#Web Guiding System for Extruder Machine

Explore tagged Tumblr posts

Link

We are Manufacturer Of Web Guiding System for Extruder Machine. Web Guide System, Web Guiding Unit, Edge Guiding, Web aligner, Web aligner Unit, Web Guide. Web Guiding Systems which serves various application for all type of flexible printing, packaging & converting machineries. Web Guiding Systems available with Edge Guiding, aligner, Tracking Roller Assembly etc. Web Guiding Systems which serves various application for all type of flexible printing, packaging & converting machineries.

#Web Guiding System for Extruder Machine#Web Guide System#Web Guide System Manufacturer#Web Guide#Web Guiding Unit#Edge Guiding#Edge Guiding system#Web aligner#Web aligner system#Web aligner unit#Web aligner Units#Web Guiding Systems

0 notes

Link

High-quality Rewinder Machine Manufacturer, Rewinding Machine, all type of high-speed Rewinder Machine with Web Aligner for different type of material and industry. All types of Rewinder Machine with Web Aligner for all types of Roto Gravure Printing Machine, Lamination, Coating Machine, Slitting Rewinding Machine, Extruder Machine, Textile Machine, Tyre Machine, etc. The Rewinder Machine is available with: Web Aligner System, Mechanical or Pneumatic Brake, Tension Control System, Line Guide System, Rollers, Safety Chucks, Bow Roller, Unwinder Drive & Control Panel (Optional), Shaft less Unwinder Unit. Rubber Roller Manufacturer, Rewinder Unwinder Manufacturer, Slitting Machine, Slitting Rewinder Machine Manufacturer in India.

#Winder Rewinder#Rewinder Machine#Rewinding Machine#Slitting Machine#Slitting Rewinding Machine#Slitter Rewinder Machine Manufacturer#Roto Gravure Printing#Printing Machine#Extruder Machine#Textile Machine#Line Guide System#Tracking Rollers Assembly#Bow Roller#Unwinder Drive#Rubber Roller Manufacturer#Coating Machine#tyre machine#Web Aligner System

2 notes

·

View notes

Link

Web Aligner for Extruder Machine, Web Guiding Systems are used to automatically guide all type of all type of flexible material of any width, under any load, at any seed. Web Guiding Systems which serves various application for all type of flexible printing, packaging & converting machineries. Also Manufacturer of Rewind Stand with Web Guiding System available with Edge Guiding, aligner, Tracking Roller Assembly etc. Web Aligner, Web Aligner system, Web Guiding System, Web Guide system, Web Aligner Unit, Web Guiding unit.

http://www.webaligner.com/web-aligner-for-extruder-machine/

#Web Aligner for Extruder Machine#Web Guide System#Web Guide System manufacturer#Web Aligner#Web Aligner system#Web Aligner systems#Web Guiding System#Web Guiding Systems#Web Guiding System Manufacturer#Web Aligner Unit#Web Guiding unit

0 notes

Link

Web Guiding System Manufacturer, Rewinding Unwinding is a process to rewind - unwind your material available in roll form like, flexible packaging, film, paper, foil, etc. Rewinding Unwinding is a repetitive process with high accuracy to wind or rewind your material in roll form. Unwinding or Rewinding Machine designed and suitable for all types of machines like Roto Gravure Printing Machine, Lamination, Coating Machine, Slitting Rewinding Machine, Extruder Machine, Textile Machine, Tyre Machine, etc. Web Guiding System Manufacturer, Rewinding Unwinding, Web Guiding System, Slitting Rewinding Machine, Doctoring Salvage Rewinder, Salvage Rewinders, Slitter Rewinder Machine , Winding Rewinding, Web Guiding Salvage Rewinding, Web Guiding System Manufacturer

#Web Guiding System Manufacturer#Rewinding Unwinding#Web Guiding System#Slitting Rewinding Machine#Doctoring Salvage Rewinder#Salvage Rewinders#Slitter Rewinder Machine#Winding Rewinding#Web Guiding Salvage Rewinding

1 note

·

View note

Link

We Are Unwinder rewinder system Manufacturing and exporting Rewinder Unwinder machine. A genuine specialized supplier of Rewinder Unwinder. Unwinder Rewinder trolley with web guiding system that allow for a simple unwinder rewinder unit machine. High speed unwinder rewinder system. We manufacture Unwinding Machine or Rewinder Unit suitable for all types of machines like Roto Gravure Printing Machine, Lamination, Coating Machine, Slitting Rewinding Machine, Extruder Machine, Textile Machine, Tyre Machine, etc.

#Unwinder Rewinder System#Unwinder Rewinder System Manufacturer#Unwinder Rewinder#Web guiding system#inspection rewinding machine#unwinding rewinder

2 notes

·

View notes

Text

Amazon is one of the app development leaders in supplying various cloud services, boasting numerous dozens and counting. Amazon EC2 is one of the maximum famous Amazon services and is the main part of the Amazon Cloud computing software development platform that changed into offered in 2006. Amazon EC2 is broadly used nowadays, however, the recognition of every other Amazon web development provider referred to as Lambda is likewise growing.

AWS lambda vs AWS EC2

AWS Lambda vs AWS EC2

AWS EC2

AWS EC2 is a provider that lets in the use of digital machines referred to as EC2 times within the app developers cloud and supplying scalability. You can extrude the quantity of disk space, CPU overall flutter development performance, reminiscence, etc. You can choose the bottom photo with the essential pre-hooked-up working machine which includes Linux or Windows after which configure maximum OS settings in addition to putting in custom app development. You have the foundation to get entry to on your Amazon EC2 times and may create extra users. Manage the whole thing you want to manipulate your EC2 along with rebooting and closing down the example. The class of AWS EC2 providers is referred to as Infrastructure as a Service.

AWS Lambda

AWS Lambda is a computing platform that lets you run a bit of code written on one of the supported app development programming languages – Java, JavaScript, or Python web development while a cause related to an occasion is fired. You don’t want to configure the digital server and surroundings to run the software development that you’ve got written. Just insert your app development code within the AWS Lambda interface, accomplice the Lambda feature with the occasion, and run the software development within the cloud while needed, without looking after server control and surroundings configuration.

AWS Lambda vs AWS EC2 process

Security

Amazon EC2: For EC2, you’ve got complete manipulate over machine-stage safety. However, due to the fact you want to configure the app developers agencies, Network ACLs, and VPC subnet course tables to manipulate visitors within and out of the example, it may take time to make certain the machine is completely steady.

Winner: Lambda is greater regular out of the box, at the same time as flutter development EC2 offers greater manage over protection.

Monitoring

Amazon EC2: When walking EC2 times, you want to intently tune numerous metrics:

Availability – To keep away from an outage in production, you want to recognize if every one of the EC2 times walking a software development is healthful or now no longer.

System mistakes – Machine mistakes may be observed within the machine log report like /var/log/Syslog. You can mixture those logs to Amazon CloudWatch with the aid of using putting in the agent or use Syslog to ahead the logs to every other device like Splunk or ELK.

Activity auditing – EC2 wishes lots of guide configuration and every now and then it is able to pass wrong.

Performance metrics – You could display CPU utilization and disk utilization thru CloudWatch logs.

Cost monitoring – EC2 times count, EBS quantity utilization, and app development community utilization are very critical to display as auto-scaling can drastically have an web development effect on AWS billing. CloudWatch affords an app developers few facts approximately the community utilization for example however doesn’t deliver basic facts of what number of times are being used, or how a whole lot garage and community bandwidth is used on the account stage.

How to Choose?

AWS Lambda and AWS EC2 have clean differences. Neither one is higher than the opposite, however, there are conditions in which one is extra flutter development ideal than the opposite. AWS Lambda is most usually used while facts manipulation wishes to arise on a constant app development basis. Let’s say which you want to add purchaser facts into the cloud, however, you want to obfuscate fabric while it lands within the S3 bucket. A lambda feature could be an excellent solution.

