#Web Corona Treater

Text

Amcor Flexibles goes for Vetaphone corona equipment

Amcor’s Gent production facility is a giant, housing gravure printing in up to nine colors, digital printing, solvent and water-based coating, lamination, coextrusion, both cast and film up to nine layers, and Vision Systems for conversion and extrusion. It all began back in 1925 with the production of cellophane, which was the first plastic material used for food packaging. In 1950, the plant became the first to extrude in Europe, and by the 1960s Amcor Flexibles was making strides in the pharmaceutical, films & packaging, and chemical sectors, with the establishment of a strong R&D culture.

Throughout the 1990s, the Group expanded with numerous acquisitions, including Danisco, A&R, Rexam, and Tobepal, with extruded volumes being consolidated at Gent and the UK plant in Ilkeston. 2008 brought a major 17m Euros investment program at Gent with four new extrusion lines and the construction of a new production hall, while the acquisition of Alcan in 2010 saw conversion and extrusion separated at Gent and in 2019, with the addition of Bemis, the group became a major global leader in package print production.

Today, the Gent plant has a broad product range including peel and barrier packaging that serves all sectors. PE, PP, PA, and PETg are extruded in up to nine layers and on the converting side, gravure and digital printing combine with lamination, coating, and slitting. Both extrusion and converting sectors are monitored by Vison Systems to assure quality.

It was into this production environment that Vetaphone set about selling its surface treatment technology, as Dirk Den Haese, sales manager of Vetaphone Benelux explained, “The challenge of working with a large and diverse group like Amcor is knowing where to start! But I knew that the company valued its reputation for quality very highly, and that the accuracy of much of the packaging it produced was critical, so there was clearly no room for any weak link in the production chain.”

Beginning in 1990, Vetaphone has supplied a diverse range of corona technology to the Belgian plant that ranges from 1400 to 2300 mm in web width and generators from 2 x 6kW for extrusion lines to 2 x 10kW for different lamination lines. For its food and pharmaceutical work, Amcor is using exclusively Vetaphone VP2 ceramic rollers to ensure no contamination from the silicone sleeves, vulcanized and aluminium backing rollers.

This has become a standard item for Amcor Flexibles in Gent, where the treaters have performed well, drawing praise for their low maintenance requirements and easy access, and reliable performance that provides the consistently even treatment essential for a quality end-product.

Speaking for Amcor, Andries Van Nieuwenhove, plant general manager at Amcor Flexibles Conversion Gent said, “It is key for us to have good partners who support us in our journey to be the reference supplier of specialty peelable and barrier laminates.”

Amcor is very proud of its customer engagement that takes a bespoke approach to the challenges of modern-day packaging. “From concept to prototype and onto production and recycling, the company works hard at being innovative,” according to commercial director Johan Van Wesemael. “Using our in-house pilot line and all the analytical assets and expertise we have gathered we can speed up developments and through real-world testing deliver validated solutions.”

Proof of this attention to detail is the number of international quality recognition awards held by Amcor, including ISO 9001, 14001, 45001, 50001, along with ISTA, Ecovadis, and BRC accreditations. They are, in fact, no more than one would expect from such a major player in the market, but are now the basic requirements for the food, pharma, and industrial sectors that Amcor supplies on a regular and global basis.

To put that size into perspective, Amcor employs 42,500 people across 220 locations in 43 countries – its packaging products are used by more than 4000 brand owners – it holds 3700 patents, trademarks, and registered designs, spends over €100m on R&D each year, enjoying an annual sales turnover of US$14 billion. As Dirk Den Haese concluded, “If Vetaphone technology is good enough for Amcor, by association it makes us a global leader too – and it’s something we are very proud of! I estimate we have now installed more than €1m’s worth of our technology at the Gent plant, making Amcor one of our largest customers in the Benelux region.”

0 notes

Text

Used Flexo Machine for SALE

Gallus - EMS 410

Get Directly from SELLER -

Manufacturer: Gallus

Year: 2008

Machine Availability: Immediately

Price: On Request

Location: United Kingdom

#print #press #machinedalal

0 notes

Text

LIVE DEMONSTRATION

Subject: Invitation to Demonstration of 8 Colors Flexographic Printing Machine (5 Servo Drive) with Full UV, Corona Treater Dual Web Guide Unit, Cold Foiling & Lamination etc & Perfect Registration.

Dear Sir/Ma'am,

We are thrilled to extend our warmest invitation to you for an exclusive demonstration of our state-of-the-art 8 Colors Flexographic Printing Machine with Full UV, Corona Treater, Web Video Camera, Dual Web Guide Unit, Cold Foiling & Lamination etc & with Perfect Registration. The event will take place on 24th, 25th, and 26th July 2023 at our premises.

