers can only be in a handful of places you wouldn’t want them which may well be the next room over**!

And this is just engineering.

*Like everything in the car world, there are exceptions to that

**For those unfamiliar, subwoofers, the speakers dedicated to, indeed, sub-bass, due to their frequent humongousness are often installed in the trunk.

#stay tuned for part 2!#sony phones *are* great btw#they are sold in actual colors and they're full of cool features#their aux jack can double as a stereo input!!!

101 notes

·

View notes

Note

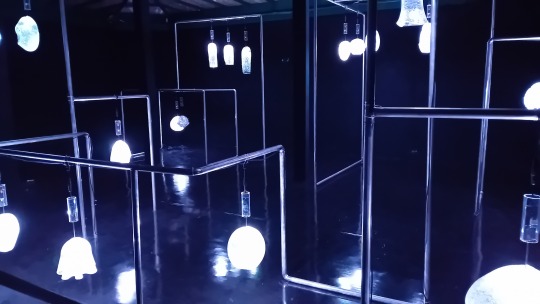

oooooohhh i would love to see more from this light art museum you went to👀

Ooooh okay okay, i'll put a few snippets under the cut here! I don't have much context for these as i've said, because i have not photographed the info pads.

Sadly tumblr only allows one video per post so i have to figure out something.

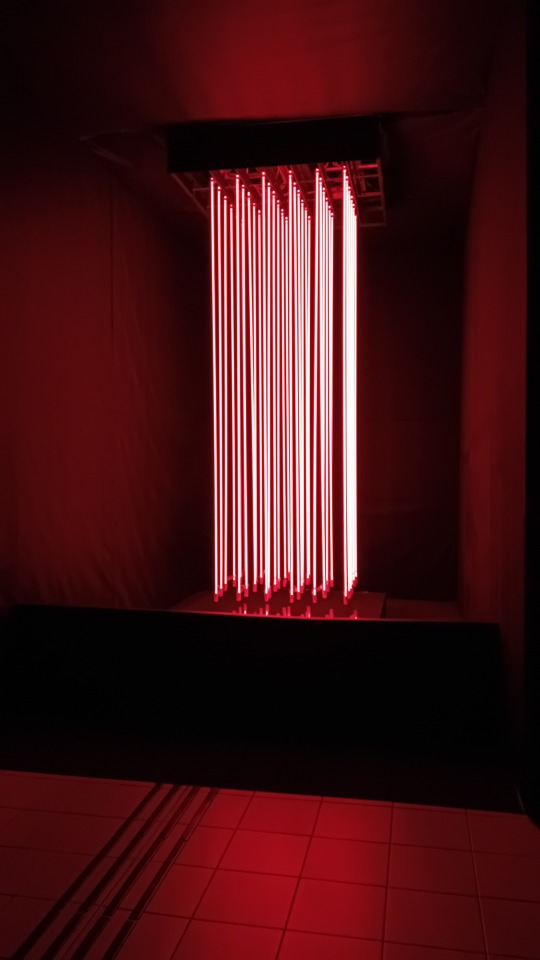

Okay so this was the very first thing that greeted us. This red column was slowly pulsating with a rithm of very slow breaths and it was almost pitch black around it so it was definitely an opening experience:

The museum takes space in an old market so the old stalls create the walls and hallwas. It is so cool. The picture doesn't really reflect it, but it was so dark. It was an interesting experience for sure.

This was at the end of it:

This room was very interesting. The light were vibrating in a way that simulated movements of a beehive.

This was just a very cool installation but it is kind of ominous, and i liked it a lot:

This was an interesting one! The colours changed from red to blue in a loop but the little pedestal you can barely see in front of it had a sensor. And if you had your hand 15 cm or above it you could manipulate a beam of light into the installation. It was so fun!

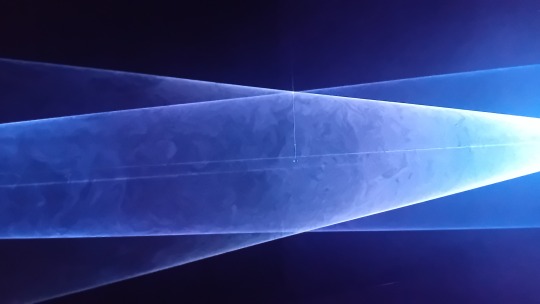

This was a simulation of a star dyieng and being born in a loop. I have a video, i'll try to post it in a separate post

And staying on theme, this is definitely one of the coolest ones.