As quickly because the document is positioned within the S3 bucket, a lambda feature will understand that occasion as something referred to as a cause. Once that cause is pulled, the lambda will loop via the bucket and mask the facts. If this system fails for a few reasons, the report could be eliminated from the S3 bucket.

EC2 is right for growing web development. You could spin up an EC2 example, and on that example, there will be a NoSQL database that includes DynamoDB to save consumer app development facts. Load balancers and gateways may also be positioned onto the example to provide get entry to the internet.

Conclusion

Today’s weblog submit has in comparison AWS EC2 and AWS Lambda due to the fact of AWS Lambda vs AWS EC2 is a famous subject matter nowadays. AWS EC2 is a provider that represents the conventional cloud infrastructure (IaaS) and lets you run EC2 times as VMs, configure environments, and run custom app development. AWS Lambda is the implementation of Function as a service by means of using amazon that lets you run your software development while not having to fear approximately underlying infrastructure. AWS Lambda affords you a serverless structure and lets you run a app developers bit of code within the cloud after an occasion cause is activated.

0 notes

Text

What Is The Web Tension Controller

Whether the web tension control is stable will directly affect the quality of the product. If the tension is insufficient, the coil materials will drift during operation, and the finished paper will be wrinkled after slitting and rewinding. Web tension controller refers to the instrument which can permanently control the tension of the coil materials when conveyed on the machine. This controller must be effective for any speed of the machine, including machine acceleration, deceleration and uniform speed, even in the case of an emergency stop. It should also be able to ensure that the slit is not damaged.

Why Choose Web Tension Controller?

In many industries, winding control problems are often encountered. For example, in the production process of coil materials, the unwinding and winding tension of the coil materials is very important to the quality of the product. For this reason, constant tension control is required. That is to make the product receive good tension during the winding process and keep it unchanged from beginning to end. The stability of the tension control is directly related to the quality of the slitting product. If the tension is too large, it will cause the tensile deformation of the processed material, if the tension is too small, the stress between the layers of the coiled material will be deformed, resulting in uneven winding and affecting the processing quality.

How Does The Web Tension Controller Work?

The tension controller is a kind of equipment that can permanently control the tension of the material belt when it is transported on the equipment. Using this equipment can well maintain the operating speed of the machine, and can not affect production in an emergency. So, how does this device work?

The web tension controller mainly works through the coil. Coil magnetostatic powder clutch and magnetic powder brake are automatic devices that can control the input current and change the output. When the coil is not energized, the input shaft rotates, the magnetic powder is pressed on the inner wall of the clamp ring under the action of centrifugal force, and the output shaft does not contact the input shaft. At this time, it is in an idle state. When the coil is energized, the magnetic powder generates a magnetic link under the action of the magnetic lines of force, so that the output shaft and the input shaft become rigid bodies and rotate, and slippage occurs when overloaded. So as to achieve the purpose of transmitting torque.

Methods Of The Web Tension Control

1. Manual Control

Constantly adjust the torque of the clutch or brake during rewinding, discharging or the process to obtain the required tension, which requires the user to check the tension of the coil materials at any time and adjust the output torque at any time. If pneumatic is used for brakes or clutches, the manual tension controller can directly select precision pressure regulators, which can save a certain amount of equipment costs, but it is only suitable for some low-speed compound machines, extruders, textile machinery and other occasions where tension control requirements are not high.

2. Semi-automatic Method

The method adopts the ultrasonic principle to automatically detect the coil diameter for adjusting the tension of the coils. The tension controller is essentially a semi-closed loop system. It can not only automatically measure the coil and control the torque output, but also has the functions of buffer start, anti-loosening and inertia compensation. The implementation cost of this scheme is low, so the method is widely used in mid-range machinery.

3. Fully automatic Method

This method is to measure the tension of the coil by a web tension sensor, and then the controller automatically adjusts the clutch or brake to control the tension of the coils. This method is a fully closed-loop tension control. In principle, this solution can reflect the change of tension in real-time, so the control accuracy is the highest. Therefore, some high-end finishing mills, high-speed slitting machines and other metallurgical applications adopt fully automatic tension controller.

Fully Automatic T500/T1000 Web Tension Controller

T500/T1000 web tension controller is manufactured by Arise Technology which is specialized in research and development, production and sale of web guiding products & accessories such as web guide sensor, web guide controller, web guide actuator, etc with advanced photoelectric, CCD, color sensitivity and ultrasonic technology. The fully automatic T500/T1000 controller provides high accurate tension control with simple & stable operation, easy installation.

0 notes

Text

26 best 3D printers under $200/$300

3D printing is becoming ever more accessible - with a brand new 3D printer now costing as little as $79! We thought that we’d do a quick round up of some of the most affordable 3D printers on the market. We haven't had the chance to test all of these personally, so if you have any feedback do let us know - but check out a selection of machines under $300 below. And don’t forget to head over to MyMiniFactory to grab free 3D-printable models when you do start printing!

----------------------------------------------------------------------------------------------------

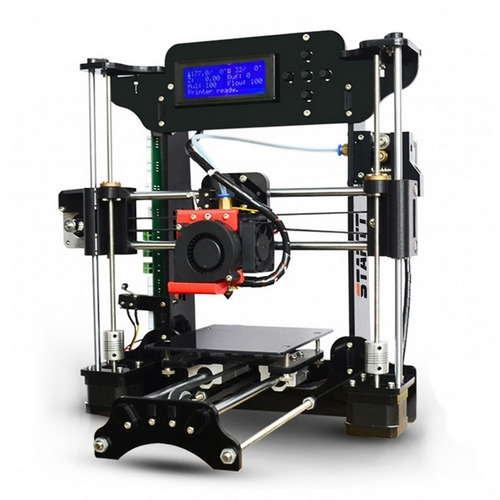

STARTT $99.99

The STARTT is a great way to start(t) with 3D printing. It is supplied as a simple kit that can be assembled in around 5 hours, enabling you to understand how a 3D printer works. Despite this model being affordably priced, the printing quality is impressive. The STARTT is compatible with any open source slicer like Cura, and is loaded with pre-sliced 3D printable designs, compliments of MyMiniFactory.

You can purchase this model here.

Check out some of STARTT’s 3D-printable designs here!

Key Statistics:

DIY kit: Yes Type: FDM Weight: 4 kg Max. build volume: 120 mm x 140 mm x 130 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

101 Hero $79

101HERO launched on Kickstarter with the objective of being the world's most affordable 3D printer - the campaign was a great success raising more than $1M. This printer will come in 2 editions the Customer Version will be a kid-friendly edition, which allows users to print designs via an SD card. The Designer & Developer version will be more advanced, with a USB connection and open-source software compatibility.

You can pre-order this printer here.

Try out some support free prints on this one to get started, grab them here.

Key Statistics:

DIY kit: 90% pre-assembled Type: FDM Weight: 1.86 kg Max. build volume: 150 mm diameter x 100 mm height Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Designer & developer version only Wireless: No

----------------------------------------------------------------------------------------------------

Tronxy X1 $187

This Chinese aluminium DIY kit is one of the cheapest 3D printers on the market. Suitable for PLA and ABS, it’s a basic model, easy to assemble and it can be recommended to beginners.

You can purchase this 3D printer here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 3.5 kg Max. build volume: 150 mm x 150 mm x 150 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Tronxy P802M $204

It makes use of Repetier-Host and Cura for slicing. The P802M is great value for its cost and is recommended for home use and to beginners.

You can purchase this model here.