During the demonstration, you will have the opportunity to witness the exceptional capabilities of Webtech's Flexographic Printing Machine in action. We will conduct live trials on lamitube & Chormo Paper material, showcasing the impeccable print quality, precise registration, and the efficiency of the UV curing system. Our team of experts will be present to explain the machine's features, answer any questions, and provide detailed insights into its performance and versatility.

After the demonstration, we invite you to join us for a delightful gathering, where you can indulge in snacks and refreshments. This will allow you to engage in further discussions, network with industry professionals, and explore potential collaborations.

Furthermore, we are excited to inform you that we have 2-3 more Flexographic Printing Machines currently in the production process which includes 8 Colors 410 mm Flexo Press for Egypt, 6 Colors Flexo Press for Hyderabad and another 6 Colors Flexo Press for Hapur.

We sincerely believe that this demonstration will provide you with valuable insights into the capabilities of our Flexographic Printing Machine and how it can revolutionize your printing operations. We are confident that witnessing the perfect registration, UV curing efficiency, and the versatility of this machine will inspire you to explore the possibilities it offers for your printing needs.

To secure your seat at this exclusive event, please RSVP by 22nd July 2023 by contacting us. Kindly inform us of your preferred date and time slot for the demonstration, enabling us to make the necessary arrangements.

Event Details :

Date: 24th, 25th, and 26th July 2023

Venue: Plot No. 20, Sector 25, Faridabad, Haryana - 121004

We eagerly anticipate your presence at this exciting event and the opportunity to showcase our cutting-edge technology. Please do not hesitate to reach out to us if you have any questions or require further information. We look forward to hosting you on 24th, 25th, or 26th July 2023.

Thank you for your attention, and we eagerly await your response.

Regards,

WEBTECH SALES TEAM

Please confirm your availability on below whatsapp numbers :

+91 9999779973 (Shiv Nandan Singh)

+91 9289289635 (Kopal Srivastava)

+91 8447686320 (Mohd. Javed)

0 notes

Text

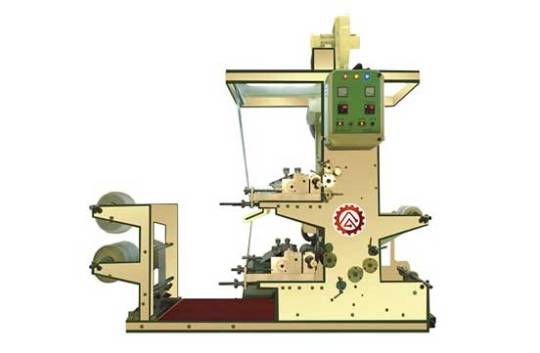

All India Machinery - Plastic Blown Film Extruders, Flexo & Rotogravure Printing Machines Manufacturer, Exporter and Supplier

All India Machinery is a renowned and world-class manufacturer, exporter, and supplier of Plastic Blown Film Extruders, Flexo and Rotogravure Printing machines. The company was established in 2017 and is based in Mumbai and has enjoyed the pinnacle of success in the world of blown film and printing machinery industries. With an experience of over 25 years and expertise in manufacturing lifecycles, sales, integrated marketing, creating events, boosting performance, and enhanced professional consultation, this organization has everything which enables it to have its presence in more than 25 countries including export to Qatar, Bahrain, Kenya, Saudi, Canada, Peru, Morocco, Italy, Mexico, Tanzania etc.

All India Machinery strives to be the largest company of offline and online printing machinery in the world by 2025 with its core values of constant innovation, collaboration, result orientation, honesty, and trustworthiness in place. With all the leadingtechnological know-how, All India machinery has participated in worldwide business meetings on how to increase profitability. Reusing and recycling plastic has been made much easier and the company focuses on total quality control. This superlative performance is because of the state of art manufacturing practices adopted that aim at precision and perfection. The team is a comprehensive one that offers solutions for all the client needs and has the ISO 9001- 2015 certification.

All India Machinery is a one-stop solution for all Blown film extruders and Flexographic and Roto Gravure printing machines with models that give an exemplary performance. The wide range of products with advanced technology enables this company to have a total grip over the market needs. Any impediment in the machinery operation is taken care of and various variants are suggested to cater to the specified needs of clients. An Outstanding bag making system is also guaranteed owing to the years of expertise in the field. We ensure that all our clients get the utmost satisfaction and end-to-end services with the best quality.

The range of Products at All India Machinery includes-

Flexo Printing Machines

Flexo printing machines come in various models like the two colors high-speed Flexographic printing machine, the medium Flexo printing machine, and the mini Flexo printing machine. These machines offer a very easy installation and operation with superlative printing results. Flexographic printing machinery offers consistent quality and great durability.