This i remember. It was supposed to evoke the destruction and birth of galaxies. I couldn't capture the entire loop but i have a good chunk of it here:

I'll share a 2 or 3 more videos soon, i'll tag you under them if you'd like (and anyone who is interested, pls let me know) because i there was some cool and pretty stuff there.

I want to go back once more before the exhibition is closed but we'll see. But i'm definitely seeing the next one they make as well!

8 notes

·

View notes

Text

Chapter 1: Mecha Girl

Narrated by Netga.

Narrator: The garage walls are vibrating with the punk EDM I’m blasting. Holed up in my pod, I’m busy testing mecha functions.

Narrator: This garage is the workspace where I recycle and modify discarded mechas.

Narrator: Lined by the wall are mechas of various styles and designs, all of them my handiwork.

Narrator: Unfortunately, the clients I have on the island don’t have much taste, and my wares aren’t selling that well.

Narrator: Putting on my sensor set and immersing myself in the vibrant music, I tap on the interface.

Narrator: And I enter the simulated test environment.

Narrator: “Select Environment: Flying/Combat/Project/Party...” The menu pops up in the air in front of me.

Choose either “Party mode?” or “Isn’t that quite an array of features?”

If “party,” ...

You: Why would a mecha have a party mode?

Narrator: Why not? I’ve designed a full set of audio, lighting, and motion effects for this mode. Perfect for getting into the partying mood.

If “features,” ...

You: Sounds like this mecha’s got a lot of functions.

Narrator: The island I’m on is part of some ruins. Mechas are widely used in all sorts of scenarios here, a staple in daily life.

--

Narrator: Low altitude flight, high altitude flight, obstacle course, homing shot, stealth mode... I check the features one by one.

Narrator: Mechas can be seen everywhere on this island.

Narrator: Some use them as transportation or in construction work. There are also popular mecha contests held regularly.

Narrator: Besides, brawls break out often on our streets, and mechas are helpful in solving conflicts.

Narrator: That’s my specialty - to come up with fun, cutting-edge functions for modified mechas in various scenarios.

Narrator: Machines are cold, intricate, and boring. They only follow orders and never deviate from what they’re told.

Narrator: Mechas are different as they have personalities. That’s my design philosophy, at least.

Narrator: However, in this city, people are mainly interested only in the large, intimidating, destructive mechas.

Narrator: My unique modifications aren’t that popular on the market, so I settle for adding bonus functions to the more boring designs.

Narrator: This often results in returned products and complaints.

Narrator: Right now, for example, a scar-faced, buff dude is hammering on the door with his robotic arm, demanding a refund.

Narrator: Behind him, a huge, macho-type mecha grins and greets me in a booming voice.

Giant Mecha: Baa!

Scarred Man: You better explain! Why does my mecha say “baa”? It sounds like an idiotic sheep!

Narrator: The owner of the mecha yells, his face all red.

Scarred Man: And why does it choose the flashiest moves in combat? What’s with that, huh?

Narrator: Scar Face rambles on about my modifications and how they totally embarrassed him in front of his opponents.

Scarred Man: Especially this funky “face” screen it’s got! What the heck is it?

Netga: It’s my newly developed emotion feedback device.

Scarred Man: Emotion? You kidding me? I don’t need my mecha to have emotions, at least not idiotic ones.

Scarred Man: Take out these stupid features, or gimme a refund!

Narrator: Come on, these are what give the mechas life, inspiration, and personality! Besides, they’re totally free.

Narrator: I mutter, but I have bills to pay after all, so I connect the wires to the terminal and rid the mecha of the extra functions.

Narrator: Scar Face is finally gone and I can continue with my tests. I glance at the small, round mecha next to me.

Narrator: I pet its round head, and a huge smile appears on the electronic screen.

Narrator: I guess a dumb smile like this would indeed make it the laughingstock on a mecha battle arena.

Netga: My clients are a boring lot. Don’t you think so?

Narrator: The screen flashes. A smile again.

Narrator: The feedback so far doesn’t have much variety. Further developments are needed.

Narrator: Still, no matter how I optimize the features, the fact remains that such a function and mecha style aren’t mainstream.

Narrator: “Ding! Monthly bills alert!” The sudden notification blares from my speakers at full volume, making me jump out of my seat.

Netga: Ugh, what do I do about the bills?