Download free electronics 3D-printable designs here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 8 kg Max. build volume: 220 mm x 220 mm x 240 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

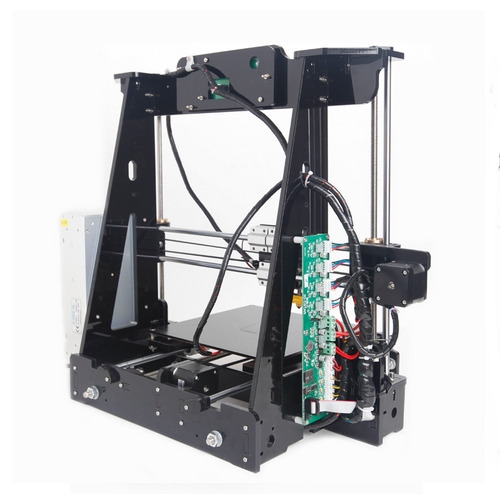

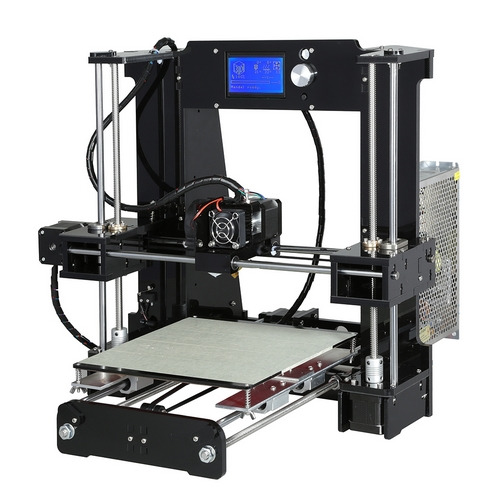

Anet A8 $170

The A8 is the cheapest model from the Chinese brand Anet. Some parts of this DIY kit can be 3D printed and changed if needed. This model is very popular which means there is a great community on the web, and lots of customisation available to kick start your 3D experience. The A8's affordable price tag makes it a favourite among consumers, but that doesn't mean that this printer isn't a 3D printing powerhouse. It boasts a large print area and very capable NEMA17 motors to navigate the print-space. The A8 comes stock with a versatile extruder and heated bed, which makes it capable of printing a diverse selection of filaments.

You can buy this 3D printer here.

And for the DIY lovers, here you can download for free thousands of 3D-printable spare parts!

Key Statistics:

DIY kit: Yes Type: FDM Weight: 8.5 kg Max. build volume: 220 mm x 220 mm x 240 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

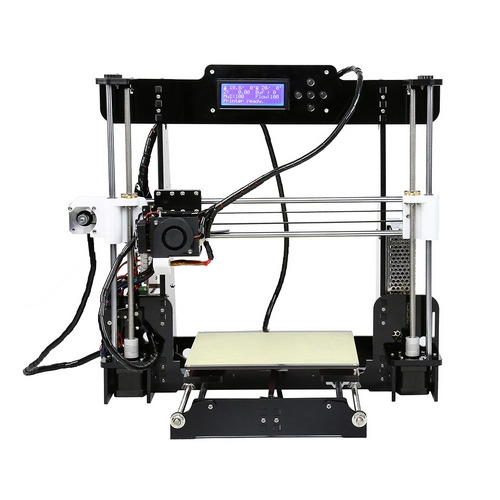

Anet A6 $198

The A6 is a bit more expensive than the A2 and A8 but has a bigger build volume.This model is a 3D printer with acrylic frame and single extruder. To maintain the garage-built feel and the handmade charms, Anet A6 3D desktop printer is also a build-it-yourself kit.

You can purchase this model here.

The build volume will enable you to print objects such as these.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 7.6 kg Max. build volume: 220 mm x 220 mm x 250 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

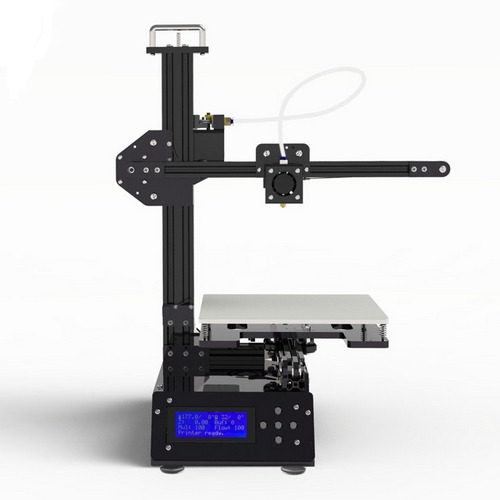

Anet A2 $203

The A2 has a build volume a bit smaller than the A6 and A8, but also a smaller minimum layer height. This 3D printer adopts the high-end configuration with stable performance, and the compact body ensures portability. It is an unassembled DIY kit, which provides you with a step-by-step guide to build the 3D printer from scratch.

You can buy this model here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 4 kg Max. build volume: 220 mm x 220 mm x 220 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Super Helper SH105 $149

Launched by the Chinese brand Winbo, the SH105 is one of the cheapest 3D printers on the market. The SH105L is $50 more expensive than the SH105 and includes a laser head. Described as being suitable for a wide variety of applications including education, design, manufacturing, and general home and business use, the Super Helper looks to be easy to use, and its portability is a big plus.

You can purchase this 3D printer here,.

Judging by the photo this one is going to be great for planters - download some here.

Key Statistics:

DIY kit: No Type: FDM Weight: 3.6 kg Max. build volume: 105 mm x 105 mm x 155 mm Min. layer height: 40 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

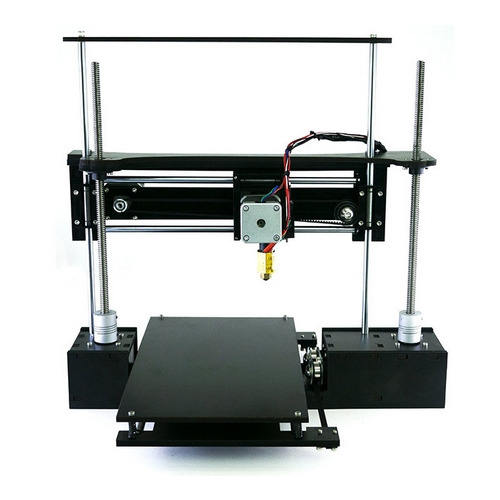

Q3D OneUp 3D $199

This self-assembled 3D printer is one of the cheapest on the market for the moment, and clearly a good and honest printer for its price. For beginners, buying and building a DIY kit like this one (2-8 hours to build) is recommended to understand the ins and outs and the ups and downs of a 3D printer. With over 7,000 units out in the wild, the OneUp is the standard for entry level 3D printer kits. This model sets itself apart from other 3D printers in its class by using the finest linear motion components, including chromed, induction hardened linear shafts, dual precision ACME screws (for the Z axis) and LM8LUU linear bearings for double the rigidity over the LM8UU bearings used in most printer kits. Each of the linear motion components is tied together with a CNC laser cut melamine frame (made in the USA) which provides not only rigidity but lightweight for high-speed printing. With improved print speeds up to 100mm/s due to the lighter weight extruder and hot end, print time is apparently cut almost in half.

You can purchase this model here.

And here are some free 3D-printable designs great for first-time printers!

Key Statistics:

DIY kit: Yes Type: FDM Weight: 4 kg Max. build volume: 100 mm x 100 mm x 125 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Optional Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Creality CR-7 $256

The Creality CR-7 is a good machine for 3D DIY enthusiasts, and suitable for a wide range of customers. This desktop 3D printer is easy to assemble, electric-proof, anti-scald and scratch resistant. With its Ilight weight, stability, and low noise, it will provide you with a good experience of 3D printing.

You can purchase this model here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 3.5 kg Max. build volume: 130 mm x 150 mm x 100 mm Min. layer height:100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Q3D TwoUp 3D $239

The TwoUp has the same specs than the OneUp except that the build volume is bigger: 175 L x 175 W x 125 H.

Buy it here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 4 kg Max. build volume: 175 mm x 175 mm x 125 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Optional Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Q3D ThreeUp 3D $279

The ThreeUp has the same specs than the OneUp and the TwoUp except that the building volume is even is bigger: 175 L x 175 W x 210 H.