Roto Printing Machines

These models include the online and the inline Roto Gravure Printing Machine, the single and two color floor mounted Roto printing machines which are greatly user-friendly and offer hassle-free operation. Any kind of wastage is reduced and production costs also are significantly curbed. The rotogravure is a cost-efficient printing process and the production speed is exemplary.

Tubing Machines

The long-lasting maintenance-free life offered by the Blown film extrusion machines which come in various mm’s offer tremendous versatility with speed. The output is voluminous depending on the size and gauge of the material and can be used to produce t-shirt bags, garbage bags, carry bags, grocery bags, and much more. The models like ABA Two layer Extruder runs electricity while the Corona treater machine offers a uniform treatment throughout the web width.

Sealing and Cutting Machine

The Bottom Sealing and cutting machine is a microprocessor-controlled one that has its speed synchronized with the stroke and size. There is a side sealing and cutting machine which has a silicon sealing roller driven by servo and has a sealer and cutter logic embedded. They offer a very good sealing effect and is simple to operate. Its efficiency makes it popular and much demanded.

Recycling Machines

The recycling machines include a vertical mixture with dryers and are suitable for light and semi-dense materials. These machines have minimalist power consumption and the high-speed mixers offer the efficiency of batch times of 10 to 15 minutes per batch.

1 note

·

View note

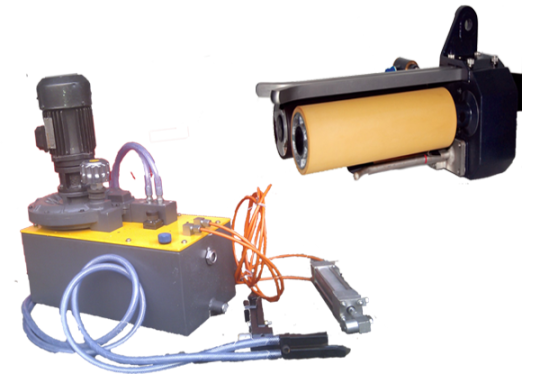

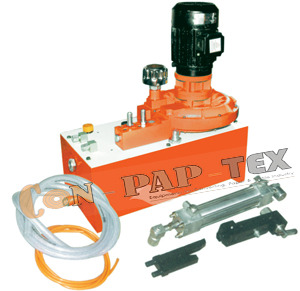

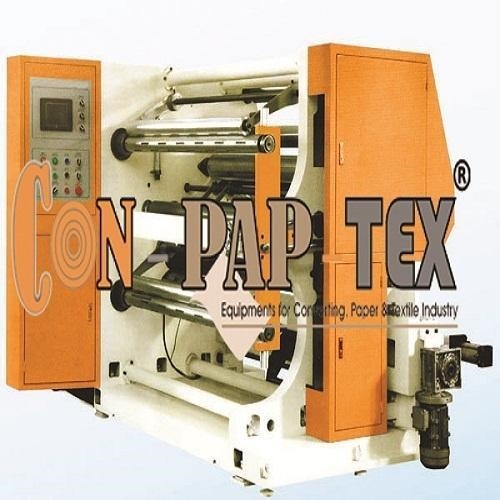

Link

We manufacture all types of Textile Machinery Spares Parts like Stenter Machine, Jigger Machine, Rotary Screen Printing Machine, Spinning Machinery, and Textile Machinery, Stenter Machine Spare Parts like Stenter Pin Bar, Stenter Clip, Cloth Guider, Chain link Bottom Parts, etc. We are also one of the leading manufacturers of Rubber Roller, Rubber Fillet, Nip Roll, Rubber Grip, Turn Bar System, PU Roll, Paper Core Cutting Machine Manufacturers, Web Corona Treater, and Wrapping Machine. We manufacture all types of Converting & Flexible Packaging Machinery, Textile Machinery & Equipment of Rubber Roller, Industrial Rubber Rollers, Web Aligner Unit, Slat Expanding Roller, Winder Rewinder Machine, Web Converting Machinery, Textile Machinery Spare Parts, Strapping Machine, Bow Roll, Stenter Machine, Pneumatic Cloth Guider, Tension Controller, Air Shaft, and more.

#Stenter Machine#Jigger Machine#Pin Bar#Stenter Clip#Cloth Guider#Chain link Bottom Parts#Rubber Roller#Rubber Fillet#Nip Roll#Rubber Grip#Turn Bar System#PU Roll#Paper Core Cutting Machine Manufacturers#Web Corona Treater#Wrapping Machine#Industrial Rubber Rollers#Web Aligner Unit#Slat Expanding Roller#Winder Rewinder#Strapping Machine#Bow Roll#Pneumatic Cloth Guider#Tension Controller#Air Shaft#Wrinkle Removing Rolls#Web Guiding Equipment#Doctoring Rewinding Machine#Slitter Rewinder Machine#Batch Coding Equipments

0 notes

Text

This can help them identify opportunities and potential threats, so they can prepare for the present and future. MRI Research helps organizations to figure out whats happening in a given industry, including demand and supply statistics, degree of competition, state of competition with other emerging industries, future prospects considering technological changes, and external factors on the industry.