Chapter 2

Chapter 3

Chapter 4

#netga#shining nikki#ssr designer#chapter 1#transcript#mecha girl#robot#mod#ruins island#ruins#garage#mecha#machine#fight#robotic#modification#programmer

7 notes

·

View notes

Text

What is an environmental test chamber and what products does it include

#Environmental test chamber#Climatic test chamber#Temperature test chamber#Humidity test chamber

An environmental test chamber is a device or system used to simulate and control specific environmental conditions. It is widely used in scientific research, engineering testing, product development and quality control.

The environmental test chamber can simulate various environmental conditions, such as temperature, humidity, air pressure, light, vibration, vibration, climate, etc. They usually consist of a closed box, and the environmental conditions inside the box can be precisely regulated and monitored by a control system. The environmental test chamber usually has functions and equipment such as temperature controller, humidity controller, sensor, data logger, etc.

By using environmental test chambers, researchers, engineers, and manufacturers can test and evaluate materials, products, or systems under controlled conditions. For example, they can use test chambers to simulate material properties under extreme temperature conditions, product stability under high humidity, and the reliability of electronic devices under different climatic conditions. These tests can help them understand how the material or product will behave in the context of actual use and make necessary improvements and optimizations.

Environmental test chambers have a wide range of applications, covering many industries, including aerospace, automotive, electronics, pharmaceuticals, food, environmental science, etc. They play an important role in product development, quality control and compliance testing to improve product reliability, stability and adaptability.

There are many different types of products on the market to meet the needs of different fields and applications. Here are some common environmental test chamber products:

Temperature test chamber: used to simulate the test environment under different temperature conditions, can provide low temperature, high temperature or temperature cycle functions.

Humidity test chamber: used to simulate the test environment under different humidity conditions, can achieve high humidity, low humidity or humidity cycle.

Thermal shock test chamber: A combination of temperature and humidity functions is used to simulate the environment of rapid temperature and humidity changes to test the heat and cold resistance of the product.

Vibration test chamber: used to simulate the test environment under different vibration conditions, which can realize sinusoidal vibration, random vibration or shock vibration.

Salt spray chamber: used to simulate the salt spray corrosion environment, often used to test the corrosion resistance of materials and coatings.

Dust test chamber: Used to simulate dust and particulate environments, often used to test the sealing performance of electronic devices and packages.

Climate test chamber: combined with temperature, humidity, light and other environmental factors, used to simulate the test environment under real climate conditions.

ESS Chamber:ESS Chamber can simulate the operation of the product under various environmental stress conditions such as temperature, humidity, vibration and shock. It provides a fast and efficient method for screening products for possible failures and reliability issues during actual use

Uv Testing Chamber:UV testing chamber is a device used to simulate the UV radiation environment and test the weather resistance of materials. It is usually composed of ultraviolet light source, temperature control system, humidity control system, transparent sample rack, etc., which can simulate ultraviolet light exposure in the natural environment, high temperature and high humidity and other conditions for evaluating the weather resistance and durability of materials.

If you want to know more about the relevant products of environmental reliability testing equipment, you can visit Environmental test chamber manufacturer,JOEO ALI testing. They are a professional manufacturer and sales of environmental test chamber and vibration test system in China. Guangdong ALI Testing Equipment Co,. Ltd. specializes in temperature and humidity testing and mechanical vibration testing systems, and is a leader in the field of environmental and reliability testing.

4 notes

·

View notes

Text

Custom Clock Inserts

Quartz Clock Movements Open Your Vistas

Quartz clock movements are the modern-day electronic matching of conventional, mechanical control centers for timekeeping. However quartz clock movements (likewise referred to as clock electric motors) have no springs, weights, wheels, or gears to track time; instead, the quartz crystal generates a stream of pulses that are extremely fast and extremely steady, meaning that checking and subdividing the pulses provides an exact step of elapsed time. Let us see how these marvelous tools can open up a brand-new globe to you.

Non-quartz clock movements run mechanically, utilizing rotational force to turn a flywheel and a collection of equipments to determine specific time units (i.e., secs). Without regulation, the flywheel would certainly spin also quick, which is where pendulums and escapement systems can be found in. The pendulum is limited to turn one extent in half a second, and the gear network converts the oscillation right into secs, minute, and hours.

Modern electronic motors work identically-- at the very least to the onlooker-- although a completely different method is utilized to obtain the exact same outcomes. The first thing one requires to comprehend is that quartz crystals normally vibrate at their resonating regularities when a voltage decrease is related to them. Next, one must realize that the entire point of clocks is to track elapsed time (resetting every 12 or 24 hr), which whether this is done mechanically or electronically is a non-issue.