You can purchase it here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 5.9 kg Max. build volume: 175 mm x 175 mm x 210 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Optional Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

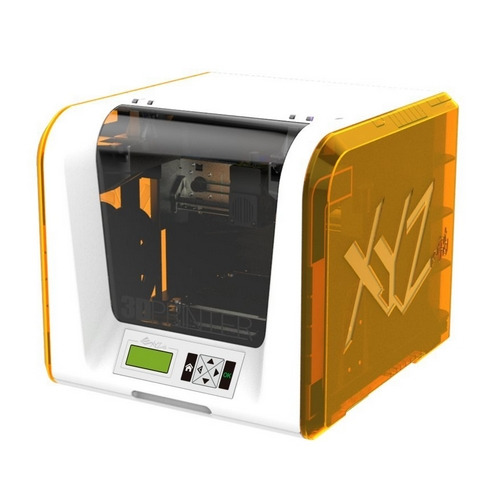

Da Vinci Junior $189.99

This 3D printer is the cheapest machine from XYZprinting, who also sell the Da Vinci miniMaker and the Da Vinci Mini. The Da Vinci Jr. has a robust build size of 5.9 x 5.9 x 5.9 inches and a resolution of 100 to 400 microns. Its design allows for the inclusion of an auto-feeding filament system, which takes the PLA filament to the extruder, and ensures that the filament is loaded properly and is ready to print. The Jr. 1.0 only prints in DEHP-free and Heavy metal-free PLA filament.

You can purchase this 3D printer here.

Key Statistics:

DIY kit: No Type: FDM Weight: 15 kg Max. build volume: 150 mm x 150 mm x150 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: Yes

----------------------------------------------------------------------------------------------------

Da Vinci miniMaker $249.99

The Da Vinci miniMaker is a desktop 3D printer for beginners and children. Eco-friendly and easy to use, its lightweight and compact design fit easily in tight places. It has an auto-leveling bed and the auto-calibrating extruder module ensures the best possible prints. The miniMaker only prints in DEHP-free and Heavy metal-free PLA filament, ensuring that prints are safe for children and family.

You can purchase this model here.

The Da Vinci miniMaker will enable you to print very cool designs, such as toys and games downloadable here for free.

Key Statistics:

DIY kit: No Type: FDM Weight: 11.5 kg Max. build volume: 150 mm x 150 mm x150 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

Da Vinci Mini $288.79

The Da Vinci Mini is a multifunctional 3D printer for beginners. This model is 30 percent smaller than da Vinci Jr. 1.0 and has a 5.9 inch x 5.9 inch x 5.9 inch aluminium print bed for larger and finer prints.

You can buy this model here.

Key Statistics:

DIY kit: No Type: FDM Weight: 10 kg Max. build volume: 150 mm x 150 mm x150 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: Yes

----------------------------------------------------------------------------------------------------

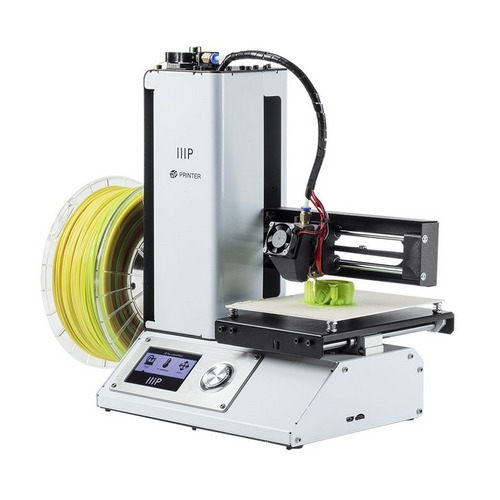

Monoprice Select Mini $199.99

The US technology company Monoprice imported the Malyan M200 from China, rebadged each unit to carry their logo and offered it for sale at the very affordable price of $199.99. Unlike most other low-cost 3D printers, this printer ships fully assembled and has already been calibrated at the factory. Sample PLA filament and a MicroSD card with preinstalled models are included so you can start printing right out of the box. Whilst there are a few defaults, the Select Mini is a good product for its price, and is a recommendable 3D printer for first-time users.

You can purchase this 3D printer here.

Key Statistics:

DIY kit: No Type: FDM Weight: 4.5 kg Max. build volume: 120 mm x 120 mm x120 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: No Wireless: Yes

----------------------------------------------------------------------------------------------------

TEVO Tarantula i3 $201

The Tarantula i3 is based on the Prusa i3, a proven design with tens of thousands users all around the world. This DIY kit features automatic bed levelling (optional) and bigger bed (optional). The auto-leveling version uses a proximity sensor to detect the aluminium print bed where the normal version of the printer uses a microswitch to detect the end of travel for the Z-Axis movement (vertical limits). It is very good value for the cost and will enable you to understand how 3D printing works.

You can buy this model here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 7.5 kg Max. build volume: 200 mm x 200 mm x 200 mm (or 200mm x 280mm x 200mm optional) Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Dual Heated bed: Yes Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

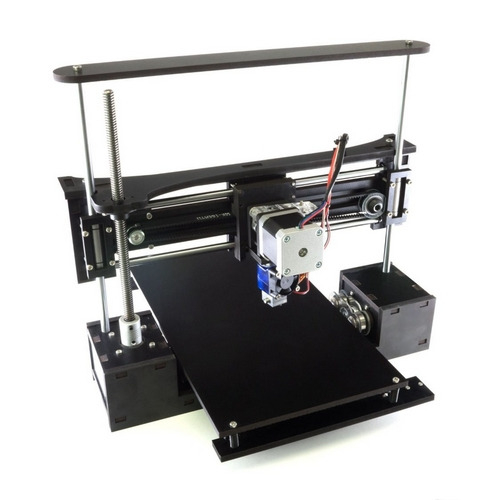

HE3D EI3 $210

This DIY 3D printer is the cheapest one from the Chinese brand HE3D. This kit has an upgraded frame using 2020 and 2040 extruded aluminium beams and 7mm reinforced acrylic supports and an upgraded ATmega2560 control board with support for up to two print heads and an intuitive LCD user interface panel. The heated 8x8x8 inch print area, 12 micron X/Y accuracy and 50-micron layer accuracy, and auto z-calibration ensure each print will achieve stunning detail and quality. The extruder’s wide temperature ranges support a variety of printer filament material including most varieties of PLA, ABS, PETG, Wood, and PVA material.

You can purchase this model here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 8.5 kg Max. build volume: 200 mm x 200 mm x 200 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single or dual/triple optional Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

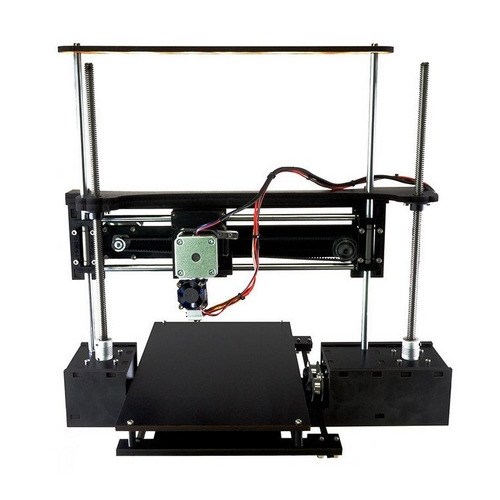

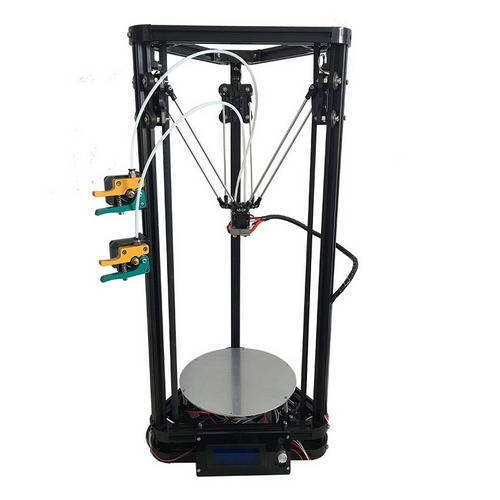

HE3D K200 $239

This DIY 3D printer, bigger than the HE3D EI3, will enable you to print objects in very good quality. The K200 breaks from the traditional limitations of Cartesian printers and offers precision and speed with a build volume over 1000 inches (11 in. diameter, 11 in. height)! The kit is built with the new enthusiast and experts in mind. With high quality 2020 aluminium extruded beams and acrylic forms the construction is simple, yet very robust. The E3D double extruder opens the possibilities to multiple print colours without having to pause, clean, and reposition. Both extruders support temperature range up to 260C to support almost all filament material including PLA, ABS, TPU, WOOD, PVA, Nylon, PVA, PP and most of their variants. The upgraded LCD interface and ATmega2560 control board with RAMPS PLUS2 and 80 step precision motors give this printer an ultra-high print quality down to 12 micron X, Y and 50-micron layer accuracy.