0 notes

Text

Zircon chooses Vetaphone for its narrow web presses

One of India’s leading label and packaging converters, Zircon Technologies, is installing an Omet Varyflex 670 press fitted with a Vetaphone corona treater at its production facility in Uttarkhand capital Dehradun, some 250km north of Delhi. The company already has Vetaphone corona technology on its existing two Omet and seven Mark Andy presses.

Established in 2007 by owner and managing director Sanjeev Sondhi, the company, which employs 450 people across five sites, produces more than 40 million square metres of printed material each year. Markets supplied include food & beverage, healthcare, industrial, and pharmaceutical sectors, with a range of products from labels and flexible packaging to anti-counterfeiting and brand authentication items, as well as shrink sleeves, pouches, and blister packs.

With a high-quality portfolio of international brand owners to service, Zircon prides itself on its end-to-end support from R&D through to delivery of the finished product. According to Sondhi, “We have stringent quality and delivery processes in place to ensure our products can be put straight onto our customers’ production lines at the time requested – what’s more, we can automate production for a seamless solution.”

Working typically with PE and aluminium foil, corona treatment was always going to be required to ensure good ink adhesion. Two of the Mark Andy presses are fitted with Vetaphone corona technology as well as the Italian-manufactured Omet VaryFlex 430 flexo press that is configured to some proprietary web passes and attachments to meet Zircon’s requirements. Fitted with automatic registration control and the facility to print back and front in a single pass, the Omet is capable of printing substrates from 12-micron film to 600-micron board.

As Mark Andy and Omet are both leading OEM customers of Vetaphone, the Danish company’s corona technology was an easy choice. The Mark Andy presses are fitted with VE1A-A corona treaters with four ceramic electrodes in their removable cartridges. Each has an iCorona-1UL generator, one with 1.5kW power, the other with 2kW. The Omet has two VE1A-A treaters with four ceramic electrodes and 2kW iCorona generators.

“We were aware of other options for surface treatment but decided to go with Vetaphone. They invented and have pioneered corona treatment and came highly-recommended as a trusted and reliable brand,” said Sondhi, who is looking to grow his business in the aluminium packaging, screen printing and stand-up pouch markets, where the non-absorbent substrates will all need surface treatment.

With Diageo, Yamaha, and Pernod Ricard among its 300 customers, Sondhi knows that only state-of-the-art technology will allow him to deliver the quality demanded. “I am very satisfied with the Omet/Vetaphone combination – it allows our team of skilled professionals to offer customers what they want, when they want it, and at a quality and price that meet their expectations.” With 7 in 10 consumers admitting that packaging influences their purchasing decision there is a premium on getting it right first time, every time.

0 notes

Link

AKO - #DeltaSeries 330/420/520

https://dl.machinedalal.com/SQQH

Manufacturer: #AKO

Year: 2022

Machine Availability: Immediately

Price: On Request

Location: India

#Flexo #machinedalal

0 notes

Link

Gallus - #EM 280

https://dl.machinedalal.com/2oiM

Manufacturer: #Gallus

Year: 2008

Machine Availability: Immediately

Price: On Request

Location: USA

#Flexo #machinedalal

0 notes

Link

Omet - Flexy 330

https://dl.machinedalal.com/zg3G

Manufacturer: #Omet

Year: 2006

Machine Availability: Immediately

Price: On Request

Location: India

#Flexo #machinedalal

0 notes

Link

Kopack - S250

https://dl.machinedalal.com/Kgib

Manufacturer: #Kopack

Year: 1998

Machine Availability: Immediately

Price: On Request

Location: USA

#S250 #Flexo #machinedalal

0 notes

Text

WEBTECH's Latest 8 Colors Fully Loaded Flexographic Label Printing Machine with below features :

~ Electronic Brake

~ Electronic Web Guide

~ Corona Treater

~ Servo Controlled

~ Sliding Turnbar

~ Cold Foiling & Lamination

~ All UV Drying Stations

~ upto 3 Die Cut Stations

~ Motorised Rewinding

~ Individual HMI/PLC Touchscreen Controls of operations

~ Delam & Relam etc.

Contact Info. :

Shiv Nandan Singh

+919999779973

www.webtechengg.com

1 note

·

View note