Nonetheless, the electronic strategy has lots of advantages that exceed just removing the bulk of flywheels, weights, and gears. Electronic motors in essence digitize the entire process, transforming what made use of to be performed in hardware into software program. This gives them a lot better adaptability and adaptability than their mechanical equivalents, and actually they can carry out essentially whatever functionality can be thought up due to the fact that shows has no hardware restraints.

As an example, suppose we intend to extend the resetting time, or the duration at which whatever wraps around to where it began? Twelve hours and twenty-four hours are prominent alternatives, but there's absolutely nothing preventing one from going a full week, and even a month!

Naturally, there's no factor implementing such time expansions if you couldn't reveal them, implying particularly adjusted dials and potentially an additional hand. For the once a week period, the days are printed in the center of the dial and the (short) extra hand leaps to the next day every 24 hr. In a similar way, for once-a-month durations, dates of the month are published along the dial's circumference and a lengthy hand ticks to the following once a day.

A neat option "clock" movement that you can obtain monitors tide level. The only actual distinction is going from a solar cycle to the lunar cycle, which is 24 hr and 50 mins. The motion has to be initialized and calibrated for neighborhood problems, but once this is done the tide degree will certainly always be accurate.

The tide-level motion (which can be combined with common timekeeping to display time and trend on one face), is a kind of lead-in to movements that depart from periodicity. Right here, the thing revealed is a weather phenomenon, such as moisture or temperature, and the single hand revolves between two extremes of a scale. Sensors are made use of to discover present worths, and the electric motor converts the value into hand position.

The astute viewers will certainly understand that we are no longer in the world of quartz movements, as there is no reason to track elapsed time. But the digital quartz innovation has freed up the imagination to assume in regards to software instead of hardware. clock parts

A fascinating by-product of all this is that there is a market for clocks and attributes of the past, such as grandfather clocks with oscillating pendulums. The digital movements can suit such needs via simulation, even though pendulums are no more working components; this is particularly valuable for clockmakers that want to bring back an old, non-functioning heirloom. Obviously, quartz clock movements open your panoramas.

youtube

2 notes

·

View notes

Text

Distributed Fiber Optic Vibration Sensor Market

0 notes

Text

What To Look for in a Fiber Optic Sensor Cable

Fiber optic sensor cable is combined with plastic or glass fiber-optic cables and is used in applications with small installation spaces or high temperatures. This article can help you learn more about fiber optic sensor cable.

What is Fiber Optic Sensor Cable?

Fiber optic sensor cable is a type of fiber optic cable that can be used for high-speed data transmission, and measures temperature, strain, vibration, and acoustic signals, even in harsh environments. A fiber optic sensor cable monitors a fiber optic cable from a single location via pulses of light traveling down the fiber. It provides continuous 24/7 monitoring over long distances. The fiber itself is the sensor, so there are thousands of sensing points along the route of whatever asset is being monitored. The fiber is passive, so no power supply is required along the asset.

Fiber optic sensor cable is available with single-mode (SM) and multi-mode (MM) fibers or a combination of both. SM fiber is used for distributed Acoustic sensing (DAS), and distributed strain sensing (DSS), while MM fiber is used for distributed temperature sensing (DTS).

Fiber optic sensor cable is available in metal-tubing, metal-free, tube-in-tube, or armored stainless steel configurations. The metal-free cable reduces the risk of induced voltages and is usually flexible, while metal armored cable has high rodent protection, is robust, and is the right choice for a harsh environment. Additionally, a wide range of appropriate sheathings is available, for example, flame retardant non-corrosive (FRNC) sheath, water-tight high-dense polyethylene (HDPE), or others.

Features and Benefits

Fiber optic sensor cable provides precise localization of events, temperature, strain, vibration, and acoustic measurement, immunity to electromagnetic interference (EMI), suitability for use in explosive hazard areas, small diameter, low weight, low cost, flexible, purely passive sensor element, and need no electrical power to function.

Applications

Fiber optic sensor cable is used in temperature monitoring ( tunnels, roadways, airport runways, buried environments), fire detection, leak detection, thermal mapping, telecom, structural health monitoring (SHM), oil and gas, power and utility, safety and security, industrial automation, transportation, and more.

Conclusion

Fiber Optic sensor cable provides a unique combination of size, robustness, and strength that enables it to be the product of choice for temperature, strain, or vibration applications. The cable is suitable for installation in tunnels, roadways, airport runways, buried environments, oil and gas, and any industrial application where there is a need for crush resistance, high-temperature performance, and quick thermal response. Sun Telecom provides all fiber optic sensor cable products and solutions to the global market.