You can buy this 3D printer here.

Printing tall objects like these won’t be an issue anymore!

Key Statistics:

DIY kit: Yes Type: FDM Weight: 9 kg Max. build volume: 200 mm diameter x 300 mm height Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single or dual optional Heated bed: Optional Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

FLSUN Prusa i3 $219

This Chinese model is a good and affordable 3D printer for beginners. The metal structure is stable and provides a good printing accuracy. It has a high precision Y-axis position plate and guarantees Y-axis positioning accuracy. The printer controller is integrated motherboard, easy to connect and support DIY spread.

You can purchase this printer here.

If you feel like this will be easy to build, try printing these objects with it!

Key Statistics:

DIY kit: Yes Type: FDM Weight: 10 kg Max. build volume: 200 mm x 200 mm x 200 mm Min. layer height:100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

Heacent i3 $145

This Chinese DIY kit is an affordable 3D printer that will give you a good step-by-step learning experience. Suitable for a wide range of customers, the quality of the product is apparently very good for its price.

Purchase this 3D printer here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 6.6 kg Max. build volume: 200 mm x 200 mm x 180 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

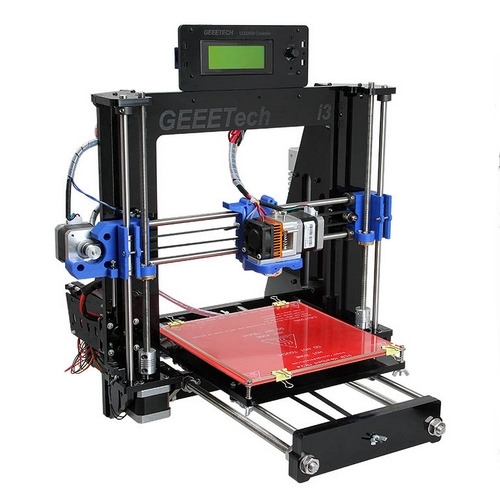

Geeetech Prusa I3 pro B $248.54

The Prusa I3 pro B is the cheapest 3D printer from Geeetech. It is based on Geeetech I3 pro, except its simple assembly, easy debugging and more stable performance, compared with the I3 pro, I3 pro B features a newly added potential for 3D printing—support 5 types of filament: ABS, PLA, Wood-Polymer, Nylon and flexible PLA., create flexible hinges, joints, shaped parts; enable you to get the most out of your 3D Printer.

You can buy this model here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 8.5 kg Max. build volume: 200 mm x 200 mm x 180 mm Min. layer height: 100 microns Filament diameter: 1.75 mm, 3.0 mm Extruder: Single Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

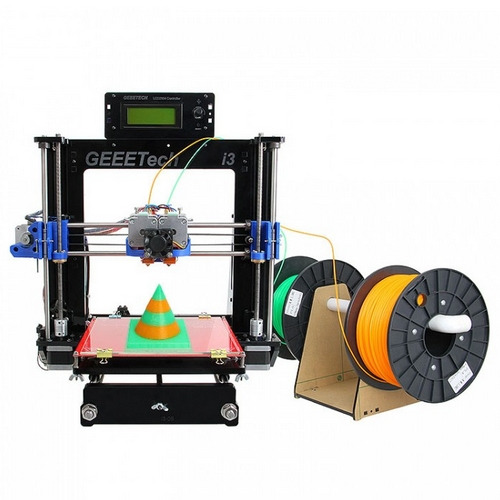

Geeetech Prusa I3 pro C $299

A little bit more expensive, the Prusa I3 pro C has the same specs than the pro B except that it has 2 extruders. You can print a single two-color object, or you can print two objects in one print job, each made from a different colour. You can also print one single-color object, as with other single-extruder 3D printers. Or you can use one extruder for infill or support. The 2 extruder motors push filament through 2 head separately, so mixing colours printing is not applicable for the moment. Geeetech I3 pro C support 5 types of filament: ABS, PLA, Wood-Polymer, Nylon and flexible PLA.

Buy this 3D printer here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 9 kg Max. build volume: 200 mm x 200 mm x 180 mm Min. layer height: 100 microns Filament diameter: 1.75 mm, 3.0 mm Extruder: Dual Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Cetus 3D $299

After a successful Kickstarter campaign, Cetus 3D launched a very basic and solid printer. Quiet, small and cheap, this model can be recommended for every beginner. At 0.25, the build volume to machine volume ratio is excellent, and the light weight will enable you to take it with you everywhere. The Cetus 3D printer features cloud-based support for remote printing and notifications as well as dedicated 3D printing software.

You can purchase the Cetus 3D here.

Key Statistics:

DIY kit: No Type: FDM Weight: 3.2 kg Max. build volume: 180 mm x 180 mm x 180 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: Yes

----------------------------------------------------------------------------------------------------

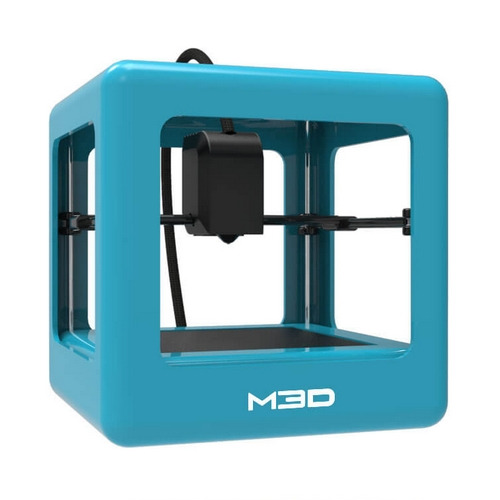

M3D Micro $299

Rated best 3D printer in class by 3D Forged & Tom's Guide, this model is the cheapest 3D printer from M3D. The Micro is the world’s first truly consumer 3D printer and is powered by "Micro Motion Technology," a series of next generation innovations, creating precision at a fraction of the cost of other 3D Printers. Sporting a compact design, cool colour choices, user-friendly software, and replaceable print beds and nozzles, it’s a great 3D printer for beginners and experts alike. The Micro comes with M3D Software for Windows operating systems. The software has an easy-to-use interface and is fully touch screen capable. The M3D Software allows you to organise the 3D models you've downloaded into an easy to view library.

You can buy this 3D printer here.

Key Statistics:

DIY kit: No Type: FDM Weight: 1 kg Max. build volume: Base:109 mm x 113 mm x 74 mm, and above the 74 mm: 91 mm x 84 mm x 42 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

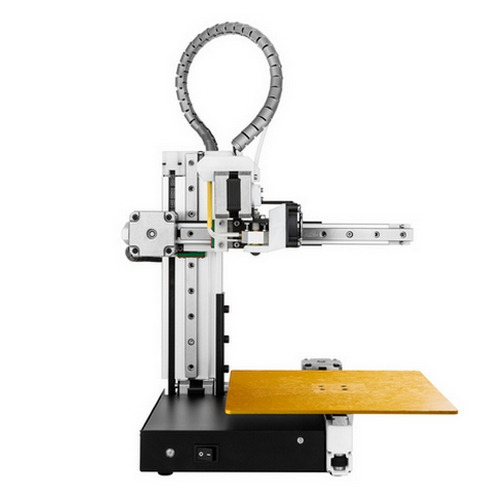

Snapmaker $299

A Kickstarter campaign has been launched to raise funds for this affordable all-metal and all-in-one 3d printer. It is easy-to-use for beginners, expandable for makers, and will enable you to do 3D printing, laser engraving and CNC carving. Designed for quick assembly, strong expandability and real affordability. Snapmaker has an innovative modular design, which enables a flat-packed and low-cost shipping, quick assembly and personalised modification. With the intuitive-to-use 3.2-inch colour touchscreen, you can conveniently control all print settings.

You can pre-order the Snapmaker here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 4.5 kg Max. build volume: 125 mm x 125 mm x 125 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

Bonus: other notable entry level 3D printers

----------------------------------------------------------------------------------------------------

Dagoma DiscoEasy200 $317

The french brand Dagoma improved its model Discovery, who became DiscoEasy. This model is based on an open source design, which makes it easy to modify. Its 3D files are accessible for free online. The Dagoma DiscoEasy200 does not provide natively a printing bed but can get one as an option. Compared to its predecessor, the DiscoEasy200 offers a new electronic card, an additional fan on the extruder and a SD card port instead of a mini SD. This 3D printer is intuitive and recommendable to the beginners.

You can purchase this model here.

And here are some cool objects designed by Dagoma that you can print with the DiscoEasy200!

Key Statistics:

DIY kit: No Type: FDM Weight: 5 kg Max. build volume: 200 mm x 200 mm x 200 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

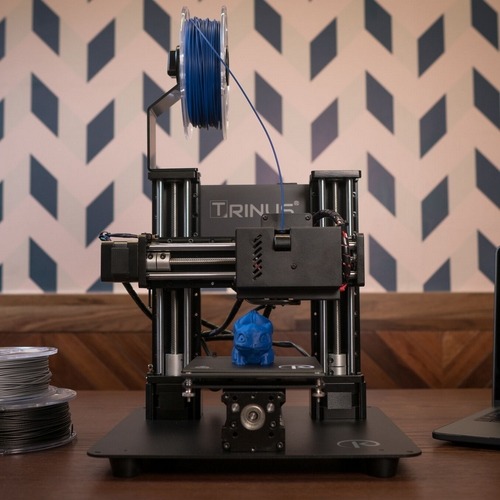

Kodama Trinus $379

Kodama launched a Kickstarter campaign to market the new affordable 2-in-1 Trinus 3D printer. Trinus is a professional-grade desktop 3D printer that can easily be converted into a laser engraver. The kit contains only 11 parts and can be assembled easily. You can also equip the Trinus with a heated bed and a safety enclosure. This all-metal 3D printer extrudes PLA, ABS, PC, Flex, wood and most other materials available on the market. This model is very quiet and print objects in good quality.

You can pre-order the Trinus here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 9.8 kg Max. build volume: 120 mm x 125 mm x 125 mm Min. layer height:50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Optional Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Honorable Mentions:

New Matter MOD-t $399

New Matter launched the MOD-t after realising an Ingiegogo campaign. This model is easy to use and has a good printing quality. The MOD-t’s beautiful clear cover and patented design makes it one of the quietest desktop 3D printers available, so it can easily live in a classroom or living room without causing disruption. The MOD-t is dependable with WiFi connectivity, a simple set-up process, and intuitive controls. If any questions arise, the New Matter Customer Support team is available for users through email, phone, and chat.The Wall Street Journal recommends the MOD-t for anybody’s “first foray into 3-D.”

You can purchase this 3D printer here.

Key Statistics:

DIY kit: No Type: FDM Weight: 5 kg Max. build volume: 150 mm x 100 mm x 125 mm Min. layer height:100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

Robo 3D C2 $699.99

The Robo 3D C2 is a small desktop 3D printer launched after a Kickstarter campaign. This model is more expensive but can print with great quality and efficiency. The Robo 3D C2 is a small desktop 3D printer. It has a nice and simple design, with an easy to access build platform. It is compatible with the Robo app and also adds a Wifi connectivity for a smooth user experience. The Robo 3D C2 print bed is not heated so it is not capable of 3D printing ABS.

You can buy this model here.

Key Statistics:

DIY kit: No Type: FDM Weight: 9.4 kg Max. build volume: 127 mm x 127 mm x 152.4 mm Min. layer height: 20 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: Yes

----------------------------------------------------------------------------------------------------

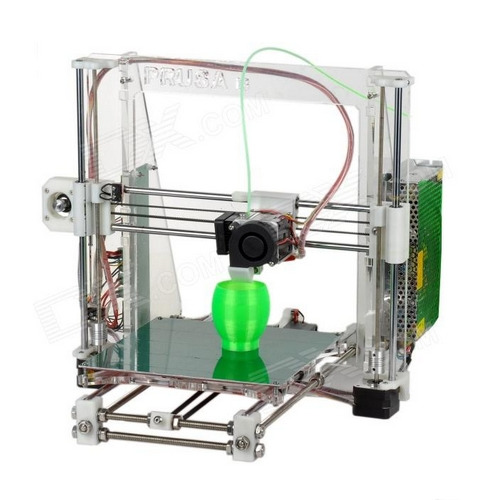

Prusa i3 MK2 kit $786

The very popular Prusa i3 from Josef Prusa is considered as the 3D printer with the best quality for its cost. It comes with a bunch of clever features and is upgradable. With tens of thousands users all around the planet, this popular model has a made a big impression on the 3D printing community since it was launched. All parts of this 3D printer are Open Source and are part of the RepRap project.

You can buy this 3D printer here,

Check out the Prusa MyMiniFactory profile here if you need spare parts!

Key Statistics:

DIY kit: Yes Type: FDM Weight: 6.5 kg Max. build volume: 250 mm x 210 mm x 200 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: Yes Wireless: No

1 note

·

View note

Text

Acquisition online static charge removal systems in India

Static charge removal systems are what creates due to the taken care of electrical prices depending up on their strength as well as bordering environment, one may see activating or licensed operator or employee in bordering area could get shock. Wherever the item remains in the type of film or sheet, it might twist around the guide rollers creating the breakdown. In printing press & layer, laminating equipment the repaired might cause fire on solvent based ink which can set off burning of machineries and also loss of human life.

In the winding procedure - instead of getting cool winding, one could obtain a fold in winding. Taking care of the fixed fee elimination system additionally brings in terrific dust little bits which provides low-grade look to the item. Greater the price of the gadget a whole lot more is the generation of repaired electric expense resulting into serious problems along with if it is not gotten rid of the rate of the device is to be lowered resulting right into manufacturing loss.

How set expenditure eliminator functions

Eliminator bars which are fixed as close as possible to the product therapy, on getting supply from the control system, ionize the bordering air as well as likewise because of the fact that of this, repaired electrical charge is conducted away to the ground.

Applications of fixed fee removal system

- Extruded tube

- Motion picture plant

- Tape plant

- Obtaining & cutting devices

- Bag making-printing maker

- Fabric processing device

- Layer gadget

- Photographic motion picture handling

- Well balanced out printing machine

- And any type of various other internet changing manufacturer

Power gadget as well as device

Power control system - can link up to 3 nos. Fixed bars of as much as 120 inches functioning dimension in the list below strategy:-.

One control power tool has an arrangement for attaching 3 fixed bar links. Added card is used within, to assure that any kind of one of the connection drops quick throughout synchronised use all the 3, the additional card can be made use of. After separating the power gadget, by hand modify the repaired wire from the unsuccessful card link to the spare card connection. To do this, simply open the top cover of the control power system as well as alter the fixed cord web link from failed card to the additional card.

The power system comes with one meter size 3 core power cable and furthermore repaired bars comes with two meter single core high power meters special cable television service as conventional size.

0 notes

Link

We are Manufacturers, Exports & Supplies Unwinder Rewinder System Manufacturer India, high-speed Winding Rewinding Machine, heavy duty Rewinder Unwinder Unit with Web Guiding System, Web Guide System, Unwinder Rewinder, Web Guiding Unit. We manufacture Unwinding Machine or Rewinder Unit suitable for all types of machines like Rotogravure Printing Machine, Lamination, Coating Machine, Slitting Rewinding Machine, Extruder Machine, Textile Machine, Tyre Machine, etc.