2 notes

·

View notes

Text

Smart Agriculture Market Dynamics, Top Manufacturers Analysis, Trend And Demand, Forecast To 2030

Smart Agriculture Industry Overview

The global smart agriculture market size was valued at USD 22.65 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 13.7% from 2024 to 2030.

Increasing automation of commercial greenhouses and growing implementation of the controlled environment agriculture (CEA) concept in greenhouses, in a bid to obtain a higher yield and maintain optimum growing conditions, are the key factors driving demand during the forecast period. Cultivators realize the potential benefits of growing plants inside a greenhouse, which has led to the development of commercial greenhouses. Cultivators have shifted from the conventional lighting systems to LED grow lights as the latter can easily be integrated into a CEA setup. Although LED grows lights are high in cost, they are an ideal option for indoor farming, owing to their long-term benefits in terms of energy efficiency.

Gather more insights about the market drivers, restrains and growth of the Smart Agriculture Market

Smart agriculture companies are shifting their focus toward the development of equipment that is integrated with advanced sensors and cameras. Key technologies driving the market demand include livestock biometrics, such as RFID, biometrics, and GPS to help cultivators automatically obtain information regarding livestock in real-time. Furthermore, infrastructural health sensors are used for monitoring material conditions and vibrations in buildings, factories, bridges, farms, and other infrastructure. Coupled with an intelligent network, infrastructural health sensors help provide information to the maintenance team in real-time. In addition, agricultural robots are being used to automate farming processes, such as soil maintenance, weeding, fruit picking, harvesting, planting, plowing, and irrigation, among others.

To sustain profits, farmers are increasingly adopting smarter and more efficient agriculture technologies to deliver high-quality products to the smart agriculture market in sufficient quantities. Mobile technology aids in offering innovative types and applications that are used across the agricultural value chain.

Machine-to-Machine (M2M) applications are particularly suited for the agricultural sector, enabling farmers to monitor equipment, assess the environmental impact on production, precisely manage livestock and crops, and keep track of tractors and other agricultural equipment. M2M is an integral part of IoT, which describes the coordination of multiple devices, appliances, and machines connected to the internet through multiple networks.

The COVID-19 pandemic has brought widespread disruption to the global supply chain, resulting in food shortages and inflation. Necessary measures are required to strengthen the food supply chain and prepare for any future crisis. The ongoing pandemic has highlighted the significance of being able to carry out agricultural operations remotely. The ability of smart agricultural practices to help farmers recoup losses in a relatively shorter lead time is expected to drive future market growth.

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

The global agriculture 4.0 market was estimated at USD 67.73 billion in 2023 and is projected to grow at a CAGR of 11.6% from 2024 to 2030.

The global AI in food & beverages market size was valued at USD 8.45 billion in 2023 and is projected to grow at a CAGR of 39.1% from 2024 to 2030.

Key Companies & Market Share Insights

Some of the key players operating in the market include Ag Leader Technology, AGCO Corporation, AgJunction, Inc., AgEagle Aerial Systems Inc., Autonomous Solutions, Inc., Argus Control Systems Ltd, BouMatic Robotic B.V., CropMetrics, CLAAS KGaA mbH, CropZilla, Deere & Company, DICKEY-john, DroneDeploy, DeLaval Inc, Farmers Edge Inc, Grownetics, Inc., Granular, Inc., Gamaya, GEA Group Aktiengesellschaft, Raven Industries, Trimble Inc., Topcon Positioning System among others.

AGCO Corporation is a U.S.-based agriculture equipment manufacturer. The company develops and sells products and solutions such as tractors, combines, foragers, hay tools, self-propelled sprayers, smart farming technologies, seeding equipment, and tillage equipment.

Deere & Company is engaged in the manufacturing & construction of agricultural and forestry machinery; drivetrains and diesel engines for heavy equipment; and lawn care machinery. Additionally, the company also manufactures and provides other heavy manufacturing equipment. The company serves diverse industries such as agriculture, forestry, construction, landscaping & grounds care, engines & drivetrain, government and military, and sports turf.

Prospera Technologies and Agrible, Inc. are some of the emerging market participants in the target market.

Prospera Technologies is a global service provider of agriculture technology for managing and optimizing irrigation and crop health. The company provides AI-based sensors and cameras that aid farmers in crop monitoring.

Agrible is a U.S.-based agriculture solution provider. The company helps customers in more than 30 countries optimize water use, crop protection, fertilization, fieldwork, research trials, food supply chains, and sustainability initiatives

Key Smart Agriculture Companies:

Ag Leader Technology

AGCO Corporation

AgJunction, Inc.

AgEagle Aerial Systems Inc.

Autonomous Solutions, Inc.

Argus Control Systems Ltd

BouMatic Robotic B.V.

CropMetrics

CLAAS KGaA mbH

CropZilla

Deere & Company

DICKEY-john

DroneDeploy

DeLaval Inc

Farmers Edge Inc

Grownetics, Inc.

Granular, Inc.

Gamaya

GEA Group Aktiengesellschaft

Raven Industries

Trimble Inc.

Topcon Positioning System

Recent Developments

In July 2023, Deere & Company announced the acquisition of Smart Apply, Inc. The company planned to leverage Smart Apply’s precision spraying to assist growers in addressing the challenges associated with input costs, labor, regulatory requirements, and environmental goals.

In May 2023, AgEagle Aerial Systems Inc. announced that it had entered into a 2-year supply agreement with Wingtra AG. This agreement is purposed to secure the supply of RedEdge-P sensor kits for incorporation with WingtraOne VTOL drones. This is specifically resourceful for those seeking to benefit materially from unparalleled, high precision, and plant-level detail in commercial agriculture, environmental research, forestry, and water management applications.

In April 2023, AGCO Corporation announced a strategic collaboration with Hexagon, for the expansion of AGCO’s factory-fit and aftermarket guidance offerings. The new guidance system was planned to be commercialized as Fuse Guide on Valtra and Massey Ferguson tractors.

In February 2023, Topcon Agriculture unveiled the launch of Transplanting Control, an exceptional guidance control solution for specialty farmers. This turnkey solution was designed to boost efficiency, reduce labor, and proliferate production. Further, it delivers GNSS-driven guidance, autosteering & control, thereby proving advantageous for the growers of perennial trees, vegetables, and fruits.

In January 2023, ASI Logistics in collaboration with SICK, Inc. announced the successful implementation of autonomous yard truck operations. In this collaboration, ASI Logistics leveraged its groundbreaking Vehicle Automation Kit (VAK) along with the industry-leading LiDAR systems of SICK.

In March 2022, Raven announced its business expansion in South Dakota and Arizona to enhance the development of AI-driven technologies for tailoring cutting-edge solutions. The strategy was also aimed at allowing access to a nearby test farm for same-day testing.

In October 2021, BouMatic announced the acquisition of SAC Group to leverage automatic and conventional milking systems. The transaction demonstrated the company’s incessant commitment to delivering best-in-class dairy farm solutions to consumers across the world.

In May 2021, AGCO announced a targeted spraying solutions strategic collaboration with Raven Industries Inc., BASF Digital, and Robert Bosch GmbH. The objective of this deal was to assess the targeted spraying technology for enhancing crop protection product applications by limiting crop input costs and addressing environmental sustainability.

Order a free sample PDF of the Smart Agriculture Market Intelligence Study, published by Grand View Research.

0 notes

Text

Shock Sensor Market Forecast & Business Opportunities by 2032

The Shock Sensor is a device designed to detect and measure sudden impacts, vibrations, or shocks. Utilized in various applications, these sensors play a critical role in safety and security systems by providing real-time alerts and data on unexpected disturbances. Shock Sensors are commonly used in automotive systems, industrial equipment, and security applications to monitor and respond to potentially harmful events. By accurately detecting impacts and vibrations, these sensors help prevent damage, enhance safety, and ensure operational reliability.

The Shock Sensor Market Size was valued at USD 1.10 billion in 2023 and is expected to reach USD 5.12 billion by 2031 and grow at a CAGR of 21.2% over the forecast period 2024-2031.

Future Scope:

The future of Shock Sensors is characterized by advancements in sensitivity, accuracy, and integration capabilities. Emerging technologies are expected to enhance the sensors’ ability to detect even minor impacts and vibrations with greater precision. The integration of Shock Sensors with IoT (Internet of Things) systems will enable real-time monitoring and automated responses to detected events. Additionally, developments in miniaturization and wireless technology will lead to more versatile and easy-to-install shock detection solutions, expanding their applications across various industries.

Trends:

Key trends in Shock Sensors include the development of highly sensitive and accurate impact detection technologies. There is a growing emphasis on integrating Shock Sensors with IoT platforms for enhanced data analysis and real-time monitoring. The market is also seeing increased adoption of wireless and compact sensor designs that offer greater flexibility and ease of installation. Additionally, advancements in machine learning and data analytics are driving improvements in the interpretation of shock events and automated response systems.