#Unwinder Rewinder System#Unwinder Rewinder#Rewinder Unwinder#Rewinder Unwinder Machine#Jumbo Unwinder System#Jumbo type Unwinder System#Rewinder Unwinders#Unwinder Machine#Winding Rewinding Machine#Winding Rewinding Machin#Winding Rewinding#Rewinder Unwinder Unit with Web Guiding System#Web Guide System

0 notes

Link

Unwinder Rewinder System Manufacturer India. Unwinder Unit, Unwinder Rewinder Machine with Web Guiding System. High quality rewinder and unwinder together for heavy-duty process. We manufacture Unwinding Machine or Rewinder Unit suitable for all types of machines like Roto Gravure Printing Machine, Lamination, Coating Machine, Slitting Rewinding Machine, Winding Rewinding machine, Web Aligner System, Mechanical or Pneumatic Brake, Tension Control System, Line Guide System, Extruder Machine, Textile Machine, Tyre Machine, etc.

#Unwinder Rewinder System#Unwinder Rewinder System Manufacturer#Unwinder Rewinder#Unwinder Unit#Winding Rewinding Machine#Winding Rewinding#Winder Rewinder Machine Manufacturer

0 notes

Link

0 notes

Link

We are dealing on manufacturing and exporting & supplies Unwinder Rewinder System. Also manufacturer Unwinder Rewinder System with Web Guiding System. Our machines are designed with wide range of quality for long lasting heavy duty Rewinder Machine for heavy rolls, Unwinder Rewinder System for different industry, Unwinder Rewinder Machine. We manufacture Unwinding Machine or Rewinder Unit suitable for all types of machines like Roto Gravure Printing Machine, Lamination, Coating Machine, Slitting Rewinding Machine, Extruder Machine, Textile Machine, Tyre Machine, etc.

#Unwinder Rewinder System#Unwinder Rewinder#Unwinder Rewinder Machine#Winding Rewinding#Winding Rewinding machine#Unwinder Rewinder Machine manufacturer#Winding Rewinding machine Manufacturer

0 notes

Link

We have been successfully manufacturing, exporting & supplying all types of Unwinder Rewinder System. Web Aligner for all types of Winding Rewinding Machine, Unwinder Rewinder System with Web Guiding Mechanical, Pneumatic Brake, Rotogravure Printing Machine, Lamination, Coating Machine, Slitting Rewinding Machine, Extruder Machine, Textile Machine, Tyre Machine, etc.

0 notes

Text

How are Plastic Bags Made? - XL Plastics

LPlastic bags enjoy their widespread popularity as they are exceptionally versatile and durable in terms of use. Plastic, otherwise known as poly bags, are extremely convenient and can be used to store food, carry goods and products, and can be Plastic Bag Machines re-used as trash liners or to collect waste, etc. They are especially popular because they are easy Bottom Seal Bag Making Machines to store and can be folded to fit any storage space, making them easily accessible when required. Once the extrusion process is completed, the product is sent to the conversion department for further processing. After the plastic is unwrapped, it is sliced with a heated knife that seals the sides while Side Seal Bag Making Machines the plastic sheet into the desired shape or size. Then, special characteristics are added for the completed product. This includes dies that are used to cutout the handles, T-Shirt Bag Making Machine wheels for production of gussets and various other features are added, those include the logo printing, and addition of seals are taken care of in this step to obtain the finished bag.

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting machinery and printing machinery. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability and quality go hand-in-hand with the company’s brand.

Due to its varied number of uses as well as its durable nature, these poly bags can be re-used multiple times. The type of material used to produce these poly bags also allow for Center Seal Pouch Making Machine easy customization in terms of shape, style, size etc., making them the preferred material for everyday storage needs in various industries.

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting machinery and printing machinery. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability and quality go hand-in-hand with the company’s brand.

The Extrusion Process :

The first step of the plastic bag making process is known as the extrusion process, where an extruder is used to heat polythene plastic resin pellets to a temperature of about 500 degree Fahrenheit. Once the pellets melt, a screw inside the extrusion machine pushes the molten plastic through the machine and into a die that controls the thickness of the product. The side seal bag making machine delivers Three Side Seal Pouch Making Machine up to 300 strokes / minute and is suitable for LDPE / HDPE / PP / BOPP films. There are a various attachments available for this machine to make a variety of bags like handle punch, pre sealer, bottom gusset, inside / outside lip former , lateral sealer, perforation, tape applicator for courier bags, web aligner etc.After which, the molten plastic is supplied with air to create a bubble, to initiate the cooling process. The air is then pinched PVC Label cutting machine out and the bubble is flattened to cut the film in the required size which is later wrapped on a spindle.

The Conversion Process :

Once the extrusion process is completed, the product is sent to the conversion department for PVC Shrink Label Sleeving further processing. After the plastic is unwrapped, it is sliced with a heated knife that seals the sides while cutting the plastic sheet into the desired shape or size. Then, special characteristics are added for the completed product. This includes dies that are used to cutout the handles, wheels for Plastic Bag Machines production of gussets and various other features are added, those include the logo printing, and addition of seals are taken care of in this step to obtain the finished bag.

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting machinery and printing machinery. It seamlessly blends professional acumen Bottom Seal Bag Making Machines with personal experiences of its founders and employees. Reliability and quality go hand-in-hand with the company’s brand.

Since the process is so simple and highly standardized, thousands of bags can be produced within Combined Pouch Making Machine short periods of time, at cost effective rates. The equipment used to produce these bags are also widely available and can be distinguished based on the type of plastic bag it produces. You can pick from a large variety of plastic processing equipment such as Bottom Seal Bag Machine, Side Seal Bag Machine, Soft Loop and Patch Handle Bag Machine, the T-Shirt Bag Making Machine, along with various other Special Purpose Bag Making Machines to name a few.

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting machinery and printing machinery. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability and quality go hand-in-hand with the company’s brand.

This Multi-purpose pouch Machine converts a lay flat sheet of Laminated film of PET-PE, BOPP-PE into three side sealed pouches as well as Center seal , Lap seal pouches with various attachments. It’s a high-speed pouch machine with a maximum speed of 160 cycles / min.

Touch screen PVC Label cutting machine control for all functions Edge guiding system on unwinder for accurate folding Auto tension control system with load cell and particle brake on Unwind and Rewind Maximum web width of machine is 580 mm before Side Seal Bag Making Machines folding Air shafts on unwind and rewind Pneumatically operated Glue Dispenser unit

All you need to do is Center Seal Pouch Making Machine identify your bag making requirements and needs to select the right equipment.Over the years, we have successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of the business. We go out PVC Shrink Label Sleeving of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors.

#Plastic Bag Machines#Bottom Seal Bag Making Machines#Side Seal Bag Making Machines#T-Shirt Bag Making Machine#Center Seal Pouch Making Machine

0 notes

Text

What You Need to Know About Fascia

Discover the connective-tissue net that weaves your entire body—which is greater than the sum of its anatomical parts—into one integrated whole.

If I asked you what a heart is like, chances are you’d say it’s like a pump. The lungs are often described as “bellows,” the kidneys “a filter,” the brain “a computer.” We tend to view the body in mechanical terms because we live in an industrial age—and because the body has been described as a “soft machine” ever since the scientist René Descartes coined the term in the early 17th century.

So it comes as no surprise that most anatomy books show you body parts—this muscle, that ligament—as if we’re assembled part by part like a car or an iPhone. But instead of timing belts and motherboards, we have hamstrings and biceps. An anatomy atlas is a helpful tool for learning, but the error comes when we start thinking that humans are actually built that way. What is actually going on under your skin is so different from what’s in those pictures.

Your body is much more like a plant than a machine. We are grown from a tiny seed—a single cell, or fertilized ovum, about the size of a pin prick—not glued together in parts. This seed contains sufficient instructions (given the proper nourishment) to create a helpless, squalling baby, who turns into an energetic toddler, a feckless teenager, and then finally a mature adult.

By the time we’re adults, we consist of approximately 70 trillion cells, all surrounded by a fluid fascial network—a kind of sticky yet greasy fabric that both holds us firmly together, yet constantly and miraculously adjusts to accommodate our every movement.

The traditional biomechanical theory of the musculoskeletal system says that muscles attach to bones via tendons that cross the joints and pull bones toward each other, restricted by other “machine parts” called ligaments. But all these anatomical terms, and the separations they imply, are false. No ligaments exist on their own; instead they blend into the periosteum—vascular connective tissue that serves as cling-wrap around the bones—and the surrounding muscles and fascial sheets. What this means is that you weren’t assembled in different places and glued together—rather, all your parts grew up together within the glue.

For example, the triceps are wedded by fascial fabric to their neighboring muscles north, south, east, and west, as well as to the ligaments deep in both the shoulder and elbow. If you contract the triceps in Plank Pose, all these other structures will have an effect and be affected. Your whole body engages in the action—not just your triceps, pectoral, and abdominal muscles.

The takeaway for yoga? When you do poses, it is useful to put your attention anywhere and everywhere in your body—not just the obviously stretched and singing bits. A release in your foot can help your hip; a change of your hand position can ease your neck.

See also Fascia: The Flexibility Factor You're Probably Missing on the Mat

Fascial Function

The fluid fascial network that lives between each cell in your body consists of bungee cord–like fibers made mostly from collagen, including reticulin, and elastin. These fibers run everywhere—denser in certain areas such as tendons and cartilage, and looser in others like breasts or the pancreas.

The other half of the fascial network is a gel-like web of variable mucopolysaccharides, or mucus. Basically, your cells are glued together with snot, which is everywhere, and is more or less watery (hydrated) depending on where it is in the body and what condition it’s in.

All the circulation in your body has to pass through these fibrous and mucousy webs. Generally speaking, the denser the fibers and the drier the mucous, the less the fascial web allows molecules to flow through it—nourishment in one direction and waste in the other. Yoga helps both stretch and ease the fiber webbing, as well as hydrate the gel, making it more permeable.

New research shows that this web of proteins runs down through the membranes of each cell and connects both aspects of the connective-tissue web through the cytoskeleton to the cell nucleus. This means that when you’re doing yoga stretches, you are actually pulling on your cells’ DNA and changing how it expresses itself. Thus, the mechanical environment around your cells can alter the way your genes function.

We’ve known for a while that the chemical environment (hormones, diet, stress catecholamines, and more) can do this, but these new connections explain some of the deeper changes we see when people start practicing regularly.

More on that mechanical environment: Cells are never more than four deep from your capillaries, which excrete food, oxygen, messenger molecules (neuropeptides like endorphins), and more. Tension in your body—slumping your shoulders forward, for example—prompts the fibroblasts (the most common cells found in connective tissue) to make more fibers that will arrange themselves along the line of stress. These bulked-up fascial fibers will form a barrier that will slow or stop capillary-sourced food from reaching your cells. You’ll get enough to survive, but function will slow down. In addition to a thicker barrier of fascial-tissue fibers, the mucus that completes your fluid fascial network will also become thicker and more turgid, which contributes to stopping the flow to your cells.

And because the exchange of goods from capillaries to cells is a two-way street, with cells delivering messenger molecules and CO2 and other waste products back into the bloodstream, a hardened fascial network can trap unprocessed cell products (toxins or metabolites) like a stream eddy traps leaves.

The fix: deep strengthening and stretching squeezes your fascial network the way you would squeeze a sponge. Those metabolites that were trapped in the mucousy bits rush in hoards to the capillaries and your bloodstream. Many of us may feel out of sorts after we release deeply held tension—that’s your liver dealing with the metabolites you squeezed from the tissues. Try an Epsom salts bath, or go back for more movement to keep the process going.

Over yoga time, fascial fibers will slowly thin out and unadhere over weeks, sometimes months, but the mucus can change to a more liquid state in as quickly as a minute, allowing more sliding, less pain, more feeling, and less resistance. Use your yoga—it’s a great tool to get fluids and information flowing to their maximum sensitivity and adaptability.

See also The Anatomy of Fascia—& What It Can Tell Us About How to Practice

Body of Knowledge: Fascia 101

Fascia is the biological fabric that holds us together—the connective-tissue network. This collagenous network of gel and fiber is made up in part by an “extra-cellular matrix,” manufactured inside a connective-tissue cell and then extruded out into intercellular space. The fiber-gel matrix remains an immediate part of the environment of every cell, similar to how cellulose helps provide structure to plant cells. (Remember, we are more like a plant than a machine.)

The Anatomy Trains body map shows our myofascial, or muscle-fascia, anatomy. These 12 whole-body myofascial meridians are more evident in dissection. While most anatomy textbooks show the muscles with the filmy fascia removed, this map illustrates fascia’s deeper function—as global lines of tension, proprioception, and interoception that embed the body’s neuromuscular network, acting to keep your skeleton in shape, guide movement, and coordinate postural patterns. Understanding how these lines function can help unlock a deeper understanding of anatomy for your yoga practice. For example, in Urdhva Mukha Svanasana (Upward-Facing Dog Pose), you are stretching the entire superficial front lines of fascia—the green lines—from the tops of your feet all the way up to the sides of your neck to the back of your skull. You are also challenging all four arm lines. When you strike the right balance in this pose, you can feel your fascial web helping you realize tension and stability, effort and ease.

Feel Your Fascia

The benefits of thinking of the body as a whole organism, instead of in parts, are profound. When we truly comprehend and feel this in our own bodies and see it in our students, we can move and teach with more integrity. That said, as yoga becomes physiotherapized, or made into a practice resembling physical therapy that helps people restore movement and function (a necessary and positive process in general), asana are often reduced to which muscles are stretched—think “Downward Dog is good for your hamstrings.” In reality, while tight hamstrings may be a common experience, your edge in this pose may be deep in your calves or butt, or along the fronts of your shoulders. It depends on your patterns—the way you were grown and what you took on.

Try this exercise to help you feel that your anatomy is more like a plant than a machine, and to help you move away from separating yourself into parts:

INSTRUCTION

Move into Down Dog. It is easy to feel your back body in this pose as you lift your hips, drop your heels from the middle of your legs, and lengthen your spine. But take time to spread your awareness and attention throughout your entire body in order to find points that lack awareness and are unique to your experience of this pose. Here are some points to ponder:

Track the front of your spine in this pose, as if you were rolling a warm red ball up the front of your spine from your tailbone, up the front of your sacrum and the lumbar and thoracic vertebrae, then behind your guts and heart.

Relax your voice box, then your tongue, then your jaw. Let your head dangle. Let yourself be stupid for a moment, then re-establish the length in your cervical spine without the tension.

Move your breath into the back of your ribs, which can be frozen in your early work in this pose. Can you feel the ribs moving under your shoulder blades? Are you moving your lower ribs behind your kidneys?

Move your weight around your feet while in the pose. This can be subtle but powerful. If your heels are off the ground, move slowly, medially then laterally, on the balls of your feet. Feel how that changes the way you feel the rest of your body. If your heels are down, move slowly all around your feet like a clock: At what position do you lock up? Work there.

Because the deep lateral rotators are often limiting in this pose, can you let the area between your sits bones bloom? Try rotating your knees inward in the pose to help find your limitation, and keep working your hips upward. Remember, you are whole. Someone may describe you as a machine, but that is not the scientific truth—wholeness is.

Join Tom Myers for a seven-week online introduction to anatomy for yoga students and teachers. You’ll learn how to think of movement in holistic, relational, and practical ways, and how to identify common postural patterns, as well as strategies for cueing to awaken parts of the body that may need work. Sign up now.

About Our ProWriter Tom Myers is the author of Anatomy Trains and the co-author of Fascial Release for Structural Balance. He has also produced more than 35 DVDs and numerous webinars on visual assessment, Fascial Release Technique, and the applications of fascial research. Myers, an integrative manual therapist with 40 years of experience, is a member of the International Association of Structural Integrators and the Health Advisory Board for Equinox. Learn more at anatomytrains.com.

from Yoga Journal http://ift.tt/2rjeZMh

0 notes