Applications:

Shock Sensors are widely used in automotive systems to monitor and protect against collisions and accidents. In industrial settings, they help detect equipment malfunctions or potential failures due to impacts or vibrations. Security systems utilize Shock Sensors to detect unauthorized access or tampering with protected areas. Additionally, these sensors are employed in consumer electronics and smart devices to enhance durability and reliability by monitoring for accidental drops or impacts.

Solutions and Services:

Solutions related to Shock Sensors include custom sensor design and integration for specific applications, real-time monitoring and alert systems, and maintenance services. Manufacturers offer technical support and calibration services to ensure optimal performance. Additionally, consulting and training services are available to help organizations implement and utilize Shock Sensors effectively in their safety and security systems.

Key Points:

Detects and measures sudden impacts, vibrations, or shocks for safety and security applications.

Enhances safety, prevents damage, and ensures operational reliability.

Future advancements focus on sensitivity, accuracy, IoT integration, and miniaturization.

Trends include wireless designs, real-time monitoring, and data analytics.

Applications span automotive, industrial, security, and consumer electronics.

Solutions include custom design, monitoring systems, maintenance, and technical support.

Read More Details: https://www.snsinsider.com/reports/shock-sensor-market-4259

Contact Us:

Akash Anand — Head of Business Development & Strategy

Email: [email protected]

Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

#Shock Sensor Market#Shock Sensor Market Size#Shock Sensor Market Analysis#Shock Sensor Market Trends#Shock Sensor Market Growth

0 notes

Text

Seismic Testing Market Opportunities: Exploring New Frontiers

The seismic testing market has witnessed remarkable growth in recent years. In 2023, it was valued at USD 11.1 billion, and projections show that it will surpass USD 18.6 billion by 2030, growing at a compound annual growth rate (CAGR) of 7.6% from 2024 to 2030. This growth is driven by various factors, including the increasing demand for energy, advancements in technology, and the growing importance of safety regulations. In this article, we will explore the seismic testing market, its key components, drivers of growth, challenges, and its future outlook.

What is Seismic Testing?

Seismic testing, also known as seismic surveys, is a technique used to investigate the properties of the Earth's subsurface. It involves generating seismic waves, typically through controlled sources like explosions or specialized machinery, and then recording how these waves travel through different layers of the Earth. The data collected is used to map geological structures, which is crucial for applications like oil and gas exploration, infrastructure development, and assessing natural hazards.

Access Full Report @ https://intentmarketresearch.com/latest-reports/seismic-testing-market-3076.html

Key Components of Seismic Testing

1. Seismic Source

The seismic source generates the waves used in testing. This can be a controlled explosion, a mechanical device (like a vibroseis truck), or even a natural event like an earthquake. The choice of source depends on the depth and precision required for the survey.

2. Sensors (Geophones)

Geophones are devices used to record the seismic waves. They capture the vibrations as the waves pass through the Earth and convert them into signals that can be analyzed. High-quality geophones are essential for obtaining accurate data.

3. Data Acquisition Systems

The data from the geophones are collected by data acquisition systems. These systems store, process, and sometimes transmit the seismic data in real-time. The quality and speed of data acquisition play a significant role in the efficiency of seismic surveys.

4. Data Processing and Interpretation

Once the seismic data is collected, it must be processed and interpreted to create detailed maps of the subsurface. This stage often involves advanced algorithms and software, turning raw data into usable insights for exploration and safety assessments.

Applications of Seismic Testing

1. Oil and Gas Exploration

One of the primary applications of seismic testing is in the oil and gas industry. Companies use seismic surveys to identify potential drilling sites by mapping underground reservoirs. The precision offered by modern seismic technology reduces the risk and cost of exploration, making it an essential tool for the industry.

2. Earthquake Risk Assessment

Seismic testing is also crucial in assessing earthquake risks. By understanding the structure of fault lines and other geological features, scientists can better predict earthquake activity and its potential impact on populated areas.

3. Infrastructure Development

Before major infrastructure projects like bridges, tunnels, or large buildings are constructed, seismic testing is often conducted to ensure the ground is stable. This helps prevent future issues with foundation stability and reduces the risk of damage from natural disasters.

4. Mining Exploration

In the mining industry, seismic testing helps identify mineral deposits deep beneath the surface. By providing detailed maps of the Earth's subsurface, companies can target their mining efforts more effectively, reducing waste and environmental impact.

Drivers of Growth in the Seismic Testing Market

1. Growing Energy Demand

As global energy demand continues to rise, so does the need for efficient exploration of new oil and gas reserves. Seismic testing plays a vital role in identifying untapped resources, especially in challenging environments like deep-water areas.

2. Technological Advancements

Advancements in seismic technology, such as 3D and 4D seismic surveys, have revolutionized the industry. These techniques provide more detailed and accurate images of the subsurface, allowing for better decision-making in exploration and development.

3. Increased Focus on Safety

Governments and regulatory bodies are placing more emphasis on safety, especially in areas prone to natural disasters. Seismic testing helps ensure that new infrastructure is built in safe locations, and it aids in the assessment of earthquake risks.

4. Environmental Concerns

Environmental regulations are becoming stricter, particularly in the oil and gas sector. Seismic testing helps companies minimize their environmental footprint by enabling more targeted exploration, thus reducing the need for unnecessary drilling.

5. Global Urbanization

The rapid growth of urban areas has led to increased demand for infrastructure projects, which in turn boosts the need for seismic testing. This is especially true in regions prone to natural disasters, where thorough seismic surveys are essential for safe construction.

Download Sample Report @ https://intentmarketresearch.com/request-sample/seismic-testing-market-3076.html

Challenges Facing the Seismic Testing Market

1. High Costs

Seismic testing, especially with advanced technology, can be expensive. The equipment, personnel, and time required for a comprehensive survey add up quickly, which can be a barrier for smaller companies or projects with tight budgets.

2. Environmental Impact

While seismic testing is essential for energy and infrastructure development, it can also have environmental consequences. The use of explosives and large machinery can disrupt wildlife and ecosystems, leading to regulatory challenges.

3. Data Complexity

Processing and interpreting seismic data is complex and requires specialized knowledge. The increasing volume of data from advanced surveys can be overwhelming, and the accuracy of the final interpretation heavily depends on the expertise of the professionals involved.

4. Geopolitical Risks

Seismic testing often takes place in politically unstable regions, particularly in the oil and gas sector. Geopolitical tensions can lead to delays or even the cancellation of projects, making it a risky endeavor for companies operating in these areas.

Future Trends in Seismic Testing

1. Digitalization and AI Integration

The future of seismic testing is likely to see greater integration of artificial intelligence (AI) and digital technologies. AI can help process large volumes of data more efficiently, leading to faster and more accurate interpretations.

2. Expansion in Renewable Energy

As the world shifts towards renewable energy, seismic testing will play a role in the exploration of geothermal energy resources. This is an emerging area of interest, and seismic surveys can help locate viable sites for geothermal plants.

3. Advanced 4D Seismic Testing

4D seismic testing, which adds the element of time to traditional 3D surveys, is gaining popularity. This technology allows companies to monitor changes in underground reservoirs over time, providing valuable insights for resource management.

4. Portable and Cost-Effective Solutions

There is growing demand for portable and more cost-effective seismic testing solutions. As technology advances, we may see smaller, more affordable equipment that can be used for quick and efficient surveys in remote locations.

5. Increased Collaboration with Governments

Governments around the world are expected to play a more significant role in seismic testing, particularly in the areas of natural disaster prevention and urban planning. Public-private partnerships may become more common as seismic testing becomes an integral part of national safety strategies.

Conclusion

The seismic testing market is on a strong growth trajectory, driven by the increasing demand for energy, advancements in technology, and a growing focus on safety and environmental concerns. With the market expected to grow at a CAGR of 7.6% from 2024 to 2030, seismic testing will continue to play a crucial role in various industries, from oil and gas exploration to infrastructure development and earthquake risk assessment. However, the industry also faces challenges, such as high costs and environmental impact, which will need to be addressed to sustain its growth.

FAQs

1. What is seismic testing used for?

Seismic testing is used to investigate the properties of the Earth's subsurface, primarily for applications in oil and gas exploration, earthquake risk assessment, and infrastructure development.

2. What are the main components of a seismic test?

The main components include a seismic source, geophones (sensors), data acquisition systems, and data processing software.

3. How does seismic testing help in oil exploration?

Seismic testing helps identify potential oil and gas reserves by mapping underground reservoirs, reducing the risk and cost of exploration.

4. What are the challenges in seismic testing?

Key challenges include high costs, environmental impact, data complexity, and geopolitical risks.

5. What is 4D seismic testing?

4D seismic testing adds the element of time to 3D surveys, allowing companies to monitor changes in underground reservoirs over time.

Contact Us

US: +1 463-583-2713

0 notes